Next-Generation Cellulosic Filaments from Hemp Pulp via Dry-Jet Wet Spinning Using HighPerCell® Technology

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Pulp Preparation (RBX)

2.3. R-18 Value

2.4. Ash Content

2.5. Elemental Analysis

2.6. Gel Permeation Chromatography

2.7. Degree of Polymerization

2.8. Dope Preparation

2.9. Rheological Measurements

2.10. Dry-Jet Wet Spinning

2.11. Scanning Electron Micrograph

2.12. Fiber Testing

2.13. Birefringence Measurements

2.14. Wide-Angle X-ray Scattering

2.15. Water Retention Capacity

2.16. Fibrillation Tests

2.17. Fabric Manufacturing

3. Results and Discussion

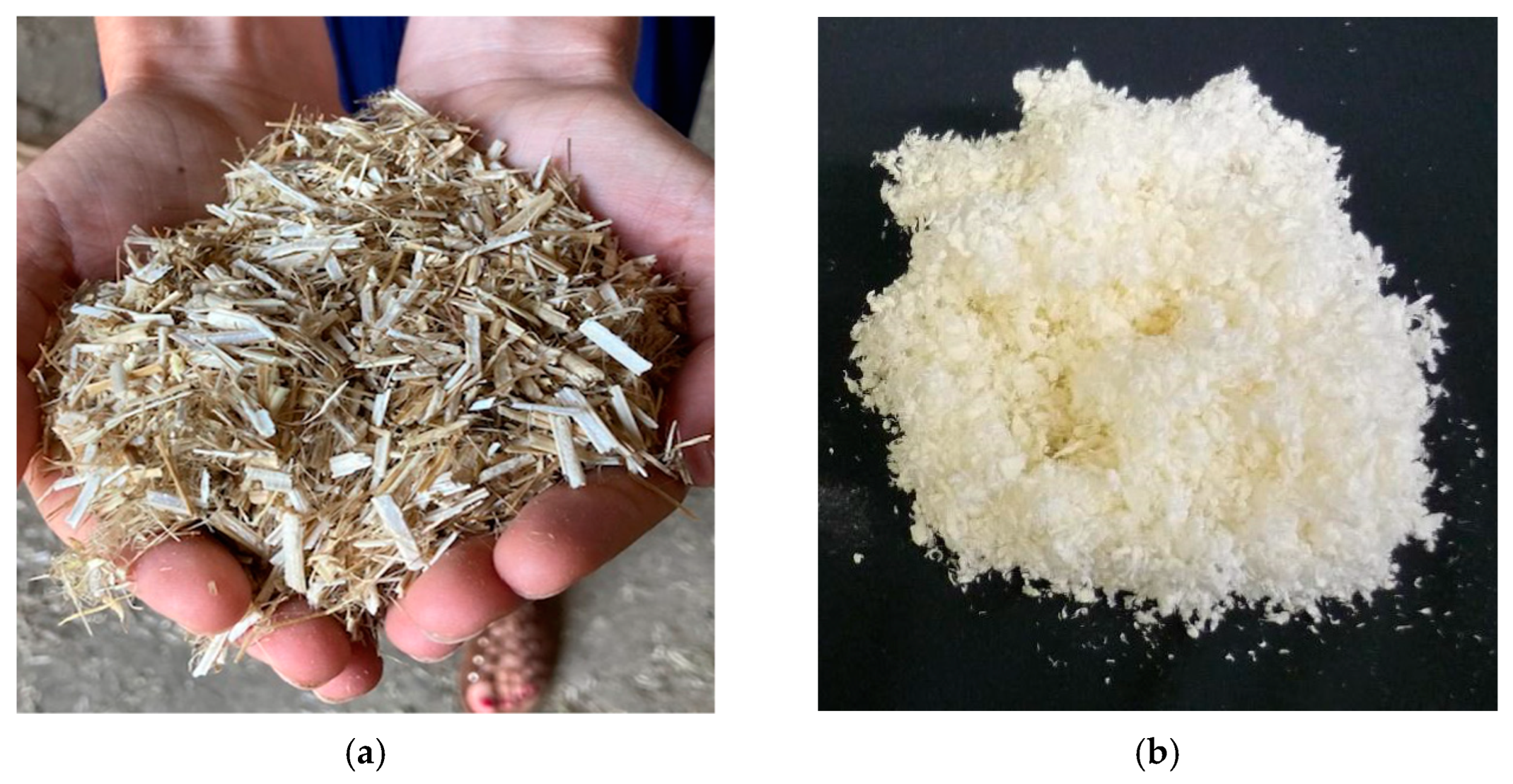

3.1. Feedstock

3.1.1. Hemp Feedstock Preparation

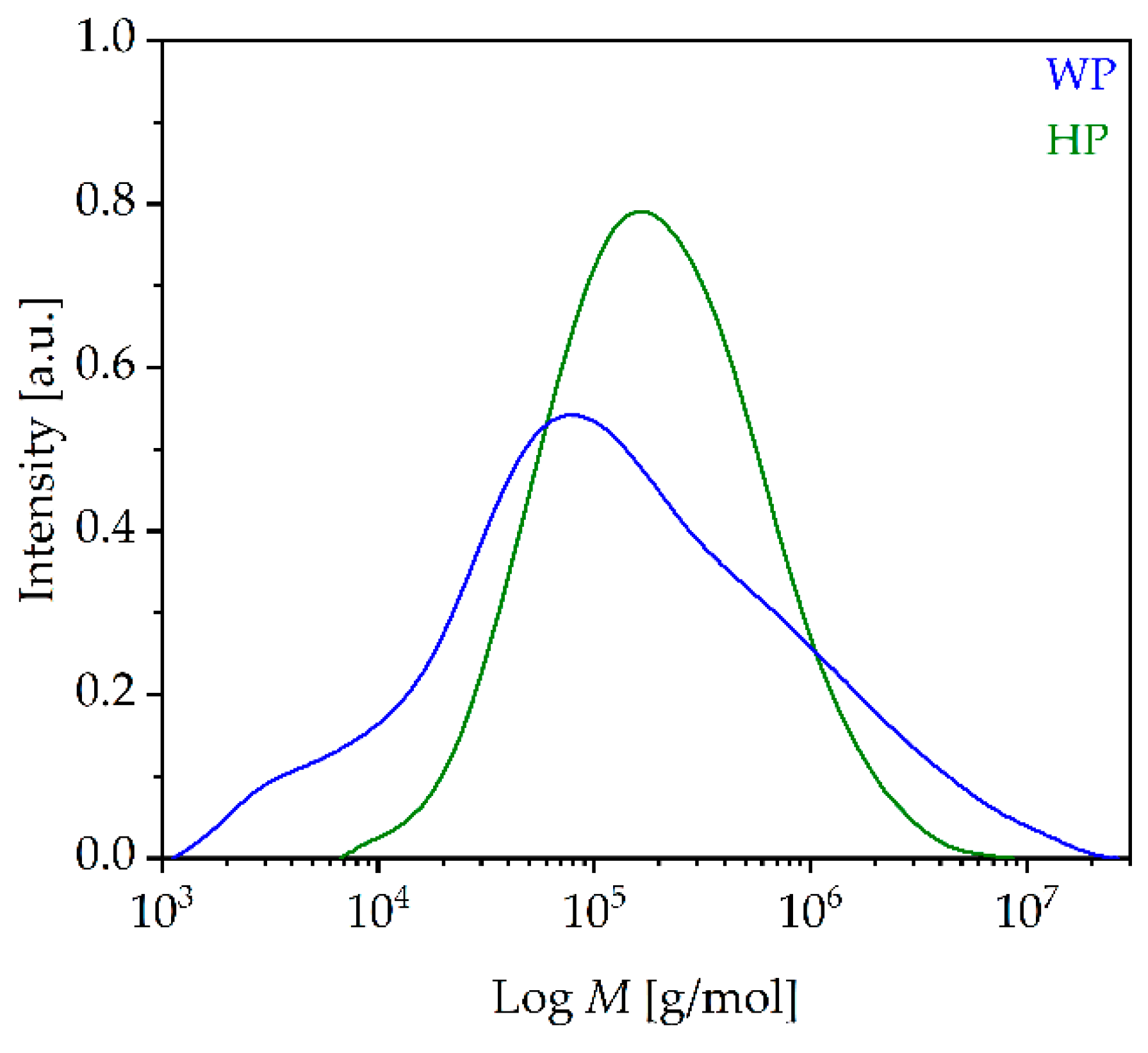

3.1.2. Feedstock Characterization

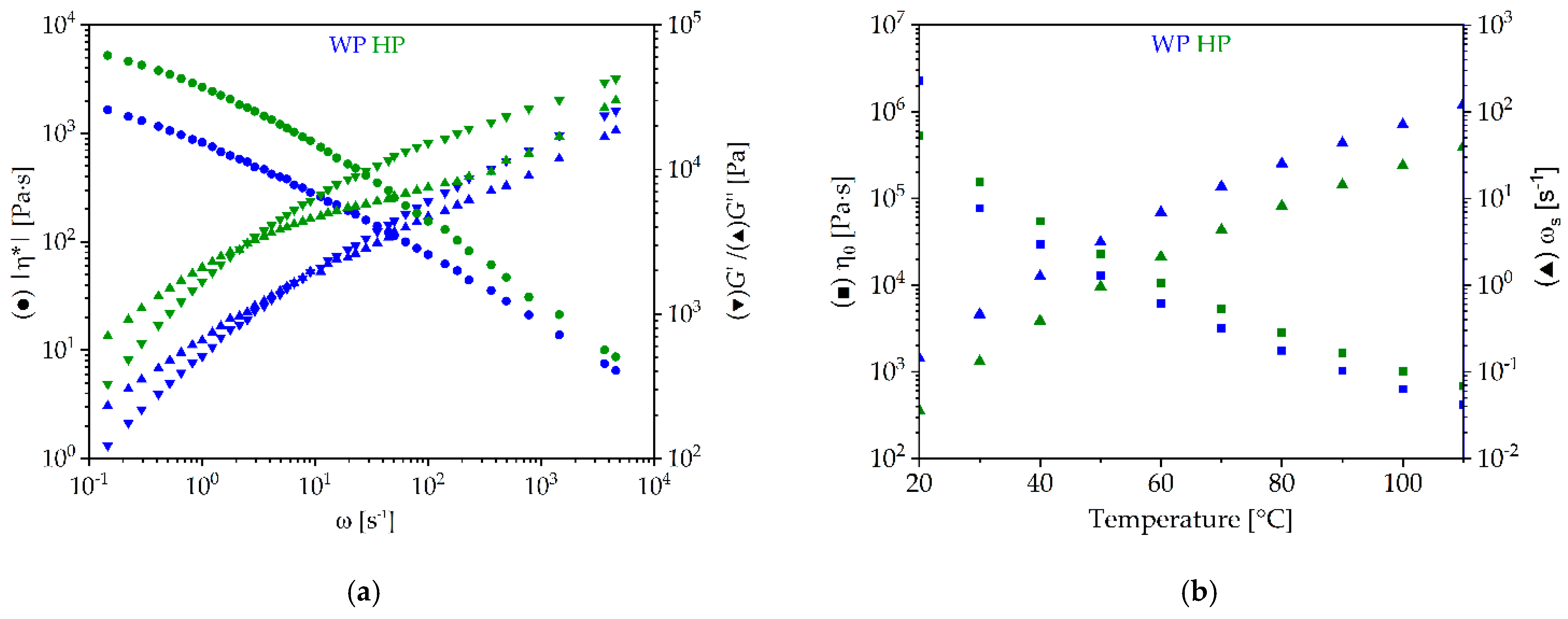

3.2. Rheology and Fiber Spinning

3.2.1. Characterization of the Filament

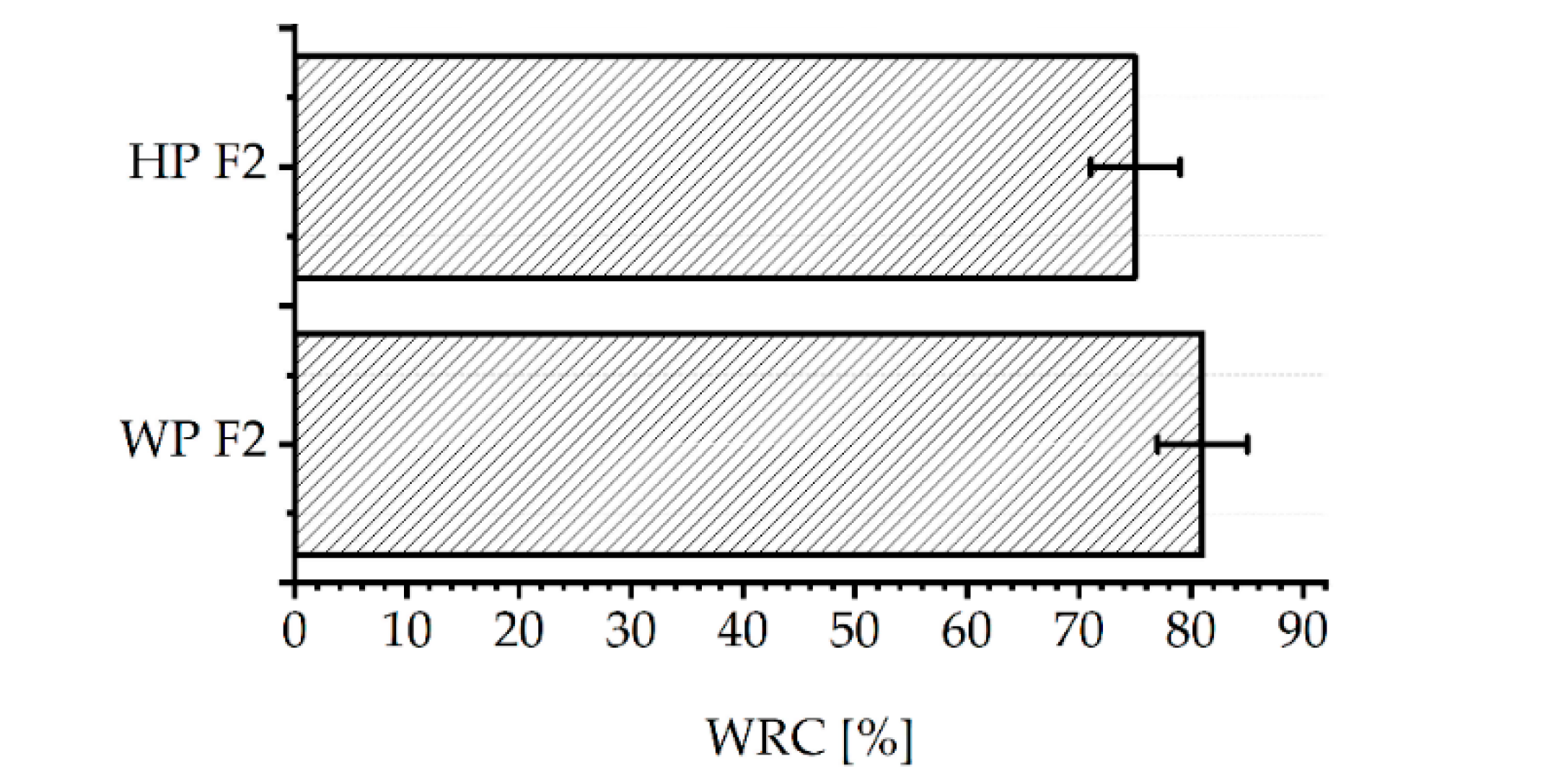

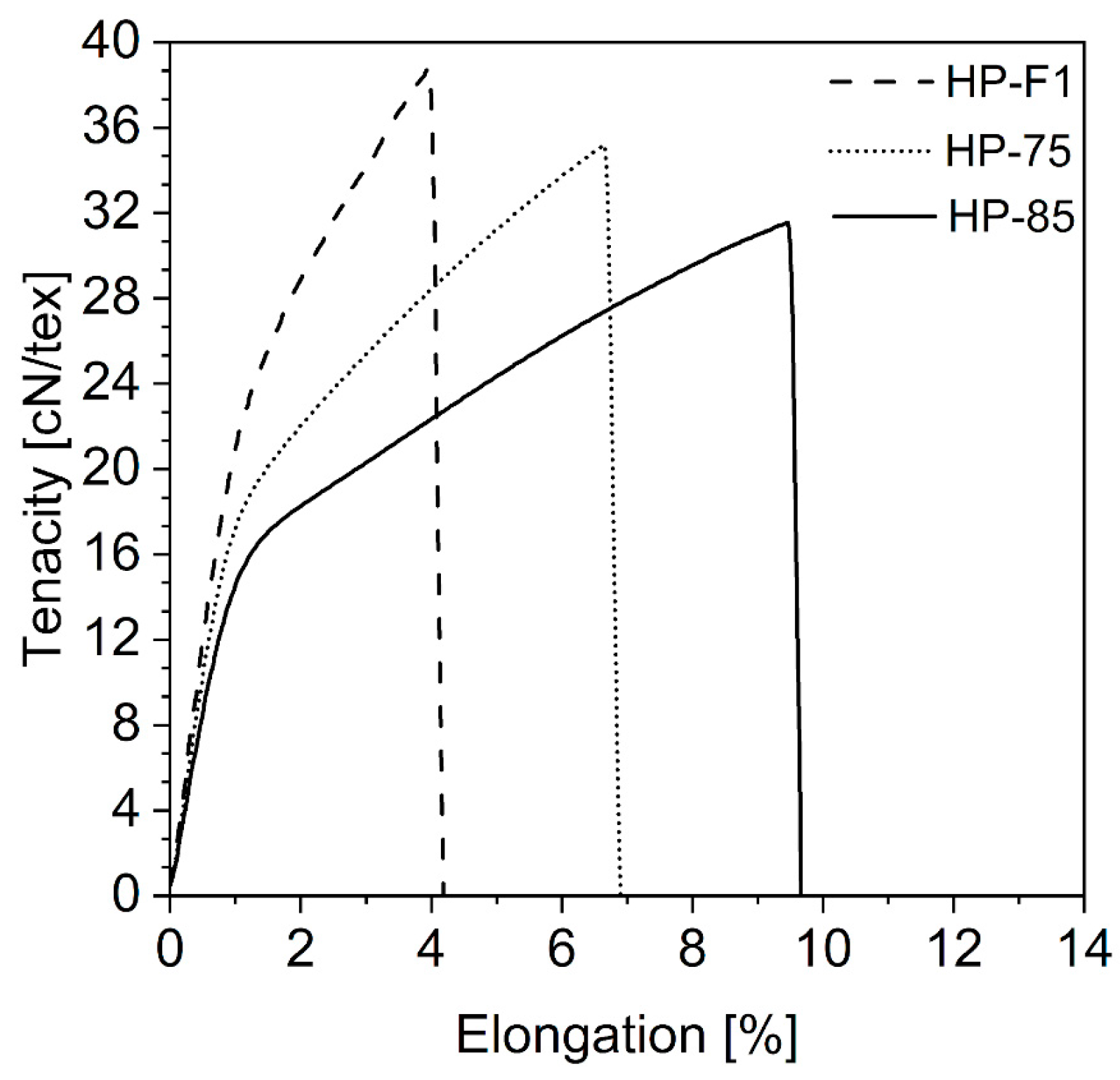

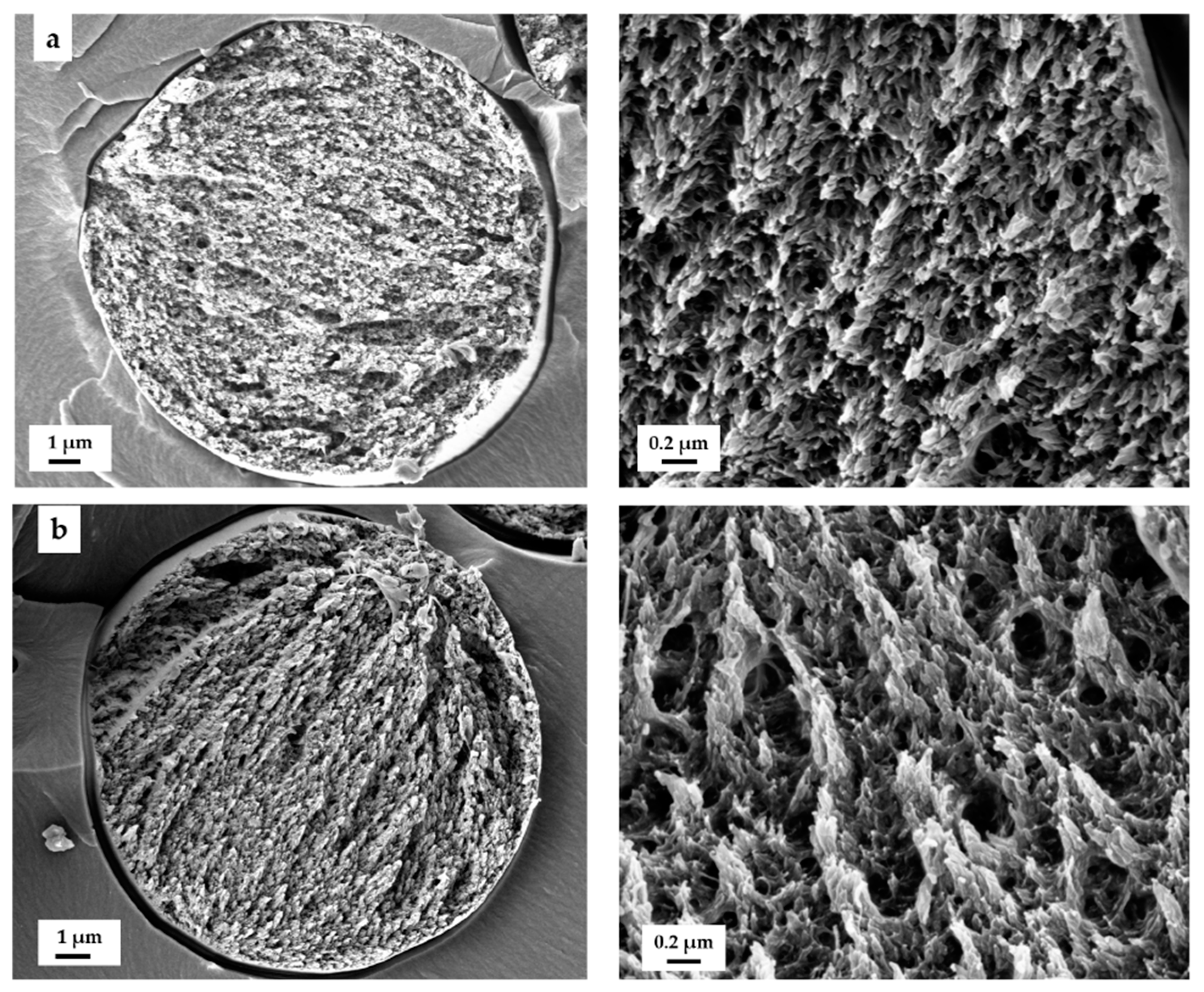

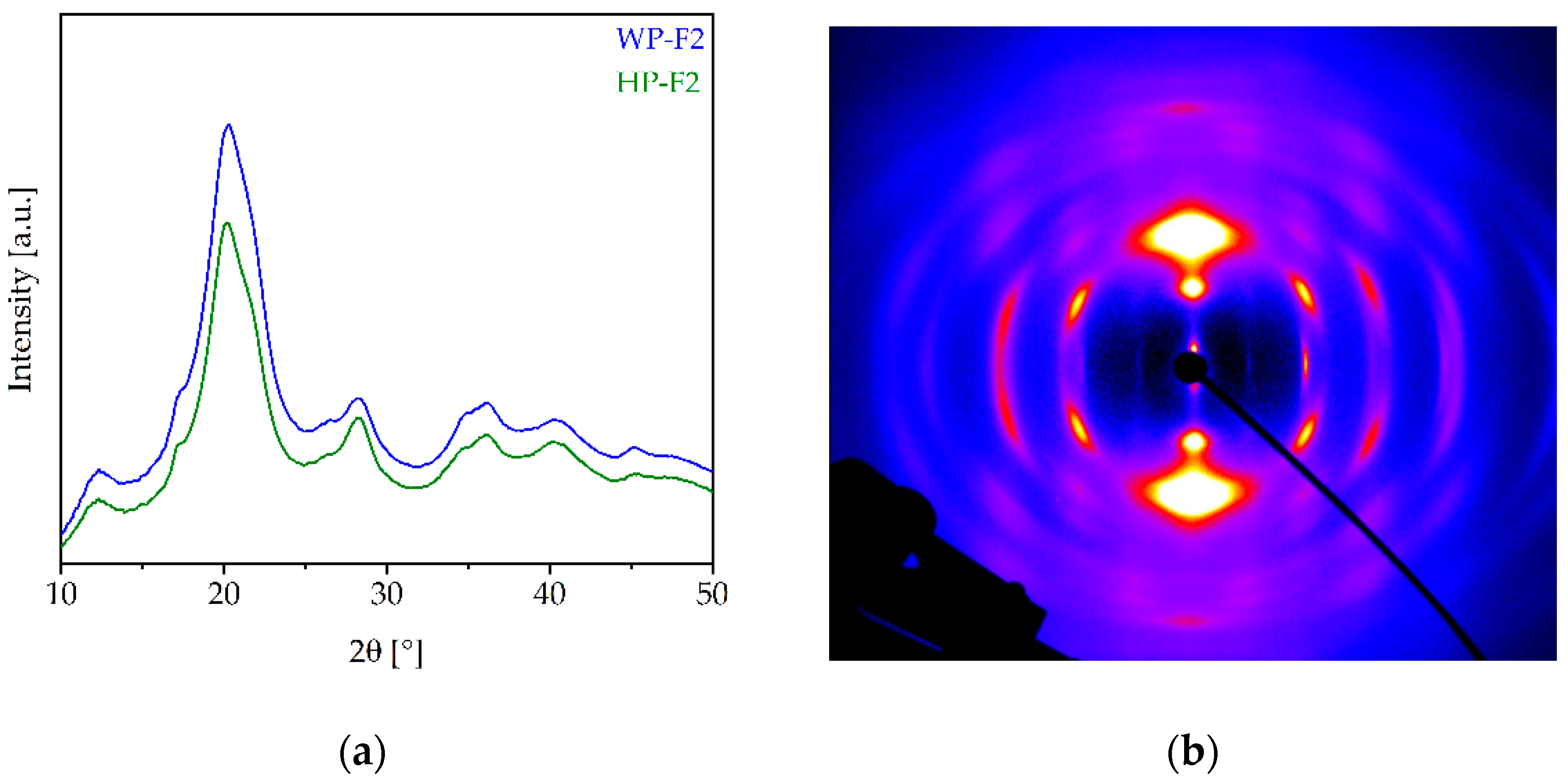

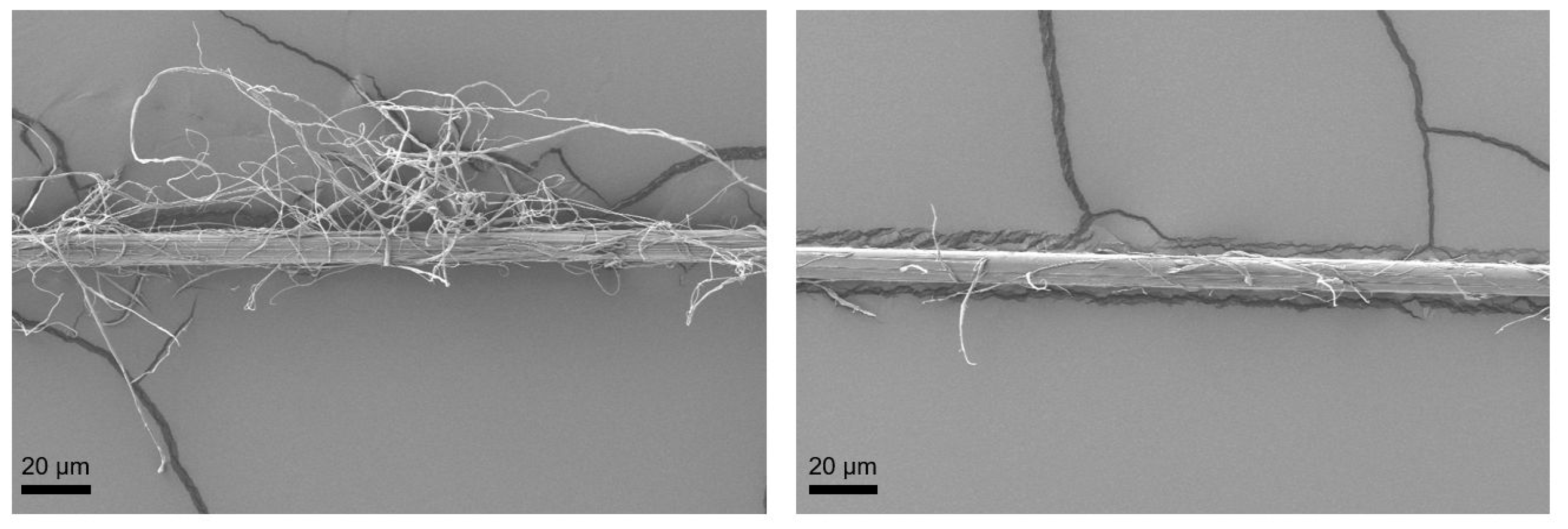

3.2.2. Structure and Morphology

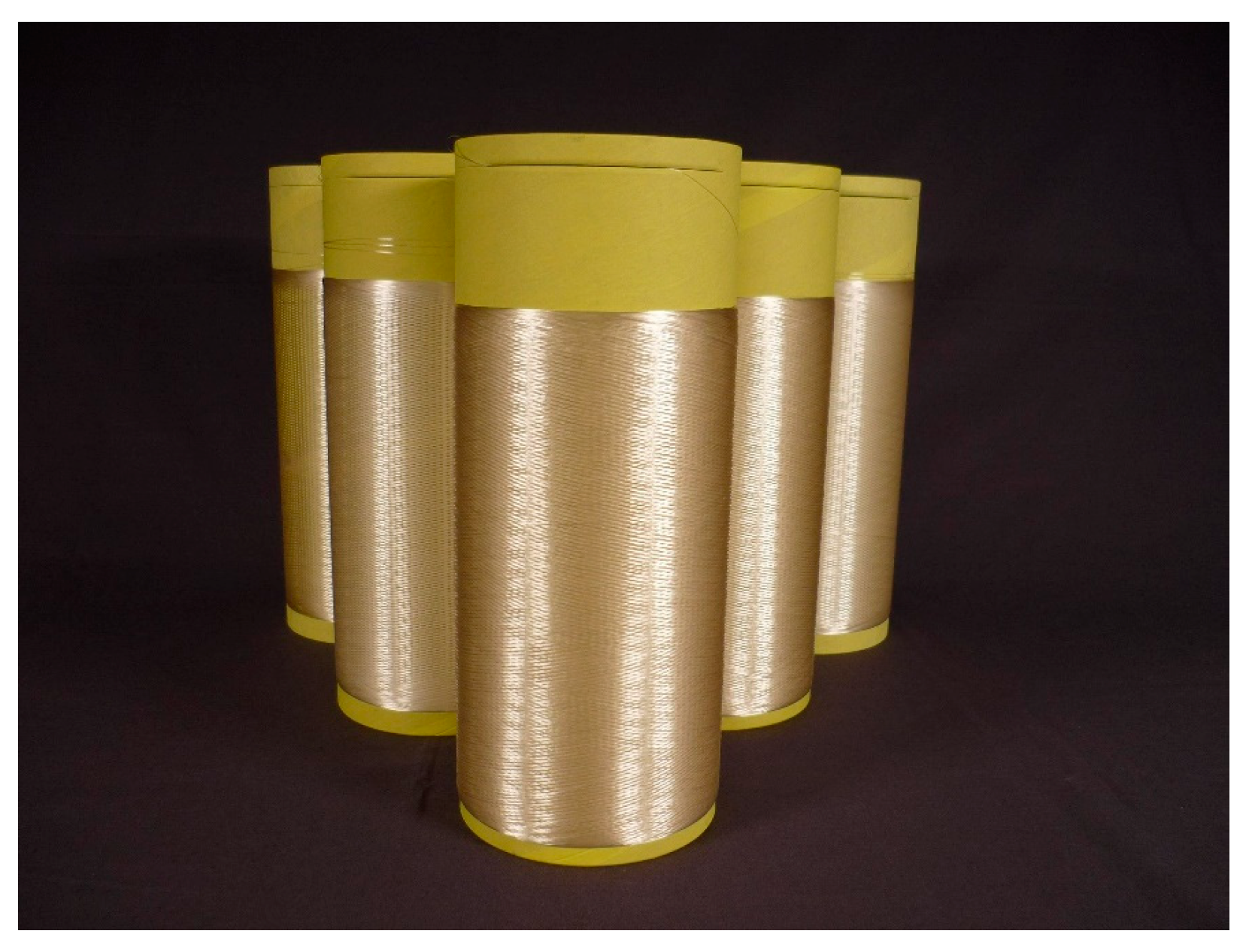

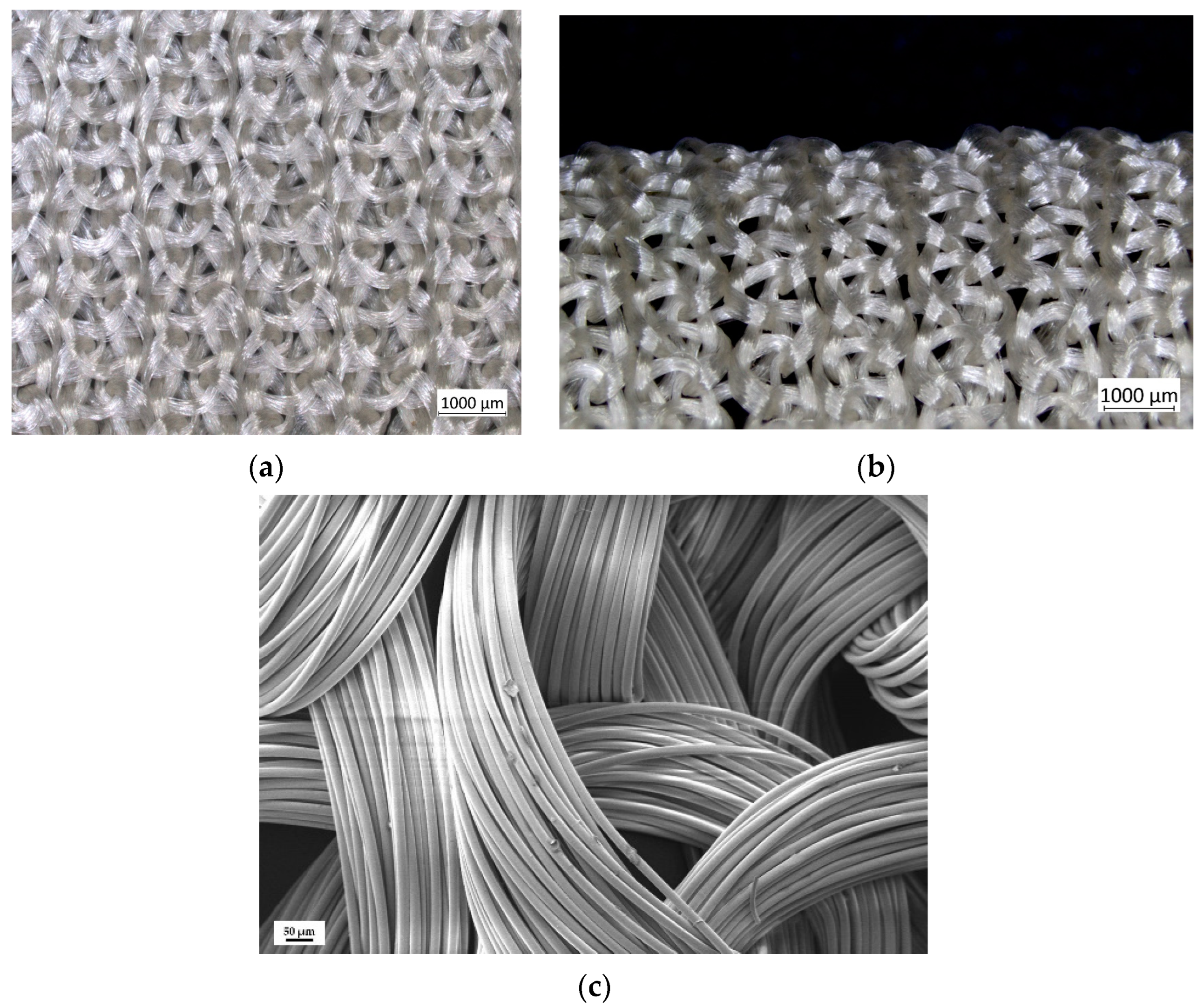

3.3. Fabric Manufacturing

4. Conclusions and Outlook

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Horne, M.R.L. Handbook of Natural Fibres; Kozłowski, R.M., Ed.; Woodhead Publishing: Cambridge, UK, 2012; Volume 1, pp. 114–145. [Google Scholar]

- Manian, A.P.; Cordin, M.; Pham, T. Extraction of cellulose fibers from flax and hemp: A review. Cellulose 2021, 28, 8275–8294. [Google Scholar] [CrossRef]

- Cultivation. Available online: https://www.interchanvre.org/la_culture#les_chiffres_cles (accessed on 30 August 2023).

- Haemmerle, F.M. The Cellulose Gap (The Future of Cellulose Fibers). Lenzing. Ber. 2011, 89, 12–21. [Google Scholar]

- El Seoud, O.A.; Kostag, M.; Jedvert, K.; Malek, N.I. Cellulose Regeneration and Chemical Recycling: Closing the “Cellulose Gap” Using Environmentally Benign Solvents. Macromol. Mater. Eng. 2020, 305, 1900832. [Google Scholar] [CrossRef]

- Bredereck, K.; Hermanutz, F. Man-made cellulosics. Rev. Prog. Color. Relat. Top. 2005, 35, 59–75. [Google Scholar] [CrossRef]

- Sayyed, A.J.; Deshmukh, N.A.; Pinjari, D.V. A critical review of manufacturing processes used in regenerated cellulosic fibres: Viscose, cellulose acetate, cuprammonium, LiCl/DMAc, ionic liquids, and NMMO based lyocell. Cellulose 2019, 26, 2913–2940. [Google Scholar] [CrossRef]

- Taokaew, S.; Kriangkrai, W. Recent Progress in Processing Cellulose Using Ionic Liquids as Solvents. Polysaccharides 2022, 3, 671–691. [Google Scholar] [CrossRef]

- Felgueiras, C.; Azoia, N.G.; Goncalves, C.; Gama, M.; Dourado, F. Trends on the Cellulose-Based Textiles: Raw Materials and Technologies. Front. Bioeng. Biotechnol. 2021, 9, 608826. [Google Scholar] [CrossRef]

- Paulitz, J.; Sigmund, I.; Kosan, B.; Meister, F. Lyocell fibers for textile processing derived from organically grown hemp. Procedia Eng. 2017, 200, 260–268. [Google Scholar] [CrossRef]

- Makarov, I.S.; Golova, L.K.; Smyslov, A.G.; Vinogradov, M.I.; Palchikova, E.E.; Legkov, S.A. Flax Noils as a Source of Cellulose for the Production of Lyocell Fibers. Fibers 2022, 10, 45. [Google Scholar] [CrossRef]

- Lawson, L.; Degenstein, L.M.; Bates, B.; Chute, W.; King, D.; Dolez, P.I. Cellulose Textiles from Hemp Biomass: Opportunities and Challenges. Sustainability 2022, 14, 15337. [Google Scholar] [CrossRef]

- Seile, A.; Spurina, E.; Sinka, M. Reducing Global Warming Potential Impact of Bio-Based Composites Based of LCA. Fibers 2022, 10, 79. [Google Scholar] [CrossRef]

- McDonald, H.; Frelih-Larsen, A.; Lóránt, A.; Duin, L.; Andersen, S.P.; Costa, G.; Bradley, H. Carbon farming, Making Agriculture Fit for 2030; Policy Department for Economic, Scientific and Quality of Life Policies Directorate-General for Internal Policies; European Union: Luxemburg, 2021; pp. 1–67. [Google Scholar]

- Conchedda, G.; Tubiello, F.N. Emissions Due to Agriculture. Global, Regional and Country Trends 2000–2018; Environmental team, F. S. D., FAOSTAT Analytical Brief Series, Eds.; FAO: Rome, Italy, 2020; Volume 18, pp. 1–67. [Google Scholar]

- da Silva, M.G.; Lisbôa, A.C.L.; Hoffmann, R.; da Cunha Kemerich, P.D.; de Borba, W.F.; Fernandes, G.D.Á.; de Souza, É.E.B. Greenhouse gas emissions of rice straw-to-methanol chain in Southern Brazil. J. Environ. Chem. Eng. 2021, 9, 105202–105215. [Google Scholar] [CrossRef]

- Jiang, X.; Bai, Y.; Chen, X.; Liu, W. A review on raw materials, commercial production and properties of lyocell fiber. J. Bioresour. Bioprod. 2020, 5, 16–25. [Google Scholar] [CrossRef]

- Thümmler, K.; Fischer, J.; Fischer, S.; Kosan, B.; Meister, F. Lyohemp™ Fibres from Hemp Shive Dissolving Pulp. Lenzing. Ber. 2022, 97, 25–31. [Google Scholar]

- Rissanen, M.; Schlapp-Hackl, I.; Sawada, D.; Raiskio, S.; Ojha, K.; Smith, E.; Sixta, H. Chemical recycling of hemp waste textiles via the ionic liquid based dry-jet-wet spinning technology. Text. Res. J. 2022, 93, 2545–2557. [Google Scholar] [CrossRef]

- Hermanutz, F.; Vocht, M.P.; Buchmeiser, M.R. Commercial Applications of Ionic Liquids. Green Chemistry and Sustainable Technology; Shiflett, M., Ed.; Springer: Cham, Switzerland, 2020; Volume 1, pp. 227–259. [Google Scholar]

- Vocht, M.P.; Beyer, R.; Thomasic, P.; Müller, A.; Ota, A.; Hermanutz, F.; Buchmeiser, M.R. High-performance cellulosic filament fibers prepared via dry-jet wet spinning from ionic liquids. Cellulose 2021, 28, 3055–3067. [Google Scholar] [CrossRef]

- Fechter, C.; Fischer, S.; Reimann, F.; Brelid, H.; Heinze, T. Influence of pulp characteristics on the properties of alkali cellulose. Cellulose 2020, 27, 7227–7241. [Google Scholar] [CrossRef]

- DIN 54355:1977-11; Testing of Pulp; Determination of the Stability of Pulp against Sodium Hydroxide Solution (Alkali Resistance). Deutsches Institut Fur Normung E.V.: Berlin, Germany, 1977.

- DIN 54370:2007-06; Testing of Paper and Board—Determination of the Residue on Ignition. Deutsches Institut Fur Normung E.V.: Berlin, Germany, 2007.

- DIN EN ISO 11885:2009-09; Water Quality—Determination of Selected Elements by Inductively Coupled Plasma Optical Emission Spectrometry (ICP-OES) (ISO 11885:2007), German version EN ISO 11885:2009. ISO: Geneva, Switzerland, 2009.

- Meister, F.; Kosan, B. A tool box for characterization of pulps and cellulose dopes in Lyocell technology. Nord. Pulp Paper Res. J. 2015, 30, 112–120. [Google Scholar] [CrossRef]

- Michud, A.; Hummel, M.; Sixta, H. Influence of molar mass distribution on the final properties of fibers regenerated from cellulose dissolved in ionic liquid by dry-jet wet spinning. Polymer 2015, 75, 1–9. [Google Scholar] [CrossRef]

- DIN 54270-1:1976-09; Testing of Textiles; Determination of the Limit-Viscosity of Celluloses, Principles. Deutsches Institut Fur Normung E.V.: Berlin, Germany, 1976.

- Gahleitner, M.; Sobczak, R. Importance of the zero shear viscosity determination to the modelling of flow curves. Kunst.-Ger. Plast. 1989, 79, 1213–1216. [Google Scholar]

- DIN EN ISO 5079:2021-02; Textile Fibres—Determination of Breaking Force and Elongation at Break of Individual Fibres (ISO 5079:2020). German version EN ISO 5079:2020; ISO: Geneva, Switzerland, 2021.

- Rongpipi, S.; Ye, D.; Gomez, E.D.; Gomez, E.W. Progress and Opportunities in the Characterization of Cellulose—An Important Regulator of Cell Wall Growth and Mechanics. Front Plant Sci. 2018, 9, 1894. [Google Scholar] [CrossRef] [PubMed]

- Scherrer, P. Bestimmung der Größe und der inneren Struktur von Kolloidteilchen mittels Röntgenstrahlen. Nachrichten von der Gesellschaft der Wissenschaften zu Göttingen Mathematisch-Physikalische Klasse 1918, 1918, 98–100. [Google Scholar]

- DIN 53814:1974-10; Testing of Textiles; Determination of Water Retention Power of Fibres and Yarn Cuttings. Deutsches Institut Fur Normung E.V.: Berlin, Germany, 1974.

- Ota, A.; Beyer, R.; Hageroth, U.; Müller, A.; Tomasic, P.; Hermanutz, F.; Buchmeiser, M.R. Chitin/cellulose blend fibers prepared by wet anddry-wetspinning. Polym. Adv. Technol. 2020, 32, 335–342. [Google Scholar] [CrossRef]

- Abels, F.; Cwik, T.; Beyer, R.; Hermanutz, F. Process for the Preparation of Polymer Fibers from Polymers Dissolved in Ionic Liquids by Means of an Air Gap Spinning Process. Patent WO2017/137284AI, 17 August 2017. [Google Scholar]

- Zhang, S.; Chen, C.; Duan, C.; Hu, H.; Li, H.; Li, J.; Liu, Y.; Ma, X.; Stavik, J.; Ni, Y. Regenerated cellulose by the lyocell process, a brief review of the process and properties. Bioresources 2018, 13, 1–16. [Google Scholar] [CrossRef]

- Moriam, K.; Sawada, D.; Nieminen, K.; Hummel, M.; Ma, Y.; Rissanen, M.; Sixta, H. Towards regenerated cellulose fibers with high toughness. Cellulose 2021, 28, 9547–9566. [Google Scholar] [CrossRef]

- Ingildeev, D.; Effenberger, F.; Bredereck, K.; Hermanutz, F. Comparison of direct solvents for regenerated cellulosic fibers via the lyocell process and by means of ionic liquids. J. Appl. Polym. Sci. 2013, 128, 4141–4150. [Google Scholar] [CrossRef]

- Olsson, C.; Westman, G. Wet spinning of cellulose from ionic liquid solutions–viscometry and mechanical performance. J. App. Polym. Sci. 2013, 127, 4542–4548. [Google Scholar] [CrossRef]

- Vocht, M.P.; Ota, A.; Frank, E.; Hermanutz, F.; Buchmeiser, M.R. Preparation of Cellulose-Derived Carbon Fibers Using a New Reduced-Pressure Stabilization Method. Ind. Eng. Chem. Res. 2022, 61, 5191–5201. [Google Scholar] [CrossRef]

- Lenz, J.; Schurz, J.; Wrentschur, E. On the Elongation Mechanism of Regenerated Cellulose Fibres. Holzforschung 1994, 48, 72–76. [Google Scholar] [CrossRef]

- Mortimer, S.A.; Peguy, A.A. The influence of air-gap conditions on the structure formation of lyocell fibers. J. Appl. Polym. Sci. 1998, 60, 1747–1756. [Google Scholar] [CrossRef]

| Counted Fibrills | Classification |

|---|---|

| 0–5 | 1 |

| 6–10 | 2 |

| 11–20 | 3 |

| 21–40 | 4 |

| 41–80 | 5 |

| >80 | 6 |

| Pulp | Water Cont. [%] | Ash Cont. [%] | Fe/Na/K/Mg/Ca [ppm] | R-18 [%] | DP | Mn a [kg/mol] | Mw b [kg/mol] | Đ c |

|---|---|---|---|---|---|---|---|---|

| WP | 4.1 | 0.11 | 4/220/17/73/3.5 | 92 | 930 (550) | 104 (31) | 613 (324) | 7.0 (10.5) |

| HP | 5.0 | 0.23 | 21/170/9/79/800 | 91 | 660 | 95 | 316 | 3.3 |

| Sample-ID | WP-F | HP-F | ||

|---|---|---|---|---|

| 1 | 2 | 1 | 2 | |

| DR | 7.7 | 9.6 | 7.7 | 9.6 |

| Fineness [dtex] | 3.1 ± 0.1 | 2.5 ± 0.2 | 4.2 ± 0.3 | 3.2 ± 0.6 |

| Elongation at break [%] | 5.8 ± 1.1 | 4.4 ± 0.5 | 4.4 ± 0.9 | 3.9 ± 0.6 |

| Tenacity [cN/tex] | 35 ± 3 | 35 ± 2 | 41 ± 4 | 41 ± 3 |

| Young’s modulus [cN/tex] | 2160 ± 110 | 2230 ± 80 | 2540 ± 110 | 2540 ± 90 |

| Sample-ID | HP-F | |

|---|---|---|

| −75 | −85 | |

| DR | 7.7 | 7.7 |

| Fineness [dtex] | 3.0 ± 0.2 | 3.1 ± 0.2 |

| Cond. a elongation at break [%] | 7.1 ± 1.1 | 9.8 ± 1.1 |

| Cond. a tenacity [cN/tex] | 37 ± 2 | 33 ± 2 |

| Cond. a Young’s modulus [cN/tex] | 2130 ± 70 | 1760 ± 100 |

| Wet b elongation at break [%] | 11 ± 2 | 12 ± 3 |

| Wet b tenacity [cN/tex] | 20 ± 3 | 17 ±2 |

| Wet b Young’s modulus [cN/tex] | 230 ± 20 | 170 ± 11 |

| Ic [%] | 65 | 68 |

| 0.043 | 0.041 | |

| ft | 0.69 ± 0.05 | 0.66 ± 0.04 |

| WRV [%] | 75 | 84 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ota, A.; Vocht, M.P.; Beyer, R.; Reboux, A.; Reboux, C.; Hermanutz, F. Next-Generation Cellulosic Filaments from Hemp Pulp via Dry-Jet Wet Spinning Using HighPerCell® Technology. Fibers 2023, 11, 90. https://doi.org/10.3390/fib11110090

Ota A, Vocht MP, Beyer R, Reboux A, Reboux C, Hermanutz F. Next-Generation Cellulosic Filaments from Hemp Pulp via Dry-Jet Wet Spinning Using HighPerCell® Technology. Fibers. 2023; 11(11):90. https://doi.org/10.3390/fib11110090

Chicago/Turabian StyleOta, Antje, Marc Philip Vocht, Ronald Beyer, Anne Reboux, Charles Reboux, and Frank Hermanutz. 2023. "Next-Generation Cellulosic Filaments from Hemp Pulp via Dry-Jet Wet Spinning Using HighPerCell® Technology" Fibers 11, no. 11: 90. https://doi.org/10.3390/fib11110090

APA StyleOta, A., Vocht, M. P., Beyer, R., Reboux, A., Reboux, C., & Hermanutz, F. (2023). Next-Generation Cellulosic Filaments from Hemp Pulp via Dry-Jet Wet Spinning Using HighPerCell® Technology. Fibers, 11(11), 90. https://doi.org/10.3390/fib11110090