The Effect of Preliminary Mixing Methods on the Properties of PA6 Composites with Molybdenum Disulphide

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

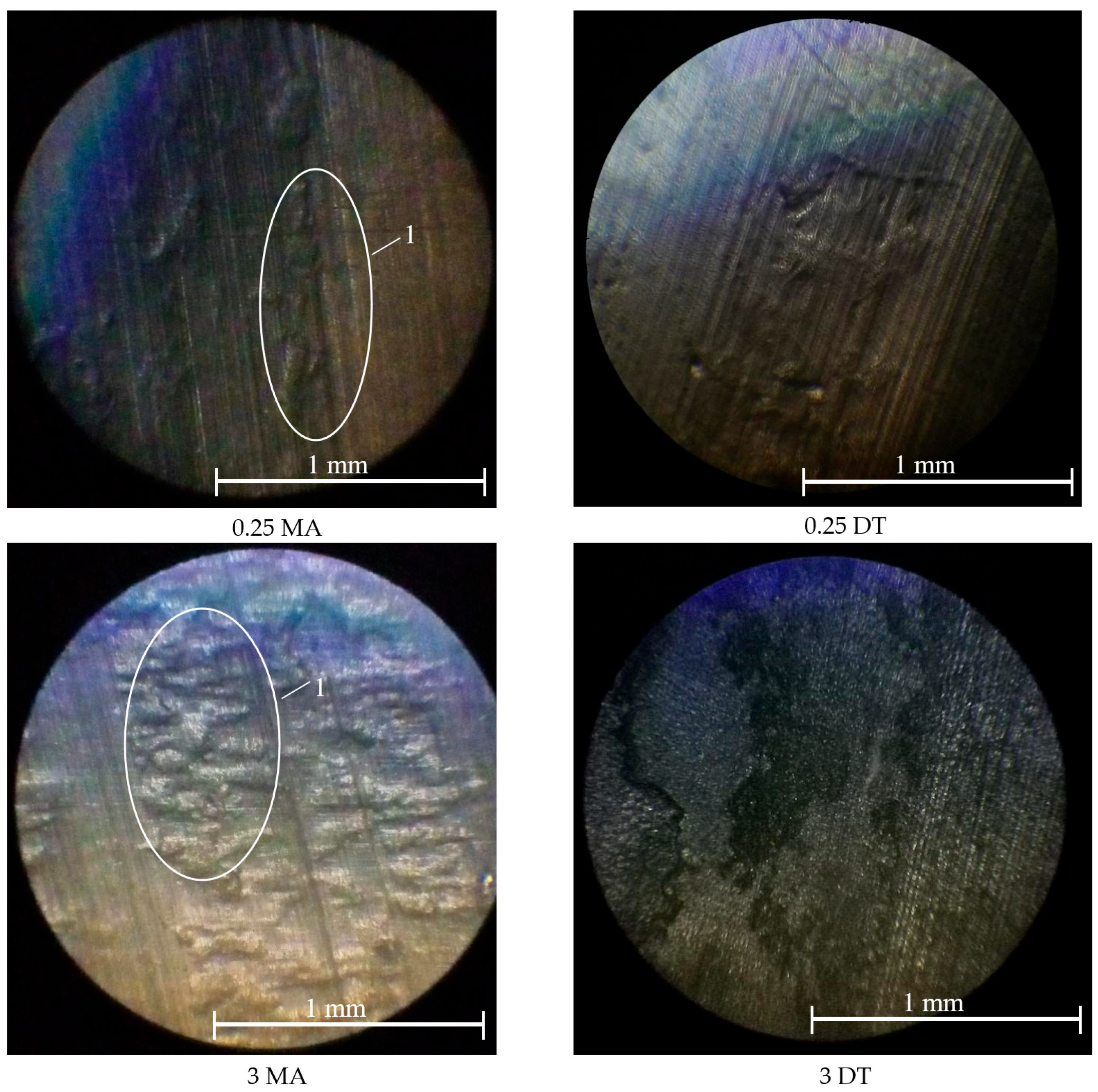

3.1. Visual Assessment of PA 6 Mixtures with MoS2

3.2. Examination of Composite Samples

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Rao, A.P.; Joshi, S.V.; Trivedi, J.J.; Devmurari, C.V.; Shah, V.J. Structure–performance correlation of polyamide thin film composite membranes: Effect of coating conditions on film formation. J. Membr. Sci. 2003, 211, 13–24. [Google Scholar] [CrossRef]

- Fukatsu, K. Thermal degradation behaviour of aromatic polyamide fiber blended with cotton fiber. Polym. Degrad. Stab. 2002, 75, 479–484. [Google Scholar] [CrossRef]

- Naffakh, M.; Marco, C.; Gómez, M.A.; Jiménez, L. Novel melt-processable nylon6/inorganic fullerene-like WS2 nanocomposites for critical applications. Mater. Chem. Phys. 2011, 129, 641–648. [Google Scholar] [CrossRef]

- Srinath, G.; Gnanamoorthy, R. Sliding wear performance of polyamide 6-clay nanocomposites in water. Compos. Sci. Technol. 2007, 67, 399–405. [Google Scholar] [CrossRef]

- Liu, S.P.; Hwang, S.S.; Yeh, J.M.; Hung, C.C. Mechanical properties of polyamide-6/montmorillonite nanocomposites-prepared by the twin-screw extruder mixed technique. Int. Commun. Heat. Mass. 2011, 38, 37–43. [Google Scholar] [CrossRef]

- Takayama, T. Vickers Hardness Mechanical Models and Thermoplastic Polymer Injection-Molded Products’ Static Friction Coefficients. J. Manuf. Mater. Process 2024, 8, 11. [Google Scholar] [CrossRef]

- Takayama, T.; Takahashi, K. Proposal and verification of a thermoplastic surface shear-strength evaluative method. Polym. Test. 2023, 123, 108049. [Google Scholar] [CrossRef]

- Straffelini, G. A simplified approach to the adhesive theory of friction. Wear 2001, 249, 78. [Google Scholar] [CrossRef]

- Steinbuch, R.T. Nylon 6 as a bearing material. Wear 1962, 5, 458–466. [Google Scholar] [CrossRef]

- Siddikali, P.; Sreekanth, P.S.R. Evaluation of Mechanical, Thermal, and Tribological Properties of 3D-Printed Nylon (PA6) Hybrid Composites Reinforced with MWCNTs and Carbon Fibers. J. Compos. Sci. 2025, 9, 155. [Google Scholar] [CrossRef]

- Ustinova, T.P.; Panova, L.G.; Kadykova, Y.A.; Levkina, N.L. The Structure Formation and Evaluation of the Properties of Polymermatric Composites Based on Sub-Microdimensional Fillers. J. Adv. Mater. Technol. 2018, 1, 47–51. [Google Scholar] [CrossRef]

- Sam-Daliri, O.; Ghabezi, P.; Steinbach, J.; Flanagan, T.; Finnegan, W.; Mitchell, S.; Harrison, N. Experimental study on mechanical properties of material extrusion additive manufactured parts from recycled glass fibre-reinforced polypropylene composite. Compos. Sci. Technol. 2023, 241, 110125. [Google Scholar] [CrossRef]

- Gadelmoula, A.; Aldahash, S.A. Tribological Properties of Glass Bead-Filled Polyamide 12 Composite Manufactured by Selective Laser Sintering. Polymers 2023, 15, 1268. [Google Scholar] [CrossRef]

- O’Connor, H.J.; Dowling, D.P. Comparison between the properties of polyamide 12 and glass bead filled polyamide 12 using the multi jet fusion printing process. Addit. Manuf. 2020, 31, 100961. [Google Scholar] [CrossRef]

- Li, D.; You, Y.; Deng, X.; Li, W.; Xie, Y. Tribological properties of solid lubricants filled glass fiber reinforced polyamide 6 composites. Mater. Des. 2013, 46, 809–815. [Google Scholar] [CrossRef]

- Li, D.; Deng, X.; Wang, J.; Yang, J.; Li, X. Mechanical and tribological properties of polyamide 6–polyurethane block copolymer reinforced with short glass fibers. Wear 2010, 269, 262–268. [Google Scholar] [CrossRef]

- Davim, P.; Cardoso, R. Effect of the reinforcement (carbon or glass fibres) on friction and wear behaviour of the PEEK against steel surface at long dry sliding. Wear 2009, 266, 795–799. [Google Scholar] [CrossRef]

- Bai, J.; Song, J.; Wei, J. Tribological and mechanical properties of MoS2 enhanced polyamide 12 for selective laser sintering. J. Mat. Proc. Technol. 2019, 264, 382–388. [Google Scholar] [CrossRef]

- Shiao, S.J.; Wang, T.Z. Dry self-lubricating composites. Compos. Part B Eng. 1996, 27, 459–465. [Google Scholar] [CrossRef]

- Chang, L.; Zhang, Z.; Ye, L.; Friedrich, K. Tribological properties of high temperature resistant polymer composites with fine particles. Tribol. Int. 2007, 40, 1170–1178. [Google Scholar] [CrossRef]

- Wang, J.; Gu, M.; Songhao, B.; Ge, S. Investigation of the influence of MoS2 filler on the tribological properties of carbon fiber reinforced nylon 1010 composites. Wear 2003, 255, 774–779. [Google Scholar] [CrossRef]

- Zaidi, H.; Richard, C.; Bui, H.S.; Tournis, S.; Aissa, M.; Bouguerra, K. Frictional Behavior of MoS2 Coatings: A Comparative Study of Dynamic and Static Friction in Vacuum and Inert Gases. Coatings 2025, 15, 500. [Google Scholar] [CrossRef]

- Vazirisereshk, M.R.; Martini, A.; Strubbe, D.A.; Baykara, M.Z. Solid Lubrication with MoS2: A Review. Lubricants 2019, 7, 57. [Google Scholar] [CrossRef]

- Zhang, L.; Song, W. Friction Behavior of Molybdenum Disulfide/Polytetrafluoroethylene-Coated Cemented Carbide Fabricated with a Spray Technique in Dry Friction Conditions. Coatings 2025, 15, 324. [Google Scholar]

- Gradt, T.; Schneider, T. Tribological Performance of MoS2 Coatings in Various Environments. Lubricants 2016, 4, 32. [Google Scholar] [CrossRef]

- Chen, Z.; He, X.; Xiao, C.; Kim, S.H. Effect of Humidity on Friction and Wear—A Critical Review. Lubricants 2018, 6, 74. [Google Scholar] [CrossRef]

- Tikhomirov, L.A.; Tarasenko, V.A.; Kostina, T.Y.; Dorofeeva, L.V. The Effect of Molybdenum Disulphide on the Tribotechnical Characteristics of Polyamide Coatings on Nitrile Rubber Compounds. Int. Polym. Sci. Technol. 2018, 42, 31–34. [Google Scholar] [CrossRef]

- Friedrich, K.; Zhang, Z.; Schlarb, A.K. Effects of various fillers on the sliding wear of polymer composites. Comp. Sci. Technol. 2005, 65, 2329–2343. [Google Scholar] [CrossRef]

- Balaz, P.; Achimovicova, M.; Balaz, M. Hallmarks of mechanochemistry: From nanoparticles to technology. Chem. Soc. Rev. 2013, 42, 7571–7637. [Google Scholar] [CrossRef]

- Real, C.; Gotor, F.J. Effects of the speed ratio on the efficiency of planetary mills. Heliyon 2019, 5, e01227. [Google Scholar] [CrossRef]

- Bobozhanov, A.R.; Kovalev, D.Y.; Vadchenko, S.G.; Rogachev, A.S. The impact of the operating mode of a planetary mill and gas atmosphere on mechanical alloying of powders in the Ni–Cu system. J. Adv. Mater. Technol. 2025, 10, 040–048. [Google Scholar] [CrossRef]

- Xue, Q.; Lim, Y.J.; Zhang, K. Engineering multi-channel water transport in surface-porous MXene nanosheets for high-performance thin-film nanocomposite membranes. J. Membr. Sci. 2025, 728, 124151. [Google Scholar] [CrossRef]

- Hooks, K.; Ferguson, W.; Morillo, P.; Cruz-Neira, C. Evaluating the user experience of omnidirectional VR walking simulators. Entertain. Comput. 2020, 34, 100352. [Google Scholar] [CrossRef]

- Scherge, M.; Shakhvorostov, D.; Pöhlmann, K. Fundamental wear mechanism of metals. Wear 2003, 255, 395–400. [Google Scholar] [CrossRef]

- Neis, P.D.; Ferreira, N.F.; Poletto, J.C.; Sukumaran, J.; Andó, M.; Zhang, Y. Tribological behavior of polyamide-6 plastics and their potential use in industrial applications. Wear 2017, 376–377, 1391–1398. [Google Scholar] [CrossRef]

- ISO 294-1:2017; Plastics—Injection Moulding of Test Specimens of Thermoplastic Materials—Part 1: General Principles, and Moulding of Multipurpose and Bar Test Specimens. ISO: Geneva, Switzerland, 2017.

- ISO 291:2008; Plastics—Standard Atmospheres for Conditioning and Testing. ISO: Geneva, Switzerland, 2008.

- ISO 527-1:2019; Plastics—Determination of Tensile Properties—Part 1: General Principles. ISO: Geneva, Switzerland, 2019.

- ISO 527-2:2012; Plastics—Determination of Tensile Properties—Part 2: Test Conditions for Moulding and Extrusion Plastics. ISO: Geneva, Switzerland, 2012.

- ISO 868:2003; Plastics and Ebonite—Determination of Indentation Hardness by Means of a Durometer (Shore Hardness). ISO: Geneva, Switzerland, 2003.

- ISO 10640:2011; Plastics—Methodology for Assessing Polymer Photoageing by FTIR and UV/Visible Spectroscopy. ISO: Geneva, Switzerland, 2011.

- ISO 11358-1:2022; Plastics—Thermogravimetry (TG) of Polymers—Part 1: General Principles. ISO: Geneva, Switzerland, 2022.

- ISO 7148-2:2012; Plain Bearings—Testing of the Tribological Behaviour of Bearing Materials—Part 2: Testing of Polymer-Based Bearing Materials. ISO: Geneva, Switzerland, 2012.

- ISO 62:2008; Plastics—Determination of Water Absorption. ISO: Geneva, Switzerland, 2008.

- Podshivalova, K.S.; Lakhno, A.V.; Valyukhov, A.A.; Erofeev, V.T. Density of dispersed-filled composites. Bull. Mordovian Univ. 2008, 18, 92–97. [Google Scholar]

- Ovchinnikov, A.A.; Obruchev, D.V.; Danilov, I.N. Composite materials based on polysturctural integration of heterogeneous materials. Smart Comp. Constr. 2021, 2, 21–31. [Google Scholar] [CrossRef]

- Ovchinnikov, A.A.; Obruchev, D.V.; Danilov, I.N. Optimisation of composite material structure based on the technology of polystructural integration of heterogeneous materials. Smart Comp. Constr. 2022, 3, 30–46. [Google Scholar] [CrossRef]

| Sample Designation | Composition | Mixing Mode |

|---|---|---|

| 0.25 MA | PA6 + 0.25% MoS2 | Mechanical activation in planetary mills |

| 0.5 MA | PA6 + 0.5% MoS2 | |

| 1 MA | PA6 + 1% MoS2 | |

| 3 MA | PA6 + 3% MoS2 | |

| 5 MA | PA6 + 5% MoS2 | |

| 0.25 DT | PA6 + 0.25% MoS2 | Turbulent mixer drum tumblers |

| 0.5 DT | PA6 + 0.5% MoS2 | |

| 1 DT | PA6 + 1% MoS2 | |

| 3 DT | PA6 + 3% MoS2 | |

| 5 DT | PA6 + 5% MoS2 |

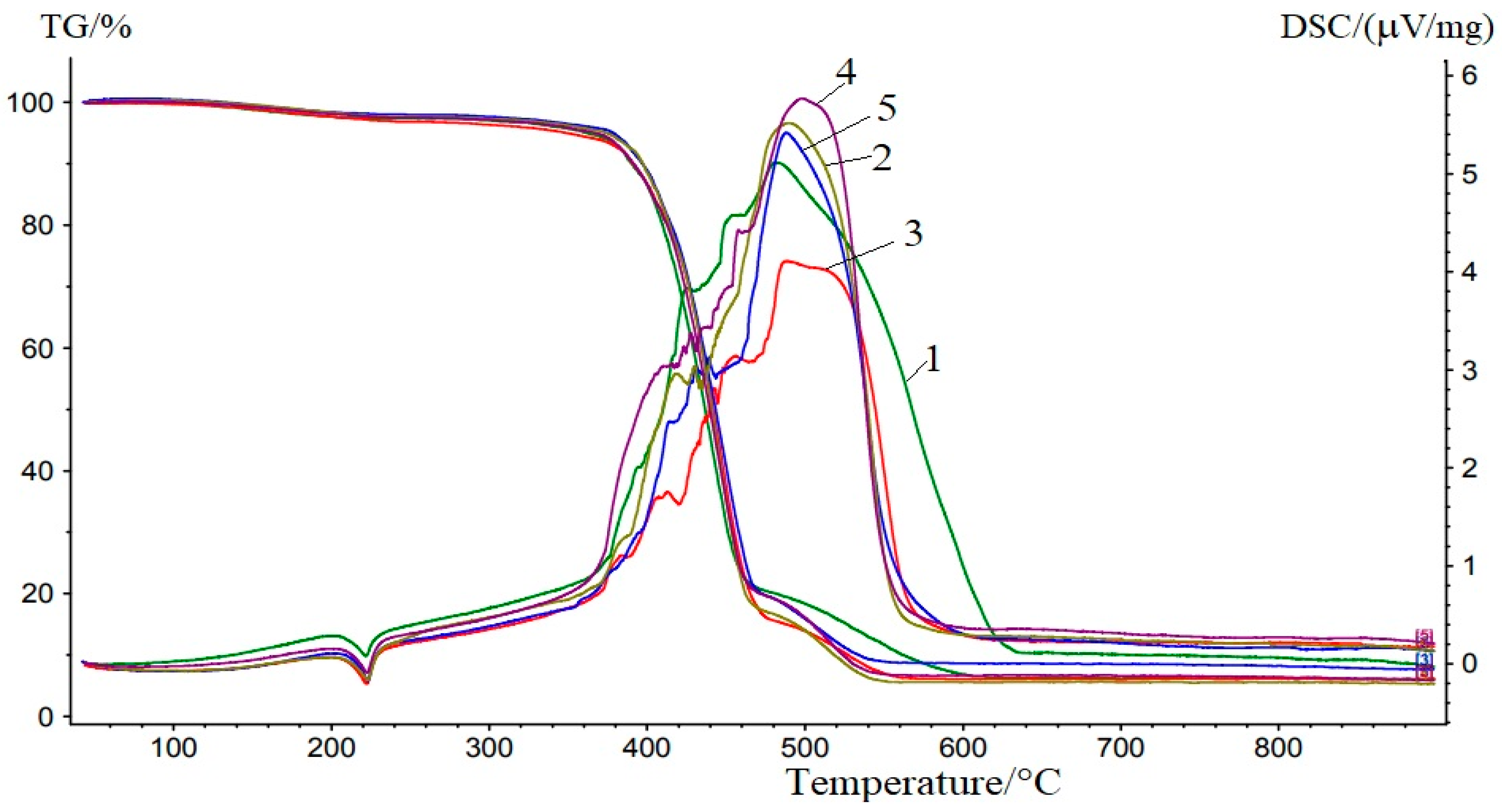

| Sample | Temperature, °C | Residual Weight, % | |

|---|---|---|---|

| 5% Weight Loss | 50% Weight Loss | ||

| PA6 | 362 | 437 | 5.7 |

| 0.5 MA | 375 | 442 | 6.2 |

| 0.5 DT | 349 | 441 | 6.1 |

| 3 MA | 379 | 444 | 6.9 |

| 3 DT | 368 | 440 | 7.7 |

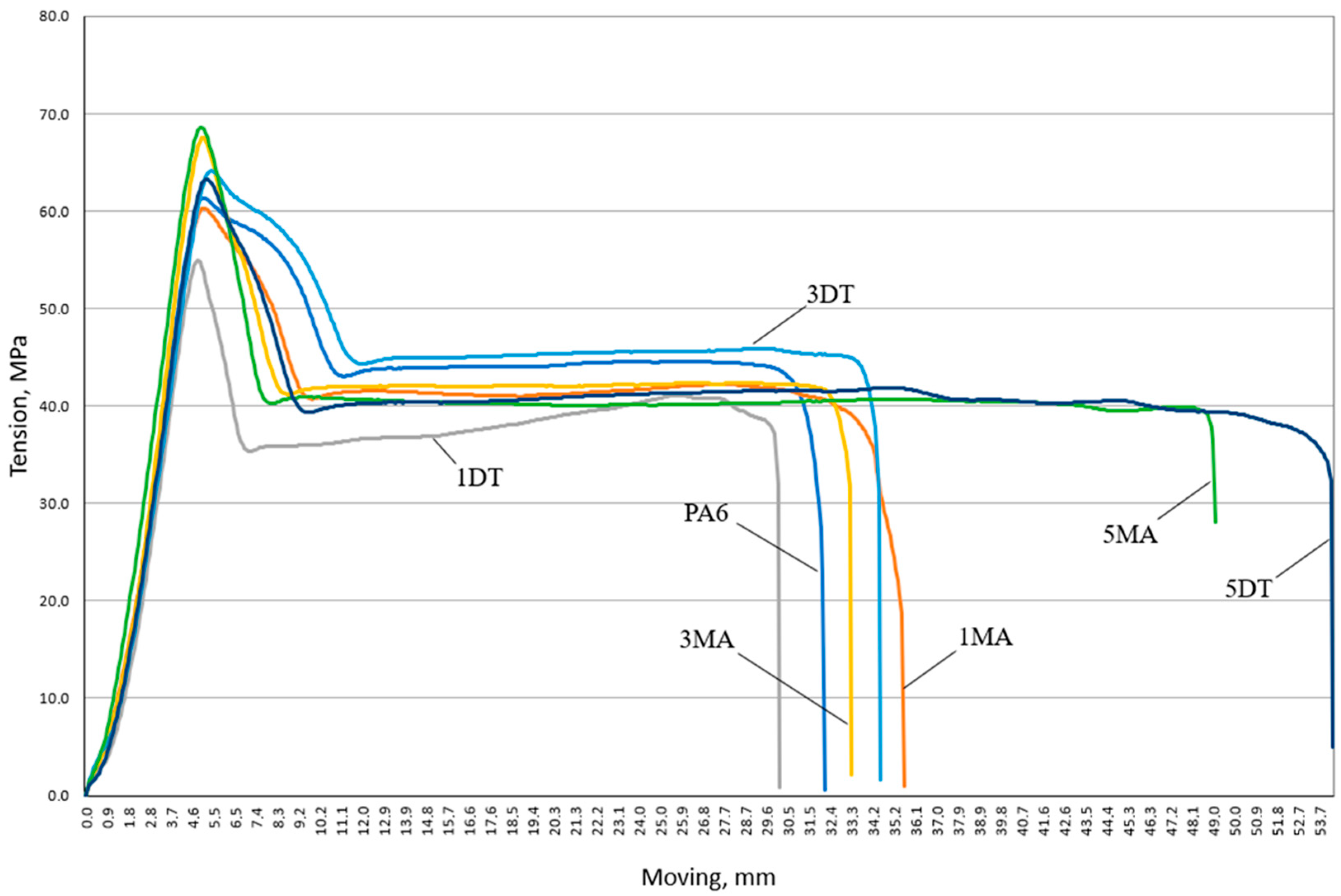

| MoS2 Concentration, Mass Percentage | Tensile Strength, MPa | Relative Extension at Tear, % | Tensile Elasticity Modulus, MPa | |||

|---|---|---|---|---|---|---|

| MA | DT | MA | DT | MA | DT | |

| 0 | 64 | 72 | 1562 | |||

| 0.25 | 70.5 | 63.5 | 75 | 77 | 1544 | 1458 |

| 0.5 | 70.8 | 68.6 | 74 | 76 | 1589 | 1508 |

| 1 | 67.5 | 56.6 | 74 | 71 | 1637 | 1602 |

| 3 | 76.2 | 68 | 57 | 55 | 1528 | 1524 |

| 5 | 73 | 70.9 | 61 | 62 | 1768 | 1722 |

| MoS2 Concentration, Mass Percentage | Hardness Index | |

|---|---|---|

| MA | DT | |

| 0 | 74 | |

| 0.25 | 78 | 77 |

| 0.5 | 77 | 76 |

| 1 | 78 | 78 |

| 3 | 78 | 77 |

| 5 | 78 | 78 |

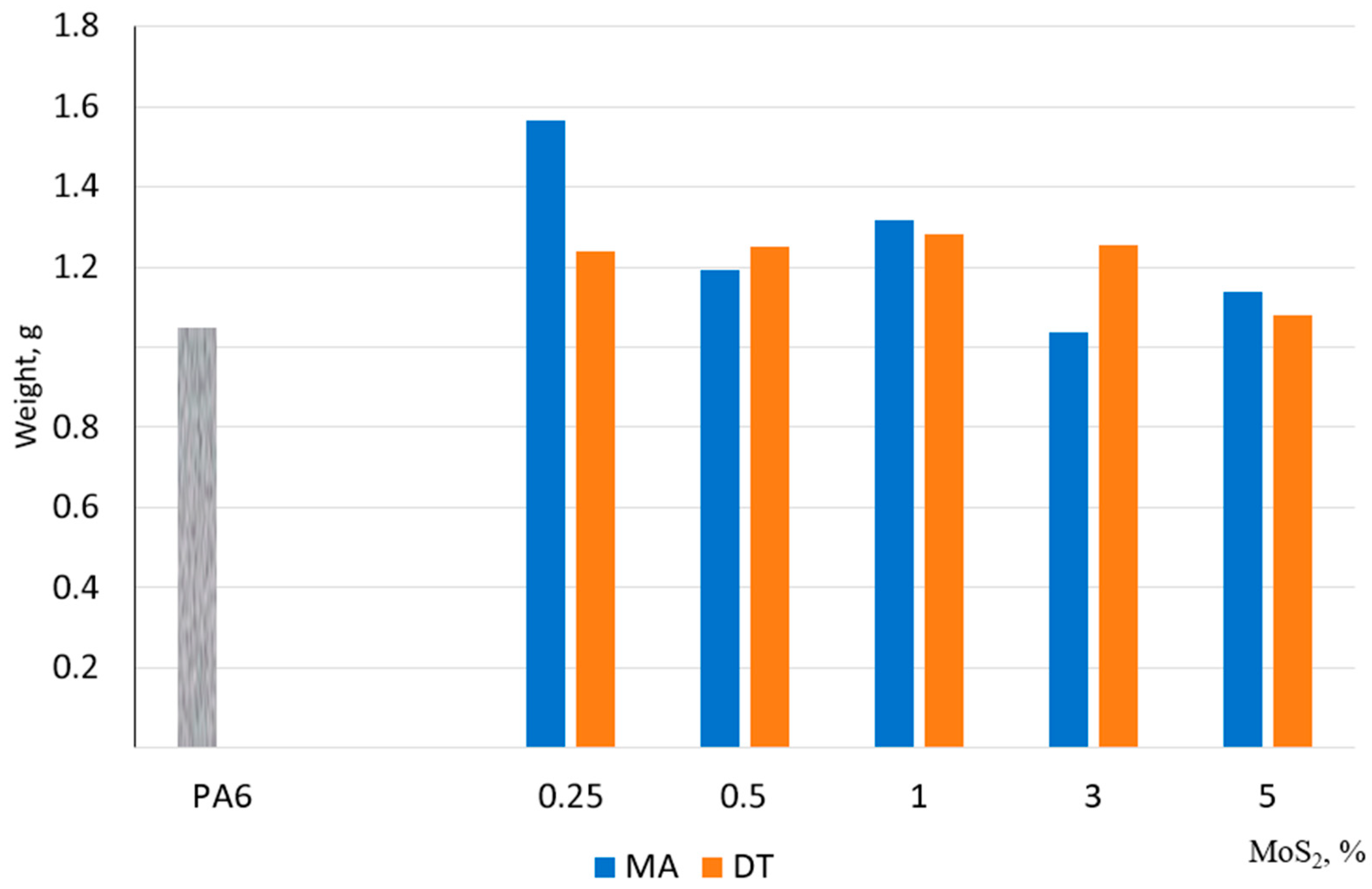

| The Content of MoS2 in the Composite, % | MA | DT |

|---|---|---|

| 0 | 0.196 | |

| 0.25 | 0.168 | 0.151 |

| 0.5 | 0.161 | 0.157 |

| 1 | 0.174 | 0.157 |

| 3 | 0.174 | 0.169 |

| 5 | 0.186 | 0.156 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zavrazhin, D.; Dyachkova, T.; Obukhov, A.; Krasnyanskiy, M.; Burakova, E.; Dedov, D.; Chuprikova, A. The Effect of Preliminary Mixing Methods on the Properties of PA6 Composites with Molybdenum Disulphide. Sci 2025, 7, 178. https://doi.org/10.3390/sci7040178

Zavrazhin D, Dyachkova T, Obukhov A, Krasnyanskiy M, Burakova E, Dedov D, Chuprikova A. The Effect of Preliminary Mixing Methods on the Properties of PA6 Composites with Molybdenum Disulphide. Sci. 2025; 7(4):178. https://doi.org/10.3390/sci7040178

Chicago/Turabian StyleZavrazhin, Dmitry, Tatiana Dyachkova, Artem Obukhov, Mikhail Krasnyanskiy, Elena Burakova, Denis Dedov, and Anastasia Chuprikova. 2025. "The Effect of Preliminary Mixing Methods on the Properties of PA6 Composites with Molybdenum Disulphide" Sci 7, no. 4: 178. https://doi.org/10.3390/sci7040178

APA StyleZavrazhin, D., Dyachkova, T., Obukhov, A., Krasnyanskiy, M., Burakova, E., Dedov, D., & Chuprikova, A. (2025). The Effect of Preliminary Mixing Methods on the Properties of PA6 Composites with Molybdenum Disulphide. Sci, 7(4), 178. https://doi.org/10.3390/sci7040178