Abstract

Thiophenic compounds constitute a class of sulfur compounds derived by thiophene, containing at least one thiophenic ring. Their presence in fuels (crude oil, etc.) is important and can reach 3% m/m. The combustion of fuels leads to the formation of sulfur oxides a severe source of environmental pollution issues, such as acid rain with adverse effects both to humans and to the environment. To reduce such problems, the EU and other regulatory agencies worldwide set increasingly stringent regulations for sulfur content in fuels resulting in the necessity for intense desulphurization processes. However, most of these processes are inefficient in the total removal of sulfur compounds. Therefore, thiophenic compounds such as benzothiophenes and dibenzothiophenes are still present in heavier fractions of petroleum, therefore, their determination is of great importance. Until now, all HPLC methods applied in similar studies use gradient elution programs that may last more than 25 min with no validation results provided. To fill this gap, the aim of the present study was to develop and validate a simple and fast HPLC-UV method in order to be used as a useful monitoring tool in the evaluation studies of novel desulfurization technologies by means of simultaneous determination of dibenzothiophene (DBT) and 4,6-dimethyl-dibenzothiophene and dibenzothiophene sulfone in the desulfurization effluents.

1. Introduction

Organosulfur compounds such as sulfides, disulfides, thiophenes, benzothiophenes, etc. contained in fossil fuels (e.g., petroleum, gasoline, diesel oil, etc.) can cause severe environmental pollution issues upon combustion due to the formation of sulfur oxides, which may cause air pollution and acid rain. Moreover, sulfur content may lead to the poisoning of automotive catalysts used to reduce emissions of pollutant hydrocarbons, carbon monoxide, and nitrogen oxides from gasoline- and diesel-fueled vehicles [1].

The growing environmental awareness resulted in a high necessity of efficient desulfurization processes. Strict environmental regulations by the U.S. Environmental Protection Agency (EPA) and other environmental regulatory agencies worldwide, require the total removal of sulfur content which is not feasible to be achieved by conventional desulfurization procedures [2,3].

European Community Member States shall ensure that gas oils are not used within their territory if their sulfur content exceeds 0.10% by mass; heavy fuel oils are not used if their sulfur content exceeds 3% by mass; marine fuels are not used within their territory if their sulfur content exceeds 0.50% by mass, except for fuels supplied to ships using emission abatement methods as reported in Directive (EU) 2016/802 [4] and Directive (EU) 2015/1513 [5].

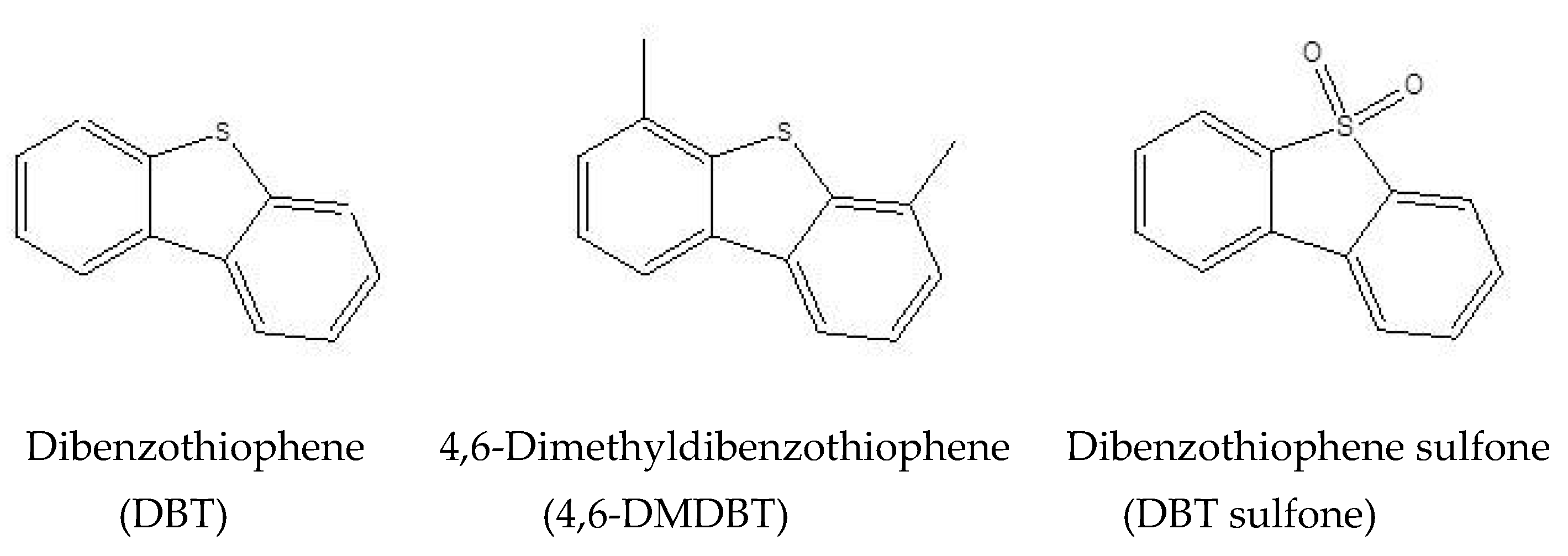

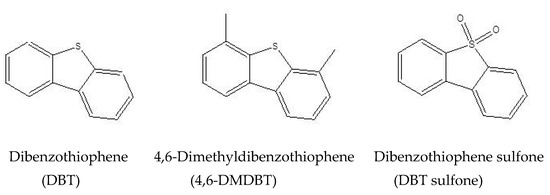

To that end, efficient desulfurization is an essential step in the petroleum refining process. Hydrodesulfurization (HDS) is the main process widely used to eliminate sulfur content. HDS processes are not economical and have a high energy demand since H2 and catalysts such as CoMo/Al2O3 and/or NiMo/Al2O3 are used at temperatures from 300 to 400 °C and high pressures [6]. Besides, among thiophenic compounds that are derived from thiophene containing at least one thiophenic ring, DBT and especially 4,6-DMDBT, the sulfur-containing compounds in diesel oil that are considered as refractory species since they resist ordinary methods of treatment, cannot be completely removed due to their structure (their chemical structures are shown in Figure 1). This fact makes the current target of a low level of 30 ppmw sulfur for diesel fuel, set by the Environmental Protection Agency (EPA) requirements, to be a difficult task.

Figure 1.

Chemical structures of the studied thiophenic compounds: dibenzothiophene (DBT), 4,6-dimethyl-dibenzothiophene (4,6-DMDBT), and dibenzothiophene sulfone.

For these reasons, alternative and/or supplementary methods are needed, including hydrodesulfurization on Co/Ni catalysts [7,8], oxidation/photo-oxidation [9,10], and adsorption [11] with adsorptive desulfurization to be of great importance especially when a removal target of a level less than 30 ppmw sulfur is considered.

Among adsorbent materials, activated carbons have been proven to be suitable adsorbents of dibenzothiophenic compounds [12,13,14,15,16,17,18,19]. Besides, their acidic oxygen functional groups on their surface lead to specific adsorption of dibenzothiophenic species via oxygen–sulfur interactions [20] and acid-base interactions with the slightly basic thiophenes [21].

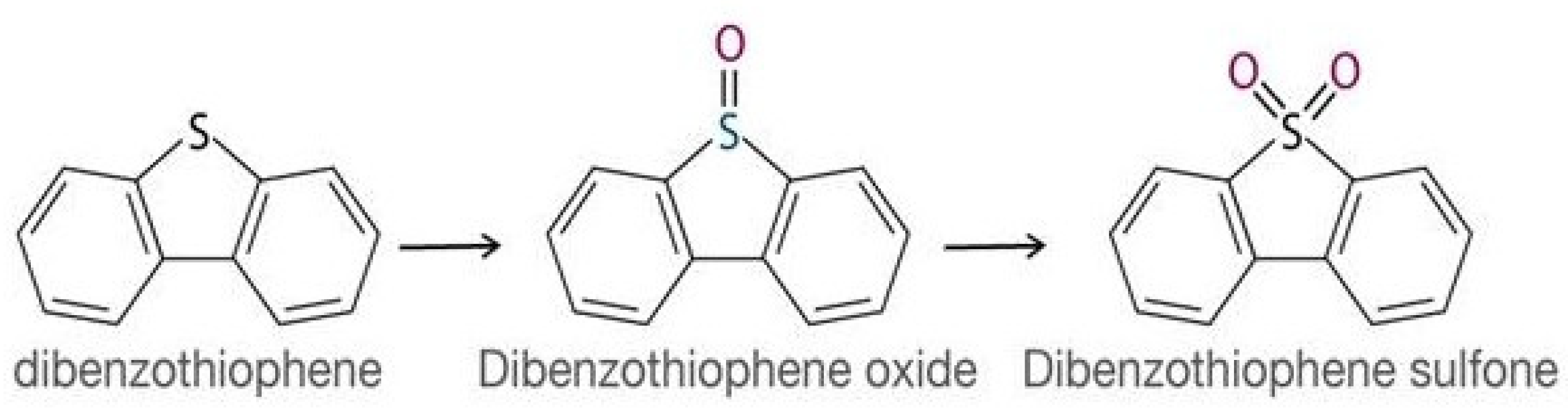

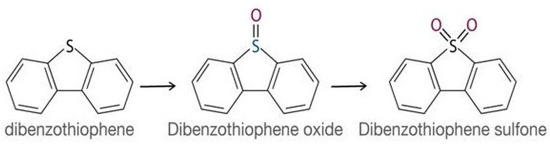

Additionally, either oxygen of these carbons’ surface oxygen functional groups or chemisorbed oxygen may take part in reactions that lead to the oxidation of adsorbed DBT and 4,6-DMDBT on the carbon’s surface to their sulfoxides and finally sulfones with the portion of 4,6-DMDBT oxidation to be less compared to DBT oxidation [17,18,20,22]. The DBT sulfone is formed according to the oxidation reaction route shown in Figure 2 [23,24].

Figure 2.

DBT sulfone formation.

For this reason, DBT, 4,6-DMDBT, and DBT-sulfone can be found in final effluent after adsorption of dibenzothiophene (DBT) and 4,6-dimethyldibenzothiophene (4,6-DMDBT) in desulfurization studies, making their analytical determination during desulfurization studies and the use of fast validated HPLC methods [25,26,27] of great importance.

Therefore, in order to evaluate the effectiveness of new technologies, an analytical method is necessary to determine the concentration of initial as well as adsorption/oxidation products. Although these compounds have been determined in several fuel samples during desulfurization studies there is a vacancy in the analytical field concerning the development, optimization, and validation of a fast analytical method for their monitoring [28,29,30,31,32,33]. Various GC and HPLC methods based on UV detection are reported using gradient elution programs that may last more than 25 min. A comprehensive review has listed most of the published methods. However, all these methods are reported as monitoring tools where neither analytical performance characteristics are provided, nor validation criteria are applied [25,34].

The aim of this study was to develop and validate a simple and fast HPLC method for the simultaneous determination of DBT, DBT-sulfone, and 4,6-DMDBT in extracts after the oxidative desulfurization process of fuels. To the best of our knowledge, there is no published method for the determination of the examined thiophenic compounds.

2. Materials and Methods

2.1. Instrumentation

The separation of the target compounds was performed by the High-Performance Liquid Chromatography (HPLC) method, using an HPLC column 250 × 4.6 mm (PerfectSil Target ODS-3 5 μm, MZ-Analysentechnik GmbH, Wohlerstrasse, Mainz, Germany) with a mobile phase consisted of a solution of acetonitrile and water (90% CH3CN: 10% H2O v/v) delivered isocratically at a flow rate of 1.0 mL/min, using a Shimadzu (Kyoto, Japan) LC-10AD pump. The pressure observed was 80 bar. Sample injection was performed via a Rheodyne 7125 injection valve (Rheodyne, Cotati, CA, USA) with a 20 μL loop. Detection was achieved by an SSI 500 UV-Vis detector (SSI, State College, PA, USA) at a wavelength of 313 nm and a sensitivity setting of 0.002 AUFS. DAQ Software for Chemists, developed by Emeritus Professor P. Nikitas (Dept. of Chemistry, Aristotle University of Thessaloniki).

The degassing of the mobile phase was performed in an ultrasonic bath Transonic 460/H (35 kHz, 170 W, Elma, Germany). All samples were filtered prior to HPLC analysis using Q-Max RR Syringe Filters 0.22 μm Nylon, 13 mm Frisenette, Knebel, Denmark.

2.2. Chemicals and Reagents

HPLC grade acetonitrile and methanol were purchased from PanReac AppliChem (Ottoweg, Darmstadt, Germany). High purity water, obtained by a Milli-Q purification system (Millipore, Bedford, MA, USA), was used throughout the entire study. Dibenzothiophene sulfone 97%, 4,6-dimethyldibenzothiophene (4,6 DMDBT, C14H12S), and dibenzothiophene (DBT, C12H8S) were supplied by JKchemical 1 (Beijing, China).

2.3. Preparation of Standard Solutions

Standard solutions of each analyte were prepared in acetonitrile (200 ng μL−1), stored at 4 °C in the dark. Working standards solutions were prepared by further dilution in acetonitrile covering the linear range from 0.1 to 30 ng μL−1. Aliquots of 20 μL were injected into the column and quantitative analysis was performed based on peak area measurements.

2.4. Method Validation

Method validation was performed following the criteria set by Commission Decision 2002/657/EC [35].

In that aspect, selectivity, linearity, accuracy, precision (repeatability and between-day precision), as well as limits of detection (LODs) and quantification (LOQs) were taken into consideration. Calibration curves were constructed by three replicates of standard solutions in the working interval of 0.1–30 ng μL−1.

Limits of detection (LODs) were calculated based on the following equation LOD = 3.3 S/N, where S = signal and N = noise. Limits of quantitation (LOQs) were calculated by the equation LOQ = 10 S/N.

Accuracy was evaluated at three concentration levels of 0.5, 2, and 10 ng/μL. Precision within-day (intra-day, n = 3) and between-day (inter-day n = 4 days by duplicate analyses) was studied at three concentration levels 0.5, 2, and 10 ng/μL.

Peak purity was checked by standard addition of respective standards.

2.5. Adsorption of DBT and 4,6-DMDBT

For the adsorption experiments a solution containing the same concentrations of DBT and 4,6-DMDBT in acetonitrile, was prepared. The concentration of each compound in solution was 20 ppmwS. The corresponding total sulfur concentration was 40 ppmwS. The mass of the carbon adsorbent was 1.25 g/L and the adsorption process was carried out at ambient temperature. The remaining concentrations of thiophenes after adsorption were determined by HPLC at a wavelength of 231 nm.

3. Results

3.1. HPLC Method

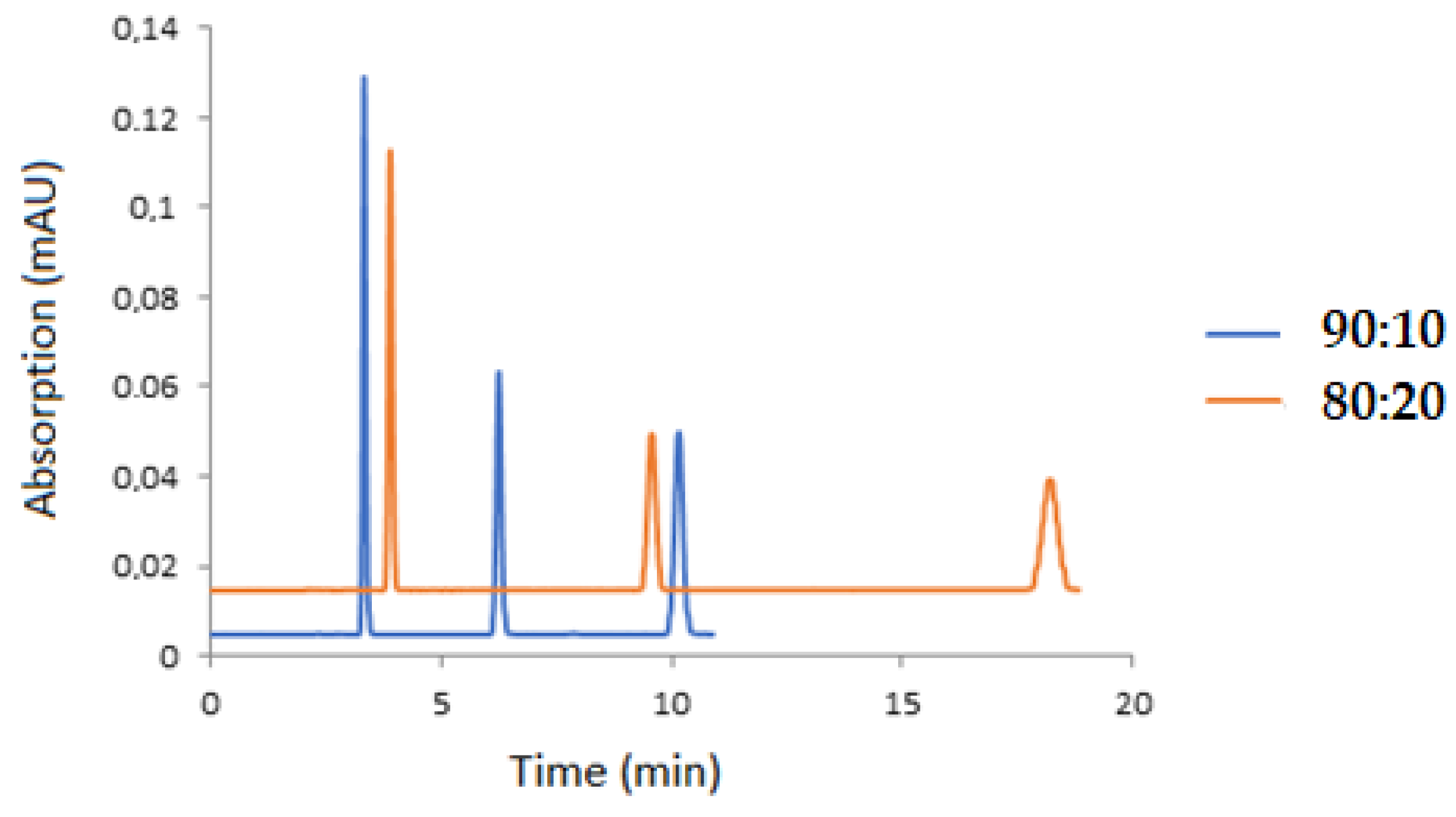

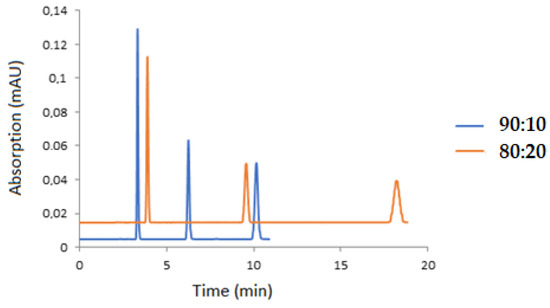

Isocratic elution was optimized in terms of mobile phase constituents and ratios. Acetonitrile as the organic modifier led to better peak shape. The ratio of 90:10 v/v of acetonitrile and water mixture provided the sufficient peak resolution and fast analysis.

A typical HPLC chromatogram at two mobile phase ratios is illustrated in Figure 3.

Figure 3.

A typical HPLC chromatogram under different eluent conditions: (90% CH3CN: 10% H2O v/v, peaks: DBT-sulfone 3.89 min, DBT 9.59 min, and 4,6-DMDBT 18.26 min) and (80% CH3CN: 20% H2O v/v, peaks: DBT-sulfone 3.33 min, DBT 6.25 min, and 4,6-DMDBT 10.20 min).

3.2. Calibration Curves

Calibration curves were constructed by least-squares linear regression analysis. All calibration data obtained by standard solution analyses are shown in Table 1. Regression equations presented satisfactory correlation coefficients ranging between 0.9925 and 0.9993 over the examined range.

Table 1.

Linearity data of developed method.

The limit of detection was found to be 0.16 ng/μL, while the limit of quantitation was found 0.5 ng/μL.

Selectivity was studied by the absence of peaks in the same Rt of analytes.

Accuracy and precision data at three concentration levels are summarised in Table 2 and Table 3 with regards to within-day and between-day repeatability respectively.

Table 2.

Accuracy and repeatability using CH3CN-H2O 90:10 v/v as mobile phase n = 3.

Table 3.

Accuracy and between-day precision using CH3CN-H2O 90:10 v/v as mobile phase (duplicate analyses in four days).

3.3. Application in Real Sample

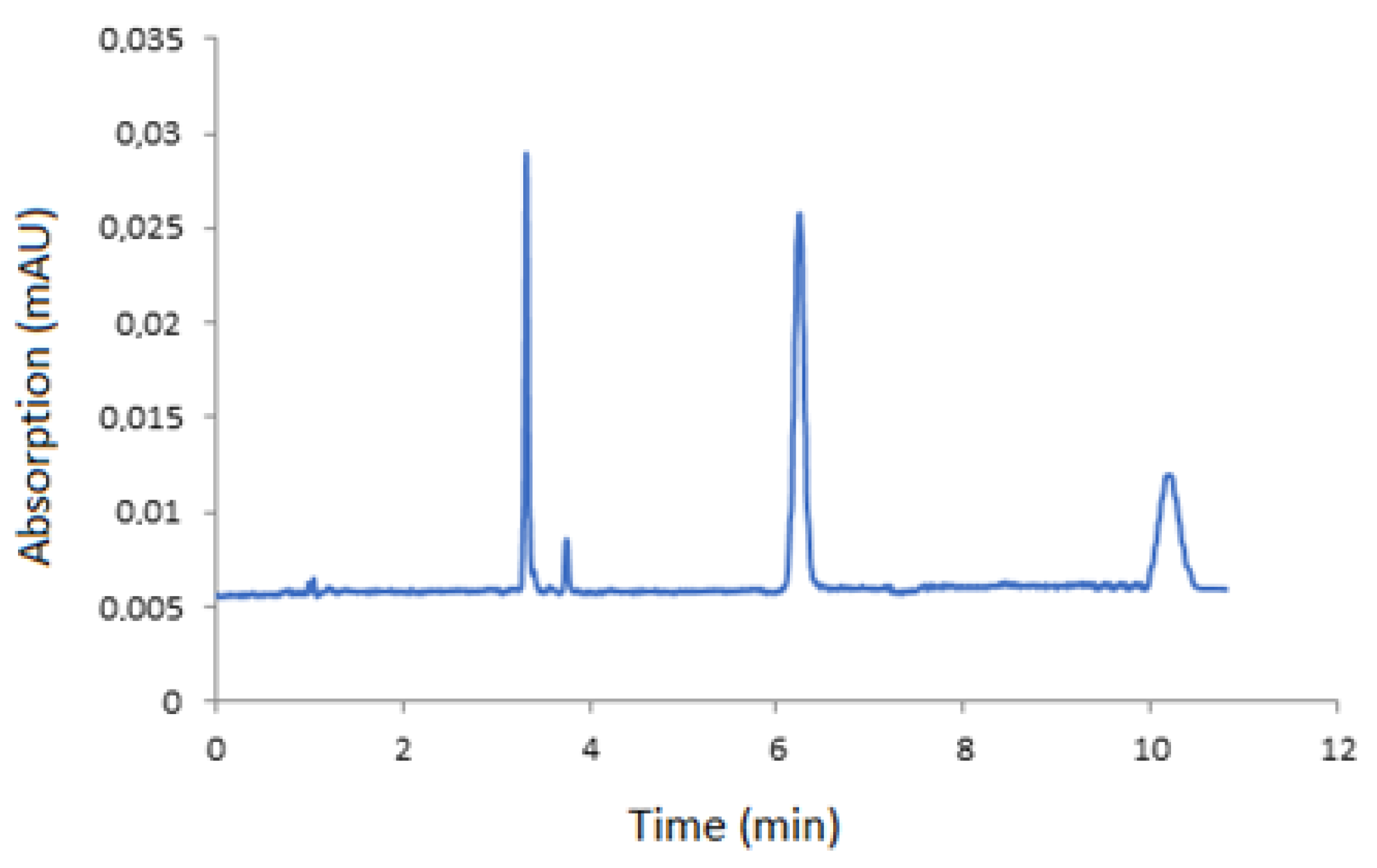

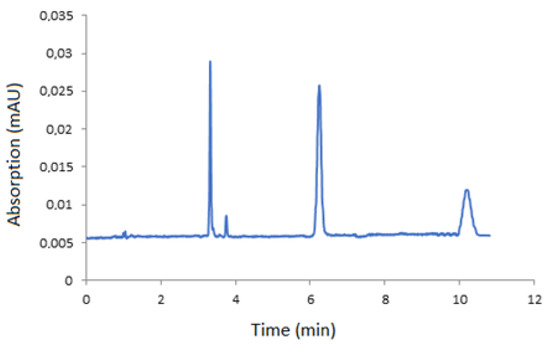

The method was applied to samples derived from desulfurization studies as described in the experimental part.

A typical chromatogram of sample obtained as described in Section 2.5 after 24 h is shown in Figure 4, which illustrates the peaks of remaining DBT and 4,6 DMDBT compounds, as well as the peak of the polar DBT sulfone, which is present in the effluent eluted in the polar acetonitrile solvent.

Figure 4.

HPLC chromatogram after a 24 h adsorption study where peaks of remaining DBT, 4,6-DMDBT, as well as the polar DBT sulfone present in the effluent due to elution by acetonitrile, peaks: DBT-sulfone 3.31 min, unknown peak 3.76, DBT 6.23 min, and 4,6-DMDBT 10.24 min.

3.4. Comparison with Other Methods

So far various GC and HPLC methods based on UV detection are reported using gradient elution programs that may last more than 25 min. All previously reported methods were applied as monitoring tools where neither analytical performance characteristics are provided, nor validation criteria are applied. The herein developed method is faster since the analysis is completed within 10 min and no equilibration time is necessary in the intervals as a benefit of isocratic elution. Therefore, six samples can be analyzed per hour increasing the productivity of the method. The cost of the analysis is also lower since no highly sophisticated instrumentation is needed.

4. Conclusions

It is vital to reduce the content of benzothiophene in liquid fuels—a process known as desulfurization. Adsorption and catalytic oxidation can be used for the removal of dibenzothiophene (DBT). Since this process is not complete, some amounts are still present in the final product, thus, it is necessary to quantitate the remaining as well as other thiophenic products in the final result.

Herein, a fast HPLC method was developed and validated to serve as an analytical tool in desulfurization studies. The analysis is completed in ca 10 min and gives results for three thiophenic compounds. The proposed method has been proved to be a useful tool in the environmental technology field providing accurate, repeatable, and reliable analytical results when applied in the respective evaluation studies.

Author Contributions

Conceptualization, K.T., E.D. and V.S.; methodology, E.D., K.T. and V.S.; validation, V.K. and V.S.; investigation K.T., E.D. and V.S.; experimental: V.K.; writing—original draft preparation, E.D. and V.S.; writing—review and editing, E.D., V.S. and K.T.; supervision, E.D. and V.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are available upon request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- European Environment Agency. EMEP/EEA Air Pollutant Emission Inventory Guidebook 2019. Available online: http://www.eea.europa.eu (accessed on 1 February 2021).

- Bandosz, T.J. Chapter 5 Desulfurization on activated carbons. Interface Sci. Technol. 2006. [Google Scholar] [CrossRef]

- Link, D.D.; Baltrus, J.P.; Rothenberger, K.S.; Zandhuis, P.; Minus, D.K.; Striebich, R.C. Class-and structure-specific separation, analysis, and identification techniques for the characterization of the sulfur components of JP-8 aviation fuel. Energy Fuels 2003, 17, 1292–1302. [Google Scholar] [CrossRef]

- Directive (EU) 2016/802 of the European Parliament and of the Council of 11 May 2016 Relating to a Reduction in the Sulfur Content of Certain Liquid Fuels (Codification); L 132/58 21.5.2016; EU: Brussels, Belgium, 2016.

- Directive (EU) 2015/1513 of the European Parliament and of the Council of 9 September 2015 Amending Directive 98/70/EC Relating to the Quality of Petrol and Diesel Fuels and Amending Directive 2009/28/EC on the Promotion of the Use of Energy from Renewable Sources (Text with EEA Relevance); L 239/1 15.09.2015; EU: Brussels, Belgium, 2015.

- Iruretagoyena, D.; Montesano, R. Selective Sulfur Removal from Liquid Fuels Using Nanostructured Adsorbents, In Nanotechnology in Oil and Gas Industries: Principles and Applications; Saleh, T.A., Ed.; Springer International Publishing: Cham, Switzerland, 2018; pp. 133–150. [Google Scholar]

- Song, T.; Zhang, Z.; Chen, J.; Ring, Z.; Yang, H.; Zheng, Y. Effect of aromatics on deep hydrodesulfurization of dibenzothiophene and 4,6-dimethyldibenzothiopene over NiMo/Al2O3 catalyst. Energy Fuels 2006, 20, 2344–2349. [Google Scholar] [CrossRef]

- Rabarihoela-Rakotovao, V.; Brunet, S.; Perot, G.; Diehl, F. Effect of H2S partial pressure on the HDS of dibenzothiophene and 4,6-dimethyldibenzothiophene over sulfided NiMoP/Al2O3 and CoMoP/Al2O3 catalysts. Appl. Catal. A Gen. 2006, 306, 34–44. [Google Scholar] [CrossRef]

- Matsuzawa, S.; Tanaka, J.; Sato, S.; Ibusuki, T. Photocatalytic oxidation of dibenzothiophenes in acetonitrile using TiO2: Effect of hydrogen peroxide and ultrasound irradiation. J. Photochem. Photobiol. A Chem. 2002, 149, 183–189. [Google Scholar] [CrossRef]

- Tao, H.; Nakazato, T.; Sato, S. Energy-efficient ultra-deep desulfurization of kerosene based on selective photooxidation and adsorption. Fuel 2009, 88, 1961–1969. [Google Scholar] [CrossRef]

- Song, C. An overview of new approaches to deep desulfurization for ultra-clean gasoline, diesel fuel and jet fuel. Catal. Today 2003, 86, 211–263. [Google Scholar] [CrossRef]

- Kim, J.H.; Ma, X.; Zhou, A.; Song, C. Ultra-deep desulfurization and denitrogenation of diesel fuel by selective adsorption over three different adsorbents: A study on adsorptive selectivity and mechanism. Catal. Today 2006, 111, 74–83. [Google Scholar] [CrossRef]

- Seredych, M.; Bandosz, T.J. Template-derived mesoporous carbons with highly dispersed transition metals as media for the reactive adsorption of dibenzothiophene. Langmuir 2007, 23, 6033–6041. [Google Scholar] [CrossRef]

- Velu, S.; Watanabe, S.; Ma, X.; Song, C. Regenerable adsorbents for the adsorptive desulfurization of transportation fuels for fuel cell applications. ACS Div. Fuel Chem. Prepr. 2003, 48, 526–528. [Google Scholar]

- Yu, G.; Lu, S.; Chen, H.; Zhu, Z. Diesel fuel desulfurization with hydrogen peroxide promoted by formic acid and catalyzed by activated carbon. Carbon 2005, 43, 2285–2294. [Google Scholar] [CrossRef]

- Yang, Y.; Lu, H.; Ying, P.; Jiang, Z.; Li, C. Selective dibenzothiophene adsorption on modified activated carbons. Carbon 2007, 45, 3042–3044. [Google Scholar] [CrossRef]

- Deliyanni, E.; Seredych, M.; Bandosz, T.J. Interactions of 4,6-dimethyldibenzothiophene with the surface of activated carbons. Langmuir 2009, 25, 9302–9312. [Google Scholar] [CrossRef] [PubMed]

- Seredych, M.; Lison, J.; Jans, U.; Bandosz, T.J. Textural and chemical factors affecting adsorption capacity of activated carbon in highly efficient desulfurization of diesel fuel. Carbon 2009, 47, 2491–2500. [Google Scholar] [CrossRef]

- Jeon, H.J.; Ko, C.H.; Kim, S.H.; Kim, J.N. Removal of refractory sulfur compounds in diesel using activated carbon with controlled porosity. Energy Fuels 2009, 23, 2537–2543. [Google Scholar] [CrossRef]

- Seredych, M.; Bandosz, T.J. Adsorption of dibenzothiophenes on nanoporous carbons: Identification of specific adsorption sites governing capacity and selectivity. Energy Fuels 2010, 24, 3352–3360. [Google Scholar] [CrossRef]

- Jiang, Z.; Liu, Y.; Sun, X.; Tian, F.; Sun, F.; Liang, C.; You, W.; Han, C.; Li, C. Activated carbons chemically modified by concentrated H2SO4 for the adsorption of the pollutants from wastewater and the dibenzothiophene from fuel oils. Langmuir 2003, 19, 731–736. [Google Scholar] [CrossRef]

- Rekos, K.; Kampouraki, Z.C.; Panou, C.; Baspanelou, A.; Triantafyllidis, K.; Deliyanni, E. Adsorption of DBT and 4,6-DMDBTon nanoporous activated carbons: The role of surface chemistry and the solvent. Environ. Sci. Pollut. Res. 2020, 24. [Google Scholar] [CrossRef]

- Triantafyllidis, K.S.; Deliyanni, E.A. Desulfurization of diesel fuels: Adsorption of 4,6-DMDBT on different origin and surface chemistry nanoporous activated carbons. Chem. Eng. J. 2014, 236, 406–414. [Google Scholar] [CrossRef]

- Seredych, M.; Deliyanni, E.; Bandosz, T.J. Role of microporosity and surface chemistry in adsorption of 4,6-dimethyldibenzothiophene on polymer-derived activated carbons. Fuel 2010, 89, 1499–1507. [Google Scholar] [CrossRef]

- Ferreira, J.P.; Viveiros, R.; Lourenço, A.; Soares Da Silva, M.; Rosatella, A.; Casimiro, T.; Afonso, C.A.M. Integrated desulfurization of diesel by combination of metal-free oxidation and product removal by molecularly imprinted polymers. RSC Adv. 2014, 4, 54948–54952. [Google Scholar] [CrossRef]

- Yue, D.; Lei, J.; Zhou, L.; Du, X.; Guo, Z.; Li, J. Oxidative desulfurization of fuels at room temperature using ordered meso/macroporous H3PW12O40/SiO2 catalyst with high specific surface areas. Arab. J. Chem. 2020, 13, 2649–2658. [Google Scholar] [CrossRef]

- Yazu, K.; Sato, S.; Sugimoto, Y.; Matsumura, A.; Saito, I. Tungstophosphoric acid-catalyzed oxidative desulfurization of naphtha with hydrogen peroxide in naphtha/acetic acid biphasic system. J. Jpn. Pet. Inst. 2007, 50, 329–334. [Google Scholar] [CrossRef][Green Version]

- Sharma, R.; Singh, J.; Verma, N. A novel spectrophotometric method for simultaneous estimation of dibenzothiophene and 2-hydroxybiphenyl in their mixed spectrum and its application in screening of specific biodesulfurizing microbes. 3 Biotech 2020, 10, 1–9. [Google Scholar] [CrossRef]

- Gratz, S.R.; Ciolino, L.A.; Mohrhaus, A.S.; Gamble, B.M.; Gracie, J.M.; Jackson, D.S.; Roetting, J.P.; McCauley, H.A.; Heitkemper, D.T.; Fricke, F.L.; et al. Screening and determination of polycyclic aromatic hydrocarbons in seafoods using QuEChERS-based extraction and high-performance liquid chromatography with fluorescence detection. J. AOAC Int. 2011, 94, 1601–1616. [Google Scholar] [CrossRef]

- Saravanabhavan, G.; Helferty, A.; Hodson, P.V.; Brown, R.S. A multi-dimensional high performance liquid chromatographic method for fingerprinting polycyclic aromatic hydrocarbons and their alkyl-homologs in the heavy gas oil fraction of Alaskan North Slope crude. J. Chromatogr. A 2007, 1156, 124–133. [Google Scholar] [CrossRef]

- Santos de Freitas, C.; Valencia-Dávila, J.A.; Lopes Pereira, R.C.; Torres Abrantes, L.; Kato, L.; Gontijo Vaz, B. Isolation and characterization of sulfur-containing compounds by positive-ion electrospray ionization and online HPLC/Atmospheric pressure chemical ionization coupled to Orbitrap mass spectrometry. Fuel 2021, 289. [Google Scholar] [CrossRef]

- Mawad, A.M.M.; Hassanein, M.; Aldaby, E.S.; Yousef, N. Desulphurisation kinetics of thiophenic compound by sulphur oxidizing Klebsiella oxytoca SOB-1. J. Appl. Microbiol. 2020. [Google Scholar] [CrossRef] [PubMed]

- Mezcua, M.; Fernández-Alba, A.R.; Rodríguez, A.; Boltes, K.; Leton, P.; García-Calvo, E. Chromatographic methods applied in the monitoring of biodesulfurization processes—State of the art. Talanta 2007, 73, 103–114. [Google Scholar] [CrossRef]

- Che, Y.; Ma, W.; Ren, Y.; Chen, C.; Zhang, X.; Zhao, J.; Zang, L. Photooxidation of dibenzothiophene and 4,6-dimethyldibenzothiophene sensitized by N-methylquinolinium tetrafluoborate: Mechanism and intermediates investigation. J. Phys. Chem. B 2005, 109, 8270–8276. [Google Scholar] [CrossRef]

- Decision 2002/657/EC of the European Communities Commission of 12 August 2002 Implementing Council Directive 96/23/EC Concerning the Performance of Analytical Methods and the Interpretation of Results; Off. J. Eur. Communities 2002. L 221/8, 17.08.2002; EU: Brussels, Belgium, 2002.

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).