Functional Modification and Applications of Rice Starch Emulsion Systems Based on Interfacial Engineering

Abstract

1. Introduction

2. Physicochemical Properties and Limitations of Rice Starch

2.1. Classification of Starch

| Classification Criteria | Type | Representative Starch | Granule Morphology | Amylose/Amylopectin Ratio | Gelatinization Temperature | Characteristics and Applications | Emulsifying Performance (Emulsifying Activity Index) | References |

|---|---|---|---|---|---|---|---|---|

| By source | Seed starch | Corn starch | Polygonal or spherical | Direct links account for approximately 25% | - | It has strong film-forming properties and is used in degradable packaging materials. | 10–30 m2/g | [11] |

| Wheat starch | - | It has strong gelling power and is suitable for traditional noodles. | 15–35 m2/g | [11] | ||||

| Wheat starch | Direct chain: 15–30% | 60–70 °C | The viscosity is moderate after gelatinization and it is prone to aging. | 10–25 m2/g | [11] | |||

| Tuber starch | Potato starch | Large particles with a smooth surface | Branched chains >80% | 58–65 °C | It has excellent film-forming properties and transparency, and is used in degradable packaging materials. | 20–40 m2/g | [21] | |

| Cassava starch | - | After gelatinization, it has high viscosity but low stability and is used for thickening food. | 15–35 m2/g | [22] | ||||

| Root and stem starch | Sweet potato starch | Irregular shape | - | - | It has a high viscosity after gelatinization and is often used for thickening food. | 10–30 m2/g | [23] | |

| According to the structure | High amylose | High amylose content in corn | - | Direct links >50% | - | The molecules are closely arranged, heat-resistant, and used in degradable packaging materials. | 5–20 m2/g | [12] |

| High amylose | Cassava starch | - | Branched chains >80% | - | The branch structure hinders rearrangement. After gelatinization, it has high viscosity and good transparency, and is used as a food gelling agent. | 20–40 m2/g | [13] | |

| According to physical and chemical properties | Common starch | Potato starch | Large particles with a smooth surface | Direct links account for approximately 20% | 58–65 °C | It is applicable to conventional food processing. | 20–40 m2/g | [17] |

| Waxy starch | Waxy corn starch | - | The direct chain is approximately 0% | - | The paste has high stability and strong anti-reflux property, and is used for frozen food. | 20–40 m2/g | [18] | |

| Waxy starch | Green banana starch | - | The direct chain is approximately 20–25% | - | It is difficult to be decomposed by enzymes, has prebiotic functions, and is used in low glycemic index foods. | 10–30 m2/g | [19] |

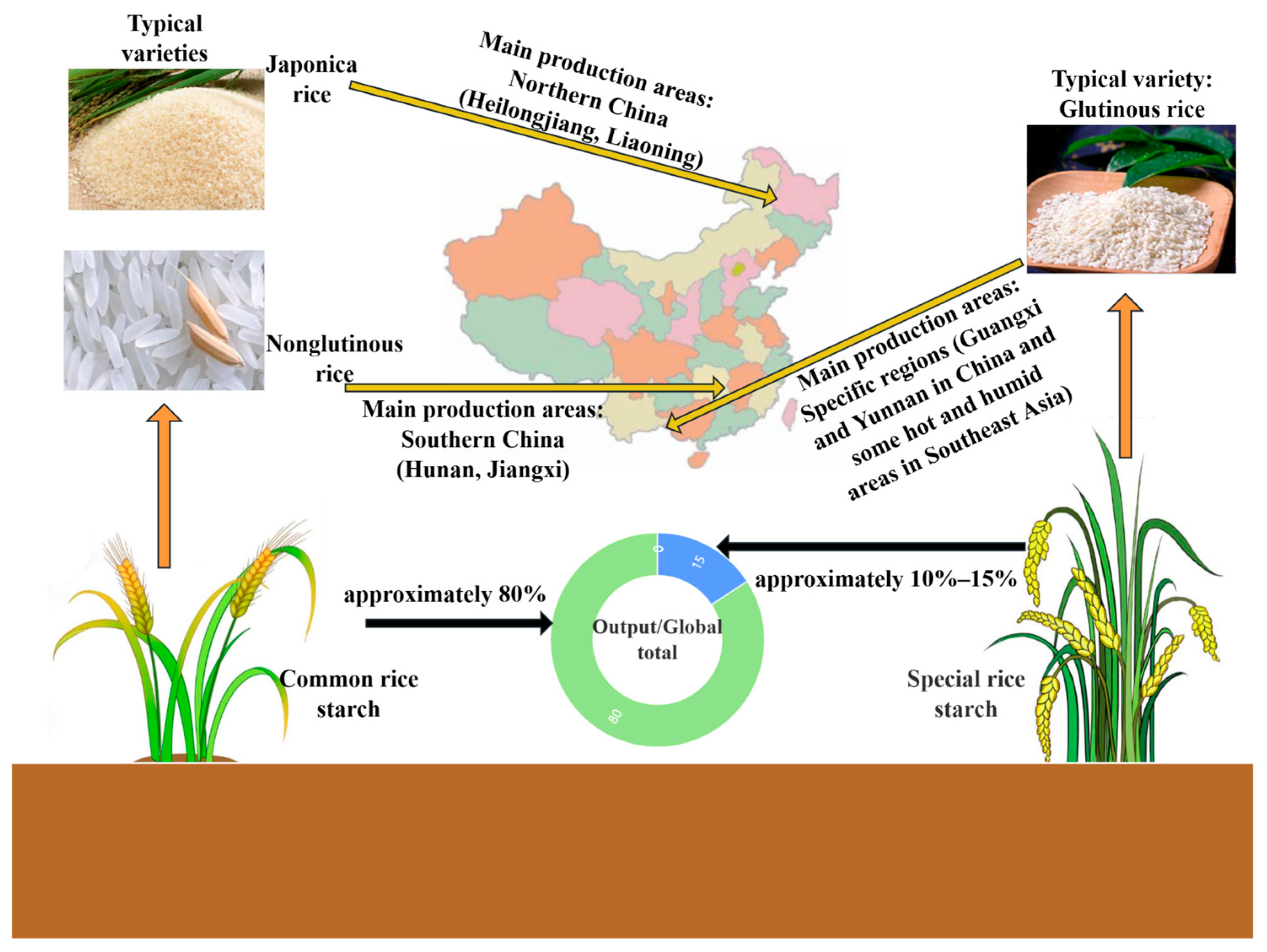

2.2. Classification of Rice Starch: Ordinary and Special Varieties

2.3. Applications of Rice Starch

3. Driving Effect of Interfacial Properties on the Functional Enhancement of Rice Starch

3.1. Limitations of Rice Starch

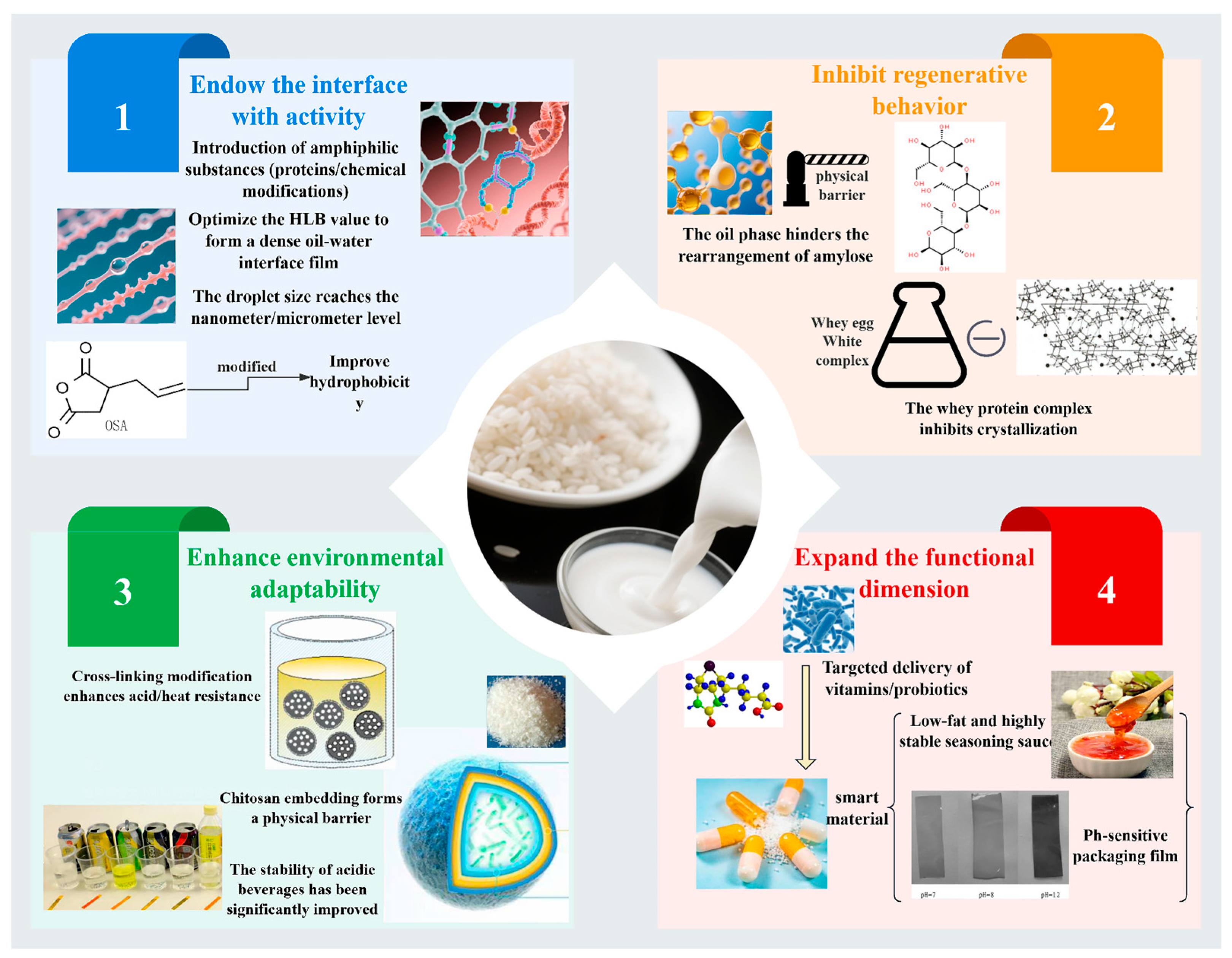

3.2. Functional Enhancement of Rice Starch via Emulsion Technology

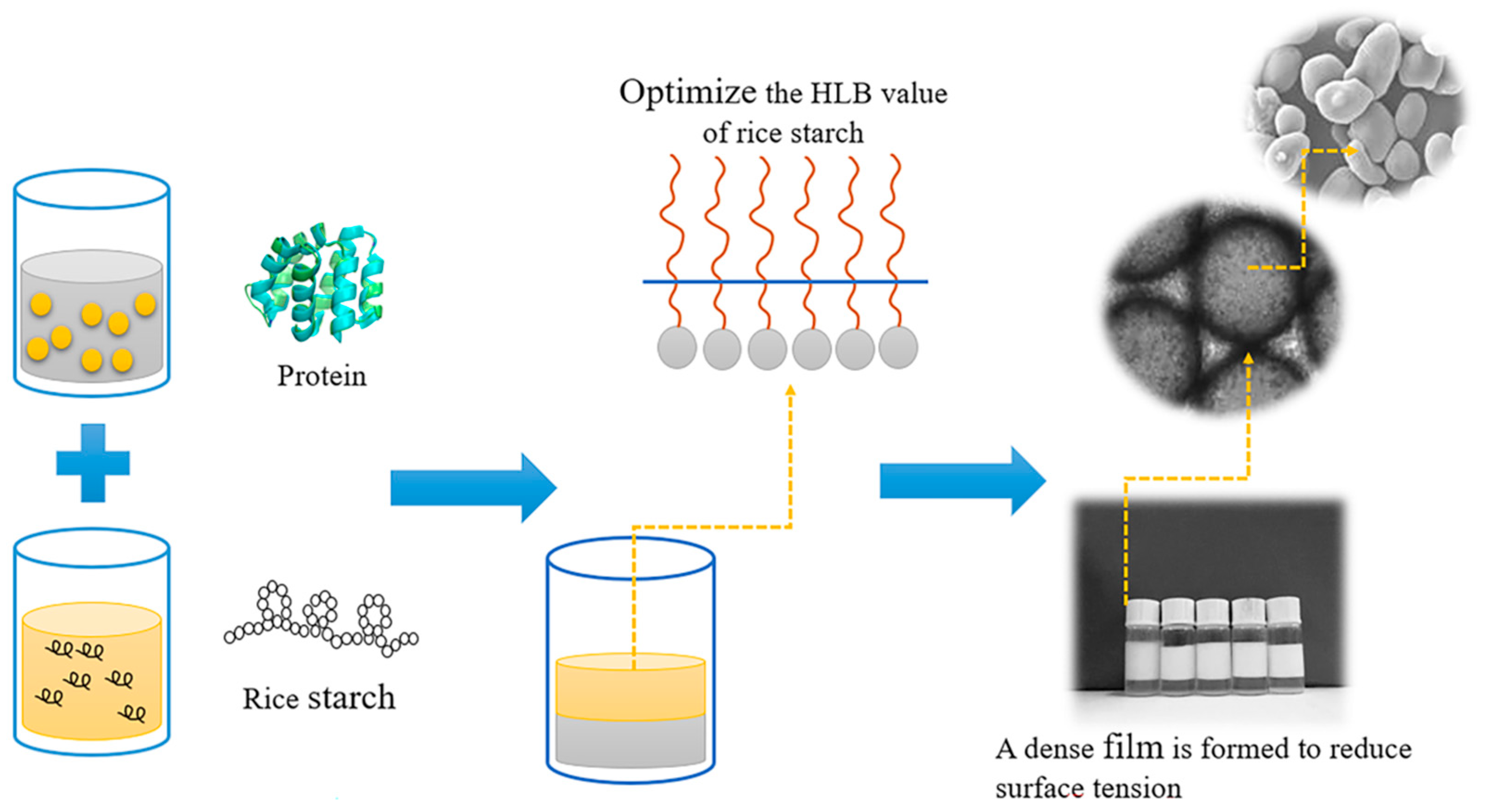

3.2.1. Imparting Interfacial Activity to Rice Starch

3.2.2. Inhibition of Rice Starch Retrogradation

3.2.3. Enhance Environmental Adaptability

3.2.4. Expanding Functional Applications

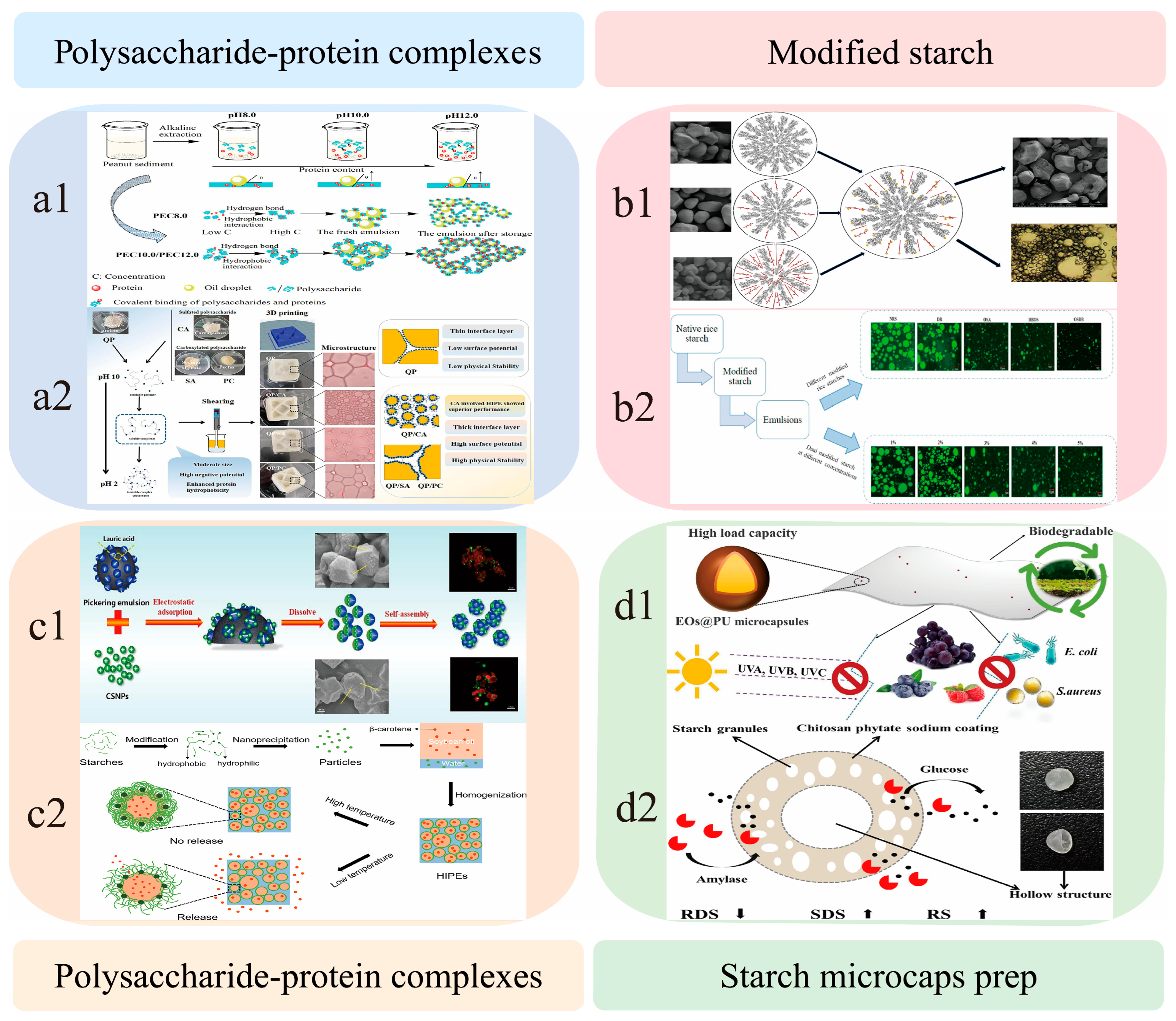

4. Application Mode of Starch in Emulsion Systems

4.1. Polysaccharide–Protein Complexes

4.2. Modified Starch

4.3. Starch-Based Pickering Emulsion

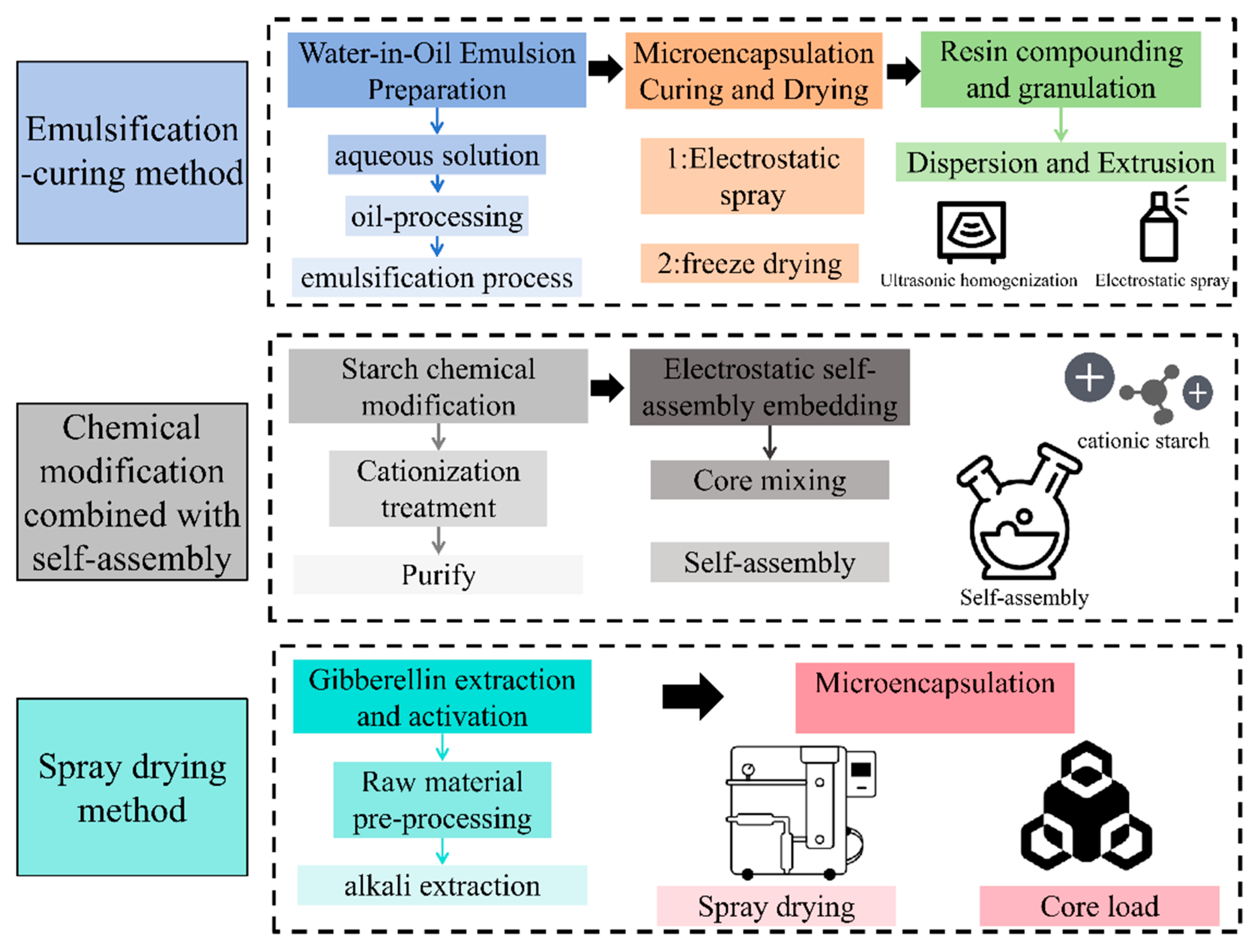

4.4. Preparation of Starch-Based Microcapsules

5. Conclusions and Outlook

5.1. Summary

5.2. Future Prospects

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xie, H.; Li, J.; Li, T.; Lu, X.; Hu, Q.; Qin, Z. GloRice, a Global Rice Database (v1.0): I. Gridded Paddy Rice Annual Distribution from 1961 to 2021. Sci. Data 2025, 12, 182. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Z.; Dong, J.; Yang, J.; Liu, L.; You, N.; Xiao, X.; Zhang, G. From Rice Planting Area Mapping to Rice Agricultural System Mapping: A Holistic Remote Sensing Framework for Understanding China’s Complex Rice Systems. ISPRS J. Photogramm. Remote Sens. 2025, 224, 382–397. [Google Scholar] [CrossRef]

- Zhang, S.; Ma, L.; Gao, S.; Zhu, C.; Yan, Y.; Liu, X.; Li, L.; Chen, H. A Value-Added Utilization Method of Sugar Production By-Products from Rice Straw: Extraction of Lignin and Evaluation of Its Antioxidant Activity. Processes 2022, 10, 1210. [Google Scholar] [CrossRef]

- Hosokawa, N.; Doi, Y.; Kim, W.; Iizumi, T. Contrasting Area and Yield Responses to Extreme Climate Contributes to Climate-Resilient Rice Production in Asia. Sci. Rep. 2023, 13, 6219. [Google Scholar] [CrossRef]

- Benito-González, I.; Ortiz-Gimeno, M.d.M.; López-Rubio, A.; Martínez-Abad, A.; Garrido-Fernández, A.; Martínez-Sanz, M. Sustainable Starch Biocomposite Films Fully-Based on White Rice (Oryza Sativa) Agroindustrial by-Products. Food Bioprod. Process. 2022, 136, 47–58. [Google Scholar] [CrossRef]

- No, J.; Shin, M. Structures and Digestibility of B-Type High-Amylose Rice Starches Compared with A-Type High-Amylose Rice Starches. J. Cereal Sci. 2023, 112, 103713. [Google Scholar] [CrossRef]

- Teobaldi, A.G.; Carrillo Parra, E.J.; Barrera, G.N.; Ribotta, P.D. The Properties of Damaged Starch Granules: The Relationship Between Granule Structure and Water–Starch Polymer Interactions. Foods 2025, 14, 21. [Google Scholar] [CrossRef]

- Gómez-Luría, D.; Vernon-Carter, E.J.; Alvarez-Ramirez, J.; Cruz-Sosa, F. Insights of the Ability of Gelatinized Fractions from Non-Chemical Modified Corn, Rice, Wheat, and Waxy Corn Starches to Stabilize O/W Emulsions. Food Hydrocoll. 2019, 89, 726–734. [Google Scholar] [CrossRef]

- MacNeill, G.J.; Mehrpouyan, S.; Minow, M.A.A.; Patterson, J.A.; Tetlow, I.J.; Emes, M.J. Starch as a Source, Starch as a Sink: The Bifunctional Role of Starch in Carbon Allocation. J. Exp. Bot. 2017, 68, 4433–4453. [Google Scholar] [CrossRef]

- He, R.; Du, C.; Li, S.; Guo, L.; Wang, K.; Yang, L. Structural-Functional Analysis of Modified Kudzu Starch as a Novel Instant Powder: Role of Modified Technology. Food Chem. X 2024, 24, 101912. [Google Scholar] [CrossRef]

- Apriyanto, A.; Compart, J.; Fettke, J. A Review of Starch, a Unique Biopolymer—Structure, Metabolism and in Planta Modifications. Plant Sci. 2022, 318, 111223. [Google Scholar] [CrossRef] [PubMed]

- Okpala, N.E.; Aloryi, K.D.; An, T.; He, L.; Tang, X. The Roles of Starch Branching Enzymes and Starch Synthase in the Biosynthesis of Amylose in Rice. J. Cereal Sci. 2022, 104, 103393. [Google Scholar] [CrossRef]

- Zhu, F. Relationships between Amylopectin Internal Molecular Structure and Physicochemical Properties of Starch. Trends Food Sci. Technol. 2018, 78, 234–242. [Google Scholar] [CrossRef]

- Guo, C.; Guo, H. Progress in the Degradability of Biodegradable Film Materials for Packaging. Membranes 2022, 12, 500. [Google Scholar] [CrossRef]

- Baronchelli, A.; Vallino, E.; Dalmazzone, S.; Ridolfi, L.; Laio, F. Large Agri-Food Corporations in the Global Staple and Cash Crops Markets: A Quantitative Analysis of Rice and Coffee through the Virtual Water Perspective. Environ. Res. Lett. 2024, 19, 074070. [Google Scholar] [CrossRef]

- Navasingh, R.J.H.; Gurunathan, M.K.; Nikolova, M.P.; Królczyk, J.B. Sustainable Bioplastics for Food Packaging Produced from Renewable Natural Sources. Polymers 2023, 15, 3760. [Google Scholar] [CrossRef] [PubMed]

- Nik Kamaruzaman, N.Q.; Al-Amsyar, S.M. Modification of Common Starch into Resistant Starch in Cassava through Optimisation of Physical and Chemical Treatments. IOP Conf. Ser. Earth Environ. Sci. 2020, 596, 012084. [Google Scholar] [CrossRef]

- Šárka, E.; Dvořáček, V. Waxy Starch as a Perspective Raw Material (A Review). Food Hydrocoll. 2017, 69, 402–409. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, S.; Xu, Q.; Kong, Q.; Li, F.; Lu, L.; Xu, Y.; Wei, Y. Synthesis and Functions of Resistant Starch. Adv. Nutr. 2023, 14, 1131–1144. [Google Scholar] [CrossRef]

- Wang, J.; Wang, C.; Yu, J.; Yang, Y.; Copeland, L.; Wang, S. A Novel Composite Resistant Starch with Improved Prebiotic Functions. Food Hydrocoll. 2025, 162, 111015. [Google Scholar] [CrossRef]

- Wang, R.; Liu, P.; Cui, B.; Kang, X.; Yu, B.; Qiu, L.; Sun, C. Effects of Pullulanase Debranching on the Properties of Potato Starch-Lauric Acid Complex and Potato Starch-Based Film. Int. J. Biol. Macromol. 2020, 156, 1330–1336. [Google Scholar] [CrossRef] [PubMed]

- Akintayo, O.A.; Obadu, J.M.; Karim, O.R.; Balogun, M.A.; Kolawole, F.L.; Oyeyinka, S.A. Effect of Replacement of Cassava Starch with Sweet Potato Starch on the Functional, Pasting and Sensory Properties of Tapioca Grits. LWT 2019, 111, 513–519. [Google Scholar] [CrossRef]

- Ye, F.; Li, J.; Zhao, G. Physicochemical Properties of Different-Sized Fractions of Sweet Potato Starch and Their Contributions to the Quality of Sweet Potato Starch. Food Hydrocoll. 2020, 108, 106023. [Google Scholar] [CrossRef]

- Mousa, A.M.A.; Ali, A.M.A.-G.; Omar, A.E.A.; Alharbi, K.; Abd El-Moneim, D.; Mansour, E.; Elmorsy, R.S.A. Physiological, Agronomic, and Grain Quality Responses of Diverse Rice Genotypes to Various Irrigation Regimes under Aerobic Cultivation Conditions. Life 2024, 14, 370. [Google Scholar] [CrossRef] [PubMed]

- Liao, C.; Chen, J.; Cao, F.; Wang, W.; Huang, M.; Zheng, H. Contrasting Starch Digestion and Physiochemical Characteristics between Japonica and Indica Rice Varieties with Comparable High-Amylose Content. Curr. Res. Food Sci. 2025, 10, 101092. [Google Scholar] [CrossRef]

- Lowithun, N.; Sagis, L.M.C.; Lumdubwong, N. Impact of Deformability and Rigidity of Starch Granules on Linear and Non-Linear Rheological Behavior of Waxy Rice Starch Gels and Applicability for Food End Uses. Foods 2024, 13, 1864. [Google Scholar] [CrossRef]

- Jeong, D.; Lee, J.H.; Chung, H.-J. Effect of Molecular Structure on Phase Transition Behavior of Rice Starch with Different Amylose Contents. Carbohydr. Polym. 2021, 259, 117712. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, X.; Xu, Y.; Xu, Z.; Li, H.; Sui, Z.; Corke, H. Gel Texture and Rheological Properties of Normal Amylose and Waxy Potato Starch Blends with Rice Starches Differing in Amylose Content. Int. J. Food Sci. Technol. 2021, 56, 1946–1958. [Google Scholar] [CrossRef]

- Luo, Z.; Wang, Z. The Role of Starch Granule-Associated Proteins in Enhancing the Strength of Indica Rice Starch Gels. Food Hydrocoll. 2022, 131, 107826. [Google Scholar] [CrossRef]

- Jiao, M.; Gao, Y.; Tian, Y. Study the Relationship between the Microstructure and Characteristics of Quinoa Starch by Compared with Common Cereal Starches. Am. J. Biochem. Biotechnol. 2020, 16, 561–567. [Google Scholar] [CrossRef]

- Sun, X.; Dong, Z.; Liang, J. Preparation of Resistant Rice Starch and Processing Technology Optimization. Starch—Stärke 2022, 74, 2100218. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, J.; Hu, Y.; Zhang, Y.; Ying, Y.; Xu, F.; Bao, J. Combined Effects of Different Alleles of FLO2, Wx and SSIIa on the Cooking and Eating Quality of Rice. Plants 2022, 11, 2249. [Google Scholar] [CrossRef]

- Dang, Y.; Imaizumi, T.; Nishizu, T.; Anandalakshmi, R.; Katsuno, N. Effect of the Addition of Pregelatinized Rice Starch Paste on the Retrogradation of Rice Starch Gel. Food Hydrocoll. 2023, 145, 109159. [Google Scholar] [CrossRef]

- Biduski, B.; Kringel, D.H.; Colussi, R.; Hackbart, H.C.d.S.; Lim, L.-T.; Dias, A.R.G.; Zavareze, E.d.R. Electrosprayed Octenyl Succinic Anhydride Starch Capsules for Rosemary Essential Oil Encapsulation. Int. J. Biol. Macromol. 2019, 132, 300–307. [Google Scholar] [CrossRef]

- Wu, W.-C.; Hsiao, P.-Y.; Huang, Y.-C. Effects of Amylose Content on Starch-Chitosan Composite Film and Its Application as a Wound Dressing. J. Polym. Res. 2019, 26, 137. [Google Scholar] [CrossRef]

- Shoukat, R.; Cappai, M.; Pilia, L.; Pia, G. Rice Starch Chemistry, Functional Properties, and Industrial Applications: A Review. Polymers 2025, 17, 110. [Google Scholar] [CrossRef] [PubMed]

- Peerapattana, J.; Phuvarit, P.; Srijesdaruk, V.; Preechagoon, D.; Tattawasart, A. Pregelatinized Glutinous Rice Starch as a Sustained Release Agent for Tablet Preparations. Carbohydr. Polym. 2010, 80, 453–459. [Google Scholar] [CrossRef]

- de Oliveira, J.P.; de Almeida, M.E.F.; Costa, J.d.S.S.; da Silva, I.B.; de Oliveira, J.S.; Oliveira, E.L.; Landim, L.B.; da Silva, N.M.C.; de Oliveira, C.P. Effect of Eucalyptus Nanofibril as Reinforcement in Biodegradable Thermoplastic Films Based on Rice Starch (Oryza Sativa): Evaluation as Primary Packaging for Crackers. Food Chem. 2025, 474, 143177. [Google Scholar] [CrossRef]

- Watcharakitti, J.; Nimnuan, J.; Krusong, K.; Nanan, S.; Smith, S.M. Insight into the Molecular Weight of Hydrophobic Starch Laurate-Based Adhesives for Paper. Polymers 2023, 15, 1754. [Google Scholar] [CrossRef]

- Chueangchayaphan, W.; Luklem, C.; Nooun, P.; Thitithanakul, S.; Pechwang, J.; Kunphakdee, S.; Chueangchayaphan, N. Incorporating Ginger Extract as a Bioactive Additive Into Eco-Friendly Fertilizer Coatings Based on Natural Rubber-Grafted-Rice Starch: A Performance Evaluation. J. Appl. Polym. Sci. 2025, 142, e56941. [Google Scholar] [CrossRef]

- Myburgh, M.W.; Cripwell, R.A.; Favaro, L.; van Zyl, W.H. Application of Industrial Amylolytic Yeast Strains for the Production of Bioethanol from Broken Rice. Bioresour. Technol. 2019, 294, 122222. [Google Scholar] [CrossRef]

- Lai, J.-X.; Chen, X.; Bu, J.; Hu, B.-B.; Zhu, M.-J. Direct Production of Astaxanthin from Food Waste by Phaffia Rhodozyma. Process Biochem. 2022, 113, 224–233. [Google Scholar] [CrossRef]

- Gangulibabu; Bhuvaneswari, D.; Kalaiselvi, N. Comparison of Corn Starch-Assisted Sol–Gel and Combustion Methods to Prepare LiMn x Co y Ni z O2 Compounds. J. Solid State Electrochem. 2013, 17, 9–17. [Google Scholar] [CrossRef]

- Singh, V.; Singh, S.K.; Pandey, S.; Kumar, P. Sol–Gel Synthesis and Characterization of Adsorbent and Photoluminescent Nanocomposites of Starch and Silica. J. Non-Cryst. Solids 2011, 357, 194–201. [Google Scholar] [CrossRef]

- Cao, F.; Lu, S.; Wang, L.; Zheng, M.; Young Quek, S. Modified Porous Starch for Enhanced Properties: Synthesis, Characterization and Applications. Food Chem. 2023, 415, 135765. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Chao, C.; Yu, J.; Copeland, L.; Wang, S. Mechanistic Studies of Starch Retrogradation and Its Effects on Starch Gel Properties. Food Hydrocoll. 2021, 120, 106914. [Google Scholar] [CrossRef]

- Wei, Q.; Zheng, H.; Han, X.; Zheng, C.; Huang, C.; Jin, Z.; Li, Y.; Zhou, J. Octenyl Succinic Anhydride Modified Starch with Excellent Emulsifying Properties Prepared by Selective Hydrolysis of Supramolecular Immobilized Enzyme. Int. J. Biol. Macromol. 2023, 232, 123383. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Lu, J.; Zhang, Y.; Liang, H.; Liang, D.; Jiang, J.; Lu, Q.; Quirino, R.L.; Zhang, C. Thermosetting Polyurethanes Prepared with the Aid of a Fully Bio-Based Emulsifier with High Bio-Content, High Solid Content, and Superior Mechanical Properties. Green Chem. 2019, 21, 526–537. [Google Scholar] [CrossRef]

- Jain, S.; Winuprasith, T.; Suphantharika, M. Encapsulation of Lycopene in Emulsions and Hydrogel Beads Using Dual Modified Rice Starch: Characterization, Stability Analysis and Release Behaviour during in-Vitro Digestion. Food Hydrocoll. 2020, 104, 105730. [Google Scholar] [CrossRef]

- Shi, Z.; Wu, J.; Wang, X.; Nie, T.; Zeng, Q.; Yuan, C.; Jin, R. Development of Pickering Water-in-Oil Emulsions Using a Dual Stabilization of Candelilla Wax and Acylated EGCG Derivatives to Enhance the Survival of Probiotics (Lactobacillus Plantarum) Powder. Food Funct. 2024, 15, 11141–11157. [Google Scholar] [CrossRef]

- Xie, A.-J.; Li, M.-H.; Li, Z.-W.; Yue, X.-Q. A Preparation of Debranched Waxy Maize Starch Derivatives: Effect of Drying Temperatures on Crystallization and Digestibility. Int. J. Biol. Macromol. 2024, 264, 130684. [Google Scholar] [CrossRef] [PubMed]

- Ning, J.; Fu, B.; Tang, X.; Hao, Y.; Zhang, Y.; Wang, X. Starch Retrogradation in Starch-Based Foods: Mechanisms, Influencing Factors, and Mitigation Strategies. Int. J. Biol. Macromol. 2025, 300, 140354. [Google Scholar] [CrossRef] [PubMed]

- Dun, H.; Liang, H.; Zhan, F.; Wei, X.; Chen, Y.; Wan, J.; Ren, Y.; Hu, L.; Li, B. Influence of O/W Emulsion on Gelatinization and Retrogradation Properties of Rice Starch. Food Hydrocoll. 2020, 103, 105652. [Google Scholar] [CrossRef]

- Zhou, J.; Tong, J.; Su, X.; Ren, L. Hydrophobic Starch Nanocrystals Preparations through Crosslinking Modification Using Citric Acid. Int. J. Biol. Macromol. 2016, 91, 1186–1193. [Google Scholar] [CrossRef]

- Bendoraitiene, J.; Lekniute-Kyzike, E.; Rutkaite, R. Biodegradation of Cross-Linked and Cationic Starches. Int. J. Biol. Macromol. 2018, 119, 345–351. [Google Scholar] [CrossRef]

- Montoya Yepes, D.F.; Murillo Arango, W.; Jiménez Rodríguez, Á.A.; Méndez Arteaga, J.J.; Aldana Porras, Á.E. Encapsulation of Phenols of Gulupa Seed Extract Using Acylated Rice Starch: Effect on the Release and Antioxidant Activity. J. Funct. Foods 2021, 87, 104788. [Google Scholar] [CrossRef]

- Lemos, P.V.F.; Marcelino, H.R.; Cardoso, L.G.; Souza, C.O.d.; Druzian, J.I. Starch Chemical Modifications Applied to Drug Delivery Systems: From Fundamentals to FDA-Approved Raw Materials. Int. J. Biol. Macromol. 2021, 184, 218–234. [Google Scholar] [CrossRef]

- Moin, A.; Ali, T.M.; Hasnain, A. Enhancing Functional Properties of Rice Starches through Hydroxypropylation for Development of Reduced-Fat White Sauces. Food Chem. 2024, 446, 138860. [Google Scholar] [CrossRef]

- Kamwilaisak, K.; Rittiwut, K.; Jutakridsada, P.; Iamamorphanth, W.; Pimsawat, N.; Knijnenburg, J.T.N.; Theerakulpisut, S. Rheology, Stability, Antioxidant Properties, and Curcumin Release of Oil-in-Water Pickering Emulsions Stabilized by Rice Starch Nanoparticles. Int. J. Biol. Macromol. 2022, 214, 370–380. [Google Scholar] [CrossRef]

- Chen, Q.; Zong, Z.; Gao, X.; Zhao, Y.; Wang, J. Preparation and Characterization of Nanostarch-Based Green Hard Capsules Reinforced by Cellulose Nanocrystals. Int. J. Biol. Macromol. 2021, 167, 1241–1247. [Google Scholar] [CrossRef]

- Zhong, W.; Wang, Q.; Shen, X. Quinoa Protein/Polysaccharide Electrostatic Complex Stabilized Vegan High Internal Phase Emulsions for 3D Printing: Role of Complex State and Gelling-Type Polysaccharides. Food Chem. 2024, 434, 137447. [Google Scholar] [CrossRef] [PubMed]

- Ye, J.; Hua, X.; Zhao, Q.; Dong, Z.; Li, Z.; Zhang, W.; Yang, R. Characteristics of Alkali-Extracted Peanut Polysaccharide-Protein Complexes and Their Ability as Pickering Emulsifiers. Int. J. Biol. Macromol. 2020, 162, 1178–1186. [Google Scholar] [CrossRef]

- Tian, L.; Roos, Y.H.; Miao, S. Interaction and Complex Formation of Sonicated Soluble Lentil Protein and Tremella Fuciformis Polysaccharide. Food Hydrocoll. 2024, 153, 109966. [Google Scholar] [CrossRef]

- Lopez-Silva, M.; Bello-Perez, L.A.; Agama-Acevedo, E.; Alvarez-Ramirez, J. Effect of Amylose Content in Morphological, Functional and Emulsification Properties of OSA Modified Corn Starch. Food Hydrocoll. 2019, 97, 105212. [Google Scholar] [CrossRef]

- Jiao, Y.; Li, L.; Cheng, L.; Li, Z.; Li, C.; Gu, Z.; Hong, Y. Correlation between Emulsification and Butyryl Group Distribution in Various Butyrylated Starches. Food Hydrocoll. 2024, 154, 110098. [Google Scholar] [CrossRef]

- Jain, S.; Winuprasith, T.; Suphantharika, M. Design and Synthesis of Modified and Resistant Starch-Based Oil-in-Water Emulsions. Food Hydrocoll. 2019, 89, 153–162. [Google Scholar] [CrossRef]

- Niu, Y.; Gao, Y.; Xiao, Z.; Mao, C.; Wang, H.; Geng, Y.; Ye, Y.; Kou, X. Preparation and Characterisation of Linalool Oil-in-Water Starch-Based Pickering Emulsions and the Effects of the Addition of Cellulose Nanocrystals on Their Stability. Int. J. Biol. Macromol. 2023, 247, 125732. [Google Scholar] [CrossRef]

- Tong, H.; Wang, J.; Qi, L.; Gao, Q. Starch-Based Janus Particle: Fabrication, Characterization and Interfacial Properties in Stabilizing Pickering Emulsion. Carbohydr. Polym. 2023, 313, 120867. [Google Scholar] [CrossRef]

- Wang, C.; Pei, X.; Tan, J.; Zhang, T.; Zhai, K.; Zhang, F.; Bai, Y.; Deng, Y.; Zhang, B.; Wang, Y.; et al. Thermoresponsive Starch-Based Particle-Stabilized Pickering High Internal Phase Emulsions as Nutraceutical Containers for Controlled Release. Int. J. Biol. Macromol. 2020, 146, 171–178. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, W.; Li, L.; Deng, W.; Liu, M.; Hu, J. Biodegradable Starch-Based Packaging Films Incorporated with Polyurethane-Encapsulated Essential-Oil Microcapsules for Sustained Food Preservation. Int. J. Biol. Macromol. 2023, 235, 123889. [Google Scholar] [CrossRef]

- Qin, K.; Sun, D.; Wang, C.; Ji, N.; Dai, L.; Qin, Y.; Xiong, L.; Wang, T.; Sun, Q. Properties and in Vitro Digestibility of Starch Encapsulated in Chitosan-Sodium Phytate Capsules. Food Hydrocoll. 2023, 135, 108127. [Google Scholar] [CrossRef]

- Liu, Q.; Luo, H.; Liang, D.; Temirlan, K.; Zheng, Y.; Li, W. Effect of Pretreatment of Maize Starch by Electron Beam Irradiation on the Formation and Structure of Starch-Oleic Acid-Whey Protein Complex. Food Hydrocoll. 2025, 164, 111217. [Google Scholar] [CrossRef]

- Hayashi, M.; Crofts, N.; Oitome, N.F.; Fujita, N. Analyses of Starch Biosynthetic Protein Complexes and Starch Properties from Developing Mutant Rice Seeds with Minimal Starch Synthase Activities. BMC Plant Biol. 2018, 18, 59. [Google Scholar] [CrossRef] [PubMed]

- Thirunavookarasu, N.; Kumar, S.; Anandharaj, A.; Rawson, A. Enhancing Functional Properties of Soy Protein Isolate—Rice Starch Complex Using Ultrasonication and Its Characterization. Food Bioprocess Technol. 2024, 17, 2619–2630. [Google Scholar] [CrossRef]

- Hwang, S.-K.; Koper, K.; Satoh, H.; Okita, T.W. Rice Endosperm Starch Phosphorylase (Pho1) Assembles with Disproportionating Enzyme (Dpe1) to Form a Protein Complex That Enhances Synthesis of Malto-Oligosaccharides. J. Biol. Chem. 2016, 291, 19994–20007. [Google Scholar] [CrossRef]

- Chen, Y.; Pang, Y.; Bao, J. Expression Profiles and Protein Complexes of Starch Biosynthetic Enzymes from White-Core and Waxy Mutants Induced from High Amylose Indica Rice. Rice Sci. 2020, 27, 152–161. [Google Scholar] [CrossRef]

- Zhong, J.; Li, Y.; Qin, X.; Li, J.; Wang, Y. Improving the Freeze–Thaw Stability of Emulsions via Combining Phosphatidylcholine and Modified Starch: A Combined Experimental and Computational Study. Int. J. Food Sci. Technol. 2022, 57, 1050–1060. [Google Scholar] [CrossRef]

- Li, H.; Gui, Y.; Li, J.; Zhu, Y.; Cui, B.; Guo, L. Modification of Rice Starch Using a Combination of Autoclaving and Triple Enzyme Treatment: Structural, Physicochemical and Digestibility Properties. Int. J. Biol. Macromol. 2020, 144, 500–508. [Google Scholar] [CrossRef]

- Jiang, S.; Yu, Z.; Hu, H.; Lv, J.; Wang, H.; Jiang, S. Adsorption of Procyanidins onto Chitosan-Modified Porous Rice Starch. LWT 2017, 84, 10–17. [Google Scholar] [CrossRef]

- Abdul Hadi, N.; Marefati, A.; Matos, M.; Wiege, B.; Rayner, M. Characterization and Stability of Short-Chain Fatty Acids Modified Starch Pickering Emulsions. Carbohydr. Polym. 2020, 240, 116264. [Google Scholar] [CrossRef]

- Rodriguez, A.M.B.; Binks, B.P. Catalysis in Pickering Emulsions. Soft Matter 2020, 16, 10221–10243. [Google Scholar] [CrossRef]

- Dong, Y.; Zhang, D.; Li, D.; Jia, H.; Qin, W. Control of Ostwald Ripening. Sci. China Mater. 2023, 66, 1249–1255. [Google Scholar] [CrossRef]

- Taghavi, E.; Andriani, C.; Nordin, N.; Awang Seruji, A.Z.R.; Wan Rasdi, N.; Abdul Hadi, N. Rheological and Stability of Mayonnaise-Based Pickering Emulsions Stabilised by Modified Rice Starch Granules as a Plant-Based Emulsifier. Int. J. Food Sci. Technol. 2024, 59, 5651–5663. [Google Scholar] [CrossRef]

- Ji, Y.; Gao, S.; Li, M.; Xu, Y.; Sun, C.; Hou, H.; Dai, Y.; Wang, W. Development of High Internal Phase Pickering Emulsions Utilizing Ternary Complexes of Octenyl Succinate Millet Starch/Chitosan Hydrochloride-EGCG Particles and Their Applications in 3D Printing. Food Chem. 2025, 479, 143648. [Google Scholar] [CrossRef]

- Gong, H.; Song, X.; Zhang, J.; Zhang, B.; Zhu, W. Effects of Dry Heat Treatment on Characteristics of Hydrophobically Modified Rice Starch and Its Emulsification in Pickering Emulsion. Starch—Stärke 2022, 74, 2100131. [Google Scholar] [CrossRef]

- Muhammad, Z.; Ramzan, R.; Zhang, R.; Zhang, M. Resistant Starch-Based Edible Coating Composites for Spray-Dried Microencapsulation of Lactobacillus Acidophilus, Comparative Assessment of Thermal Protection, In Vitro Digestion and Physicochemical Characteristics. Coatings 2021, 11, 587. [Google Scholar] [CrossRef]

- Wu, L.; Tian, J.; Ye, X.; Fang, H.; Zhang, Z.; Xu, C.; Zhang, H. Encapsulation and Release of Curcumin with the Mixture of Porous Rice Starch and Xanthan Gum. Starch—Stärke 2021, 73, 2000042. [Google Scholar] [CrossRef]

- Espinosa-Solís, V.; García-Tejeda, Y.V.; Portilla-Rivera, O.M.; Barrera-Figueroa, V. Tailoring Olive Oil Microcapsules via Microfluidization of Pickering o/w Emulsions. Food Bioprocess Technol. 2021, 14, 1835–1843. [Google Scholar] [CrossRef]

- Ashwar, B.A.; Gani, A.; Gani, A.; Shah, A.; Masoodi, F.A. Production of RS4 from Rice Starch and Its Utilization as an Encapsulating Agent for Targeted Delivery of Probiotics. Food Chem. 2018, 239, 287–294. [Google Scholar] [CrossRef]

| Research Object | Research Methods | Conclusions and Application Values | References |

|---|---|---|---|

| Starch–protein (whey protein, soy protein) composite systems | Physical mixing or chemical cross-linking | Utilize the synergistic effect of the hydrophobicity of proteins and the hydrophilicity of starches to stabilize the interface, which has important application value in fermented foods such as yogurt. Process optimization is required to balance functionality and economy. | [72] |

| ss1 L/ss2a L/ss3a mutant rice | Analysis of the activities of three major starch synthases, starch content in grains, apparent amylose content, and protein analysis | Starch synthesis in the mutants was retained, with fewer branched chains and more linear chains, revealing the relationship between starch properties and protein complexes. | [73] |

| Soy protein–rice starch complexes | Ultrasonic treatment (60% amplitude, 450 W) combined with heat treatment, molecular docking study using 11S protein (1 FXZ) | The formed complexes have excellent functional properties, expanding their application range in the food industry. | [74] |

| Rice endosperm starch phosphorylase (Pho1) and disproportionase (Dpe1) | Pull-down experiments, immunoprecipitation, chromatographic co-elution, electrophoretic co-migration, etc. | Verified the formation of the Pho1—Dpe1 complex and demonstrated the advantages of this complex in substrate utilization and catalytic reactions. | [75] |

| White-core (GM645) and waxy (GM077) mutants of high-amylose indica rice Guangluai 4 | Determination of gene expression profiles and immunoprecipitation analysis | The protein–protein interactions in starch biosynthesis in mutants have changed, providing insights into the mechanism of starch biosynthesis, especially in indica rice. | [76] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ge, P.; Tian, Y.; Yan, H.; Li, Q.; Yao, T.; Yao, J.; Xiao, L.; Zhu, M.; Han, Y. Functional Modification and Applications of Rice Starch Emulsion Systems Based on Interfacial Engineering. Foods 2025, 14, 2228. https://doi.org/10.3390/foods14132228

Ge P, Tian Y, Yan H, Li Q, Yao T, Yao J, Xiao L, Zhu M, Han Y. Functional Modification and Applications of Rice Starch Emulsion Systems Based on Interfacial Engineering. Foods. 2025; 14(13):2228. https://doi.org/10.3390/foods14132228

Chicago/Turabian StyleGe, Pingyuan, Ye Tian, Heng Yan, Qingqing Li, Tianle Yao, Jie Yao, Liuyu Xiao, Meng Zhu, and Yu Han. 2025. "Functional Modification and Applications of Rice Starch Emulsion Systems Based on Interfacial Engineering" Foods 14, no. 13: 2228. https://doi.org/10.3390/foods14132228

APA StyleGe, P., Tian, Y., Yan, H., Li, Q., Yao, T., Yao, J., Xiao, L., Zhu, M., & Han, Y. (2025). Functional Modification and Applications of Rice Starch Emulsion Systems Based on Interfacial Engineering. Foods, 14(13), 2228. https://doi.org/10.3390/foods14132228