Abstract

We investigated the effect of chlorine dioxide (ClO2) under low temperature drying to suppress rice cake stickiness during the cutting process by initiating the onset of retrogradation until the stickiness is minimized for shelf-life extension. The intermittent ClO2 application at low-temperature drying was conducted at 10 °C for different drying periods (0, 6, 12, 18, and 24 h). Texture analysis showed significant differences with increasing values of hardness (901.39 ± 53.87 to 12,653 ± 1689.35 g) and reduced values of modified adhesiveness (3614.37 ±578.23 to 534.81 ± 89.37 g). The evaluation of rice cake stickiness during the cutting process revealed an optimum drying period of 18 h with no significant difference (p ≤ 0.05) compared to the 24 h drying process. Microbial contamination during the drying process increased, with microbial load from 6.39 ± 0.37 to 7.94 ± 0.29 CFU/g. Intermittent ClO2 application at 22 ppm successfully reduced the microbial load by 63% during drying process. The inhibitory property of ClO2 was further analyzed on a sample with high initial microbial load (3.01 ± 0.14 CFU/g) using primary and modified secondary growth models fitted to all experimental storage temperatures (5–25 °C) with R2 values > 0.99. The model demonstrated a strong inhibition by ClO2 with microbial growth not exceeding the accepted population threshold (106 CFU/g) for toxin production. The shelf-life of rice cake was increased by 86 h and 432 h at room temperature (25 °C) and 5 °C respectively. Microbial inactivation via ClO2 treatment is a novel method for improved food storage without additional thermal sterilization or the use of an additional processing unit.

1. Introduction

Rice products are staple foods, especially in Asia with more than 50% of the population depending on rice as the primary source of dietary calories [1]. Utilizing starch gelatinization, rice products have many unique attributes, such as ease of digestion, bland taste, and hypoallergenic properties [2]. Many popular oriental foods, such as rice pasta, rice noodles, rice starch, and rice cakes are rapidly growing home meal replacements (HMR) in the market space due to their ease of access and short re-cooking periods [3]. In addition to gelatinization, starch retrogradation is another important physicochemical phenomenon involved in cooked rice or rice-cake products. Retrogradation is caused by the recrystallization of amylose and amylopectin in starch-based foods. In the presence of water, amylose and amylopectin are swollen and gelatinized. When cooled over time, the gelatinized amylose and amylopectin are reorganized into a more ordered structure by hydrogen bonding [4,5]. Retrogradation of starch in rice cakes greatly affects the processing conditions, such as molding and cutting, as well as the quality of products, such as the taste, texture and overall acceptance. This is because retrogradation increases the hardness of rice cake while decreasing its stickiness. Starch gelation and retrogradation are fully utilized in rice cake manufacturing to increase the production rate, especially during the molding and cutting process. The molding process requires suitable deformability of gelatinized rice cakes to form certain shapes using the molder or the extrusion die. However, the sticky characteristics of gelatinized rice cake may result in a difficulty in cutting to sizes suitable for the consumers, thereby creating a barrier during continuous large scale production. Therefore, since stickiness and deformability decreases with the retrogradation of rice starch, the process of retrogradation prior to the cutting process becomes necessary, especially during continuous rice cake processing. Retrogradation of rice cakes usually occurs during storage or drying at temperatures lower than 60 °C [4,5,6]. Practically, the steamed rice cakes are stored at 10 °C for 24 to 48 h to initiate the retrogradation before the cutting process [7]. During such low-temperature drying, rice cakes are associated with chemical, biological, and physical changes, which typically result in moisture reduction, increased microbial level from the second contamination, and hardening of the texture due to retrogradation.

The texture of rice products is highly dependent on the storage time and the temperature due to retrogradation [8,9,10,11,12,13]. The hardness of cooked rice is positively correlated with the degree of retrogradation and amylose content in rice during storage [8]. During rice cake processing, molding requires a soft and elastic texture following the gelatinization of rice starch. However, the cutting process requires a firm texture following retrogradation. Nonetheless, the relationship between starch retrogradation and the texture of cooked rice cake during drying is still not clearly established.

Generally, rice cakes have a short shelf-life of fewer than 1 day at room temperature due to the high moisture and nutritional content, and as a result, it is mostly refrigerated in sales outlets at temperatures below 10 °C to extend the shelf-life [14]. Additionally, the microbial level is dramatically increased during the low-temperature drying when the inlet air is not properly managed. The microbial level is increased by about 102 CFU/g due to secondary contamination during the low-temperature drying [14]. Therefore, several technologies have been adopted to prolong the shelf-life of rice cakes [15,16,17]. The microbial level was reduced via non-thermal treatments using antimicrobial agents (i.e., alcohol, acidulants, and electrolytic water with ultrasonic) or thermal treatments [18,19,20,21,22]. However, such treatments reduced food quality, shape and appearance, which diminished the market value. In addition, the high-temperature sterilization may require additional equipment such as a retort or specially designed sterilizer, which may not be readily available for the manufacture.

Bacillus cereus is a major spore-forming pathogen associated with rice-based products and causes food poisoning in humans by producing enterotoxins and emetic toxin [14]. Although an accurate number of food poisons caused by B. cereus in different countries is not known due to the lack of accurate reports, however, as much as 192 outbreaks involving more than 1000 cases were reported in the United Kingdom between 1971 and 1984 [23]. Furthermore, in the Republic of Korea, the consumption of rice cake was linked to about 27 outbreaks of B. cereus between 2001 and 2008 [18]. Therefore, controlling the growth of B. cereus in rice-based products is necessary to improve public health.

Chlorine dioxide (ClO2) is a powerful oxidizing agent that is 2.5-fold more effective than hypochlorite as an antimicrobial agent. It is effective for microbial inactivation of food at a pH range of 3.0–8.0 [22]. ClO2 was used effectively for complete inactivation of Escherichia coli O157:H7 on radish seeds [24]. The high degree of acceptability of ClO2 is attributed to its high sterilization efficiency both in liquid and gaseous states. Its application in water treatment has been reported safe for human consumption at concentrations of 50–200 ppm [25]. However, aqueous ClO2 contains residual moisture in food and surfaces in contact with food, which may promote the growth of molds after treatment with aqueous ClO2. In contrast, the gaseous form may result in smaller amounts of ClO2 residues on food surfaces and is more effective in killing hazardous microorganisms in food that are protected by hydrophilic components in food surfaces [25,26]. This unique processing technique can be used to control the contamination level during low-temperature drying of rice cake because the secondary microbial contamination is on the surface. However, the role of ClO2 as an antimicrobial agent for rice cake has yet to be reported.

The intermittent application of ClO2 may be a solution to the usual challenges faced during drying using ClO2 gas as an antimicrobial agent. The concentration of ClO2 above 10 ppm usually provides the desired antimicrobial effect. However, the quality of food products, such as color, is affected by long-term exposure to such high concentrations of ClO2 [27]. Intermittent exposure may be a readily available solution. In most food treatment processes, in which long-term application results in depletion of food quality, such as in hot-air drying process, intermittent application is employed to reduce the undesirable effects such as those reported during the hot-air drying of soybean [28]. Furthermore, low-temperature drying has been used to reduce moisture in food with delicate nutritional compounds to preserve its qualities [29,30]. A combination of intermittent ClO2 treatment and low-temperature drying will be a novel process to control the microbial level of rice cakes, preserve the nutritional quality and appearance as well as to extend the shelf-life of rice cakes.

Thus the objectives of this study were: (1) to extend the storage of rice cake via intermittent application of ClO2 and low-temperature drying, (2) to investigate ClO2 inhibition of Bacillus cereus contamination of treated dried rice cake, and (3) to evaluate the effect of low-temperature drying on rice cake texture appropriate for cutting process.

2. Materials and Methods

2.1. Experimental Setup

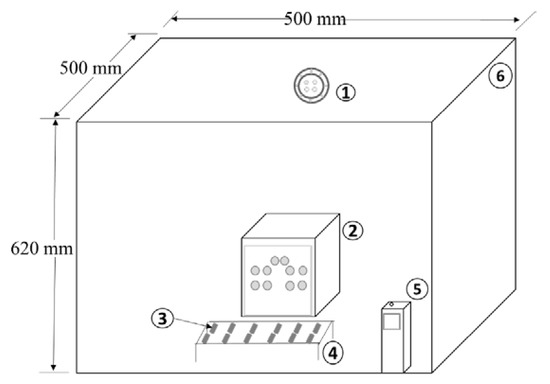

The schematic diagram representing the intermittent drying process of rice cake using ClO2 under low temperature is shown in Figure 1. The drying system consists of a drying chamber measuring 155,000,000 mm3 in volume (Clean air oven LBO-3050H, DAIHAN LABTECH CO., LTD., Namyangju-si, Gyeonggi-do, Republic of Korea) with a temperature regulatory fan set to adjust the drying temperature to 10 °C and relative humidity (RH) of 58%. Gaseous ClO2 was generated from ClO2 wax (Sun clean bactericide, Mirai CO., LTD., Tokyo, Japan) with the aid of a gas generator (Mini Breeze, Kimurasteel Industry Co., LTD, Tokyo, Japan). Twelve pieces of cylindrical shape of cooked rice cake (length 40 mm × diameter 15 mm) weighing approximately 130 g were arranged 20 mm apart from each piece on a perforated tray (200 mm length × height 100 mm) to ensure even circulation of gaseous ClO2 around the rice cake samples. A portable chlorine dioxide gas detector (Yantai Stark Instrument Co., Ltd., Shandong, China) was placed adjacent to the perforated drying stand, and the concentration (ppm) of ClO2 gas in the chamber was measured simultaneously with drying.

Figure 1.

A schematic diagram of batch process showing low-temperature drying of rice cake. 1. Low-temperature inlet (10 °C), 2. ClO2 generator, 3. Pre-cooked rice cake, 4. Perforated drying stand, 5. Chlorine dioxide gas detector, 6. Enclosed drying chamber.

2.2. Rice Cake Preparation

Rice flour (Oryza sativa) was purchased from Nongshim CO., LTD. (Seoul, Republic of Korea). Other ingredients such as salt and oil were purchased from a local market (Chuncheon, Republic of Korea). Rice flour (750 g) with a moisture content of 16.38%, 7.5 g of oil, 1.5 g of salt, and 360 mL of distilled water were used to prepare the rice cake. Briefly, the rice flour and salt were first mixed for 1 min followed by the addition of oil and distilled water with subsequent mixing for 15 min in a dough mixer (Model SZM-20, Xuzhong Machinery CO., LTD.,Guangzhou, China). The batter was then placed in an electric steaming machine (Model KRRSB10W, Koresta, Jingwa, Seoul, Republic of Korea) for gelatinization at 80 °C for 40 min. Finally, the rice dough was cooled at room temperature for 10 min and then extruded using a lab-scale extrusion machine (Shandong Luerya Machinery Co., LTD., Shandong, China) to form a cylindrical rice cake measuring 15 mm in diameter.

2.3. Drying of Rice Cakes under Intermittent ClO2

A batch of steamed rice cakes (12 pieces, 130 g) were dried at each experimental run (at 10 °C and RH 58%). The low-temperature drying was conducted for a period of 6, 12, 18, and 24 h. Prior to drying, the ClO2 gas generator was operated for 465 min, to achieve an average ClO2 concentration of 17 ppm before samples were placed in the drying chamber. The target initial concentration of ClO2 was set at 15 ppm, which was effective in reducing the microbial load in most food [24]. Similarly, due to the transient nature of the ClO2 gas, samples were placed in the drying chamber within 30 s of opening, and thus drying was started with an average ClO2 concentration of 15 ppm (as determined in the preliminary experiment, result not presented) and the process was conducted in a dark room to prevent photodissociation of the gas [31]. The ClO2 intermittent period was varied at 30, 45, and 60 min generation time with a resting period of 15 min at intervals to achieve maximum ClO2 concentration range of 22–25 ppm through the drying process. This concentration was chosen based on the inactivation effect without a significant influence on the sample color as determined from the preliminary experiment. The ClO2 gas was emitted in the drying chamber with a constant rate and no gas could escape into the atmosphere since the drying chamber was adequately sealed. Under these circumstances, the absorption rate of the ClO2 gas by rice cake was measured as a factor of the differences in the reduction ratio of ClO2 concentration within the drying chamber during the intermittent resting period.

2.4. Determination of Color Change during Intermittent Drying

The color of ClO2-treated dried rice cake and control sample was measured by a digital color analyzer (Model CA-310, Konica Minolta, Tokyo, Japan). Prior to each color measurement, the instrument was calibrated with a standard calibration plate with Y = 82.40, x = 0.3158, y = 0.3322 using the setting of D65 (daylight, 65 light angle) (Model no. 1383315, Konica Minolta, Tokyo, Japan). The color values were expressed as (lightness/darkness), (redness/greenness) and (yellowness/blueness). The whiteness index was determined using the method of Feng et al., [32], and represented in Equation (1). All experiments were performed 10 times.

2.5. Texture Analysis

2.5.1. Texture Determination of Dried Rice Cake by Cutting Test

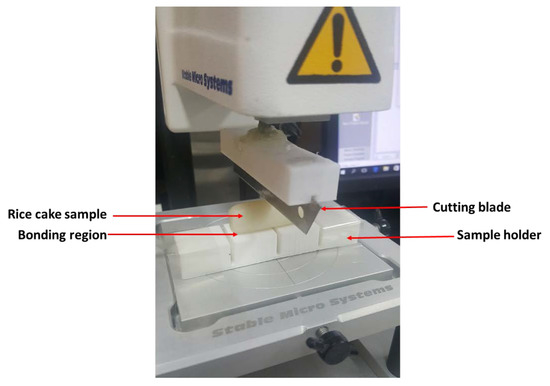

Texture analysis was performed using a cutter blade on a steamed rice cake (control) and a dried rice cake following exposure to intermittent ClO2 treatment at a low temperature (10 °C) after 6, 12, 18, and 24 h of drying using a texture analyzer (TA-XT Plus, Stable Micro systems Ltd., Surrey, UK). Samples were immediately removed from the dryer at the end of the drying process followed by texture analysis within 15 min at room temperature (25 ± 1 °C). Hardness (g) and adhesiveness (g) of control and dried rice cake were estimated using the cutting test as described by Epstein et al. [33]. The hardness (g) is defined as the maximum force achieved during the compression phase. The ends of rice cake sample were affixed using a glue (Loctite, Dusseldorf, Germany) on a polyplastic 3D-printed sample holder (Figure 2). The cutting test of rice cakes was conducted using a cutter blade with a sharp edge measuring less than 0.5 mm thickness (Model PMGA-EVO2, NT Incorporated, Osaka, Japan). The texture analyzer was set to a test speed of 0.5 mm/s and a post-test speed of 5.0 mm/s. The average thickness of dried rice cake after 24 h drying at low temperature (10 °C) was 13.50 ± 0.27 mm. The sample holder was designed during the cutting test to ensure that the cutting blade penetrates 100% through the sample. To estimate the degree of retrogradation during drying and its corresponding effect on rice cake stickiness, the adhesiveness indicated by the negative area on the texture curve during blade retraction was integrated using the method described by Epstein et al. [33]. The points at which the force curve crosses the x-axis during compression and retraction were used as the corresponding x values (start and endpoints, respectively) for each drying period. The average of at least 10 replicates was considered to determine the respective values of hardness and adhesiveness.

Figure 2.

Texture analysis of intermittent ClO2-low temperature-dried rice cake.

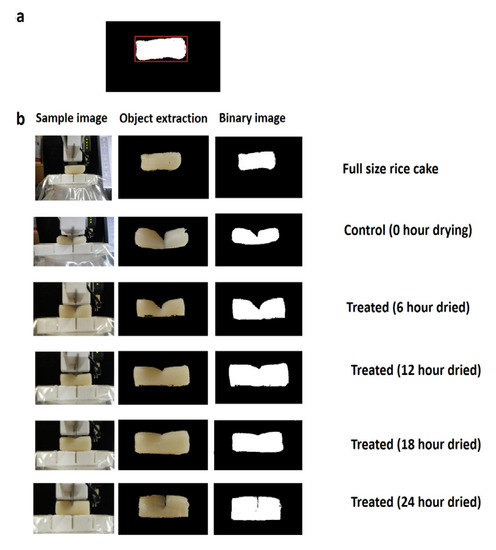

2.5.2. Image Processing

Gelatinized rice cake sticks to the blade during cutting and interferes with its operation due to the degree of stickiness and is reduced during retrogradation [13]. Therefore, the level of retrogradation in the dried rice cake sample was analyzed as a measure of rice cake sticking to the blade during the cutting test as presented in Figure 3. To facilitate accurate detection and processing of the image of rice cake at the point of cutting (i.e., the point at which the blade penetrates the rice cake), a video of the cutting process was recorded using a digital camera (DSLR-500D, Canon Inc., Tokyo, Japan) with an image resolution of 2.1 million pixels at a distance of 180 mm from the sample. The videotape was processed into image frames and the frame at the point of penetration was selected for analysis using the method of Park and Yoon [34] with a few modifications. In this study, the image processing tool in MATLAB (Mathworks® Inc., Natick, MA, USA) was used via the following steps: (1) conversion of videotape to frame, (2) image background extraction, (3) binarization, (4) object extraction, and (5) object area measurement as shown in Figure 3. Threshold-based segmentation (0.3) was used to separate the solid object from the background. The segmented image was converted to a gray image and to a binary image subsequently, after which the binary objects were extracted and analyzed for object area. The pixels from image analysis were converted to area size by comparing the size of the control sample as shown in the bounding box function (Figure 3a).

Figure 3.

Overall procedure of the image analysis of treated dried rice cake during cutting test, (a) control sample with bounding box function, (b) Treated rice cake by drying period.

2.6. Sensory Evaluation of Rice Cake

Rice cake samples subjected to ClO2 intermittent drying (0–24 h) were steamed for 10 min and evaluated for sensory properties. To minimize the effect of age, we selected a 15 member panel in the age range of 20 to 30 years, and familiar with rice cake properties. Sensory parameters, including color, flavor, and hardness, were evaluated using a quantitative descriptive test focused on attribute scoring from 1 (low intensity) to 7 (high intensity). The sensory attributes consisted of color (lighter–darker), flavor (poor flavor–pronounced flavor), and hardness (soft-hard). In order to determine the overall consumer acceptability of rice cakes, a seven-point hedonic scale (1 indicated extreme dislike, 4 indicated neither like nor dislike, and 7 indicated extreme like) was used. The samples offered for sensory tests were 40 mm in size. After each evaluation, the panelists rinsed their mouth with water and waited for at least 5 min before the next test.

2.7. Effect of Intermittent ClO2 Drying at Low Temperature on Microbial Inactivation Of Steamed Rice Cake

To estimate the inactivation of gaseous ClO2 during low-temperature drying and its effect under refrigerating temperature, the initial microbial load and after ClO2 treatment time (6, 12, 18, and 24 h) was analyzed. The influence of ClO2 treatment on microbial growth was analyzed at 4 °C. The dried samples were immediately packed in a sterile sample bag after drying and stored for a period of 21 days. The steamed (control) and dried (treated) rice cakes (10 g) were placed in Stomacher bags containing 100 mL of buffered peptone water and homogenized for 5 min at every experimental point (Polytron PT 2100 homogenizer, Kinematica, AG Inc., Lucerne, Switzerland). Samples were serially diluted 10-fold with 9 mL of sterile buffered peptone water. The diluted samples were spread plated on plate count agar (PCA) (Difco Laboratories Inc., Franklin Lakes, NJ, USA). All plates were incubated at 37 °C for 24–48 h under aerobic conditions.

2.8. EpH Analysis of ClO2 Treated Rice Cake

To measure the pH of rice cake samples, 20 g of rice cake was placed in sample bags with 80 mL distilled water and homogenized with a polytron PT 2100 homogenizer. The pH was measured five times using a pH meter. The initial pH of untreated rice cake sample was 6.11 ± 0.03 and after 24 h drying with intermittent ClO2 application, the pH of sample was 5.82 ± 0.02. The two measured pH served as the environmental pH conditions for the microbial growth model.

2.9. Growth Model of Treated Rice Cake

2.9.1. Preparation of Bacillus cereus Spore Suspension

B. cereus is the major microbial contaminant of rice products [14,18]. Therefore, B. cereus used for the growth model analysis was isolated by direct plating of homogenized and steamed but not treated rice cake sample, using the method described by Moore et al. [35]. The strains were incubated at 37 °C for 24 h. Colonies with the typical appearance of B. cereus, i.e., crenated, i.e., about 5 mm in diameter and with a distinct turquoise-to-peacock blue color surrounded by substantial egg yolk precipitate of the same color, were isolated and scooped using a sterile loop [35]. The spore was cleaned and washed with 1 mL of distilled water into a test tube containing 9 mL distilled water for serial dilution. Dilution was carried out until an estimated bacterial concentration of about 3 log CFU/mL was achieved.

2.9.2. Inoculation of B. cereus Spores on Sterile Rice Cake

The rice cake sample was sterilized using the method described by Jung et al., [20] with slight modification, and microbial analysis was used to confirm the sterility of the sample. After sterilization, rice cake samples were further dried using intermittent gaseous ClO2 application for 24 h. A subsequent microbial analysis was conducted to ensure that contamination during the drying process did not occur. Rice samples were inoculated under a laminar airflow, on a clean bench with 0.1 mL of approximately 3 log CFU/mL of B. cereus strains, on about 5–10 spots on the sterile rice cake sample. Inoculated samples were allowed to dry for 10 min on a clean bench before packing in a sterile sample bag and stored at varying temperatures (5, 10, 15, 20 and 25 °C).

2.9.3. Primary Model

The growth of B. cereus was studied as a function of the storage temperature (5, 10, 15, 20 and 25 °C) and pH of the rice cake sample after treatment with ClO2 for 24 h. Baranyi model proposed by Baranyi and Robert [36] was used to fit the isothermal growth curves (Equation (2)). The primary models were fits to the experimental growth data using MATLAB curve fitting tools (Mathworks® Inc., Natick, MA, USA).

where

represent the cell concentration expressed as CFU/g at time ; denotes the initial cell concentration in CFU/g; indicates the maximum cell concentration in CFU/g; refers to the maximum specific growth rate in CFU/h; indicates the rate of increase in the limiting substrate, assumed to be equal to is equal to ; and is the duration of the lag time phase in hours. The parameter is constant when the pre-inoculation history of the bacterial cells is identical [36]. Therefore, initially, four parameters of the Baranyi model were estimated: , , and . The average value, was then calculated and the other three parameters were estimated again with the term in Equations (2) and (3) fixed at .

To characterize the effect of the temperature on the growth parameter estimated by Equation (2), the average estimated and values for the model were plotted with respect to storage temperature using the modified Ratkowsky secondary model [37]. The model was fitted to the average (Equation (4));

where represents the storage temperature in °C, minimum growth temperature for B. cereus as measured from the experiment (4 °C) and is the maximum growth temperature for B. cereus growth as measured from the experiment (47 °C), and are regression coefficients.

2.9.4. Validation of the Growth Model

The goodness of fit of the secondary model was used to validate the predicted result. The performance at each temperature level was assessed using the root mean square error (RMSE), sum of squared errors of prediction (SSE), and coefficient of determination (R2). The statistics are represented by Equations (5) and (6).

where represents sample size, and denotes model prediction error at the term calculated as the predicted value minus the observed value. Furthermore, by following the method described by Juneja et al. [38] the prediction error (PE) for each observation with log10 CFU/g units carrying a value of 0 was considered a perfect prediction. Prediction error values ranging between and 0.5 were considered “acceptable”.

2.9.5. Statistical Analysis

All microbial experiments were repeated three times, and dilutions were plated in duplicate. We further carried out one-factor ANOVA analysis with SPSS v19.0 (IBM Corp., Armonk, NY, USA), and the average differences were evaluated by the Tukey test using a 95% confidence interval. Image analysis and texture properties are presented as mean values of at least 10 measured replicates. Trends were considered significant when the means of compared sets differed at p < 0.05 (Student’s t-test).

3. Results and Discussion

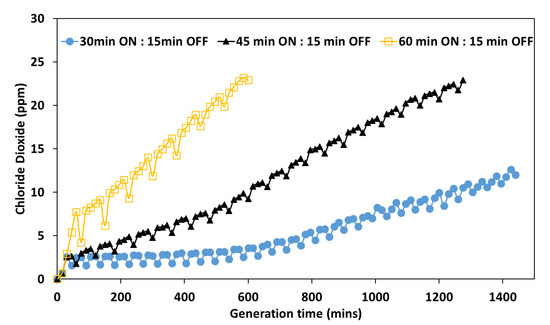

3.1. Determination of ClO2 Intermittent Drying Period

The result of the intermittent generation period and the rest period is presented in Figure 4. Achievable ClO2 concentration increased with a generation time, with intermittent period of 30 min and 45 min generation time having a maximum concentration of 12.01 ± 1.28 and 22.91 ± 1.89 ppm at the end of 24 h drying period, which does not provide sufficient inactivation time for sample treatments during the drying process (6, 12 and 18 h) (as determined from preliminary, result not shown). On the other hand, 60 min generation period achieved a ClO2 concentration of 23.89 ± 1.74 ppm at 552 min, offering samples sufficient inactivation period at all drying levels. Therefore, an intermittent drying period of 60 min and 15 min rest period was selected as the optimum intermittent time and used for all experiments.

Figure 4.

Changes in ClO2 concentration at various intermittencies.

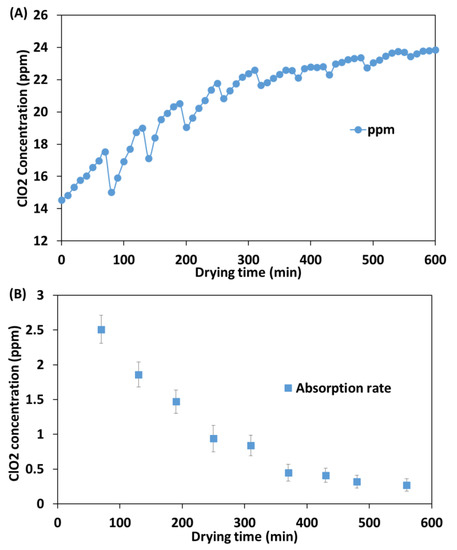

3.2. ClO2 Absorption Rate by Steamed Rice Cake Sample

The drying chamber was operated under continuous ClO2 emission into the chamber until approximately 17 ppm concentration was obtained before samples were placed in the chamber. Changes in ClO2 gas concentration (ppm) in the drying chamber during the intermittent treatment are presented in Figure 5A. At the onset of drying, the ClO2 gas released in the drying chamber increased from about 15.14 ± 1.67 ppm with increasing duration of operation of the gas generator. During the intermittent resting period (i.e., 15 min every 1 h of generator operation), the concentration of the gas showed a decrease, which indicated the absorption of ClO2 by the rice cake samples during drying as no gas escaped outside the drying chamber. The concentration of ClO2 attained a steady state after 490 min. Even under the resting period, the concentration showed no significant changes with time (Figure 5B), which might be attributed to the interruption of gas diffusion into the sample due to surface hardening associated with drying and retrogradation of rice cake [39,40]. This result implies that a drying period of 24 h might be appropriate for intermittent ClO2 treatment at the initial concentration (15.14 ppm) of ClO2 to initiate the onset of retrogradation.

Figure 5.

ClO2 concentration during low-temperature (10 °C) drying, (A) concentration of ClO2 gas in the drying chamber during intermittent drying, (B) quantity of ClO2 absorbed by rice cake sample during the rest period.

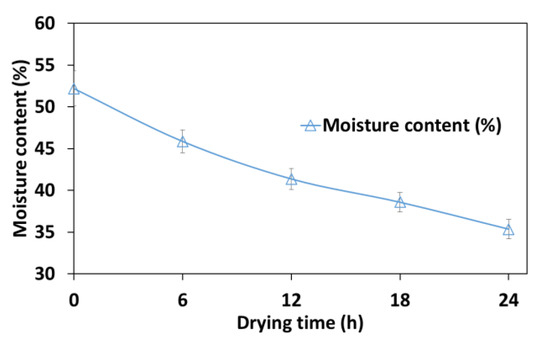

3.3. Moisture Loss in Sample during Drying

The initial moisture content of rice cake 52.18 ± 2.17% and the moisture loss during low-temperature drying process are presented in Figure 6. Moisture loss is a general observation during drying, both at low and high temperatures. It has been reported to be helpful in extending the shelf-life of rice cake products. However, due to secondary contamination during drying, the shelf-life can be shortened, especially during low-temperature drying [17]. The moisture loss in rice cake showed a gradual decrease during low-temperature drying with a total moisture loss of 34.26 ± 1.23% (dry base) at the end of 24 h drying period. The drying rate is gradually decreased as the drying time increased. The declined rate during drying might be due to the effect of hardening of rice cake associated with retrogradation and a lower quantity of moisture presented in the sample as it is being dried. A similar observation was reported during the low-temperature storage of rice cake [40]. Since moisture is an import aspect of rice cake texture, this result shows the possibilities of reducing rice cake stickiness, which is mainly attributed to the moisture and the extent of gelatinization of the rice cake sample [4]. After 24 h of drying, the moisture content was reduced to 34.30 ± 1.83% as shown in Figure 6. The moisture content of dried rice cake or drying time is correlated to the rice cake stickiness during cutting and the degree of restoration during cooking [40].

Figure 6.

Moisture loss in rice cake sample during drying process.

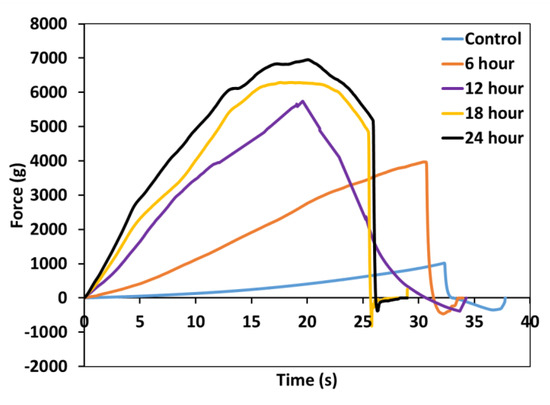

3.4. Texture Analysis of Dried Rice Cake

The force required to cut the dried rice cake sample is affected by the drying period as shown in Figure 7. The data show that with increased drying period, the hardness (i.e., the peak of the positive area) of the rice cake sample dried at 10 °C increased significantly (p ≤ 0.05) for all drying periods from 901.39 ± 53.87 to 7285.52 ± 638.35 (g). Increasing hardness during low-temperature drying has also been reported and attributed to retrogradation, which is accelerated at low temperatures [8,12,17]. Adhesiveness, which may be interpreted as the stickiness of the rice cake sample to the blade during the withdrawal of the cutting blade from the sample, is represented as the negative force area indicating a decreasing value with increasing drying time (3614.37 ± 518.23, 3119.62 ± 482.17, 2765.21 ± 451.36, 618.23 ±98.54, and 534.81 ± 89.37 g respectively). The effect of adhesiveness is also apparent from the texture curve: samples with less adhesive response (18 and 24 h dried rice cake) were cut faster (at about 26 s cutting process time) compared with those exhibiting a larger adhesive effect. Similarly, the adhesiveness was insignificantly different for 0, 6 and 12 h drying period as against what was observed for the hardness value, which may suggest that the degree of retrogradation depends on the drying time. This finding suggests that even though the surface hardness due to drying increased with drying period, the effect of sample sticking to the cutting blade occurred after 12 h of drying rice cake. Therefore, the sticky effect can be further reduced over a longer drying period (>12 h) at low temperatures. From a textural perspective as shown in this study, the challenges associated with sample stickiness can be reduced by drying rice cake at low temperature (10 °C) for 18 h without adversely affecting the texture of the rice cake. However, the microbial analysis should be combined with the results of texture analysis.

Figure 7.

Changes in force (g) during the cutting test of retrograded rice cake after various drying times.

3.5. Analysis of Rice Cake Retrogradation Rate Via Image Processing

Changes in retrogradation properties of rice cake during low-temperature drying were studied as a function of rice cake stickiness by measuring the area of the rice cake compressed during cutting since the gelatinized rice cake sample usually sticks to the cutting blade and bends at regions close to the cutting zone. The results are presented in Table 1. Based on the image analysis, a greater area of compression was observed in the control sample (14.12 ± 1.25 mm compressed area), which is reduced with increasing drying time. Starch retrogradation consists of two different processes: gelation of amylose solubilized during gelatinization, and amylopectin recrystallization within the gelatinized granules, which occurs on cooling, during low-temperature storage or drying [40]. During low-temperature drying, the gelatinized starch molecules reassociate into an ordered structure, which reduces sample stickiness and increases brittleness facilitating sample cutting. Also, since rice cake contains very low amylose and very high amylopectin, amylopectin recrystallization occurs readily [8,39]. Hence, rice cake showed high retrogradation under a prolonged drying period. However, the compressed area of samples dried at 18 and 24 h varied insignificantly. Therefore, drying the rice cake sample at a low temperature of 10 °C for 18 h reduces the effect of stickiness similar to drying for 24 h. Therefore, 18 h of low-temperature drying is sufficient to reduce the stickiness effect with enhanced texture.

Table 1.

Image analysis of dried rice cake.

3.6. Effect of Intermittent ClO2 Treatment on Dried Rice Cake Sample Color and Sensory Properties

The color of rice cake treated intermittently with ClO2 is presented in Table 2a. The lightness (L), whiteness index (WI), and redness values vary significantly at all treatment levels with a reduction in lightness and an increasing redness as the drying period increased. The reduction in L-value was attributed to surface starch interaction with the ClO2 gas rather than a temperature effect since color changes of rice cake at higher temperature occur usually due to starch granule collapse during gelatinization, which produces a transparent glossy layer [40]. In contrast, the yellowness after 24 h drying period was significantly higher than in other treatments, but not significantly different during 6, 12, and 18 h of drying period. Interestingly, a strong correlation existed between the instrumental yellowness measured and the color observed during sensory evaluation (Table 2b). Accordingly, it can be stated that no significant changes occurred in the expected color of rice cake treated with ClO2 application as it was within the range known to consumers. The flavor score was slightly lower than in the control sample with increasing drying time. The hardness score was reduced with increased drying duration and was correlated with the hardness measured, and indicated reduced stickiness as observed in the image processing. Consequently, all samples except the sample dried for 24 h exhibited a high overall acceptability score (>4) (Table 2b). The lower score of the 24 h sample may be attributed to the reduced flavor and hardness, mostly due to the drying time.

Table 2.

(a) Color of ClO2-treated rice cake at different drying periods; (b) Sensory evaluation scores of gelatinized rice cake.

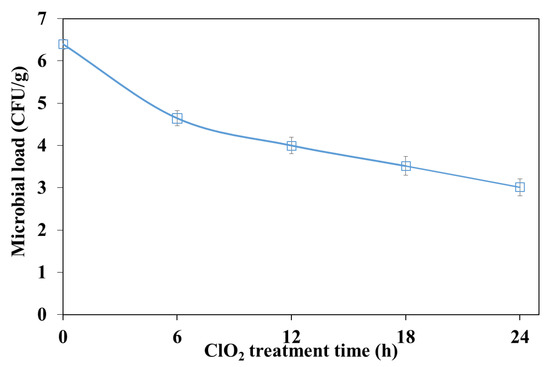

3.7. Inactivation of Microorganisms on Rice Cake by Sequential Treatment with ClO2 and Low-Temperature Drying

The effect of intermittent ClO2 application combined with low-temperature drying on foodborne pathogens in the rice cake sample was analyzed at 0, 6, 12, 18 and 24 h of treatment, as shown in Figure 8. Treatment with gaseous ClO2 reduces the microbial load in the rice cake sample from 6.39 ± 0.37 to 4.64 ± 0.25, 3.99 ± 0.31, 3.51 ± 0.13 and 3.01 ± 0.22 log CFU/g as the drying period increased from 0 to 24 h, respectively (Figure 8). A similar inactivation by ClO2 has been reported with red chili pepper using liquid ClO2 combined with hot air treatment [41]. A rapid reduction in the levels of B. cereus was also recorded. However, when liquid ClO2 is used, utmost care should be taken as the moisture usually triggers or initiates the growth of mold. However, gaseous ClO2 can be used over a wide range with limited chances of accumulation on the surface of the treated food, and thus not hazardous when a higher quantity is used for the treatment of solid foods [24].

Figure 8.

Inactivation by ClO2 gaseous treatment of steamed rice cake.

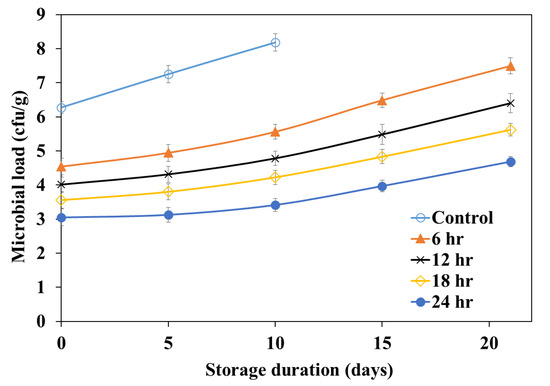

3.8. Microbial Growth on Rice Cake during Storage at 4 °C

Microbial analysis during storage of the control and the ClO2-treated samples are presented in Figure 9. First, the treatment of rice cake with intermittent gaseous ClO2 application during drying influences the reduction ratio of the initial microbial load at each testing level. The growth of B. cereus, which is the predominant microorganism found in rice cake, is optimum at 38 °C and its growth rate is limited at lower temperatures [37]. Nonetheless, the microbial growth of control rice cake sample was found to rapidly increase and attained the optimum growth level (9.1028 CFU/g) in about 12 days, even at a low temperature of storage (4 °C), suggesting the possible occurrence of other microbial contaminants in rice cake. For example, Escherichia coli O157:H7, which has also been reported in rice cake samples shows an optimum growth at 15 °C and grows better at lower temperatures than at higher temperatures in contrast to the growth of B. cereus [42]. Therefore, the rapid growth rate observed for the control rice cake sample may be attributed to other microorganisms rather than just B. cereus. Furthermore, ClO2 treatment resulted in effective inactivation and inhibition of other microorganisms with increasing treatment time by reducing the microbial load in the rice cake sample by up to 63% of the initial concentration (6.39 CFU/g). A similar result was reported during the treatment of oriental rice cake [43]. Consequently, ClO2 treatment for 24 h inhibited microbial growth on rice cake at low temperatures with a maximum growth of 1 log CFU/g during 21 days of storage. This result, therefore, suggests that the intermittent ClO2 treatment of rice cake leads to effective microbial inactivation and an extension of the shelf-life of rice cake without additional unit operations.

Figure 9.

Microbial growth curve of rice cake treated with gaseous ClO2 during 21 days storage at 4 °C.

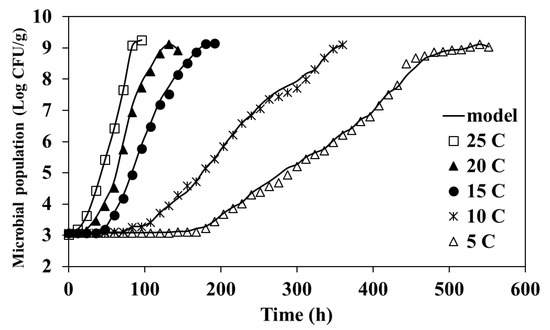

3.9. Growth Model and Validation

To estimate the effect of intermittent ClO2 application during low-temperature drying on the growth of B. cereus in rice cake, the primary model parameters at various storage temperatures were evaluated. The model-fitting results are shown with the microbial data (Figure 10, Table 3). The lag time (λ) values of B. cereus in ClO2-treated rice cake at 5, 10, 15, 20, and 25 °C show a decreasing value with increase in the storage temperature (9.83, 8.66, 7.83, 7.33, and 7.16 h, respectively) (Figure 10, Table 3). Sterile rice cake samples were inoculated with a very high initial concentration (approximately 3.06 log CFU/g) of B. cereus, to replicate the worst-case scenario under inadequate steaming or cooking, especially while processing rice cake at home. The result during the storage period shows different growth characteristics based on the storage temperature, antimicrobial inactivation and inhibitory effect of gaseous ClO2 (Figure 10). Recently, many studies have reported the preparation of rice cake with zero tolerance to B. cereus at different storage levels using different methods of inactivation, such as acid soaking and high-temperature sterilization [14,20]. Unfortunately, the high-temperature sterilization may affect the structure and shape of rice cake, despite ensuring microbial sterility. Similarly, the whiteness values of the rice cake may be reduced by 50% based on soaking time or treatment conditions due to Maillard reaction, resulting in altered structure and appearance, which reduces the market value [14]. Our results of experimental lag time are similar to those reported during high-temperature treatment of rice cake stored at 25, 20, and 17 °C [43]. Furthermore, the optimum growth rate studied as a function of temperature is reduced with decreasing storage condition such that the growth rate at 25 °C (0.035 CFU/g) is 35-fold faster than the growth rate at low temperature (5 °C), which explains the rapid growth observed at higher temperatures (25, 20, and 15 °C) (Figure 10). The optimum growth temperature for B. cereus has been reported as 38 °C [36], and can be attributed to the reduced growth rate at low-temperature due to inhibition of B. cereus in rice cake. A similar observation has been reported with the inhibition of B. cereus growth at low temperatures [21,38,43].

Figure 10.

B. cereus growth during storage at 5–25 °C fitted with Baranyi growth model.

Table 3.

Growth rate () and lag time (λ) of B. cereus on rice cake treated at varying storage temperatures.

The observed and predicted growth patterns under storage temperature conditions were analyzed using Equations (2) and (3) and presented in Table 3. In general, all storage temperatures showed a good fit with the Baranyi primary model predicting the growth of B. cereus on ClO2-treated rice cake. Higher fitness was observed under storage at 10 °C and 15 °C with a higher R2 and lower RMSE values. However, at a few experimental points, higher prediction was observed especially at higher storage temperatures, which yielded lower R2 and RMSE values. Similar results were reported for growth models of B. cereus in rice cake [38], which were attributed to an altered physiological state of the microorganism due to cold shock-inducing a lag phase, especially close to growth levels near the optimum growth points [38]. Furthermore, the results of prediction error in the range of −1.0 to 0.5, suggesting the acceptability of the models predicting bacterial growth [38], shows that the predictive model validates the effect of storage temperature in our study under all temperatures tested.

4. Conclusions

In conclusion, this study validated the effect of intermittent ClO2 treatment during low-temperature drying to reduce the stickiness of rice cake during cutting and decrease the microbial load, resulting in extension of shelf-life by 86 h and 432 h during storage at room temperature (25 °C) and 5 °C, respectively. The drying conditions determined using texture analysis combined with image processing results showed that drying rice cake at a low temperature of 10 °C for 18 h reduces stickiness 7-fold without interfering with other textural properties. However, contamination during the drying process may occur with an increase of about 2 log CFU/g. Therefore, microbial inactivation in rice cake using a combination of intermittent gaseous ClO2 application was verified by determining the absorption rate and color changes. Furthermore, the inhibition of B. cereus by ClO2 at extremely high initial concentration of > 3 log CFU/g was evaluated. Intermittent treatment showed the inhibition of microbial growth for about 18 days at a storage temperature of 5 °C without exceeding the acceptable population threshold (106 CFU/g) for toxin production. Consequently, the data fitted the Baranyi model at all experimental temperatures (5–25 °C) with R2 values > 0.99.

Author Contributions

Conceptualization, T.M.O., and W.B.Y., methodology, T.M.O., and W.B.Y.; investigation, T.M.O.; writing-original draft preparation, T.M.O.; writing-review and editing, T.M.O., and W.B.Y.; supervision, W.B.Y.; project administration, W.B.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by Korea Institute of Planning and Evaluation for Technology in Food, Agriculture and Forestry (IPET) through Agro and Livestock Products Safety· Flow Management Technology Development Program, funded by Ministry of Agriculture, Food and Rural Affairs (MAFRA) (318079-2).

Conflicts of Interest

The authors declare no conflict of interest

References

- Zhang, H.; Feng, X.; Larssen, T.; Qiu, G.; Vogt, R.D. In inland China, rice, rather than fish, is the major pathway for methylmercury exposure. Environ. Health Perspect. 2010, 118, 1183–1188. [Google Scholar] [CrossRef] [PubMed]

- Román, L.; Reguilón, M.P.; Gómez, M. Physicochemical characteristics of sauce model systems: Influence of particle size and extruded flour source. J. Food Eng. 2018, 219, 93–100. [Google Scholar] [CrossRef]

- Collins, J.E. Impact of changing consumer lifestyles on the emergence/reemergence of foodborne pathogens. Emerg. Infect. Dis. 1997, 3, 471. [Google Scholar] [CrossRef] [PubMed]

- Ai, J.; Witt, T.; Cowin, G.; Dhital, S.; Turner, M.S.; Stokes, J.R.; Gidley, M.J. Anti-staling of high-moisture starchy food: Effect of hydrocolloids, emulsifiers and enzymes on mechanics of steamed-rice cakes. Food Hydrocoll. 2018, 83, 454–464. [Google Scholar] [CrossRef]

- Lian, X.; Kang, H.; Sun, H.; Liu, L.; Li, L. Identification of the main retrogradation-related properties of rice starch. J. Agric. Food Chem. 2015, 63, 1562–1572. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Li, C.; Copeland, L.; Niu, Q.; Wang, S. Starch retrogradation: A comprehensive review. Compr. Rev. Food Sci. Food Saf. 2015, 14, 568–585. [Google Scholar] [CrossRef]

- Inaba, H.; Hatanaka, Y.; Iimura, H.; Matsumura, Y.; Mori, T. Production of rice cake doughs with a twin screw extnder and their retrogradation properties. Nippon Shokuhin Kogyo Gakkaishi 1988, 35, 15–22. [Google Scholar] [CrossRef][Green Version]

- Yu, S.; Ma, Y.; Sun, D.W. Impact of amylose content on starch retrogradation and texture of cooked milled rice during storage. J. Cereal Sci. 2009, 50, 139–144. [Google Scholar] [CrossRef]

- Cameron, D.K.; Wang, Y.J. A better understanding of factors that affect the hardness and stickiness of long-grain rice. Cereal Chem. 2005, 82, 113–119. [Google Scholar] [CrossRef]

- Cameron, D.K.; Wang, Y.J. Physicochemical properties and leaching behavior of eight US long-grain rice cultivars as related to rice texture. Discov. Stud. J. Dale Bump. Coll. Agric. Food Life Sci. 2003, 4, 14–20. [Google Scholar]

- Patindol, J.; Gu, X.; Wang, Y.J. Chemometric analysis of cooked rice texture in relation to starch fine structure and leaching characteristics. Starch Stärke 2010, 62, 188–197. [Google Scholar] [CrossRef]

- Yu, S.; Ma, Y.; Sun, D.W. Effects of freezing rates on starch retrogradation and textural properties of cooked rice during storage. LWT Food Sci. Technol. 2010, 43, 1138–1143. [Google Scholar] [CrossRef]

- Perdon, A.A.; Siebenmorgen, T.J.; Buescher, R.W.; Gbur, E.E. Starch retrogradation and texture of cooked milled rice during storage. J. Food Sci. 1999, 64, 828–832. [Google Scholar] [CrossRef]

- Park, H.W.; Yoon, W.B. A quantitative microbiological exposure assessment model for Bacillus cereus in pasteurized rice cakes using computational fluid dynamics and Monte Carlo simulation. Food Res. Int. 2019, 125, 108562. [Google Scholar] [CrossRef] [PubMed]

- Deng, H.; Wang, S.; Wang, Z.; Zhou, Z.; Xiao, H. Effects of enzyme treatments and drying methods on gelatinization and retrogradation of instant rice porridge. Food Sci. Techno. Res. 2012, 18, 341–349. [Google Scholar] [CrossRef]

- Choi, Y.H.; Kim, S.L.; Jeong, E.G.; Song, J.; Kim, J.T.; Kim, J.H.; Lee, C.G. Effects of low-temperature storage of brown rice on rice and cooked rice quality. Korean J. Crop Sci. 2008, 53, 179–186. [Google Scholar]

- Ondier, G.O.; Siebenmorgen, T.J.; Mauromoustakos, A. Low-temperature, low-relative humidity drying of rough rice. J. Food Eng. 2010, 100, 545–550. [Google Scholar] [CrossRef]

- Jung, S.M.; Kim, N.O.; Cha, I.; Na, H.Y.; Chung, G.T.; Kawk, H.S.; Hong, S. Surveillance of Bacillus cereus Isolates in Korea from 2012 to 2014. Osong Public Health Res. Perspect. 2017, 8, 71. [Google Scholar] [CrossRef]

- Park, D.L.; Rua JR, S.M.; ACKER, R.F. Direct application of a new hypochlorite sanitizer for reducing bacterial contamination on foods. J. Food Prot. 1991, 54, 960–965. [Google Scholar] [CrossRef]

- Jung, H.; Yu, C.R.; Park, H.W.; Yoon, W.B. Effect of acid soaking and thermal sterilization on the shape and quality characteristics of Tteokbokki rice cake. Korean J. Food Nutri. 2018, 31, 737–750. [Google Scholar]

- Lanciotti, R.; Sinigaglia, M.; Gardini, F.; Vannini, L.; Guerzoni, M.E. Growth/no growth interfaces of Bacillus cereus, Staphylococcus aureus and Salmonella enteritidis in model systems based on water activity, pH, temperature and ethanol concentration. Food Microbiol. 2001, 18, 659–668. [Google Scholar] [CrossRef]

- Nam, H.; Seo, H.S.; Bang, J.; Kim, H.; Beuchat, L.R.; Ryu, J.H. Efficacy of gaseous chlorine dioxide in inactivating Bacillus cereus spores attached to and in a biofilm on stainless steel. Int. J. Food Microbiol. 2014, 188, 122–127. [Google Scholar] [CrossRef] [PubMed]

- Tewari, A.; Abdullah, S. Bacillus cereus food poisoning: International and Indian perspective. J. Food Sci. Technol. 2015, 52, 2500–2511. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.; Kim, H.; Bang, J.; Beuchat, L.R.; Ryu, J.H. Synergistic effect of chlorine dioxide and drying treatments for inactivating Escherichia coli O157: H7 on radish seeds. J. Food Prot. 2010, 73, 1225–1230. [Google Scholar] [CrossRef]

- Knapp, J.E.; Battisti, D.L. Chlorine dioxide. Disinfect. Steriliz. Preserv. 2001, 5, 215–228. [Google Scholar]

- Han, Y.; Linton., R.H.; Nielsen, S.S.; Nelson, P.E. Reduction of Listeria monocytogenes on green peppers (Capsicum annuum L.) by gaseous and aqueous chlorine dioxide and water washing and its growth at 7 C. J. Food Prot. 2001, 64, 1730–1738. [Google Scholar] [CrossRef]

- Demirci, A.; Ngadi, M.O. (Eds.) Microbial Decontamination in the Food Industry: Novel Methods and Applications; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Park, H.W.; Han, W.Y.; Yoon, W.B. Drying characteristics of soybean (Glycine max) using continuous drying and intermittent drying. Int. J. Food Eng. 2018, 14, 9–10. [Google Scholar] [CrossRef]

- Santacatalina, J.V.; Rodríguez, O.; Simal, S.; Cárcel, J.A.; Mulet, A.; García-Pérez, J.V. Ultrasonically enhanced low-temperature drying of apple: Influence on drying kinetics and antioxidant potential. J. Food Eng. 2014, 138, 35–44. [Google Scholar] [CrossRef]

- Ozuna, C.; Cárcel, J.A.; Walde, P.M.; Garcia-Perez, J.V. Low-temperature drying of salted cod (Gadus morhua) assisted by high power ultrasound: Kinetics and physical properties. Innov. Food Sci. Emerg. Technol. 2014, 23, 146–155. [Google Scholar] [CrossRef]

- McDonald, P.A.; Innes, K.K. Assignment of the mechanism of predissociation of the ClO2 molecule by analysis of single-rotational-level lifetimes. Chem. Phys. Lett. 1978, 59, 562–566. [Google Scholar] [CrossRef]

- Feng, N.; Tang, S.; Zhou, M.; Lv, Z.; Chen, Y.; Li, P.; Wu, Q. Optimizing the texture and retrogradation properties of Niangao (Rice Cake) made with naturally fermented rice flour. Food Sci. Technol. 2019, 39, 810–817. [Google Scholar] [CrossRef]

- Epstein, J.; Morris, C.F.; Huber, K.C. Instrumental texture of white salted noodles prepared from recombinant inbred lines of wheat differing in the three granule bound starch synthase (waxy) genes. J. Cereal Sci. 2002, 35, 51–63. [Google Scholar] [CrossRef]

- Park, H.W.; Yoon, W.B. Development of a novel image analysis technique to detect the moisture diffusion of soybeans [Glycine max (L.)] during rehydration using a mass transfer simulation model. Food Bioprocess Technol. 2018, 11, 1887–1894. [Google Scholar] [CrossRef]

- Moore, R.E.; Millar, B.C.; Panickar, J.R.; Moore, J.E. Microbiological safety of spices and their interaction with antibiotics: Implications for antimicrobial resistance and their role as potential antibiotic adjuncts. Food Qual. Saf. 2019, 3, 93–97. [Google Scholar] [CrossRef]

- Baranyi, J.; Roberts, T.A.; McClure, P. A non-autonomous differential equation to model bacterial growth. Food Microbiol. 1993, 10, 43–59. [Google Scholar] [CrossRef]

- Ratkowsky, D.A.; Lowry, R.K.; McMeekin, T.A.; Stokes, A.N.; Chandler, R. Model for bacterial culture growth rate throughout the entire biokinetic temperature range. J. Bacteriol. 1983, 154, 1222–1226. [Google Scholar] [CrossRef]

- Juneja, V.K.; Golden, C.E.; Mishra, A.; Harrison, M.A.; Mohr, T.B. Predictive model for growth of Bacillus cereus at temperatures applicable to cooling of cooked pasta. J.Food Sci. 2019, 84, 590–598. [Google Scholar] [CrossRef]

- Yu, S.; Ma, Y.; Zheng, X.; Liu, X.; Sun, D.W. Impacts of low and ultra-low temperature freezing on retrogradation properties of rice amylopectin during storage. Food Bioprocess Technol. 2012, 5, 391–400. [Google Scholar] [CrossRef]

- Taniguchi, M.; Nakanaga, R.; Yano, N. Inventors; House Foods Corp, Assignee. Method of Manufacturing Dried Rice with Pregelatinized Starch Content. United States Patent US 4,794,012, 27 December 1988. [Google Scholar]

- Hoon, J. Inactivation of bacillus cereus spores on red chili peppers using a combined treatment of aqueous chlorine dioxide and hotâ air drying. J. Food Sci. 2017, 82, 1892–1897. [Google Scholar]

- Lee, J.I.; Kim, S.S.; Kang, D.H. Susceptibility of Escherichia Coli O157: H7 grown at low temperatures to the krypton-chlorine excilamp. Sci. Rep. 2019, 9, 1–9. [Google Scholar] [CrossRef]

- Lee, S.Y.; Chung, H.J.; Shin, J.H.; Dougherty, R.H.; Kang, D.H. Survival and growth of foodborne pathogens during cooking and storage of oriental-style rice cakes. J. Food Prot. 2006, 69, 3037–3042. [Google Scholar] [CrossRef] [PubMed]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).