1. Introduction

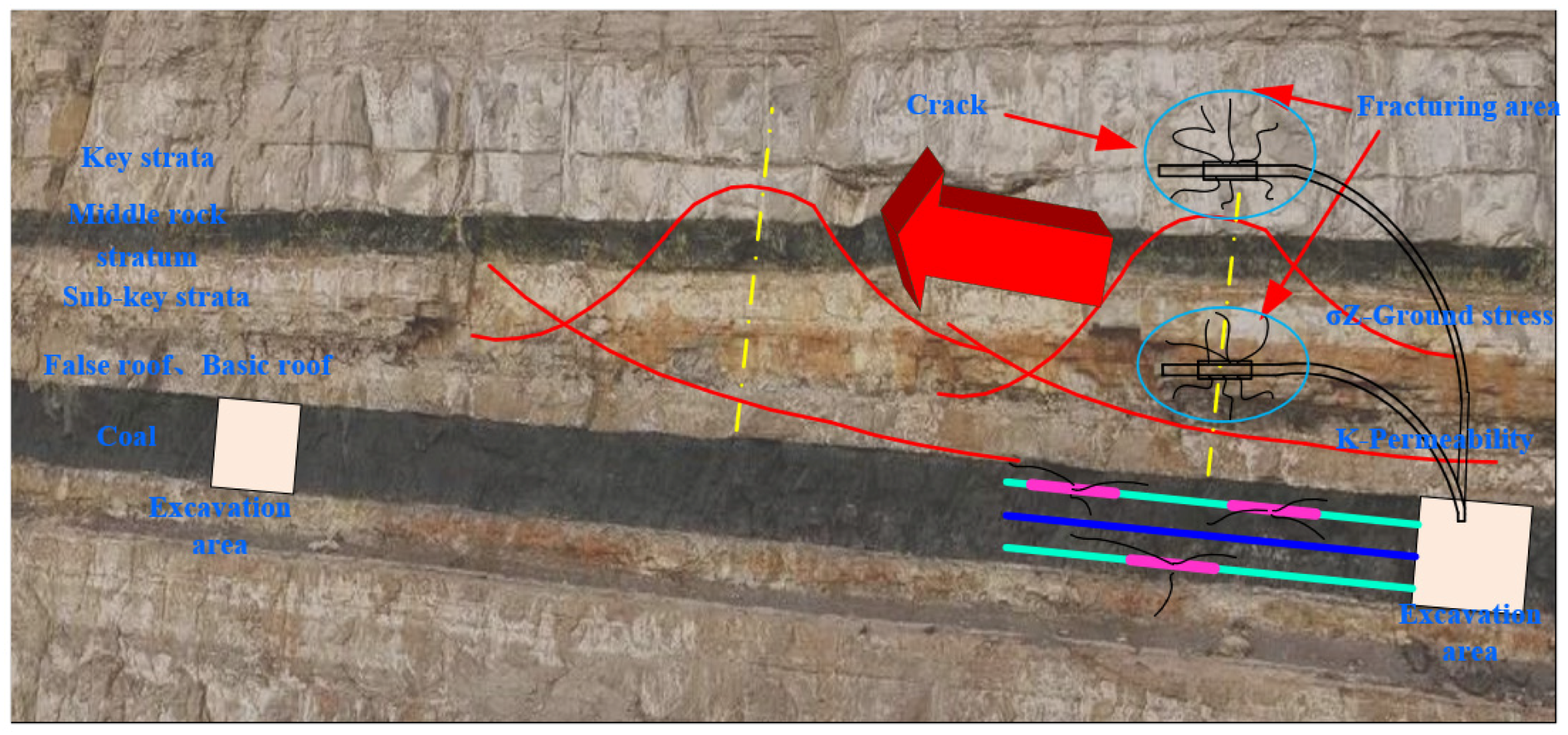

As coal mining operations progressively extend to greater depths, the associated challenges intensify accordingly. Under the complex multi-field coupling conditions prevalent in deep mining environments, coal seam permeability is significantly reduced, substantially increasing the difficulty of regional gas prevention and control. To address these issues, this paper proposes an innovative methodology termed “synergistic pressure relief and static fracturing for anti-reflection.” This approach leverages the combined effects of staged high-pressure hydraulic fracturing in key roof strata and static fracturing of the coal body using solid expansion materials. The integrated process achieves comprehensive stress unloading, enables long-term anti-reflection through sustained pressure release, and ensures low-damage modification of the coal seam via static expansion, thereby establishing a complete technical framework for enhanced gas control and ground stability in deep mining contexts.

In the pressure-relief process following key stratum fracturing, Wang [

1] established a mechanical model of the surrounding rock in roadways to investigate stress distribution characteristics within the plastic zone and implemented full-section bolting–grouting reinforcement technology. Yu [

2] derived analytical expressions for the vertical and horizontal stress distributions in the roof and analyzed the distribution and evolution behavior of the stress and displacement fields in the surrounding rock through numerical simulations. Ma [

3] and Xu [

4] observed that increased mining activity in the working face led to elevated vertical stress, increased maximum shear stress, and expansion of the plastic zone in the surrounding rock, with deformation and failure predominantly occurring in the floor, sides, and corners of the roadway. Meng [

5] proposed a combined support design to control large deformations in deep soft rock roadways and alleviate stress in the surrounding rock. Based on key stratum theory, Zou [

6] analyzed how the movement of key strata controls surface subsidence. Yu [

7,

8,

9] indicated that ground hydraulic action alters the fracture structure of high-level rock strata and mitigates stress concentration around the working face. Gao [

10] modified the formation’s structural characteristics through fracturing, thereby reducing energy release intensity and the movement range of the overburden. Zhu [

11] performed cutting and fracturing in the roof to sever the mechanical connection between the goaf roof and the roadway roof, enhancing roadway stability. Yang [

12] demonstrated via simulation and monitoring that a novel support design successfully restrains large deformations in roadways. Sun [

13] investigated the use of coal–concrete composites produced by jet grouting technology to improve support in soft coal seams adjacent to roadways.

The application of expansion agent-based static cracking technology is progressively expanding in mining engineering. Among recent studies, Zhang [

14] systematically re-viewed the state of research on expansion cracking techniques and emphasized the critical influence of drilling parameters on cracking effectiveness. Their findings indicate an inverse correlation between optimal borehole spacing and borehole diameter, with a spacing of 0.8 m identified as suitable for a 40 mm diameter borehole. Furthermore, a damage mechanics model of coal was developed, unveiling the dynamic evolution of crack propagation and offering theoretical guidance for optimizing parameters of static fracturing agents. Jiao Dengming [

15] introduced a method involving blasting cracking with proppant-containing cartridges, in which explosions drive proppants into fractures to maintain conductivity. A comparative analysis revealed that static crushing agents offer superior performance in preserving fracture stability. When the maximum proppant migration distance reached 175 mm, permeability increased by 43%, suggesting a promising approach for the synergistic use of static crushing agents and proppants. Liu Wuze [

16] tackled gas accumulation issues in the upper corners of high-level drainage roadways by developing a static fracturing agent technology to induce roof fracturing and enhance permeability. Through numerical simulations and field validation, a borehole spacing of 0.8 m for charge placement was identified, which increased gas extraction concentration by 2–3 times and reduced upper-corner gas concentration by 68%. The water–cement ratio and reaction temperature were also optimized to balance expansive pressure and operational safety. Cui Xiao [

17,

18] established a multi-field coupling model incorporating thermal, seepage, stress, and chemical fields, elucidating the spatiotemporal evolution of coal permeability under static cracking agent action: permeability decreases during the elastic compression stage and increases exponentially in the yield damage stage. By optimizing the CaO-C3S-C3A system, the retardation time was extended to 175 min and the reaction temperature lowered to 100 °C, effectively eliminating the risk of coal spontaneous combustion. Field tests demonstrated a 1.6-fold increase in gas extraction volume. Xie Xiong [

19,

20] experimentally confirmed that static cracking agents can generate expansion pressures of 30–50 MPa, sufficient to fracture coal and surrounding rock strata. They proposed a three-stage permeability enhancement mechanism involving crack initiation, propagation, and coalescence, and identified the water–cement ratio, borehole diameter, and temperature as key factors influencing expansion performance.

Existing permeability enhancement methods suffer from several limitations: fractures created by hydraulic fracturing are prone to re-closure under in situ stress, leading to non-durable permeability improvement; while blasting fracturing effectively breaks coal, it generates intense dynamic disturbances that can trigger coal and gas outbursts and severely damage surrounding rock integrity; and thermal or chemical injection methods face the challenges of high cost, operational complexity, and potential environmental pollution.

In contrast, the synergistic “key stratum fracturing–coal seam static fracturing” approach proposed in this study demonstrates distinct advantages: key stratum fracturing enables long-term regional stress field control, fundamentally reducing coal seam stress, and static expansion fracturing creates stable fracture networks within the coal seam through low-disturbance means, eliminating dynamic disturbance risks. This combination achieves an organic integration of “regional pressure relief” and “local permeability enhancement,” offering both long-term effectiveness and safety, making it particularly suitable for permeability enhancement in deep high-stress, low-permeability coal seams.

3. Results (Experimental Investigation)

3.1. Experimental Study on Key Strata Fracturing

Previous studies have established the fundamental role of key strata in controlling ground pressure behavior. Kuang [

22] identified the fracture and movement of overlying key strata as the root cause of mining hazards such as rib spalling and roof collapse, demonstrating that techniques including hydraulic fracturing can effectively weaken these strata to mitigate energy release. Kong [

23] revealed significant interlayer differences in ground pressure influence through microseismic monitoring during thick seam extraction. Yan [

24] attributed pressure generation primarily to structural instabilities in overlying rock masses, while Zhang [

25] addressed mining-induced vibrations by employing deep-hole blasting to modify stress distribution and energy accumulation. Complementing these, Zhou [

26] systematically investigated the mechanical behavior, permeability evolution, and fracture tendencies of coal under various pressure-relief conditions, analyzing the interplay between effective stress and the Klinkenberg effect across different relief modes.

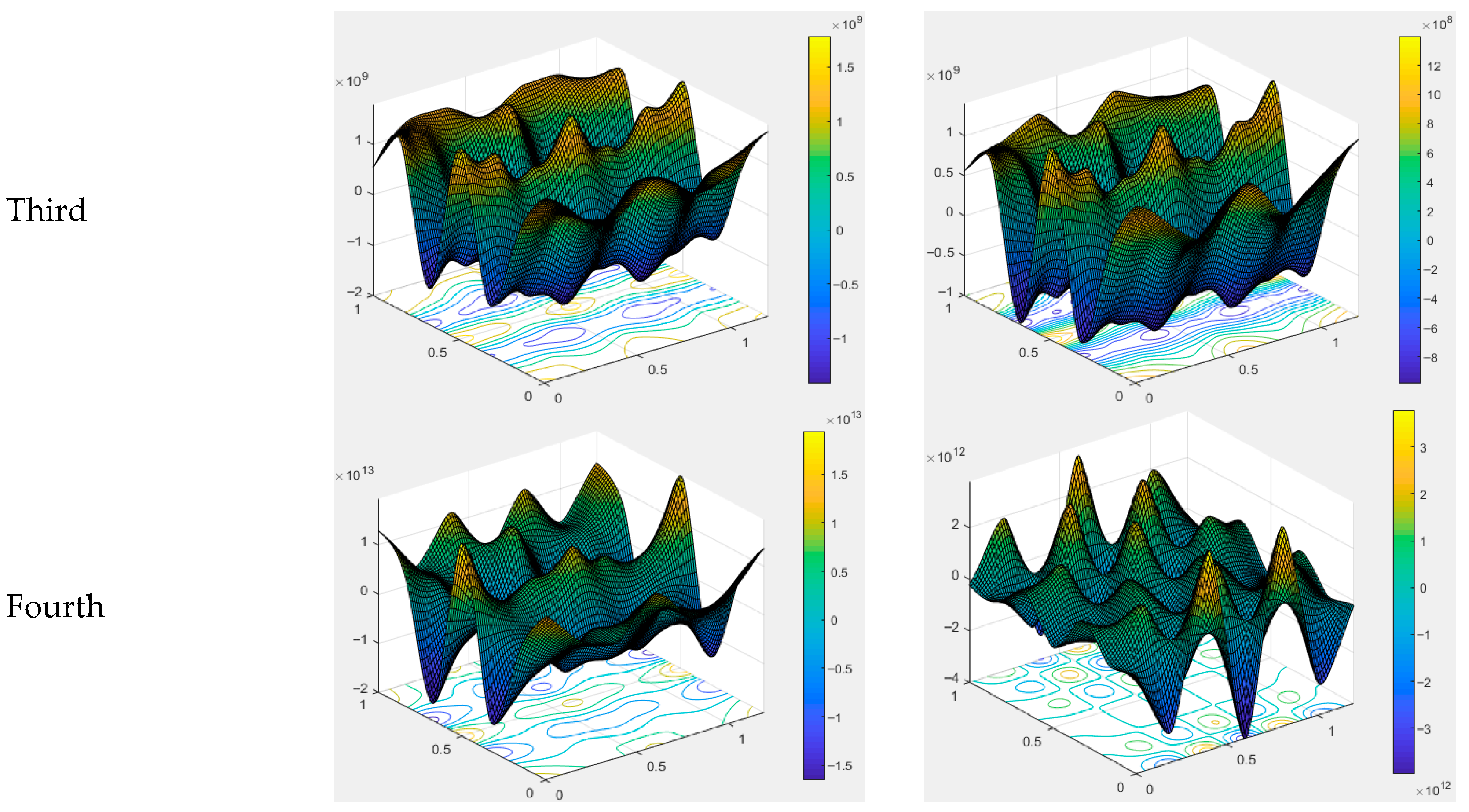

Building upon previous findings that weakening key rock strata effectively mitigates mine ground pressure risks and enhances mining safety, this study posits that interrupting stress transfer within these strata can reduce stress concentrations in underlying coal seams and attenuate dynamic coal failure. To investigate this, a layered overburden model was constructed using a triaxial loading impact test system. The model comprised four layers with thicknesses of 30 mm, 20 mm, 30 mm, and 20 mm from bottom to top, where the lowest layer represented a soft coal seam. The third layer was designated as the key stratum, incorporating four working conditions: an intact (non-fractured) zone and three pre-weakened zones with areas of 20 × 20 mm, 30 × 30 mm, and 40 × 40 mm. Pressure sensors were installed beneath the treated zones, with symmetric reference groups established for comparative impact testing, as illustrated in

Figure 2. Data from the intact zone, showing consistent impact response, are omitted here for brevity. The impact tests were conducted under triaxial loading conditions, yielding the pressure curves presented in

Figure 3. Analysis of these curves reveals that, under impact loading, the 20 × 20 mm fracturing zone exhibited a pressure of 1.15 MPa, compared to 1.49 MPa in the non-fractured zone, resulting in a stress attenuation ratio of 22.7% between the two regions. For the 30 × 30 mm fracturing zone, the post-impact pressure measured 0.95 MPa versus 1.57 MPa in the intact zone, corresponding to an attenuation ratio of 39.8%. In the case of the 40 × 40 mm fracturing zone, pressures of 0.897 MPa and 1.61 MPa were recorded in the treated and untreated areas, respectively, achieving an attenuation ratio of 44.1%. These results demonstrate that increasing the fracturing area consistently degrades the efficiency of stress transfer, confirming that the targeted fracturing of key strata effectively disrupts stress propagation pathways.

Following the treatment of the key strata, a distinct stress arch develops above the fractured zone. This structure effectively interrupts the transmission pathway of in situ stress, thereby reducing the ground stress burden on the underlying coal seam. The results indicate that this technique not only alleviates the stress state within the coal seam but also mitigates dynamic failures induced by high ground stress, such as rock bursts and coal-gas outbursts. The experimental observations align well with the theoretical analysis, confirming that the stress transfer path is effectively severed within the pressure-relief zone. Based on this validated mechanism, the study proposes the implementation of high-pressure staged hydraulic fracturing as a technically viable method for achieving controlled stress transfer interruption.

3.2. Determination of Key Rock Strata Position

The determination of the key stratum can be calculated using the key stratum displacement theory. The key stratum is a hard rock layer that can control the collapse of the overlying strata. The location of the hard rock layer can be identified by calculating the load magnitude of each rock layer, and the fracture spacing of the hard rock layer can be computed. By comparing the fracture spacing of the hard rock layers, the position of the key stratum can be determined. The mechanical properties of the overlying strata of the coal seam are shown in

Table 1.

(1) Hard rock stratum determination

According to Equation (18), we can calculate the load (q

m) n borne by the overlying strata, which includes its own n layers and the m layers above them.

In the equation, Ei is the elastic modulus of the i-th layer of rock, Gpa; ri is the unit weight of the i-th layer of rock, kg/m3; and hi is the thickness of the i-th layer of rock.

If the inequality relationship of Equation (19) is satisfied, it can be determined that the layer is a hard rock layer.

According to the calculation of Equations (18) and (19), the second layer, the fifth layer, and the eleventh layer in the overlying fracture zone of the working face are hard rock strata.

(2) Calculation of breaking distance of hard rock stratum

From the above, the second, fifth, and eleventh strata above the coal seam are all hard rock strata. According to the mechanics of materials, the overlying strata of the coal seam are simplified as a mechanical model with fixed ends. When the normal stress of the rock stratum is equal to the tensile strength of the rock stratum, the initial fracture occurs. According to the following Equations, the first breaking distance (L

a)

i and the periodic breaking distance (L

b)

i of the i layer are calculated:

In the equation, hi is the height of the i-th layer, m; Ri is the tensile strength of the i-th layer, MPa; qi is the load borne by the i-th hard rock layer from its controlled rock strata, MPa.

The calculation equations yields (Lb)i = (La)i/2.45. According to the computational results, the initial fracture spans of the 2nd, 5th, and 11th layers are 45.5 m, 68.1 m, and 13.4 m, respectively, while their periodic fracture spans are 18.6 m, 27.8 m, and 5.5 m, respectively.

(3) Determine the key stratum based on the fracture distance

Determine whether the inequalities (La)i < (La)i+1 (i = 1, 2, 3) all hold. If all of them are satisfied, then the second and fifth layers in the overlying strata are sub-key strata, and the eleventh layer is the main key stratum. If any of the inequalities do not hold, it indicates that the i+1-th layer is not a key stratum, and the i-th layer will control the synchronous fracture of the i+1-th layer. According to the calculation results (La)2 > (La)3, which means that the eleventh layer is not a key stratum at this point, the fifth hard rock layer will control its synchronous fracture. Therefore, it can be concluded that, within the height of the fractured zone above the working face, the second layer is a sub-key stratum, and the fifth layer above the coal seam is the main key stratum.

3.3. Fracture Simulation Study of Key Strata

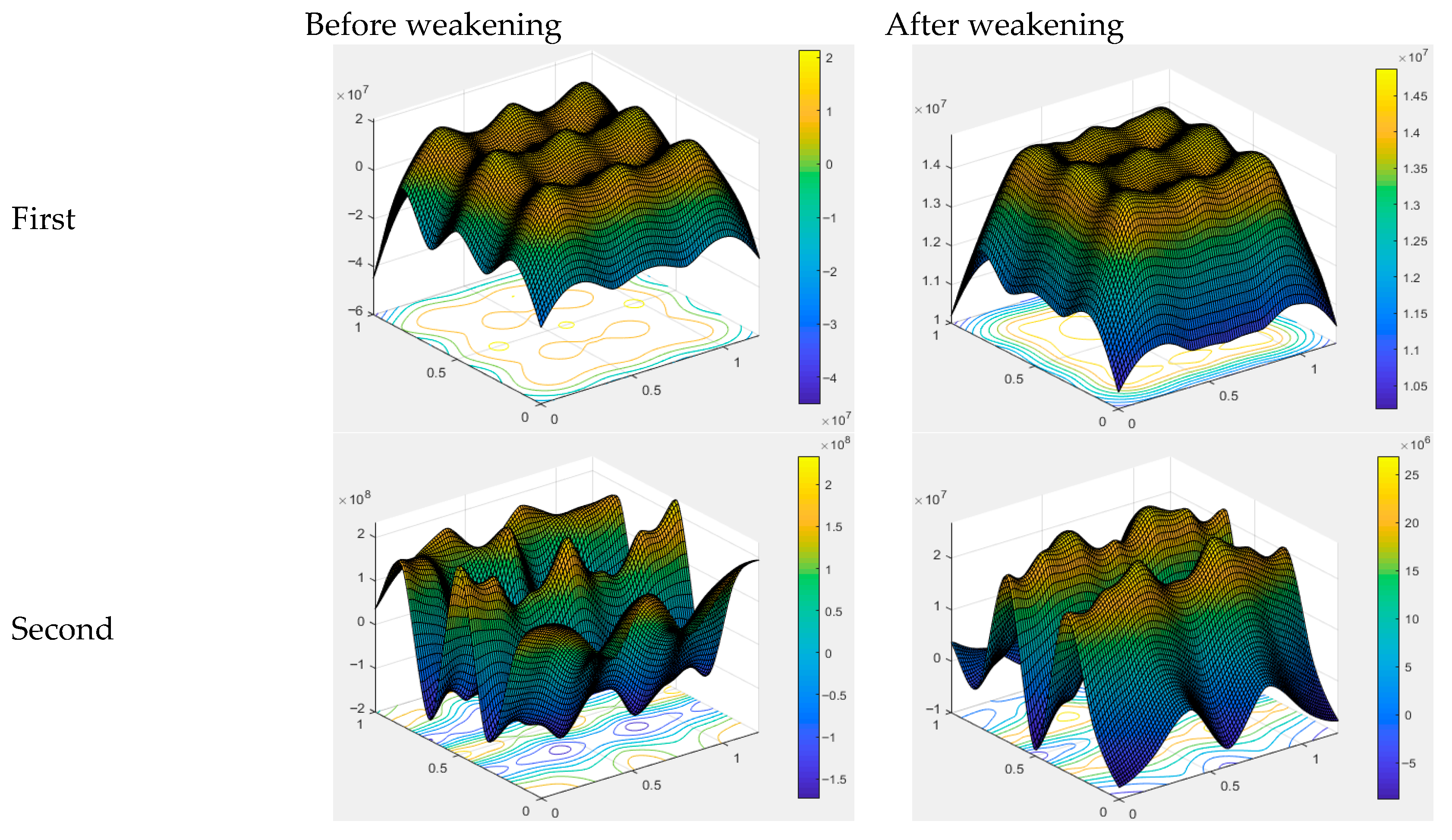

Based on the numerical simulation software, a three-dimensional segmented pre-fracturing model of sub-key strata and main key strata during the working face mining process was established. By comparing the mining performance under conditions without pre-fracturing, the pressure-relief effects on the coal seam ahead of the working face under different key stratum pre-fracturing scenarios were analyzed in sequence. Furthermore, the stress release effect of the coal seam due to roof pressure relief based on dual pre-fracturing of key strata was investigated in depth.

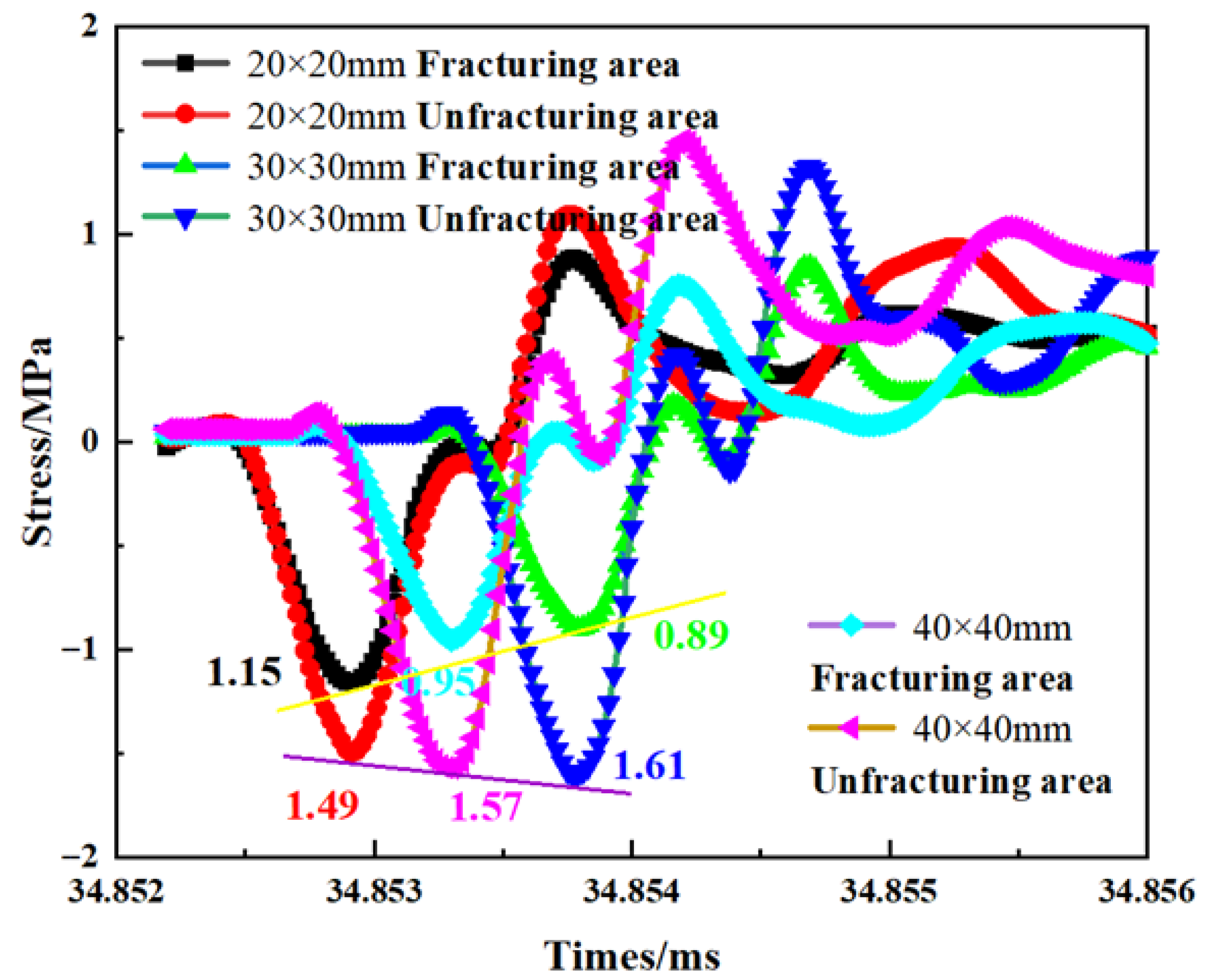

3.3.1. Simulation of the Effect Without Pre-Fracturing in Overlying Strata

Based on the basic conditions of the mine site and in combination with the distribution and mechanical properties of the overlying strata above the coal seam, a three-dimensional segmented pre-fracturing model of the overlying strata was established using the numerical simulation software. To simplify the computational process, based on the findings from

Section 2, the total height of the model was set to 80 m, the dip length to 220 m, and the strike length to 300 m. The working face mining width was set to 150 m, with 5 m coal pillars reserved at both ends. Two roadways were also set up at both ends of the working face. The coal seam was placed at the bottom, and the overlying strata were divided into 15 layers. According to the actual geological conditions of the mine, the horizontal stress of the coal seam and the overburden pressure were assigned. The excavation of the coal seam was carried out using FISH language in numerical simulation software.

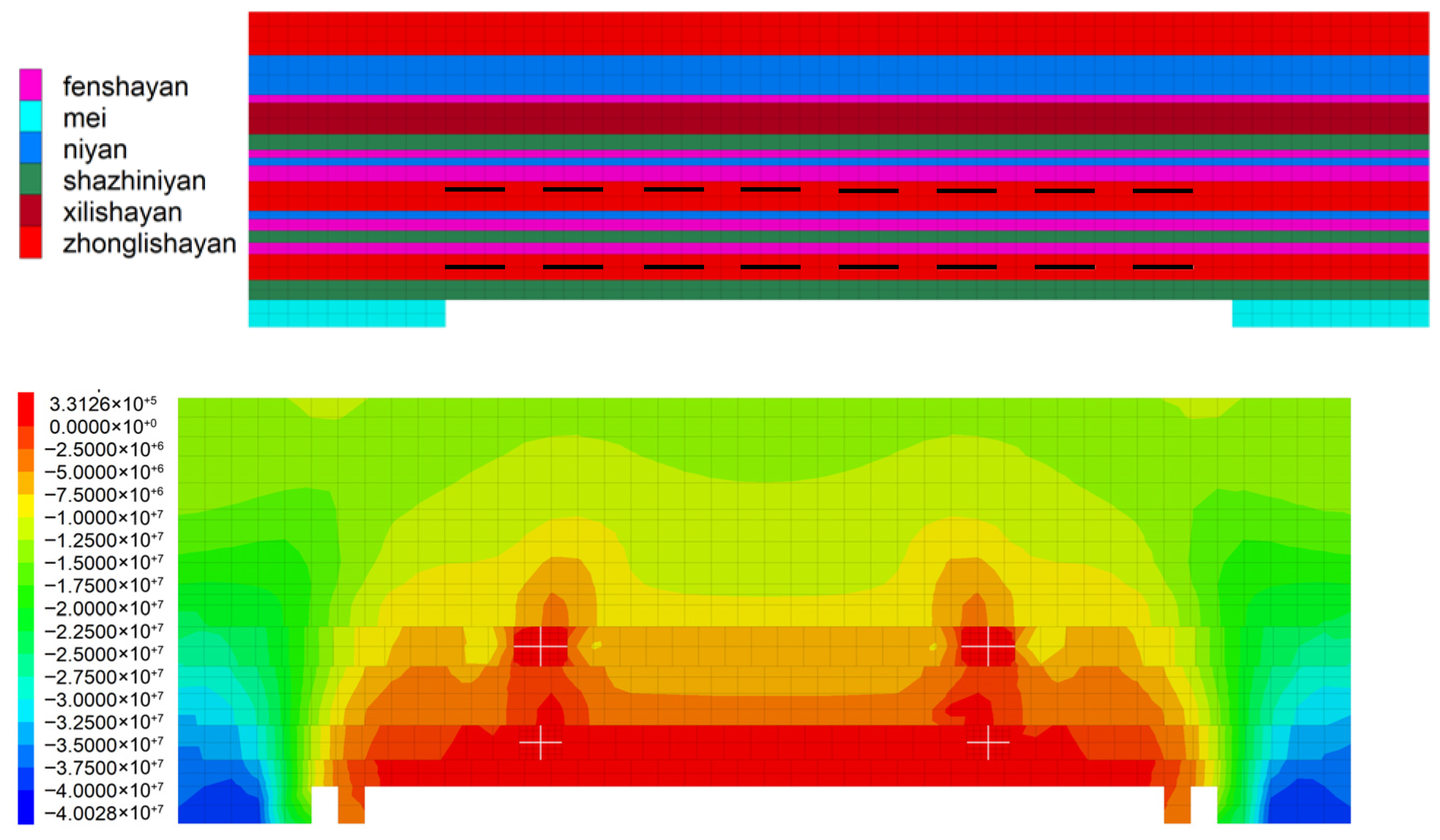

The model is shown in

Figure 4. Based on the simulation results, the stress distribution cloud diagrams during the mining process at 50 m, 100 m, 150 m, and 200 m of advancement were selected and are presented in

Figure 5.

According to the simulation results, the stress change cloud diagram of the working face along the coal seam when mining 50 m, 100 m, 150 m and 200 m is selected as shown in

Figure 5. Based on the basic model in

Figure 5, to better analyze the pressure-relief effect, a new model was established that includes both an unprefractured mining area and a segmented pre-fractured mining area within the same simulation. In this model, the mining process involves three excavation steps, while the pre-fracturing is also conducted in three stages, allowing for a comparative analysis before and after the intervention. As shown in

Figure 5, as the working face advances continuously, the stress redistributes at the cutting-eye and ahead of the working face, resulting in the formation of stress peaks. The roof of the goaf area experiences a decrease in stress due to caving. With further mining progress, the stress concentration on both sides of the goaf gradually increases.

Based on the three-dimensional model without pre-fracturing, this section adopts simultaneous pre-fracturing of the sub-key strata. On the basis of

Figure 6, a pre-fractured zone is added to the sub-key strata. The same segmented pre-fracturing method is applied to achieve the effect of simultaneous pre-fracturing of the sub-key strata.

In order to better analyze the changes in roof stress above goaf and coal seam stress in front of working face, twenty-five monitoring points were selected in the coal seam in front of the working face, and the spacing was 8 m. The stress changes under pre-splitting and non-pre-splitting were studied. In order to analyze the influence of pre-splitting on the coal seam, the stress changes in the coal seam in front of the working face of 50 m, 100 m, 150 m, and 200 m are selected, as shown in

Figure 7.

As clearly shown in

Figure 7, the stress in the coal seam ahead of the working face is lower with sub-key stratum fracturing than without. In both cases, the stress initially increases and then decreases, allowing the zone to be divided into high and low pressure-relief areas. This distribution is primarily attributed to the inclined layout of the mining face: the lower dip side is subjected to higher in situ stress, resulting in a weaker pressure-relief effect, whereas the high pressure-relief area exhibits more pronounced stress reduction. In this high-relief zone, the peak stress reaches 20.15 MPa without fracturing. With sub-key stratum fracturing, peak stresses at 50 m, 100 m, 150 m, and 200 m are 17.23 MPa, 14.63 MPa, 13.52 MPa, and 15.92 MPa, respectively. Significant stress reduction is observed up to 150 m, with decreases of 2.92 MPa, 5.52 MPa, and 6.63 MPa, respectively—progressively increasing to a maximum reduction of 32.9%. At 200 m, stress rebounds by 4.23 MPa due to concentration in the remaining coal influenced by in situ stress during downward mining. Nevertheless, the stress remains 21% lower than the non-fractured case, demonstrating the positive contribution of sub-key stratum fracturing to coal seam pressure relief.

The original coal seam pressure (20.15–13.52 MPa) exhibits a pattern of gradual natural attenuation, while the pressure curve following fracturing intervention reveals a three-stage evolutionary behavior: an initial phase (within 50 m) characterized by a steep, cliff-like decline—representing the peak pressure-relief efficiency; a middle phase (100–150 m) transitioning into gradient release; and a later phase (around 200 m) tending toward stress re-equilibration. This nonlinear response reflects the dynamic evolution of the fracture network generated by fracturing, which undergoes “initial dominant fracture propagation–intermediate activation of secondary fractures–late-stage fracture closure and rebalancing” under mining-induced stresses. The key implication is that sub-key stratum fracturing not only transforms the conventional passive support paradigm of “strong support–yield pressure” but also enables coordinated control of the “stress field–fracture field” through active modification of the overburden structure. The attenuation of pressure-relief efficiency in later mining stages results from fracture closure or stress redistribution due to goaf compaction, underscoring the importance of optimizing fracturing timing and spatial strategy—such as implementing staged repeated fracturing—to sustain long-term pressure-relief performance.

3.3.2. Analysis of the Influence of Pre-Splitting Pressure-Relief Effect of Main and Sub-Key Strata

Based on the three-dimensional model without pre-splitting, this section adopts simultaneous pre-splitting of the main key layer and the sub-key layer. The main key layer is selected to add a fracture pre-splitting area, in which the main key layer is 22.5 m away from the coal seam and the thickness of the rock mass is 7.5 m. The method of subsection pre-splitting is also adopted to achieve the effect of simultaneous pre-splitting of the main and sub-key layers. The model is shown in

Figure 8.

In order to analyze the influence of the main and sub-pre-splitting on the coal seam, the stress changes in the coal seam in front of the working face of 50 m, 100 m, 150 m, and 200 m were selected, as shown in

Figure 9.

As clearly observed in

Figure 9, the stress in the coal seam ahead of the working face is lower when employing combined fracturing of both main and sub-key strata compared to the non-fractured case, following a trend consistent with fracturing only the sub-key strata. In both scenarios, the stress initially rises and subsequently declines. Within the high pressure-relief zone, the peak stress reaches 20.15 MPa without fracturing. With simultaneous fracturing of main and sub-key strata, the peak stresses measured at 50 m, 100 m, 150 m, and 200 m are 14.81 MPa, 13.55 MPa, 12.72 MPa, and 14.09 MPa, respectively. A significant pressure-relief effect is observed up to 150 m, with stress reductions of 5.34 MPa, 6.60 MPa, and 7.43 MPa at each interval—progressively increasing to a maximum reduction of 36.9% at 150 m, consistent with the sub-key strata-only condition. At 200 m, stress rebound occurs, yet the net reduction remains 6.06 MPa, corresponding to a 30% decrease. These results demonstrate that simultaneous fracturing of main and sub-key strata produces a more pronounced pressure-relief effect compared to fracturing only the sub-key strata. By comparing coal seam pressure evolution at different mining distances under combined main and sub-key strata fracturing, this study reveals the synergistic control mechanism of composite key strata fracturing on the stope stress field. The data indicate that combined fracturing produces more pronounced staged pressure-relief characteristics compared to single sub-key layer fracturing. In the initial stage (50 m), a substantial stress drop occurs, reflecting overall structural instability induced by main key stratum fracture. During the middle stage (100–150 m), a fluctuating descending plateau forms, attributable to the dynamic coupling between the sub-key stratum fracture network and the rotational movement of the main key stratum. In the later stage (200 m), the stress stabilizes but retains residual levels, as a result of renewed “stress arch” formation following goaf compaction. This behavior elucidates a binary control mechanism in deep mining: the main key stratum governs macroscopic structural failure, while the sub-key stratum regulates local fracture propagation. The engineering significance lies in transcending the limitations of conventional single-layer fracturing, achieving hierarchical risk management through coordinated intervention in dual key strata-enabling integrated “global pressure relief and local fracture control.”

3.4. Experimental Study on Static Expansion

The purpose of the whole hole expansion fracturing experiment is to study the damage and fracture development law of the expansion hole under the whole hole expansion pressure, and to study the influence degree and influence mechanism of the guide hole on the fracture development under the condition of the guide hole. By comparing the experimental fracture damage and development degree with the numerical simulation results, the simulation effect of numerical simulation on the whole hole expansion is verified, which provides a basis for the design of the guide hole layout parameters.

The damage and fracture development law of the specimen under the four-hole expansion single guide hole is set. The experimental scheme is as follows. The expansion hole and the guide hole are arranged in the position of the specimen, as shown in the diagram. When the specimen is completely dried, the disassembled specimen is loaded back into the mold, and the mold is fixed around to play a fixed role. After the static expansion agent is mixed in proportion, it is poured into the expansion hole to observe and record the damage and crack development of the specimen.

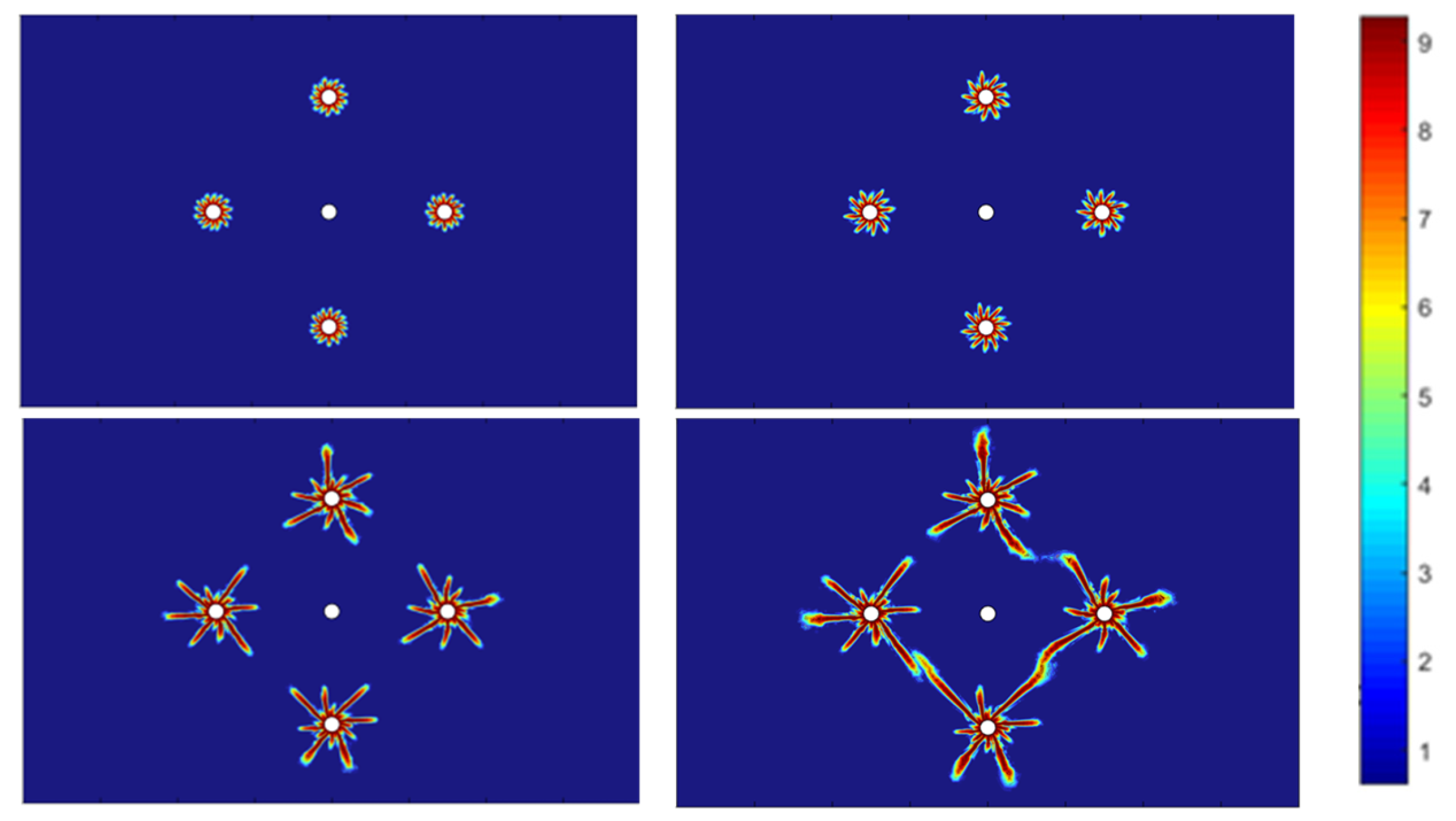

As shown in

Figure 10, 12 h after adding the cracking agent into the expansion hole, it can be observed that 1–3 fractures develop around the hole as the center. These fractures have interconnected after propagation, with multiple cracks extending to and linking with the guide hole.

The experimental results of this group demonstrate that, during multi-hole expansion, fractures preferentially propagate along the inter-centerline of expansion holes, while simultaneously developing toward the guide holes until ultimately connecting with fractures emanating from them.

Under the expansion experiment of a single guiding hole with multiple expansion holes, it can be found that the cracks on the connection line of the expansion hole have been completely connected. It can be seen that the stress between the expansion holes is larger than the stress between the guiding hole and the expansion hole. The crack development first connects the connection between the expansion holes, and then the guiding hole produces cracks due to stress concentration and develops cracks between the expansion holes. Conduction. In the case of multi-guiding hole expansion, due to the large number of expansion holes, the cracks on the specimen due to expansion are much more than those caused by single hole expansion.

3.5. Numerical Simulation Study on Static Expansion

In order to study the formation and development of cracks when expanding under multiple expansion holes and a single guide hole, the guide hole is designed in the center of the specimen, and four expansion holes are around the guide hole. The experimental design of this group is different from the position of the expansion hole in the previous group, and the expansion hole is arranged in a rectangular four-corner position in the guide hole.

As shown in

Figure 11, in the process of numerical simulation of four expansion holes with a single guide hole, it can be found that the generation and development trend of cracks under the action of expansion force is as follows: first, damage is formed around the expansion hole, then, with the increase in expansion pressure, the dominant cracks begin to develop, and the cracks on the connection line of adjacent expansion holes develop fastest. When the cracks on the connection line of adjacent expansion holes are connected, the guide hole cracks appear on the connection line between the guide hole and the expansion hole and develop, and the expansion hole cracks are connected. Comparing the results of the numerical simulation and the experiment, it can be found that the crack development and the occurrence and development of cracks in the numerical simulation are roughly the same as the experimental results.

Through experimental and numerical simulation studies, it can be found that the damage of coal and rock mass under the action of full-hole expansion can be divided into three stages, namely, elastic strain stage, damage stage, and fracture development stage. The dominant fracture is formed after the damage of coal and rock mass and gradually develops. In the absence of a guide hole, 4~6 dominant cracks will be formed and radiate around with the expansion hole as the center, and the crack angles are roughly the same. In the case of guiding holes and multiple expansion holes, the priority of the development direction of the dominant cracks is as follows: the development of cracks between guiding holes > the development of their own dominant cracks > the connection between the cracks of guiding holes and the development of their own cracks. In the process of guiding expansion, regardless of the diameter of the guiding hole and the expansion hole, the development of the fracture is closely related to the arrangement and distance of the expansion hole and the guiding hole. It can be found that the development of the dominant fracture is basically centered on the expansion hole and radiates around. The radiation direction is mainly positive left, right, up, and down, and the expansion fracture does not extend directly to the direction of the guiding hole, but, after the stress concentration of the guiding hole, the fracture is generated and connected with the expansion fracture.

The comparison between the numerical simulation and the experimental results shows that the fracture development and conduction are roughly the same, but the final fracture development length is quite different from the experiment. The main consideration is that the numerical simulation is performed with the same size as the experiment, which is greatly affected by the boundary conditions. Therefore, it can be considered that it is feasible to use numerical simulation software to simulate the development and conduction of cracks under full-hole expansion.

4. Discussion (Field Verification)

Hydraulic fracturing technology has gained extensive application in recent years due to its advantages in reducing labor intensity and minimizing environmental pollution. The high-pressure water jets employed in this technique offer distinct benefits for rock pressure relief. Currently, it is primarily utilized for pressure relief throughout the excavation and mining cycle, demonstrating strong performance in complex high-gas geological environments and ensuring high operational safety. However, challenges remain in controlling the direction and morphology of fracture propagation, presenting certain limitations when applied to structured rock formations. Moreover, hydraulic fracturing requires a complete set of technical equipment and involves relatively complex procedures. In the specific case of directional long boreholes in the transport roadway roof, the hydraulic fracturing depth reaches 240 m. The borehole azimuth is set at 90° relative to the roadway centerline (defined as 0°). The borehole inclination is designed as the coal seam dip angle plus 10° (with the seam dip ranging from 6.5° to 12.5°), subject to appropriate adjustments based on actual geological conditions. The application diagram and field application of coal seam drilling expansion device are shown in

Figure 12. The technical application steps are as follows:

(1) Through the drilling machine, multiple parallel boreholes are arranged in the vertical coal seam in the roadway and cleaned up, and the expansion and fracturing boreholes are arranged on both sides of the gas drainage boreholes;

(2) Connect the extraction borehole to the underground gas extraction equipment, and seal the borehole to check its sealing performance;

(3) After mixing the expansion material and water in proportion, the coal seam expansion fracturing device is put into the expansion drilling hole, and the polyurethane sealing material is blocked and fixed by the grouting pump, waiting for its initial condensation reaction;

(4) The fracture network is formed in the coal seam by expansion cracking, and then the gas extraction is carried out.

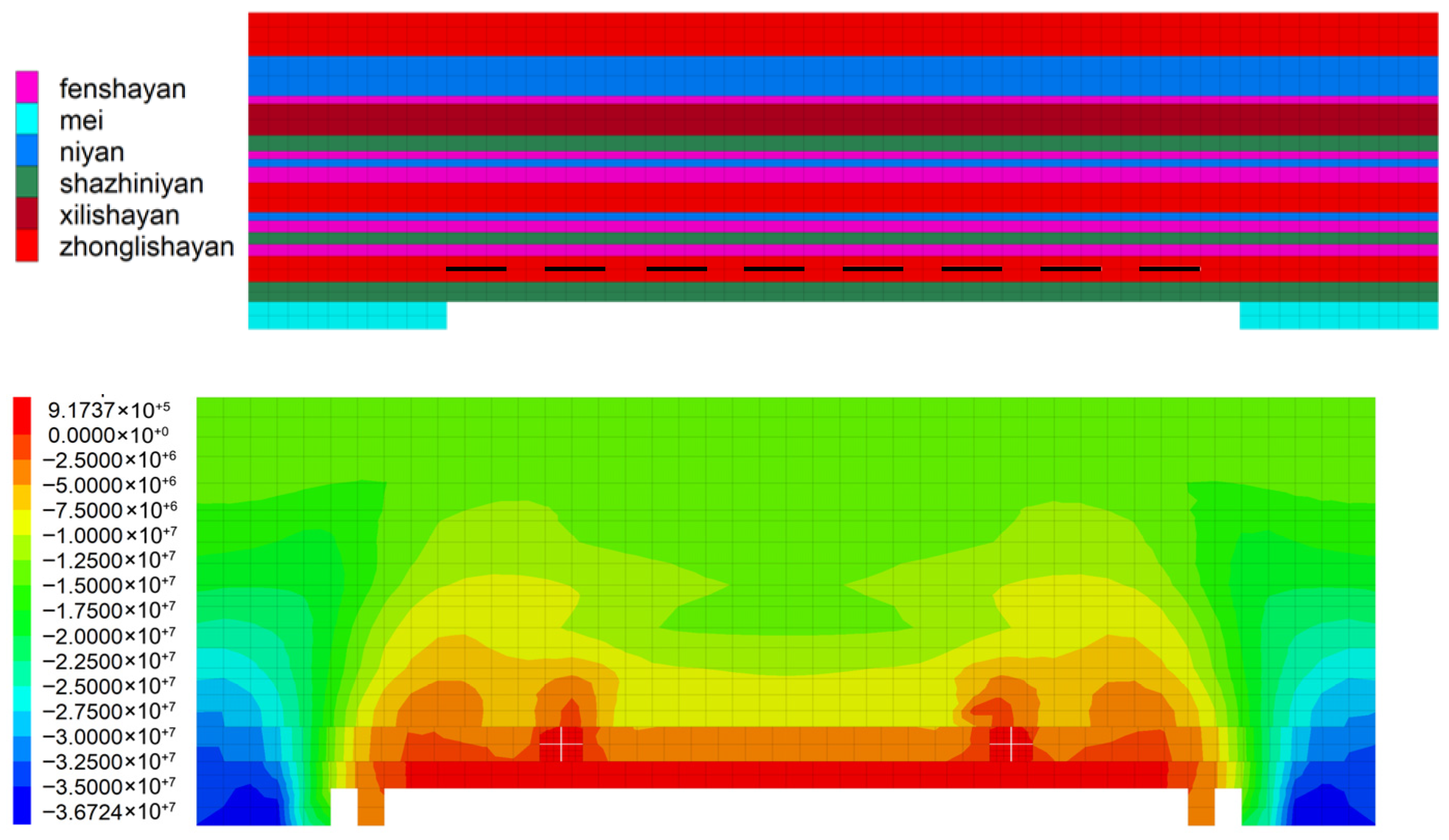

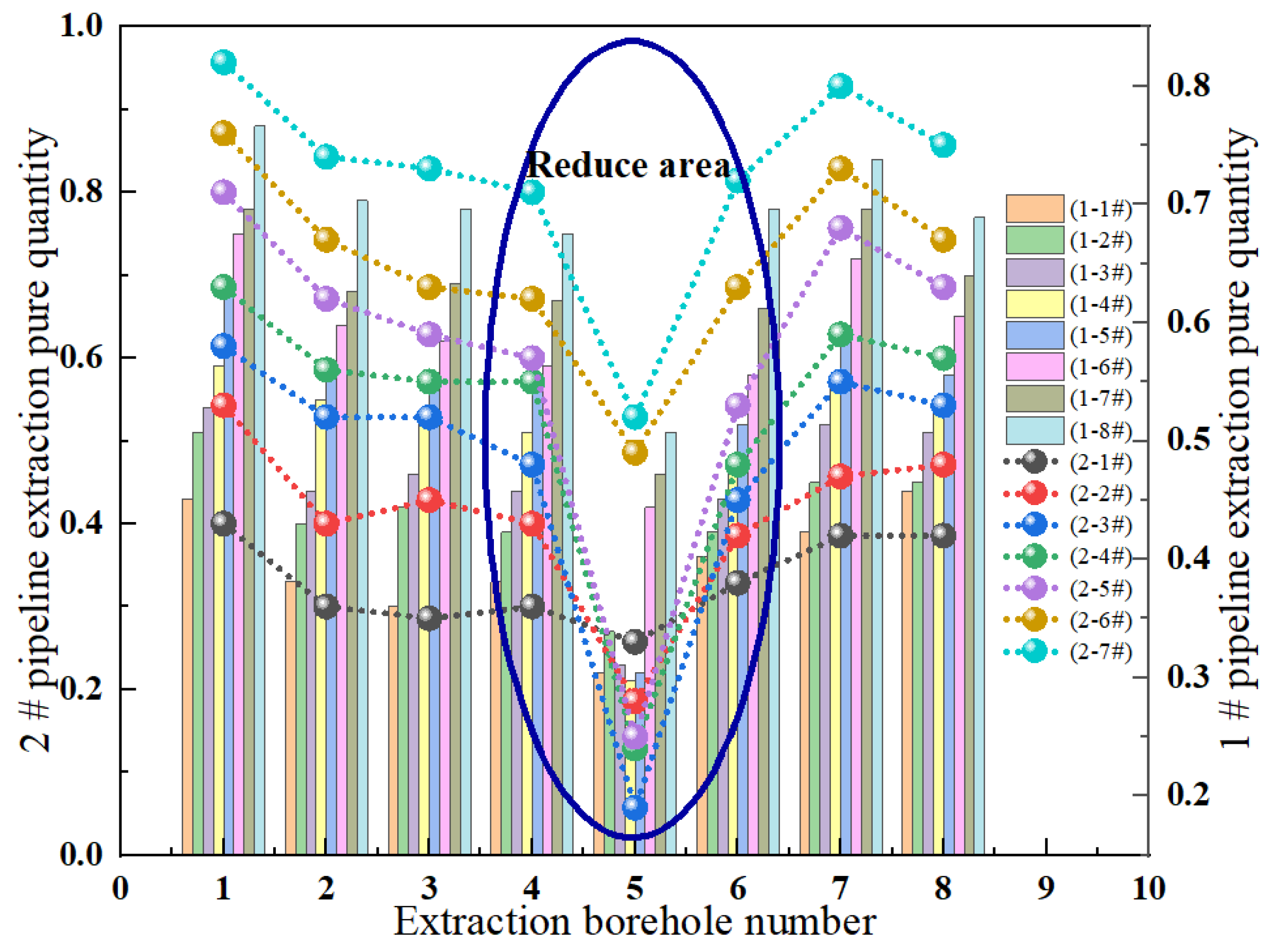

From

Figure 13, it can be seen that, after the double-peak collaborative pressure-relief project was successively implemented on the 1 # to 8 # boreholes (horizontal axis), the pure methane extraction volume of the 1 # pipeline (left longitudinal axis) gradually increased, from 0.22 Nm

3/min at 1 # borehole to 0.64 Nm

3/min at 5 # borehole, and then stabilized in the range of 0.55–0.58 Nm

3/min at 6 # to 8 # boreholes. The peak value of 0.61 Nm

3/min was recorded at the same peak point in the 2 # pipeline (right longitudinal axis), which was 2.4 times higher than that before the 4 # borehole, and then decreased by less than 5% in the next three boreholes. It shows that the hydraulic fracture network in the main and sub-key strata plays the role of pressure relief, effectively blocks the transmission of ground stress, and interacts with the static expansion cracks in the coal seam. The ground stress decreases, the expansion and cracking are easier, and more cracks are generated, forming a relatively developed fracture network, which makes the gas pressure form a low pressure zone and slows down the attenuation of the effective extraction purity change.

With 5 # borehole as the demarcation point, the average growth slope of pipeline 1 from 1 # to 4 # borehole is 0.095 Nm3/min/borehole, while the average decline slope from 6 # to 8 # borehole is only 0.02 Nm3/min/borehole. The attenuation coefficient decreases from 0.18 to 0.04, which indicates that, after the staged fracturing of the upper main key layer and the sub-key layer, the rock movement angle decreases from 65° to 48° according to the field test, and the bending subsidence rate of the key layer slows down. The in situ stress reduction remains above 25%, thus maintaining the cracks in the coal seam for a long time. The curve of pipeline 2 is always kept in the range of 0.03 Nm3/min of 1 # pipeline curve. The two curves rise synchronously and reach the peak at the same point, indicating that the interference between the two extraction pipelines is minimal. The data analysis of the comprehensive drilling shows that the high-pressure staged hydraulic fracturing technology cuts off the stress transfer path of the overlying strata in advance; the static cracking technology generates multi-stage tensile cracks in the coal seam. The space-time staggered distance between the two processes is less than 15 m, forming a double pressure relief superposition area, and the No. 5 borehole is established as the stress release center. The observation results show that the peak value of gas extraction volume of the two extraction pipelines appears at the same time; the attenuation slope of the subsequent three boreholes is less than 4% of the peak value, and the in situ stress field continues to be in a low pressure state under the action of this area. The crack opening remains stable; the methane desorption channel remains smooth; and the extraction target of high efficiency and continuous and low attenuation of regional coal seam gas has been successfully realized.

Integrated data from all eight boreholes demonstrate that high-pressure staged hydraulic fracturing effectively preempted stress transfer from the overlying strata, while static expansion fracturing generated multi-level tensile fractures within the coal seam. With a spatiotemporal offset of less than 15 m between the two processes, a synergistic dual pressure-relief zone was formed, establishing borehole 5 as the principal stress release center. Peak gas extraction volumes were achieved simultaneously in both extraction pipelines, and the subsequent decay slope observed across the following three boreholes remained below 4% of the maximum value, confirming sustained connectivity between the fracture networks in the main and sub-key strata and the expansion fractures within the coal seam. Throughout this period, the in situ stress field maintained a low-pressure state, fracture apertures remained stable, and methane desorption pathways stayed fully open. As a result, the difficulty coefficient of coal seam methane extraction was reduced from an initial value of 0.73 to 0.18, accomplishing the objective of efficient, sustained, and low-decline regional coal seam gas extraction.

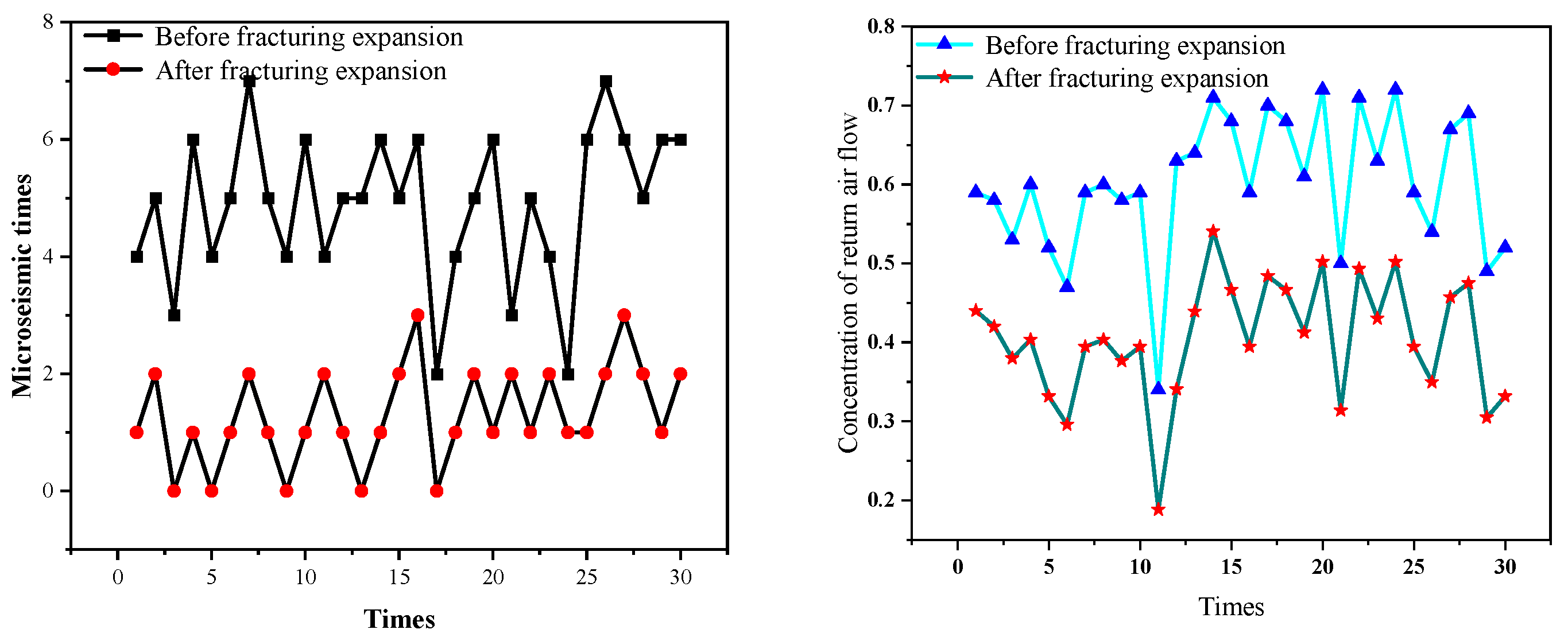

By collecting and analyzing three-shift data over ten consecutive days, this study systematically monitored microseismic events and return airflow gas concentration before and after pressure relief, revealing the dual mechanism of combined main/sub-key stratum pressure relief and coal seam static expansion for preventing coal mine dynamic disasters and controlling gas. The data in

Figure 14 indicates, post-pressure relief, microseismic events decreased by 50–80%, accompanied by a synchronous gas concentration reduction of 0.05–0.25%. This strong correlation reflects the chain reaction of “stress release–fracture closure–gas dissipation,” demonstrating that the integrated technique disrupts the energy storage structure of coal–rock mass—reducing high-energy microseismic events—while also decreasing fracture channel density for gas migration through macro-fracture penetration. Notably, abnormal fluctuations observed from days 4–6, such as a peak gas concentration of 0.71% during the middle shift on day 5, suggest that stress shadow effects from pressure relief may induce stress concentration in adjacent untreated zones, revealing an uneven redistribution of the rock stress field characterized as “local relief–neighborhood transfer.” At a deeper level, the smaller reduction in gas concentration (averaging 8.6%) compared to microseismic frequency (averaging 75%) indicates that pressure relief more effectively regulates macroscopic mechanical behavior than gas adsorption–desorption processes, validating the feasibility of the composite pressure relief approach for implementing integrated “shock–gas” dual-control disaster prevention.

5. Conclusions

(1) The integrated application of hydraulic fracturing and static expansion techniques effectively interrupts stress transfer pathways within overlying strata, achieving a reduction in ground pressure exceeding 25% and markedly alleviating dynamic disasters such as rock bursts and coal-gas outbursts, thereby substantially enhancing operational safety in deep mining environments.

(2) Field validation confirms a notable enhancement in gas extraction performance, manifesting as a 3.7-fold increase in permeability and a reduction in the methane decay coefficient from 0.58 to 0.21. These improvements facilitate sustained high-concentration gas drainage and contribute to the prolonged stability of generated fracture networks under complex geo-mechanical conditions.

(3) By synergistically combining mechanical stress regulation with efficient gas management through optimized fracture initiation and propagation control, the proposed methodology offers a holistic strategy to address critical challenges in deep mining. It represents a theoretically grounded and practically viable advancement toward safer and more sustainable coal extraction.