Abstract

In this work, we have presented a soft encapsulating gripper for gentle grasps. This was enabled by a series of soft origami patterns, such as the Yoshimura pattern, which was directly printed on fabric. The proposed gripper features a deformable body that enables safe interaction with its surroundings, gentle grasps of delicate and fragile objects, and encapsulated structures allowing for noninvasive enclosing. The gripper was fabricated by a direct 3D printing of soft materials on fabric. This allowed for the stiffness adjustment of gripper components and a simple fabrication process. We evaluated the grasping performance of the proposed gripper with several delicate and ultra-gentle objects. It was concluded that the proposed gripper could manipulate delicate objects from fruits to silicone jellyfishes and, therefore, have considerable potential for use as improved soft encapsulating grippers in agriculture and engineering fields.

1. Introduction

Traditional rigid robots have been used in industries owing to their repeatability and time efficiency, which can reduce costs and production time [1,2,3]. However, these require additional sensors and actuators [4]. These components complicate the robot’s operating system and require more space. Moreover, they require complex measurements and control systems to integrate information from sensors and regulate multiple actuators, making it complicated to control and expensive to manufacture traditional robots.

Recently, soft robotics has received considerable attention in robotics fields as a complement to traditional robots [5,6,7,8,9,10]. By utilizing the adaptability and compliance of their soft body, soft robotic grippers can manipulate rigid objects and deformable and brittle objects without extra devices [11,12,13,14,15,16]. Several soft robotic grippers have been proposed to safely manipulate objects: pneumatic grippers, Shape Memory Alloys (SMA) grippers, and Dielectric Elastomer Actuator (DEA) grippers.

Pneumatic pressurizes soft chamber to obtain deformations such as bending. The characteristics of pneumatic grippers make them appealing, such as large deformation, fast actuation speed, and easy operation [15,17,18]. For example, a pneumatic gripper combined with 3D knitting can be manufactured cheaply, lifting objects up to 8.7 times the actuator weight [17]. Y. Wu et al. also propose a pneumatic gripper composed of different lengths of segments and capable of grasping different fruits with sizes from 20 mm to 70 mm and weights from 11 g to 225 g [19]. Despite the excellent performance of pneumatic grippers, it is still challenging to grasp gelatinous organisms. Furthermore, bulky air compressors are required to operate pneumatic grippers.

SMA soft grippers are grippers that embed shape memory alloy into an elastomer and apply current to induce deformation such as bending [11,20,21]. SMA grippers are known for their silence, high energy density, and simple operation method. Lee et al. show that a soft gripper with free-sliding SMA can grip objects weighing up to 1.5 kg and the maximum pulling force is measured to be 30 N [11]. However, the heat generation during the operation of the grippers makes SMA grippers difficult to interact with organisms and their slow operation speed hinders continuous use.

DEA grippers operate by applying electric force on elastomer [22,23]. Due to their lightweight, low cost, and fast response, DEA grippers have the potential to be used in various applications. The flexibility of DEA allows the gripper to stably and gently grip objects. There is an example showing that DEA grippers can grip highly deformable objects such as water-filled balloons, raw eggs, and a sheet of paper [24]. Nevertheless, high voltage applied to their electrodes may inflict serious damage to their target objects and themselves, diminishing the range of DEA gripper’s applications.

In an orthogonal approach to utilizing soft materials or actuators, encapsulating structures are utilized through a rigid foldable polyhedron rather than soft fingers. Z. E. Teoh et al. propose a dodecahedrons origami-based encapsulating gripper [25]. They demonstrate that polyhedral foldable grippers can be used to non-destructively capture delicate specimens from the deep sea, such as scyphomedusa, jellyfish, and squid. Despite the advantages of the dodecahedral capsulate gripper, the rigid materials used to fabricate the gripper still leave possible danger from rigid polygonal faces. Their heavy weight, complex operating method, and large size are also problems to overcome.

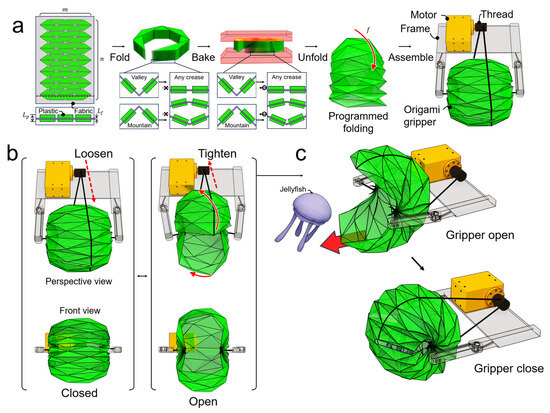

In this paper, we have proposed a method utilizing 3D printing origami patterns on fabric to address the polyhedral enveloping gripper problems mentioned above (Figure 1). It offers the following advantages: First, the size and shape of this gripper can be easily modified. Since we make the gripper based on an origami structure, its size and shape can be easily changed by adjusting the value of geometric parameters according to the field of the application. Second, the gripper can be manufactured in a simple structure with a facile manufacturing process. In particular, our on-fabric 3D printing technique exhibited the programmed folding property of a 3D origami structure, and our origami-based soft encapsulating gripper can operate with a single motor. As a result, the gripper manufacturing process is simplified and the cost and weight of the gripper are reduced. Last, it provides the ability to interact with objects safely. The gripper body is made of a soft material, so when the gripper wraps around an object, it is not destroyed even if it touches the gripper surface. We demonstrate this by manipulating brittle objects such as an egg, a cherry tomato, and a silicon jellyfish.

Figure 1.

Fabrication and application of programmable 3D on-fabric origami structure. (a) Schematic illustration of the fabrication of origami gripper. (b) Illustrations of the operation of the origami gripper. The ori-gripper is opened by tightening the wire using the motor and is closed by loosening the wire. (c) Illustrations demonstrating the application of origami soft encapsulating gripper.

2. Materials and Methods

We employed the Yoshimura pattern to design an enveloping gripper owing to its easy tunability and simple pattern. The Yoshimura pattern can be easily modified by adjusting the geometric parameters of the basic components, such as the angle of triangles and the number of triangles placed in the width of the pattern. Moreover, the pattern of isosceles triangles is simple and easy to manufacture, making it applicable to various fields. Therefore, we decided to use the Yoshimura pattern since these characteristics allowed us to easily fabricate the desired gripper design.

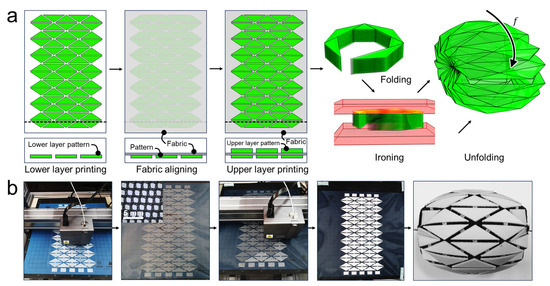

A 120 Denier polyester woven fabric (thickness = 0.22 mm) and thermoplastic polyurethane (TPU) were used to fabricate the gripper. The fabric (Part# 07-0666, Kohas, Republic of Korea) worked as a flexure material owing to its flexible but inextensible properties. These properties allowed the gripper to fold and unfold while maintaining its shape without disarray of TPU components. Moreover, since the fabric is resistant to tearing, the gripper’s structure remains sturdy even after being folded and unfolded multiple times. An array of facets for the Yoshimura pattern and bridges for unfolding were made of TPU and their thickness was adjusted according to their purpose of printing. Specifically, the facets and bridges were printed at 2 mm and 1 mm, respectively, since the former should be rigid to maintain the structure and the latter should be flexible to be folded and unfolded.

We utilized a technique of direct printing on fabric and baking to manufacture the abovementioned origami structure for a gripper (Figure 2). The proposed gripper consists of three components: facets, bridges, and fabric. The facets and bridges were printed with TPU filament (Raise3D) using an FDM printer (Snapmaker 2.0). Then, we inserted the fabric fixed in place with four magnets so that the fabric laid asymmetrically to help unfold the gripper (Figure 2b). When printing resumed, the melt of TPU seeped into the holes of the mesh fabric and well-bonded with the previous layer, resulting in a stable origami pattern. After printing, we sewed the edges of the origami pattern with thread to create a 3D soft encapsulating gripper structure. The structure created by sewing the pattern was folded into the desired fold shape. We placed this folded structure in an oven (JSOF-150; JSR) and baked it for 20 min at 60 °C. As the melting temperature of the TPU was around 70 °C, we chose this temperature to enable the shape-memory effect without melting. After baking, the structure was taken out of the oven and cooled while maintaining the folded state at room temperature. Finally, we attached permanent magnets (10 × 5 × 1T (mm) NDFeB; JLMAGNET) to both entrances of the gripper to further increase the sealing force when the gripper wraps around the objects.

Figure 2.

Fabrication of on-fabric 3D origami pattern with programmed folding. (a) Schematic illustration and (b) digital photograph image of each step of the fabrication of on-fabric 3D origami pattern with programmed folding.

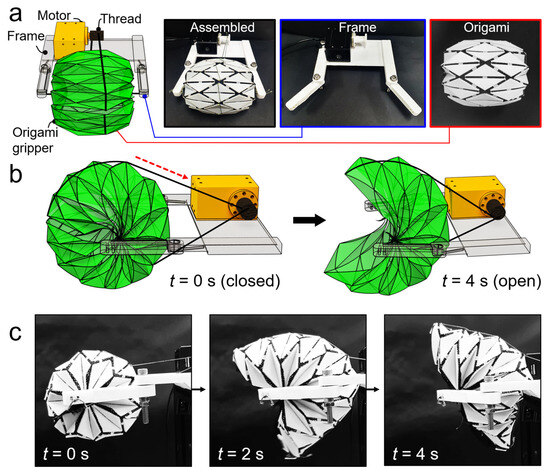

The designed frame and legs were 3D printed using an FDM printer (Raise3D pro2) with PLA filament (Raise3D). To help the operation of a gripper, torsion springs were inserted into the connection between the frame body and the leg, pressing or pulling on both sides of the gripper. After the assembly of the frame and legs was completed, the motor and gripper were mounted on the frame (Figure 3a). To operate the gripper, we connected the gripper and motor. When the head was rotated, the wire was pulled, and the gripper opened. When the motor rotated in the opposite direction, the wire was released and the gripper closed (Figure 3b,c). During the process, the wire was pulled causing the bridges to fold, storing strain energy. Releasing the wire resulted in the gripper returning to its initial state.

Figure 3.

Fabrication of an origami-based soft encapsulating gripper. (a) Illustration of the complete structure of the origami-based soft encapsulating gripper, which consists of origami gripper, frame, and motor. (b) Schematic illustration and (c) digital photograph image of the operation of the origami-based soft encapsulating gripper.

3. Results and Discussion

3.1. Origami Pattern Design

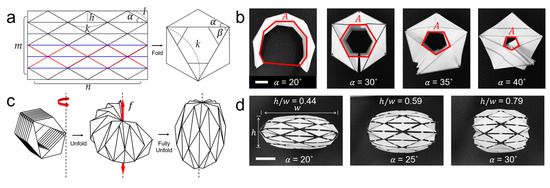

In order to find a suitable parameter for our gripper, we optimized various parameters of the Yoshimura origami pattern. At first, the planar area (A), which is proportional to the volume for encapsulating target objects (represented in red lines in Figure 4b), is investigated. The size of this area can be changed according to the number of isosceles triangles along the horizontal direction (n) and the angle of the isosceles triangle (α). If n is constant, α determines the size of the planar area because the interior angle β of the figure forming the planar area is obtained by Equation (1) below:

β = π − 2α.

Figure 4.

Optimization of 3D origami pattern. (a) Schematic illustration of the 2D origami crease pattern (Yoshimura pattern). The blue line is valley fold line, the red line is mountain fold line. (b) The folded Yoshimura–ori structure with various angles (α = 20°, 30°, 35° and 40°). (c) Schematic illustration of 3D origami gripper structure by unfolding 2D origami crease pattern. (d) Digital photograph image of the fabricated 3D origami gripper structure with respect to various angles (α = 20°, 25°, and 30°).

Specifically, as depicted in Figure 4b, A increased with the decrease α, while the area decreased with the increase in the α. The planar area when the α was 20° increased by 4.15 times compared to the area when the α was 30°. In order to do this, when the α is 35° and 40°, the planar area was reduced to 0.37 and 0.07 of the area with the α of 30°. In addition, when the α is more than 30°, the distal triangles overlap, hindering the folding process of the origami structure. Based on these results, we have set the α to less than 30°. Therefore, we fabricated 3D origami gripper structures with α < 30° in Figure 4d. Also, the length of the base (k) and height (h) of the triangle changes according to Equations (2) and (3).

k = 2l cosα,

h = l sinα.

The horizontal and vertical lengths of the gripper structure are also affected by the angle α value. Since we set the α to 30 degrees or less according to the previous analysis, the length of the legs of the triangle (l) forming the pattern and the number of repetitions of the basic rhombus (m) was fixed. Only the α value was modified to 20°, 25°, and 30° to create the structure. We took pictures of the structures and measured the vertical and horizontal lengths of the structure in Python and divided the vertical length by the horizontal length. As a result, it was found that the ratio was 0.44 when the α was 20°, 0.59 when the α was 25°, and 0.79 when the α was 30°. In order for the gripper to cover the entire object, the lengths of the horizontal and vertical had to be similar, we set 30° as the optimal value of the origami-based soft encapsulating gripper fabrication.

3.2. Programmed Folding by Heat Treatment

Although origami structure exhibits advantages, such as transforming 2D to 3D structure or large volume change, folding and unfolding to the desired crease pattern is necessary. Therefore, we developed the programmed folding of origami to the desired pattern by heat treatment under a folded state (see Figure 1a). We utilized the shape-memory effect of thermoplastic materials, which can be molded at elevated temperatures and solidified when cooled.

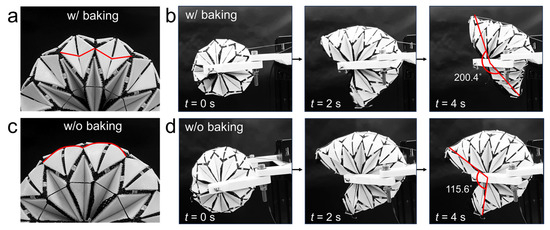

We empirically investigated the effect of heat treatment on an origami structure directly printed on a fabric (Video S1). We fabricated two grippers with the same structure; one went through the baking process (Figure 5a,b) and the other did not (Figure 5c,d). As shown in Figure 5, there is a huge difference between the two grippers with and without heat treatment. In the case of the gripper with heat treatment (Figure 5a,b), the gripper with creases gradually opened and the angle at which the gripper opened was over 180° at which the gripper had the maximum cross-section area. Thus, it could fully employ its grasping capability determined by its design. However, the gripper without heat treatment (Figure 5c,d) does not provide a sufficient opening. The angle of the gripper without creases was much smaller than that of the other one and was little more than 100°. This result was mainly because the bridges of the gripper had to be buckled when the gripper was folded. Even though it could grasp small objects, it cannot fully utilize its full potential of grasping performance. It appears that the heat treatment to an origami structure printed on a fabric enabled programmable folding and achieved the full potential of the grasping capability of a gripper.

Figure 5.

Programmed shape-morphing of the origami-based gripper (a,b) with and (c,d) without heat treatment. In heat-treated gripper (a,b), origami pattern is exhibited inward folding according to the programmed direction as well as wider open angle (θ = 200.4°). However, origami pattern is exhibited outward folding as well as narrower open angle (θ = 115.6°) in the gripper without heat treatment (c,d).

3.3. Origami-Based Soft Encapsulating Gripper Applications

Finally, we demonstrated the applications of our origami-based soft encapsulating gripper. To show the performance of our enveloping gripper that could manipulate fragile and brittle objects in various situations, we chose three objects: an egg, a cherry tomato, and a silicone model jellyfish.

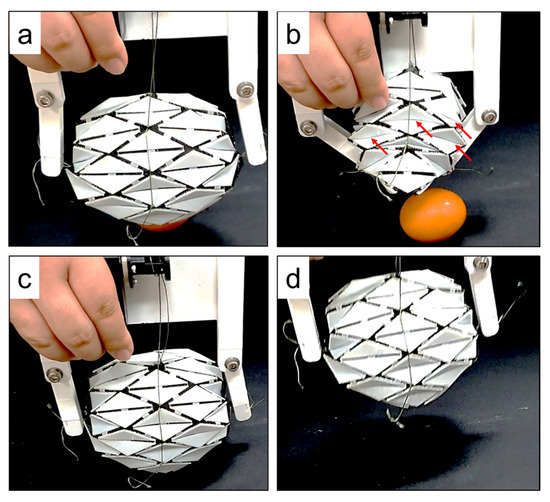

First, we experimented with picking up an egg with the gripper (Figure 6 and Video S2). For this experiment, we placed the egg on a table and moved the gripper near the egg. When the gripper was positioned near the egg, the motor rotated to pull the wire to open the gripper. When the egg was located in the center of the gripper, the motor rotated to release the wire. As the wire was released, the gripper unfolded, wrapping around the egg on the table and placing the target inside the gripper. This experiment confirmed that the wrapped eggs were picked up safely and neatly without any damage on the surface.

Figure 6.

Origami-based soft encapsulating gripper Application 1: pick up an egg. (a) Approach to the target (b) open gripper, (c) close and encapsulate and (d) pick up the target.

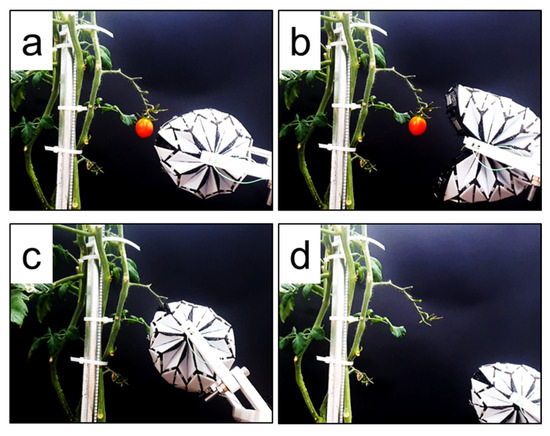

The second demonstration was cherry tomato harvesting (Figure 7 and Video S3). Similar to the previous experiment, we set a target to harvest and moved the gripper to approach the target. When the target was located in the center of the gripper, the motor rotated to close the gripper. After enveloping around the tomato with the gripper, we pulled it to harvest the target. When we opened the gripper and checked the harvested tomatoes, we confirmed that they were harvested with a clean surface without any crush marks.

Figure 7.

Origami-based soft encapsulating gripper Application 2: tomato harvesting. (a) Approach to the target (b) open gripper, (c) close and encapsulate and (d) harvest the target.

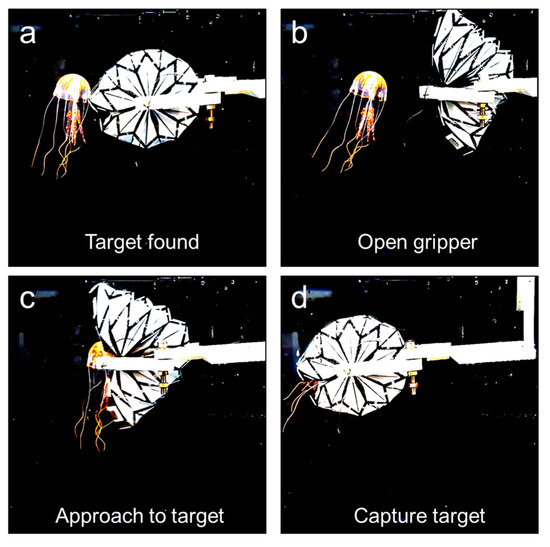

The last demonstration was capturing a silicone model jellyfish (Figure 8 and Video S4). For this experiment, silicone jellyfish were installed in an acrylic tank filled with water. In order to bring the target into the water, the motor frame was attached to a stage that could move in the x, y, and z axes. After setting the axes according to the target’s position, the gripper was moved, and when the gripper was located close to the jellyfish, the motor rotated to open the gripper and capture the silicone jellyfish. Although the legs did not completely enter the gripper, when we took the gripper out of the water and checked the captured object, we could confirm that it was captured intact and without damage.

Figure 8.

Origami-based soft encapsulating gripper Application 3: jellyfish capturing. (a) Approach to the target (b) open gripper, (c) close and encapsulate and (d) capture the target.

The proposed origami-based soft gripper overcomes the limitation of the existing soft gripper by utilizing on-fabric 3D printing. Existing soft grippers use large actuators or operate at high voltages, which limits their use. However, our origami-based soft encapsulating gripper can be operated with a single motor due to the programmed folding and unfolding of the 3D origami structure. With this simple structure, our origami-based soft encapsulating gripper exhibited three demonstrations of encapsulating brittle, fragile, and soft objects (Table 1).

Table 1.

A comparative analysis table that distinguishes the fundamental characteristics of conventional robotic grippers, soft grippers, and origami-based soft encapsulating grippers.

4. Conclusions

We have demonstrated a soft encapsulating gripper for gentle grasps using on-fabric 3D printing. We demonstrated a programmed folding and unfolding of complex 3D origami structures by heat treatment, enabling manufacture in a simple structure by operating with a motor. As a result, the gripper manufacturing process is simplified and the cost and weight of the gripper are reduced. Also, the size and shape of this gripper can be easily modified. Since we make the gripper based on an origami structure, its size and shape can be easily changed by adjusting the value of geometric parameters according to the field of the application. If this property is combined with deep learning-based structure modeling, it is possible to fabricate a structure that is suitable for the task so that we expect the function of our origami gripper can be enhanced. Therefore, we expect that our soft encapsulating gripper could manipulate delicate objects from fruits to silicone jellyfish and have considerable potential for use as improved soft encapsulating grippers in agriculture and engineering fields.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/robotics12060150/s1, Video S1: Gripper with or without heat treatment, Video S2: Picking up an egg, Video S3: Tomato harvesting, Video S4: Jellyfish capturing.

Author Contributions

Conceptualization, H.C. and T.P.; methodology, H.C., T.P., G.H., Y.K. and D.L.; software, H.C. and T.P.; validation, G.H., Y.K. and D.L.; formal analysis, H.C. and T.P.; writing—original draft preparation, H.C. and T.P.; writing—review and editing, T.L., J.-O.P. and D.B.; supervision, T.L., J.-O.P. and D.B.; project administration, T.L., J.-O.P. and D.B.; funding acquisition, J.-O.P. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Institute of Information and Communications Technology Planning and Evaluation (IITP) under the Artificial Intelligence Convergence Innovation Human Resources Development (IITP-2023-RS-2023-00256629) grant funded by the Korean government (MSIT), and also by the Technology Innovation Program (or Industrial Strategic Technology Development Program) (grant number: 20017903), funded by the Ministry of Trade, Industry and Energy (MOTIE, Korea). This work was also supported by the Korea Medical Device Development Fund grant funded by the Korea government (the Ministry of Science and ICT, the Ministry of Trade, Industry and Energy, the Ministry of Health & Welfare, the Ministry of Food and Drug Safety) (Project Number: 1415184155, RS-2021-KD000001) This study was also financially supported by Chonnam National University (grant number: 2021-2195).

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Grau, A.; Indri, M.; Bello, L.L.; Sauter, T. Robots in Industry: The Past, Present, and Future of a Growing Collaboration with Humans. IEEE Ind. Electron. Mag. 2020, 15, 50–61. [Google Scholar] [CrossRef]

- Sherwani, F.; Asad, M.M.; Ibrahim, B.S.K.K. Collaborative Robots and Industrial Revolution 4.0 (IR 4.0). In Proceedings of the 2020 International Conference on Emerging Trends in Smart Technologies (ICETST), Karachi, Pakistan, 26–27 March 2020. [Google Scholar] [CrossRef]

- Bae, J.H.; Park, S.W.; Park, J.H.; Baeg, M.; Kim, H.D.; Oh, S.R. Development of a low cost anthropomorphic robot hand with high capability. In Proceedings of the 2012 IEEE/RSJ International Conference on Intelligent Robots and Systems, Vilamoura-Algarve, Portugal, 7–12 October 2012; pp. 4776–4782. [Google Scholar] [CrossRef]

- Li, P.; Liu, X. Common Sensors in Industrial Robots: A Review. J. Phys. Conf. Ser. 2019, 1267, 012036. [Google Scholar] [CrossRef]

- Majidi, C. Soft Robotics: A Perspective—Current Trends and Prospects for the Future. Soft Robot. 2014, 1, 5–11. [Google Scholar] [CrossRef]

- Kim, S.; Laschi, C.; Trimmer, B. Soft robotics: A bioinspired evolution in robotics. Trends Biotechnol. 2013, 31, 287–294. [Google Scholar] [CrossRef] [PubMed]

- Laschi, C.; Mazzolai, B.; Cianchetti, M. Soft robotics: Technologies and systems pushing the boundaries of robot abilities. Sci. Robot. 2016, 1, eaah3690. [Google Scholar] [CrossRef]

- Whitesides, G.M. Soft Robotics. Angew. Chem. Int. Ed. 2018, 57, 4258–4273. [Google Scholar] [CrossRef]

- Mao, Z.; Nagaoka, T.; Yokota, S.; Kim, J.-W. Soft fiber-reinforced bending finger with three chambers actuated by ECF (electro-conjugate fluid) pumps. Sens. Actuator. A Phys. 2020, 310, 112034. [Google Scholar] [CrossRef]

- Peng, Y.; Sakai, Y.; Nakagawa, K.; Funabora, Y.; Aoyama, T.; Yokoe, K.; Doki, S. Funabot-Suit: A bio-inspired and McKibben muscle-actuated suit for natural kinesthetic perception. Biomim. Intell. Robot. 2023, 3, 134036. [Google Scholar] [CrossRef]

- Lee, J.-H.; Chung, Y.S.; Rodrigue, H. Long Shape Memory Alloy Tendon-based Soft Robotic Actuators and Implementation as a Soft Gripper. Sci. Rep. 2019, 9, 11251. [Google Scholar] [CrossRef] [PubMed]

- Hong, Y.; Zhao, Y.; Berman, J.; Chi, Y.; Li, Y.; Huang, H.; Yin, J. Angle-programmed tendril-like trajectories enable a multifunctional gripper with ultradelicacy, ultrastrength, and ultraprecision. Nat. Commun. 2023, 14, 4625. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Vella, K.; Holmes, D.P. Grasping with Kirigami Shells. Sci. Robot. 2021, 6, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Shintake, J.; Cacucciolo, V.; Floreano, D.; Shea, H. Soft Robotic Grippers. Adv. Mater. 2018, 30, e1707035. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Stampfli, J.J.; Xu, H.J.; Malkin, E.; Diaz, E.V.; Rus, D.; Wood, R.J. A Vacuum-driven Origami “Magic-ball” Soft Gripper. In Proceedings of the 2019 International Conference on Robotics and Automation (ICRA), Montreal, QC, Canada, 20–24 May 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 1–9. [Google Scholar] [CrossRef]

- Samadikhoshkho, Z.; Zareinia, K.; Janabi-Sharifi, F. A Brief Review on Robotic Grippers Classifications. In Proceedings of the 2019 IEEE Canadian Conference of Electrical and Computer Engineering (CCECE), Edmonton, AB, Canada, 5–8 May 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 1–4. [Google Scholar] [CrossRef]

- Sanchez, V.; Mahadevan, K.; Ohlson, G.; Graule, M.A.; Yuen, M.C.; Teeple, C.B.; Weaver, J.C.; McCann, J.; Bertoldi, K.; Wood, R.J. 3D Knitting for Pneumatic Soft Robotics. Adv. Funct. Mater. 2023, 33, 2212541. [Google Scholar] [CrossRef]

- Kim, Y.; Cha, Y. Soft Pneumatic Gripper With a Tendon-Driven Soft Origami Pump. Front. Bioeng. Biotechnol. 2020, 8, 461. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Zeng, G.; Xu, J.; Zhou, J.; Chen, X.; Wang, Z.; Chen, Z.; Xu, Z.; Zheng, J.; Wu, D. A bioinspired multi-knuckle dexterous pneumatic soft finger. Sens. Actuator. A Phys. 2023, 350, 114105. [Google Scholar] [CrossRef]

- Rodrigue, H.; Wang, W.; Han, M.-W.; Kim, T.J.; Ahn, S.-H.; Robertson, M.A.; Sadeghi, H.; Florez, J.M.; Paik, J.; Kim, H.-S.; et al. An Overview of Shape Memory Alloy-Coupled Actuators and Robots. Soft Robot. 2017, 4, 3–15. [Google Scholar] [CrossRef] [PubMed]

- Liu, M.; Hao, L.; Zhang, W.; Zhao, Z. A novel design of shape-memory alloy-based soft robotic gripper with variable stiffness. Int. J. Adv. Robot. Syst. 2020, 17, 1–12. [Google Scholar] [CrossRef]

- Xu, L.; Gu, G. Bioinspired Venus flytrap: A dielectric elastomer actuated soft gripper. In Proceedings of the 2017 24th International Conference on Mechatronics and Machine Vision in Practice (M2VIP), Auckland, New Zealand, 21–23 November 2017; pp. 1–3. [Google Scholar] [CrossRef]

- Shintake, J.; Schubert, B.; Rosset, S.; Shea, H.; Floreano, D. Variable stiffness actuator for soft robotics using dielectric elastomer and low-melting-point alloy. In Proceedings of the 2015 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Hamburg, Germany, 28 September–2 October 2015; pp. 1097–1102. [Google Scholar] [CrossRef]

- Shintake, J.; Rosset, S.; Schubert, B.; Floreano, D.; Shea, H. Versatile Soft Grippers with Intrinsic Electroadhesion Based on Multifunctional Polymer Actuators. Adv. Mater. 2016, 28, 231–238. [Google Scholar] [CrossRef] [PubMed]

- Teoh, Z.E.; Phillips, B.T.; Becker, K.P.; Whittredge, G.; Weaver, J.C.; Hoberman, C.; Gruber, D.F.; Wood, R.J. Rotary-actuated folding polyhedrons for midwater investigation of delicate marine organisms. Sci. Robot. 2018, 3, 1–9. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).