A Pilot-Scale Treatment of Steel Plant Wastewater by PVDF Hollow Fiber Ultrafiltration Membrane with Low Packing Density

Abstract

:1. Introduction

2. Materials and Methods

2.1. Wastewater Effluent

2.2. Ultrafiltration Setup

2.3. Process Method

2.4. Membrane Performance Analysis

2.5. Characterization Method

3. Results and Discussion

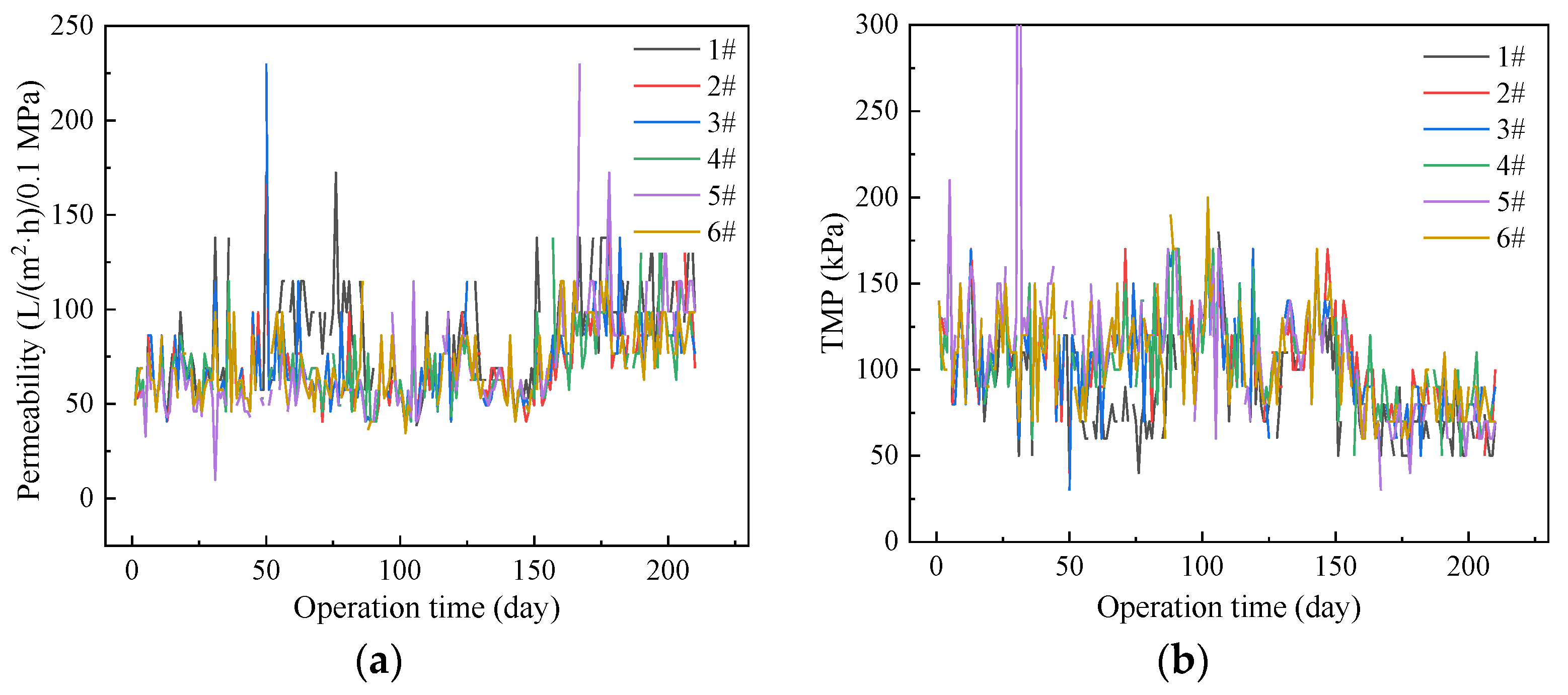

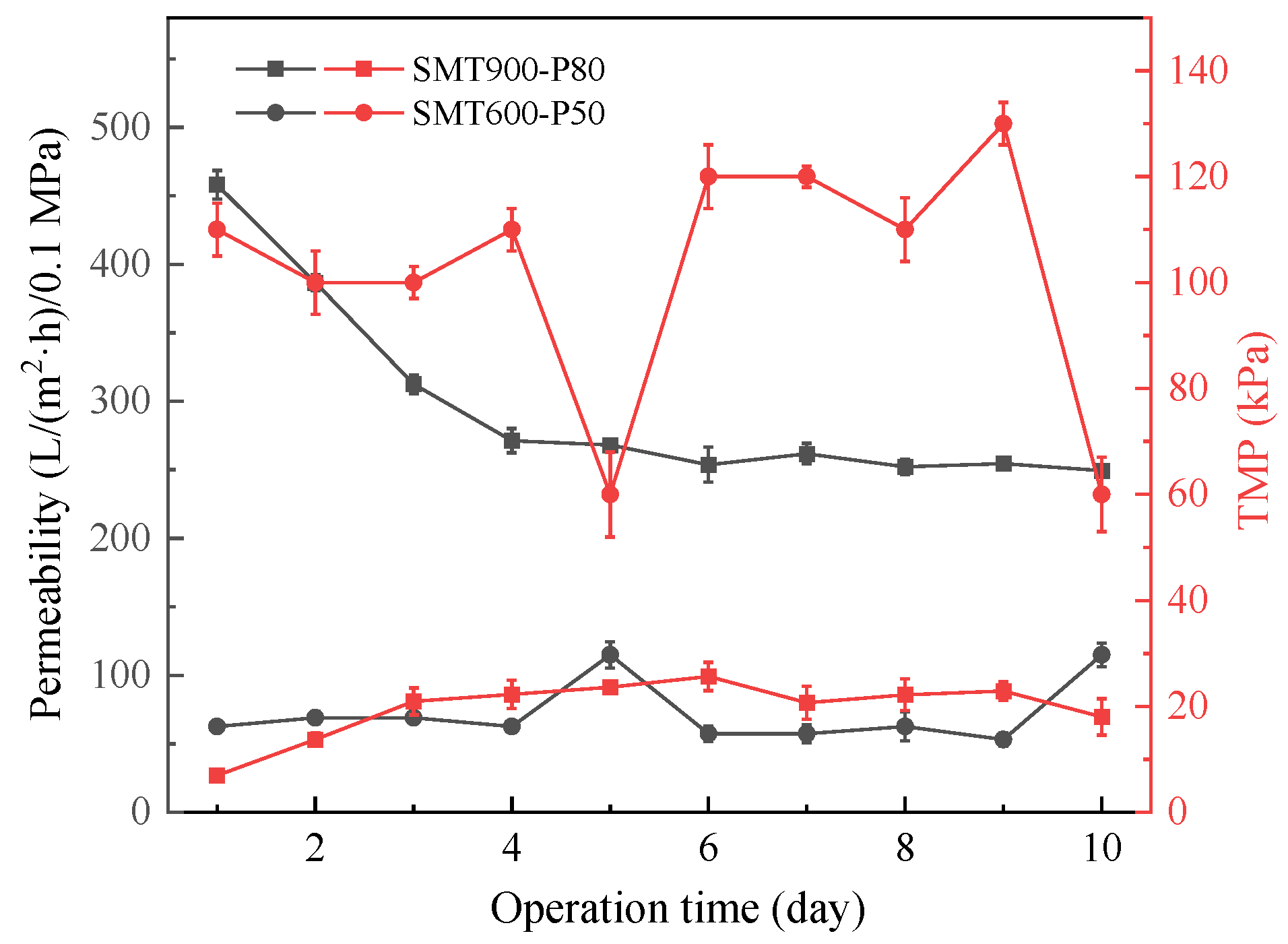

3.1. Effect of Packing Density on Filtration Performance

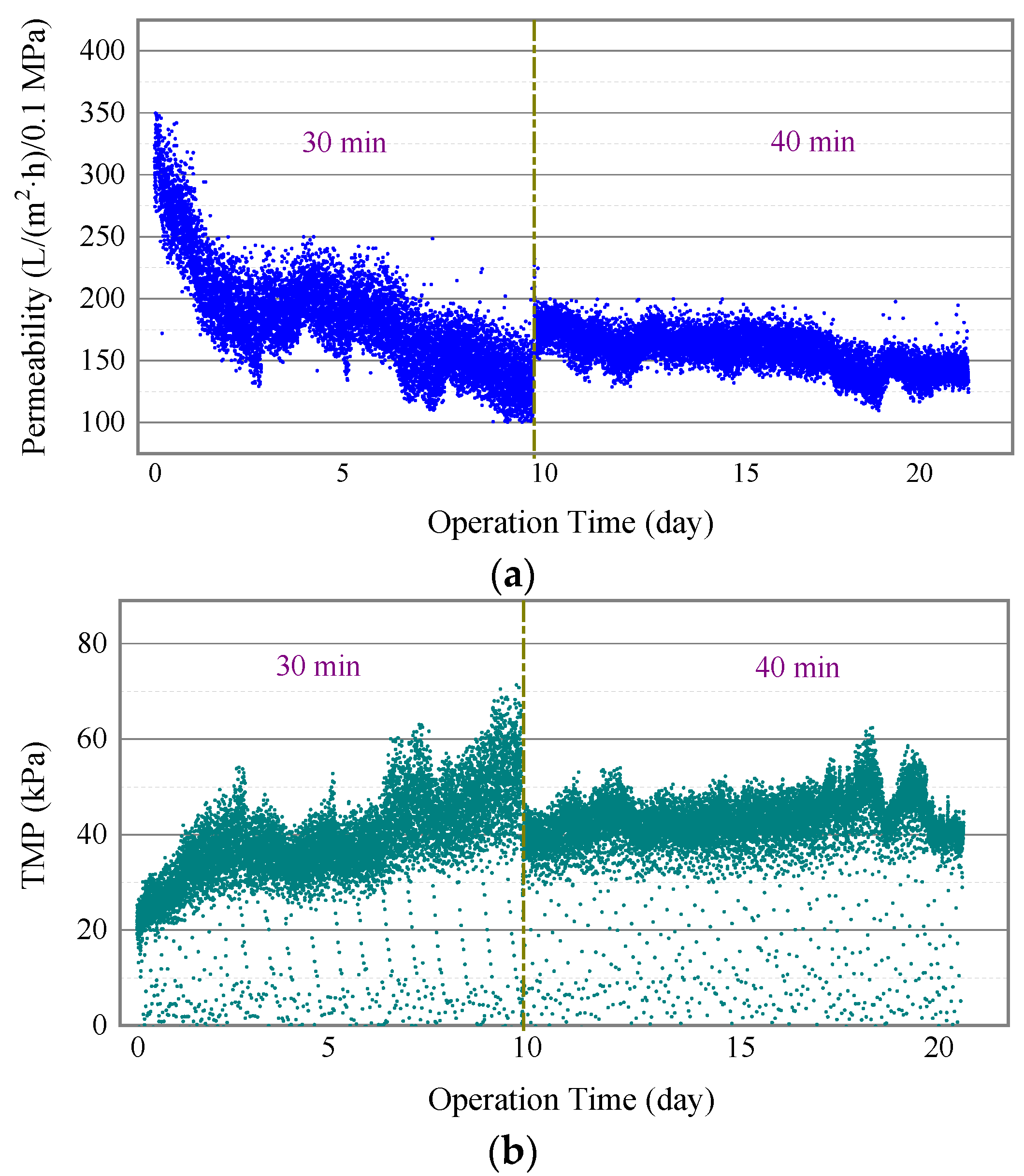

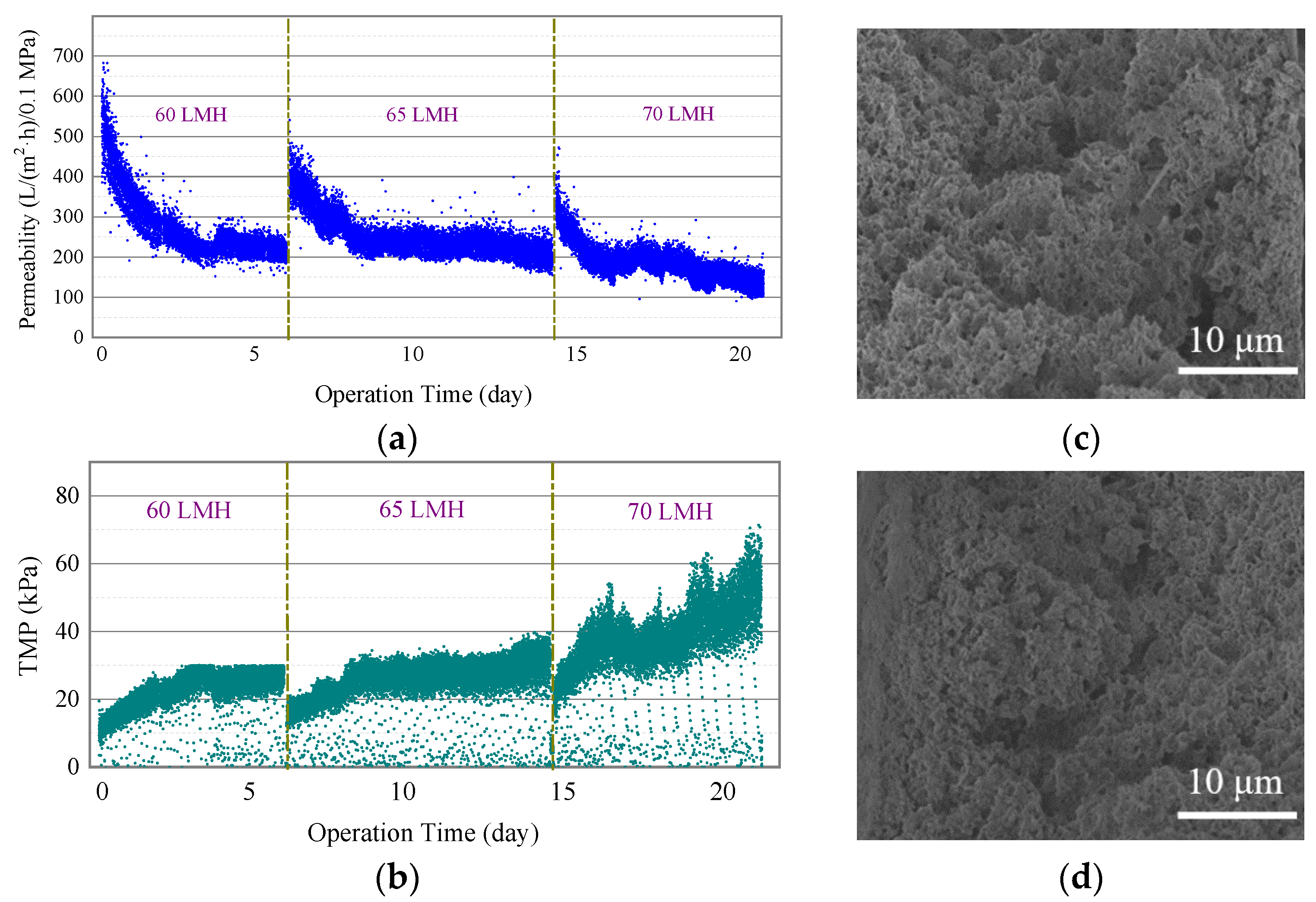

3.2. Effect of Operating Parameters on Filtration Performance of SMT900-P80

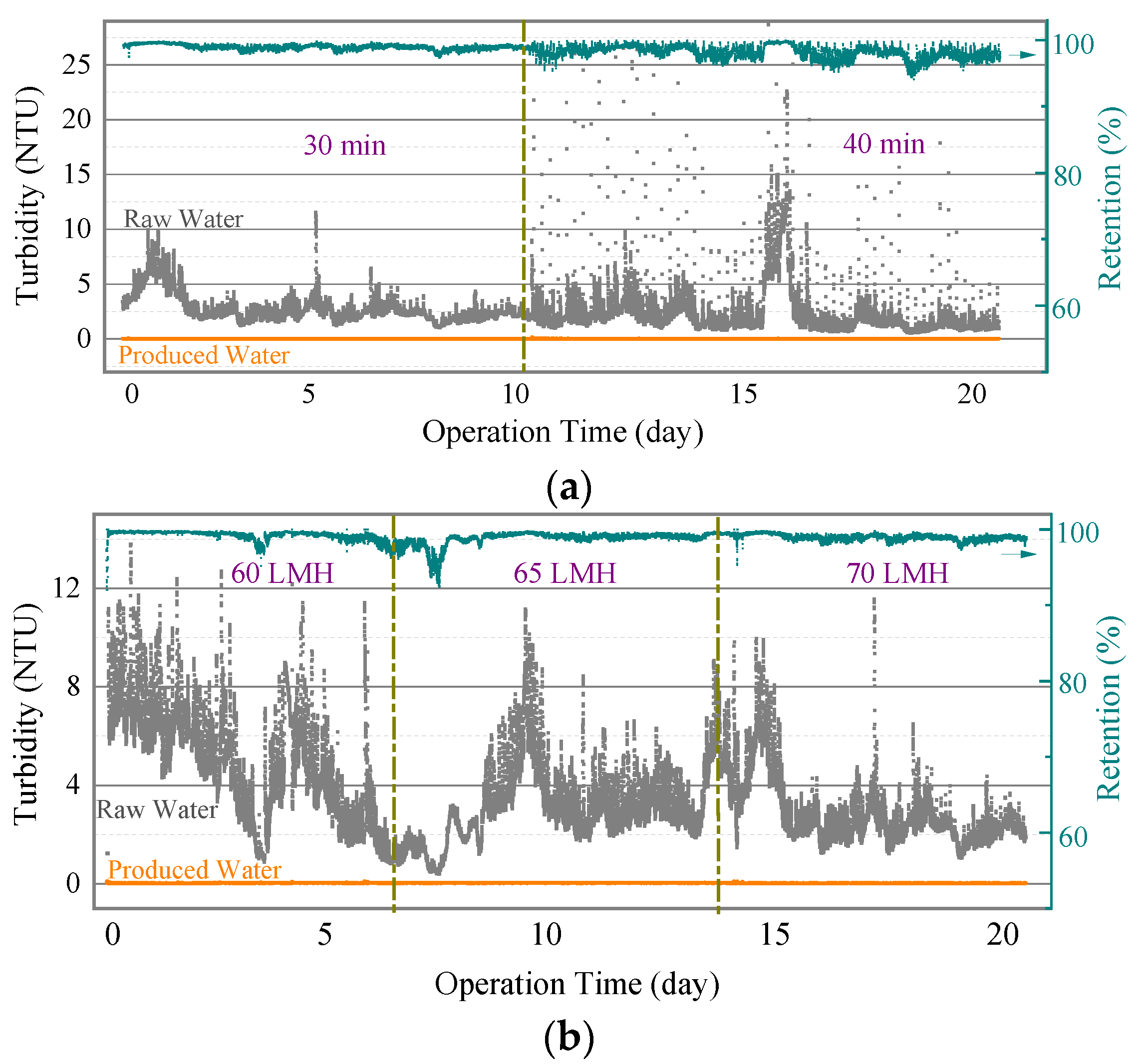

3.3. Effect of SMT900-P80 Membrane Retention on Water Turbidity

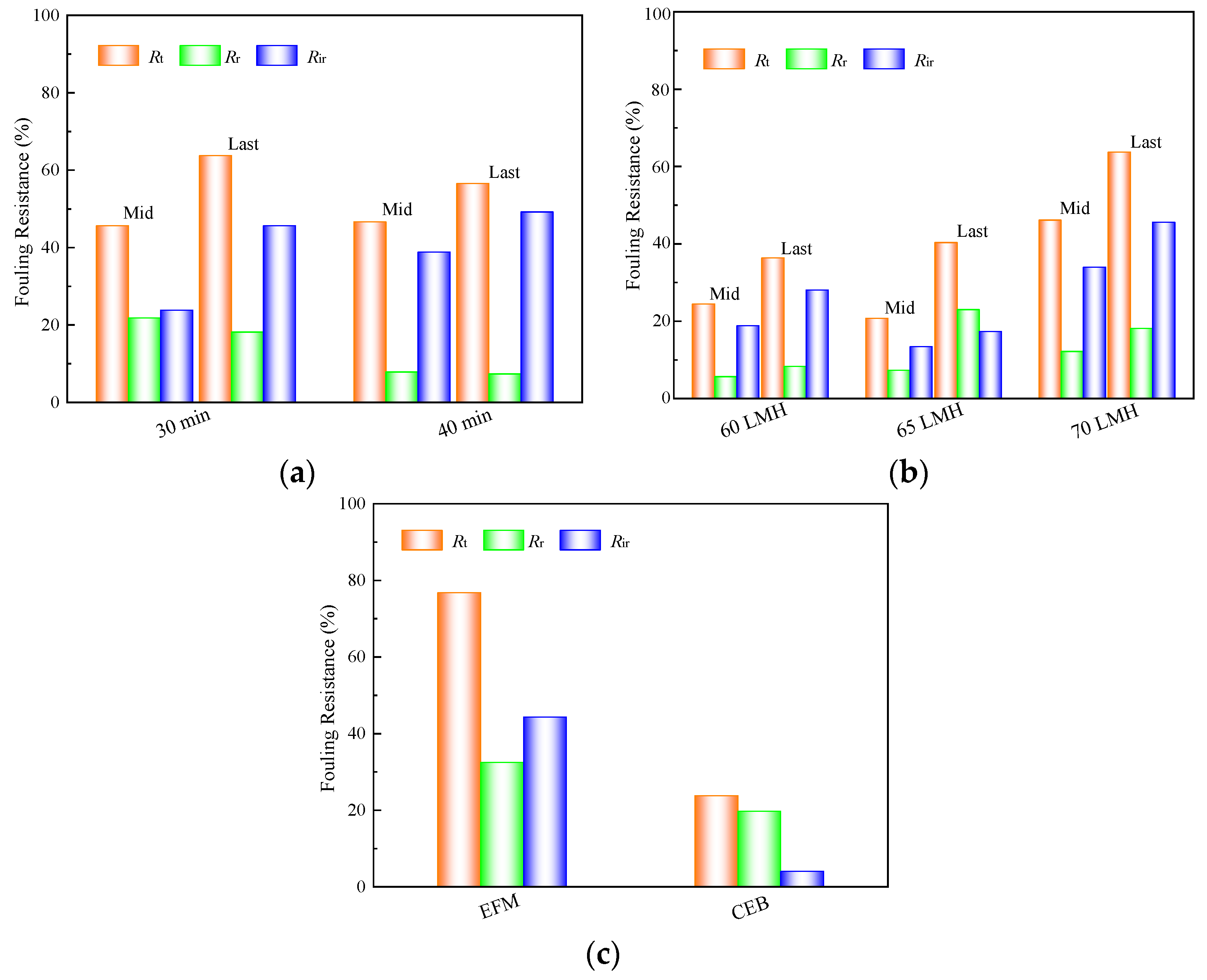

3.4. Membrane Fouling Ratio and Reversibility of SMT900-P80 Module

3.5. Membrane Fouling Mechanism of SMT900-P80 Module

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Long, H.; Lin, B.; Ou, Y.; Chen, Q. Spatio-temporal analysis of driving factors of water resources consumption in China. Sci. Total Environ. 2019, 690, 1321–1330. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Yang, X.; Liang, L.; Gao, Y.; Cheng, H.; Li, X.; Zou, M.; Ma, R.; Yuan, Q.; Duan, X. Large-area graphene-nanomesh/carbon-nanotube hybrid membranes for ionic and molecular nanofiltration. Science 2019, 364, 1057–1062. [Google Scholar] [CrossRef] [PubMed]

- Yeo, J.; Jung, G.S.; Martín-Martínez, F.J.; Beem, J.; Qin, Z.; Buehler, M.J. Multiscale Design of Graphyne-Based Materials for High-Performance Separation Membranes. Adv. Mater. 2019, 31, 1805665. [Google Scholar] [CrossRef] [PubMed]

- Gui, Z.; Chen, X.; He, Y. Spatiotemporal analysis of water resources system vulnerability in the Lancang River Basin, China. J. Hydrol. 2021, 601, 126614. [Google Scholar] [CrossRef]

- Choi, M.Y.; Theerthagiri, J.; Maia, G. 2D advanced materials and technologies for industrial wastewater treatment. Chemosphere 2021, 284, 131394. [Google Scholar] [CrossRef]

- Devanesan, S.; AlSalhi, M.S. Effective removal of Cd2+, Zn2+ by immobilizing the non-absorbent active catalyst by packed bed column reactor for industrial wastewater treatment. Chemosphere 2021, 277, 130230. [Google Scholar] [CrossRef]

- Carrera, P.; Casero-Díaz, T.; Castro-Barros, C.M.; Méndez, R.; Val del Río, A.; Mosquera-Corral, A. Features of aerobic granular sludge formation treating fluctuating industrial saline wastewater at pilot scale. J. Environ. Manag. 2021, 296, 113135. [Google Scholar] [CrossRef]

- Palani, G.; Arputhalatha, A.; Kannan, K.; Lakkaboyana, S.K.; Hanafiah, M.M.; Kumar, V.; Marella, R.K. Current Trends in the Application of Nanomaterials for the Removal of Pollutants from Industrial Wastewater Treatment—A Review. Molecules 2021, 26, 2799. [Google Scholar] [CrossRef]

- Sun, W.; Xu, X.; Lv, Z.; Mao, H.; Wu, J. Environmental impact assessment of wastewater discharge with multi-pollutants from iron and steel industry. J. Environ. Manag. 2019, 245, 210–215. [Google Scholar] [CrossRef]

- Li, A.L.; Wang, Z.H.; Sun, B.X.; Gao, S.W. Analysis of Water Consumption Intensity for Steel Production in China. Mater. Sci. Forum 2020, 993, 1465–1472. [Google Scholar] [CrossRef]

- Tong, Y.; Zhang, Q.; Cai, J.; Gao, C.; Wang, L.; Li, P. Water consumption and wastewater discharge in China’s steel industry. Ironmak. Steelmak. 2018, 45, 868–877. [Google Scholar] [CrossRef]

- Jiao, K.; Yu, X.; Yuan, Z.; Zhang, Y.; Liu, J. Enhanced filtration performance of Al2O3-SiC porous ceramic composite tube depending on microstructure and surface property. Desalin. Water Treat. 2019, 150, 99–104. [Google Scholar] [CrossRef]

- Biswas, P.; Bhunia, P.; Saha, P.; Sarkar, S.; Chandel, H.; De, S. In situ photodecyanation of steel industry wastewater in a pilot scale. Environ. Sci. Pollut. Res. Int. 2020, 27, 33226–33233. [Google Scholar] [CrossRef] [PubMed]

- Colla, V.; Matino, I.; Branca, T.A.; Fornai, B.; Romaniello, L.; Rosito, F. Efficient Use of Water Resources in the Steel Industry. Water 2017, 9, 874. [Google Scholar] [CrossRef] [Green Version]

- Zhang, K.; Zhao, Y.; Cao, H.; Wen, H. Multi-scale water network optimization considering simultaneous intra- and inter-plant integration in steel industry. J. Clean. Prod. 2018, 176, 663–675. [Google Scholar] [CrossRef]

- Wu, L.; Liu, Y.; Hu, J.; Feng, X.; Ma, C.; Wen, C. Preparation of polyvinylidene fluoride composite ultrafiltration membrane for micro-polluted surface water treatment. Chemosphere 2021, 284, 131294. [Google Scholar] [CrossRef]

- Santosh, V.; Palodkar, K.K.; Veerababu, P.; Sainath, A.V.S.; Reddy, A.V.R. Polysulfone with glycopolymer for development of antifouling ultrafiltration membranes. J. Polym. Res. 2021, 28, 240. [Google Scholar] [CrossRef]

- Güneş-Durak, S. Examination and Evaluation of a Metal Industry Wastewater Treatment and Recycle. Eurasian J. Environ. Res. 2018, 1, 8–17. [Google Scholar]

- Ashok Kumar, S.; Subathra, K.; Srinivasan, G.; Sundaramurthy, J.; Gnanasekaran, G.; Kanimozhi, G.; Govindaradjane, S. Impact of Tween-80 and Deep Eutectic Solvent-Based Micellar-Enhanced Ultrafiltration in Dairy Wastewater Treatment. Chem. Eng. Technol. 2021, 44, 913–922. [Google Scholar] [CrossRef]

- Sponza, D.T. Treatment of Textile Industry Wastewater by Sequential Hybrid Processes Photo-Fenton, Ultrafiltration (UF), Reverse Osmosis (RO) and Recovery of some Dyes, Salt and Perfluoroalkyl Sulfonate from the Retentate. J. Membr. Sci. Technol. 2020, 10, 214. [Google Scholar]

- Öztel, M.D.; Kuleyin, A.; Akbal, F. Treatment of zinc plating wastewater by combination of electrocoagulation and ultrafiltration process. Water Sci. Technol. 2020, 82, 663–672. [Google Scholar] [CrossRef] [PubMed]

- Benito, A.; Garcia, G.; Gonzalez-Olmos, R. Fouling reduction by UV-based pretreatment in hollow fiber ultrafiltration membranes for urban wastewater reuse. J. Membr. Sci. 2017, 536, 141–147. [Google Scholar] [CrossRef]

- Yoon, S.-H.; Kim, H.-S.; Yeom, I.-T. Optimization model of submerged hollow fiber membrane modules. J. Membr. Sci. 2004, 234, 147–156. [Google Scholar] [CrossRef]

- Ye, Y.; Sim, L.N.; Herulah, B.; Chen, V.; Fane, A.G. Effects of operating conditions on submerged hollow fibre membrane systems used as pre-treatment for seawater reverse osmosis. J. Membr. Sci. 2010, 365, 78–88. [Google Scholar] [CrossRef]

- Wang, Q.; Peng, Y.; Ji, X.; Hadi, M.K.; Zhang, S.; Tang, J.; Ran, F. Conductive 3D networks in a 2D layer for high performance ultrafiltration membrane with high flux-retention and robust cyclic stability. J. Membr. Sci. 2021, 640, 119781. [Google Scholar] [CrossRef]

- Bai, H.; Lin, Y.; Qu, H.; Zhang, J.; Zheng, X.; Tang, Y. Technical and Economic Evaluation of WWTP Renovation Based on Applying Ultrafiltration Membrane. Membranes 2020, 10, 180. [Google Scholar] [CrossRef]

| Item | Unit | Parameter |

|---|---|---|

| CODCr | mg/L | 19–36 |

| Turbidity | NTU | 3–5 |

| SS | mg/L | 5–10 |

| Total hardness | mg/L | 167–249 |

| Cl− | mg/L | 176–227 |

| Electrical conductivity | μs/cm2 | 1240–1641 |

| Total dissolved solids | mg/L | 772–913 |

| Petroleum | mg/L | ≤0.04 |

| Anionic surfactant | mg/L | ≤0.05 |

| Fe | mg/L | ≤0.46 |

| Mn | mg/L | ≤0.05 |

| BOD5 | mg/L | ≤20 |

| Chromaticity | ° | ≤30 |

| Total P | mg/L | ≤1 |

| NH4+-N | mg/L | ≤1 |

| pH | 6.8–7.9 |

| Model | SMT600-P50 | SMT900-P80 |

|---|---|---|

| Material | PVDF | PVDF |

| Membrane area (m2) | 50 | 80 |

| Membrane wire inner/outer diameter (mm) | 0.7/1.3 | 0.7/1.3 |

| Packing density (m2/m3) | 1.27 | 0.97 |

| Effective fiber length (mm) | 1958 | 2030 |

| Fouled Membrane | Cleaned Membrane | ||||

|---|---|---|---|---|---|

| Element | Mass/% | Element | Mass/% | Element | Mass/% |

| S K | 0.32 | Pt M | 5.43 | Si K | 0.03 |

| Na K | 0.43 | F K | 10.68 | O K | 3.09 |

| Cu K | 1.3 | Mn K | 13.09 | Pt M | 3.7 |

| Si K | 1.34 | Fe K | 15.82 | C K | 43.77 |

| P K | 1.97 | C K | 16.62 | F K | 49.41 |

| Ca K | 2.38 | O K | 26.59 | ||

| Al K | 4.02 | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Yuan, Z.; Bai, H.; Zhao, L.; He, L.; Shi, C. A Pilot-Scale Treatment of Steel Plant Wastewater by PVDF Hollow Fiber Ultrafiltration Membrane with Low Packing Density. Separations 2022, 9, 37. https://doi.org/10.3390/separations9020037

Zhang Y, Yuan Z, Bai H, Zhao L, He L, Shi C. A Pilot-Scale Treatment of Steel Plant Wastewater by PVDF Hollow Fiber Ultrafiltration Membrane with Low Packing Density. Separations. 2022; 9(2):37. https://doi.org/10.3390/separations9020037

Chicago/Turabian StyleZhang, Yangang, Zhangfu Yuan, He Bai, Linfei Zhao, Liudong He, and Chunhong Shi. 2022. "A Pilot-Scale Treatment of Steel Plant Wastewater by PVDF Hollow Fiber Ultrafiltration Membrane with Low Packing Density" Separations 9, no. 2: 37. https://doi.org/10.3390/separations9020037

APA StyleZhang, Y., Yuan, Z., Bai, H., Zhao, L., He, L., & Shi, C. (2022). A Pilot-Scale Treatment of Steel Plant Wastewater by PVDF Hollow Fiber Ultrafiltration Membrane with Low Packing Density. Separations, 9(2), 37. https://doi.org/10.3390/separations9020037