Effects of Lactic Acid Bacteria-Directed Screening on Flavor and Functional Properties of Fermented Corn Protein Hydrolysate

Abstract

1. Introduction

2. Materials and Methods

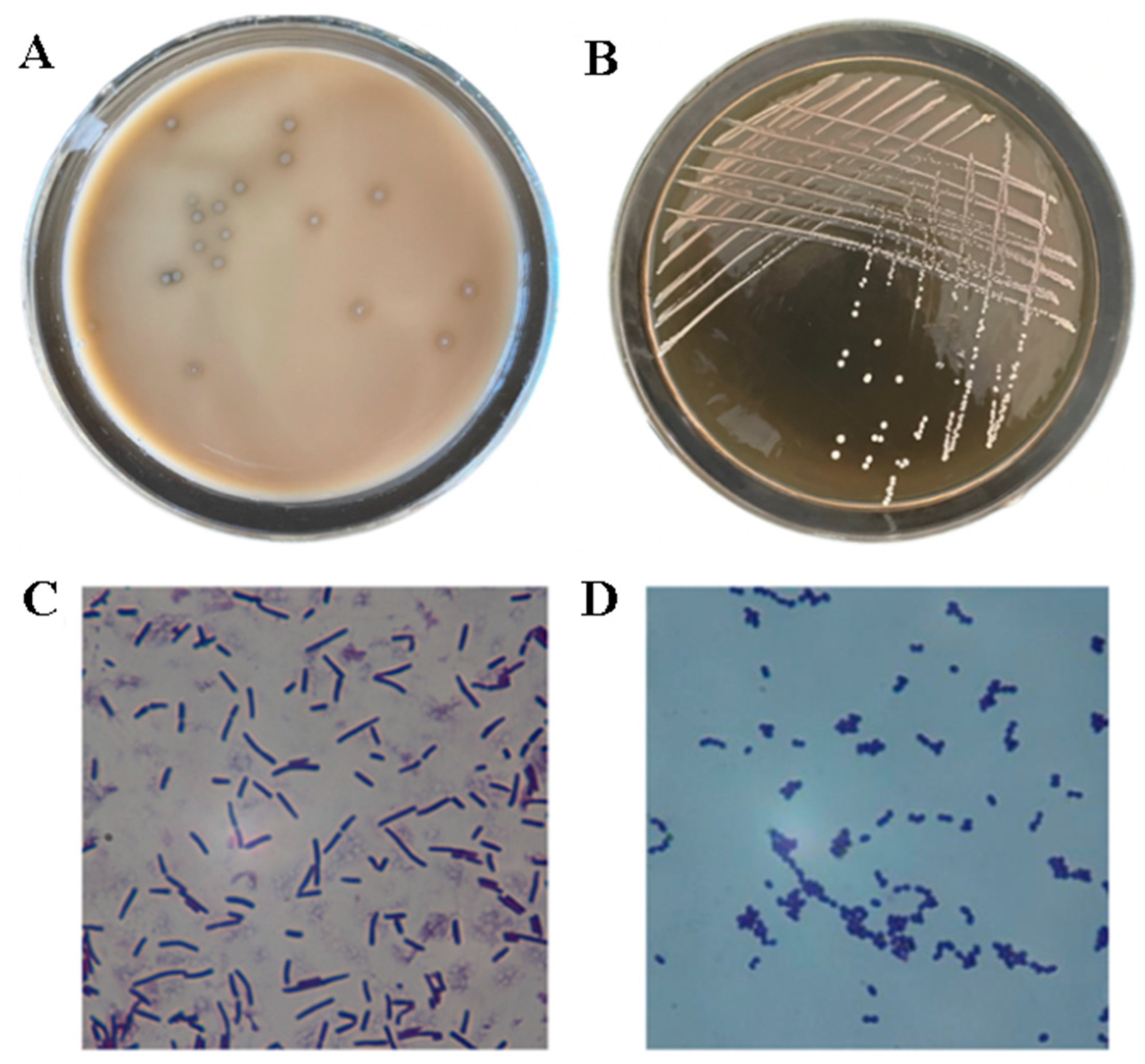

2.1. Isolation and Purification of LAB in Cheese

2.2. Morphological Identification and Physicochemical Analysis of LAB

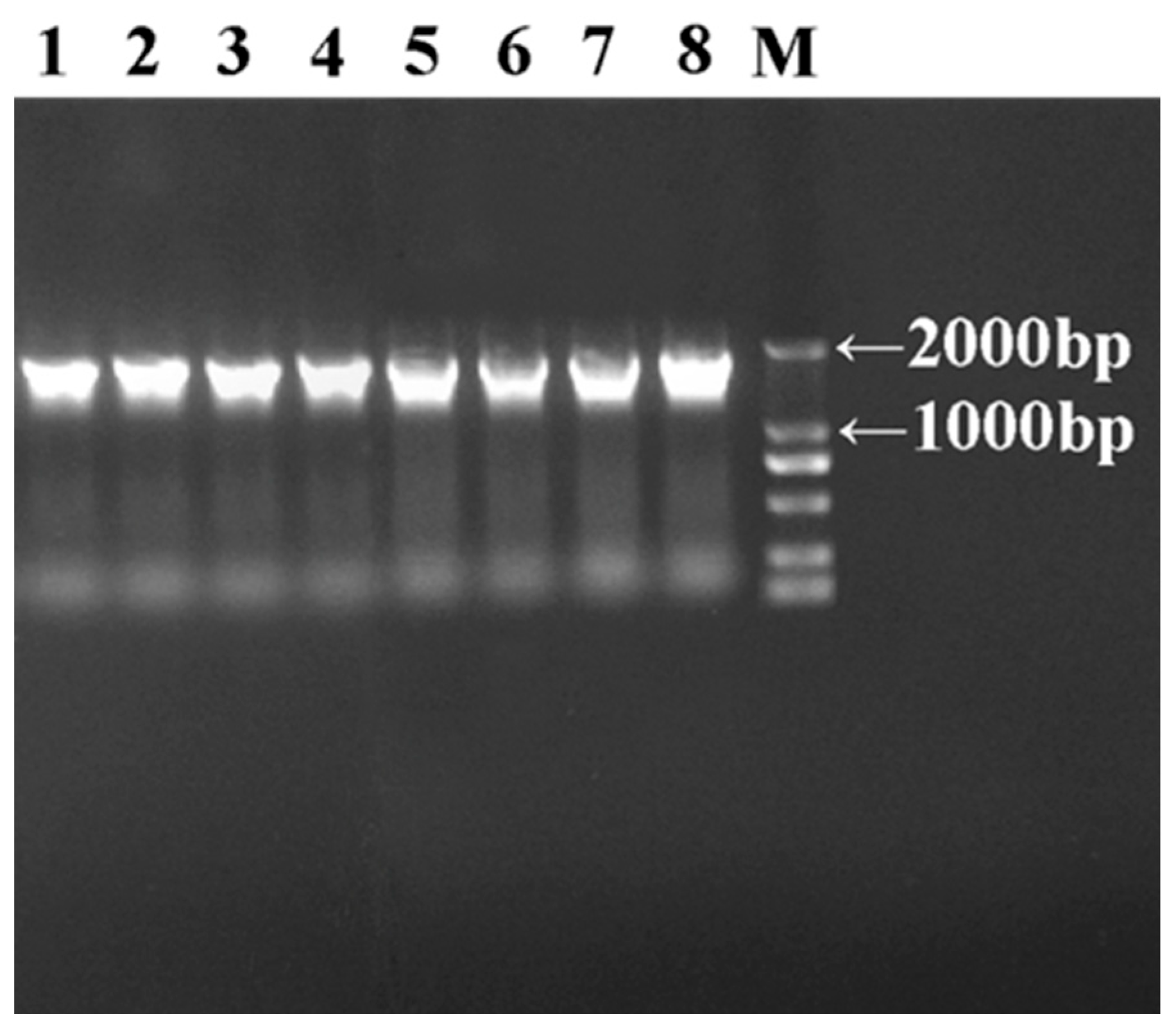

2.3. Identification of Bacterial Strains by 16S rDNA

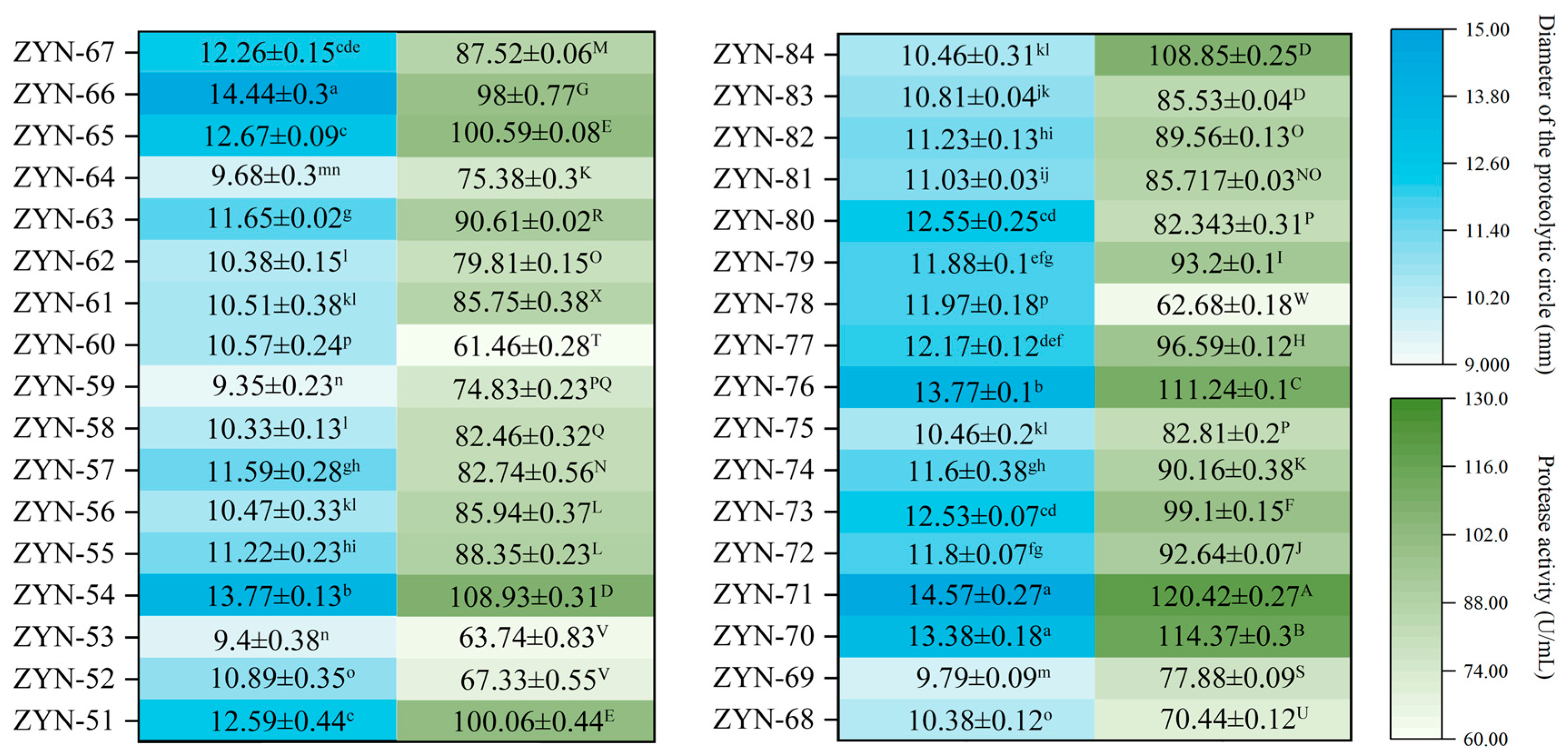

2.4. Screening of High-Yield Protease-LAB

2.5. Physicochemical Properties of High-Yield Protease LAB

2.5.1. Viable Counting Method of LAB and Preparation of Bacterial Suspension

2.5.2. Determination of Acid Production Capacity of LAB

2.5.3. Determination of LAB Hydrolyzing CGM

2.5.4. Extracellular Tolerance of LAB to Gastric Juice and Bile Salts

2.6. Process Parameters of LAB-Fermented CPH

2.7. Determination of Antioxidant Activity of LAB-Fermented CPH

2.8. Determination of Processing Characteristics of LAB-Fermented CPH

2.8.1. Preparation of CPH

2.8.2. Determination of Solubility

2.8.3. Determination of Water- and Oil-Holding Properties

2.8.4. Measurement of Foaming and Foam Stability

2.8.5. Determination of Emulsification and Emulsion Stability

2.9. Determination of Volatile Substances in LAB-Fermented CPH

2.10. Determination of Amino Acid Content in LAB-Fermented CPH

2.11. Data Processing

3. Results and Analysis

3.1. Screening of LAB

3.2. The Extracellular Protease Activity of Suspected LAB

3.3. DNA Extraction and PCR Amplification of Suspected LAB

3.4. Characteristic Analysis of High-Yield Protease-LAB

3.4.1. The Ability of LAB to Produce Acid and Hydrolyze CGM

3.4.2. Resistance to Artificial Bile and Gastric Juice

3.4.3. Principal Component Analysis (PCA)

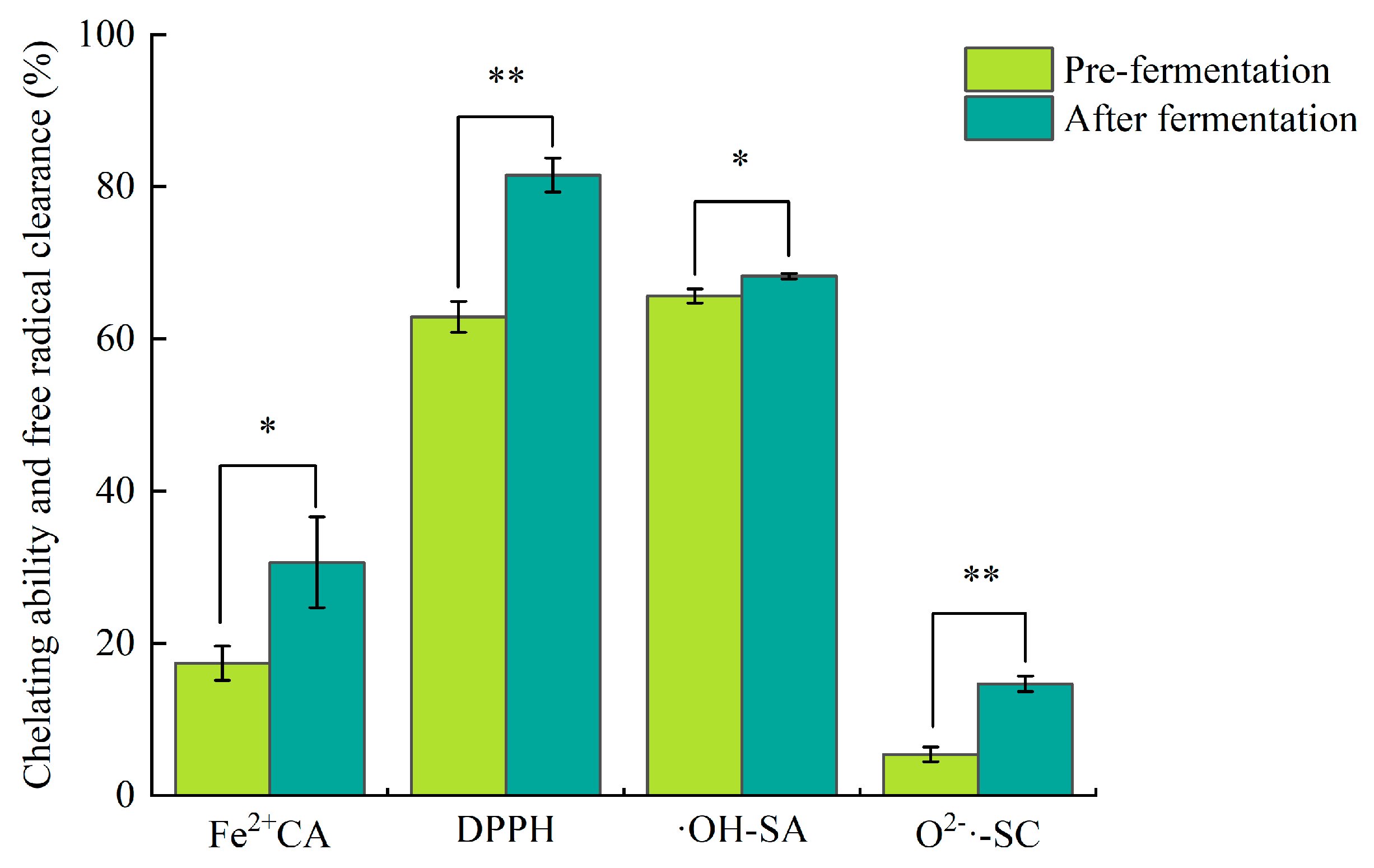

3.5. Effect of LAB Fermentation on Antioxidant Activity of CPH

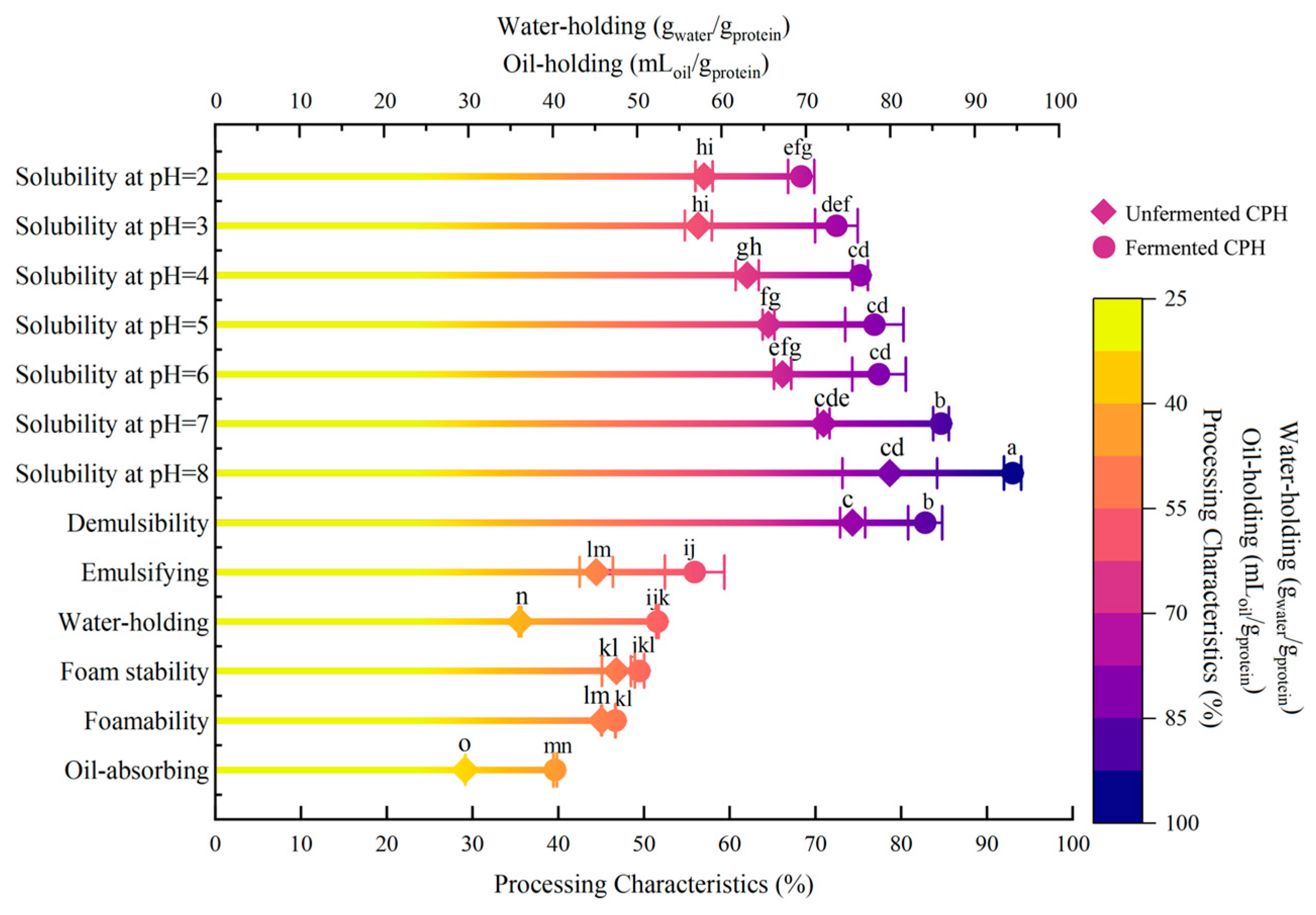

3.6. Effects of LAB Fermentation on Processing Characteristics of CPH

3.7. Changes in Amino Acid Content of LAB-Fermented CPH

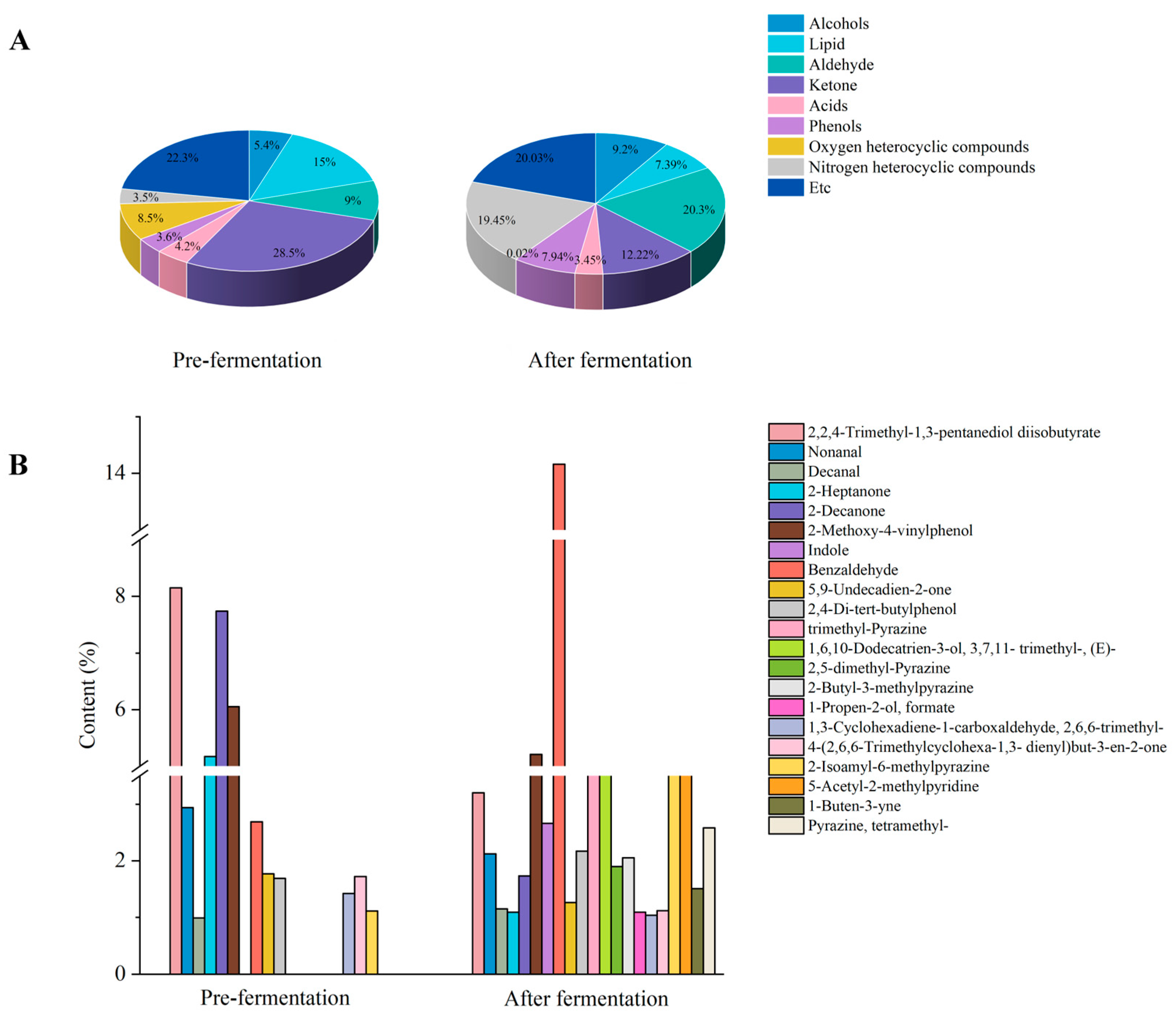

3.8. Effects of LAB Fermentation on the Volatile Substances of CPH

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yu, X.; Chen, Y.; Qi, Z.; Chen, Q.; Cao, Y.; Kong, Q. Preparation and identification of a novel peptide with high antioxidant activity from corn gluten meal. Food Chem. 2023, 424, 136389. [Google Scholar] [CrossRef] [PubMed]

- Hou, Y.; Wu, Z.; Dai, Z.; Wang, G.; Wu, G. Protein hydrolysates in animal nutrition: Industrial production, bioactive peptides, and functional significance. J. Anim. Sci. Biotechnol. 2017, 8, 24. [Google Scholar] [CrossRef] [PubMed]

- Zhang, R.; Ma, S.; Li, L.; Zhang, M.; Tian, S.; Wang, D.; Liu, K.; Liu, H.; Zhu, W.; Wang, X. Comprehensive utilization of corn starch processing by-products: A review. Grain Oil Sci. Technol. 2021, 4, 89–107. [Google Scholar] [CrossRef]

- Vilcacundo, E.; Montalvo, V.; Sanaguano, H.; Moran, R.; Carrillo, W.; García, A. Identification of phytochemical compounds, functional properties and antioxidant activity of germinated purple corn protein concentrate and its gastrointestinal hydrolysates. Agron. J. 2022, 12, 2217. [Google Scholar] [CrossRef]

- Liu, H.; Fan, H.; Teng, X.; Sun, T.; Zhang, S.; Wang, N.; Zhang, X.; Liu, T.; Zhang, Y.; Wang, D. Exploring novel antioxidant cyclic peptides in corn protein hydrolysate: Preparation, identification and molecular docking analysis. Food Chem. 2025, 464, 141747. [Google Scholar] [CrossRef]

- Nurhartadi, E.; Rodtong, S.; Thumanu, K.; Park, S.H.; Aluko, R.E.; Yongsawatdigul, J. Antibacterial activity of enzymatic corn gluten meal hydrolysate and ability to inhibit Staphylococcus aureus in ultra-high temperature processed milk. Food Control 2025, 169, 110998. [Google Scholar] [CrossRef]

- Mirzapour-Kouhdasht, A.; McClements, D.J.; Taghizadeh, M.S.; Niazi, A.; Garcia-Vaquero, M. Strategies for oral delivery of bioactive peptides with focus on debittering and masking. npj Sci. Food 2023, 7, 22. [Google Scholar] [CrossRef]

- Shi, C.; Maktabdar, M. Lactic acid bacteria as biopreservation against spoilage molds in dairy products—A review. Front. Microbiol. 2022, 12, 819684. [Google Scholar] [CrossRef]

- Han, C.; Yang, X.; Li, L. Physicochemical properties and microstructure of soybean protein isolate-vegetable oil complex gels induced by lactic acid bacteria: Effects of vegetable oil types and concentrations. Food Hydrocoll. 2023, 145, 109109. [Google Scholar] [CrossRef]

- El Youssef, C.; Bonnarme, P.; Fraud, S.; Péron, A.C.; Helinck, S.; Landaud, S. Sensory improvement of a pea protein-based product using microbial co-cultures of lactic acid bacteria and yeasts. Foods 2020, 9, 349. [Google Scholar] [CrossRef] [PubMed]

- Cong, S.; Zhang, X.; Zhao, H.; Sun, M.; Hu, N. Process optimization and analysis of product quality of blueberry and corn peptide fermented by mixed lactic acid bacteria. Fermentation 2024, 10, 454. [Google Scholar] [CrossRef]

- Cong, S.; Zhang, X.; Ji, J.; Liu, X.; Hu, N. Isolation and identification of blueberry-derived lactic acid bacteria and their probiotic, antioxidant, and fermentation properties. Food Biosci. 2024, 62, 104497. [Google Scholar] [CrossRef]

- Liu, N.; Miao, S.; Qin, L. Screening and application of lactic acid bacteria and yeasts with L-lactic acid-producing and antioxidant capacity in traditional fermented rice acid. Food Sci. Nutr. 2020, 8, 6095–6111. [Google Scholar] [CrossRef] [PubMed]

- Sun, F.; Li, Q.; Liu, H.; Kong, B.; Liu, Q. Purification and biochemical characteristics of the protease from Lactobacillus brevis R4 isolated from Harbin dry sausages. LWT-Food Sci. Technol. 2019, 113, 108287. [Google Scholar] [CrossRef]

- Hu, N.; Lei, M.; Zhao, X.; Zhang, Z.; Gu, Y.; Zhang, Y.; Wang, S. Analysis of the microbial diversity and characteristics of fermented blueberry beverages from different regions. Foods 2020, 9, 1656. [Google Scholar] [CrossRef]

- Zheng, X.; Wang, J.; Liu, X.; Sun, Y.; Zheng, Y.; Wang, X.; Liu, Y. Effect of hydrolysis time on the physicochemical and functional properties of corn glutelin by Protamex hydrolysis. Food Chem. 2015, 172, 407–415. [Google Scholar] [CrossRef]

- Purkiewicz, A.; Stasiewicz, M.; Nowakowski, J.J.; Pietrzak-Fiećko, R. The influence of the Lactation Period and the type of milk on the content of amino acids and minerals in human milk and infant formulas. Foods 2023, 12, 3674. [Google Scholar] [CrossRef]

- Utama, G.L.; Meliana, S.; Djali, M.; Yuliana, T.; Balia, R.L. Probiotic candidates yeast isolated from Dangke-indonesian traditional fermented buffalo milk. Acta Univ. Agric. Silvic. Mendel. Brun. 2019, 67, 18. [Google Scholar] [CrossRef]

- Cong, S.; Cao, Y.; Zhang, X.; Li, G.; Liu, X.; Hu, N. Optimization of technological conditions and antioxidant activity of corn protein hydrolysates fermented by lactic acid bacteria. Food Res. Dev. 2024, 45, 152–162. [Google Scholar]

- Fu, J.; Wang, X.; Chen, B.; Liu, H.; Wu, S.; Tong, X.; Ma, X.; Qiao, Y. Optimising decolourization and nitrogen component properties of corn protein hydrolysate: Impact of activated carbon dosage and pH. Int. J. Food Sci. Technol. 2024, 59, 2917–2926. [Google Scholar] [CrossRef]

- Tran, M.T.; Nakamura, A.; Li, R.; Corredig, M. Pea soluble polysaccharide improves stability of acidic pea protein dispersions. Food Hydrocoll. 2024, 147, 109423. [Google Scholar]

- Ji, H.; Tang, X.; Li, L.; Peng, S.; Yu, J. Surface modification of peanut meal with atmospheric cold plasma: Identifying the critical factors that affect functionality. Int. J. Food Sci. Technol. 2022, 57, 7267–7274. [Google Scholar] [CrossRef]

- Hu, G.; Zhang, J.; Wang, Q.; Ma, M.; Ma, L.; Li, S. Succinylation modified ovalbumin: Structural, interfacial, and functional properties. Foods 2022, 11, 2724. [Google Scholar] [CrossRef] [PubMed]

- He, Z.; Zhang, H.; Wang, T.; Wang, R.; Luo, X. Effects of five different lactic acid bacteria on bioactive components and volatile compounds of oat. Foods 2022, 11, 3230. [Google Scholar] [CrossRef]

- Boeck, T.; Ispiryan, L.; Hoehnel, A.; Sahin, A.W.; Coffey, A.; Zannini, E.; Arendt, E.K. Lentil-Based Yogurt Alternatives Fermented with Multifunctional Strains of Lactic Acid Bacteria-Techno-Functional, Microbiological, and Sensory Characteristics. Foods 2022, 11, 2013. [Google Scholar]

- Li, G.; Liu, X.; Wang, Q.; Miao, Z.; Zheng, X. Anti-adhesive activity peptides against Helicobacter pylori from corn protein: Properties, identification, structural characterization and molecular docking in vitro and in silico. Food Biosci. 2024, 59, 104267. [Google Scholar] [CrossRef]

- Ma, H.; Wang, L.; Yu, H.; Wang, W.; Wu, G.; Qin, G.; Tan, Z.; Wang, Y.; Pang, H. Protease-producing lactic acid bacteria with antibacterial properties and their potential use in soybean meal fermentation. Chem. Biol. Technol. Agric. 2022, 9, 40. [Google Scholar] [CrossRef]

- Wronkowska, M.; Szawara-Nowak, D.; Piskuła, M.K.; Zieliński, H. Bioaccessibility of maillard reaction products from biscuits formulated from buckwheat flours fermented by selected lactic acid bacteria. Microorganisms 2023, 11, 883. [Google Scholar] [CrossRef]

- Li, X.; He, T.; Mao, J.; Sha, R. Effects of lactic acid bacteria fermentation on physicochemical properties, functional compounds and antioxidant activity of edible grass. Fermentation 2022, 8, 647. [Google Scholar] [CrossRef]

- Zeng, L.; Wang, Z.; He, Z.; Zeng, M.; Qin, F.; Chen, J. Physicochemical and gel properties of pumpkin seed protein: A comparative study. Int. J. Food Sci. Technol. 2023, 58, 1639–1651. [Google Scholar] [CrossRef]

- de Melo Pereira, G.V.; de Oliveira Coelho, B.; Júnior, A.I.M.; Thomaz-Soccol, V.; Soccol, C.R. How to select a probiotic? A review and update of methods and criteria. Biotechnol. Adv. 2018, 36, 2060–2076. [Google Scholar] [CrossRef]

- Rianingsih, L.; Sumardianto. Antioxidant activity in seaweed (Sargassum sp.) extract fermented with Lactobacillus plantarum and Lactobacillus acidophilus. Earth Environ. Sci. 2020, 530, 012011. [Google Scholar]

- Bryukhanov, A.L.; Klimko, A.; Netrusov, A. Antioxidant properties of lactic acid bacteria. Microbiology 2022, 9, 463–478. [Google Scholar] [CrossRef]

- Wei, L.; Li, Y.; Hao, Z.; Zheng, Z.; Yang, H.; Xu, S.; Li, S.; Zhang, L.; Xu, Y. Fermentation improves antioxidant capacity and γ-aminobutyric acid content of Ganmai Dazao Decoction by lactic acid bacteria. Front. Microbiol. 2023, 14, 1274353. [Google Scholar] [CrossRef] [PubMed]

- Bie, J.; Teng, W.; Peng, Z.; Cao, J.; Wang, J.; Zhang, Y.; Wang, Y. Investigation on the physicochemical properties and volatile components of egg yolk fermented by different lactic acid bacteria and quality evaluation of mayonnaise prepared from fermented egg yolk. Food Biosci. 2025, 66, 106261. [Google Scholar] [CrossRef]

- Dos Santos Morais, R.; Louvet, N.; Borges, F.; Dumas, D.; Cvetkovska-Ben Mohamed, L.; Barrau, S.; Scher, J.; Gaiani, C.; Burgain, J. Impact of Lacticaseibacillus rhamnosus GG on the Emulsion Stability of Raw Milk. Foods 2021, 10, 991. [Google Scholar] [CrossRef]

- Wang, D.; Cheng, F.; Wang, Y.; Han, J.; Gao, F.; Tian, J.; Zhang, K.; Jin, Y. The changes occurring in proteins during processing and storage of fermented meat products and their regulation by lactic acid bacteria. Foods 2022, 11, 2427. [Google Scholar] [CrossRef]

- Liang, B.; Bai, X.; Wang, Y.; Li, X.; Kong, Y.; Li, X.; Zeng, X.; Liu, W.; Li, H.; Sun, S. Effect of five lactic acid bacteria on the flavor quality of fermented sweet potato juice. Food Chem. X 2024, 24, 102023. [Google Scholar] [CrossRef]

- Wang, J.; Wei, B.; Xu, J.; Jiang, H.; Xu, Y.; Wang, C. Influence of lactic acid fermentation on the phenolic profile, antioxidant activities, and volatile compounds of black chokeberry (Aronia melanocarpa) juice. J. Food Sci. 2024, 89, 834–850. [Google Scholar] [CrossRef]

- Prihanto, A.A.; Umam, N.I.; Bangun, J.D. Unveiling the Secrets of Indonesian fermented Fish: Characteristics of lactic acid bacteria, roles, and potential in product development. Food Biosci. 2024, 61, 104629. [Google Scholar] [CrossRef]

- Yao, H.; Su, H.; Ma, J.; Zheng, J.; He, W.; Wu, C.; Hou, Z.; Zhao, R.; Zhou, Q. Widely targeted volatileomics analysis reveals the typical aroma formation of Xinyang black tea during fermentation. Food Res. Int. 2023, 164, 112387. [Google Scholar] [CrossRef]

| Generic Name | Specific Name | Strain Number |

|---|---|---|

| Lactiplantibacillus | plantarum | ZYN-51, ZYN-65, ZYN-66, ZYN-70, ZYN-84 |

| Limosilactobacillus | fermentum | ZYN-76 |

| Lacticaseibacillus | paracasei | ZYN-54 |

| rhamnosus | ZYN-71 |

| Serial Number | Survival Rate in Artificial Bile (%) | Survival Rate in Artificial Gastric Juice (%) |

|---|---|---|

| ZYN-51 | 4.03 ± 0.54 f | 8.03 ± 1.54 g |

| ZYN-54 | 13.3 ± 0.11 d | 32.95 ± 3.11 d |

| ZYN-65 | 10.22 ± 0.92 e | 13.45 ± 2.90 f |

| ZYN-66 | 19.54 ± 0.24 b | 55.65 ± 3.42 c |

| ZYN-70 | 16.83 ± 0.05 c | 55.41 ± 3.25 c |

| ZYN-71 | 20.43 ± 0.80 a | 63.77 ± 2.80 a |

| ZYN-76 | 19.41 ± 0.05 b | 62.38 ± 3.85 b |

| ZYN-84 | 10.87 ± 0.28 e | 15.49 ± 6.28 e |

| Taste | Amino Acid | CPH (g/100 g) | CPH After Fermentation (g/100 g) | Amino Acid | CPH (g/100 g) | CPH After Fermentation (g/100 g) |

|---|---|---|---|---|---|---|

| Palatable taste | Asp | 4.57 | 3.61 | Glu | 17.66 | 13.65 |

| Amount | 22.23 | 17.26 | ||||

| Sweet taste | Gly | 1.89 | 1.48 | Ser | 4.02 | 3.00 |

| Thr | 2.71 | 2.03 | Ala | 6.23 | 4.40 | |

| Pro | 5.62 | 4.88 | ||||

| Amount | 20.05 | 15.79 | ||||

| Bitter taste | Lys | 0.99 | 0.97 | Tyr | 3.70 | 2.31 |

| His | 1.40 | 1.28 | Val | 3.42 | 2.61 | |

| Met | 1.79 | 1.29 | Phe | 4.46 | 3.38 | |

| Arg | 1.94 | 1.30 | Leu | 13.16 | 9.60 | |

| Ile | 2.92 | 2.21 | ||||

| Amount | 33.79 | 24.95 | ||||

| Hydrophobic amino acid | 37.61 | 28.37 | ||||

| Total amino acids | 76.48 | 58 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cong, S.; Sun, M.; Cao, Y.; Zhao, H.; Sun, J.; Li, G.; Liu, X.; Hu, N. Effects of Lactic Acid Bacteria-Directed Screening on Flavor and Functional Properties of Fermented Corn Protein Hydrolysate. Foods 2025, 14, 3074. https://doi.org/10.3390/foods14173074

Cong S, Sun M, Cao Y, Zhao H, Sun J, Li G, Liu X, Hu N. Effects of Lactic Acid Bacteria-Directed Screening on Flavor and Functional Properties of Fermented Corn Protein Hydrolysate. Foods. 2025; 14(17):3074. https://doi.org/10.3390/foods14173074

Chicago/Turabian StyleCong, Shanzi, Meng Sun, Yujia Cao, Hongji Zhao, Jingyi Sun, Guanlong Li, Xiaolan Liu, and Nan Hu. 2025. "Effects of Lactic Acid Bacteria-Directed Screening on Flavor and Functional Properties of Fermented Corn Protein Hydrolysate" Foods 14, no. 17: 3074. https://doi.org/10.3390/foods14173074

APA StyleCong, S., Sun, M., Cao, Y., Zhao, H., Sun, J., Li, G., Liu, X., & Hu, N. (2025). Effects of Lactic Acid Bacteria-Directed Screening on Flavor and Functional Properties of Fermented Corn Protein Hydrolysate. Foods, 14(17), 3074. https://doi.org/10.3390/foods14173074