Grain Size-Controlled Mechanical Behavior and Failure Characteristics of Reservoir Sandstones

Abstract

1. Introduction

2. Mechanical Characterization of Sandstones with Different Grain Sizes

2.1. Grain Size Characteristics of the Sandstone Samples

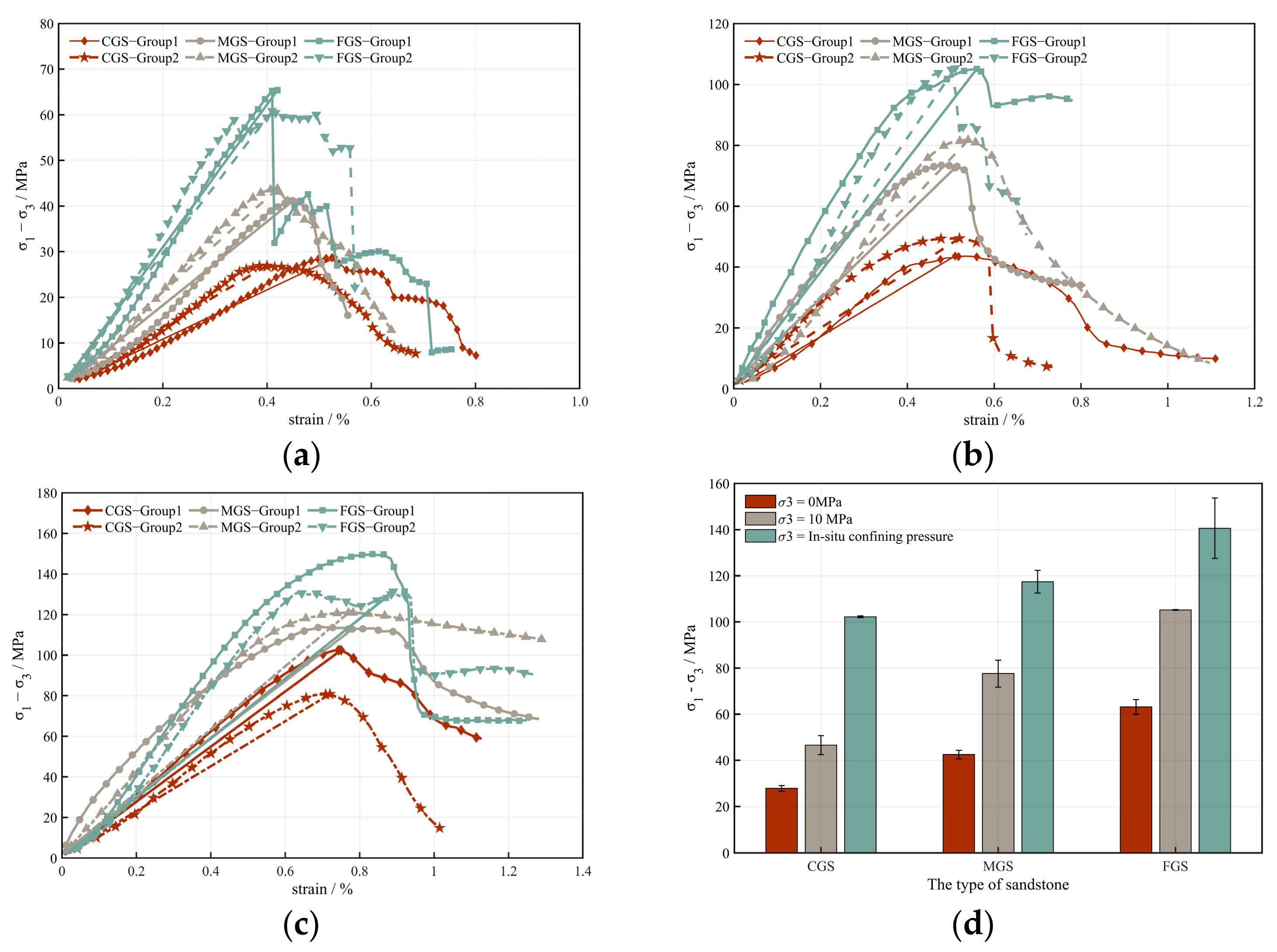

2.2. Size Dependence of Triaxial Strength and Deformation Behavior

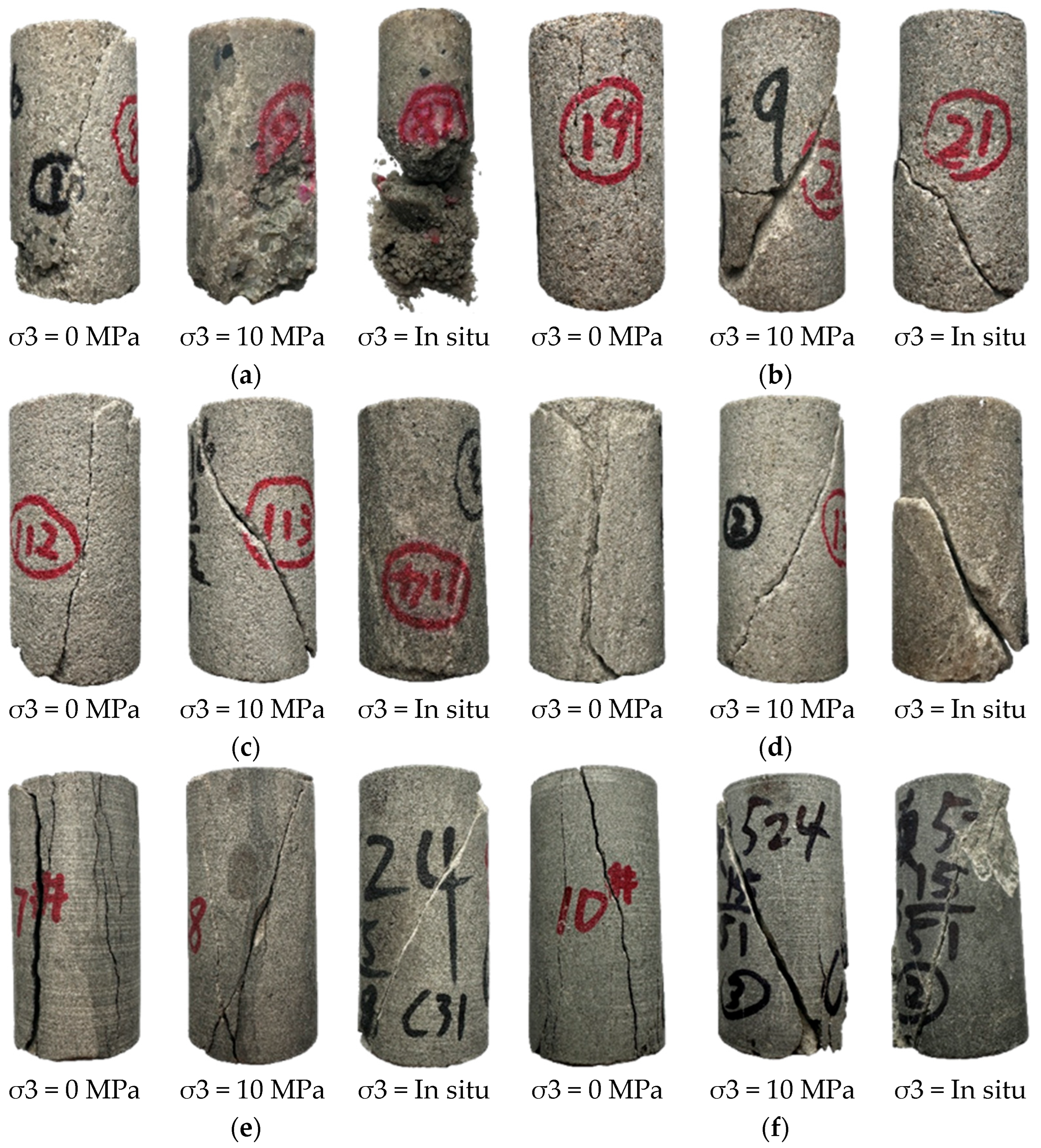

3. Micromechanical Failure Behavior of Sandstones with Different Grain Sizes

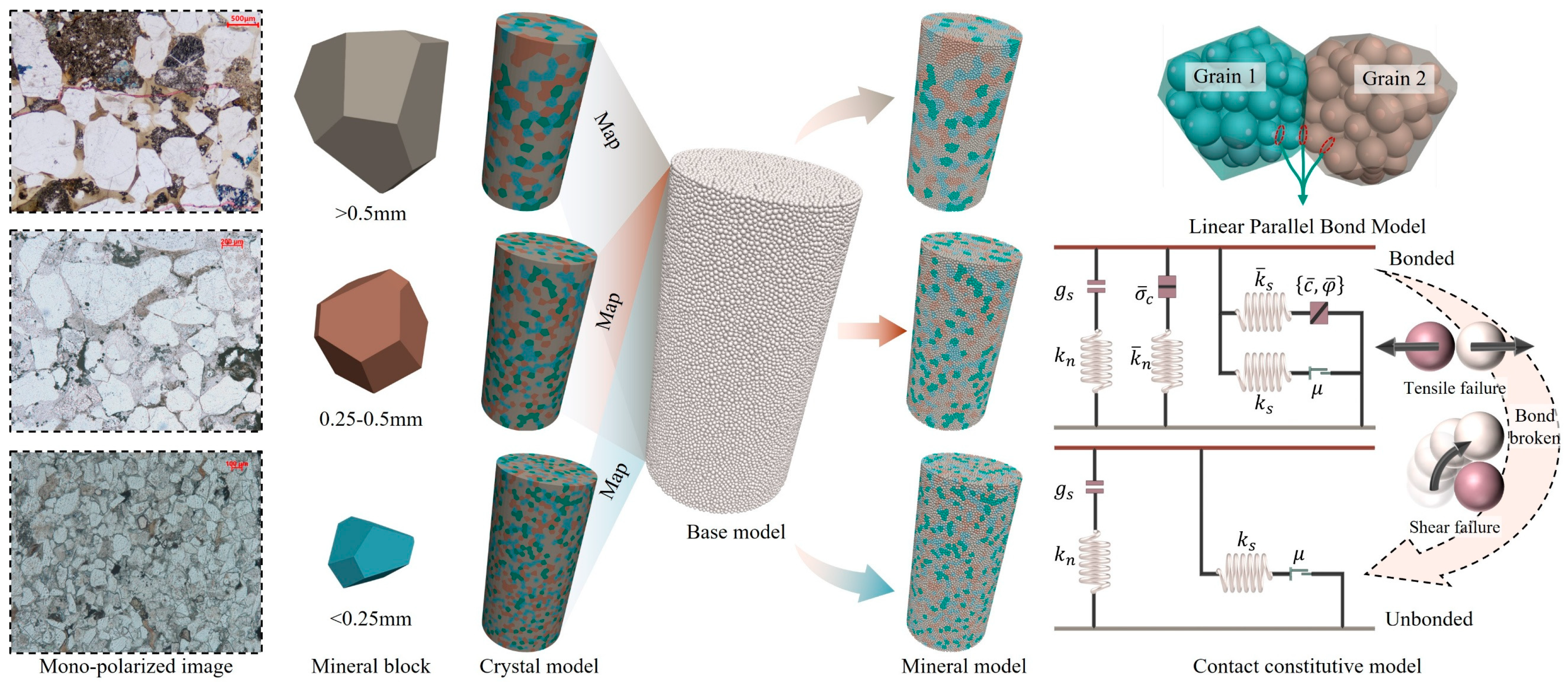

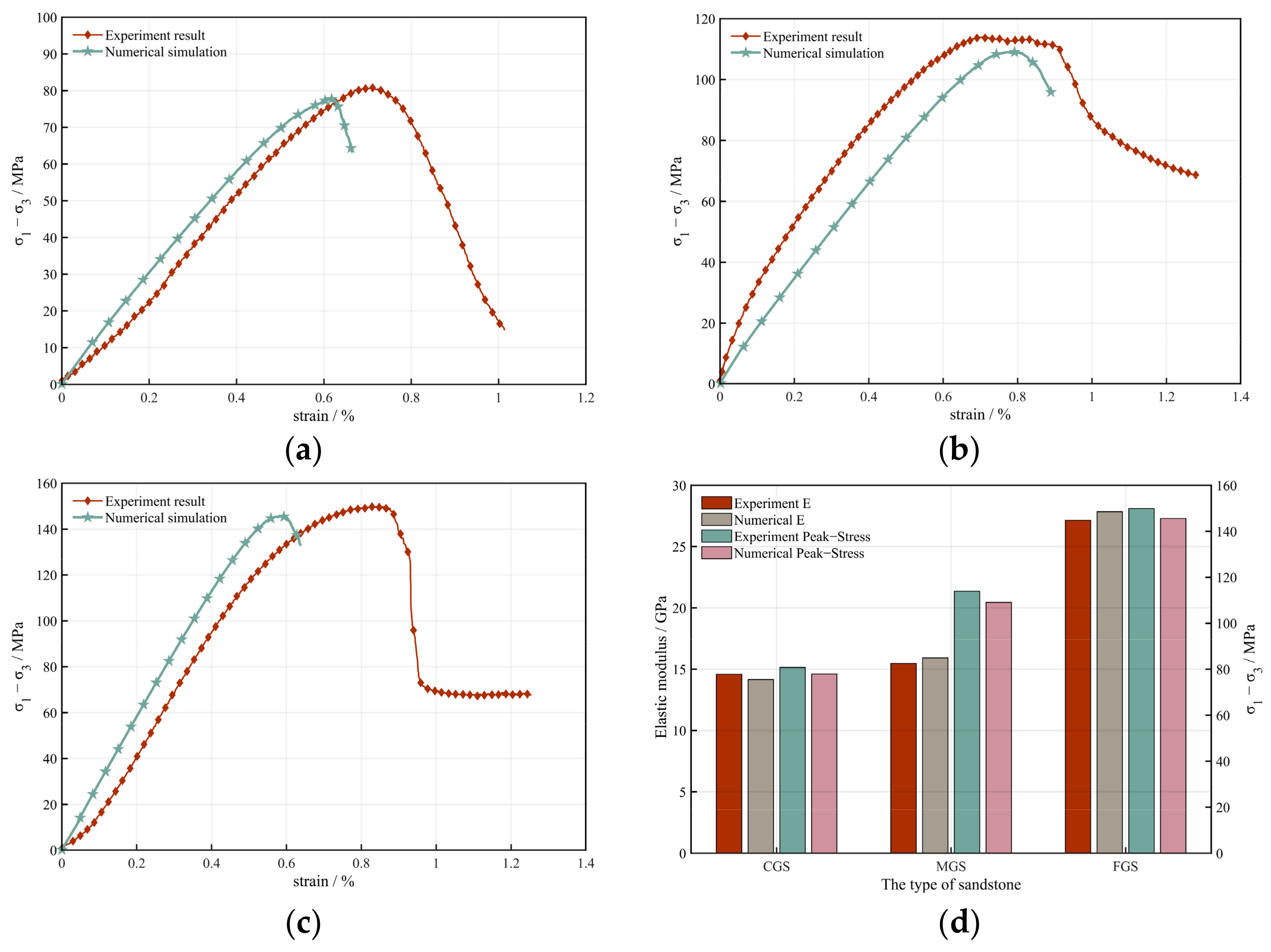

3.1. Construction and Validation of Digital Rock Models

3.2. Mechanical Responses and Microcrack Evolution in Sandstones with Different Grain Sizes

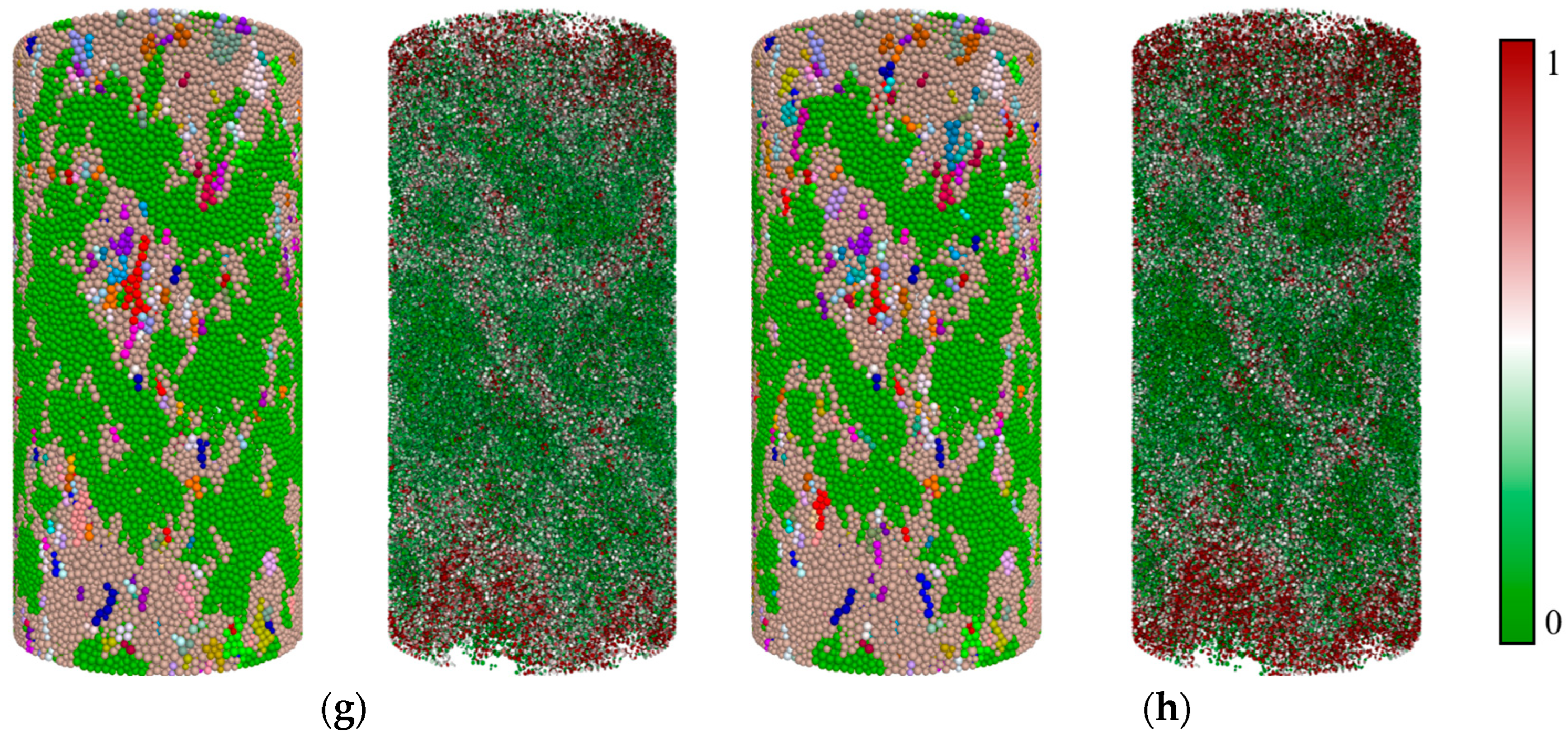

3.3. Spatiotemporal Evolution of Damage and Failure Modes in Sandstones of Different Grain Sizes

4. Conclusions

- (1)

- Laboratory results show clear grain size control on strength and ductility. Under uniaxial compression, fine-grained sandstone exhibits the highest strength but the most pronounced brittleness; coarse-grained sandstone shows lower strength but greater axial strain at peak (on average about 17% higher than that of FGS) and a more gradual post-peak response; medium-grained sandstone lies between these two end-members. With increasing confining pressure, fine- and medium-grained sandstones undergo a marked transition toward more ductile behavior, whereas coarse-grained sandstone exhibits only limited ductility enhancement, indicating weak confinement sensitivity.

- (2)

- The calibrated DEM simulations reproduce these macroscopic trends and clarify the link between crack evolution and mechanical response. Under uniaxial loading, fine-grained sandstone is dominated by intergranular tensile cracking, leading to splitting-type failure along grain boundaries, whereas coarse-grained sandstone develops a higher proportion of intragranular cracks associated with more distributed deformation. Intragranular cracks account for about 22.1%, 34.7% and 42.8% of the total number of microcracks in FGS, MGS and CGS, respectively. As confining pressure increases, the failure process evolves from intergranular tension-dominated behavior to a mixed intragranular tension–shear mechanism, accompanied by progressive enhancement in macroscopic ductility.

- (3)

- Analyses of crack aperture distributions and fragment development reveal a continuous transition from microscopic damage accumulation to macroscopic instability. Fine-grained sandstone under uniaxial compression rapidly develops a through-going tensile fracture band, and fragments separate along a distinct splitting plane, characteristic of brittle failure. In contrast, coarse-grained sandstone at high confinement forms central shear bands combined with localized end failure; although post-peak cracking continues, the response remains governed by early shear localization and retains an overall brittle nature.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jaeger, J.C.; Cook, N.G.W.; Zimmerman, R. Fundamentals of Rock Mechanics; John Wiley & Sons: Hoboken, NJ, USA, 2009. [Google Scholar]

- Hallbauer, D.K.; Wagner, H.; Cook, N.G.W. Some observations concerning the microscopic and mechanical behaviour of quartzite specimens in stiff, triaxial compression tests. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1973, 10, 713–726. [Google Scholar] [CrossRef]

- Tapponnier, P.; Brace, W.F. Development of stress-induced microcracks in Westerly granite. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1976, 13, 103–112. [Google Scholar] [CrossRef]

- Kranz, R.L. Microcracks in rocks: A review. Tectonophysics 1983, 100, 449–480. [Google Scholar] [CrossRef]

- Atkinson, B.K. Subcritical crack growth in geological materials. J. Geophys. Res. Solid Earth 1984, 89, 4077–4114. [Google Scholar] [CrossRef]

- Fredrich, J.T.; Evans, B.; Wong, T.F. Effect of grain size on brittle and semibrittle strength: Implications for micromechanical modelling of failure in compression. J. Geophys. Res. Solid Earth 1990, 95, 10907–10920. [Google Scholar] [CrossRef]

- Peng, J.; Wong, L.N.Y.; Teh, C.I. Influence of grain size heterogeneity on strength and microcracking behavior of crystalline rocks. J. Geophys. Res. Solid Earth 2017, 122, 1054–1073. [Google Scholar] [CrossRef]

- Fonseca, J.; Bésuelle, P.; Viggiani, G. Micromechanisms of inelastic deformation in sandstones: An insight using x-ray micro-tomography. Géotech. Lett. 2013, 3, 78–83. [Google Scholar] [CrossRef]

- Wang, W.; Nardelli, V.; Coop, M.R. Micro-mechanical behaviour of artificially cemented sands under compression and shear. Géotech. Lett. 2017, 7, 218–224. [Google Scholar] [CrossRef]

- Brace, W.F.; Bombolakis, E.G. A note on brittle crack growth in compression. J. Geophys. Res. 1963, 68, 3709–3713. [Google Scholar] [CrossRef]

- Wong, T.; Baud, P. The brittle-ductile transition in porous rock: A review. J. Struct. Geol. 2012, 44, 25–53. [Google Scholar] [CrossRef]

- Heap, M.J.; Baud, P.; Meredith, P.G.; Bell, A.F.; Main, I.G. Time-dependent brittle creep in Darley Dale sandstone. J. Geophys. Res. Solid Earth 2009, 114. [Google Scholar] [CrossRef]

- Baud, P.; Meredith, P.; Townend, E. Permeability evolution during triaxial compaction of an anisotropic porous sandstone. J. Geophys. Res. Solid Earth 2012, 117. [Google Scholar] [CrossRef]

- Potyondy, D.O.; Cundall, P.A. A bonded-particle model for rock. Int. J. Rock Mech. Min. Sci. 2004, 41, 1329–1364. [Google Scholar] [CrossRef]

- Hazzard, J.F.; Young, R.P. Simulating acoustic emissions in bonded-particle models of rock. Int. J. Rock Mech. Min. Sci. 2000, 37, 867–872. [Google Scholar] [CrossRef]

- Scholtès, L.; Donzé, F.V. A DEM model for soft and hard rocks: Role of grain interlocking on strength. J. Mech. Phys. Solids 2013, 61, 352–369. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, Y.; Li, G.; Li, Z.; Feng, J.; Wang, K. Mesoscopic modeling approach and application based on rock thin slices and nanoindentation. Comput. Geotech. 2024, 165, 105875. [Google Scholar] [CrossRef]

- Yan, D.; Zhao, L.; Wang, Y.; Zhang, Y.; Cai, Z.; Song, X.; Geng, J. Heterogeneity indexes of unconventional reservoir shales: Quantitatively characterizing mechanical properties and failure behaviors. Int. J. Rock Mech. Min. Sci. 2023, 171, 105577. [Google Scholar] [CrossRef]

- Sun, Y.; Kwok, C.Y.; Duan, K. Size effects on crystalline rock masses: Insights from grain-based DEM modeling. Comput. Geotech. 2024, 171, 106376. [Google Scholar] [CrossRef]

- Yan, D.; Zhao, L.; Song, X.; Tang, J.; Zhang, F. Fracability evaluation model for unconventional reservoirs: From the perspective of hydraulic fracturing performance. Int. J. Rock Mech. Min. Sci. 2024, 183, 105912. [Google Scholar] [CrossRef]

- Feng, J.; Yang, X.; Zhang, Y.; Li, G.; Li, Z.; Wang, Y.; Kuang, X. Mechanical Properties and Crack Evolution Characteristics of Sandstone Under Tensile Stress Based on DIC and Digital Simulation Technology. Rock Mech. Rock Eng. 2025, 1–20. [Google Scholar] [CrossRef]

- Zhang, T.; Yu, L.; Peng, Y.; Ju, M.; Yin, Q.; Wei, J.; Jia, S. Influence of grain size and basic element size on rock mechanical characteristics: Insights from grain-based numerical analysis. Bull. Eng. Geol. Environ. 2022, 81, 347. [Google Scholar] [CrossRef]

- Peng, J.; Wong, L.N.Y.; Teh, C.I. Effects of grain size-to-particle size ratio on micro-cracking behavior using a bonded-particle grain-based model. Int. J. Rock Mech. Min. Sci. 2017, 100, 207–217. [Google Scholar] [CrossRef]

- Peng, J.; Wong, L.N.Y.; Teh, C.I. Influence of grain size on strength of polymineralic crystalline rock: New insights from DEM grain-based modeling. J. Rock Mech. Geotech. Eng. 2021, 13, 755–766. [Google Scholar] [CrossRef]

- Liang, K.; Xie, L.Z.; He, B.; Zhao, P.; Zhang, Y.; Hu, W. Effects of grain size distributions on the macro-mechanical behavior of rock salt using micro-based multiscale methods. Int. J. Rock Mech. Min. Sci. 2021, 138, 104592. [Google Scholar] [CrossRef]

- Ashby, M.F.; Sammis, C.G. The damage mechanics of brittle solids in compression. Pure Appl. Geophys. 1990, 133, 489–521. [Google Scholar] [CrossRef]

- Sammis, C.G.; Ashby, M.F. The failure of brittle porous solids under compressive stress states. Acta Metall. 1986, 34, 511–526. [Google Scholar] [CrossRef]

- Scholz, C.H. The frequency-magnitude relation of microfracturing in rock and its relation to earthquakes. Bull. Seismol. Soc. Am. 1968, 58, 399–415. [Google Scholar] [CrossRef]

- Yan, D.; Zhao, L.; Lu, M.; Zhang, Y.; Chen, M.; Zhang, F. Quantifying the effects of laminae on mechanical and damage characteristic of shale: Numerical investigation on digital rock models. Int. J. Rock Mech. Min. Sci. 2025, 194, 106218. [Google Scholar] [CrossRef]

- Yang, Z.; Tao, M.; Ranjith, P.G. Novel insights into grain size effect of stressed crystalline rock using weakened grain boundary model. Int. J. Rock Mech. Min. Sci. 2025, 189, 106098. [Google Scholar] [CrossRef]

- Xu, J.; Zhang, Y.; Rutqvist, J.; Hu, M.S.; Wang, Z.Z.; Tang, X.H. Thermally induced microcracks in granite and their effect on the macroscale mechanical behavior. J. Geophys. Res. Solid Earth 2023, 128, e2022JB024920. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, Q.; Feng, G.; Lyu, Q.; Liu, S.; Wang, Y.; Tang, X. Upscaling mechanical properties of shale obtained by nanoindentation to macroscale using accurate grain-based modeling (AGBM). Energy 2025, 314, 134126. [Google Scholar] [CrossRef]

- Tang, X.; Zhang, Y.; Xu, J.; Rutqvist, J.; Hu, M.; Wang, Z.; Liu, Q. Determining Young’s modulus of granite using accurate grain-based modeling with microscale rock mechanical experiments. Int. J. Rock Mech. Min. Sci. 2022, 157, 105167. [Google Scholar] [CrossRef]

- Wang, T.; Huang, H.; Zhang, F.; Han, Y. DEM-continuum mechanics coupled modeling of slot-shaped breakout in high-porosity sandstone. Tunn. Undergr. Space Technol. 2020, 98, 103348. [Google Scholar] [CrossRef]

| Mineral Type | Linear and Bond Elastic Modulus/GPa | Contact Stiffness Ratio | Cohesive Strength/MPa | Tensile Strength/MPa | Friction Angle/° | Friction Coefficient |

|---|---|---|---|---|---|---|

| Quartz | 98 | 1.5 | 1800 | 78 | 33 | 0.5 |

| K-Feldspar | 86 | 1.5 | 600 | 65 | ||

| Plagioclase | 74 | 1.5 | 560 | 61 | ||

| Clay | 6.3 | 1.5 | 270 | 32 | ||

| CGS—Interphase | 0.09 | 1 | 0.06 | 0.08 | 1 | 1 |

| MGS—Interphase | 0.14 | 1 | 0.09 | 0.11 | 1 | 1 |

| FGS—Interphase | 0.18 | 1 | 0.12 | 0.15 | 1 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, R.; Liu, S.; Zhang, X.; Li, G.; Yang, X.; Nie, W.; Zhong, J.; Li, G. Grain Size-Controlled Mechanical Behavior and Failure Characteristics of Reservoir Sandstones. Processes 2025, 13, 4067. https://doi.org/10.3390/pr13124067

Yan R, Liu S, Zhang X, Li G, Yang X, Nie W, Zhong J, Li G. Grain Size-Controlled Mechanical Behavior and Failure Characteristics of Reservoir Sandstones. Processes. 2025; 13(12):4067. https://doi.org/10.3390/pr13124067

Chicago/Turabian StyleYan, Ronghui, Sanjun Liu, Xiaogang Zhang, Gaoren Li, Xu Yang, Wancai Nie, Jibin Zhong, and Gao Li. 2025. "Grain Size-Controlled Mechanical Behavior and Failure Characteristics of Reservoir Sandstones" Processes 13, no. 12: 4067. https://doi.org/10.3390/pr13124067

APA StyleYan, R., Liu, S., Zhang, X., Li, G., Yang, X., Nie, W., Zhong, J., & Li, G. (2025). Grain Size-Controlled Mechanical Behavior and Failure Characteristics of Reservoir Sandstones. Processes, 13(12), 4067. https://doi.org/10.3390/pr13124067