Abstract

Freeze-drying is an important processing unit operation in food powder production. It offers dehydrated products with extended shelf life and high quality. Unfortunately, food quality attributes and grinding characteristics are affected significantly during the drying process due to the glass transition temperature (during drying operation) and stress generated (during grinding operation) in the food structure. However, it has been successfully applied to several biological materials ranging from animal products to plants products owning to its specific advantages. Recently, the market demands for freeze-dried and ground food products such as spices, vegetables, and fruits are on the increase. In this study, the effect of the freeze-drying process on quality attributes, such as structural changes, the influence of glass transition during grinding, together with the effect on grinding efficiency in terms of energy requirement, grinding yield, and morphological changes in the powder as a result of temperature, drying time were discussed. An overview of models for drying kinetics for freeze-dried food sample, and grinding characteristics developed to optimize the drying processes, and a prediction of the grinding characteristics are also provided. Some limitations of the drying process during grinding are also discussed together with innovative methods to improve the drying and grinding processes.

1. Introduction

Drying is a unit operation by which free water in the food is significantly reduced, thus promoting the concentration of dry matter without damaging the tissue, wholesomeness, and physical appearance of the food. The practice of drying differs among food processors. However, all methods are driven to achieving an extended storability by reducing the water activity from food products which can slow down the rate of deterioration and maintain its quality. Drying of food products is advantageous as it minimizes packaging, storage, and transportation costs [1]. It has been practiced as sun-drying method, which is considered as a traditional method practiced in most of the developing countries, or it can be conducted with improved technology such as spray drying, hot air drying, vacuum drying and freeze-drying [2]. Though the operational methods of conventional drying differ from modern technology, drying from these methods is all achieved either through radiation, convection, conduction, or a combination of heat transfer mechanisms. All of these drying methods consequently may affect partially or totally the quality of the product [2]. However, in recent times, vacuum freeze-drying has gained a lot of recognitions especially for the drying of high quality, nutritional delicate and expensive products. Freeze-drying is based on the sublimation mechanism by direct dehydration of frozen products. The wide acceptability of this method thus lies in its process which involve freezing of all available moisture, thereby maintaining the quality by reducing deterioration by low-temperature effect, retaining the solid structure by preventing compression and it ability to maintain soft texture of the dried food, especially those consumed in dried form e.g., dried squid fish, and dried apple fruit [3,4].

The rate of transfer of heat during freeze-drying operation is influenced by the food thermal properties, such as specific heat and thermal conductivity [5]. The thermal properties of foods are important in the design of food storage and refrigeration equipment as well as in the estimation of process times for refrigerating, freezing, heating, or drying of foods. Drying models have been used to describe freeze-drying process in agricultural produce. It shows the diffusion of moisture from the food and its relationship to variables as drying is conducted over time [6]. Consequently, the proper drying of food products before grinding has helped to achieve efficiency in grinding because less energy is required during the process and an increase in powder product yield has been reported [7]. Therefore, before the dry grinding process, the unit operation of drying must be ensured to have properties that will enhance the grinding unit operation.

Grinding as a unit operation is widely used in the food industry and designed to reduce the size of materials to yield a usable form or to separate their components. Many food processes frequently require size reduction, which is accomplished by applying diverse forces to create particles with certain sizes and shapes. The process of size reduction results from external mechanical forces acting on a material that is great enough to break the internal molecular binding force of the material through the generation of stress around the structure of the food. It makes use of a wide range of equipment, such as crushers, grinders, mills, disintegrators, cutters, shredders, mincers, and homogenizers [8]. The energy required is a direct function of the particle fineness or the generated surface area, and this is affected by the moisture content present or the material hardness [9]. Numerous research has been conducted to evaluate the energy requirement during the grinding process. Based on this, models such as the stress model, Rettingger’s law and Bond’s law were developed. These are aimed at estimating the required energy needed for size reduction and consequently features grinding parameters such as friction, adhesion to grinder, particle size, and grinder size for the stress model, while Rettinger’s and Bond’s law features the initial and final particle sizes [10,11].

The result of grinding depends on the nature of the food material, the technology applied, and the time of grinding. Grinding is important to the food industries as it helps to reduce the bulk density and improve the surface area, thereby creating a larger surface for chemical and biochemical reactions. However, the drying and grinding conditions during powder processing, greatly influence (separately) the quality attributes of the final powder product. The amount of moisture content before grinding is an important factor because it helps determine the materials’ physical properties and powder properties. Many researchers have investigated the efficiency of the grinding process as applied to grains and other food materials with various moisture contents [10,11,12]. Similarly, the resulting dried product from the drying operation can also affect the physical, textural, sensory, and functional properties of the powder resulting from the modification of the rheological and structural properties of the sample to be ground [12]. Liao and Chen [13] and Pan et al. [14] confirmed that the type and method of grinding potentially have a great impact on the physicochemical characteristics of rice flour. These changes are of great importance and need to be controlled through retro-engineering approaches. Other limiting factors include reductions in quality as a result of friction during grinding, reduction in flavor, aromatic components, and the removal of essential oils. Consequently, all these aforementioned properties affect the quality of the resulting powder product from grinding unit operation.

The market for dried food products has grown rapidly over the years and most products are in powder form. Zhang [15] reported a growth rate of 3.3% yearly for dehydrated fruits and vegetables for most countries worldwide. Powdered food has garnered interest in the food industry because it serves as either raw materials for production or the powder itself is the final product. For instance, fruits and vegetables are widely used in their powder form by the confectionery, bakery, sweets, and distilling industries in various sauces, teas, puddings, garnishments, natural colorants, additives, and food for infants and children [16]. In addition, cereals, roots, and tubers are also preserved in their powder form and have a wide range of uses, e.g., rice flour, wheat flour, and yam flour. However, to get the best-powdered products, the quality of the drying process, determines the efficiency that would be observed during the grinding process. Therefore, drying and grinding unit operations are coherent towards the production of food powder, and as such, the parameters involved should be critically considered. These lead to a number of researches being conducted with the aim of improving food powder quality by freeze-drying operations [17,18,19]. In the last few decades, a number of reviews have been conducted on the subject freeze-drying. However, most of these reviews have centered on the quality characteristics of the food product and improving the freeze-drying process with limited emphasis on the effect of the drying process on the grinding characteristics of the food [20,21,22]

Therefore, the primary objective of this review was to provide an overview of the effect of freeze-drying on the quality attributes of agricultural products and to state the influence of freeze-drying on the grinding process. A review of the mathematical models for freeze-drying will also be provided. Further discussions will be made on future trends and solution to grinding challenges.

2. Freeze-Drying of Food Produce

Freeze-drying as an industrial process involves the dehydration by sublimation of frozen ice present within the food molecules. It is a preferred method for drying foods containing compounds that are thermally sensitive and prone to oxidation since it operates at low temperatures and under a high vacuum. It has been applied to various food products such as strawberry, apple, tomato, potatoes, asparagus, and pumpkins. However, its limitations lie in the resulting shrinkage and collapse that is sometimes experienced during the drying process when not properly conducted. This led to much research conducted on freeze-drying in the last 3 decades. Recently, freeze-drying has become a welcomed idea especially in the pharmaceutical and other bioproduct industries and gradually becoming a well-utilized processing method in the food industries owing to the assumptions of product quality good perform at low temperature, a reduction in injuries caused to liable bioproducts that drying at high temperature or ambient temperature would have caused and subsequently due to its approval by the food standard bodies. However, when deciding on the type of processing methods to be used for a particular product, it is required that we look beyond the surface, as freeze-drying is reported to be accompanied by several complex interactions which may prove to be a problem at varying processing stages [23,24,25]. Consequently, chemical and physical changes may also be accompanied by freezing, heating and mass transfer within the equipment.

In lieu of this, the authors would like to state that our intention is not to rule out the importance and advantages derived from freeze-drying, but to emphasize the possible situations or occurrences that could be observed during freeze-drying as a preprocess for grinding unit operation.

2.1. Basis of Freeze-Drying

The process of freeze-drying can be visualized in terms of three steps: initial freezing, primary drying, and secondary drying. The combination of the process thus involves the dehydration of more than 99% water from the initial dilute solution, which is a direct function of the temperature rather than a function of the initial solution concentration. The steps during freeze-drying have been previously discussed, therefore, it is presented briefly in this review [26]. The initial freezing process involves the formation of ice nuclei which are dependent on factors such as the cooling rate, interfacial energy, and the interfacial morphology or the nanostructure of foreign bodies [27]. Thus, ice formation may take place at a temperature below 0 °C. A faster freezing rate results in the formation of small ice crystals within the food structure. The consequence of this is that sublimation is faster during the primary drying and slower in the secondary drying stage due to the size and formation of the ice at this level. Hence, viscosity at this level is increased as moisture is dehydrated and at some point, the saturation level is attained and there is no further increase in concentration or viscosity. Thereby at this level, the glass transition temperature which is associated with the maximum freeze concentration is said to take place. In food components such as carbohydrates, the initial freezing level may be of importance, this is because, carbohydrates can be easily verified during the freezing, based on the . The values of disaccharides and higher oligomeric sugars lie above −30 °C [28,29]. However, the is not a true thermodynamic change in state, but rather a kinetic limit at high viscosity (Detail on freeze-drying of carbohydrate will be discussed later), thus it can only be used in critical cases when the sample is difficult to freeze-dry.

The stage of primary drying is the period at which the ice crystals separate from the solute phase via sublimation. At this point, the water vapor is continuously removed from the food by keeping the pressure in the freeze drier cabinet below the vapor pressure at the surface of the ice, and subsequent removal of vapor with a vacuum pump and condensing it on refrigeration coils. This creates a partly dried food sample. The sublimation rate can, however, be affected by the sample thickness and the material cellular structure creating a constraint in the mass transfer coefficient, thereby reducing the rate of dehydration. This is because the freezing process of food materials occur either in natural convection conditions or a forced convection environment (especially for the materials at the upper surface), and because the material is made-up of cellular structures that are separated by air space and can influence the medium through which heat and mass transfer occur [30]. Nowak et al. [30] established in their study of celery the influence of plant material structure (tissue) during freeze-drying. They reported the disruption of the cell walls resulting from a mechanically damaged sample to influence the water vapor transportation to the surface of the sample for sublimation. Thus, thermal changes occurring in the sample material caused the thermal field during freezing to be uneven with a different temperature recorded for the upper layers and the lower layers. This consequently influenced the material heat transfer capability during freeze-drying. At this point, the sample temperature, therefore, becomes a critical parameter to continue the drying process. To maintain sublimation, heat energy is applied to the product to compensate for sublimation cooling. Craig et al. [31], reported that an increase of temperature by 1 °C gave rise to a faster drying process by 13%. However, the heat extracted from the drying sample as water vapor must carefully balance the amount of energy added to the sample, as an increase above the , results in melting of the ice into a solute phase. Consequently, conducting primary drying of food sample at temperature above the will lead to the production of inferior qualities. This temperature point during drying is known as “critical temperature” [32]. At the critical temperature point, the concentrated solutes in the food are sufficiently mobile to flow under the forces operating within the food structure. When this occurs, there is an instantaneous irreversible collapse of the food structure, which restricts the rate of vapor transfer and effectively ends the drying operation. Table 1, shows the collapse temperature for selected foods during freeze-drying. Therefore, in practice, there is a maximum ice temperature, a minimum condenser temperature, and a minimum chamber pressure, and these control the rate of mass transfer.

Table 1.

Collapse temperature for selected foods during freeze-drying.

The secondary drying level is a dynamic process associated with high vapor flow rates, this level of drying is much less efficient, as it involves a usage time representing 30–40% of the total process time but only a total of about 5–10% of sample moisture is dehydrated [42]. This stage begins after all the frozen water has sublimed and thus can be facilitated by increasing the product temperature. However, attention must be focused on certain delicate properties of food, such as protein. Proteins have low thermal stability and can collapse at a temperature higher than its stability, therefore it is necessary to consider the thermal stability of food products based on its component to prevent collapse. The collapse is because of the ‘bound water’ (to protein molecules) or the water molecules ‘trapped’ in the glass phase which are removed during this stage. Although sample collapse during secondary drying is generally less likely than collapse during primary drying. It is possible to induce collapse in the dried matrix by exposing the sample to a temperature above its [42]. The increased mobility of this rubbery zone after collapse can accelerate protein degradation [28]. This is observed at the ice concentration interface of the freeze-drying system. Growing evidence has shown that the loss of protein activity is due to accumulation and unfolding of the molecules at this interface which upon drying becomes solid or air. The main source for protein stress during freeze-drying, apart from the drying itself, is associated with the freezing process. The destabilizing effects of freezing are significant but yet to be fully explained, however, it is known to be highly protein-dependent. Cold denaturation of proteins is caused by a decrease in hydrophobic effects and the hydration of non-polar residues and may explain the denaturation of some proteins even though cold denaturation kinetics might be too slow to unfold the protein during the freeze-drying process [43]. In general, the capability of providing a very high quality dehydrated product by freeze-drying is an expensive method and the high costs of process limit its application to industrial scale. Therefore, the quality of dehydrated products, complex biochemical criteria, e.g., units of biological activity per milligram of product, as well as cost and time for processing, should all be taken into consideration to carry out the operation under optimal conditions.

2.2. Glass Transition during Freeze-Drying

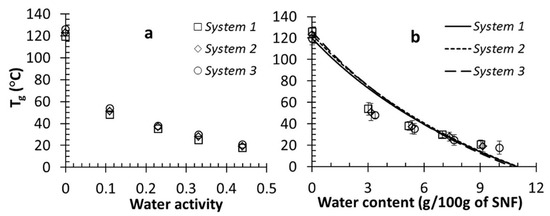

, was earlier defined as the temperature at which an amorphous system changes from the glassy to the rubbery state, and it specifically denotes the property of the amorphous material [44]. is a second-order thermodynamic phase transition altering the intrinsic properties of foods including heat capacity, free volume, and viscosity. An amorphous food is formed at non-equilibrium conditions either by removing the dispersing medium (such as water), or from the melt by cooling, or by rapid supercooling. This material is not at thermodynamic equilibrium and therefore is unstable relative to the crystalline form [45]. Since the last decade, the quality of food has become the main focus of food research. The application of the knowledge learned in the area of glass transition of polymers to food systems had contributed a lot of success to understanding and predicting the behavior of foodstuffs [46]. Dried products obtained from most of the common drying processes especially freeze-drying are predominantly in a glassy amorphous form. The mobility of the solid matrix in this state is highly limited. For the product to be stable for long periods of storage, this physical state should not be altered. When the temperature is above an amorphous solid exists in a “rubbery” state. In this state, the molecular mobility of the matrix and the reactants are accelerated, which results in an increased rate of Physico-chemical changes in dried products, such as sticking, caking, collapse, crystallization, agglomeration, loss of volatiles, browning, and oxidation [47,48,49]. In freeze-drying, collapse is a frequent problem if certain operation variables are not well set [50]. This phenomenon occurs when the solid matrix of the foodstuff can no longer support its weight, leading to drastic structural changes shown as a marked decrease in volume, increase in the stickiness of dry powders, and loss of porosity. The collapse temperature is related to the of the maximally frozen concentrated solute [51], and it represents the temperature above which the solute matrix loses its shape and quality is decreased. Therefore the relationship between rehydration and should be interpreted from porosity and collapse during freeze-drying. In most recent studies, was measured using differential scanning calorimetry (DSC), by analyzing the changes in heat capacity due to altering the heat flow over a range of temperature. Therefore, several authors prefer to report the temperature at which the begins, stating that changes in water mobility causing a quality loss in dried products beginning at this temperature [52]. In an earlier report by Anglea et al. [53], the value obtained for for several plant tissues including potato, apple, and sweet potato as well as the osmotically dehydrated potato was −45 °C. The similarity in the glass transition temperature for these fruits as well as for some osmotically treated potato samples was the foundation some research followed in determining the of plant products and thereby assumptions that of plant products are close to −45 °C is made [54]. However, in recent research by Caballero-Ceron et al. [55], the should rather be treated as a factor of the critical moisture content , and water activity in the sample, this is because the and increases with the molecular weight of the components in the glassy structure. Therefore, is certain to change with critical moisture content , and water activity in the food product. This phenomenon was reported for the carbohydrate-protein system using encapsulated trehalose-whey protein isolate as shown in Figure 1. The finding supported the phenomena that plasticizing effect by water resulted to a decrease of the [56]. Therefore, a similar plant product can show different based on the critical moisture content.

Figure 1.

Effects of water activity (a) and water content (g/100 g of SNF) (b) on the onset in anhydrous and humidified trehalose-WPI-SO systems 1, 2, 3 (stages of emulsion) stored for 360 h at 25 ± 2 °C. Source: Maidannyk et al. [56].

Furthermore, the glass transition temperature of food products has been pointed out to be responsible for the deterioration mechanisms during processing, and an indicator of food stability [57]. It has been also reported that when the temperature of some processes exceeds , the quality of foodstuffs is seriously altered [58]. However, most available literature discussed quality in terms of structure, collapse, and shrinkage effect. This is because, shrinkage and are interrelated in that significant change in volume can be noticed only if the temperature of the process is higher than the of the material at that particular moisture content [59]. Therefore, there’s a need to intensify and establish the influence of glass transition temperature on the biochemical component of food, as these parameters may also serve as a useful tool for the choice of the appropriate materials to be freeze-dried.

2.3. Selected Changes Associated with Freeze-Drying

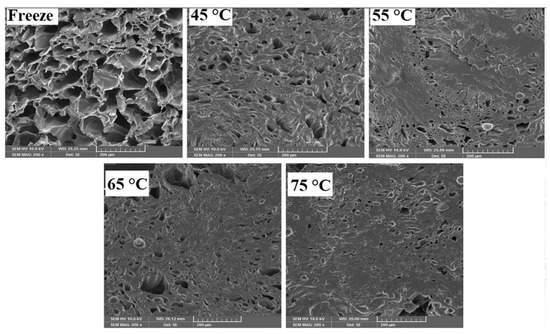

Freeze-drying is an important step to other processing units such as grinding unit operation. It is one of the basis that prepares the food sample towards grinding and as well determines to a large extent the expected quality of the product at the grinding stage. For the food technologist, properties such as shrinkage and rehydration capacity are the determinant for the quality of a dried product. During freeze-drying, the pure water present is converted to ice crystals within the solid matrix of the food. This usually modifies the structure, as the volume increases because of the lower density of ice compared to the liquid water. The interaction between kinetic constraints on the formation of crystal and thermodynamic driving forces is generally responsible for the pattern of microstructure in freeze-dried foods. Unlike in properly freeze-dried food material, shrinkage is usually observed in the morphological structures of foods that are dried at high temperatures. This occurs due to the dehydration effect resulting from the contraction of the viscoelastic matrix that was previously occupied by water. Izli and Polat [60], verified the influence of freeze-drying and convective drying method on the microstructure of the quince fruits. In the report (as presented in Figure 2), it was obvious from the photograph that the freeze-dried quince possesses a homogeneous honeycomb structure. This indicates that freeze-drying has a minimal effect on the cell structure due to dehydration via sublimation. Consequently, shrinkage was higher in the convective dried sample as a result of excess microstructural stress induced due to high moisture gradients within the product. The effect was dependent on the drying temperature, as increasing cell wall and microcavity breakage is observed in the sample as temperature increases. In essence, the porosity of the food sample increases with less shrinkage, which in turn, favors the rehydration ratio of the dried samples [60]. However, higher porosity in food also means an increase in the surface area, which implies a shorter shelf-life due to surface exposure and a higher rehydration ratio owing to the development of many open pores serving as capillaries for water uptake [61]. Consequently, higher pores also create pathways for oxygen permeability which can result in rancidity especially in food containing lipids. Therefore, it is essential to control the drying method to suit the intended purposes and achieve the desired porosity.

Figure 2.

Micrographs of quince fruits during freeze and convective drying. Source; Izli and Polat [60].

Furthermore, it should be noted that freeze-drying could be critical as it can cause cell damage to food samples e.g., fruits and vegetables. This is because, during freeze-drying, ice crystals within the food cells increase as the temperature decreases, which causes a compression force, pushing and rupturing the cell walls of the food material [61]. Thus, to minimize the damage, other methods, such as microwave-drying is used alongside freeze-drying [62].

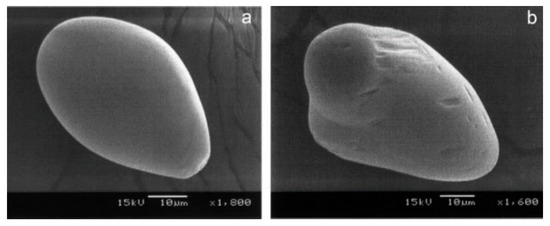

Carbohydrates are favored as excipients because they are chemically safe and can be easily vitrified during freezing by the . However, drying conditions have been reported to damage the surface and alter the interior structure of starch granules, eventually affecting their properties, such as chemical reactivity, gelatinization, retrogradation, and pasting properties. In a study conducted by Apinan et al. [63] on potato starch, it was found that freeze-dried potato starch granules displayed higher enzymatic susceptibility than native potato starch granules (dried by convective method), this occurred due to the alteration of the surface structure during the drying process (Figure 3), as hydrolysis of the starch granule are increased by -amylase. A change in the structure of mannitol and lactose has also been reported during freeze-drying [64], which occurred as a result of the separation of a frozen solution in the form of crystalline phase. This process is dependent on processing conditions. Mannitol is crystallized during freezing, whereas sucrose remains in the amorphous state right through the drying process [64]. The presence of porous particles is expected after the sublimation of ice crystals during the freeze-drying process. However, this mostly influences the sample bulk density and compressibility. Samples having greater porosity were reported to usually show smaller compressibility. In the report of Mirhosseini et al. [65], the compressibility and compatibility of powder affected its flow properties in the micro-scale through the adhesion forces between the particles. The angle of repose is also one of the critical features indicating the degree of flow characteristics of powder granules. Thus, the increase in the angle of repose is associated with decreasing the flowability characteristics, which measures the powder resistance to flow under gravity due to frictional forces resulting from the surface properties of the granules.

Figure 3.

Scanning electron micrograph of potato starch granules (a) and, Freeze-dried potato starch granules (b), Source: Apinan et al. [63].

From the textural viewpoint, freeze-drying plays a major role in determining the textural characteristics of food during chewing of ready-to-eat food e.g., dried squid, potato, apple, and mushroom. It also influences post-processing unit operations of drying such as grinding. In most food scenario, food hardness is usually evaluated based on the grinding and breakage energy requirement. Therefore it is important to maintain a good texture property for optimum efficiency during grinding to achieve high food powder quality and yield. Arumuganathan et al. [66], established the influence of freeze-drying conditions on the structural properties which influence the mushroom texture. In their report, they described maintaining the structure of mushroom resulting from freeze-drying process to be of great influence to achieving soft texture property. This is because, during cellular structure deformation during dehydration, tissues are fused together leading to an increase in firmness that causes sample hardness. However, when the original dimensions are maintained during drying, the effect of concentration of water-soluble components due to the mobility of aqueous phase is prevented and hence the resulting product is of a tender texture and consequently requires minimal breakage or grinding energy.

2.4. Drying Kinetic

The study of drying kinetics is very important to engineering and process optimization as it helps to select the best and most appropriate drying methods and control the drying process. It shows the diffusion of moisture from food and its relationship with drying variables over time [5]. It has often been used in describing the microscopic and macroscopic mechanisms of mass, heat, and momentum transfer in the drying processes, which are majorly influenced by thermodynamic conditions, the drying system, and the material properties of the agricultural product. Drying kinetics also describes the influence of moisture removal and other variables involved and thus, could be used for making appropriate choices of dryers and operating conditions for food product processing. Fick’s law type models are commonly used to represent the air-drying kinetics in the falling rate period. However, this simple model is not always adequate to represent the complex process of drying. On the other hand, some complex theories that represent the drying process from the microscopic standpoint of mass and heat transfer between each phase inside the food particle [67]. This approach thus makes use of volume averaging method to solve the governing transport equations, however, it is sometimes too complex for practical use since the required parameters are difficult or impossible to determine experimentally. For practical purposes, it is often useful to use a lumped-parameter model supported by carefully designed experimentation at a laboratory scale. Ratti and Crapiste [68] developed a lumped parameter model for hygroscopic shrinking food systems. This model is represented in Equation (1);

where water flux, is mass transfer coefficient, is water activity, is water vapor saturation, is the water vapor at equilibrium, is characteristic drying parameter, is water content in dry base and is the Biot number for mass transfer defined as;

and is the equilibrium relationship at the solid gas interface, that is obtained from

is the sample thickness (m). is effective mass diffusivity inside the sample ( is mass density. The parameter in Equation (1) was shown theoretically and experimentally to be independent of drying conditions and particle geometry, and only a function of moisture content [68] and it is represented as

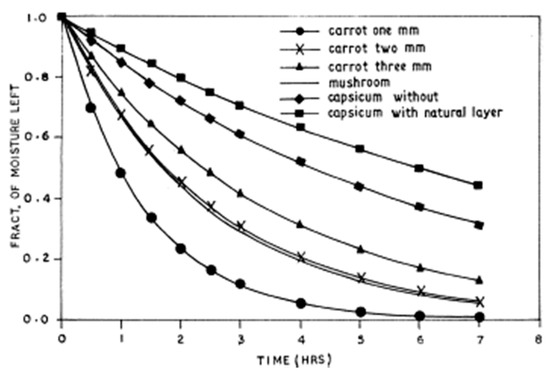

Recently simulation has been used as a preliminary evaluation of freeze-drying, and several models concerning the heat and mass transfer phenomena during freeze-drying were reported [69]. However, in most cases, adjustable parameters are needed to match the model predictions with experimental data. A new model developed by George and Datta [70], for validation of heat and mass transfer in frozen dried vegetables base on sample thickness as shown in Figure 4 was developed. This model considers the heat and mass flux which are responsible for moisture transfer from a frozen sample in the freeze-dryer due to the higher temperature of the plate on which the sample is rested during drying. Therefore, heat flux occurs through the frozen layer. Thus the model was analyzed as a function of the drying time or the effective mass diffusivity inside the sample, and it is represented as;

or

where is the effective mass diffusivity inside the sample (, is the drying time, is the initial water content (, and is the fraction of initial moisture remaining (dimensionless). is the universal gas constant, temperature (°C), thickness of sample (m), is mass density, is solid, is the vapor pressure, is the freezing point and of water at the environment. Both sublimation and desorption are taken into account in the set of coupled non-linear partial differential equations. These equations were solved numerically by using a finite element scheme, and the simulation results agreed closely to experimental data as shown in Figure 4 for fresh carrot, capsicum and mushroom for all sample thickness.

Figure 4.

Fraction of initial moisture left vs time relationship from equation . Source: George and Datta [70].

3. Relationship between Drying and Grinding

During the drying process, most foods experience volumetric changes accompanied by internal stress formation across the food structure due to their viscoelastic properties [71]. These changes, which are mostly influenced by the drying temperature, drying speed, mobility of the solid matrix, and the volume of moisture removed per time, has a substantial effect on the food mechanical strength, which is noticeable in the sensitivity to breakage, stress cracking, and dry-grinding quality [72,73]. When water is removed from the material, an unbalanced pressure is created between the inner components of the material and the external pressure, generating contracting stresses that lead to material shrinkage and changes in shape and, occasionally, hardening effects [74]. This is the reason why drying under vacuum in a freeze-dryer is suitable for foods intended to be made into powdered products as less shrinkage and high porosity as a result of the mode of mass transfer through sublimation is obtained with freeze-drying, resulting in a less hard dried product [75]. However, just as mentioned in the previous subsection, the tendency of freeze-drying modifying the structure of food product is possible especially food with starch component due to hydrolysis. For example, rice flour with high damaged starch content was reported due to rapid hydration and hydrolysis by α- and β-amylase. This damage to the food starch component during drying and subsequent grinding is a big concern to the flour production, as it is separate from the intact granules impacting both the solubility and the susceptibility to enzymatic digestion. Thus, flour with a fine particle size has more swelling power and it’s more prone to form rigid gel structures than coarse particles [76]. Despite the importance of drying to grinding, it appears that most reports studied the effect of drying on the nutritional and physicochemical properties of food and there are very limited reports focusing on the effect of drying on the grinding process. Nevertheless, since drying directly influences the process of grinding and the final powdered product, it is necessary to present useful facts from the limited information available. Therefore, the influence of the freeze-drying process on the grinding energy requirement, grindability, and the grinding yield will be discussed in the next subsections.

3.1. Energy Consumption

During grinding, mechanical energy is required to breakdown the particle size and also to overcome the frictional force between the moving parts of the machine and the food material [77]. However, this energy is a direct function of how well the drying process was carried out. Drying as a pre-process before grinding has been reported to alter the physical and chemical characteristics of the food in terms of moisture content, hardness, and size, causing a reduction in the required time and energy needed for grinding and particle size distribution [78]. The initial moisture content of several foods before grinding is one of the most important factors determining particle size distribution, grinding energy, product yield, and ground loss. Thus, it is important to control the drying process. Several reports have confirmed that food materials with high moisture prior to grinding gave rise to larger particle sizes, low product yield, and consumed higher amounts of energy than food material of low moisture content because the food with high moisture content became tough since water act as a plasticizer between the food materials, making it difficult to grind [79,80]. A few other researchers who reported a slight deviation from the general belief that moisture content increases the energy requirement during grinding stated that, although the difference in moisture content of the food samples tested was insignificant, the energy requirement for grinding was linked to some other parameters, such as the size, hardness, and fracturability of the food material as larger food sizes and hardness used more energy, irrespective of the moisture present [81]. Several factors influence the rate of dehydration during freeze-drying, such as the sample thickness, material properties, and the quality of air velocity. Therefore, it is important to pay attention to the preliminary freezing process of food products, as the possibility of sample stiffening could occur to the sample structure at the initial stage of freeze-drying, thereby preventing solute and liquid motion during freeze-drying. The implication of this is observed in the sample hardness which results in greater energy requirement at the grinding stage. Furthermore, rehydration can occur in freeze-dried sample owning to the poor quality and/or alterations of freeze-dried products. This occurrence that is sometimes encountered is generally linked to the quality of the raw material (i.e., nature of the material) and to processing conditions (operating pressure, heating temperature, freezing rate, freeze-drying process control) This is why freeze-dried products are sometimes adulterated to prevent stiffness and enhance moisture dehydration [82].

Another important feature that influences the energy requirement is drying duration. The drying duration has characteristic effects on the physical and chemical nature of food by altering its natural state, which in turn, determines the grinding characteristics of the food. However, in the freeze-drying operation, the duration of drying has more implications on the energy consumption at the drying period than at grinding operation. Generally, freeze-drying requires a long drying period to achieve a complete dehydration process. This is due to poor internal heat transfer inside the product and low working pressures. The principal heat transfer phenomenon is radiation and since there is poor ambient convection and poor conduction between surfaces making contact under vacuum. To solve this, the freezing rate is adjusted, thus affecting primarily the size of ice crystals that are formed within the matrix of food sample, and thereafter the final porosity of the freeze-dried product [83]. From the standard law of mass transfer through porous media, it can be deduced that the larger the pore size, the easier it will be to remove water vapor from the product [84]. Thus, larger pore sizes result, in a quicker dried product and a less hard food sample, which will have a fragile structure that requires minimal crushing energy. Similarly, the shrinkage effect occurring mostly due to collapse during freeze-drying especially when the sample is drying at a temperature greater than the result in increased hardness and thus influences the grinding ability [85].

The energy size reduction principles which were formulated by Kick, Bond, and Rittinger for designing grinding operations and envisioning the grinding performance has been used to determine the grinding energy requirement of various types of food materials [78,86]. In the principles, the constants, i.e., Bond’s (work index), Kick’s, and Rittinger’s constants, are determined based on the initial and final particle sizes of the material. The Equations (7)–(10) are used for the evaluation of energy and grinding constants:

where is the energy requirement for grinding, and are the mean diameters of the initial and final ground particle size of samples, respectively, and , and are the Bond, Kick, and Rittinger constants, respectively. The work index () is referred to as the energy required to grind the material with large particle size well enough for it to pass through a sieve with a diameter size of 100 μm [86].

Another method of analyzing energy requirements during the grinding process involves the use of a stress model [87]. The model was initially developed for estimating the energy requirement during wet grinding and has been recently modified for dry grinding processes [10,88]. In this model, the stresses acting upon each particle are estimated since the specific surface area or the particle sizes were found to be influenced by the overall operational parameters. The basic principle of the stress model is that, for every given food, the product fineness is dependent on the crushing process, which is determined by two conditions (i) how often each of the food particles and its resulting fragments are stressed, and thus, denoted as the ‘number of stress event’ of each sample particle , and (ii) how large the specific energy at each stress event is, which is denoted as stress intensity . Since the values obtained for and are dependent on the overall operation process parameters, when evaluating the actual energy used for grinding any feed, it is important to consider the parameters of the grinder (which is independent of the size of the food or the particle sizes obtained). Therefore, instead of focusing on the product-related model only, the grinder-related model is also considered and involves (i) the crushing behavior of the grinder, which is determined by the number of stress events supplied by the grinder per unit time, (ii) the frequency stress event (SFM), and (iii) the energy supplied to the food particle by the grinder at each stress event, known as the stress energy (SE).

In a report by Mucsi and Racz [88] on red grape seed, the dispersibility of the sample was analyzed using the product-related stress model and in this report, the stress intensity (SI) on the grinding media (GM) was used to describe the effect of the operational parameters and thus, the stress number was estimated by Equation (11):

where is the revolution number, is the resistance time, is the porosity of the grinding media, is the porosity of bulk grinding media, is the particle size, is the diameter of the grinding media, and is the material filling ratio, estimated by Equation (12):

where is the material volume and is the pore volume between the grinding media. The number of stress events and the stress intensities acting on each feed particles determine the crushing result. Since the stress intensity ) can be considered to be the specific energy consumed at each stress event (i.e., by each particle), the overall specific energy consumption of the grinder is a good measure of the product stress number and stress intensity. Therefore, at a constant stress intensity, the product fineness can be correlated either with the stress number or the specific energy input.

In a different opinion, Bunge [89] proposed that the stress intensity ) is not constant, and therefore, suggested that the stress intensity is a function of the energy density in the grinder. In physical considerations, grinding mechanisms take place in two different ways. The first is due to high-velocity gradients near the blade (crusher) and near the chamber wall (grinder wall) so that the grinding media moves with different velocities. Therefore, grinding media (particles) with high velocities bump on grinding media with lower velocities and lose a part of their kinetic energy, which can be used for crushing. The second view is that, at the area close to the grinder wall, the crushing of particles is based on centrifugal acceleration. Therefore, in this zone, the particles are stressed by pressure between the grinding media and the wall. However, the stress intensity by centrifugal force is relatively small compared to that of kinetic energy. Based on this finding, a characteristic parameter for stress intensity was derived. For the derivation, a number of assumptions were made: (i) it was assumed that only single particles are stressed intensively between the grinding media, (ii) that the tangential velocity of the grinding media is proportional to the circumferential speed of the blade, (iii) that the diameter of the blade is kept constant, and (iv) that the elasticity of the food material is small compared to that of the particles. Therefore, the stressed particle volume does not depend on the grinding media size and the stress intensity ) is expressed by Equation (13):

where is the stress intensity of the grinding media, is the diameter of the blade, is the elasticity of the food material, and is the tangential velocity. In recent work reported by Racz and Csoke [10], the authors stated that Equation (12) proposed by Bunge [89] is only possible assuming one single particle is involved and no particles are sticking to the wall of the grinder. This, however, not practicable, because during ultrafine and nano-grinding the drastically increasing specific surface is accompanied by very high free surface energy, which leads to an agglomeration phenomenon. Therefore, the effect of the adhered particles to the grinding media should be accounted for during the evaluation of stress intensity (Equation (14)):

where is the thickness of the adhered particle layer onto the grinding media surface. The advantage of the stress model for analysis energy requirement for freeze-dried sample thus lies in its ability to estimate the quality of energy required based on the porosity. Therefore, samples with varying pore value or quality can easily be shown to require different energy values for grinding. However, at the moment of making this review, no report was found for the analysis of grinding energy on sample freeze-dried. Therefore, to establish the effect of porosity in food during grinding, more work is needed to be conducted.

3.2. Grinding Yield and Morphological Characteristics

For many food materials, the grinding yield is dependent on several factors, such as the initial moisture content, shape, hardness, and the nature of the food sample, which are directly related to the drying process as the drying process usually influence the factors listed. For example, products with high moisture content resulting from insufficient drying give rise to less grinding yield, just as it requires greater energy for grinding as explained in the previous subsection, whereas a product with less moisture becomes more brittle and is easily broken and converted to more powder. During the freeze-drying process, the freezing step is one of the most important steps because it fixes the structure and the physical properties of the frozen material and, consequently, it determines the final characteristics of the freeze-dried material stability and morphology [19]. When conducting freezing at a low rate, larger pores are obtained. This consequently gives rise to a more brittle and easily broken material. This is because the sublimation of ice crystals grown within the food cellular structure leaves a dried matrix representing a fingerprint of the ice crystal sizes and shapes. However, when conducting freeze-drying at a high freezing rate, it results in a lesser growth of the ice crystal [19]. In a poorly conducted freeze-drying process, the growth of ice crystals can result in ruptures, pushes, and compression of the cells, which cause damage to the frozen tissue. This damage is more pronounced during slow freezing rate and will be discussed in the next subsection. Caparino et al. [90] reported the influence of freeze-drying on the microstructure of mango powder produced from the puree. They established that freeze-drying mango at a low temperature of −25 °C gave rise to a more porous structure due to less shrinkage and collapse and generated a fine homogenous powder. However, the report of Larder et al. [91] showed evidence that the freeze-drying treatment altered starch morphology and disrupted double helices and crystalline structures. The mechanism behind these changes was attributed to the disordering effects of the freezing of water and the sublimation of ice crystals on native starch granules. Thus, the starch hydrogels experienced volume reduction which, in turn, caused a reduction in the mesh size due to a loss of ordered structure of starch gels. However, the influence of the morphological changes experienced during freeze-drying can be dependent on the nature of the material. The crystalline structure formed during the freeze-drying of starch is packed by ordered double helices [92]. If the orderly-arranged double helices are disordered or disassociated, starch crystallinity is reduced. In the report of Larder et al. [91] on normal maize starch and high amylose maize starch during freeze-drying, the variation of the amylopectin to amylose determined the behavior of the cellular structure during freeze-drying. Normal maize starch gel contained more amylopectin but less amylose compared to the high amylose maize starch. Therefore, native maize starch showed more crystals from amylopectin, but structures were less ordered compared to the high amylose maize starch. Zhang et al. [93] stated that Amylose-derived crystals always required more energy to disassociate, indicating amylose-based reassembled aggregates may be less damaged during freeze-drying treatment. This gives food with more amylose along with an amylose-based component to keep their ordered structure with greater gel strength and resistance to destruction during freeze-drying. In regards to the ordered structure, reassembled aggregates compactness and network features of starch gels determined their changes in microstructures during freeze-drying treatment [94]. Thus, the combined effect from the freeze-drying process and the resulting influence of how the freezing process was conducted could possibly influence the grinding yield. This is because a collapsed structure during freeze-drying will result in an increase in firmness of the sample, thereby increasing hardness and requiring a high energy for an increased grinding yield.

4. Limitations in Grinding as a Result of the Drying Process

Grinding is a very important unit operation to achieve powdered food products during dry grinding because it determines, to a great extent, the quality of food materials and what the food powder will be used for, as judged by its characteristics. During grinding operations, most food is faced with limitations that result in poor grinding ability. Several research studies have reported factors that limited the grinding ability in relation to the drying processes prior to grinding [95,96]. Baudelaire [7] in the handbook of food powder, grouped the limitations observed during grinding as intrinsic (water content) and extrinsic (glass transition and caking) factors. Awareness of these factors is of great importance in optimizing the grinding process.

4.1. Impact of Freezing Rate On Crystallization and Microstructure

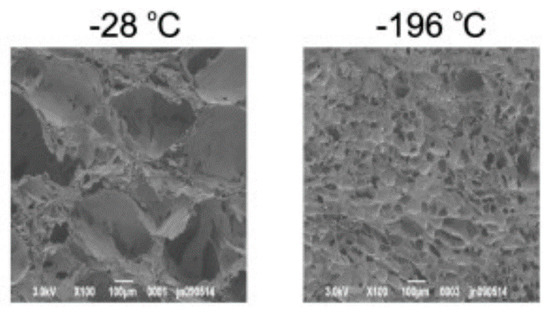

The phase transition part of the freezing process involves the conversion of water to ice through the crystallization process, and is the key step determining the efficiency of the process and the quality of the frozen product [97]. As mentioned in the early part of this review, the formation of large ice crystals within the tissue of foods results in a significant structural deformation in the tissue. On the other hand, the formation of fine crystals results in evenly distributed ice crystals within and outside the cells which prevent cell damage and an improved texture property requiring less energy during grinding. This process of crystallization consists of two main successive stages; nucleation and crystal growth [50]. For large-sized foods, the nucleation will start predominantly at the exterior surface of the food, which is exposed to the coolant [19]. The interaction between these two steps determines the crystal characteristics, i.e., size, distribution and morphology of the crystals. In fresh foods that have retained a cellular structure at the start of freezing, the nucleation can be extracellular and/or intracellular. At slow freezing rates, the nucleation is extracellular, while at fast freezing rates during cryogenic freezing the nucleation is mainly intracellular. The turgor pressure inside the cell makes it thermodynamically favorable that nucleation starts extracellular [98]. Additionally, the changes of intercellular ice nucleation depend on the ratio of freezing rate and the time scale of water permeation through the cell membrane and it is mainly determined by the temperature gradient. The freezing rate is, however, a critical parameter contributing to the distribution and morphological variation observed in the microstructure of freeze-dried food materials. Silva-Espinoza et al. [99] reported the influence of the freeze-drying rate on orange puree with added gum arabic and bamboo fiber. In the research, it was established that a slow rate of freezing resulted in the formation of bigger ice crystals and an expansion of the cells in the structure, resulting in larger pore formation. Similarly, Voda et al. [19] reported the impact of freezing conditions, such as drying at a very low temperature (−196 °C) as compared to a slightly low temperature (−28 °C) to also have an effect on the microstructure of carrot apart from the freezing rate. In their report as shown in Figure 5, the sample frozen at a lower temperature shows smaller pores as ice crystals formed at slow rate, especially during fast cooling conditions. On the other hand, slow freezing allows ice crystals to grow outside cells, causing damage by cell collapse and rupture. The implication of the resulting product from such slow freeze-drying usually would result in difficulty during the grinding of food as a consequence of increased firmness and hardness. Similarly, due to food material collapse, moisture can be trapped inside the food material, thereby causing a caking effect during grinding.

Figure 5.

SEM image of carrot freeze-dried at −28 °C and −196 °C. Source: Voda et al. [100].

4.2. Caking during Grinding

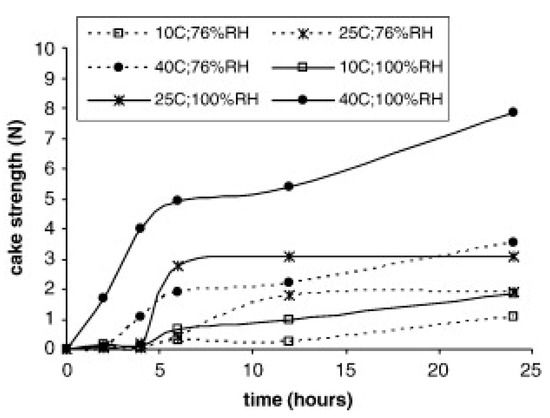

Cake formation is a major issue that occurs during drying and grinding to form food powder due to the high cohesive force existing between the powder particles [100]. Caking has been an issue for further powder utilization in the food industry and the major contributing factors are the extent of drying, the temperature during grinding, the moisture content of the food material, and the ambient humidity [101]. Many available publications stated only whether caking was observed and under what conditions it was noted. However, quantitative methods have been utilized for the characterization of caking phenomena. Among these methods for accessing powder caking are the technique of powder flowability, angle of repose, inter-particle cohesion, size reduction and particle morphology [100] Collapse, stickiness and caking are a common occurrence with improper freeze-drying process. This is due to the interparticle bridging manifesting from the loss of structure and a decrease in the sample volume when the solid matrix collapse beyond the . The occurs over a temperature range and this is often a relatively narrow range of about 10 to 20 °C for amorphous sugars. However, a much larger range of about 50 °C may be expected for the glass transition of polymers in foods. Within this temperature range, the can be referred to as the temperature initiating the onset of glass transition or the mid-point temperature of the change in specific heat capacity [101,102]. Many food samples contain amorphous glassy components, e.g., amorphous sugars, and these components are thermodynamically unstable and can crystallize. However, this requires that the molecules can move. When an amorphous component is given sufficient conditions of temperature and water content, they can mobilize as a highly viscous flow, which can make them sticky and lead to caking [103]. The of powder increases the molecules interacting at the surface of powders in contact [45]. However, some cautions should be exercised when interpreting the response of caking with . This is because many other factor associated with powder such as storage temperature, exposure time, and atmospheric humidity may alter the handling behavior and appearance of the powder therefore causing caking effect, and also because glass transition only occurs over a range of temperature (10–20 °C for amorphous sugar, and 50 °C for food polymers). Such case as found in the report of Fitzpatrick et al. [100] who stated that the resulting cake formation found in lactose was dependent on the relationship between, cohesiveness and exposure time as lactose power water content was found to increase with the exposure period leading to cake formation. However, the temperature had less significant effect except for condition at 40 °C (100% RH) which lead to greater water uptake and a resulting cake formation (Figure 6).

Figure 6.

Effect of temperature, relative humidity (RH) and exposure time on the cake strength of skim milk powder. Source: Fitzpatrick et al. [101].

Furthermore, the caking of dried mango during the grinding process is a usual occurrence that limits the process due to stickiness and this sticky nature of the powder has been described as the ‘‘amorphous viscosity’’ theory [101]. Based on this theory, the critical factor causing stickiness is viscosity and an increase in viscosity usually observed as increased grinding time results in the formation of more cakes in food powder [101]. However, from the literature reviewed, we can also deduce that not only the grinding time causes caking in the powder. For instance, caking may be due to the strengthening of the liquid junction that occurs in products during processing and storage [104]. Fortunately, to correct caking errors, as should have been evident at this point, the strict control of moisture content and storage at low temperatures, when possible, are key factors in minimizing the effects of caking of powders. Furthermore, the addition of food additives in food, such as glucose syrups in a range of about 40–60%, has also been reported to reduce the stickiness and improve the powder recovery by reducing the cohesive forces between the particles [105].

5. Effect of Grinding Technology on Food Powder Component

The content and bioavailability of the nutrients depends on food nature but also on their processing methods. Reducing material size during grinding or shearing to fine particles with 10 to 25 μm particle diameters or less increases the food products’ interfacial activities [106]. Powder with particle size below 25 μm is usually called superfine powder. At this level, the food shows an improve dissolution rate of the effective component present in the food products, by increasing effective release of the bioactive component. However, the particle size obtainable from the grinding process is a function of the type of the mill or grinding technology used. For instance, the report of Dewettinck et al. [107] indicated that the type of mill and the flow diagram used during grinding process influenced how the bran and germ are separated by the starchy endosperm. When high amounts of bran and germ are separated, the flour obtained from the starchy endosperm have lower amounts of micronutrient, because they are concentrated in bran and germ. Additionally, the type of force (e.g., shear, compression, or impact) used to break the grain for reaching the starchy endosperm and to further grind the starchy endosperm into flour can also influence the availability of nutrients [108]. This was similar to the report of Violeta et al. [109] who investigated the influence of milling method on the bioactive components of multigrain flour (base on wheat, rye, and triticle). In their report, they discovered that the multigrain flours obtained from Buhler laboratory mill had bioactive compounds values of about 1.75–2 times higher compared to the corresponding multigrain flours obtained with laboratory disc mill. These results indicate that the intensity of the grinding process varies with the milling equipment. When compared to the laboratory disc mill, the Buhler mill ensured a more intense grinding process, which resulted in higher amounts of particles originating mainly from pericarp and testa with lower size.

However, when discussing the size generated from grinding operation, precaution and proper check must be ensured. This is because the majority of bioactive compounds such as lipids, proteins, carbohydrates, and vitamins present in food are readily exposed with smaller size and they are sensitive to high acidic environment, enzyme activity, and may react with oxygen in the environment. For instance, Polyunsaturated fatty acids of the n-3 family such as docosahexaenoic acid and eicosapentaenoic acid which can be found in nuts and seed are known to have various health benefits, such as ameliorative effects on hypertension, inflammation, immune problems, and other diseases [110]. However, n-3 fatty acids are susceptible to oxidative deterioration, limiting their use in foods because of flavor degradation by oxidation. In addition, hydroperoxide and their secondary products originating due to lipid oxidation are thought to be toxic [111]. Furthermore, issues relating to health safety could also be a factor to consider, as the larger surface area increases the risk for bioaccumulation of microorganisms.

In functional foods where bioactive component often gets degraded and eventually led to inactivation due to the hostile environment, encapsulation of these bioactive components is a readily available solution that has been used for extending the shelf-life of food products by slowing down the degradation processes or prevents degradation until the product is used. Moreover, the edible coatings on various food materials could provide a barrier to moisture and gas exchange and deliver colors, flavors, antioxidants, enzymes, and anti-browning agents and could also increase the shelf-life of manufactured foods, even after the packaging is opened [112].

6. Innovations in Freeze-Drying Technology towards Achieving Grinding Efficiency

Food structure porosity is an important and distinct attribute of a freeze-dried product. Though directly related to some physical and chemical changes observed in a freeze-dried product such as rancidity and oxidation [113]. It remained a desirable attribute during food processing as well as the grinding operation of the freeze-dried products as it aids the production of a highly crispy texture. The desirability of porosity during drying is mainly due to its tendency to create a pathway through which heat and mass are transferred during the drying operation. This, in turn, affects the drying characteristics of a material and, hence, its time/temperature history, which has a direct relationship with the chemical and/or biochemical change [114]. Therefore, controlling the development of pores in food during freeze-drying is crucial. The process of pore formation during freeze-drying is affected by either the intrinsic (chemical composition and the initial structure before drying operation) and extrinsic factors (temperature, pressure, gas atmosphere) [115]. During freeze-drying, the ice sublimation creates pores - the walls of which may shrink or collapse due to surface forces, capillary suction pressure or gravity. This, however, can be controlled or reduced by lowering the surface tension through the use of a surfactant, organic solvent or the introduction of pretreatment such as blanching can be applied prior to drying operation. A review of the pretreatment methods has been recently published [116].

During the initial stage of freeze-drying, the composition of the freeze-concentrated phase surrounding the ice dictates the . The theory is one of the concepts that has been proposed to explain the process of shrinkage and collapse during the drying processes. According to this concept, there is negligible collapse (more pores) in material if it is processed below glass transition, and the higher the difference between the process temperature and the , the higher the collapse. Fan et al. [117] found that shrinkage or collapse stopped when the processing temperature was below the . In primary drying, is very relevant and the vacuum must be sufficient to ensure that sublimation is occurring. At the end of primary drying, the pore size and the porosity are dictated by ice crystal size, if the collapse of the wall of the matrix that surrounded the ice crystal does not occur [54]. Consequently, the degree of liquid saturation also affects the pore pressure of the matrix; thus, a higher saturated matrix has a greater possibility of collapse (i.e., fewer pores). Flashing off the moisture instantaneously causes increased pressure inside the matrix, which can be a counterbalancing force to the capillary forces of collapse [118]. The high viscosity (i.e., mechanical strength) of the concentrated amorphous solution around the ice may as well prevent or retard shrinkage. In the report of Bhandari et al. [45], the collapse rate increases as the viscosity of the drying matrix decrease below 107 Pa s, above its . For various food liquids during freeze-drying, the collapse temperature can vary between −5 and −60 °C depending on their composition. The collapse temperatures can be raised by the addition of high-molecular-weight materials. However, it should be noted that the increase in collapse temperature is directly related to the increase in glass transition temperature. Ratti [119] also reported that at a low drying rate, the moisture profiles prevail in the sample, stresses inside the food are minimal, and shrinkage is pronounced but uniform. At a high drying rate, the surface moisture decreased very fast so that the surface became stiff (case hardening phenomenon), limiting subsequent shrinkage. Thus, the moisture transport mechanisms and the drying rate plays an important role in the formation of pores. Consequently, this consequently will improve the grinding efficiency, provided that an adequate drying process, porosity, and moisture content are ensured.

7. Conclusions

Drying and grinding processes are the predominant unit operation that determines the quality of powdered food products. Among the several drying operation methods, freeze-drying is widely used for dehydrating agricultural products such as fruits, vegetables. Despite the long processing time and being an expensive method, it is mostly preferred due to its high final product quality. Although during freeze-drying, the glass transition temperature is a critical point that requires high consideration and monitoring to achieve a high-quality product. Energy models are used for quantifying the required energy for grinding. The stress model showed a tendency to be the most appropriate model for analyzing energy during grinding of freeze-dried samples, as it incorporates the quality of porosity, volume, the dimension of sample and as well considers the effect of adhesion and grinder properties. In addition, limitations of grinding such as the impact of freeze-drying rate on crystallization and caking occurring during freeze-drying can be solved by monitoring the glass transition temperature, ensuring adequate porosity during drying and maintaining a suitable moisture content of sample during drying and grinding.

Author Contributions

Conceptualization, T.M.O., and W.B.Y., methodology, T.M.O., and W.B.Y.; investigation, T.M.O.; writing-original draft preparation, T.M.O.; writing-review and editing, T.M.O., and W.B.Y.; supervision, W.B.Y.; project administration, W.B.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Korea Institute of Planning and Evaluation for Technology in Food, Agriculture and Forestry (IPET) through Agro and Livestock Products Safety Flow Management Technology Development Program (grant number: 318079-2), and the IPET was funded by Ministry of Agriculture, Food and Rural Affairs (MAFRA).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Afolabi, I.S. Moisture migration and bulk nutrients interaction in a drying food systems: A review. Food Nutr. Sci. 2014, 58, 692–714. [Google Scholar] [CrossRef]

- Dalmau, M.E.; Eim, V.; Rosselló, C.; Cárcel, J.A.; Simal, S. Effects of convective drying and freeze-drying on the release of bioactive compounds from beetroot during in vitro gastric digestion. Food Funct. 2019, 10, 3209–3223. [Google Scholar] [CrossRef] [PubMed]

- Deng, Y.; Luo, Y.; Wang, Y.; Yue, J.; Liu, Z.; Zhong, Y.; Zhao, Y.; Yang, H. Drying-induced protein and microstructure damages of squid fillets affected moisture distribution and rehydration ability during rehydration. J. Food Eng. 2014, 123, 23–31. [Google Scholar] [CrossRef]

- Moreira, R.; Figueiredo, A.; Sereno, A. Shrinkage of apple disks during drying by warm air convection and freeze drying. Dry. Technol. 2000, 18, 279–294. [Google Scholar] [CrossRef]

- Gupta, S.V.; Bhagyashree, N.P. Convective drying of osmo-dehydrated sapota slice. Int. J. Agric. Food Sci. Technol. 2014, 5, 219–226. [Google Scholar]

- Lee, Y.J.; Lee, M.J.; Yoon, W.B. Effect of seed moisture content on the grinding kinetics, yield and quality of soybean oil. J. Food Eng. 2013, 119, 758–764. [Google Scholar] [CrossRef]

- Baudelaire, E.D. Grinding for food powder production. In Handbook of Food Powders; Woodhead Publishing: Sawston, Cambridge, UK, 2013; pp. 132–149. [Google Scholar]

- Wu, X.; Wang, R. Factors impacting ethanol production from grain sorghum in the dry-grind process. Cereal Chem. 2007, 84, 130–136. [Google Scholar] [CrossRef]

- Karam, M.C.; Petit, J.; Zimmer, D.; Djantou, E.B.; Scher, J. Effects of drying and grinding in production of fruit and vegetable powders. Rev. J. Food Eng. 2016, 188, 32–49. [Google Scholar] [CrossRef]

- Rácz, A.; Csőke, B. Application of the product related stress model for product dispersity control in dry stirred media milling. Int. J. Miner. Process. 2016, 157, 28–35. [Google Scholar] [CrossRef]

- Kamdem, A.T.K.; Hardy, J. Influence of various conditions on meat grinding characteristics. J. Food Eng. 1995, 25, 179–196. [Google Scholar] [CrossRef]

- Vadivambal, R.; Jayas, D.S. Changes in quality of microwave-treated agricultural products—A review. Biosyst. Eng. 2007, 98, 1–16. [Google Scholar] [CrossRef]

- Liao, T.W.; Chen, L.J. A neural network approach for grinding processes: Modelling and optimization. Int. J Mach. Tools Manuf. 1994, 34, 919–937. [Google Scholar] [CrossRef]

- Pan, S.Y.; Wang, K.X.; Liu, Q. Study on physical and chemical properties of different sizes rice powder. J. Food Sci. 2004, 5. [Google Scholar]

- Zhang, M.; Tang, J.; Mujumdar, A.S.; Wang, S. Trends in microwave-related drying of fruits and vegetables. Trends Food Sci. Technol. 2006, 17, 524–534. [Google Scholar] [CrossRef]

- Camire, M.E.; Dougherty, M.P.; Briggs, J.L. Functionality of fruit powders in extruded corn breakfast cereals. Food Chem. 2007, 101, 765–770. [Google Scholar] [CrossRef]

- Wang, H.C.; Zhang, M.; Adhikari, B. Drying of shiitake mushroom by combining freeze-drying and mid-infrared radiation. Food Bioprod. Process. 2015, 94, 507–517. [Google Scholar] [CrossRef]

- Shofian, N.M.; Hamid, A.A.; Osman, A.; Saari, N.; Anwar, F.; Pak Dek, M.S.; Hairuddin, M.R. Effect of freeze-drying on the antioxidant compounds and antioxidant activity of selected tropical fruits. Int. J. Mol. Sci. 2011, 12, 4678–4692. [Google Scholar] [CrossRef]

- Voda, A.; Homan, N.; Witek, M.; Duijster, A.; van Dalen, G.; van der Sman, R.; Nijsse, J.; van Vliet, L.; Van As, H.; van Duynhoven, J. The impact of freeze-drying on microstructure and rehydration properties of carrot. Food Res. Int. 2012, 49, 687–693. [Google Scholar] [CrossRef]

- Fan, K.; Zhang, M.; Mujumdar, A.S. Recent developments in high efficient freeze-drying of fruits and vegetables assisted by microwave: A review. Crit. Rev. Food Sci. Nutr. 2019, 59, 1357–1366. [Google Scholar] [CrossRef]

- Bhatta, S.; Stevanovic Janezic, T.; Ratti, C. Freeze-Drying of Plant-Based Foods. Foods 2020, 9, 87. [Google Scholar] [CrossRef]

- Ciurzyńska, A.; Lenart, A. Freeze-drying-application in food processing and biotechnology-a review. Polish J. Food Nutri. Sci. 2011, 61, 165–171. [Google Scholar] [CrossRef]

- Harper, J.C.; Tappel, A.L. Freeze-drying of food products. Adv. Food Res. 1957, 7, 171. [Google Scholar]

- Franks, F. Freeze-drying of bioproducts: Putting principles into practice. Eur. J. Pharm. Biopharm. 1998, 45, 221–229. [Google Scholar] [CrossRef]

- Livesey, R.G.; Rowe, T.W. A discussion of the effect of chamber pressure on heat and mass transfer in freeze-drying. PDA J. Pharm. Sci. Technol. 1987, 41, 169–171. [Google Scholar]

- Zhang, Z.; Liu, X.Y. Control of ice nucleation: Freezing and antifreeze strategies. Chem. Soc.Rev. 2018, 47, 7116–7139. [Google Scholar] [CrossRef]

- Arakawa, T.; Prestrelski, S.J.; Kenney, W.C.; Carpenter, J.F. Factors affecting short-term and long-term stabilities of proteins. Adv. Drug Deliv. Rev. 2001, 46, 307–326. [Google Scholar] [CrossRef]

- Franks, F. Freeze-drying: From empiricism to predictability. The significance of glass transitions. Dev. Biol. Stand. 1992, 74, 9–18. [Google Scholar]

- Franks, F. Freeze-Drying: A Combination of Physics, Chemistry, Engineering and Economics (Papers presented at the 38th Annual Meeting). Jpn. J. Freez. Dry. 1992, 38, 5–16. [Google Scholar]

- Nowak, D.; Piechucka, P.; Witrowa-Rajchert, D.; Wiktor, A. Impact of material structure on the course of freezing and freeze-drying and on the properties of dried substance, as exemplified by celery. J. Food Eng. 2016, 180, 22–28. [Google Scholar] [CrossRef]

- Craig, D.Q.; Royall, P.G.; Kett, V.L.; Hopton, M.L. The relevance of the amorphous state to pharmaceutical dosage forms: Glassy drugs and freeze dried systems. Int. J. Pharm. 1999, 179, 179–207. [Google Scholar] [CrossRef]

- Hatley, R.H. The effective use of differential scanning calorimetry in the optimisation of freeze-drying processes and formulations. Dev. Biol. Stand. 1992, 74, 105–109. [Google Scholar] [PubMed]

- Ratti, C. Freeze drying for food powder production. In Hand Book of Food Powders; Woodhead Publishing: Sawston, UK, 2013; pp. 57–84. [Google Scholar]

- Goula, A.M.; Karapantsios, T.D.; Achilias, D.S.; Adamopoulos, K.G. Water sorption isotherms and glass transition temperature of spray dried tomato pulp. J. Food Eng. 2008, 85, 73–83. [Google Scholar] [CrossRef]

- Roos, Y.H. Glass transition temperature and its relevance in food processing. Annu. Rev. Food Sci. Technol. 2010, 1, 469–496. [Google Scholar] [CrossRef] [PubMed]

- Khalloufi, S.; El-Maslouhi, Y.; Ratti, C. Mathematical model for prediction of glass transition temperature of fruit powders. J. Food Sci. 2000, 65, 842–848. [Google Scholar] [CrossRef]

- Meda, L.; Ratti, C. Rehydration of freeze-dried strawberries at varying temperatures. J. Food Process Eng. 2005, 28, 233–246. [Google Scholar] [CrossRef]

- Tsourouflis, S.; Flink, J.M.; Karel, M. Loss of structure in freeze-dried carbohydrates solutions: Effect of temperature, moisture content and composition. J. Sci. Food Agric. 1976, 27, 509–519. [Google Scholar] [CrossRef]

- Rahman, M.S. Food Properties Handbook; CRC Press: Boca Raton, FL, USA, 2009. [Google Scholar]

- Passot, S.; Fonseca, F.; Alarcon-Lorca, M.; Rolland, D.; Marin, M. Physical characterisation of formulations for the development of two stable freeze-dried proteins during both dried and liquid storage. Eur. J. Pharm. Biopharm. 2005, 60, 335–348. [Google Scholar] [CrossRef]

- Roos, Y.; Laine, J.J. Freeze-drying and its application to some Finnish agricultural products. Agric. Food Sci. 1985, 57, 125–131. [Google Scholar] [CrossRef]

- Adams, G. The principles of freeze-drying. In Cryopreservation and Freeze-Drying Protocols; Humana Press: Totowa, NJ, USA, 2007; pp. 15–38. [Google Scholar]

- Bhatnagar, B.S.; Bogner, R.H.; Pikal, M.J. Protein stability during freezing: Separation of stresses and mechanisms of protein stabilization. Pharm. Dev. Technol. 2007, 12, 505–523. [Google Scholar] [CrossRef]

- Karmas, R.; Pilar Buera, M.; Karel, M. Effect of glass transition on rates of nonenzymic browning in food systems. J. Agric. Food Chem. 1992, 40, 873–879. [Google Scholar] [CrossRef]

- Bhandari, B.R.; Howes, T. Implication of glass transition for the drying and stability of dried foods. J. Food Eng. 1999, 40, 71–79. [Google Scholar] [CrossRef]

- Schenz, T.W. Glass transitions and product stability—An overview. Food Hydrocolloids 1995, 9, 307–315. [Google Scholar] [CrossRef]

- Chuy, L.; Labuza, T.P. Caking and stickiness of dairy-based food powders as related to glass transition. J. Food Sci. 1994, 59, 43–46. [Google Scholar] [CrossRef]

- Palzer, S. The effect of glass transition on the desired and undesired agglomeration of amorphous food powders. Chem. Eng. Sci. 2005, 60, 3959–3968. [Google Scholar] [CrossRef]

- Schmelzer, J.W.; Tropin, T.V. Glass transition, crystallization of glass-forming melts, and entropy. Entropy 2018, 20, 103. [Google Scholar] [CrossRef]

- Roos, Y.H.; Drusch, S. Phase Transitions in Foods; Academic Press: Cambridge, MA, USA, 2015; p. 5. [Google Scholar]

- Pansare, S.K.; Patel, S.M. Practical considerations for determination of glass transition temperature of a maximally freeze concentrated solution. AAPS PharmSciTech 2016, 17, 805–819. [Google Scholar] [CrossRef]