Impact of Nitrogen Sparging on Chemical and Sensory Characteristics of Verdejo and Sauvignon blanc Wines

Abstract

1. Introduction

2. Materials and Methods

2.1. White Wines and Sparging Treatment

2.2. Chemical Analysis of White Wines

2.3. Sensory Analysis of White Wines

2.4. Statistical Analysis

3. Results and Discussion

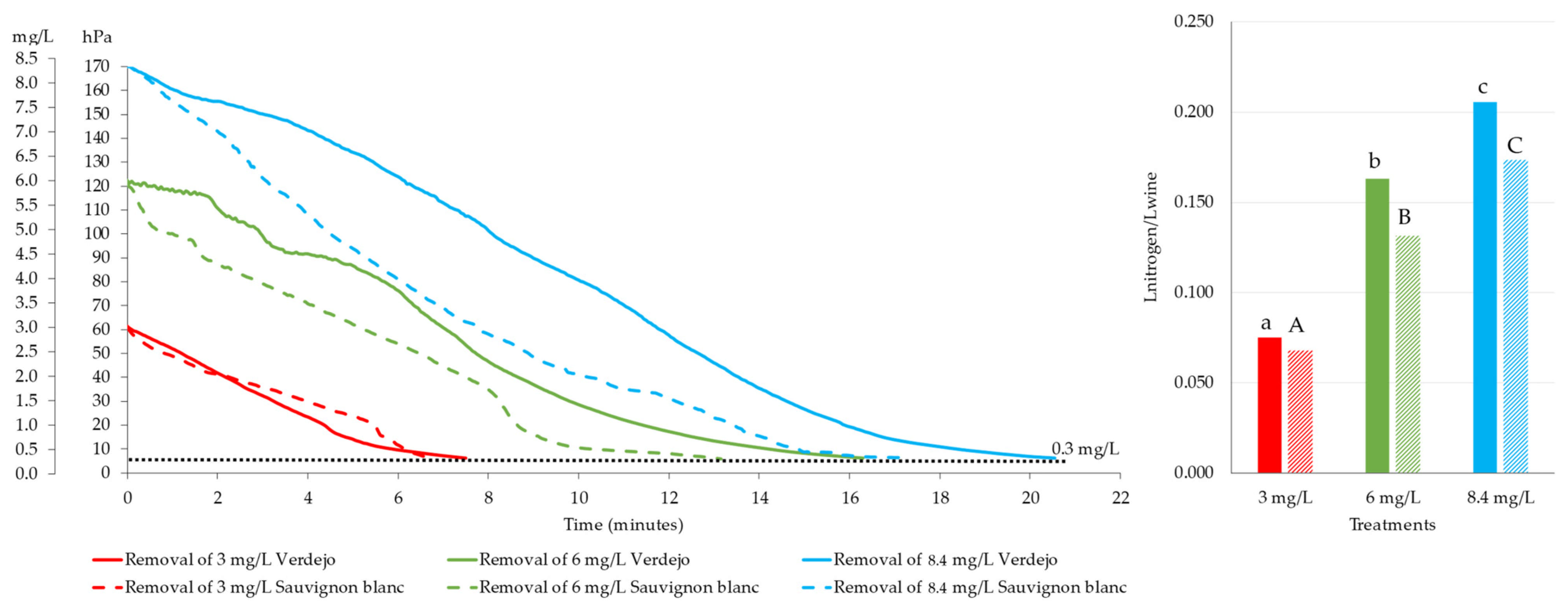

3.1. Efficacy of the Use of N2 for DO Removal in White Wines

3.2. Effect of Sparging on the Chemical Parameters of White Wines with Different DO Levels

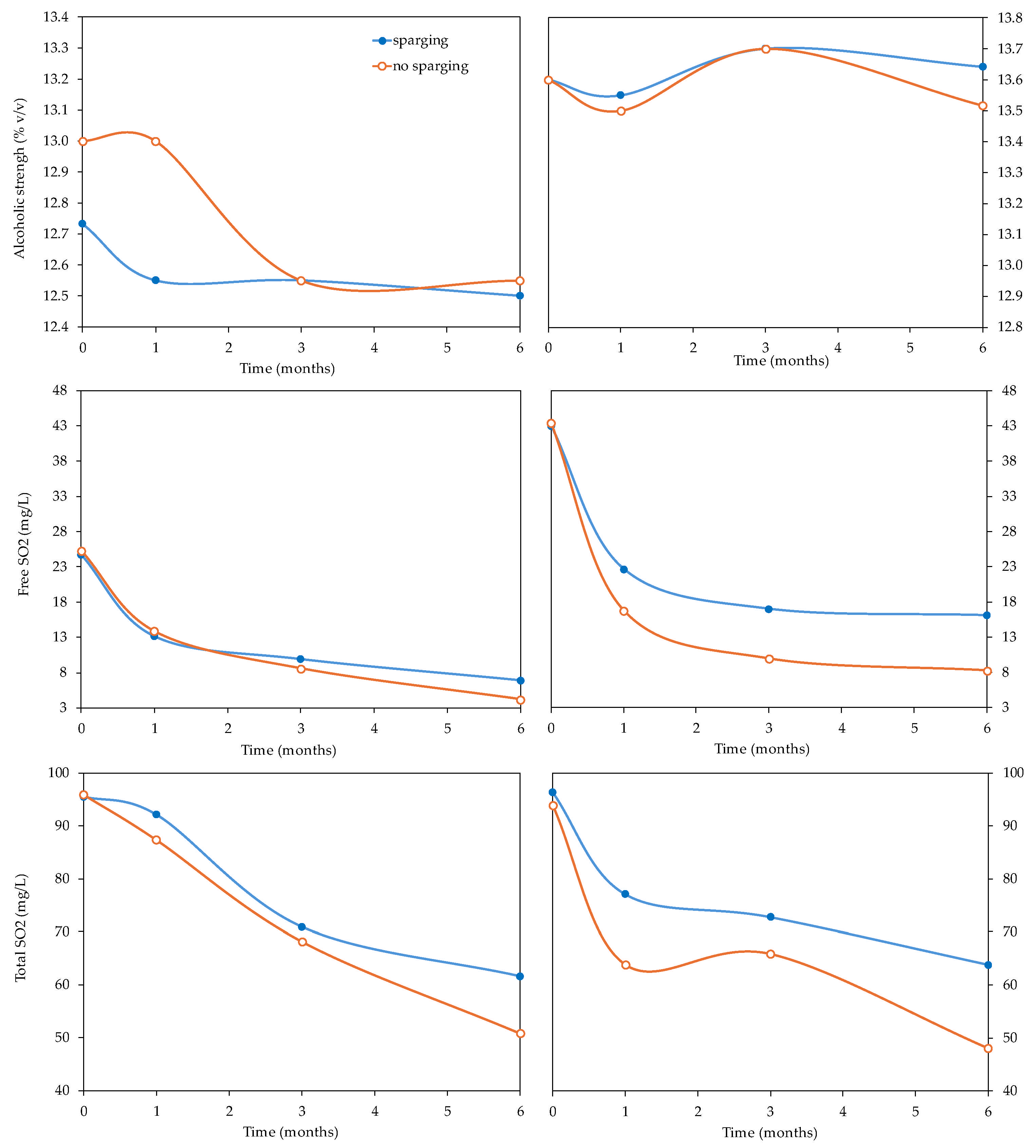

3.2.1. Effect of Sparging on Basic Chemical Parameters

3.2.2. Effect of Sparging on Phenolic Compounds in Wines

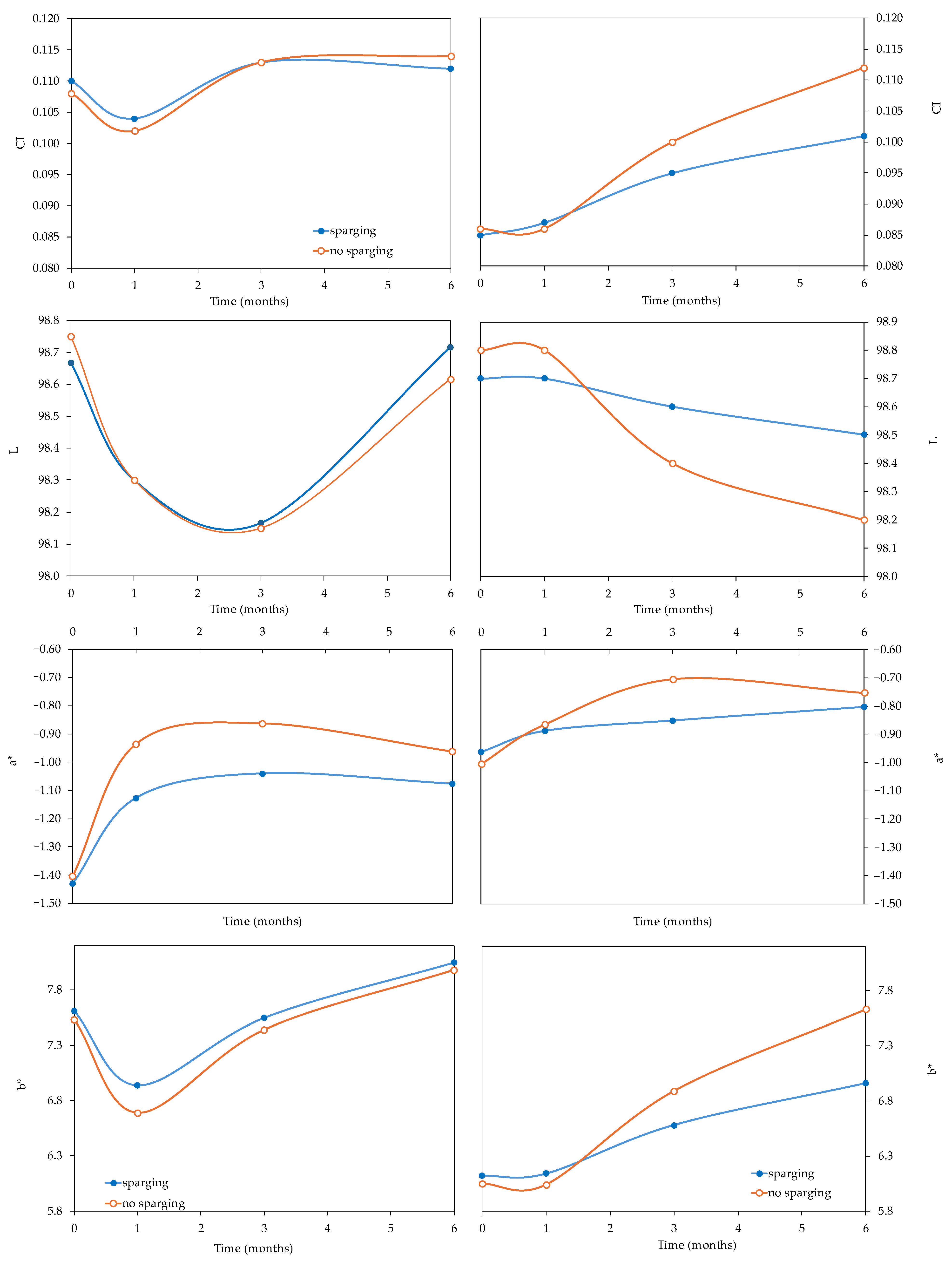

3.2.3. Effect on Wine Color

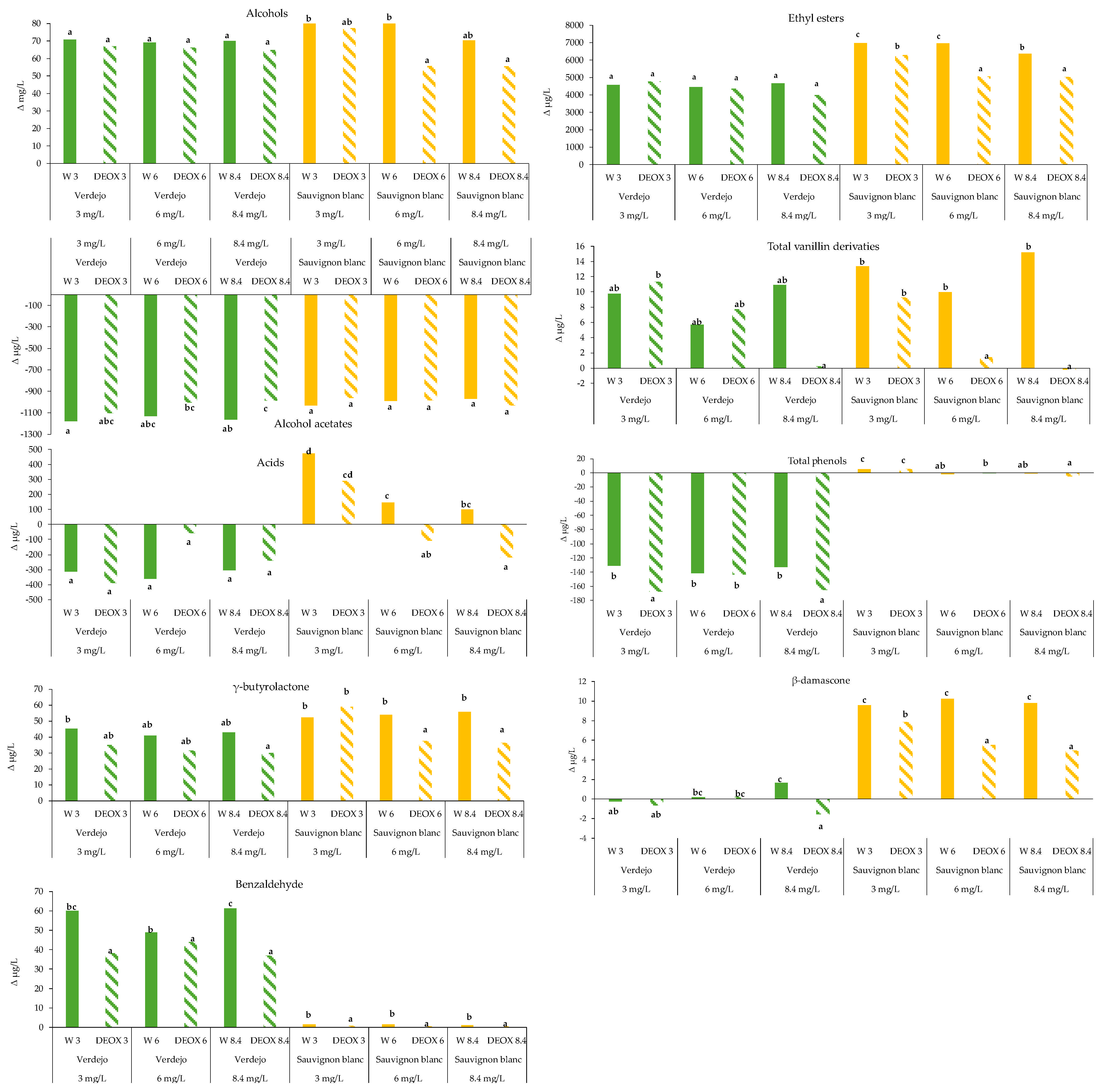

3.2.4. Effect on Volatile Compounds in Wines

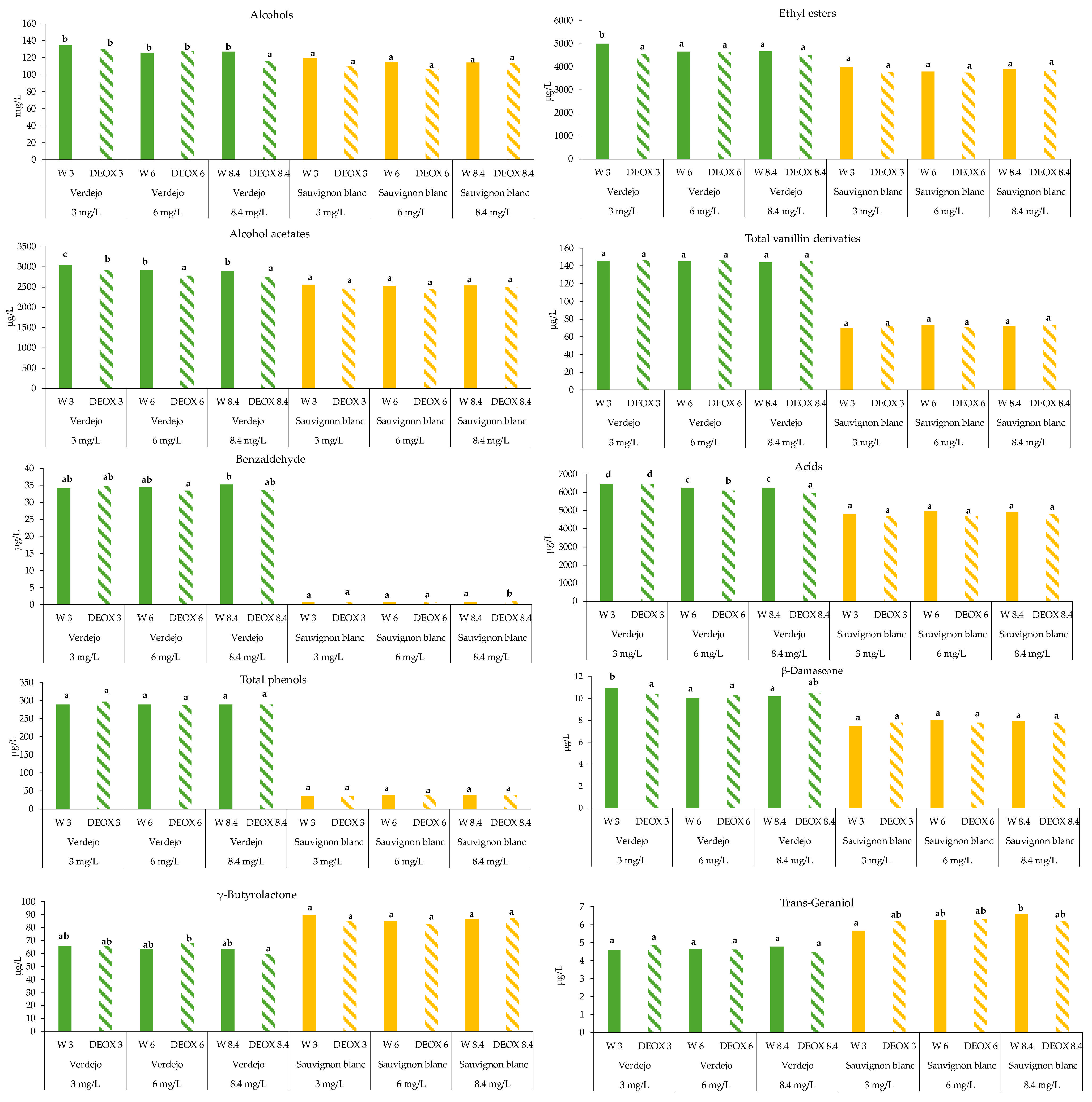

- Effect of sparging treatment

- Effect of time in bottles

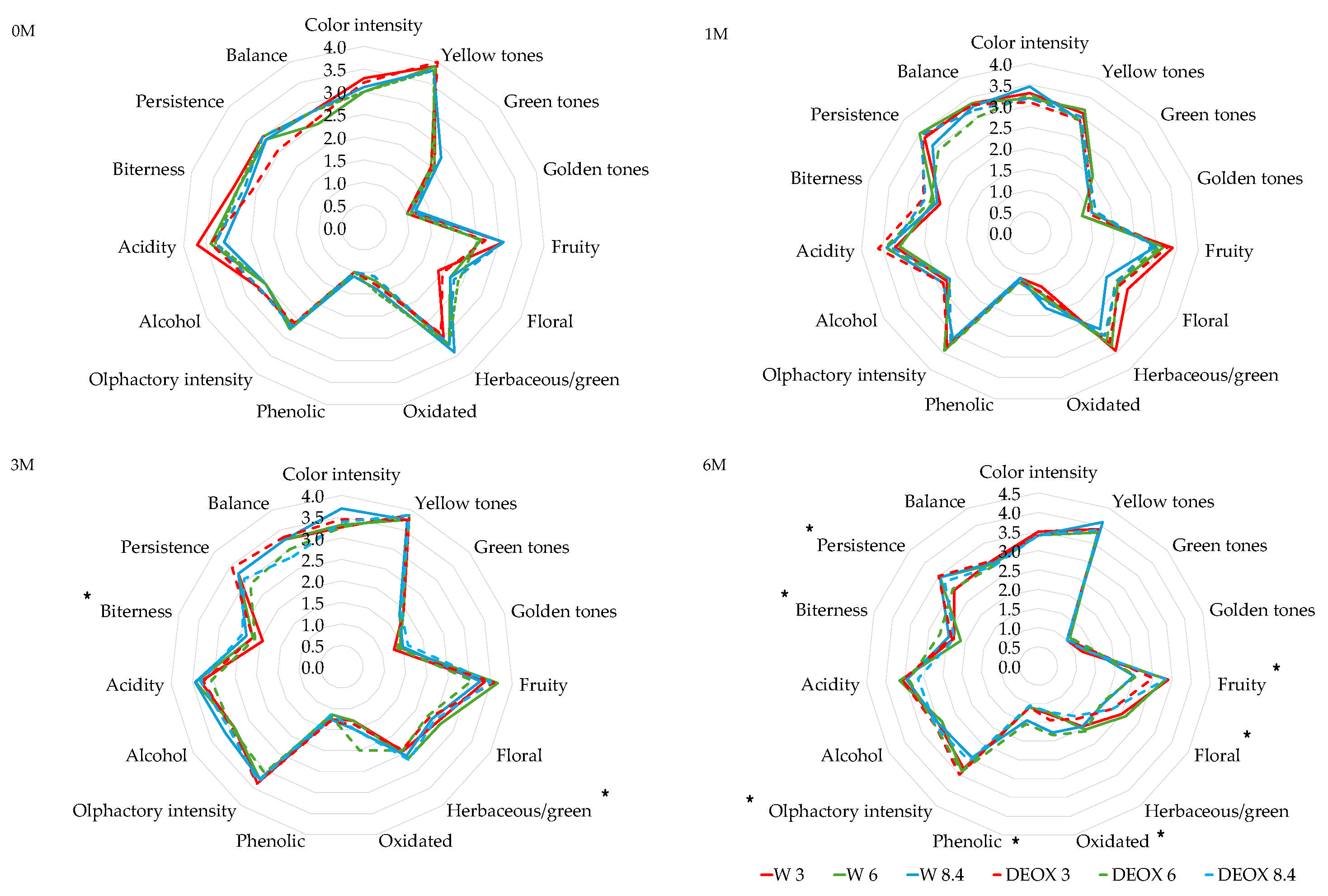

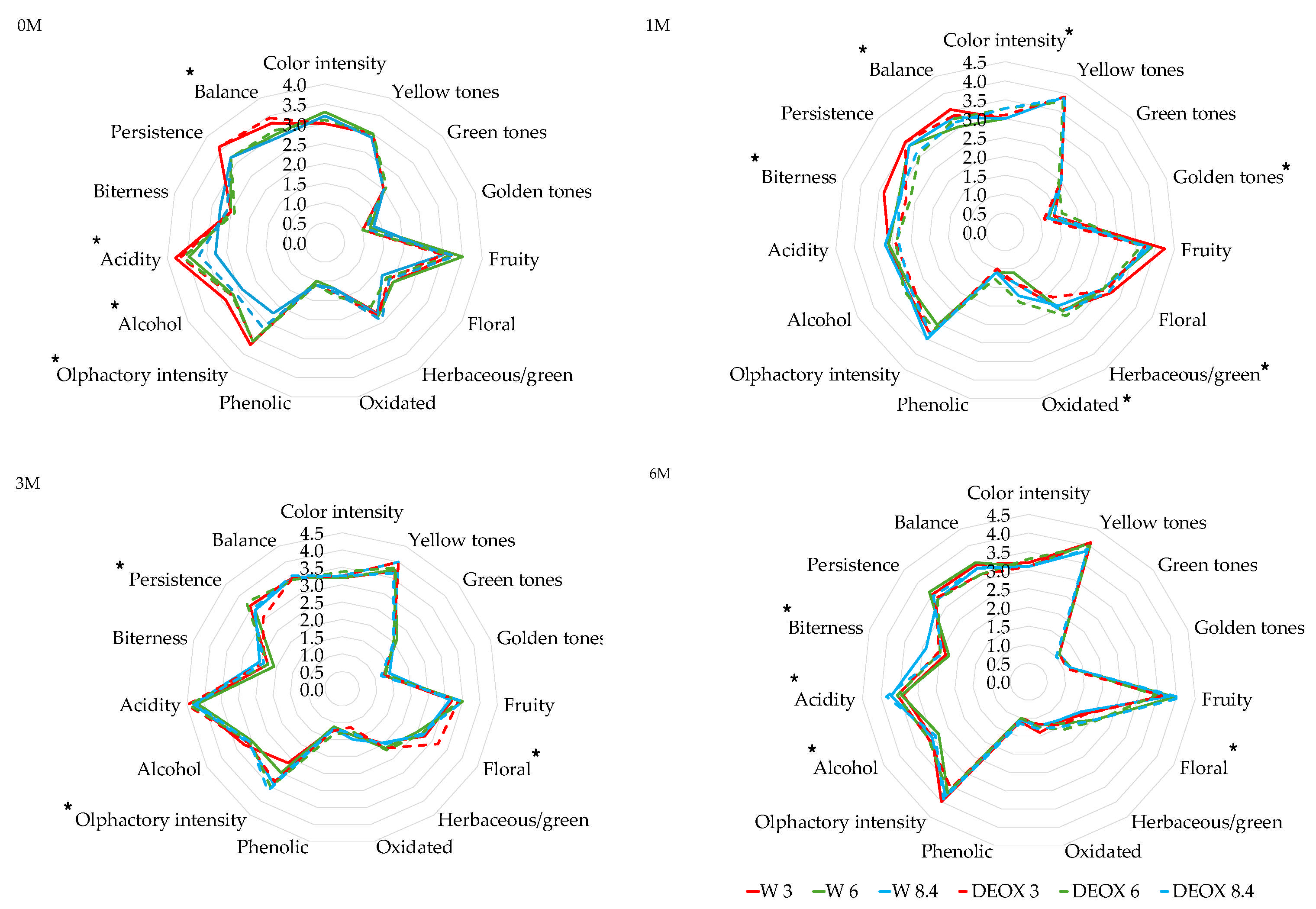

3.3. Effect on the Sensory Profile of the Wines

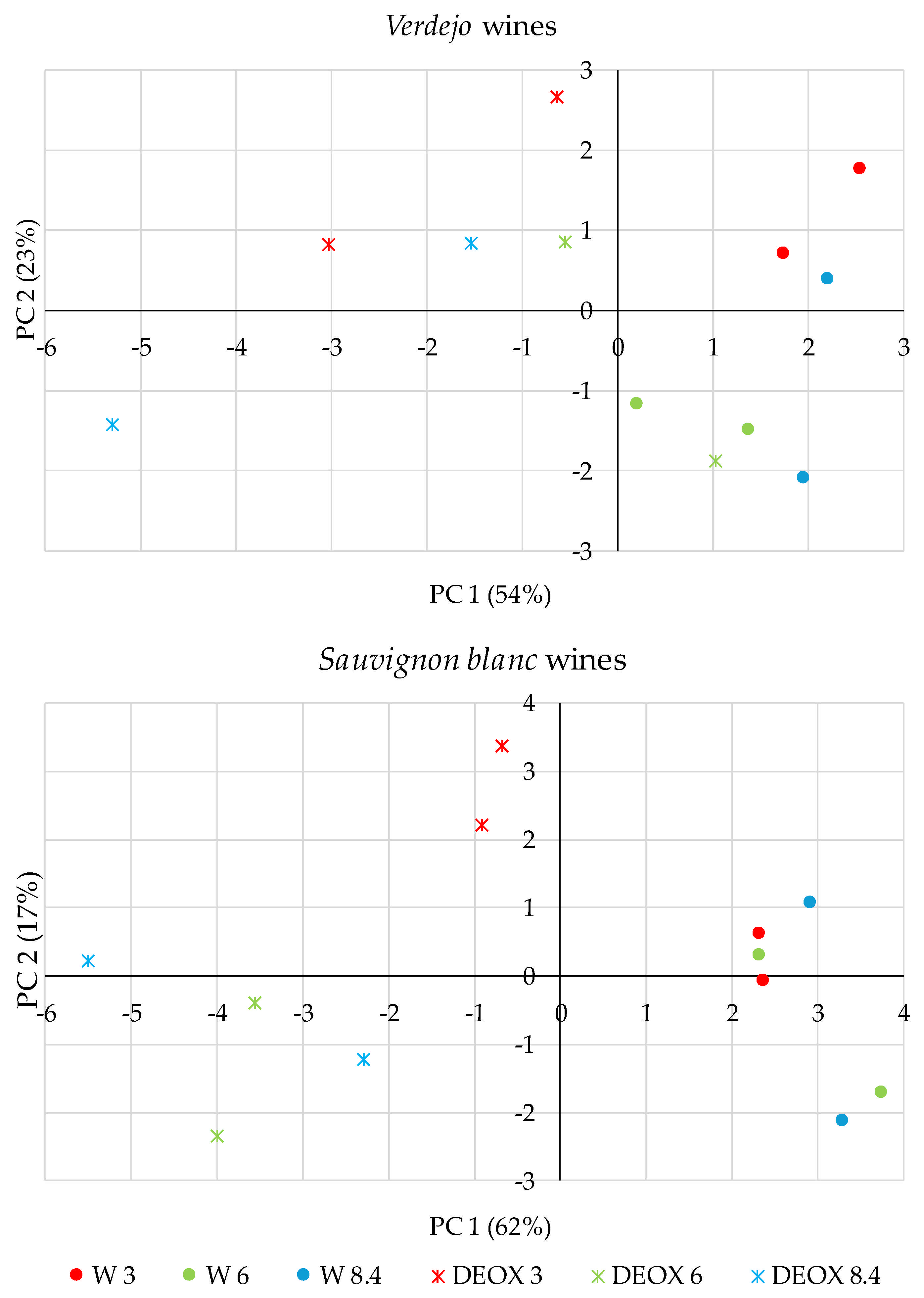

3.4. Multivariate Statistical Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Coetzee, C.; du Toit, W.J. A Comprehensive Review on Sauvignon blanc Aroma with a Focus on Certain Positive Volatile Thiols. Food Res. Int. 2012, 45, 287–298. [Google Scholar] [CrossRef]

- del Barrio-Galán, R.; Nevares, I.; Pérez-Magariño, S.; del Alamo-Sanza, M. Dissolved Oxygen Removal in Wines by Gas Sparging, its Optimization and Chemical Impact. Beverages 2024, 10, 3. [Google Scholar] [CrossRef]

- Steiner, T. Wines & Vines-Strategies to Manage Dissolved Oxygen. 2013. Available online: https://winebusinessanalytics.com/features/article/119752/Strategies-to-Manage-Dissolved-Oxygen (accessed on 20 November 2024).

- Cant, R.R. The Effect of Nitrogen and Carbon Dioxide Treatment of Wines on Dissolved Oxygen Levels. Am. J. Enol. Vitic. 1960, 11, 164–169. [Google Scholar] [CrossRef]

- Saa, P.A.; Pérez-Correa, J.R.; Celentano, D.; Agosin, E. Impact of Carbon Dioxide Injection on Oxygen Dissolution Rate during Oxygen Additions in a Bubble Column. Chem. Eng. J. 2013, 232, 157–166. [Google Scholar] [CrossRef]

- Hidalgo Togores, J. Empleo de gases de inertizado. In Tratado de Enología, 2nd ed.; Mundiprensa: Madrid, Spain, 2011; Volume 2, pp. 1267–1286. [Google Scholar]

- Walls, J.; Sutton, S.; Coetzee, C.; du Toit, W.J. Sparging of White Wine. Aust. J. Grape Wine Res. 2022, 28, 450–458. [Google Scholar] [CrossRef]

- Devatine, A.; Chiciuc, I.; Poupot, C.; Mietton-Peuchot, M. Micro-Oxygenation of Wine in Presence of Dissolved Carbon Dioxide. Chem. Eng. Sci. 2007, 62, 4579–4588. [Google Scholar] [CrossRef]

- Chiciuc, I.; Farines, V.; Mietton-Peuchot, M.; Devatine, A. Effect of Wine Properties and Operating Mode Upon Mass Transfer in Micro-Oxygenation. Int. J. Food Eng. 2010, 6. [Google Scholar] [CrossRef]

- Nitrogen Gas Sparging. 2014. Available online: https://www.southteksystems.com/es/nitrogen-gas-sparging/ (accessed on 3 November 2024).

- Girardon, P. Gases in enology. In Gases in Agro-Food Processes, 1st ed.; Cachon, R., Girardon, P., Voilley, A., Eds.; Academic Press: London, UK, 2019; pp. 433–449. [Google Scholar]

- Farkaš, J. Biotechnológia Vína, 2nd ed.; Alfa: Bratislava, Slovakia, 1983; p. 984. [Google Scholar]

- Grainger, K.; Tattersall, H. Wine Production: Vine to Bottle; Blackwell Publishing Ltd.: Oxford, UK, 2005. [Google Scholar]

- Jung, R. Impact of Oxygen Level in Wine at Bottling. Pr. Winery Vinerard J. 2009, 30, 37–41. [Google Scholar]

- Báleš, V.; Furman, D.; Timár, P.; Ševcík, M. Oxygen Removal from the White Wine in Winery. Acta Chim. Pharm. Indica 2017, 7, 107. [Google Scholar]

- Besagni, G.; Gallazzini, L.; Inzoli, F. On the Scale-up criteria for Bubble Columns. Petroleum 2019, 5, 114–122. [Google Scholar] [CrossRef]

- Sutton, S.; Pott, R.W.M.; Du Toit, W. Desorption of oxygen from wine and model wine solutions in a bubble column. Chem. Eng. Sci. 2022, 255, 117648. [Google Scholar] [CrossRef]

- Butler, I.B.; Schoonen, M.A.A.; Rickard, D.T. Removal of Dissolved Oxygen from Water: A Comparison of Four Common Techniques. Talanta 1994, 41, 211–215. [Google Scholar] [CrossRef] [PubMed]

- Schenk, W.; Bach, H.P.; Nobis, P. Ein Versuch zur Prüfung verschiedener Gasüberlagerungs-Meth- oden in Wein-Anbruchgebinden. Z. Für Weinbau Und Kellerwirtsch. 1977, 24, 65–81. [Google Scholar]

- Sutton, S. Evaluating the Desorption of Oxygen from Wine. Master’s Thesis, Stellenbosch University, Stellenbosch, South Africa, 2022. [Google Scholar]

- Nordestgaard, S. Gains in Speed, Labour and gas Consumption for Winemakers. Aust. NZ Grape Wine 2018, 648, 61–67. [Google Scholar]

- Vidal, J.C.; Vidal, V.M.; Waidelich, G. Exact Management of Dissolved Gases of Wines by Membrane Contactor. Bull. De L’oiv 2011, 84, 179–187. [Google Scholar]

- Blank, A.; Vidal, J.C. Utilisation d’un contacteur membranaire pour la gestion exacte des gaz dissous. Rev. Fr. Oenol. 2013, 261, 7–12. [Google Scholar]

- Waidelich, G.; Vidal, J.C. Eight years of experiences in gas management in wine with membrane contactors. In Proceedings of the Mempro 5, Toulouse, France, 9–11 April 2014. [Google Scholar]

- OIV (International Organisation of Vine and Wine). Compendium of International Methods of Wine and Must Analysis; OIV: Paris, France, 2022; Volumes 1 and 2. [Google Scholar]

- Mazza, G.; Fukumoto, L.; Delaquis, P.; Girard, B.; Ewert, B. Anthocyanins, phenolics and color of Cabernet Franc, Merlot, and Pinot Noir wines from British Columbia. J. Agric. Food Chem. 1999, 47, 4009–4017. [Google Scholar] [CrossRef]

- MSCV. Available online: https://www.unirioja.es/color/descargas.shtml (accessed on 14 September 2024).

- Garde-Cerdán, T.; Rubio-Bretón, P.; Marín-San Román, S.; Baroja, E.; Sáenz de Urturi, I.; Pérez-Álvarez, E.P. Study of wine volatile composition of Tempranillo versus Tempranillo Blanco, a New White Grape Variety. Beverages 2021, 7, 72. [Google Scholar] [CrossRef]

- BS EN ISO 8589:2010/A1:2014; Sensory Analysis: General Guidance for the Design of Test Rooms. British Standards Institution: London, UK, 2014; ISBN 9780580779015.

- Boulton, R.B.; Singleton, V.L.; Bisson, L.F.; Kunkee, R.E. Principles and Practices of Winemaking; Chapman & Hall: New York, NY, USA, 1996; p. 459. [Google Scholar]

- Castillo-Muñoz, N.; Gómez-Alonso, S.; García-Romero, E.; Hermosín-Gutierrez, I. Flavonol profiles of Vitis vinifera white grape cultivars. J. Food Comp. Anal. 2010, 23, 699–705. [Google Scholar] [CrossRef]

- Arcari, S.G.; Caliari, V.; Sganzerla, M.; Godoy, H.T. Volatile Composition of Merlot Red Wine and Its Contribution to the Aroma: Optimization and Validation of Analytical Method. Talanta 2017, 174, 752–766. [Google Scholar] [CrossRef]

- del Barrio-Galán, R.; del Valle-Herrero, H.; Bueno-Herrera, M.; de la Cuesta, P.L.; Pérez-Magariño, S. Chemo-Sensory Profile of White Wines: Importance of Grape Variety and Aging Technique. Eur. Food Res. Technol. 2024, 250, 1949–1958. [Google Scholar] [CrossRef]

- Welke, J.E.; Zanus, M.; Lazzarotto, M.; Alcaraz Zini, C. Quantitative Analysis of Headspace Volatile Compounds Using Comprehensive Two-Dimensional Gas Chromatography and Their Contribution to the Aroma of Chardonnay Wine. Food Res. Int. 2014, 59, 85–99. [Google Scholar] [CrossRef]

- Naranjo, A.; Martínez-Lapuente, L.; Ayestarán, B.; Guadalupe, Z.; Pérez, I.; Canals, C.; Adell, E. Aromatic and Sensory characterization of Maturana Blanca Wines Made with Different Technologies. Beverages 2021, 7, 10. [Google Scholar] [CrossRef]

- Del Barrio-Galán, R.; del Valle-Herrero, H.; Bueno-Herrera, M.; López-de-la-Cuesta, P.; Pérez-Magariño, S. Volatile and Non-volatile Characterization of White and Rosé Wines from Different Spanish Protected Designations of Origin. Beverages 2021, 7, 49. [Google Scholar] [CrossRef]

- Jiang, B.; Xi, Z.; Luo, M.; Zhang, Z. Comparison on Aroma Compounds in Cabernet Sauvignon and Merlot Wines from Four Wine Grape-Growing Regions in China. Food Res. Int. 2013, 51, 482–489. [Google Scholar] [CrossRef]

- Peinado, R.A.; Moreno, J.A.; Muñoz, D.; Medina, M.; Moreno, J. Gas Chromatographic Quantification of Major Volatile Compounds and Polyols in Wine by Direct Injection. J. Agric. Food Chem. 2004, 52, 6389–6393. [Google Scholar] [CrossRef]

- Clarke, R.J.; Bakker, J. Wine Flavour Chemistry; Blackwell Publishing: Oxford, UK, 2004; pp. 120–186. [Google Scholar]

- Zhang, D.; Wei, Z.; Han, Y.; Duan, Y.; Shi, B.; Ma, W. A Review on Wine Flavour Profiles Altered by Bottle Aging. Molecules 2023, 28, 6522. [Google Scholar] [CrossRef]

- Xie, Y.; Jiang, J.; Cui, M.; Chen, Y.; Li, Y.; Hu, Y.; Yin, R.; Ma, X.; Niu, J.; Cheng, W.; et al. Influence of Different Geographical Origins and Bottle Storage Times on the Chemical Composition, Antioxidant Activity and Sensory Properties of Cabernet Sauvignon wine. Food Chem. 2024, 24, 101978. [Google Scholar] [CrossRef]

- Vázquez-Pateiro, I.; Arias-González, U.; Mirás-Avalos, J.M.; Falqué, E. Evolution of the Aroma of Treixadura wines during Bottle Aging. Foods 2020, 9, 1419. [Google Scholar] [CrossRef]

- Iobbi, A.; Di, Y.; Tomasino, E. Revealing the Sensory Impact of Different Levels and Combinations of Esters and Volatile Thiols in Chardonnay Wines. Heliyon 2023, 9, e12862. [Google Scholar] [CrossRef]

- Huang, X.; Jiang, Z.; Tan, J.; Li, R. Geographical Origin Traceability of Red Wines Based on Chemometric Classification via Organic Acid Profiles. J. Food Qual. 2017, 2017, 2038073. [Google Scholar] [CrossRef]

- Prida, A.; Chatonnet, P. Impact of Oak-Derived Compounds on the Olfactory Perception of Barrel-Aged Wines. Am. J. Enol. Vitic. 2010, 61, 408–413. [Google Scholar] [CrossRef]

- Ferreira, V.; Lopez, R. The Actual and Potential Aroma of Winemaking Grapes. Biomolecules 2019, 9, 818. [Google Scholar] [CrossRef]

- Culleré, L.; Escudero, A.; Cacho, J.; Ferreira, V. Gas Chromatography-Olfactometry and Chemical Quantitative Study of the Aroma of Six Premium Quality Spanish Aged Red Wines. J. Agric. Food Chem. 2004, 52, 1653–1660. [Google Scholar] [CrossRef]

- Echave, J.; Barral, M.; Fraga-Corral, M.; Prieto, M.A.; Simal-Gandara, J. Bottle Aging and Storage of Wines: A Review. Molecules 2021, 26, 713. [Google Scholar] [CrossRef]

- De Esteban, M.L.G.; Ubeda, C.; Heredia, F.J.; Catania, A.A.; Assof, M.V.; Fanzone, M.L.; Jofre, V.P. Impact of closure type and storage temperature on chemical and sensory composition of Malbec wines (Mendoza, Argentina) during aging in bottle. Food Res. Int. 2019, 125, 108553. [Google Scholar] [CrossRef]

- Ristic, R.; van der Hulst, L.; Capone, D.L.; Wilkinson, K.L. Impact of Bottle Aging on Smoke-Tainted Wines from Different Grape cultivars. J. Agric. Food Chem. 2017, 65, 4146–4152. [Google Scholar] [CrossRef]

| Verdejo Wines | Sauvignon blanc Wines | |||||

|---|---|---|---|---|---|---|

| O2 Level | Sparging | Time | O2 Level | Sparging | Time | |

| pH | 0.3041 | 0.0003 | 0.0000 | 0.3653 | 0.0463 | 0.0000 |

| Total acidity (g/L) | 0.5591 | 0.0106 | 0.0197 | 0.8243 | 0.0000 | 0.0000 |

| Alcoholic content (% v/v) | 0.6357 | 0.1341 | 0.0890 | 0.4025 | 0.0238 | 0.0032 |

| Volatile acidity (g/L) | 0.0039 | 0.0390 | 0.0003 | 0.4285 | 0.6178 | 0.0000 |

| F-SO2 content (mg/L) | 0.0000 | 0.3513 | 0.0000 | 0.0062 | 0.0000 | 0.0000 |

| T-SO2 content (mg/L) | 0.0000 | 0.0139 | 0.0000 | 0.1883 | 0.0000 | 0.0000 |

| TPI | 0.3715 | 0.8940 | 0.0000 | 0.8572 | 0.0542 | 0.0000 |

| Tartaric ester content (mg/L) | 0.0189 | 0.9451 | 0.0000 | 0.4177 | 0.3198 | 0.0000 |

| Flavonol content (mg/L) | 0.0039 | 0.1475 | 0.0000 | 0.2629 | 0.0499 | 0.0000 |

| Color intensity | 0.0057 | 0.3551 | 0.0000 | 0.0091 | 0.0000 | 0.0000 |

| L* | 0.0004 | 0.8941 | 0.0001 | 0.9145 | 0.3167 | 0.0015 |

| a* | 0.0275 | 0.0006 | 0.0000 | 0.4296 | 0.0679 | 0.0000 |

| b* | 0.7542 | 0.0484 | 0.0000 | 0.1327 | 0.0011 | 0.0000 |

| Total alcohol content (mg/L) | 0.0815 | 0.8589 | 0.0000 | 0.0053 | 0.0757 | 0.0000 |

| Total ethyl ester content (µg/L) | 0.0220 | 0.3871 | 0.0000 | 0.0000 | 0.0000 | 0.0001 |

| Total acetate ester content (µg/L) | 0.0045 | 0.6331 | 0.0000 | 0.0000 | 0.0000 | 0.1042 |

| Total fatty acid content (µg/L) | 0.2607 | 0.5942 | 0.0018 | 0.0373 | 0.0184 | 0.0054 |

| Total vanillic derivative content (µg/L) | 0.8128 | 0.0755 | 0.0000 | 0.0253 | 0.0008 | 0.0000 |

| Benzaldehyde content (µg/L) | 0.0956 | 0.0003 | 0.0000 | 0.6656 | 0.0227 | 0.0000 |

| γ-butyrolactone content (µg/L) | 0.0035 | 0.6617 | 0.0000 | 0.8329 | 0.0250 | 0.0000 |

| β-damascenone content (µg/L) | 0.9014 | 0.4556 | 0.0000 | 0.2904 | 0.0000 | 0.0000 |

| Total terpene content (µg/L) | 0.0811 | 0.0003 | 0.0000 | 0.3388 | 0.8668 | 0.0000 |

| Total phenol content (µg/L) | 0.3927 | 0.9556 | 0.0000 | 0.0010 | 0.9571 | 0.0034 |

| Verdejo Wines | Sauvignon blanc Wines | |||

|---|---|---|---|---|

| PC1 | PC2 | PC1 | PC2 | |

| pH | −0.33 | 0.52 | ||

| Total acidity | 0.82 | −0.48 | ||

| Alcoholic strength | −0.63 | −0.46 | ||

| F-SO2 content | −0.81 | 0.06 | −0.77 | 0.46 |

| F-SO2 content | −0.73 | 0.57 | −0.76 | 0.54 |

| Color intensity | 0.64 | −0.58 | 0.85 | −0.41 |

| Tartaric ester content | 0.47 | 0.56 | ||

| Flavonol content | 0.69 | 0.24 | ||

| L* | −0.58 | 0.62 | −0.82 | 0.43 |

| a* | 0.83 | −0.2 | 0.23 | −0.38 |

| b* | 0.81 | −0.35 | ||

| Total alcohol content | 0.82 | 0.41 | ||

| Total alcohol acetate content | 0.37 | 0.65 | ||

| Total ethyl ester content | 0.9 | 0.31 | ||

| Total acid content | 0.66 | 0.63 | 0.89 | 0.36 |

| Total vanillic derivative content | 0.89 | 0.04 | 0.92 | 0.21 |

| Benzaldehyde content | 0.48 | 0.61 | 0.89 | −0.04 |

| γ-butyrolactone content | 0.86 | 0.36 | 0.74 | 0.63 |

| β-damascenone content | 0.79 | 0.09 | 0.97 | 0.13 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rubén, d.B.-G.; Maria, d.A.-S.; María, M.-G.A.; Miriam, G.-L.; Ignacio, N. Impact of Nitrogen Sparging on Chemical and Sensory Characteristics of Verdejo and Sauvignon blanc Wines. Foods 2025, 14, 2272. https://doi.org/10.3390/foods14132272

Rubén dB-G, Maria dA-S, María M-GA, Miriam G-L, Ignacio N. Impact of Nitrogen Sparging on Chemical and Sensory Characteristics of Verdejo and Sauvignon blanc Wines. Foods. 2025; 14(13):2272. https://doi.org/10.3390/foods14132272

Chicago/Turabian StyleRubén, del Barrio-Galán, del Alamo-Sanza Maria, Martínez-Gil Ana María, González-Lázaro Miriam, and Nevares Ignacio. 2025. "Impact of Nitrogen Sparging on Chemical and Sensory Characteristics of Verdejo and Sauvignon blanc Wines" Foods 14, no. 13: 2272. https://doi.org/10.3390/foods14132272

APA StyleRubén, d. B.-G., Maria, d. A.-S., María, M.-G. A., Miriam, G.-L., & Ignacio, N. (2025). Impact of Nitrogen Sparging on Chemical and Sensory Characteristics of Verdejo and Sauvignon blanc Wines. Foods, 14(13), 2272. https://doi.org/10.3390/foods14132272