Abstract

How to select the right suppliers has become a crucial strategic decision for manufacturing companies facing various performance measures. This study proposed a hybrid selection model integrating factor analysis, structural equation modeling (SEM), and the fuzzy Technique for Order Performance by Similarity to Ideal Solution to (TOPSIS) design a supplier selection model. The study distilled 70 original selection criteria from the relevant literature and identified eight main influencing factors based on factor analysis. The relevance of factors was evaluated by SEM and the performance of suppliers assessed by fuzzy TOPSIS. The model was applied in a manufacturing company in China to verify its practical significance. By combining different methods, the model can select relevant and important supplier selection criteria and include unquantifiable, incomplete, and vague information in the decision model. The hybrid model merges the advantages of each method and takes into account of uncertainty associated with supplier selection process.

MSC:

90-08

1. Introduction

Selecting the right suppliers is critical for the competitiveness of manufacturing firms. The decision on supplier selection affects the performance of supplier collaboration and competitive capabilities of the focal firm in terms of cost, delivery, innovation, and environmental preservation etc. [1]. For example, Apple’s success relies on the way in which Apple selects its suppliers. Based on the priorities such as quality, technological ability, and scale, Apple selects its first-tier suppliers such as Samsung, Toshiba and Foxconn to ensure its leading value innovation in the global mobile phone market. In essence, supplier selection (SS) is a decision-making process that measures the efficiency and effectiveness of supplier performance, then selects the right supplier based on predefined objectives and evaluation criteria. As the key function of purchasing and supply chain management, SS has an enhanced effect on firm capabilities and received numerous concerns in both theoretical and practical fields [2].

However, at least four key challenges can be identified in extant literature. First, SS can be very complex since decision makers (DMs) need to consider a large number of various performance measures [3]. Since the 1960s, the list of supplier evaluation criteria has become longer and longer due to the cumulative effect of global competitiveness. For example, Kant & Dalvi [4] listed almost 151 important criteria. Some popular SS mathematical methods such as analytic hierarchy process (AHP) impose a limitation on the number of factors. Trade-offs do exist between reducing the number of criteria and including all important information. As such, a SS model should first cope with the challenge of reducing the dimensionality of criteria but not omitting important information. Second, weights of the criteria are typically determined by subjective and intuitive approaches by DMs who lack sufficient information about the weighting procedure. When group DMs are involved, reaching consistency is costly or even impossible. Wetsztein et al. [5] found that more than 44% of the reviewed studies chose an easy form of single DM though group DMs lead to better outcomes. Therefore, finding a more objective approach to determine the weight needs further exploration. Third, incomplete or inaccurate information about the supplier’s performance imposes additional challenges. The criteria are not only quantitative but also qualitative. The performance of each supplier is not precisely known in the real-life world [6]. Managers always make the decision based on intuition. As such, a logic and systematic approach is required to treat qualitative and intuitive information to improve the confidence of managers when deciding. Fourth, the procedure and methods of SS should also be practical and accurate, two contradictory objects in nature. To meet the practical purpose, the procedure and method should be simple and understandable and validated by real-world applications. However, many selection methods are not validated by real-world applications. When a practice is presented, the purpose is frequently illustrative, only occasionally for real applications. They, among others, suggest that the practical validation for those models should be extended.

This study addresses the above challenges by developing an innovative and hybrid model that combines factor analysis, structural equation modelling (SEM) and the Fuzzy Technique for Order Performance by Similarity to Ideal Solution (FTOPSIS) to assess the performance of different suppliers and choose the best and most suitable supplier to maintain and develop the efficiency of supply chain management. Factor analysis is useful to reduce the dimensionality of numerous criteria while at the same time retaining important information. SEM is introduced to validate the significance of each criterion and obtains the objective weight of each criterion. FTOPSIS are feasible methods to treat qualitative and uncertain information for large scale problem of SS used by several authors [7]. A combination of these models is a viable way to produce a more simple, objective and accurate SS model. However, few efforts have been made to combine these three methods to solve SS problems. The practical merit of the hybrid model is also validated in a real company environment, an attempt to fill the practical gap of extant SS research [5].

Using all three methods makes it easier to break down complex problems and find solutions. The contributions of this study may be as follows. First, dimensionality reduction of a large number of selection criteria (up to 70) was achieved by merging some of the factors without omitting important information. Second, using SEM, the study verified the relationships between the evaluation criteria and results. In addition, it determined the relative weight of each factor. This is helpful to improve the relevance of the criteria and the practicality of the final SS result. Third, the FTOPSIS method was applied to choose the ideal solution. This study mainly used fuzzy set theory to reduce the uncertainty created by the subjective evaluation of candidate suppliers by DMs, as this method provides a reliable computer language and function to assess the elements in a set. Finally, a case study was conducted to give readers a practical illustration of the evaluation of candidate suppliers.

The remainder of the paper is as follows. After the introduction, Section 2 presents a literature review on supplier selection criteria and supplier selection methods. Section 3 identifies up to 70 supplier selection criteria and Section 4 introduces FTOPSIS approach supplier rating system that will be used in the model development. Section 5 develops the hybrid model of supplier selection based on factor analysis, SEM and fuzzy TOPSIS, and applies this model in a manufacturing company in Shenzhen, China. Discussions and conclusions are presented in Section 5.

2. Literature Review

Two issues have often been discussed in previous studies on supplier selection decisions: the criteria to be used and the most appropriate methods [8].

2.1. Supplier Selection Criteria

The increasing intensity and cumulative effect of global competitiveness is continuously adding new criteria to supplier selection. Studies of SS have defined many evaluation criteria and frameworks leading to a long list of criteria that are important in SS. The ground-breaking work of Dickson [9] identified 23 criteria affecting supplier evaluation. Although evaluation criteria may change due to the evolution of the industry environment, these 23 criteria cover the majority of those presented in the related literature to date [10]. Krause et al. [11] were the first to consider innovation, which they incorporated into their vendor selection model. Akarte et al. [12] also surveyed 18 supplier evaluation criteria for consideration by manufacturers. These criteria can be divided into four categories: product development capability, manufacturing capability, quality capability, and cost and delivery. Kant and Dalvi [4] identified 151 supplier evaluation criteria through a literature review. Their results showed that quality, on-time delivery, and cost were the most frequently considered criteria, followed by performance or reputation in the industry, technical capability, flexibility, service, financial position, and net price. Furthermore, based on Stević’s [13] summary of 24 relevant articles, economic parameters, quality, and delivery were the criteria used in almost all supplier evaluation studies. Deshmukh and Chaudhari [14] suggested expanding the scope of supplier evaluation criteria and adding green supply chain management in future studies. Similarly, Govindan et al. [15] examined all studies on green supplier selection published between 1996 and 2011 and showed that the main criteria considered were environmental management systems and quality. These findings show that certain influencing factors have frequently appeared in the literature on supplier evaluation criteria. Therefore, the initial evaluation criteria can be determined accordingly, such as cost, quality, delivery, and environmental management.

As so many SS criteria involved, it is critical to select relevant and important factors for a practical SS procedure. This paper uses factor analysis to reduce the dimensionality of the criteria, and applies SEM to verify the relevance of each factor in SS. This approach is helpful to identify important SS criteria and improve the relevance of the criteria and the practicality of the final SS result.

2.2. Supplier Selection Methods

Various approaches to solving MCDM supplier selection problems have been used to develop selection models. The methods used in previous studies can be categorised as individual, hybrid or fuzzy hybrid methods. With changes in the social environment, supplier selection problems have become more complex due to the increasing number of factors to be considered. Therefore, it has become common to use hybrid methods to solve these types of problems [16,17,18]. This study used a hybrid approach integrating factor analysis, SEM, TOPSIS and fuzzy set theory to take uncertainty into account.

As factor analysis is a well-known dimensionality reduction technique, only the application of SEM and TOPSIS is reviewed here. SEM is a multivariate statistical analysis technique to find a model that fits the empirical data well enough to serve as a useful representation of reality. Scholars have started using SEM in supply chain management. Garg [19] used SEM to verify the critical supplier selection criteria derived from literature and evaluated each key factor’s impact. SEM can also be applied to determine relative weights. Nguyen et al. [20] developed a hybrid model using SEM, the fuzzy hierarchy process and artificial neural network to identify the key factors affecting individuals’ behavioral vaccination intention against COVID-19 in Vietnam. Jakhar and Barua [21] used the same hybrid method to analyse supply chain performance in India. They demonstrated the effectiveness of the proposed model in a case study of a textile-apparel-retail supply chain.

TOPSIS is a linear weighting approach. It was first proposed by Hwang and Yoon [22], and further developed by Yoon [23] and Hwang [24]. Since then, TOPSIS has been widely adopted to solve multiple-criteria decision-making (MCDM) problems in real situations [25]. TOPSIS is based on the idea that the ideal solution should have the shortest geometric distance from the positive ideal solution (PIS) and the longest geometric distance from the negative ideal solution (NIS) simultaneously [26].

The supplier selection process also involves ambiguous needs and uncertain preferences relating to relationships, historical performance, etc. This inaccurate, subjective and vague information must be transformed into quantitative data during the calculations. In response to the preference of DMs for accurate numerical values, uncertainty has become the new consideration and fuzzy set theory has started to be used to solve decision-making problems in recent years.

The basic definition of the fuzzy method was proposed by Zadeh [27] as an extension of the notion of a set. It is generally applied to model the decision-making process based on indistinct and imprecise information. Zadeh’s [28] introduction of the concept of linguistic variables allowed calculations to be performed with words instead of numbers; thus linguistic terms defined by fuzzy sets are widely required in various fields. Fuzzy numbers (FNs) have been used to express linguistic variables and quantitatively describe the subjective judgement of a decision maker. Triangular FNs [29], trapezoidal FNs [30], and Gaussian FNs [31] are the most widely used FNs. Since Bellman and Zadeh [32] first developed fuzzy sets in MCDM techniques, a growing number of studies have focused on more practical supplier selection and evaluation problems using fuzzy hybrid approaches.

The use of fuzzy set theory allows decision makers to include unquantifiable, incomplete, and vague information in the decision model [33]. Therefore, the FTOPSIS method has been developed to consider uncertainty. This method has been used in many fields, such as supplier assessment and selection, location problems, renewable energy, and sustainability. For example, Şengül et al. [34] used this approach to analyse renewable energy supply systems in Turkey, which involved different criteria.

As the above literature review shows, hybrid methods have been shown to have advantages and have thus been used in various fields. However, few authors have developed a hybrid model combining factor analysis, SEM, and FTOPSIS for SS. The reason for selecting the proposed model was to merge the advantages of these methods. When many factors must be considered, SS are time-consuming processes. The accuracy of the model may be reduced when numerous criteria are considered [35]. In this study, principal component analysis was performed to adjust and simplify the model and reduce the dimensionality of the data set by streamlining and merging certain factors. Then SEM has been used to explore the effect of supplier evaluation and selection criteria and determine the relative weights. Furthermore, the application of fuzzy set theory considered the vagueness of opinions, making the evaluation process more reliable. Finally, triangular FNs were chosen because they are easy for decision makers to calculate and use.

3. Development of the Hybrid Supplier Selection Model

3.1. The Methodology

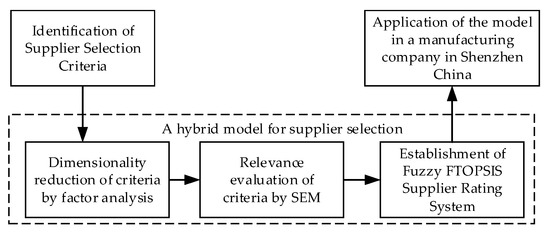

The methodology of this research is shown in Figure 1. First, up to 70 initial supplier selection criteria will be identified from an overall literature review. These selection criteria will first conceivably put into eight supplier selection dimensions, which as well were derived from the overall literature review process. We then performed factor analysis to reduce the dimensionality of the selection criteria and verify the eight selection dimensions. We used SEM to evaluate the relevance and significance of these criteria in selecting suppliers. These two processes allowed us to remain most important factors while improve the practice of the model. The performance of suppliers was evaluated by group DMs and data were processed by fuzzy TOPSIS. Fuzzy TOPSIS includes unquantifiable, incomplete and vague information in the decision model. The hybrid model was implemented in a manufacturing company in Shenzhen China to evaluate its applicability in real world.

Figure 1.

The methodology of the study.

3.2. Identification of Supplier Selection Criteria

The initial evaluation criteria used in the supplier selection process were first collected from the relevant literature [10,36]. In total, 70 criteria were identified. The selection criteria were conceived as a set of eight main dimensions according to literature review. These eight dimensions and associated criteria form a supplier selection framework. Detailed information on the key criteria identified in this study is provided in Appendix A.

3.2.1. Relationships

Alliances or cooperative relationships between suppliers and manufacturing firms have received increasing attention [37]. Compared with traditional price-driven transactional relationships, collaboration and close relationships can reduce time to market and costs and improve quality and delivery efficiency [38]. Many manufacturing firms treat their long-standing suppliers as partners and even involve them in supply chain design and new product development to achieve quality control and technological innovation objectives.

3.2.2. Company Management

The success of a company depends on its management capability. Organisational structure, corporate reputation, decision-making, operational procedures, employees, and resource utilisation are the factors that affect the maximisation of management capability. A supplier’s management capability in business affects various aspects of its performance.

3.2.3. Cost

Cost can be considered as one of the main concerns of manufacturers when selecting suppliers, including whether suppliers can provide appropriate prices or are willing to negotiate and offer discounts for large quantities [39,40]. Kannan and Haq [41] considered payment terms as a sub-criterion of cost, affecting the decision process.

3.2.4. Delivery

Delivery has been identified as a dominant supplier evaluation criterion in almost all relevant studies [13]. The importance of reducing lead times has become more evident with the great success of the just-in-time methodology. Shorter lead times lead to reduced inventory and improved inventory turnover and efficient supply chain management [42]. Moreover, the punctuality and accuracy of delivery are crucial for buyers. Delays in delivery or an incorrect product quantity or category have huge negative effects on subsequent production planning. In addition, the ability to respond quickly to urgent orders is valued by many manufacturers.

3.2.5. Quality

Since the 1960s, numerous studies have shown that quality is one of the main factors in supplier evaluation [10,43]. Schonberger and Gilbert [44] argued that more than half of all product quality problems can be attributed to the inferior quality of the materials supplied. Quality can be defined as the ability of a product or service to systematically meet or exceed customer expectations [45]. Thus, the quality of a product must at least meet the expectations of customers to gain their trust in the product and the supplier [16].

3.2.6. Production Management

The production process includes functions that transform parts into a finished product to meet expected demand. Configuration facilities and staff efficiency are essential to operate at optimum capacity. Moreover, due to the development of environmental management and the negative effect of production on the environment, environmental factors have become major concerns. Suppliers should respond to environmental concerns by developing products that use an environmentally friendly production process and reduce pollution or energy consumption [46]. Thus, production management has a major effect on supply chain performance.

3.2.7. Engineering and Technology Management

Engineering and technology management is considered a key supplier decision criterion. Design and R&D capability, new product development capability, and up-to-date engineering technology development all fall under this criterion. Engineering management is a crucial consideration for manufacturing companies, unlike companies in other industries, when selecting suppliers.

3.2.8. Service

High-quality service is essential for any organisation to maintain its dominance in today’s competitive market [47]. Several authors, such as Choi and Hartley [48], have suggested that the service provided by a supplier has a huge effect on supplier selection. After-sales service and support, responsiveness, and the customer complaint management process are essential components of the level of service. Improving the level of service can directly lead to customer satisfaction and eventually increase competitiveness.

3.3. Establishment of Supplier Rating System

The FTOPSIS approach was used to construct the supplier rating system.

3.3.1. Fuzzy Set Method

One of the most commonly used fuzzy methods, the triangular FN (TFN) method, was used in this study because of its intuitive and computational simplicity [49]. A triangular FN à is defined as (l, m, u) where l, m, and u indicate the smallest potential value, the greatest possible value, and the largest promising value, respectively. A fuzzy set is defined by its membership function. The membership function μÃ(x) of à is described as follows:

In this study, a five-point scale was adopted because it allowed the decision makers to easily make subjective judgements, defined as very poor (VP), poor (P), medium (M), good (G), or very good (VG). The TFN method was applied to specify the linguistic values of the variables. The FNs defined by Chou et al. [50] were included in this study and are presented in Table 1.

Table 1.

Linguistic scale to evaluate the performance of alternatives.

3.3.2. FTOPSIS Model

Suppose that there are k alternatives and n evaluation criteria. The linguistic variables are used by the decision makers, DMr (r = 1, …, p), to score these alternatives according to n criteria. W = (w1, w2,…, wn) is defined as the relative weight vector of the criteria, satisfying . In addition, indicates the rating of the ith alternative, Ai (I = 1, …, n), related to evaluation criterion j. As a result, the FTOPSIS method includes the following steps [51,52]:

Step 1: The initial evaluation scores given by decision makers are aggregated using a geometric mean method. Thus, the fuzzy decision matrix of k alternatives () is given by Equation (2):

C1 … Cn

Step 2: The decision matrix is normalised using a linear scale transformation. The normalised fuzzy decision matrix can be represented as follows:

Step 3: The weighted normalised decision matrix is calculated using Equation (9):

Step 4: The fuzzy positive ideal solution (FPIS, A+) and the fuzzy negative ideal solution (FNIS, A−) can be calculated as follows:

where and , i = 1, 2, …, k and j = 1, 2, …, n.

Step 5: The Euclidean distance of each criterion from the FPIS () and the FNIS (), respectively, can be calculated as follows:

Step 6: The relative closeness coefficient (CCi) of alternative Ai to the ideal solution can be computed as follows:

Step 7: The ranking of all alternatives is determined based on the CCi values.

CCi is between 0 and 1. As the CCi value approaches 1, alternative Ai is closer to the FPIS and farther from the FNIS. Therefore, the best alternative is the one with the highest CCi.

4. Analysis and Application

4.1. Data Collection

This study first used a large-scale survey approach to reduce the dimensionality of 70 criteria and determined the weight of each criterion. The survey questionnaire included all supplier evaluation criteria plus an optional question to identify additional supplier evaluation criteria. The respondents were asked to rate the level of importance of the criteria on a seven-point Likert-type scale, ranging from 1 (extremely unimportant) to 4 (neutral) to 7 (extremely important). An N/A option was included in case a respondent had no relevant experience.

As this study explored supplier selection in manufacturing firms, the data collection focused on the procurement departments, quality departments, and technology departments of manufacturing companies in mainland China. Respondents from these departments were likely to be knowledgeable about SS. Based on Dillman’s [53] survey methods, a mixed-mode survey was used. The survey was mainly conducted online. In addition, an email survey and follow-up telephone calls were used for some respondents if necessary and to remind them to return their completed questionnaires.

The questionnaires were sent to 150 professionals and 130 responses were obtained. A questionnaire was considered invalid if more than 10% of the items had not been completed or if the options selected were consistent. Thus, seven questionnaires were eliminated before further analysis, yielding an effective response rate of 82.0%. The 130 responses were obtained from manufacturing companies. The directors, CEOs, general managers, and department managers of these companies were interviewed. The majority of the 122 respondents were men (57.4%), were aged 30 to 39 (46.7%), and had a Bachelor’s degree. More than half of the respondents had more than 10 years of work experience and communicated frequently with suppliers. As the most widely used method of estimating reliability, Cronbach’s alpha was adopted in this study. In general, an alpha value greater than 0.7 indicates sound reliability. All Cronbach’s alpha values were above the threshold of 0.70, indicating that all of the items were reliable.

4.2. Factor Analysis Results

Exploratory factor analysis was used to reduce instability due to the large number of evaluation criteria [54]. The KMO values are between 0.610 and 0.902 and Bartlett’s significance value is 0.000 for all of the criteria, indicating that the model is suitable for factor analysis.

The factors were extracted with SPSS using principal component analysis with varimax rotation. All factors with an eigenvalue greater than or equal to 1 were extracted [55]. Table 2 summarises the results of the exploratory factor analysis of the sub-criteria.

Table 2.

Summary of the exploratory factor analysis results for the sub-criteria.

The initial 70 selection criteria identified from literature were reduced to eight selection dimensions and 19 sub-criteria of these eight dimensions. The factor analysis results are presented below.

Relationships (R): three variables observed, Supplier Participates in Supply Chain Management (SPSCM), Business Cooperation (BC), and Communication Ability (CA).

Company Management (CM): two variables observed, Human Resource Management (HRM) and Company Operations (CO).

Cost (C): two variables observed, Price (P) and Payment Terms (PT).

Delivery (D): three variables observed, Order Schedule Control (OSC), Delivery Management (DM), and Logistics Management (LM).

Quality (Q): two variables observed, Quality Management System (QMS) and Product Quality Control (PQC).

Production Management (PM): three variables observed, Environmental Management (EM), Raw Materials Management (RMM), and Site Management (SM).

Engineering and Technology Management (ETM): two variables observed, Engineering Application Management (EAM), and Technology Management System (TMS).

Service (S): two variables observed, Response Capability (RC) and After-sales Service (AS).

4.3. Application of the SEM Approach

SEM was used to evaluate the effects of supplier selection criteria on SS process. The eight evaluation dimensions are considered as second-order latent variables, with the factors observed from factor analysis as the lower-order variables. This model analysed the relationships between a cluster of observed variables and a predetermined number of latent variables. First, reliability and validity were tested and checked. Next, the model was analysed and synthesised to determine the relative weight of each factor for SS. The data were analysed using SPSS 24 and LISREL 8.8. Maximum likelihood estimation was used for the second-order confirmatory factor analysis in this study.

The variables in the lower-order model are significant at the 0.05 level, as all t-values are greater than 1.697. Statistical significance and the factor estimate also indicate that the variables are valid. In addition, the eight variables (evaluation dimensions) have positive values. These results are further confirmed by the goodness-of-fit measures used to evaluate the overall model fit. The fit indices (CMIN/df = 1.462, RMSEA = 0.062, NFI = 0.91, NNFI = 0.96, CFI = 0.97 and SRMSR = 0.052) indicate a reasonable fit [54,56].

Table 3 shows that all path coefficients are positive. In addition, the t-values of the variables range from 2.58 to 10.77, well within the significance level of 0.05. Therefore, the effects of Relationships, Company Management, Cost, Delivery, Quality, Production Management, Engineering and Technology Management, and Service on the SS process are significant.

Table 3.

The effects of supplier selection and evaluation criteria on SS process.

These results indicate that the proposed model explains a large percentage of the variance in the SS process. Therefore, the SEM model ensures that the proposed model is consistent and acceptable. The objective weight of each evaluation dimension and criterion was computed from the normalised path coefficient. The results are tabulated in Table 4.

Table 4.

Relative weights of the selection dimensions and criteria.

4.4. Application of the Model

4.4.1. Background of the Case Company and Problem Description

The model was implemented in a manufacturing company in Shenzhen. This company offered a suitable case study setting. It was a pioneer in the manufacturing of certain electronic products in China but selected its suppliers mainly based on their product prices. However, the supplier with the lowest prices could not consistently control the quality of its products or deliver materials within the predetermined time frame. The supplier’s failure ultimately resulted in a double loss of reputation and money. To solve this problem, the proposed SS system was implemented in this company. Five alternative suppliers, A1, A2, A3, A4 and A5, were considered to supply hardware components to the company. These suppliers were shortlisted based on important criteria affecting the supplier evaluation process.

4.4.2. Supplier Performance Evaluation by Group DMs

To assess the performance of each supplier, a questionnaire was designed to collect data from the company. A decision-making group of three experts (DM1, DM2, and DM3) was asked to independently evaluate the five suppliers (A1, A2, A3, A4 and A5) based on the evaluation dimensions. The three experts came from the procurement department and had rich experience and knowledge of the supply chain of this firm. Table 5 presents basic information on these experts. The performance of each supplier was rated using the following linguistic scale: very good (VG), good (G), medium (M), poor (P), and very poor (VP). The initial assessment scores given by the three experts are reported in Table 6.

Table 5.

Basic information on the three experts.

Table 6.

Initial evaluation scores given by the three experts.

4.4.3. Application of the Supplier Rating System

The linguistic variables used to assess the performance of alternative vendors are defined in Table 1. The scores of the three experts were aggregated according to Equation (2). The fuzzy aggregated decision matrix is shown in Table 7.

Table 7.

Fuzzy aggregated decision matrix.

Next, the weighted normalised fuzzy decision matrix was obtained based on Equations (3)–(7) and the weight matrix. The results are reported in Table 8.

Table 8.

Weighted normalised decision matrix.

The FPIS and FNIS were determined based on the above results and Equations (8) and (9). Subsequently, the distance of each alternative from the FPIS and FNIS was calculated using Equations (10) and (11), respectively. The results are reported in Table 9.

Table 9.

Distance from A+ and A− based on the rating of each alternative.

As a last step, the CC for each alternative was computed. The results are presented in Table 10, including their ranking. The CCs of the five alternatives are 0.67, 0.63, 0.91, 0.89, and 0.65, respectively. These results show that alternative A3 is the best supplier for this company to manufacture hardware components. The supplier A4 is only slightly weaker than the top performer (supplier A3). Thus, supplier A4 can be used as an alternative plan in case of emergency. However, suppliers A1, A2, and A5 should not be considered, due to their unsatisfactory performance.

Table 10.

CC for FTOPSIS and ranking.

5. Discussion and Conclusions

5.1. Discussion

This study applying a hybrid method to select suppliers for manufacturing firms. First, we propose a supplier selection framework that has eight dimensions and their associated criteria. The selection framework developed in this study clearly identified the criteria to consider when evaluating alternatives, and its reliability and validity were confirmed. We use factor analysis to reduce the dimensionality of the selection factors and apply SEM to evaluate the significance and weight of each dimension and criterion. Therefore, this selection framework can give manufacturing companies an accurate and comprehensive representation of suppliers. The framework also suggests actions to be undertaken by organisations. It can help to determine the relative weight of each criterion, enabling manufacturers to review their focus to improve the efficiency of the decision-making process. In addition, the FTOPSIS approach is applied as the supplier rating system. This supplier rating system considerably improves the accuracy of the supplier selection process as it can transform subjective and qualitative information into quantitative data. It allows DMs to include inaccurate, incomplete and intuitive information in SS process.

Each method of the hybrid method plays an important role in the SS process. First, the factor analysis helps to reduce the dimensionality. As a large number of factors are involved during SS process and up to 70 sub-criteria are included in this study, the method of factor analysis helps to realize the feasibility of only using limited dimensions and criteria during SS process while without omitting important information. Second, the SEM is used to evaluate the significance and assign a weight to each selection dimension and criteria to indicate its relative importance. SEM first validates the significance of each dimension and criterion for SS process by estimating a second-order confirmatory factor model, then determines the weight of each dimension and criterion via a more objective way than other subjective approaches that a DM assigns a precise rate to the relative importance of each criterion. Third, the FTOPSIS supplier rating system considers the vagueness associated with SS. It allows to specify the values of linguistic variables and choose the ideal solution that has the shortest distance from the positive ideal solution and the farthest from the negative ideal solution. Finally, a case study in a Chinese company validates the practical nature of the proposed hybrid model. The SS can be performed by group DMs and is simple and accurate in its nature. Therefore, the simpleness, accuracy and practicability of the hybrid mothed are obtained by merging the advantages of each mothed.

The proposed hybrid model was proved to have the capability to deal with the SS challenges identified in the literature. When a large number of criteria are involved, the SS process can be very complex, and inviable to determine the weight by rating the relative importance of each criterion. Factor analysis helps to reduce the dimensionality of numerous criteria, while includes all the important information. Determination of the criteria weight is usually subjective and intuitive, and costly when DMs have to rate the relative importance of criteria by ranking or by pair comparison. As the large number of criteria is reduced to limited dimensionality, the significance of each dimension and criterion is validated by SEM, the combination of factor analysis and SEM propose a more viable, cheap, and objective way to determine the weight. This approach also avoids reaching a consensus among a group of DMs. The data were collected via a large-scale survey, and DMs only need to rate the performance of each alternative supplier. The proposed hybrid SS model also practically validated via a case study, help a real-world company establish a more comprehensive multi-criteria SS process. For many years, this company only select suppliers simply based on price. As new competitive priorities are frequently added to global competitiveness, the old mode based on price is outdated, and the new hybrid model is helpful to enhance its competitiveness. Therefore, the practical nature of the hybrid model is validated through a case study.

The managerial implication of this study may be as follows. Companies should first reduce the dimensionality of numerous supplier selection criteria to a practical degree. Though the number of the criteria is increasing due to intensive competitiveness, the operability should be considered to balance the cost and the complexity of SS process considering the local context. Second, the model can help manufacturing firms identify the important factors in supplier selection. The weight from the SEM result indicates the relative importance of each criterion. A firm can use this information as a reference and assesses the performance of suppliers to find out improvement opportunities in supplier management. Finally, this selection framework and rating system can not only help manufacturing firms make decisions; it can also be used by suppliers to perform self-assessment and fill gaps in the aforementioned areas. In addition, it can provide guidance on the formulation of suppliers’ future development strategies.

5.2. Conclusions

This study developed a scientific framework using factor analysis, SEM, and FTOPSIS to solve the supplier selection problem for manufacturing firms. Through a literature review, a case study of the framework’s practical application in a company, and the verification of manufacturing experts, the study clearly identified and defined the key elements to consider in the SS process. A total of 70 factors were identified as influencing the supplier selection process. After simplifying the model using factor analysis, the study used SEM to test the main influencing factors and the eight derived selection criteria and obtain the relative weight of each evaluation dimension and criterion. The results indicated the significant effects of the eight evaluation dimensions on the supplier decision process. In the last step, a rating system was developed. It applied fuzzy set theory to present the linguistic values of alternatives based on the subjective judgements of a group of DMs, then adopted the FTOPSIS method to integrate these judgements and calculate the optimal solution.

The study also implemented the proposed model in a manufacturing company in Shenzhen. First, this model provides a reference for manufacturing companies to select the right suppliers. Second, it can help suppliers develop appropriate strategic plans for their future management and development. As a result, based on the proposed model, both suppliers and manufacturers can benefit, achieve a win-win situation, and further improve the efficiency and effectiveness of the supply chain process.

5.3. Limitations and Future Research

Although the proposed model is believed to be a valuable reference, it has limitations. First, the scope of this study is limited in several ways. The sample size was small. The number of respondents should be increased to improve reliability and validity. Second, the proposed model only applies to a specific type of manufacturer, as it was based on the opinions of experts from the Chinese manufacturing industry. The results of survey questionnaires in other industries or countries may be different. With constantly evolving development and requirements, expert opinions may also change and result in different weights for the criteria. However, with new data, the proposed model could solve other decision-making problems in other contexts. Therefore, future research should focus on supplier selection problems in other industries or compare the evaluation frameworks used in different industries. In addition, future research should assign weight to decision makers based on their professionalism, experience, responsibilities, and other types of assessment criteria that can vary among experts. Third, though this model attempts to handle qualitative and subjective information more accurate, it is worth noting that companies must ensure the objectivity and accuracy of the opinions of experts when evaluating alternatives. Suppliers also need not conceal or falsify their actual situations to influence the final evaluation results. The accuracy of the data is conducive to the development of both parties. Finally, in addition to the FTOPSIS approach presented in this study, other MCDM methods, such as VIKOR, MABAC, and ARAS etc. should be applied in a fuzzy environment.

Author Contributions

Conceptualization, H.S. and W.N.; formal analysis, B.Z.; writing—original draft preparation, B.Z., and H.S.; writing—review and editing, H.S. and W.N. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

The study did not require ethical approval.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to business reason.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A. Selection Dimensions and Criteria for SS

| Selection Dimension | Code | Selection Criterion |

| Relationships | R1 | Ease of communication |

| R2 | Family relationships | |

| R3 | Friendship | |

| R4 | Business partnerships | |

| R5 | Merger and acquisition relationships | |

| R6 | Information sharing (sales forecasts, production plans, delivery status, stock level) | |

| R7 | Joint decision-making (product and process design/modification, quality improvement) | |

| R8 | Supplier participation in new product development | |

| Company Management | CM1 | Company development potential |

| CM2 | Corporate financial performance | |

| CM3 | Corporate reputation | |

| CM4 | Production capability | |

| CM5 | Organisational structure | |

| CM6 | Position function and definition of authority | |

| CM7 | Special job qualification | |

| CM8 | Regular training | |

| CM9 | Occupational health and safety management system | |

| Cost | C1 | Product price |

| C2 | Product cost | |

| C3 | Corporate tax rate | |

| C4 | Business and payment terms | |

| C5 | Cost reduction plan | |

| Delivery | D1 | Lead time |

| D2 | On-time rate | |

| D3 | Order fulfilment rate | |

| D4 | Geographical location | |

| D5 | Type of delivery | |

| D6 | Emergency order processing system and cooperation | |

| D7 | Order scheduling plan | |

| D8 | Progress control of product processing | |

| D9 | Guidance document for delivery control | |

| Quality | Q1 | Passed the quality management system certification |

| Q2 | Quality system operation | |

| Q3 | Document management | |

| Q4 | Quality improvement action | |

| Q5 | Correction and prevention of quality problems | |

| Q6 | Quality control of the production process (TQM, Six Sigma project, QQC activity) | |

| Q7 | Configuration of quality inspection staff | |

| Q8 | Configuration of quality inspection equipment | |

| Q9 | Quality inspection document | |

| Q10 | Statistical process control | |

| Production Management | PM1 | Effective means of detection and control |

| PM2 | Differentiation and identification of materials | |

| PM3 | Configuration and application of detection instruments | |

| PM4 | Environmental certification | |

| PM5 | Timely handling of bad materials | |

| PM6 | Product identification | |

| PM7 | Visual management | |

| PM8 | 5S implementation | |

| PM9 | Operational guidelines and standards | |

| PM10 | Supplier management measures | |

| PM11 | Strategic preparation of long-term materials required | |

| PM12 | Timely capture the market status of materials | |

| Engineering and Technology Management | ETM1 | Engineering Change Notice (ECN) control system |

| ETM2 | R&D equipment and software | |

| ETM3 | New product development system | |

| ETM4 | R&D recruitment | |

| ETM5 | Product update | |

| ETM6 | Product customisation | |

| ETM7 | Normative engineering drawings | |

| ETM8 | Guidance on engineering materials | |

| ETM9 | Rationality of jig and fixture | |

| ETM10 | Management of jig and fixture | |

| ETM11 | Management of engineering documents | |

| Service | S1 | Response speed |

| S2 | Efficient information system | |

| S3 | Emergency priority | |

| S4 | Customer complaint system and fault correction system | |

| S5 | Solicit customer feedback | |

| S6 | Professional service staff |

References

- Gallear, D.; Ghobadian, A.; He, Q.; Kumar, V.; Hitt, M. Relationship between routines of supplier selection and evaluation, risk perception and propensity to form buyer–supplier partnerships. Prod. Plan. Control 2021, 1–17. [Google Scholar] [CrossRef]

- Sureeyatanapas, P.; Sriwattananusart, K.; Niyamosoth, T.; Sessomboon, W.; Arunyanart, S. Supplier selection towards uncertain and unavailable information: An extension of TOPSIS method. Oper. Res. Perspect. 2018, 5, 69–79. [Google Scholar] [CrossRef]

- McCardle, J.G.; Rousseau, M.B.; Krumwiede, D. The effects of strategic alignment and competitive priorities on operational performance: The role of cultural context. Oper. Manag. Res. 2019, 12, 4–18. [Google Scholar] [CrossRef]

- Kant, R.; Dalvi, M.V. Development of questionnaire to assess the supplier evaluation criteria and supplier selection benefits. Benchmarking Int. J. 2017, 24, 359–383. [Google Scholar] [CrossRef]

- Wetzstein, A.; Hartmann, E.; Benton, W.C., Jr.; Hohenstein, N.-O. A systematic assessment of supplier selection literature—State-of-the-art and future scope. Int. J. Prod. Econ. 2016, 182, 304–323. [Google Scholar] [CrossRef]

- Xie, L.; Ma, J.; Goh, M. Supply chain coordination in the presence of uncertain yield and demand. Int. J. Prod. Res. 2020, 59, 4342–4358. [Google Scholar] [CrossRef]

- Nădăban, S.; Dzitac, S.; Dzitac, I. Fuzzy TOPSIS: A General View. Procedia Comput. Sci. 2016, 91, 823–831. [Google Scholar] [CrossRef]

- Zhang, Z.; Lei, J.; Cao, N.; To, K.; Ng, K. Evolution of supplier selection criteria and methods. In Proceedings of the Second Globelics Conference Innovation Systems and Development, Emerging Opportunities and Challenges, Beijing, China, 16–20 October 2004. [Google Scholar]

- Dickson, G.W. An Analysis of Vendor Selection Systems and Decisions. J. Purch. 1966, 2, 5–17. [Google Scholar] [CrossRef]

- Dutta, P.; Jaikumar, B.; Arora, M.S. Applications of data envelopment analysis in supplier selection between 2000 and 2020: A literature review. Ann. Oper. Res. 2021, 315, 1399–1454. [Google Scholar] [CrossRef]

- Krause, D.R.; Pagell, M.; Curkovic, S. Toward a measure of competitive priorities for purchasing. J. Oper. Manag. 2001, 19, 497–512. [Google Scholar] [CrossRef]

- Akarte, M.M.; Surendra, N.V.; Ravi, B.; Rangaraj, N. Web based casting supplier evaluation using analytical hierarchy process. J. Oper. Res. Soc. 2001, 52, 511–522. [Google Scholar] [CrossRef]

- Stević, Ž. Criteria for supplier selection: A literature review. Int. J. Eng. Bus. Enterp. Appl. 2017, 19, 23–27. [Google Scholar]

- Deshmukh, A.J.; Chaudhari, A.A. A Review for Supplier Selection Criteria and Methods; Shah, K., Gorty, V.R.L., Phirke, A., Eds.; Springer: Berlin/Heidelberg, Germany, 2011; Volume 145, pp. 283–291. [Google Scholar]

- Govindan, K.; Rajendran, S.; Sarkis, J.; Murugesan, P. Multi criteria decision making approaches for green supplier evaluation and selection: A literature review. J. Clean. Prod. 2015, 98, 66–83. [Google Scholar] [CrossRef]

- Durmić, E.; Stević, Z.; Chatterjee, P.; Vasiljević, M.; Tomašević, M. Sustainable supplier selection using combined FUCOM—Rough SAW model. Rep. Mech. Eng. 2020, 1, 34–43. [Google Scholar] [CrossRef]

- Badi, I.; Academy, M.L.; Pamucar, D. Supplier selection for steelmaking company by using combined Grey-Marcos methods. Decis. Mak. Appl. Manag. Eng. 2020, 3, 37–48. [Google Scholar] [CrossRef]

- Kazemitash, N.; Fazlollahtabar, H.; Abbaspour, M. Rough Best-Worst Method for Supplier Selection in Biofuel Companies based on Green criteria. Oper. Res. Eng. Sci. Theory Appl. 2021, 4, 1–12. [Google Scholar] [CrossRef]

- Garg, R.K. Structural equation modeling of E-supplier selection criteria in mechanical manufacturing industries. J. Clean. Prod. 2021, 311, 127597. [Google Scholar] [CrossRef]

- Nguyen, P.-H.; Tsai, J.-F.; Lin, M.-H.; Hu, Y.-C. A Hybrid Model with Spherical Fuzzy-AHP, PLS-SEM and ANN to Predict Vaccination Intention against COVID-19. Mathematics 2021, 9, 3075. [Google Scholar] [CrossRef]

- Jakhar, S.K.; Barua, M.K. An integrated model of supply chain performance evaluation and decision-making using structural equation modelling and fuzzy AHP. Prod. Plan. Control 2013, 25, 938–957. [Google Scholar] [CrossRef]

- Hwang, C.-L.; Yoon, K. Methods for Multiple Attribute Decision Making. In Multiple Attribute Decision Making; Springer: Berlin/Heidelberg, Germany, 1981; pp. 58–191. [Google Scholar]

- Yoon, K. A reconciliation among discrete compromise solutions. J. Oper. Res. Soc. 1987, 38, 277–286. [Google Scholar] [CrossRef]

- Hwang, C.-L.; Lai, Y.-J.; Liu, T.-Y. A new approach for multiple objective decision making. Comput. Oper. Res. 1993, 20, 889–899. [Google Scholar] [CrossRef]

- Bottani, E.; Rizzi, A. A fuzzy TOPSIS methodology to support outsourcing of logistics services. Supply Chain Manag. Int. J. 2006, 11, 294–308. [Google Scholar] [CrossRef]

- Kizielewicz, B.; Bączkiewicz, A. Comparison of Fuzzy TOPSIS, Fuzzy VIKOR, Fuzzy WASPAS and Fuzzy MMOORA methods in the housing selection problem. Procedia Comput. Sci. 2021, 192, 4578–4591. [Google Scholar] [CrossRef]

- Zadeh, L.A. Fuzzy sets. Inf. Control. 1965, 8, 338–353. [Google Scholar] [CrossRef]

- Zadeh, L.A. The concept of a linguistic variable and its application to approximate reasoning—I. Inf. Sci. 1975, 8, 199–249. [Google Scholar] [CrossRef]

- Liou, T.-S.; Wang, M.-J.J. Ranking fuzzy numbers with integral value. Fuzzy Sets Syst. 1992, 50, 247–255. [Google Scholar] [CrossRef]

- Abbasbandy, S.; Hajjari, T. A new approach for ranking of trapezoidal fuzzy numbers. Comput. Math. Appl. 2009, 57, 413–419. [Google Scholar] [CrossRef]

- Feng, Y. Gaussian fuzzy random variables. Fuzzy Sets Syst. 2000, 111, 325–330. [Google Scholar] [CrossRef]

- Bellman, R.E.; Zadeh, L.A. Decision-making in a fuzzy environment. Manag. Sci. 1970, 17, B-141–B-164. [Google Scholar] [CrossRef]

- Dağdeviren, M.; Yavuz, S.; Kılınç, N. Weapon selection using the AHP and TOPSIS methods under fuzzy environment. Expert Syst. Appl. 2009, 36, 8143–8151. [Google Scholar] [CrossRef]

- Şengül, Ü.; Eren, M.; Shiraz, S.E.; Gezder, V.; Şengül, A.B. Fuzzy TOPSIS method for ranking renewable energy supply systems in Turkey. Renew. Energy 2015, 75, 617–625. [Google Scholar] [CrossRef]

- Govindan, K.; Darbari, J.D.; Agarwal, V.; Jha, P. Fuzzy multi-objective approach for optimal selection of suppliers and transportation decisions in an eco-efficient closed loop supply chain network. J. Clean. Prod. 2017, 165, 1598–1619. [Google Scholar] [CrossRef]

- Ristono, A.; Santoso, P.B.; Tama, I.P. A literature review of design of criteria for supplier selection. J. Ind. Eng. Manag. 2018, 11, 680–696. [Google Scholar]

- Hoque, I.; Rana, M.B. Buyer–supplier relationships from the perspective of working environment and organisational performance: Review and research agenda. Manag. Rev. Q. 2019, 70, 1–50. [Google Scholar] [CrossRef]

- Mady, M.T.; Mady, T.T.; Mady, S.T. Procurement performance and manufacturer-supplier relationships: A multivariate analysis in Kuwaiti manufacturing companies. J. Bus. Ind. Mark. 2014, 29, 417–426. [Google Scholar] [CrossRef]

- Kannan, D.; Khodaverdi, R.; Olfat, L.; Jafarian, A.; Diabat, A. Integrated fuzzy multi criteria decision making method and multi-objective programming approach for supplier selection and order allocation in a green supply chain. J. Clean. Prod. 2013, 47, 355–367. [Google Scholar] [CrossRef]

- Olorunniwo, F.; Jolayemi, J. Using supplier selection sub-criteria: Selected illustrative demographic analyses. Int. J. Bus. Perform. Supply Chain Model. 2014, 6, 94–108. [Google Scholar] [CrossRef]

- Kannan, G.; Haq, A.N. Analysis of interactions of criteria and sub-criteria for the selection of supplier in the built-in-order supply chain environment. Int. J. Prod. Res. 2007, 45, 3831–3852. [Google Scholar] [CrossRef]

- DeCampos, H.A.; Rosales, C.R.; Narayanan, S. Supply chain horizontal complexity and the moderating impact of inventory turns: A study of the automotive component industry. Int. J. Prod. Econ. 2021, 245, 108377. [Google Scholar] [CrossRef]

- Lim, A.-F.; Lee, V.-H.; Foo, P.-Y.; Ooi, K.-B.; Tan, G.W.H. Unfolding the impact of supply chain quality management practices on sustainability performance: An artificial neural network approach. Supply Chain. Manag. 2022, 27, 611–624. [Google Scholar] [CrossRef]

- Schonberger, R.J.; Gilbert, J.P. Just-in-Time Purchasing: A Challenge for U.S. Industry. Calif. Manag. Rev. 1983, 26, 54–68. [Google Scholar] [CrossRef]

- Luis, F.; Amaral, A.; Oliveira, J. Quality 4.0: The EFQM 2020 Model and Industry 4.0 Relationships and Implications. Sustainability 2021, 13, 3107. [Google Scholar]

- Bao, B.; Ma, J.; Goh, M. Short- and long-term repeated game behaviours of two parallel supply chains based on government subsidy in the vehicle market. Int. J. Prod. Res. 2020, 58, 7507–7530. [Google Scholar] [CrossRef]

- Punniyamoorty, M.; Mathiyalagan, P.; Lakshmi, G. A combined application of structural equation modeling (SEM) and analytic hierarchy process (AHP) in supplier selection. Benchmarking Int. J. 2012, 19, 70–92. [Google Scholar] [CrossRef]

- Choi, T.Y.; Hartley, J.L. An exploration of supplier selection practices across the supply chain. J. Oper. Manag. 1996, 14, 333–343. [Google Scholar] [CrossRef]

- Chou, S.; Chang, Y. A decision support system for supplier selection based on a strategy-aligned fuzzy SMART approach. Expert Syst. Appl. 2008, 34, 2241–2253. [Google Scholar] [CrossRef]

- Chou, Y.-C.; Sun, C.-C.; Yen, H.-Y. Evaluating the criteria for human resource for science and technology (HRST) based on an integrated fuzzy AHP and fuzzy DEMATEL approach. Appl. Soft Comput. 2012, 12, 64–71. [Google Scholar] [CrossRef]

- Ravikumar, M.; Marimuthu, K.; Parthiban, P.; Zubar, H.A. Evaluating lean execution performance in Indian MSMEs using SEM and TOPSIS models. Int. J. Oper. Res. 2016, 26, 104–125. [Google Scholar] [CrossRef]

- Junior, F.R.L.; Osiro, L.; Carpinetti, L.C.R. A comparison between Fuzzy AHP and Fuzzy TOPSIS methods to supplier selection. Appl. Soft Comput. 2014, 21, 194–209. [Google Scholar] [CrossRef]

- Dillman, D.A.; Smyth, J.D.; Christian, L.M. Internet, Phone, Mail, and Mixed-Mode Surveys: The Tailored Design Method; John Wiley & Sons: Hoboken, NJ, USA, 2014. [Google Scholar]

- Karaveg, C.; Thawesaengskulthai, N.; Chandrachai, A. A combined technique using SEM and TOPSIS for the commercialization capability of R & D project evaluation. Decis. Sci. Lett. 2015, 4, 379–396. [Google Scholar]

- Deshmukh, A.; Vasudevan, H.; Principal, D. Analysis of Supplier Selection Criteria in Traditional as well as Green Supply Chain Management in Indian MSMEs. Int. J. Bus. Quant. Econ. Appl. Manag. Res. 2016, 3, 73–85. [Google Scholar]

- Dash, G.; Paul, J. CB-SEM vs PLS-SEM methods for research in social sciences and technology forecasting. Technol. Forecast. Soc. Change 2021, 173, 121092. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).