Abstract

The effect of preparing the commercial yeast prise de mousse S. cerevisiae IOC 18-2007 on the second fermentation kinetics of a Macabeo white base wine was evaluated. The influence of yeast preparation on the final “Cava” sparkling wines was determined. The medium glucose, peptone, yeast extract (GPY medium), and the characteristic classic pied de cuve procedure were used to prepare the inoculum, which was placed besides a tirage liqueur inside bottles in which a second fermentation took place by the “traditional method”. The fermentation kinetics were similar for the first 60 days regardless of the employed yeast inoculum preparation. In both cases, glucose was exhausted and a few grams of fructose remained on day 30. The ethanol concentration after 60 days was the same in all of the wines. The sparkling wines inoculated with the GPY-grown yeasts showed higher titratable acidity, lower total polysaccharide and protein contents, and greater foamability (HM) and foam stability (HS). Regarding volatile compounds, these wines contained higher esters, fatty acids, higher alcohols, and γ-butyrolactone. Differences in the wine’s visual and flavor attributes were not significant no matter what inoculum was used. However, the aroma score was significantly higher in the wines inoculated with the pied de cuve-prepared yeasts.

1. Introduction

The production of sparkling wine by the “traditional method” requires two successive alcoholic fermentations (AFs). The first fermentation in regular white winemaking results in dried wine to be bottled. A mixture of sugars and yeasts (tirage liqueur) and riddling agents (usually bentonite) is added to each bottle to perform a second fermentation inside capped bottles. This fermentation runs at a low temperature (12–15 °C) and takes 14–45 days. The main consequences are a slight increase in ethanol (around 1.4 degrees) and considerable CO2 gain, which dissolves in wine and increases the pressure inside of the bottles. The second fermentation is followed by an aging period, during which wine remains in contact with dead yeast cells and undergoes a process called autolysis (see Kemp, et al. [1]). Yeast autolysis can be defined as the irreversible enzymatic degradation of cell components, and occurs after cell death [2]. Degraded components are slowly released to extracellular media to, thus, modify the sparkling wine’s composition and its organoleptic characteristics: roundness, flavor, complexity, and foaming [3,4].

High-quality sparkling wines, such as “Champagne” (France), “Cava” (Spain), or “Talento” (Italy), are fermented in closed bottles following either the “traditional method” or the AOC Champagne “Champenoise” method (described above), and remain in contact with yeast lees in bottles for several months, or even years [5].

Winemakers generally use active commercial dried yeast to perform the second fermentation. Sometimes the yeast used for this secondary fermentation is the same as that employed for the first one. Invariably, however, this yeast must be chosen for its ability to ferment high-acidity and low-pH wines, and must be ethanol-tolerant [4,6]. To overcome the harsh conditions inside bottles (low pH, ethanol, low sugar content, and rising CO2 pressure), dry yeast must be adapted to ensure that fermentation is successfully completed. One of the methodologies for adaptation involves the culture of the selected yeast in several media that contain increasing ethanol concentrations. This adaptation process is known as pied de cuve [7].

Research into sparkling wine production has focused mostly on aging and autolysis by analyzing changes in polysaccharides, oligosaccharides, and nitrogenous compounds during the aging period [8,9]. Many studies have also evaluated the influences of different factors (e.g., yeast strain, base wine, production method, and aging time) on the aromatic profile and sensory properties of sparkling wines [3,10,11,12]. However, very few research works have studied the influences of yeast inoculation or preparation procedures on secondary fermentation kinetics, volatile compounds, or the sensorial attributes of sparkling wines [3,7,13]. Yeast inoculated to perform secondary fermentation faces different stressful conditions: high CO2 pressure, ethanol, low pH, scarce nutrients, etc. Kunkee and Ough [14] report that pressure is most inhibitory to growth, especially at a low pH or a high alcohol concentration. This inhibition diminishes when yeast cells are adapted to wine before inoculation, which reveals the need for previous yeast preparation. Adapting yeast cells to ethanol results in a larger and more viable population [15]. Laurent and Valade [16] analyzed the effect of adding nitrogen (N) to the pied de cuve in both adaptation and proliferation steps. They conclude that N addition produces a bigger biomass and faster sugar consumption in the media. Martí-Raga, Martín, Gil, Sancho, Zamora, Mas, and Beltran [3] showed that inorganic N or inactive dry yeast additions in yeast proliferation steps significantly influence the pressure gain during the second fermentation.

For routine yeast growing, culture media such as glucose-peptone-yeast (GPY) extract broth is used in laboratories. GPY has organic N sources, such as peptone and yeast extract, that promote rapid growth and a large final cell biomass, and also act as protective agents in the adaptation and proliferation steps of the yeast starter culture before the second fermentation in sparkling wines. Johansson, et al. [17] demonstrated that S. cerevisiae grown on a medium consisting of a mixture of spent sulfite liqueur (SSL) and a medium containing glucose yeast extract and (NH4)2SO4 (YD) produces more ethanol than when grown on SSL or YD.

The main objective of this study was to investigate the influence of the preparation method of the commercial S. cerevisiae IOC 18-2007 dry yeast on fermentation kinetics, foaming properties, and other parameters related to autolysis, and also on the volatile composition of sparkling wines after 9 months of aging. The effects of the two yeast preparation methodologies on the fermentation kinetics, the foaming properties, and the parameters related to yeast autolysis on both volatile composition and on the sensorial properties of the finished sparkling wines were studied.

2. Materials and Methods

2.1. Microorganisms and Yeast Starter Culture Preparation

The commercial yeast for the prise de mousse of S. cerevisiae IOC 18-2007 (Institute OEnologique de Champagne, Reims, France) was used to accomplish the second fermentation of sparkling wines. The IOC 18-2007 yeast was prepared following two different methodologies. Dry yeast was prepared in two ways: (a) by a pied de cuve methodology at the winery; (b) by using the routine medium (GPY) in the laboratory. The pied de cuve preparation comprised different steps: first, a tirage liqueur was prepared by adding 50 kg of sucrose to 1200 L of the base wine (80% Macabeo and 20% Chardonnay). The components were mixed and kept at 20 °C; second, 1 kg of yeast IOC 18-2007 was rehydrated in 10 L of water at 37 °C. To this blend, 1 kg of the Fortifrem yeast nutrient (Lallemand, Inc., Montreal, QC, Canada) was added and mixed for 15 min; third, every 10 min, 10% of the tirage liqueur was added to the previously prepared yeast solution. Maintaining the difference in temperature between the yeast solution and the tirage liqueur below 10 °C was important; fourth, O2 (10 mL/L, once a day) was added to the mixture and left at 20 °C for 3 days. After this time, yeast cells had grown and fermentation had started. At this time, a microscopic cell count was carried out to calculate the pied de cuve volume needed to obtain a concentration of 1.5 × 106 cells/mL inoculum in the bottle. Alternatively, the IOC 18-2007 yeast was rehydrated directly in the GPY [18] at a concentration of 10% (w/v), and maintained at 37 °C for 1 h in the laboratory. Following this, the yeast was inoculated in fresh GPY and incubated overnight at 25 °C to reach 2 × 108 CFU/mL. The laboratory-prepared culture was transported to the winery and used to inoculate the base wine at the same concentration as the yeast prepared by pied de cuve in the winery.

2.2. Sparkling Wine Production and Sampling Times

Vinification trials were run with a base wine that consisted of a coupage of 80% Macabeo and 20% Chardonnay base wines at a winery of the Denominación de Origen Protegida (D.O.P., Designation of Protected Origin), Utiel-Requena, Spain. The second fermentation was performed by the “traditional method” (inside capped bottles) according to EU and Spanish government specifications [19,20]. The base wine (1 g/L reducing sugars; 11% ethanol v/v; pH 3.15; titratable acidity 8.50 g/L, expressed as tartaric acid; volatile acidity 0.16 g/L, expressed as acetic acid) was distributed inside transparent glass bottles. The tirage liqueur was prepared to obtain a final concentration of 12 g/L glucose and 12 g/L fructose in the final blend, and the yeast starter culture was prepared as either pied de cuve at the winery or grown in GPY in the laboratory, to be added to obtain 1.5 × 106 cells/mL in the bottle (2 mL of GPY culture or 15 mL of pied de cuve were added to a 750 mL bottle of the base wine). The bottles were kept at 11–13 °C and at a relative humidity of 75–85% for 9 months. Twenty-four bottles per experiment were inoculated. All of the bottles were analyzed throughout the second fermentation to accomplish the different objectives (kinetics of sugar consumption and ethanol production, chemical characteristics of sparkling wines, parameters related to yeast autolysis and foaming properties, and volatile aroma analysis and sensory analysis). Every week for the first month, at the end of the second month, and at 9 months aging, three bottles per experiment were opened to determine glucose, fructose, and ethanol concentrations, to know the second alcoholic fermentation kinetics. High-pressure liquid chromatography (HPLC) quantified both sugars and ethanol (see below). The volatile composition of the resulting sparkling wines was determined by gas chromatography at the end of the aging period (9 months). Before the analysis, the bottles were riddled and disgorged. Brut nature sparkling wines were obtained, and no expedition liqueur was added. The experiments were performed in triplicate.

2.3. Analytical Methods

The glucose, fructose, and ethanol contents were quantified by HPLC (Agilent series 1200 system, Agilent Technologies, Barcelona, Spain) equipped with an isocratic pump (Agilent G1310A) following the procedure described by Frayne [21], with minor modifications. The mobile phase consisted of a solution of 0.75 mL of 85% H3PO4 (Panreac, Castellar del Vallès, Barcelona, Spain) per liter of deionized water at a flow rate of 0.7 mL/min. An Agilent G1322A degasser was employed. Samples (5 µL) were automatically injected (Agilent G1367B). Compounds were separated in an Aminex HPX-87H precolumn (Bio-Rad, Hercules, CA, USA) coupled with two ion-exclusion columns of 300 mm by 7.8 mm, Aminex HPX-87H (Bio-Rad), which were thermostatically controlled at 65 °C (Agilent G1316A). Compounds were detected by a G1314B variable-wavelength detector (Agilent) set at 210 nm and a refractive index detector (Agilent G1362A) set in series. The elution time was 45 min. External calibration was performed with the reference standards of glucose, fructose, and ethanol (Panreac). All of the samples were centrifuged at 6000 g for 10 min (PrismR centrifuge, Labnet, Madrid, Spain). After this, the supernatant was filtered through a membrane filter with a mean pore size of 0.22 µm before injection (Labbox, Premià de Dalt, Barcelona, Spain). Quantification was performed by measuring the peak heights compared to those of the external standards.

The analytical methods recommended by the OIV were used to determine titratable acidity and volatile acidity [22]. pH was determined by a Hanna Instruments HI 8424 pH meter (Smithfield, RI, USA). Foaming, proteins, and polysaccharides measurements were taken as described by Canals, et al. [23], Ayestarán, et al. [24], and Maujean, et al. [25].

2.4. Volatile Aroma Compound Analysis and Odor Activity Value (OAV) Estimation

Volatile compounds were analyzed by the procedure proposed by Ortega, et al. [26], with slight modifications. A volume of 2.7 mL of the samples was transferred to a 10-mL screw-capped centrifuge tube containing 4.05 g of ammonium sulfate (Panreac), to which the following compounds were added: 6.3 mL of milliQ water (Panreac), 20 μL of standard internal solution (2-butanol, 4-methyl-2-pentanol and 2-octanol from Aldrich (St. Louis, MO, USA)), at 140 μg/mL each in absolute ethanol from LiChrosolv-Merck (Darmstadt, Germany), and 0.25 mL of dichloromethane (LiChrosolv-Merck). The tube was shaken mechanically for 120 min and then centrifuged at 2900× g for 15 min. The dichloromethane phase was recovered with a 0.5 mL syringe (Labbox), transferred to the autosampler vial, and analyzed. The chromatographic analysis was carried out in a HP-6890 (Hewlett Packard, San José, CA, USA), equipped with a ZB-Wax plus column (60 m × 0.25 mm × 0.25 µm) from Phenomenex (Torrance, CA, USA). The column temperature, initially set at 40 °C and maintained at this temperature for 5 min, was raised to 102 °C at a rate of 4 °C/min, to 112 °C at a rate of 2 °C/min and to 125 °C at a rate of 3 °C/min, and then this temperature was maintained for 5 min before being raised to 160 °C at a rate of 3 °C/min, and to 200 °C at a rate of 6 °C/min. Finally, this temperature was maintained for 30 min. The carrier gas was helium (Carburos Metálicos, Massalfassar, Valencia, Spain), which was fluxed at a rate of 3 mL/min. The injection was carried out in the split mode 1:20 (injection volume 2 μL) with a flame ionization detector (FID detector, Hewlett Packard).

In addition, Kovats retention indices (KI) were calculated for the corresponding GC peaks, to identify the substance by the interpolation of the retention time of normal alkane (C8–C20) (Fluka Buchs, Schwiez, Switzerland) analyzed under the same chromatographic condition. The calculated KI were compared to those reported in the literature for the same stationary phase.

2.5. Parameters Related to Yeast Autolysis and Foaming Properties

To determine the total protein content of the finished sparkling wines, samples were concentrated following a two-step dialysis in tubes with an MM cut-off of 3.5 kDa (Merck, Darmstadt, Germany), and were then lyophilized (Virtis manifold benchtop freeze dryer, Virtis Co. Inc., Gardner, NY, USA) and frozen at −20 °C. The lyophilized samples were resuspended in 0.6 μL of ammonium acetate solution (300 mmol/L) (Panreac) and centrifuged. The supernatant was filtered through 0.22 μm acetate cellulose filters (Labbox), and then 100 μL of the supernatant were injected into the chromatographic system. Analyses were carried out by HPLC (Agilent 1200 Series system (Agilent Technologies) with an agilent 1290 Infinity II Diode Array Detector (DAD) to monitor outputs at 230 and 320 nm (for details, see Canals, Arola, and Zamora [23]).

Polysaccharide extraction and determination using HRSEC-RID were performed according to Ayestarán, Guadalupe and León [24]. Polysaccharide extraction entailed a 5-fold concentration of 10 mL of the finished sparkling wines using a vacuum evaporator, a subsequent precipitation of polysaccharides with 10 mL hydrochloric acid 0.3 mol/L (Panreac) in absolute ethanol, centrifugation, sediment recovery in 1 mL ultrapure water, freezing at −20 °C, and lyophilization. The lyophilized samples were resuspended in 1 mL of 50 mmol/L ammonium formate (Panreac) and filtered through 0.22 μm acetate cellulose filters, before undergoing total polysaccharides quantification by high-resolution size-exclusion chromatography (HRSEC) using a refractive index detector (RID) (for details, see Ayestarán, Guadalupe and León [24]).

The procedure that was followed in order to measure foaming properties was the Mosalux method [25]. Measurements of the maximum height (HM) of the foam after CO2 injection through the glass frit, and of the stable height (HS) during CO2 injection, were taken. HM represents foamability and HS denotes foam stability. A Mosalux device (Station Oenotechnique de Champagne, Epernay, France) was used to measure these parameters.

2.6. Sensory Analysis

A panel of 16 experts carried out a sensory analysis of the resulting sparkling wines. The panel consisted of six men and ten women aged between 30 and 60 years. These panelists were all experts in sparkling wine tasting, and were previously trained during two preparatory sessions to align their assessment criteria. The visual, aroma, and flavor characteristics were analyzed according to the score sheet for sparkling and pearl wines published by the OIV [27]. The intensity of each attribute was rated on a scale from 0 to 10 with indented anchor points of ‘low’ and ‘high’, respectively.

2.7. Statistical Analysis

The final residual sugar, ethanol, total and volatile acidities, pH, volatile aroma, total polysaccharide and protein contents, and foam properties of “Cava” wines were statistically analyzed by the Statgraphic Plus 5.1. software (Statgraphics Technologies, Inc., The Plains, VA, USA). ANOVA and discriminant analyses were employed. The statistical significance of each considered factor was calculated at α = 0.05 by the Student’s t-test. To simplify the results, a principal component analysis (PCA) and orthogonal projections to the latent structures discriminant analysis were performed with SIMCA, version 10 (MKS Umetrics, Malmo, Sweden). A PCA was used to identify the main factors that explained most of the variances observed from a much larger number of manifest variables.

3. Results and Discussion

3.1. Kinetics of Sugar Consumption and Ethanol Production in Capped Bottles

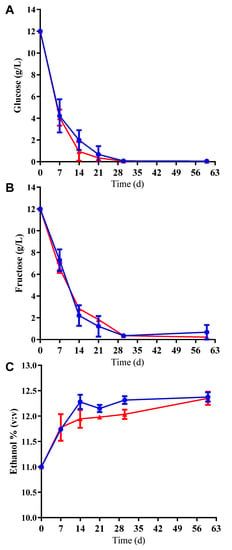

The kinetics of glucose and fructose consumption and ethanol production during the second fermentation were recorded to discern if differences between the two yeast preparation methodologies existed. The final sugar and ethanol concentrations were similar in the sparkling wines fermented with the two starter cultures, regardless of the yeast culture preparation methodology followed; the glucose and fructose were practically exhausted over 30 days, and the ethanol increased by 1.5% after 60 days (Figure 1) under both inoculation conditions. The yeast grown on GPY metabolized glucose slightly slower and fructose slightly quicker than the pied de cuve yeast, although slightly more residual fructose was found in the GPY-inoculated wines on day 60. From days 7 to 28, the ethanol production kinetics showed that ethanol production was quicker in the wines inoculated with the GPY-grown yeast than in those inoculated with the pied the cuve-prepared yeast. However, the final ethanol concentration after 60 days was the same in both sparkling wine types.

Figure 1.

Glucose (A) and fructose (B) consumption and ethanol (C) production kinetics on the first 60 days of the second base wine fermentation performed by S. cerevisiae IOC 18–2007 GPY-grown (●) or pied de cuve-prepared, following the manufacturer’s instructions (▲). Compounds concentrations were determined by HPLC.

It is well-known that dry yeast acclimatization by the pied de cuve methodology is essential for avoiding cell viability loss in the base wine. Low cell viability may result in either failure to ferment or an extended fermentation time [7]. Interestingly, the GPY-grown yeasts seemed to properly prepare yeast to cope with wine conditions with no loss of activity. The GPY culture showed higher cell viability and a higher cell concentration than the cell preparation from the pied de cuve (85% vs. 60% and 5 × 108 vs. 5 × 107 ufc/mL, respectively). It seemed clear that more viable cells could counterbalance yeast stress during the second fermentation, because small, but non-significant, differences were found in both glucose and fructose consumption and ethanol production (Figure 1).

GPY contains organic N sources, such as peptone and yeast extract, that can act as protective agents and fermentative enhancers by reducing stress and increasing wine yeast resistance and viability [28,29,30]. These components also play an important role as nutrient sources, because they include a soluble fraction that is rich in amino acids, vitamins, and minerals. Organic N improves growth, biomass production [31,32], cell vitality, and survival under adverse conditions [33], and is the preferred N source for maintaining metabolic activity in the growth stationary phase [34]. Thus, proper nutrition and active growth conditions prior to inoculation in the base wine could determine good behavior during the second fermentation. In addition, N uptake by yeasts during GPY growth could cover the low N availability during the second fermentation. The positive N nourishment of cells grown in the GPY medium compensated for the lack of adaptation of the cells prepared by pied de cuve.

3.2. Chemical Characteristics of Sparkling Wines

The pH value, titratable and volatile acidities, residual sugars, and the ethanol concentrations of the base and finished sparkling wines can be seen in Table 1. All of the values obtained from the sparkling wines were similar, no matter what inoculum was used, except for those of titratable acidity. The data comparison of the sparkling and base wine parameters showed significant differences in titratable acidity (greater in the base wine), and in the residual sugar and ethanol concentrations (higher and lower, respectively, in the base wine).

Table 1.

Chemical parameters of the resulting sparkling wines fermented with the S. cerevisiae strain IOC 18-2007, GPY-grown or pied de cuve-prepared.

Titratable acidity was the only parameter that significantly affected sparkling wines. It was 7.65 g/L and 6.30 g/L in the wines inoculated with the GPY-grown and the pied de cuve-prepared yeast, respectively. Differences in titratable acidity were not reflected in the corresponding pH values. In fact, the wines with higher acidity had higher pH values than those with lower acidity.

Differences in titratable acidity could be explained by the different malolactic fermentation occurrences, tartrate salts crystallizations, or S. cerevisiae organic acid productions. These distinct scenarios could be influenced by the inoculum preparation procedure. Differences in the acid concentrations of sparkling wines at the end of the aging process are shown in Supplementary Table S1. As malolactic fermentation occurred in the overall wines no matter what inoculum was used, this fermentation was not the reason for the differences in titratable acidity. A slightly higher succinic acid concentration and a lower acetic acid concentration (all non-significant) were found in the wines inoculated with the GPY-grown yeasts. This means that yeast produced different quantities of organic acids during the second fermentation depending on the inoculum preparation. Tartaric acid content was significantly higher in the GPY-inoculated wines. The origin of this acid was not yeast metabolism, and the different concentrations found in the wines at the end of the aging process were due to tartaric salt crystallization. The cause of this phenomenon could lie in the low volume of the GPY yeast culture added to the base wine yeasts containing less potassium than the 4-fold higher volume of pied de cuve. The increased ethanol content caused by the second fermentation could provoke potassium hydrogen tartrate crystallization if the wine was not completely stable. When potassium hydrogen tartrate crystallizes, a proportion of the hydrogen tartrate anion is removed from the tartaric acid equilibrium, which leads to displacement toward the release of protons [35] and brings about a simultaneous decrease in titratable acidity and pH. It is known that S. cerevisiae is able to produce small amounts of organic acids, such as ac. pyruvic, L-lactic, L-(−)malic, fumaric, and succinic, among others [36]. The production of these acids depends largely on environmental conditions, such as the fermentation temperature, sugar and N concentrations, pH [37,38], and also on yeast growth [36,39]. The chemical composition of the GPY and the conditions under which S. cerevisiae IOC 18–2007 was cultured in the laboratory were very different from the composition of the medium and the conditions used to make the pied de cuve in the winery. One reason to explain the higher succinic acid production in the GPY-inoculated “Cava” wines was that the yeast grown in GPY had more N supply than in the pied de cuve (40-fold more). This would make yeast more capable of producing this acid. Heerde and Radler [40] described that succinic acid production by S. cerevisiae was more affected by the N concentration, and that the higher the N concentration, the bigger the succinic acid production should be. Martí-Raga, et al. [41] observed that the addition of organic N to the pied de cuve affected second fermentation development more than inorganic N addition or the N content in the base wine. A greater viable and active population of the GPY-grown yeast was introduced into the base wine than when the pied de cuve-prepared yeast was used. Several authors have shown that the production of organic acids by S. cerevisiae is closely related to the growth phase, and occurs mainly during the first hours of growth in both must and synthetic medium [37,39,42].

In any case, these slight differences in the concentration of the analyzed acids only explain part of the difference found in the titratable acidity between the sparkling wines made with the GPY-grown and pied de cuve-prepared yeasts. The probable explanation is that the higher titratable acidity of the sparkling wine prepared with the GPY-grown yeasts could be due to the sum of small amounts of many other acids produced by yeasts, such as pyruvic, citric, butyric, and other short- and medium-chain fatty acids, etc.

3.3. Parameters Related to Yeast Autolysis and Foaming Properties

The total proteins and total polysaccharide concentrations were lower in the sparkling wines inoculated with the GPY-grown yeast than in those inoculated with the pied de cuve-prepared yeast, although only the polysaccharide content showed significant differences (Table 2). The proteins and polysaccharides in the sparkling wines came from the base wine and the cellular autolysis [43]. If we bear in mind that the base wine was the same, then the differences found in the protein and polysaccharide contents in wines would likely be due to distinct autolysis degrees of yeast prepared by differing procedures. Our results indicate that the yeast grown on GPY developed autolysis more slowly than those prepared by pied de cuve. Although we did not monitor yeast viability from 60 days after yeast inoculation, the concentration of some volatile compounds related to autolysis support this hypothesis (see Section 3.4).

Table 2.

Effect of the S. cerevisiae strain IOC 18-2007 inoculum preparation method on foaming properties: foamability (HM) and foam persistence (HS) (expressed as mm), and total polysaccharides and proteins (expressed as mg/L).

Significant differences appeared in foamability (HM), foam persistence (HS), and total polysaccharide concentrations among the sparkling wines (Table 2). The sparkling wines inoculated with the GPY-grown yeast showed greater foamability (66 mm) and foam persistence (61 mm) than those inoculated with the pied de cuve-prepared yeast at the winery.

From the exhaustive review of Martínez-Lapuente, et al. [44] regarding the influence of wine chemical compounds on the foaming properties of sparkling wines, we can deduce that although some studies have shown positive correlations between proteins and the HM parameter [2,45], other studies have not [45,46]. Contradictory results have been recorded regarding correlations between protein and the HS parameter [45,46]. Most studies have found a positive influence of total polysaccharides on both foamability and foam stability [46], although some authors have reported the opposite [45]. In our case, the wines with a lower protein content obtained higher HM and HS parameter values.

Polysaccharides come from the glucans and mannoproteins present in the yeast cell wall, and are released from it during yeast autolysis. Polysaccharides contribute to the mouth-feel properties of wine by providing ‘mellowness’ and body sensations, but can also influence sparkling wine’s foam characteristics [10,47]. Although differences in polysaccharide contents existed between both sparkling wines, there were no positive relations between polysaccharide concentrations and the HM and HS parameters. Contradictory results regarding the relations between polysaccharides and foam properties have been published. Moreno-Arribas [48] found that they positively correlated, but Martínez-Lapuente, et al. [49] indicated that polysaccharides were poor foam formers, but good foam stabilizers. Esteruelas, González-Royo, Kontoudakis, Orte, Cantos, Canals, and Zamora [45] reported that the high-molecular-weight polysaccharide fraction had a negative effect on HM, but they associated this negative contribution to the presence of β-glucans secreted by Botrytis cinerea, and stated that other polysaccharides would probably not have a negative effect. Martínez-Lapuente, Guadalupe, Ayestarán, and Pérez-Magariño [49] reported that different families of polysaccharides contributed unequally to foam properties. They found that mannoproteins, glucans, polysaccharides rich in arabinose and galactose, rhamnogalacturonans type II, and homogalacturonans did not influence the foamability of sparkling wines, but all wine polysaccharides had a positive influence on foam stability (HS).

3.4. Volatile Aroma Analysis

Thirty volatile compounds were identified in the produced sparkling wines. The concentrations of these compounds differed between the sparkling wines fermented with the GPY-grown and the pied de cuve-prepared yeasts (Table 3).

Table 3.

Odor descriptor, odor threshold value, concentration, and OAV value for each component of the aromas found in the sparkling wines fermented with the GPY-grown and the pied de cuve-prepared S. cerevisiae IOC 18-2007. The ANOVA analysis results are shown as letters on the data corresponding to the concentration of aromatic compounds: different letters on the same line denote significant differences of 95%. OAV calculated by dividing the concentration by the odor threshold value of the compound.

The concentrations of benzaldehyde, ethyl esters of acetic, butyric, hexanoic, decanoic and isovaleric acids, hexyl acetate, isobutyl acetate, and 2-phenethyl acetate, 2-ethylhexanoic, octanoic, and isopentanoic acids, 2,3-butanodiol, 1-butanol, isoamyl alcohol, 2 phenylethanol, and γ-butyrolactone were significantly higher in the wines inoculated with the GPY-grown yeasts. Only the isobutyric acid concentration was significantly higher in the wines fermented with the pied de cuve-prepared yeasts. When considering compound families differences, we found that the total aldehydes content was significantly higher in the wines inoculated with the pied de cuve-prepared yeasts, whereas total esters, total fatty acids, total alcohols, and lactones were significantly higher in the wines inoculated with the GPY-grown yeasts.

The formation of aroma compounds by yeast is intrinsically linked with the metabolism of yeast cells [58], but also to the release of some intracellular components during autolysis for sparkling wines [1]. From our results regarding total protein and polysaccharides, we can deduce that the GPY-grown yeasts were more resistant to autolysis than the pied de cuve-prepared ones. The differential concentration of hexyl acetate, 2-phenylethyl acetate (lower in the pied de cuve-inoculated Cava wines), diethyl succinate, and ethyl decanoate (higher in the pied de cuve-inoculated wines) support this hypothesis. Welke, et al. [59] described how the esterases released by yeast degradation during autolysis led to the hydrolysis of hexyl acetate and 2-phenylethyl acetate and, thus, promoted their reduction. In addition, succinic acid esterification and volatile hydrophobic compounds desorption increase the levels of diethyl succinate and ethyl decanoate as autolysis progresses. Kemp, Alexandre, Robillard, and Marchal [1] described diethyl succinate as a good marker of aging because it increased as aging progressed. The N content in the GPY is higher than in the pied de cuve. These results indicate that while preparing yeast, N intake is crucial for second fermentation development [41]. N promotes yeast growth to complete alcoholic fermentation, but also plays a central role in the production of volatile aromas [60,61]. Fairbairn, McKinnon, Musarurwa, Ferreira, and Bauer [60] found that minor changes in the amino acid concentration not only impact S. cerevisiae growth, but also the formation of aromatic compounds.

From the volatile compounds data that showed significant differences, only those compounds with concentrations/odor threshold value (AOVs) ratios above 1 contributed to the sparkling wine aroma, according to Ferreira, et al. [62] and Moyano, et al. [63]. By considering the AOVs values, the compounds that contributed to aroma were diacetyl, ethyl butyrate, ethyl hexanoate, ethyl octanoate, ethyl decanoate, ethyl isovalerate, hexanoic and octanoic acids, and isoamyl alcohol. The way in which yeast was prepared significantly affected all of these compounds, except for the hexanoic acid concentration.

The sparkling wines fermented with the GPY-grown yeasts contained benzaldehyde, ethyl isovalerate, and ethyl hexanoate, which were not detected in the wines fermented with the yeasts prepared at the winery by the pied de cuve method. These compounds confer almond, fruity, and anise aromas. Taking into account the AOVs, the results suggested that growing yeast cells in GPY was a good option because they generated more esters with a value of OAV > 1 than the yeast culture prepared by pied de cuve. However, the high concentrations of fatty acids (such as hexanoic and octanoic acid) and isoamyl alcohol in the wines fermented with the GPY-grown yeasts could contribute negatively, because they confer fusel and fatty aromas [13].

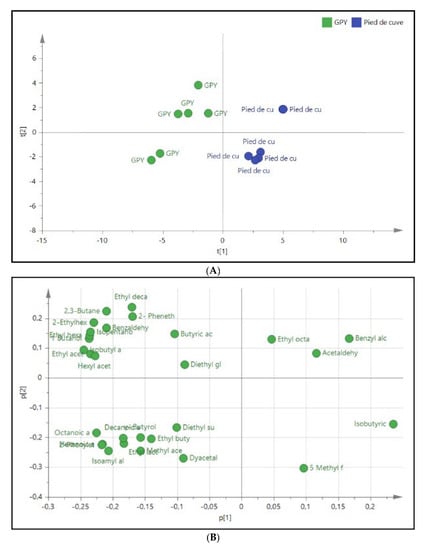

A PCA analysis of the volatile data was carried out to know if the yeast preparation strategy discriminated sparkling wines. Figure 2 shows the plots of the two principal component loadings and the two principal component scores. Sparkling wines are separated on the plane, which means that wine’s volatile composition differed significantly depending on the yeast preparation methodology that had taken place. In Figure 2A, the wines fermented with the GPY-grown yeasts are to the left of the PC1 component, while the wines fermented with the pied de cuve-prepared yeasts are to the right of this component. Figure 2B shows the arrangement of the different aromatic compounds on the plane. This arrangement provides a clue of the main differences in wine volatile composition concerning the applied yeast starter culture preparation methodology.

Figure 2.

Principal component analysis (PCA) of volatile compounds in sparkling wines inoculated with the GPY-grown and pied de cuve-prepared S. cerevisiae IOC 18-2007. The analysis was performed with the SIMCA software, version 10 (MKS Umetrics, Malmo, Sweden): (A) plot of the two principal component scores; (B) plot of the two principal component loadings.

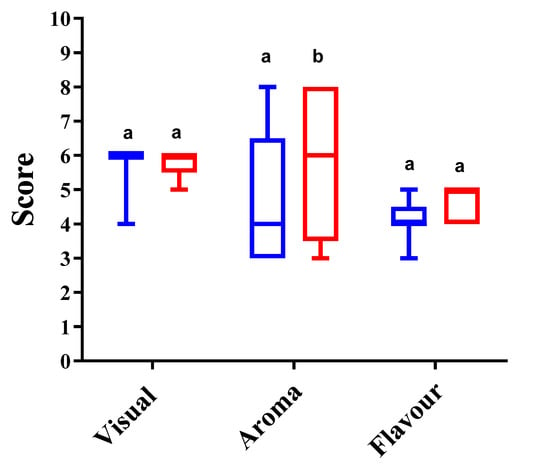

3.5. Sensory Analysis

The sensory analysis of the sparkling wines was performed by evaluating the visual, aroma, and flavor characteristics. The scores for the wines are displayed in Figure 3. There were no significant differences in the visual and flavor scores between the wines inoculated with both the GPY-grown yeasts and pied de cuve prepared yeasts. Significant differences were found in the aroma scores. The wines inoculated with the GPY-grown yeasts obtained a significantly lower score (4.89 points) than those inoculated with the pied de cuve-prepared yeasts (5.89 points). One explanation for this result is that part of the sensory panel was made up of staff members from the winery where the experiment took place. These tasters are more accustomed to the “Cava” aromas produced by the pied de cuve methodology, which is the one they normally use and, therefore, the aromatic deviations from this profile were less appreciated. Although a higher esters content was found in the wines inoculated with the GPY-grown yeasts, and these compounds conferred on wine a fruitier aroma, it is also noted that the concentrations of fatty acids and higher alcohols (or fusel alcohols) in these wines were higher than in those inoculated with the pied de cuve-prepared yeast. These aroma families contribute negatively to aroma [64].

Figure 3.

Sensory evaluations of the sparkling wines obtained with the two yeast starter cultures for the second fermentation, displayed as means and LSD intervals at 95%. Blue depicts the GPY-grown yeasts and red the pied de cuve-prepared yeasts. Different letters indicate significant differences between wines. The sensorial panel was made up of 16 persons.

4. Conclusions

This study determined the impact of yeast culture preparation on not only second fermentation development, but also on the organoleptic characteristics of the final product after 9 months of aging. We investigated differences in the protein and polysaccharide concentrations, foamability and foam stability, volatile composition, and sensoriality of the wines inoculated with the yeast S. cerevisiae IOC 18-2007, which was either GPY-grown or pied de cuve-prepared.

In both cases, sugar exhaustion was completed in less than 60 days, ethanol concentrations were similar, and no significant differences were found in the fermentation kinetics. The sparkling wines analyses showed higher significant values for total acidity, foamability, foam persistence, and content of total polysaccharides in the wines inoculated with the GPY-grown yeast. Regarding the concentration of volatile compounds, higher contents of esters, alcohols, and fatty acids with an OAV >1 were obtained in the sparkling wines inoculated with the GPY-grown yeast. The sensory analysis indicated no significant differences for the visual or flavor parameters. However, in aromatic terms, the sparkling wines inoculated with the pied de cuve-prepared yeast was better scored than those inoculated with the GPY-grown yeast.

Both sparkling wines were produced with the same base wine and were inoculated with the same yeast strain. The only factor that differentiated them was the way in which the yeast was prepared before wine inoculation.

Additional research is necessary to confirm if the differences in viability, autolysis, and metabolisms of the yeasts prepared in either GPY or pied de cuve could explain the differences found in sparkling wines.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/fermentation8070313/s1, Table S1. Acid concentrations of base wine and of the resulting sparkling wines fermented with S. cerevisiae strain IOC18-2007 GPY-grown or pied de cuve-prepared, after 9 months aging.

Author Contributions

Conceptualization, I.Á., I.P. and M.J.G.-E.; methodology, I.Á., I.P., F.Z., M.J.G.-E. and S.F.; validation, C.B., L.P., I.Á., I.P. and S.F.; formal analysis, C.B., I.P. and M.J.G.-E.; investigation, C.B., F.Z., L.P. and M.J.G.-E.; writing—original draft preparation, C.B., I.P. and M.J.G.-E.; writing—review and editing, C.B., F.Z., I.P. and M.J.G.-E.; visualization, I.Á., S.F. and M.J.G.-E.; supervision, I.Á., I.P. and M.J.G.-E.; project administration, I.Á. and I.P.; funding acquisition, I.Á. and I.P. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the “Programa Valoritza i Transfereix” 2013 (Ref: UV-CPI13274-159983) of the Universitat de València, Valencia, Spain. This institution has not intervened in the collection, analysis, and interpretation of the data, nor in the report writing or the decision to publish the manuscript.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available upon request from the corresponding author.

Acknowledgments

To the “Dominio de la Vega” winery (San Antonio de Requena, Spain) for providing the materials and work power to produce, and also for the sensorial characterization of the “Cava” sparkling wines.

Conflicts of Interest

The authors declare no conflict of interest. The funders have not intervened in the collection, analysis and interpretation of the data, nor in the report writing or the decision to publish the manuscript.

References

- Kemp, B.; Alexandre, H.; Robillard, B.; Marchal, R. Effect of production phase on bottle-fermented sparkling wine quality. J. Agric. Food Chem. 2015, 63, 19–38. [Google Scholar] [CrossRef] [PubMed]

- Alexandre, H.; Guilloux-Benatier, M. Yeast autolysis in sparkling wine—A review. Aust. J. Grape Wine Res. 2006, 12, 119–127. [Google Scholar] [CrossRef]

- Martí-Raga, M.; Martín, V.; Gil, M.; Sancho, M.; Zamora, F.; Mas, A.; Beltran, G. Contribution of yeast and base wine supplementation to sparkling wine composition. J. Sci. Food Agric. 2016, 96, 4962–4972. [Google Scholar] [CrossRef] [PubMed]

- Garofalo, C.; Arena, M.; Laddomada, B.; Cappello, M.; Bleve, G.; Grieco, F.; Beneduce, L.; Berbegal, C.; Spano, G.; Capozzi, V. Starter cultures for sparkling wine. Fermentation 2016, 2, 21. [Google Scholar] [CrossRef]

- Buxaderas, S.; López-Tamames, E. Sparkling wines: Features and trends from tradition. In Advances in Food and Nutrition Research; Henry, J., Ed.; Academic Press: Cambridge, MA, USA, 2012; Volume 66, pp. 1–45. [Google Scholar]

- Pozo-Bayón, M.Á.; Martínez-Rodríguez, A.; Pueyo, E.; Moreno-Arribas, M.V. Chemical and biochemical features involved in sparkling wine production: From a traditional to an improved winemaking technology. Trends Food Sci. Technol. 2009, 20, 289–299. [Google Scholar] [CrossRef]

- Benucci, I.; Liburdi, K.; Cerreti, M.; Esti, M. Characterization of active dry wine yeast during starter culture (pied de cuve) preparation for sparkling wine production. J. Food Sci. 2016, 81, M2015–M2020. [Google Scholar] [CrossRef]

- Martínez-Lapuente, L.; Guadalupe, Z.; Ayestarán, B.; Ortega-Heras, M.; Pérez-Magariño, S. Changes in polysaccharide composition during sparkling wine making and aging. J. Agric. Food Chem. 2013, 61, 12362–12373. [Google Scholar] [CrossRef]

- Martínez-Lapuente, L.; Apolinar-Valiente, R.; Guadalupe, Z.; Ayestarán, B.; Pérez-Magariño, S.; Williams, P.; Doco, T. Polysaccharides, oligosaccharides and nitrogenous compounds change during the ageing of Tempranillo and Verdejo sparkling wines. J. Sci. Food Agric. 2018, 98, 291–303. [Google Scholar] [CrossRef]

- Culbert, J.A.; McRae, J.M.; Condé, B.C.; Schmidtke, L.M.; Nicholson, E.L.; Smith, P.A.; Howell, K.S.; Boss, P.K.; Wilkinson, K.L. Influence of production method on the chemical composition, foaming properties, and quality of Australian carbonated and sparkling white wines. J. Agric. Food Chem. 2017, 65, 1378–1386. [Google Scholar] [CrossRef]

- Martínez-García, R.; García-Martínez, T.; Puig-Pujol, A.; Mauricio, J.C.; Moreno, J. Changes in sparkling wine aroma during the second fermentation under CO2 pressure in sealed bottle. Food Chem. 2017, 237, 1030–1040. [Google Scholar] [CrossRef]

- Torrens, J.; Urpí, P.; Riu-Aumatell, M.; Vichi, S.; López-Tamames, E.; Buxaderas, S. Different commercial yeast strains affecting the volatile and sensory profile of cava base wine. Int. J. Food Microbiol. 2008, 124, 48–57. [Google Scholar] [CrossRef]

- Berbegal, C.; Polo, L.; García-Esparza, M.J.; Lizama, V.; Ferrer, S.; Pardo, I. Immobilisation of yeasts on oak chips or cellulose powder for use in bottle-fermented sparkling wine. Food Microbiol. 2019, 78, 25–37. [Google Scholar] [CrossRef]

- Kunkee, R.E.; Ough, C.S. Multiplication and fermentation of Saccharomyces cerevisiae under carbon dioxide pressure in wine. Appl. Microbiol. 1966, 14, 643–648. [Google Scholar] [CrossRef]

- Juroszek, J.R.; Feuillat, M.; Charpentier, C. Effect of the champagne method of starter preparation on ethanol tolerance of yeast. Am. J. Enol. Vitic. 1987, 38, 194–198. [Google Scholar]

- Laurent, M.; Valade, M. La préparation du levain de tirage à partir de levures sèches actives. Vign. Champen. 2007, 128, 74–95. [Google Scholar]

- Johansson, E.; Brandberg, T.; Larsson, C. Influence of cultivation procedure for Saccharomyces cerevisiae used as pitching agent in industrial spent sulphite liquor fermentations. J. Ind. Microbiol. Biotechnol. 2011, 38, 1787–1792. [Google Scholar] [CrossRef]

- Belloch, C.; López, M.D.; Esteve, B.; Martínez, P.V.; García-López, M.D.; Uruburu, F. Catálogo de Cepas. Colección Española de Cultivos Tipo, 4th ed.; Universitat de València: Valencia, Spain, 1998. [Google Scholar]

- BOE-A-1991-28079. Reglamentación de la Denominación «Cava» y de su Consejo Regulador. Orden del 14 de Noviembre de 1991. Bol. Of. Estado 1991, 278, 37587–37593. [Google Scholar]

- EEC-358/79. Council Regulation (EEC) No 358/79 of 5 February 1979 on sparkling wines produced in the Community and defined in item 13 of Annex II to Regulation (EEC) No 337/79. Off. J. Eur. Communities 1979, L 54, 130–135.

- Frayne, R.F. Direct analysis of the major organic components in grape must and wine using high performance liquid chromatography. Am. J. Enol. Vitic. 1986, 37, 281–287. [Google Scholar]

- OIV. Compendium of International Methods of Analysis of Wines and Musts; International Organization of Vine and Wine: Paris, France, 2016. [Google Scholar]

- Canals, J.M.; Arola, L.; Zamora, F. Protein fraction analysis of white wine by FPLC. Am. J. Enol. Vitic. 1998, 49, 383–388. [Google Scholar]

- Ayestarán, B.; Guadalupe, Z.; León, D. Quantification of major grape polysaccharides (Tempranillo v.) released by maceration enzymes during the fermentation process. Anal. Chim. Acta 2004, 513, 29–39. [Google Scholar] [CrossRef]

- Maujean, A.; Poinsaut, P.; Dantan, H.; Brissonnet, F.; Cossiez, E. Étude de la tenue et de la qualité de mousse des vins effervescents: II- Mise au point d’une technique de mesure de la moussabilité, de la tenue et de la stabilité des vins effervescents. Bull. Off. Int. Vin. 1990, 711–712, 405–427. [Google Scholar]

- Ortega, C.; López, R.; Cacho, J.; Ferreira, V. Fast analysis of important wine volatile compounds development and validation of a new method based on gas chromatographic-flame ionisation detection analysis of dichloromethane microextracts. J. Chromatogr. A 2001, 923, 205–214. [Google Scholar] [CrossRef]

- OIV. OIV standard for international wine and spirituous beverages of vitivinicultural origin competitions. In OIV Resolution/Concours 332A/2009; International Organisation of Vine and Wine, Ed.; OIV: Paris, France, 2009. [Google Scholar]

- González-Marco, A.; Ancín-Azpilicueta, C. Influence of lees contact on evolution of amines in Chardonnay wine. J. Food Sci. 2006, 71, C544–C548. [Google Scholar] [CrossRef]

- González-Marco, A.; Jiménez-Moreno, N.; Ancín-Azpilicueta, C. Influence of nutrients addition to nonlimited-in-nitrogen must on wine volatile composition. J. Food Sci. 2010, 75, S206–S211. [Google Scholar] [CrossRef]

- Soubeyrand, V.; Luparia, V.; Williams, P.; Doco, T.; Vernhet, A.; Ortiz-Julien, A.; Salmon, J.-M. Formation of micella containing solubilized sterols during rehydration of active dry yeasts improves their fermenting capacity. J. Agric. Food. Chem. 2005, 53, 8025–8032. [Google Scholar] [CrossRef]

- Gutiérrez, A.; Beltran, G.; Warringer, J.; Guillamón, J.M. Genetic basis of variations in nitrogen source utilization in four wine commercial yeast strains. PLoS ONE 2013, 8, e67166. [Google Scholar] [CrossRef] [Green Version]

- Gutiérrez, A.; Chiva, R.; Sancho, M.; Beltran, G.; Arroyo-López, F.N.; Guillamon, J.M. Nitrogen requirements of commercial wine yeast strains during fermentation of a synthetic grape must. Food Microbiol. 2012, 31, 25–32. [Google Scholar] [CrossRef]

- Martínez-Moreno, R.; Morales, P.; González, R.; Mas, A.; Beltrán, G. Biomass production and alcoholic fermentation performance of Saccharomyces cerevisiae as a function of nitrogen source. FEMS Yeast Res. 2012, 12, 477–485. [Google Scholar] [CrossRef]

- Beltrán, G.; Esteve-Zarzoso, B.; Rozès, N.; Mas, A.; Guillamón, J.M. Influence of the timing of nitrogen additions during synthetic grape must fermentations on fermentation kinetics and nitrogen consumption. J. Agric. Food Chem. 2005, 53, 996–1002. [Google Scholar] [CrossRef]

- Devatine, A.; Gerbaud, V.; Gabas, N.; Blouin, J. Prediction and mastering of wine acidity and tartaric precipitations: The Mextar® software tool. OENO One 2002, 36, 77. [Google Scholar] [CrossRef]

- Whiting, G.C. Organic acid metabolism of yeasts during fermentation of alcoholic beverages-A review. J. Inst. Brew. 1976, 82, 84–92. [Google Scholar] [CrossRef]

- Yéramian, N.; Chaya, C.; Suárez Lepe, J.A. L-(−)-malic acid production by Saccharomyces spp. during the alcoholic fermentation of wine. J. Agric. Food Chem. 2007, 55, 912–919. [Google Scholar] [CrossRef]

- Shimazu, Y.; Watanabe, M. Effects of yeast strains and environmental conditions on formation of organic acids in must during fermentation. J. Ferment. Technol. 1981, 59, 27–32. [Google Scholar]

- Ramon-Portugal, F.; Seiller, I.; Taillandier, P.; Favarel, J.-L.; Nepveu, F.; Strehaiano, P. Kinetics of production and consumption of organic acids during alcoholic fermentation by Saccharomyces cerevisae. Food Technol. Biotechnol. 1999, 37, 235–240. [Google Scholar]

- Heerde, E.; Radler, F. Metabolism of the anaerobic formation of succinic acid by Saccharomyces cerevisiae. Arch. Microbiol. 1978, 117, 269–276. [Google Scholar] [CrossRef]

- Martí-Raga, M.; Sancho, M.; Guillamón, J.M.; Mas, A.; Beltrán, G. The effect of nitrogen addition on the fermentative performance during sparkling wine production. Food Res. Int. 2015, 67, 126–135. [Google Scholar] [CrossRef]

- Yeramian, N. Acidificación Biológica de Mostos en Zonas Cálidas. Ph.D. Thesis, Universidad Politécnica de Madrid, Madrid, Spain, 2003. [Google Scholar]

- Pons-Mercadé, P.; Giménez, P.; Vilomara, G.; Conde, M.; Cantos, A.; Rozès, N.; Ferrer, S.; Canals, J.M.; Zamora, F. New insights about the influence of yeasts autolysis on sparkling wines composition and quality. In Grapes and Wine; Morata, A., Loira, I., González, C., Eds.; IntechOpen: London, UK, 2021. [Google Scholar] [CrossRef]

- Martínez-Lapuente, L.; Ayestarán, B.; Guadalupe, Z. Influence of wine chemical compounds on the foaming properties of sparkling wines. In Grapes and wines—Advances in Production, Processing, Analysis and Valorization; InTech: London, UK, 2018; Volume 10, pp. 195–223. [Google Scholar]

- Esteruelas, M.; González-Royo, E.; Kontoudakis, N.; Orte, A.; Cantos, A.; Canals, J.M.; Zamora, F. Influence of grape maturity on the foaming properties of base wines and sparkling wines (Cava). J. Sci. Food Agric. 2015, 95, 2071–2080. [Google Scholar] [CrossRef]

- Pueyo, E.; Martín-Alvarez, P.J.; Polo, M.C. Relationship between foam characteristics and chemical composition in wines and cavas (sparkling wines). Am. J. Enol. Vitic. 1995, 46, 518–524. [Google Scholar]

- Gawel, R.; Smith, P.A.; Cicerale, S.; Keast, R. The mouthfeel of white wine. Crit. Rev. Food Sci. Nutr. 2018, 58, 2939–2956. [Google Scholar] [CrossRef]

- Moreno-Arribas, V. Influence of the polysaccharides and the nitrogen compounds on foaming properties of sparkling wines. Food Chem. 2000, 70, 309–317. [Google Scholar] [CrossRef]

- Martínez-Lapuente, L.; Guadalupe, Z.; Ayestarán, B.; Pérez-Magariño, S. Role of major wine constituents in the foam properties of white and rosé sparkling wines. Food Chem. 2015, 174, 330–338. [Google Scholar] [CrossRef]

- Jiang, B.; Zhang, Z. Volatile compounds of young wines from Cabernet Sauvignon, Cabernet Gernischet and Chardonnay varieties grown in the Loess Plateau Region of China. Molecules 2010, 15, 9184. [Google Scholar] [CrossRef] [Green Version]

- Francis, L. Fermentation derived aroma compounds and grape-derived monoterpenes. In Proceedings of the 15th Australian Wine Industry Technical Conference, Sydney, NSW, Australia, 13–18 July 2013. [Google Scholar]

- Gambetta, J.M.; Bastian, S.E.P.; Cozzolino, D.; Jeffery, D.W. Factors influencing the aroma composition of Chardonnay wines. J. Agric. Food Chem. 2014, 62, 6512–6534. [Google Scholar] [CrossRef]

- Sánchez-Palomo, E.; Gómez García-Carpintero, E.; Gómez Gallego, M.Á.; González Viñas, M.Á. The aroma of Rojal red wines from La Mancha Region—Determination of key odorants. In Gas Chromatography in Plant Science, Wine Technology, Toxicology and Some Specific Applications; Salih, B., Çelikbıçak, Ö., Eds.; IntechOpen: London, UK, 2012; pp. 147–170. [Google Scholar] [CrossRef] [Green Version]

- Guth, H. Quantitation and sensory studies of character impact odorants of different white wine varieties. J. Agric. Food Chem. 1997, 45, 3027–3032. [Google Scholar] [CrossRef]

- Aznar, M.; López, R.; Cacho, J.; Ferreira, V. Prediction of aged red wine aroma properties from aroma chemical composition. Partial least squares regression models. J. Agric. Food Chem. 2003, 51, 2700–2707. [Google Scholar] [CrossRef]

- Zea, L.; Moyano, L.; Moreno, J.; Cortes, B.; Medina, M. Discrimination of the aroma fraction of Sherry wines obtained by oxidative and biological ageing. Food Chem. 2001, 75, 79–84. [Google Scholar] [CrossRef]

- Belitz, H.-D.; Grosch, W.; Schieberle, P. Food Chemistry, 4th ed.; Springer: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- Lambrechts, M.G.; Pretorius, I.S. Yeast and its importance to wine arom—A review. S. Afr. J. Enol. Vitic. 2000, 20, 97–129. [Google Scholar]

- Welke, J.E.; Dachery, B.; Dal Magro, L.; Hernandes, K.C.; Zini, C.A. Volatile compounds formation in sparkling wine. In Volatile Compounds Formation in Specialty Beverages; CRC Press: Boca Raton, FL, USA, 2022; pp. 109–141. [Google Scholar]

- Fairbairn, S.; McKinnon, A.; Musarurwa, H.T.; Ferreira, A.C.; Bauer, F.F. The impact of single amino acids on growth and volatile aroma production by Saccharomyces cerevisiae strains. Front. Microbiol. 2017, 8, 2554. [Google Scholar] [CrossRef] [Green Version]

- Bell, S.-J.; Henschke, P.A. Implications of nitrogen nutrition for grapes, fermentation and wine. Aust. J. Grape Wine Res. 2005, 11, 242–295. [Google Scholar] [CrossRef]

- Ferreira, V.; Ortín, N.; Escudero, A.; López, R.; Cacho, J. Chemical characterization of the aroma of Grenache rosé wines: Aroma extract dilution analysis, quantitative determination, and sensory reconstitution studies. J. Agric. Food Chem. 2002, 50, 4048–4054. [Google Scholar] [CrossRef] [PubMed]

- Moyano, L.; Zea, L.; Moreno, J.; Medina, M. Analytical study of aromatic series in Sherry wines subjected to biological aging. J. Agric. Food Chem. 2002, 50, 7356–7361. [Google Scholar] [CrossRef] [PubMed]

- Mingorance-Cazorla, L. Contribution of different natural yeasts to the aroma of two alcoholic beverages. World J. Microbiol. Biotechnol. 2003, 19, 297–304. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).