1. Introduction

Supply chain management (SCM) is a critical component in today’s demanding and ever-changing markets ensuring the seamless flow of goods and services from suppliers to consumers. In an environment characterized by intense global competition and rising consumer expectations, optimized SCM has become essential. Effective supply chain strategies enable businesses to remain agile, respond quickly to market fluctuations, and maintain a competitive advantage [

1]. By optimizing supply chains, organizations can reduce costs, increase efficiency, and simultaneously enhance customer satisfaction [

2,

3].

Moreover, SCM plays a fundamental role in sustainability initiatives by optimizing resource use and minimizing waste, making it essential for long-term resilience and growth. Sustainability in SCM is essential for businesses striving to balance profitability with environmental and social responsibility [

4,

5]. By integrating sustainable practices, namely reducing carbon emissions, minimizing waste, and sourcing ethically, companies can lower costs, enhance brand reputation, and meet growing consumer expectations for the increasingly demanding market [

6,

7]. Sustainable supply chains also help mitigate risks related to resource scarcity and regulatory compliance, ensuring long-term resilience. In light of growing environmental challenges, embedding sustainability into supply chain operations is no longer optional but strategically necessary [

5,

7].

In our previous work [

8], we conducted a systematic review examining the integration of operations research (OR) and business intelligence (BI) for efficient SCM. We investigated how the mathematical models and algorithms (both exact methods and heuristics) provided by OR can enhance forecast and analysis in BI for SCM. We also investigated how BI know-how and tools can support and optimize decision-making processes by offering real-time data forecasting and analysis, allowing supply chains to dynamically adapt to the market. Together, BI and OR provide complementary perspectives that jointly advance efficiency, adaptability, and sustainability in SCM.

In this review, we focus on how BI and OR enhance sustainability in SCM. BI has become a vital element of SCM, enabling organizations to transform large volumes of data into actionable insights. BI tools increase supply chain transparency by assessing environmental metrics and social responsibility, optimize resource allocation through predictive analysis, reduce waste by improving production processes, enhance collaboration through real-time information sharing, and strengthen resilience by supporting risk management.

The integration of BI with OR, as discussed in Ref. [

8], provides powerful mathematical and analytical techniques to optimize supply chain operations. These tools optimize logistics and transportation, reduce carbon footprint, improve inventory management by minimizing waste and ensuring sustainable resource allocation, enhance production planning by balancing sustainable practices with economic goals, and support decision-making processes through simulation and modeling, allowing organizations to find the best strategic approaches.

The purpose of this study is to investigate relevant existing research addressing how the integration of BI and OR can help the industry achieve sustainability goals in the context of SCM. The increasing importance and demand for industry to embrace sustainability has led companies to address and incorporate certain behaviors and issues into their policies, values, and mission. Consequently, we explore both the methodological contributions of BI and OR and their application in various sustainability-related contexts, positioning sustainability as a core analytical dimension within SCM. These challenges cannot be effectively addressed without BI and OR tools. In fact, BI provides data-driven insights needed to make informed decisions. This is possible because BI tools are capable of analyzing complex supply chain data, such as resource consumption, energy use, and supplier performance, enabling companies to identify inefficiencies and reduce waste [

9,

10]. Businesses can track sustainability metrics such as carbon emissions, water usage, and recycling rates across their supply chains in real time with these tools. OR methods help companies measure progress toward sustainability goals, identify risks, and optimize operations to minimize environmental impact [

6,

11]. The integration of BI and OR supports transparent decision-making by providing detailed reports and enabling simulations to find compromises between several eventually conflicting business objectives and processes. Ultimately, this integration helps organizations transform sustainability into a strategic advantage, fostering ethical practices while maintaining operational efficiency and profitability [

12,

13].

The main research issues addressed in this systematic review are as follows:

(RQ1) How does BI enhance sustainable SCM?

(RQ2) How does OR enhance sustainable SCM?

(RQ3) How do sustainability practices align with the United Nations Sustainable Development Goals (SDGS)?

Addressing these questions will clarify how organizations can effectively use BI and OR to support sustainable practices with economic objectives. By examining these research questions, organizations can better understand how to improve efficiency through data-driven and optimized processes, reduce waste, optimize inventories and product production, comply with sustainability mandates, and embrace social responsibility.

Integrating BI and OR into sustainable SCM also supports alignment with key SDGs, helping organizations comply with environmental and social regulations, reduce legal and financial risks, and promote responsible business practices [

5,

9,

10]. Sustainable practices encourage organizations to develop innovative products, services, and business models, creating new market opportunities, enhancing cost-saving strategies, and improving efficiency. These practices also strengthen supply chains in terms of transparency, resilience, and collaboration [

7,

14,

15]. Aligning with the SDGs is a strategic business decision in today’s market, driving long-term profitability, ensuring compliance with global regulations, fostering innovation, and strengthening stakeholder relationships. Organizations that proactively integrate the SDGs into their supply chain and operations will be well positioned for sustainable success in an evolving global economy [

5,

6,

16].

This paper is organized as follows.

Section 2 describes the methodology used in the systematic review, discussing the criteria for the included studies.

Section 3 focuses on RQ1, i.e., how does BI enhances sustainability in the studies included in the review. In turn,

Section 4 focuses on RQ2, i.e., how OR enhances sustainability in the studies included in the review.

Section 5 discusses other sustainability practices featuring in the included studies but not mentioned in the previous sections.

Section 6 focuses on RQ3, i.e., analyzing how the sustainability practices discussed in the studies align with the United Nations Sustainability Development Goals (SDGs).

Section 7 concludes the paper with final considerations, summarizing the main contributions and discussing how BI and OR enhance sustainability across the supply chain, and how these practices impact communities and align with the SDGs.

2. Methodology

In this section, we explain the methodology used for the systematic review. As in Ref. [

8] and in

Supplementary Materials, we use the Preferred Reporting Items for Systematic Reviews and Meta-Analyses (PRISMA) method [

17,

18]. This standardized method allows the review to be conducted in a comprehensive manner, while ensuring transparency and reproducibility and minimizing bias.

We used the database of records obtained in Ref. [

8] retrieved from Scopus, with 106 papers assessed for eligibility. We recall that the string of keywords used for the search was

business AND intelligence AND (“optimi*” OR “decision mak*”) OR “business intelligence” AND “supply chain”, aiming to retrieve records featuring BI and OR in the context of SCM. This gave us 311 records in total, limited to articles and to the English language.

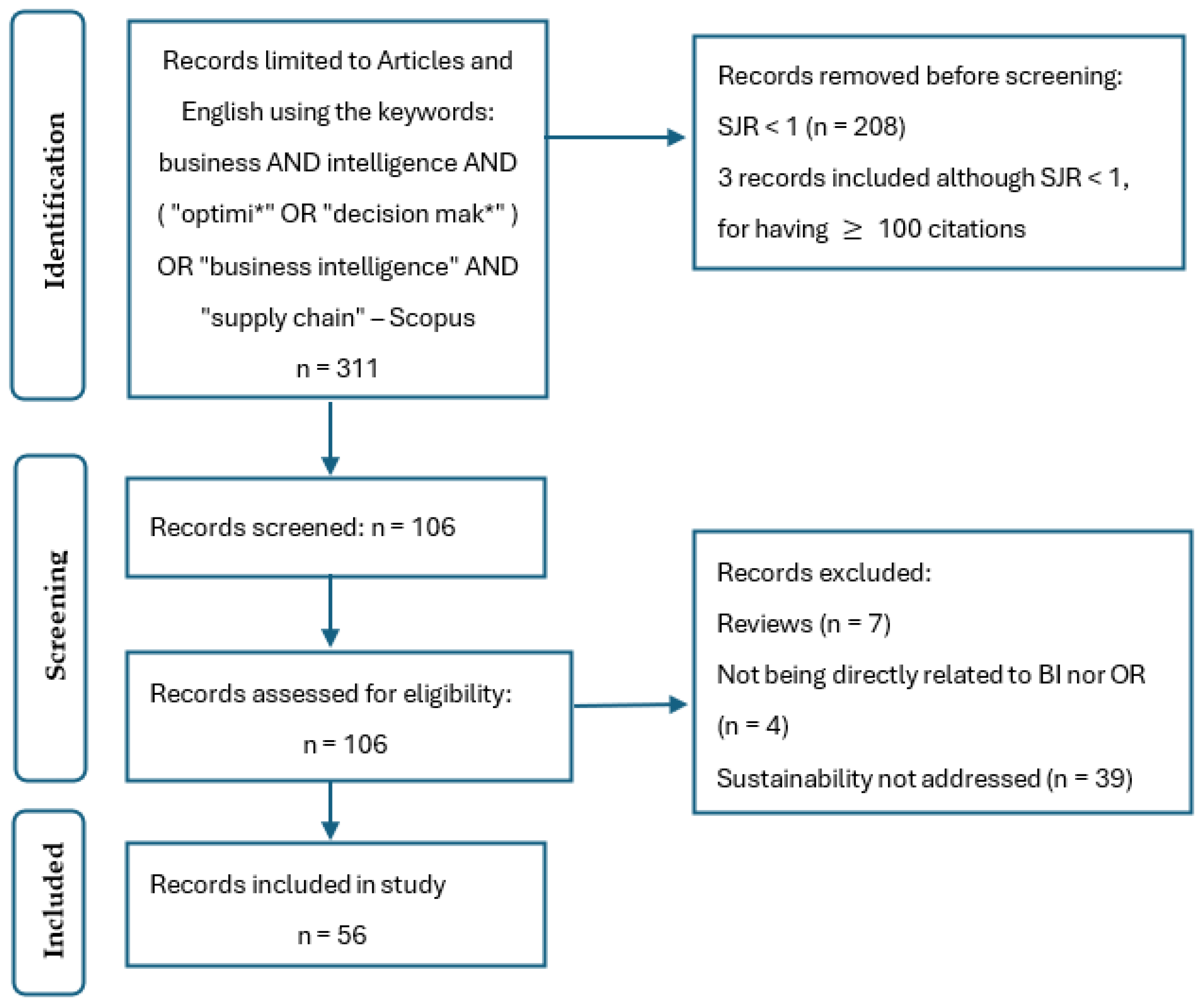

From these 311 records, those from journals with a Scimago Journal Rank (SJR) below 1 were excluded. The SJR is a valuable metric accepted by the scientific community to assess the impact and quality of academic journals. It is a well-accepted criterion that journals with an SJR higher than 1 are considered good journals. Journals with an SJR ≥ 1 were retained, although three high-impact papers from journals with an SJR < 1 were included due to their strong citation counts (over 100 citations), indicating relevance despite lower journal ranking. Therefore, a total of 205 records were excluded, leaving 106 records to be assessed for eligibility.

Among these 106 works, 7 were reviews and therefore were excluded. Furthermore, four of the remaining papers did not directly address BI or OR methods, and so these were also excluded since they did not contribute to the purpose of our study. Unlike in the previous study [

8], papers focusing solely on BI were not excluded, since the current review examines how BI and/or OR can enhance sustainability issues and goals in supply chains, and not only how they are integrated together. However, in this study, papers unrelated to sustainability were omitted, eliminating 39 records. Thus, the final sample comprises 56 peer-reviewed papers.

The above is summarized in the flow diagram based on the PRISMA framework shown in

Figure 1 for the systematic review conducted herein, where the various phases of the record selection are shown. We recall that the records were identified from the Scopus database, which is one of the best and most trusted databases to represent knowledge in the scientific community.

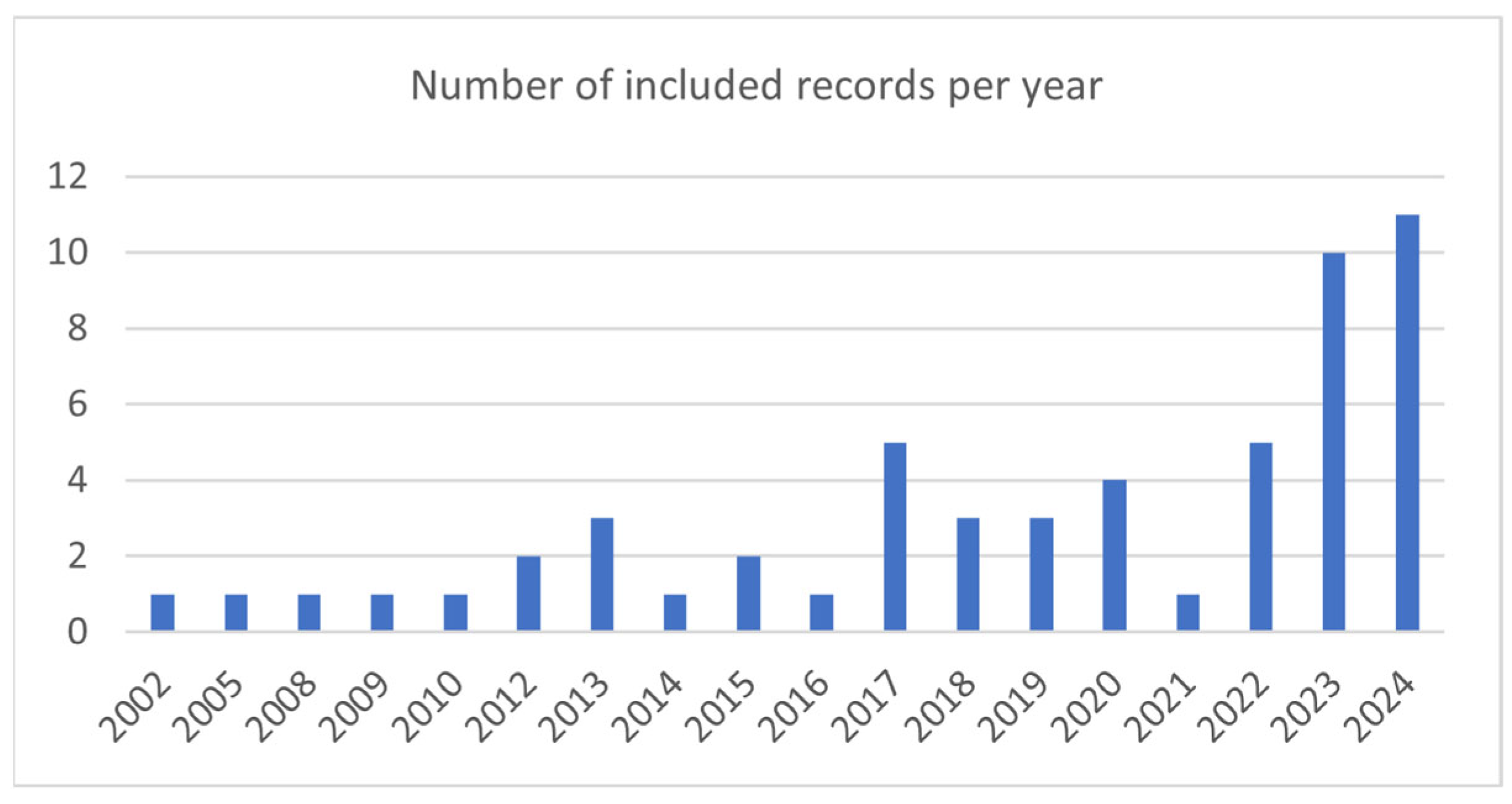

The 56 papers included in this study were published between the years 2002 and 2024, more than half of which were published from 2020 onwards, as summarized in

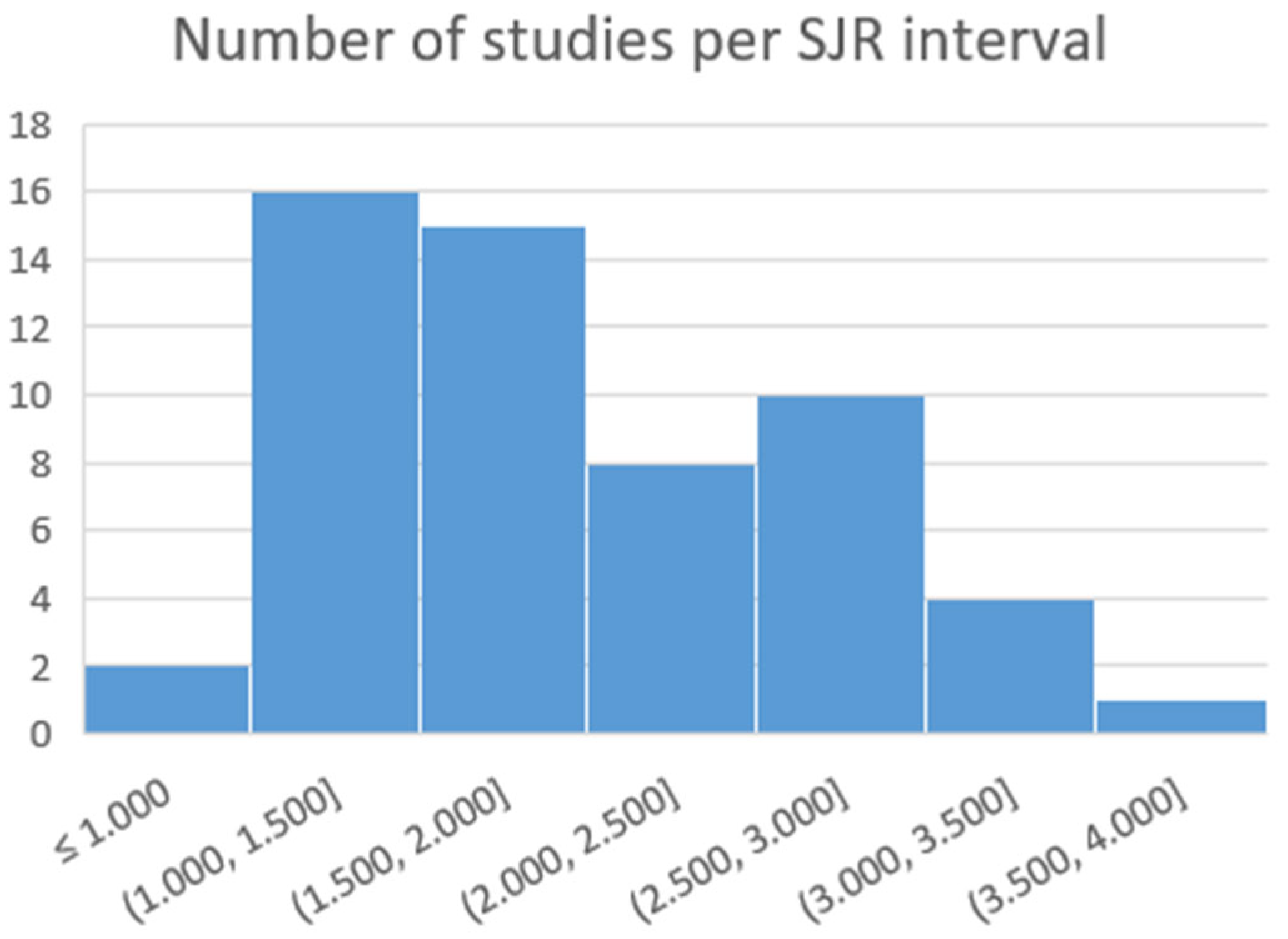

Figure 2. Moreover, the number of papers per SJR interval is also shown in

Figure 3. Note that there are two papers belonging to the ≤1 interval, which includes one of the three studies with more than 100 citations in a journal with an SJR < 1 (the other two studies were excluded in the screening phase) and a paper from a journal with an SJR = 1. Of the 56 papers, almost 60% are in journals with an SJR between 1.5 and 3.

3. Enhancing Sustainable SCM with BI

This section provides a comprehensive review of how BI can enhance sustainability in SCM considering the records retrieved in the previous section. While our earlier study [

8] examined the integration of BI and OR in SCM, the present review focuses specifically on the sustainability dimension, acknowledging that BI and OR may also contribute independently to sustainability-related outcomes.

We summarize some of the most relevant BI tools and techniques. It should be noted that although these are usually considered in the context of BI, they can also be used as OR techniques or integrated synergistically with the latter. We then pursue an exploration of the retrieved studies in the domains where sustainability practices are incorporated and facilitated by these BI techniques. Each study is related to one or more domains and to one or more techniques. The results of this analysis are summarized in

Table 1.

3.1. Most Relevant BI Tools and Techniques

BI techniques encompass data collection, analysis, visualization, and predictive modeling methods aimed at enhancing demand forecasting, optimizing inventory and transportation strategies, and supporting evidence-based strategic decisions.

Big Data Analysis (BDA): BDA is a core component in BI systems, using advanced analytical methods to process and interpret large, complex, and often real-time datasets. It enables companies to gain deeper insights into supply chain dynamics, anticipate disruptions, optimize resource allocation, and support data-driven strategic decisions, all while promoting sustainable practices such as reducing waste, lowering carbon emissions, and ensuring efficient use of resources. Most studies included in this review use BDA capabilities to strengthen sustainability initiatives.

Decision Support Systems (DSSs): DSSs are computer-based tools that assist managers in analyzing complex supply chain data, evaluating alternatives, and making informed decisions. In the context of sustainable SCM, DSSs can help organizations optimize resource use, reduce environmental impact, improve logistics efficiency, and balance economic and sustainability objectives by providing scenario analysis, simulation, and predictive modeling capabilities. The majority of the studies include DSSs to support decision-making processes.

Predictive Analysis (PA): PA uses statistical methods, machine learning, and data modeling to forecast future trends and outcomes based on historical and real-time data. PA can help anticipate demand fluctuations, optimize inventory and production planning, reduce waste, lower environmental impact, and support proactive, data-driven decisions that balance economic and sustainability goals.

Artificial Intelligence (AI): AI enables BI systems to learn from data, recognize patterns, and make autonomous decisions. AI can enhance forecasting, optimize logistics, support dynamic inventory management, and identify strategies to reduce waste and carbon emissions. By integrating AI with BI tools, companies can achieve smarter, data-driven decisions that balance operational efficiency with sustainability objectives.

Simulation Modeling: Simulation modeling involves creating digital models of supply chain processes to test and evaluate different scenarios before implementation. In SCM, simulation modeling allows companies to analyze the environmental and operational impacts of various strategies, optimize resource allocation, reduce waste, and improve logistics and production planning. By integrating simulation modeling with BI techniques such as BDA and PA, organizations can make data-driven, sustainability-oriented decisions with lower risk and higher efficiency.

3.2. Sustainable Decision-Making in Supply Chains

Sustainable decision-making in supply chains involves integrating eco-efficient practices to optimize resource use, reduce waste, minimize environmental impacts [

6,

7,

15], and optimize inventory [

7,

15,

19,

20] and expedient allocation [

10,

21]. DSSs play a crucial role in business analytics, allowing for the analysis and structuring of large datasets to support decisions. These systems enhance the balance between economic growth and environmental and societal factors [

7,

20,

21], enable circular economy practices [

10,

22], and advance sustainability.

Two main techniques are highlighted in this domain: DSSs and simulation modeling. Integrating DSSs with BI and OR techniques helps refine and adjust decision-making processes so that they are more efficient and adapt to fast-changing conditions in the supply chain [

6,

15,

19,

21,

22]. This integration also supports reverse logistics [

22,

23,

24], promotes circular economy practices [

22,

25,

26], and improves overall supply chain transparency and efficiency [

6,

14,

15,

26].

In Ref. [

6], BI and OR are integrated into a DSS that functions as a comprehensive framework to assist organizations in reducing carbon emissions across their supply chains while optimizing production. This DSS allows simulation modeling to study the trade-offs between alternative scenarios. Related to the healthcare sector, Ref. [

15] proposes a patient-oriented DSS for hospital supply chains. The system aims to achieve real-time tracking and inventory optimization, reducing waste and enhancing responsiveness in the supply chain. The strategies therein promote lean management practices aiming to improve patient care. In a related sector, the medical equipment manufacturing industry [

27], a DSS integrating multicriteria optimization analyzes supplier data to support sustainable supplier evaluation. The DSS incorporates economic, environmental, social, and institutional perspectives, ensuring robust and efficient evaluation and reducing labor and costs.

In Ref. [

20], neural networks and metaheuristics are integrated into a DSS to forecast demands and optimize inventory. In Ref. [

28], the use of IoT is discussed for collecting and analyzing data into a DSS, enhancing supply chain visibility and traceability. In the pharmaceutical sector, Ref. [

29] proposes a conceptual framework that integrates BI capabilities into a DSS to support sustainable decision-making, improving drug distribution, inventory visibility, and environmental performance through waste reduction and resource optimization.

In Ref. [

30], DSSs supports decision-making and optimization in biomass supply chains. The work studies investment benefits and risks in biomass supply chains, seeking to maximize profitability through operational efficiency. The entire biomass-to-energy supply chain is modeled, including biomass collection, transportation, processing into pellets or co-generation, and distribution to end consumers, to enhance supply chain logistics and reduce costs. Sustainability is achieved through the use of agricultural residues as biomass, which reduces waste and carbon emissions, where environmental benefits of using biomass over traditional fossil fuels are emphasized.

Similarly, in the forest fuel industry, business analytics and optimization methods are integrated into a DSS to optimize logistics involved in transporting forest fuel from harvesting sites to heating plants, as outlined in Ref. [

31]. The system incorporates simulation modeling to support decisions regarding chipping technologies, transportation routes, and inventory levels. By optimizing the efficiency of forest fuel logistics, this contributes to the sustainable use of forest biomass for energy production, reducing reliance on fossil fuels and supporting renewable energy goals.

In Ref. [

32], business analytics integrates lifecycle assessment and stakeholder analysis systems to identify and manage environmental risks. The methodology helps in designing processes that minimize environmental impact and the associated risks, leading to optimized business operations and reduced costs. The work focuses on managing environmental risks along the entire supply chain, emphasizing the need for comprehensive risk assessment from feedstock selection to waste disposal, leading to a more sustainable supply chain.

In conclusion, DSSs play a pivotal role in advancing organizational sustainability by integrating diverse analytical tools, real-time data, and optimization methods across various sectors. DSSs enable organizations to simulate trade-offs between production efficiency and environmental impact, providing a structured platform for evaluating sustainability scenarios in supply chains, healthcare, and energy sectors. DSSs and simulation modeling may help transform sustainability from a compliance-driven activity into a data-informed, integrated management practice. However, the effectiveness of DSSs depends on the quality of input data and the level of collaboration across the supply chain.

3.3. Big Data Analytics and Sustainability

BDA plays a significant role in enhancing the sustainability of supply chains by enabling the analysis of data related to energy use, emissions, and resource consumption [

4,

5,

6,

27,

33]. BDA can process large volumes of data to provide actionable insights, forecast demand, optimize inventory, and streamline operations [

5,

10,

12]. Data analytics is a major drive for smart systems, enhancing the efficiency and reliability of decision-making processes [

6,

11,

14].

In Ref. [

4], BDA is combined with optimization methods to design sustainable supply chain networks for vehicle routing problems, minimizing costs and exhibiting environmental and social impacts. In Ref. [

5], BDA leverages optimization methods, such as predictive analytics and ML algorithms, to improve demand forecasting, inventory management, and logistics optimization. BDA further addresses potential social impacts, such as improving labor conditions and ensuring ethical sourcing. In Ref. [

6], BDA is employed to collect and analyze environmental impact data that are fed into the DSS, providing insights into the carbon footprint of different supply chain activities. Optimization methods are integrated into the DSS to optimize transportation routes, inventory levels, and production schedules, aiming to lower carbon emissions.

BDA is a key enabler for Industry 4.0 supply chains [

10], enhancing operational management, closed-loop supply chain, technical and data sharing capabilities, sustainable manufacturing, collaborative planning, and environmental performance. BDA can ensure trusted data sharing across the supply chain, enhance logistics and transportation optimization, assist in sustainable practices through improved supply chain integration, and help track and detect products through the supply chain for lifecycle management.

The integration of BDA with optimization methods is proposed for smart process manufacturing in Ref. [

11]. The work highlights the importance of data-driven decision-making in smart manufacturing, improving process coordination, reducing lead times, and enhancing supply chain responsiveness. Smart manufacturing processes lead to energy efficiency, waste reduction, and resource optimization, contributing to more sustainable supply chains. Collaborative information sharing is further facilitated through BDA combined with statistical and predictive analysis [

13].

In Ref. [

14], BDA is used with optimization methods to monitor and analyze supply chain activities, predict demand, optimize inventory, reduce costs, and ensure timely delivery of products. The focus of this work is to analyze the requirements for an e-supply chain, discussing how to integrate different components of the supply chain through electronic means. The work highlights the need for seamless communication and data exchange between suppliers, manufacturers, and retailers to ensure smooth operations and enhance collaboration across the supply chain. Adopting e-supply chain practices leads to more sustainable and eco-friendly supply chain operations.

In Ref. [

23], BDA is integrated with optimization techniques to refine decision-making processes concerning circular economy principles. In the pharmaceutical supply chain [

33], BDA helps to enhance planning, delivery, and return processes within supply chain operations. It allows for inventory optimization, reducing drug shortages as well as excessive inventory, improving overall supply chain efficiency. In another case, where classification techniques are used to optimize supplier evaluation, BDA plays a crucial role in processing and analyzing supplier data to support strategic decision-making [

27].

In the semiconductor sector [

34], BDA is integrated with optimization models to determine optimal production and resource usage while promoting sustainable practices. In Ref. [

35], BDA is used for sharing and analyzing information in interactions with supply partners. Together with optimization methods, these tools help optimize manufacturing processes, contributing to more efficient supply chains. In Ref. [

36], BDA is integrated with multicriteria optimization methods to improve resource allocation and supply transparency and resilience.

Smart grid technologies also rely on BDA and other BI tools which are integrated with OR models and methods [

37]. BDA enables analysis of vast amounts of data generated by smart grids to improve the efficiency and reliability of electricity supply chains. Optimization methods adjust and refine decision-making, balancing supply and demand, reducing operational costs, and improving grid stability. These tools provide insights that help grid operators make informed decisions regarding energy distribution, demand response, and load management. Sustainability is inherent in such systems with a reduction in energy consumption and the integration of renewable energy sources into the grid.

Overall, BDA plays a transformative role in advancing sustainability across diverse sectors. By integrating BDA with other BI and OR tools, organizations can leverage economic growth while promoting optimal resource use and social responsibility. BDA facilitates processing and analyzing large amounts of data for real-time monitoring, demand forecasting, and inventory optimization, while also supporting ethical and social considerations such as labor conditions and responsible sourcing. In smart manufacturing, circular economy initiatives, and smart grid systems, BDA allows organizations to analyze complex, multidimensional data (OLAP) to optimize production, logistics, and energy usage, thereby promoting environment tally and socially sustainable practices.

3.4. AI-Driven Sustainability

Artificial intelligence (AI) is increasingly employed to support sustainable practices in supply chains, helping companies analyze large datasets to reduce energy consumption, optimize logistics, and minimize waste [

9,

12,

13,

26]. BI tools integrated with optimization techniques, such as fuzzy set optimization, can be used in optimizing resource allocation, improving production efficiency, adjusting thresholds, and fostering adaptability to changing market dynamics [

13]. AI-driven tools can help predict disruptions and identify trends that could impact supply chain operations. Optimization methods integrated with ML algorithms can be used to further optimize inventory management, production scheduling, and logistics planning [

38].

In Ref. [

12], AI drives BI tools employing BDA and PA to analyze operational data and provide insights that enhance efficiency. Combined with OR tools, ML algorithms optimize processes while evaluating trade-offs among multiple objectives, addressing sustainability through process optimization and waste reduction. In Ref. [

25], AI adoption in small and medium-sized enterprises is shown to enhance competitiveness while supporting sustainable practices. AI-powered tools offer support in decision-making and aid in the creation of more resilient and efficient supply chains, while managing the carbon footprint and other environmental issues. In Ref. [

26], AI is integrated to create a high-level ecosystem, focusing on closed-loop lifecycle management. For this to be possible, trusted data sharing is crucial since this is one of the bottlenecks encountered across industries.

In Ref. [

36], BDA integrated with AI and multicriteria optimization methods enhances robust strategies that contribute to resilient and agile supply chains, reducing environmental impacts while ensuring economic objectives. In Ref. [

38], AI-driven business analytics are employed to predict disruptions and identify market trends while monitoring environmental impact. An e-commerce business in international trade [

39] employs AI-driven BI tools to analyze large datasets for optimizing logistics and supply chain operations by integrating data analysis more efficiently. Optimization techniques are integrated to improve logistics distribution and vehicle routing by reducing vehicle competition ratios and enhancing delivery times; these techniques achieve optimal resource usage, waste reduction, and environmental goals.

AI applications extend to customer modeling, as in Ref. [

40], where personalization tools guide customer preferences toward more sustainable options. In Ref. [

41], AI technologies, such as data mining, ML, and neural networks, are used to analyze large datasets within supply chains. These technologies use BDA and PA to help identify patterns, predict trends, and provide actionable insights to improve supply chain operations. This work discusses several AI-based optimization methods, including genetic and evolutionary algorithms, to optimize inventory control, routing, and scheduling. Sustainability is addressed in optimal resource utilization, waste management, and lowering the overall environmental impact.

In Ref. [

42], AI enables digital knowledge sharing platforms to expedite decision-making processes in supplier selection, addressing environmental responsibility. In Ref. [

43], the impact of BI is explored in SCM by improving data integration and information sharing across the supply chain. AI helps in monitoring and managing supply chain risks, enhancing efficiency and resilience, while assessing environmental performance.

Further integrating BI with blockchain technology, as in [

7,

44,

45], enhances supply chain transparency and traceability. In Ref. [

44], BDA and PA are integrated with blockchain technology, ensuring data integrity and transparency, to enhance decision-making processes. In Ref. [

45], blockchain is also used to facilitate better data management and visibility.

Cloud computing for business analytics is discussed in Ref. [

46], exploring how this can enhance service delivery and customer satisfaction by providing scalable and flexible solutions. Cloud-based systems enable faster and more accurate decision-making processes in dynamic environments, improving supply chain coordination and collaboration. Optimization methods are integrated to deal with load balancing, resource allocation, and logistics. Cloud computing contributes to sustainable practices since it reduces energy consumption and optimizes resource use.

AI-based systems employ BDA and PA, serving as powerful enablers of sustainability. By integrating BI and OR techniques, intelligent decision-making can be incorporated into supply chain operations. AI leverages large-scale data to optimize processes, balancing both environmental regulations and operational efficiency. Its ability to forecast disruptions, identify trends, and support dynamic decision-making enhances supply chain resilience and agility. Nevertheless, AI implementation can be resource-intensive, potentially widening the gap between large corporations and smaller firms.

3.5. Blockchain for Sustainable Supply Chains

Blockchain technology enhances sustainability by ensuring the transparency and traceability of materials and products in supply chains [

7,

44,

45,

47]. AI tools can optimize various supply chain operations, including material and data handling processes, while blockchain enhances the reliability and efficiency of these processes by providing a secure and transparent ledger system [

7]. In Ref. [

44], one of the first frameworks to integrate BDA with blockchain technology is proposed, employing AI-driven technology to aid in accountable multicriteria decision-making. In the semiconductor industry [

45], which has been highly affected by supply chain disruptions, blockchain technology has been shown to support supply chain integration by improving information sharing, data gathering, and knowledge asset status, thus improving coordination and integration. BI tools can be used to track, analyze, and visualize blockchain data, increasing supply chain transparency and trust [

47].

Blockchain technology plays a fundamental role in sustainable supply chains through enhanced transparency, traceability, and trust. By providing a secure and immutable ledger, blockchain strengthens the reliability of data used in decision-making, ensuring that information on materials, production processes, and logistics can be verified and shared without distortion. This is particularly valuable in industries vulnerable to disruptions, such as semiconductors, where improved data sharing and integration can lead to more resilient and sustainable operations. Furthermore, the use of BI tools to visualize blockchain data enhances stakeholder trust and promotes informed, sustainability-oriented choices.

3.6. Sustainability in Supply Chain Resilience

Sustainability is closely linked to the resilience of supply chains, as both require the ability to adapt to changing conditions and recover from disruptions. Studies have explored the role of BI tools in enhancing supply chain resilience by integrating sustainability considerations into risk management strategies [

15,

25,

33,

41]. By using BI tools to assess potential risks and develop contingency plans, companies can ensure that their supply chains are both resilient and sustainable [

5,

21,

32,

48], capable of withstanding shocks while maintaining their commitment to environmental and social goals [

33,

37,

43,

48,

49].

Resilient supply chains are inherently sustainable, as they are designed to operate effectively under a wide range of conditions. In Ref. [

5], BDA and PA integrated with OR methods enhance demand prediction, optimizing logistics. The work shows how BI tools improve supply chain resilience, agility, and responsiveness. In Ref. [

15], a DSS is proposed for integrating hospital pharmacy and medical equipment supply chains, aiming to improve patient care. This system enhances supply chain coordination, efficiency, and resilience.

In Ref. [

21], BI-based decision-making helps prioritize the use of contrast material in critical situations, particularly during shortages caused by the COVID-19 pandemic, leading to more efficient and resilient medical supply chains. In Ref. [

32], a framework is proposed that integrates lifecycle assessment methodologies to assess environmental risks in the process industry. The framework assists in decision-making processes, managing environmental impacts and risks, while optimizing operational processes and reducing costs, contributing to a more sustainable and resilient supply chain. In Ref. [

33], BDA and optimization methods are employed to enhance planning, delivery, and return processes in the pharmaceutical sector. These tools aim to optimize inventory management, reduce supply chain shortages, and improve efficiency, sustainability, and resilience.

The integration of AI and BI in various supply chain processes, including procurement, production, distribution, and logistics, helps in improving visibility across the supply chain, enabling better coordination and collaboration among supply chain partners [

38]. In Ref. [

36], BDA and multicriteria decision-making are integrated to determine the best strategies for resource allocation and improving supply chain resilience and transparency. These tools improve transparency, flexibility, and efficiency in supply chain operations, contributing to better resilience in today’s fast-changing market.

In Ref. [

37], BDA and PA are integrated with OR in smart grid technologies for sustainable energy distribution. Smart grids aim to enhance efficiency and reliability in the electric network, improving stability and promoting new renewable energy sources. The study in Ref. [

43] focuses on the impact of BI on SCM by improving data integration and information sharing across the supply chain. BI helps in monitoring and managing supply chain risks, leading to more efficient and resilient supply chain operations. This contributes to promoting more sustainable practices and achieving long-term environmental and economic benefits.

In Ref. [

48], BI tools employing BDA and PA are integrated with robust optimization, assessing uncertainties in value-based management. A DSS architecture is proposed to mitigate risk impact and improve value-based performance. Optimization models involving uncertainties are used for strategic business development, capital budgeting, and risk portfolio management. This contributes to strategic network planning, sales and operations management, and order fulfillment, leading to more resilient supply chains and financial management. In Ref. [

49], a meta-approach, integrating BI tools and OR methods, is used to combine information-seeking services and extract reliable facts. The tool improves the accuracy and efficiency of the information retrieval process, eliminating discrepancies among different sources and enabling faster and more robust decision-making.

In Ref. [

50], a simulation-based DSS is proposed for additive manufacturing and supply chain design. The DSS aims to optimize the supply chain in terms of lead times and costs, improving product quality and manufacturing processes. This contributes to a more flexible and resilient supply chain. In Ref. [

51], data-driven decision-making facilitated by an OLAP-based DSS enhances the integration of multiple data sources and the application of BI to support strategic and operational decisions within the supply chain. The work proposes a conceptual collaborative framework to improve competitiveness in the wood supply chain. Optimization methods are employed for the implementation of collaborative rules, quality control rules, and production rules, aiming to ensure efficient collaboration, maintain product quality, optimize production processes, and improve overall performance. This contributes to a lower carbon footprint by optimizing resource utilization and improving supply chain efficiency.

In Ref. [

52], intelligent agents are used to collect and analyze data via BDA, providing real-time insights through PA, while autonomously adjusting inventories and transportation routes and improving communication across the supply chain to minimize delays and inefficiencies. AI-based intelligent agents offer real-time data and predictive analytics, allowing managers to respond promptly to changing conditions, making the supply chain more responsive, reliable, and agile, while reducing waste, lowering transportation emissions, and leveraging more sustainable practices. In Ref. [

53], the goal is to design a resilient food supply chain to ensure business continuity even in the event of risks or disruptions. The model seeks to use multiple sources to promote resilience in the food supply chain through optimal resource allocation while ensuring food safety, sustainability, and quality.

In particular, supply chain resilience can enhance sustainability, as resilient supply chains are better able to adapt to disruptions. BI tools, such as BDA, PA, and simulation modeling, integrated with OR methods, play a central role in enhancing this resilience by improving risk assessment, demand prediction, logistics optimization, and real-time decision-making. DSSs and AI tools contribute to greater visibility, flexibility, and coordination across supply chain networks, enabling rapid responses to shocks such as pandemics or resource shortages, aiming to build robust and agile supply chains.

3.7. Sustainability in Supply Chain Transparency

Transparency is a key aspect of sustainable supply chains, enabling companies to track the environmental and social impacts of their operations. BI tools enhance transparency by providing real-time data on supply chain activities, such as sourcing, production, and distribution. Studies have highlighted the importance of transparency in promoting sustainable practices, as it allows companies to monitor compliance with sustainability standards and make data-driven decisions to improve their environmental performance [

6,

14,

15,

28,

51].

Transparency also builds stakeholder trust and supports sustainability objectives. In Ref. [

6], BI and OR tools are employed for decarbonizing product supply chains. A DSS tool allowing for simulation modeling is used to assess the environmental impact of supply chain activities. The work focuses on decarbonizing the entire supply chain, from material sourcing to product production and delivery. This contributes to more transparent and sustainable SCM.

In Ref. [

49], a BI-based meta-approach aids in decision-making by providing a more reliable supply of accurate information. The BI tool enhances data accuracy and reliability by delivering robust business analytics, integrating multiple fact-seeking services, and using triangulation methods to eliminate discrepancies among different sources. The approach ensures continuous and reliable access to accurate information, which is critical for effective and transparent SCM. In Ref. [

51], a simulation-based DSS is proposed for the wood industry supply chain. The tool aims to enhance supply chain collaboration and improve competitiveness in the wood supply chain. This contributes to a more transparent supply chain for the industry.

BI tools also facilitate trusted information sharing, which strengthens transparency and resilience. A DSS is proposed in Ref. [

54], integrating BDA and PA with OR methods, to handle the uncertainties of collected data before sharing. The DSS aims to evaluate the trust levels of information sharing regarding supply chain partnerships in the textile industry. Enhancing trust within the supply chain not only promotes greater transparency, but also greater resilience and efficiency.

One key technology for trusted data sharing in the supply chain network is blockchain [

7,

44,

45,

47]. It enables real-time tracking of goods, reduces fraud risk, enhances ethical sourcing, and ensures trust in the network. Blockchain can automate transactions and ensure data integrity by integrating PA and BDA, leading to more reliable and transparent supply chains [

44], reducing fraud, and ensuring trusted data sharing.

In the petroleum industry [

55], a DSS integrates BI visualization tools with OR models to optimize logistics and evaluate various investment alternatives related to transportation, storage, and commercial operations. The proposed DSS aids in understanding interdependencies in the supply chain, facilitating informed decisions, and leading to greater transparency.

Transparency is a vital part of resilient and trustworthy supply chains. Tools such as simulation-based DSSs and BI-driven approaches improve data accuracy, reliability, and collaboration among supply chain partners. Additionally, blockchain technology strengthens transparency by enabling trusted data sharing, real-time tracking, and reducing risk fraud through immutable records. When combined with optimization and visualization tools, these approaches support effective information flow, strengthen decision-making, and foster open, reliable, and sustainable supply chain networks.

3.8. Sustainability in Supply Chain Innovation

Innovation is essential for advancing sustainability in supply chains, as new technologies and practices are needed to address emerging environmental challenges. Studies have explored how BI tools support innovation by providing the data and insights required to develop and implement new sustainability initiatives. Whether through the adoption of renewable energy sources, the development of sustainable materials, or the implementation of circular economy practices, innovation is key to driving the next generation of sustainable supply chains [

11,

12,

14,

25,

27]. BI tools are central in supporting these innovative efforts, ensuring that companies stay at the forefront of sustainability [

14,

26,

52].

In Ref. [

12], ML and AI algorithms combined with BDA and PA drive supply chain innovation in the delivery logistics sector, balancing economic objectives with eco-friendly practices. In Ref. [

14], e-supply chains drive innovation by integrating the different components of the supply chain electronically. The work highlights the importance of seamless communication and data exchange between suppliers, manufacturers, and retailers, driving better supply chain integration and collaboration, enabled by the integration of BI tools such as BDA and PA.

In the uncertain and volatile market that organizations face today, AI can enhance smart DSS and allow business processes to be flexible and adapted [

25], contributing to economic resilience while promoting sustainability.

Industry Commons, a high-level shared digital ecosystem within industry supply chains, fosters innovation by providing access to shared data models, AI-driven insights, and interoperable platforms [

26]. The proposed ecosystem sharing data across organizations can improve efficiency, accelerate technological adoption, and foster collaborative innovation. The work enables cross-domain innovation, emphasizing trusted data sharing and circular economy practices for greater sustainability.

In the medical equipment manufacturing sector [

27], a DSS is proposed to aid in strategic decision-making and ensure robust and efficient supplier evaluation, integrating BDA and PA. The work discusses how the proposed system can improve supply chain integration and innovation. In Ref. [

28], IoT technologies are used to monitor conditions and track products throughout the supply chain, fostering innovative SCM. IoT integrates AI-based systems with BI tools, such as BDA and PA, to help SCM by providing real-time data, enabling informed decisions in rapidly changing environments. In Ref. [

42], MCDM techniques are employed together with business analytics to help prioritize supplier selection based on various criteria regarding cost, quality, and environmental responsibility. The work discusses how sharing platforms enhance SCM innovation, providing real-time data and insights.

In Ref. [

46], cloud-based systems enable faster and more accurate decision-making processes in dynamic environments. Cloud computing contributes to sustainability by optimizing processes and driving innovation. In Ref. [

52], supply chain innovation is achieved by intelligent multi-agent systems that autonomously adjust inventories, optimize routing, and improve communication across the supply chain to minimize delays and inefficiencies.

The synergistic integration of BI tools and OR techniques leverages sustainability practices in organizations by enhancing supply chain innovation, integration, and decision-making. Organizations can achieve greater efficiency while aligning their economic goals with environmental and social responsibility, promoting transparency across the supply chain. Smart DSSs, enabled by AI, adapt more readily to uncertain and volatile markets, strengthening both resilience and transparency. IoT technology incorporated with BDA and PA allows companies to track real-time product and environmental conditions, minimizing inefficiencies. Furthermore, cloud-based and data sharing ecosystems foster innovation, circular economy practices, and resource optimization.

3.9. Sustainability in Data-Driven Decision-Making

Data-driven decision-making is essential for achieving sustainability in supply chains, as it allows companies to base their decisions on accurate and timely information. BI tools that support data-driven decision-making help organizations identify sustainability opportunities, assess the impact of their operations, and implement effective strategies for improvement. Studies have highlighted the importance of using data to guide sustainability efforts, as it ensures that companies can track their progress and make informed adjustments [

14,

22,

27,

28,

52]. Data-driven DSSs, employing PA and OR methods, are essential to supply chain innovation and visibility [

14,

46,

48,

52].

Circular economy applications illustrate the impact of data-driven decision-making. In Ref. [

24], data-driven analysis identifies opportunities for resource recovery, promoting sustainable and circular supply chains. In Ref. [

27], a data-driven DSS is proposed for sustainable supplier evaluation, incorporating multicriteria optimization methods. The evaluation framework incorporates economic, environmental, social, and institutional perspectives, demonstrating how the DSS can support long-term sustainable development. The DSS aids in decision-making and optimization by providing objective and data-driven evaluation criteria for improving supplier selection processes.

In Ref. [

35], data-driven decisions using BDA integrated with optimization methods are emphasized, providing detailed operational insights and demand forecasting. The work discusses how big data can help managers make informed decisions in predicting demand and optimizing inventory. In Ref. [

38], AI-driven business analytics are employed to process large datasets and provide insights into supply chain performance. Integrating OR methods such as ML algorithms and predictive analytics helps enhance supply chain efficiency by optimizing inventory, production scheduling, and logistics. This work discusses how AI can support sustainable supply chain practices by monitoring and minimizing the environmental impact of supply chain activities.

Data-driven optimization model customization is proposed in Ref. [

47], where BI and OR are integrated with blockchain technology to automate transactions and ensure data integrity, reduce fraud, and contribute to more efficient, resilient, and transparent supply chains. A simulation-based DSS is proposed for additive manufacturing and supply chain design [

50], integrating BI tools, multicriteria optimization methods, and metaheuristics. This data-driven DSS aims to optimize the supply chain configuration for a personalized product under various demand uncertainties. This involves evaluating different design configurations, material usage, production scheduling, and logistics planning to achieve a more flexible, robust, and resilient supply chain, lowering the environmental impact in terms of energy consumption, waste production, and resource usage.

In Ref. [

51], a data-driven DSS facilitated by OLAP analysis, integrating ML algorithms, improves supply chain integration and collaboration while promoting quality control and production rules. The framework tends to improve supplier integration, visibility, and competitiveness in the wood industry, while optimizing resource utilization and production processes. In Ref. [

52], intelligent agents, powered by the synergy of BI and OR, are used to enhance supply chain efficiency. The focus is on optimizing the beverage logistics network using agent technology for streamlining operations, enhancing coordination, and managing the flow of goods more efficiently. These practices leverage sustainability across the supply chain by optimizing resource use and delivery routes.

In the food supply sector [

53], network optimization methods are employed to design a resilient food supply chain that reduces disruptions through optimal and sustainable sourcing allocation. In Ref. [

56], BDA capabilities integrated with optimization tools are used for identifying inefficiencies and bottlenecks in supply chain processes, assisting in optimizing inventory levels, production schedules, and logistics operations. The work focuses on how BI can improve various aspects of supply chain management, including supplier performance, order fulfillment, and customer satisfaction, while keeping track of energy use, carbon emissions, and waste management.

The interplay between BI and OR allows smart manufacturing processes to optimize production and enhance operational efficiency and flexibility. The data-driven DSS supports strategic decision-making, making the manufacturing processes more intelligent, efficient, and agile, contributing to optimal resource usage, efficient energy usage, and managing environmental factors. In Refs. [

48,

49], the importance of business analytics, using data-driven concepts, is emphasized. In Ref. [

48], the need to integrate these concepts with model-driven approaches to support strategic decision-making in financial management is highlighted. Strategic business development and risk management are leveraged by means of data-driven, robust optimization techniques, enhancing value-based management. In Ref. [

49], business analytics are integrated into multiple fact-seeking services, providing more robust and reliable information retrieval.

In Ref. [

54], BI tools are integrated with fuzzy optimization methods to model uncertainties in evaluating trust levels for data quality and sharing. The associated DSS provides a structured approach to assess trust in suppliers, improving supply chain integration, transparency, and collaboration.

In the petroleum industry [

55], BI and OR are integrated into a DSS to optimize logistic network performance and support strategic decision-making. Optimization models are employed to minimize costs and optimize logistic planning. The DSS provides a detailed analysis of different investment scenarios, evaluating the viability of projects and understanding their interdependencies. In Ref. [

57], ontological frameworks, which represent shareable and reusable knowledge across the supply chain, are proposed for managing and sharing information related to environmental impacts within an organization. This involves integrating data from various sources to support environmental decision-making and improve sustainability practices.

Data-driven DSSs constitute a fundamental aspect in today’s SCM context. Organizations not only have to consider competitiveness in the marketplace, but they also still have to balance their economic objectives with sustainability issues, such as environmental assessment indicators and social responsibility. This can only be achieved by fostering data-driven and evidence-based decision-making via the synergistic integrations of BI and optimizations methods. Moreover, the integration of BI with technologies such as blockchain strengthens data integrity, transparency, and trust across the supply chain network. AI facilitates automation and analysis of large amounts of data, promoting greater supply chain integration and collaboration.

The studies mentioned above related to one or more domains and to one or more techniques, are mapped in

Table 1.

Table 1.

BI and OR techniques related to the domains studied in

Section 3.

Table 1.

BI and OR techniques related to the domains studied in

Section 3.

| | Sustainable DM | BCT | SC Resil | SC Transp | SC Innov |

|---|

| BDA | [4,5,6,7,10,11,12,13,14,16,20,23,24,27,28,29,31,33,34,35,36,37,41,44,46,48,49,50,51,52,53,56,57,58,59,60,61] | [44] | [5,7,33,36,37,41,48,49,50,51,53,59] | [6,7,14,28,29,36,44,49,51,54,61] | [11,14,27,28,37,46,50,52,56] |

| DSS | [6,14,15,19,22,23,24,25,27,28,29,30,31,35,37,40,42,46,47,48,49,50,51,52,55,56,57,61,62] | [45,47] | [15,21,25,26,32,37,43,48,49,50,51,52,53] | [6,14,15,26,28,29,45,47,49,51,54,55,61] | [14,25,26,27,28,37,42,46,50,52,56] |

| PA | [5,9,10,12,14,16,22,27,28,29,37,44,46,48,52,58,62] | [44] | [5,37,48] | [14,28,54] | [14,28,46,52] |

| AI | [7,9,12,13,14,25,38,39,40,41,42,44,52,58] | [7,44] | [7,25,26,36,38,41] | [7,14,26,28,38,44], | [12,14,25,26,28,36,42,52] |

| Simulation | [6,7,10,31,34,46,50] | [7] | [7,50] | [6,7] | [46,50] |

| DEA | [19,20,23] | | | | |

| MCDM | [4,27,31,36,42,48,50,53,55,60] | | [36,42,48,50,53] | [36,55] | [36,42,50] |

| ML | [5,6,9,11,12,14,16,20,27,33,34,37,38,41,47,51,58] | [47] | [5,33,37,41,51] | [6,14,38,47,51] | [11,12,14,27,37] |

| OMT | [6,10,11,13,14,15,19,22,29,30,31,33,35,37,39,41,44,47,48,49,50,51,52,55,56,57,60,62] | [44,47] | [15,21,32,33,37,41,48,49,50,51,53] | [6,14,15,29,44,47,49,51,55], | [11,14,37,50,52,56], |

| MH | [4,5,6,9,10,11,12,20,23,29,37,41,42,46,50,51,53,57,60] | | [5,37,41,42,50,51,53] | [6,51,54] | [11,12,37,42,46,50] |

4. Enhancing Sustainable SCM with OR

This section provides a comprehensive review of how OR leverages sustainability in SCM. When integrated with BI tools, OR methods and models refine and adjust decision-making processes to better reflect the dynamic nature of today’s markets. The following subsections present key OR models and methods used in the literature to leverage sustainability practices while maintaining economic growth.

We summarize some of the most relevant OR tools and techniques, which are usually integrated into BI tools and DSSs. In this context, OR tools usually refine and enhance decision-making processes. We then explore the retrieved studies across the different domains. The explored domains are those more readily related to OR. The results are summarized in

Table 2.

4.1. Most Relevant OR Tools and Techniques

OR techniques provide mathematical and analytical methods to support optimal decision-making by modeling complex supply chain processes, optimizing resources, reducing costs, and improving overall efficiency. Integrated with BI tools, they address production planning, inventory control, transportation routing, and demand forecasting, enabling decision-makers to evaluate multiple scenarios, constraints, and trade-offs and design more efficient, resilient, and sustainable supply chains.

Data Envelopment Analysis (DEA): DEA is a non-parametric efficiency method based on linear programming that compares inputs and outputs, without requiring a predefined functional form. It is widely used to evaluate the performance of companies, supply chain nodes, or public institutions. In supply chain management, DEA supports the analysis of supplier performance, logistics efficiency, resource utilization, and sustainability practices, providing rankings and insights for improvement.

Multicriteria Decision-Making (MCDM): MCDM offers a structured approach to decisions involving multiple and often conflicting criteria. It integrates economic, environmental, social, and operational dimensions, enabling systematic analysis of trade-offs and more holistic evaluations.

Machine Learning (ML): ML plays a key role in DSSs by identifying patterns in large historical and real-time datasets. ML enhances forecasting, inventory management, demand planning, and logistics operations. When combined with optimization and metaheuristics, ML provides predictive guidance, optimization defines objectives and constraints, and metaheuristics efficiently explore solution spaces, together enabling faster, smarter, and more sustainable decisions in complex systems.

Optimization Models and Techniques (OMTs): Optimization methods are central to BI-enabled systems, helping transform data into actionable decisions. Integrated with BI platforms, they support scenario simulation, prediction, and sensitivity analysis. MCDM can act as an optimization approach for analyzing trade-offs and selecting the most appropriate solution. Combined with real-time data and reporting, optimization enables organizations not only to monitor performance but also to recommend improved decisions.

Metaheuristics (MHs): Metaheuristics address complex optimization problems that exact methods cannot solve efficiently. Evolutionary algorithms support MCDM by generating diverse trade-off solutions. ML-enhanced metaheuristics increase adaptability and make these techniques valuable for dynamic environments where variables and constraints evolve frequently.

Simulation Modeling: Simulation, closely linked to OR, supports scenario analysis and sensitivity assessments, indicating how changes in inputs affect model outcomes. In supply chain and BI contexts, it helps identify key drivers such as demand variability or resource availability. Combined with ML, simulation-based sensitivity analysis quantifies the impact of predicted changes, while metaheuristics explore alternative solutions under varying conditions.

4.2. Data Envelopment Analysis (DEA) and Sustainability

DEA is a mathematical programming-based technique used to evaluate the relative performance of organizations. It is used in decision-making for various purposes. The eco-efficiency of hydrogen supply chains is assessed using network DEA, which balances environmental and economic performance [

19], by modeling the complex eco-efficiency of different viable options and analyzing the projections for each stage of the process.

A sustainable practice of just-in-time and just-enough inventory can be achieved by integrating BI tools using BDA with OR methods, namely DEA and evolutionary algorithms, for demand forecasting and supplier selection [

20]. Integrating BDA with DEA tools and MHs allows organizations to adjust and enhance DSSs, helping them leverage sustainability practices while achieving financial goals [

23].

DEA is a tool that, when integrated with BI and DSS, leverages sustainability by providing a systematic framework to evaluate and improve the efficiency of organizations. In the context of SCM, network DEA assesses the efficiency of various indicators by modeling performance across multiple stages, enabling decision-makers to identify the most sustainable operational options. When integrated with BI and other optimization methods, DEA supports practices such as just-in-time inventory, demand forecasting, and sustainable supplier selection, promoting more sustainable SCM.

4.3. Machine Learning in Sustainable Supply Chains

ML enables supply chains to optimize resource utilization, reduce waste, improve efficiency, and enhance decision-making. By analyzing large datasets, ML supports demand forecasting, logistics optimization, ethical sourcing, and real-time environmental monitoring [

5,

12,

20,

38,

41].

In Ref. [

5], ML algorithms are integrated into BI tools, improving SCM from procurement to distribution. These tools enhance inventory and logistics management while addressing environmental impacts and social responsibility. In Ref. [

12], AI-powered BI and ML algorithms support route planning, demand prediction, and inventory optimization. These techniques help to minimize costs and optimize management while reducing environmental impact. In Ref. [

16], ML algorithms and real-time data processing improve supply chain operations by reducing lead times, minimizing costs, and enhancing resource allocation.

In Ref. [

20], neural networks are combined with evolutionary algorithms for demand prediction and inventory optimization. BI supports data analytics, and ML helps to adjust and optimize processes involving supplier selection and demand prediction, aiming to achieve just-enough inventory, contributing to optimal resource utilization and lowering environmental impact. In the semiconductor sector [

34], BDA is integrated with optimization models to determine optimal production and resource usage while promoting sustainable practices. In Ref. [

38], business analytics integrated with ML algorithms optimize inventory, production scheduling, and logistics, reducing disruptions and thereby enabling more resilient supply chains.

In Ref. [

41], AI-powered BI tools are integrated with ML algorithms using neural networks and genetic and evolutionary algorithms to support decision-making in complex and dynamic supply chain environments. These algorithms seek to optimize supply chain processes, including procurement, production planning, logistics, and distribution. The focus is on enhancing efficiency and coordination across the supply chain and leveraging sustainable practices. In Ref. [

58], optimization methods refine BI tools to automate inventory management, as well as provide dynamic pricing strategies and personalized marketing campaigns. Data analytics and automation drive the retail sector, helping to explain customer behavior and improve overall operational efficiency, thus optimizing resource usage and lowering the environmental impact of retail operations.

ML is a powerful technique which effectively integrates optimization methods and MHs, providing more intelligent and responsive solutions. This integration, together with BDA and PA, leverages sustainability in SCM by enabling data-driven optimization of operations while exerting societal and environmental impacts. Techniques such as neural networks and ML-guided evolutionary algorithms improve demand prediction, resource allocation and planning, and optimized inventory and logistic strategies, ensuring the most appropriate utilization of materials and energy without jeopardizing economic competitiveness.

4.4. Sustainable Product–Service Systems

The development of smart product–service systems plays a critical role in promoting sustainability within supply chains. These systems help companies transition towards circular economy practices by optimizing the entire lifecycle of products—from production to disposal and recycling [

5,

6,

12,

20,

33]. BI tools play a crucial role in circular economy participation; for example, statistical factor analysis can be used to leverage environmental goals while ensuring financial capabilities [

50,

58,

59]. BI frameworks employing tools such as BDA, PA, and simulation modeling help design optimized product–service systems and, when integrating OR techniques such as MCDM and ML-guided MHs, enhance the efficiency of decision support systems [

6,

23,

31].

In Ref. [

6], optimization methods enhance environmental assessment BI tools by optimizing end-to-end supply chain activities and lowering environmental impacts. These tools implemented as ML-guided MHs optimize transportation routes, production scheduling, and logistics planning. In Ref. [

11], BI and OR are integrated into a DSS for smart manufacturing processes, contributing to sustainable product–service systems, optimizing production coordination, reducing lead times, and enhancing responsiveness. These actions contribute directly to sustainable practices such as energy efficiency, waste reduction, and optimal resource allocation.

In Ref. [

22], optimization methods are combined with BI analysis for optimizing reverse logistics management, leading to sustainable supply chains. Uncertainties are modeled via robust optimization methods to better reflect the dynamic nature of newsvendor supply chains. In Ref. [

30], a decision support system for potential investors, using a detailed optimization model to compare the financial yields and risks of two biomass energy systems, is discussed for biomass energy supply chains. Optimization methods are used to model biomass collection, processing, and distribution, supporting decision-making regarding investments in the sector.

In Ref. [

31], BI and OR come together in a DSS to monitor and optimize the performance of various logistics operations, including chipping, transportation, and inventory management. The optimization methods employed include mixed-integer programming models, aiming to maximize the profit of forest fuel logistics by optimizing resource allocation, transportation routes, and chipping operations while considering multiple constraints and objectives. In Ref. [

32], lifecycle assessment methods are integrated with BI tools to assess environmental risks and optimize industrial processes. The work highlights how risks in one part of the supply chain can affect the entire process, emphasizing the need for a holistic approach. Optimization methods refine the framework, aiming to minimize environmental impact and the associated risks, leading to optimized business operations and reduced costs.

In the pharmaceutical industry [

33], ML-guided optimization methods are integrated with BDA to support resiliency and efficiency in SCM while observing sustainable practices and social responsibility. In the semiconductor supply chain, BDA is integrated with ML, supporting sustainability practices by balancing resource efficiency with production costs while ensuring economic stability [

34]. Moreover, the work discusses how cooperation between upstream technology suppliers and manufacturers is improved, aided by BI tools with simulation modeling capabilities.

In Ref. [

50], a DSS based on simulation models is proposed, considering additive manufacturing to design an optimized and flexible supply chain. This simulation-based approach aims to assess and optimize various aspects of the supply chain and manufacturing processes, involving evaluation of design configurations, material usage, production scheduling, and logistics planning. To this end, the DSS integrates MCDM techniques implemented as MHs. Sustainability is enhanced by efficient resource utilization and optimized supply chain operations.

In smart grid technology [

37], BI and OR are integrated to enhance agile and reliable coordination between energy generation and distribution, demand response, and load management. Here, ML is incorporated into optimization methods. While BI tools primarily analyze large amounts of data generated in smart grids, optimization methods deal with load forecasting and real-time optimization of electricity distribution. Smart grids enable efficient energy usage and optimal energy distribution while promoting new renewable energy sources, contributing to a more sustainable energy system.

In Ref. [

57], a BI-powered framework is integrated with optimization methods for enterprise sustainability. BI plays an important role in managing and sharing information related to environmental impacts within an enterprise. Optimization methods use non-linear models to balance trade-offs between economic performance and environmental sustainability. The proposed framework integrates lifecycle assessment methodologies to evaluate and reduce the environmental impact of enterprise activities.

In conclusion, combining OR methods with BI tools delivers powerful frameworks that promote sustainable product–service systems across diverse supply chains. Especially when incorporating ML strategies into MHs to solve MCDM problems, these frameworks not only help optimize several dimensions across the supply chain, but also provide insights into possible scenarios and solutions not accessible otherwise.

4.5. Multicriteria Decision-Making and Sustainability

Multicriteria decision-making (MCDM) consists of optimization models and techniques involving problems with several criteria or objective functions, which can be conflicting. This means that there may not be an optimal solution, but rather a set of optimal solutions representing different compromises between the criteria [

31,

36,

42,

53]. These problems better reflect real-life situations and enhance strategic decision-making in contexts inherently complex in nature [

48,

60,

61,

62].

In Ref. [

4], evolutionary algorithms for multiple-objective optimization are used for sustainable supply chain network design. Algorithms such as Particle Swarm Optimization (PSO) and Artificial Bee Colony (ABC), often hybridized with Variable Neighborhood Search (VNS), are used to solve network design problems, comprising multiple criteria for vehicle routing problems, addressing economic growth, environmental management, and corporate social responsibility.

In Ref. [

27], a DSS for sustainable supplier evaluation employs MCDM techniques to identify core criteria, reduce noise factors, determine dependency weights, and classify supplier performance. Integrating these techniques into the BI tool enhances decision-making by reducing bias while balancing economic growth with sustainability. In Ref. [

31], a DSS is discussed with the objective of monitoring and optimizing logistics operation in the forest fuel sector. Optimization methods are integrated into the DSS to maximize profits and cut costs. These methods include mixed-integer programming models, considering multiple constraints and objectives, and providing solutions representing compromises between the different objectives.

In Ref. [

36], MCDM is integrated into an AI-powered DSS, in the context of Industry 5.0, for resource management and improving environmental factors, thus promoting supply chain sustainability and resilience. In Ref. [

42], MCDM techniques are integrated into a decision-making platform for supplier selection, involving several criteria such as manufacturing capabilities, production quality, and cost, while also considering environmental and social responsibility. In Ref. [

48], robust optimization methods are used to mitigate risk impact and improve value-based performance. These methods balance multiple conflicting criteria into solutions that represent a compromise between strategic business development, capital budgeting, and risk portfolio management.

In Ref. [

50], simulation models for additive manufacturing and supply chain design involve multicriteria decision-making, optimizing design configurations, material usage, production scheduling, and logistics planning and improving environmental factors. The simulation-based framework identifies trade-off solutions across criteria. In Ref. [

53], network optimization methods based on graph theory are used for designing a food supply chain resilient to disruptions, ensuring business continuity. The problem is formulated as a bi-objective mixed-linear integer programming model aiming to (i) maximize the total profit over a 1-year time span (ii) and minimize the total lead time of the product along the supply chain. An evolutionary algorithm based on ant colony optimization is able to find good-quality solutions.

In Ref. [

55], optimization models are formulated to optimize logistics operations for the petroleum industry. The multicriteria optimization problem is formulated into a mixed-linear programming model, where the multiple criteria are amalgamated into an objective function. These models, integrated into the BI tool, help evaluate logistic strategies, as well as investment planning, while seeking to minimize costs related to transportation, storage, demurrage, and commercial operations. This enhances resource and operational efficiency, contributing to more sustainable practices.

In Ref. [

62], MCDM optimization techniques are integrated into BI tools. They propose a generic decision support framework for inventory procurement planning in distribution centers, which suggests a structured system for making procurement and inventory decisions. Given that procurement planning inherently involves multiple criteria and that sustainability is increasingly embedded in procurement decisions, the framework accommodates analysis of different scenarios.

In summary, MCDM plays a crucial role in balancing economic growth with sustainability regulations by enabling decision-makers to evaluate and integrate multiple, often conflicting, objectives into strategic planning. Through its ability to model trade-offs between economic performance, environmental preservation, and social responsibility, MCDM provides structured and transparent frameworks for complex decision-making scenarios.

4.6. Sustainability in Lean Supply Chains

Lean supply chain management practices are designed to optimize processes by eliminating waste, reducing costs, and improving efficiency. Sustainability is a key focus in lean supply chains, where efforts to minimize waste and resources align closely with environmental goals. Key features of lean practices are just-in-time inventory, continuous improvement, and value stream mapping. While sustainability may not be the primary focus of lean supply chains, they inherently contribute to more sustainable SCM. This subsection complements

Section 4.4.

Studies highlight the role of BI tools in promoting lean practices that contribute to sustainability, particularly in manufacturing and logistics. By integrating sustainability metrics into lean management systems, companies can enhance both their operational efficiency and their environmental performance [

20,

33,

35,

56,

62]. Thus, lean supply chains offer a practical pathway to sustainability through efficiency.

Inventory optimization is one key aspect of lean supply chains. In Ref. [

20], BI and OR are integrated to optimize inventory in the automotive industry, allowing for just-enough inventory via demand forecasting and supplier selection. Just-enough inventory is also crucial in the pharmaceutical industry [

15,

29,

33], reducing drug shortages and excessive inventory in the supply chain. In Ref. [

15], BI and OR are integrated to create a patient-oriented, lean and agile supply chain for hospital, pharmacy, and medical equipment. The work focuses on lean management principles, agile methodologies for real-time tracking, and inventory management. In Ref. [

29], OR is integrated with BI to enhance inventory visibility and support supply chain operations from production to delivery. In Ref. [

33], BDA is the major tool employed for SCM, supporting strategic and operational decision-making. It improves supplier collaboration and coordination while lowering the environmental impact of retail operations.

One important sector where lean supply chains are crucial is the forest fuel industry [

31]. BI and OR methodologies are integrated to maximize the profit of forest fuel logistics while optimizing resource allocation, transportation routes, and chipping operations. By improving the efficiency of forest fuel logistics, organizations contribute to the sustainable use of forest biomass for energy production, reducing reliance on fossil fuels and supporting renewable energy goals. Sustainability considerations with BDA are discussed in Ref. [

35], including resource optimization and waste reduction. The work highlights how BDA can help create lean supply chains. Other BI tools can also be integrated to enhance lean supply chains, as in Ref. [

56] where BI contributes to sustainability by enabling companies to monitor and reduce their environmental impact. The work discusses how BI tools can track key indicators related to energy use, emissions, and waste management.