3.1.1. Cumulative Water Absorption

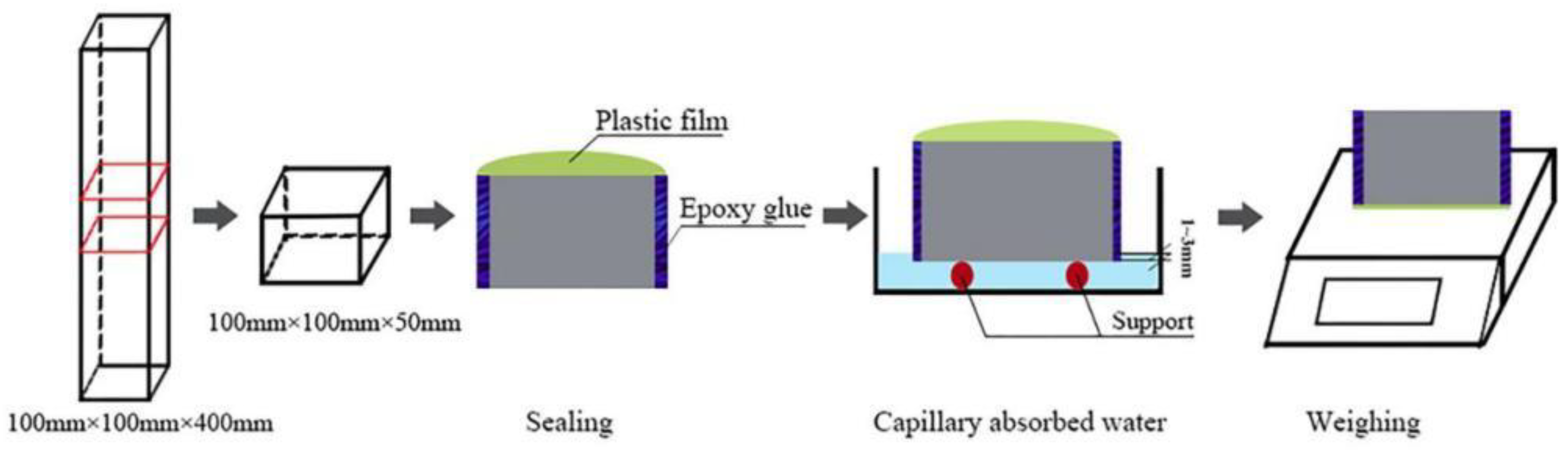

In general, the cumulative water absorption per unit area

I is used to describe the ability of water to transfer inside the recycled aggregate concrete under freeze–thaw cycles, as shown in Formula (2).

where

I is the cumulative water absorption per unit area (mm);

Mt is the mass difference of the test block before and after water absorption (g);

A is the contact area between the test block and water (mm); and

ρ is the density of water (g/mm

3).

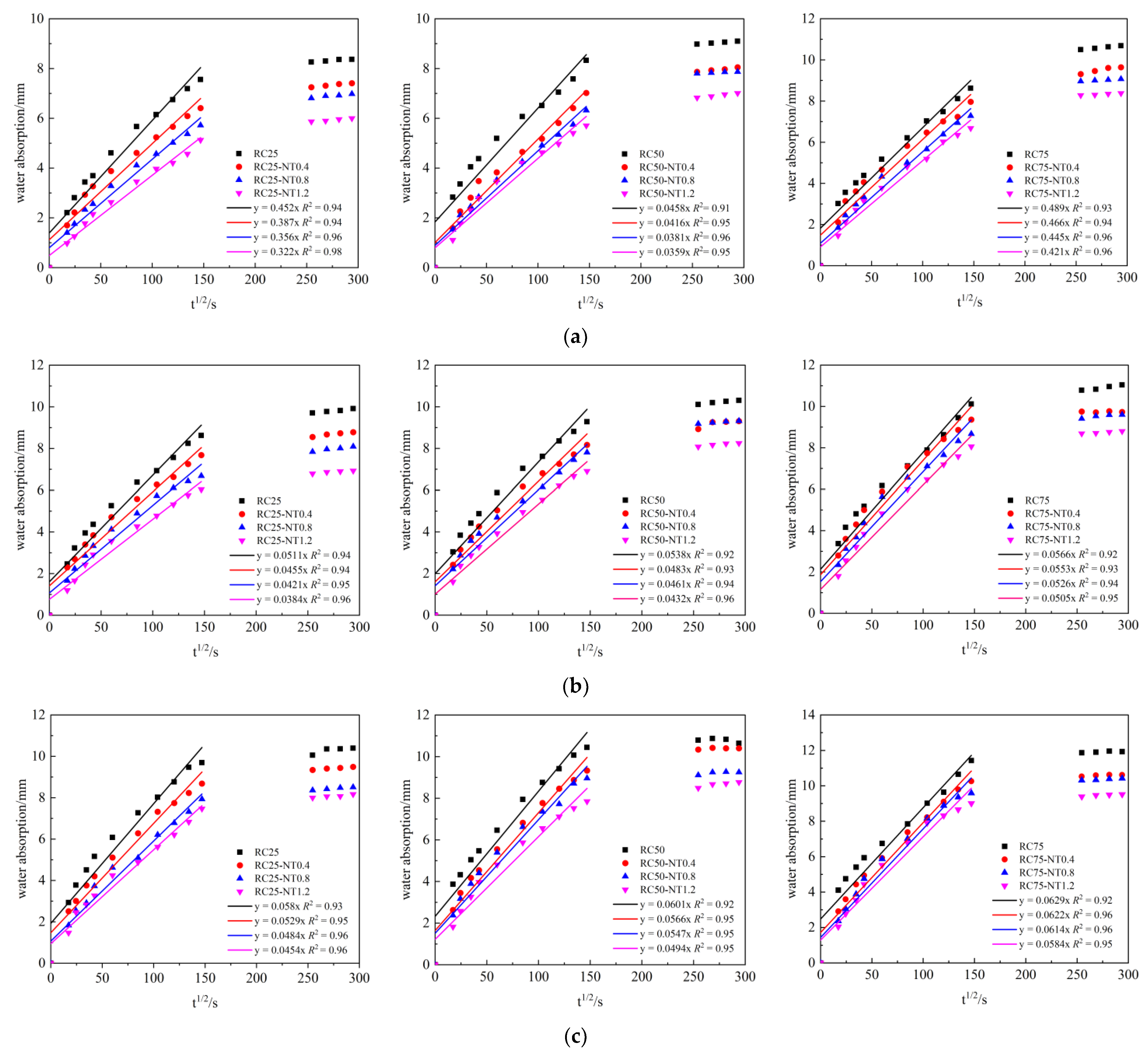

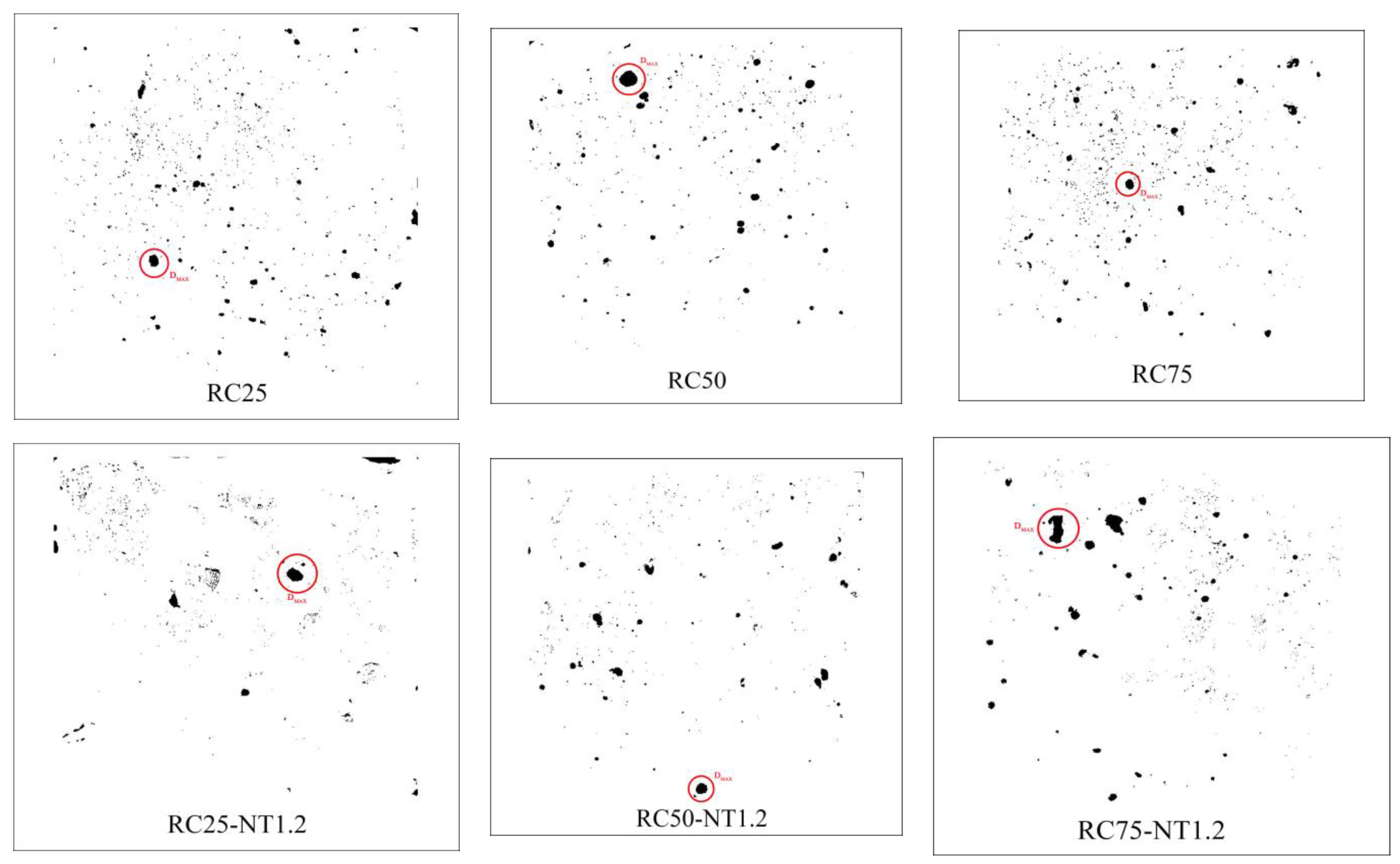

By measuring the mass difference before and after the water absorption of the test block in unit time, the relationship between the cumulative water absorption per unit area of nano-TiO

2 recycled aggregate concrete and the square root of time under different freeze–thaw cycles, R25, R50, and R75 (three groups of different RCA content), as shown in

Figure 5. The cumulative water absorption per unit area of the test block increases sharply in the first 6 h (t

1/2 = 147 s) and then tends to level off. The variation in the accumulated water absorption

I of the test block can be roughly divided into two stages: primary absorption and secondary absorption.

When the RCA doping is the same, the cumulative water absorption of the four test-block groups varies as follows: NT0 < NT0.4 < NT0.8 < NT1.2. It can be seen from the figure that the cumulative water absorption of the three test-block groups was not much different in the first 60 min. With the increase in time and the number of freeze–thaw cycles, the cumulative water absorption of the test blocks without nano-TiO2 continued to rise. In the whole process of freeze–thaw cycles, the cumulative water absorption of the R25 group was relatively stable. In the R50 group, the overall upward trend of RC50 was large, and the upward trend of NT0.4 and NT0.8 was close when freeze–thawed 50 times and 100 times, and the changing trend of water absorption was not large. The R75 group showed a more obvious upward trend, with the highest water absorption. During the whole water-absorption process, the effect of nano-TiO2 content on the R75 group was not as obvious as that of the previous two groups, and the cumulative water absorption of the three test-block groups was the best when the nano-TiO2 content was 1.2 %. Specifically, when the freeze–thaw cycle was zero times, the cumulative water absorption of the three groups of nano-TiO2 test blocks with 1.2% content was reduced by 28.3%, 22.97%, and 21.61%, respectively, compared with the undoped. At 150 times of freezing and thawing, the reduction was 25.52%, 16.88%, and 15.48%, respectively. It can be seen that the larger the amount of nano-TiO2 added, the higher the cumulative-water-absorption decline rate.

When the RCA content was different, the cumulative water-absorption trend of the test block was R25 group < R50 group < R75 group. With the increase in RCA content, the cumulative-water-absorption trend of the test block decreased. Compared with RC50 and RC75, the cumulative water absorption of RC25 decreased by 8.02% and 21.7%, respectively, at 0 freeze–thaw cycles, and decreased by 3.86% and 11.74%, respectively, at 150 freeze–thaw cycles.

3.1.2. Water Absorption

Using water absorption

S instead of the capillary coefficient is an important index to describe the water-absorption performance of recycled aggregate concrete, which is widely used to evaluate the water-absorption characteristics of building materials. After fitting the two stages of cumulative water absorption

I, the initial water absorption

S1 (t

1/2 = 0–147 s) and the secondary water absorption

S2 (t

1/2 = 147–294 s) of recycled aggregate concrete can be obtained, as shown in Formula (3):

where

S is water absorption (mm/s

1/2) and

t is time (s).

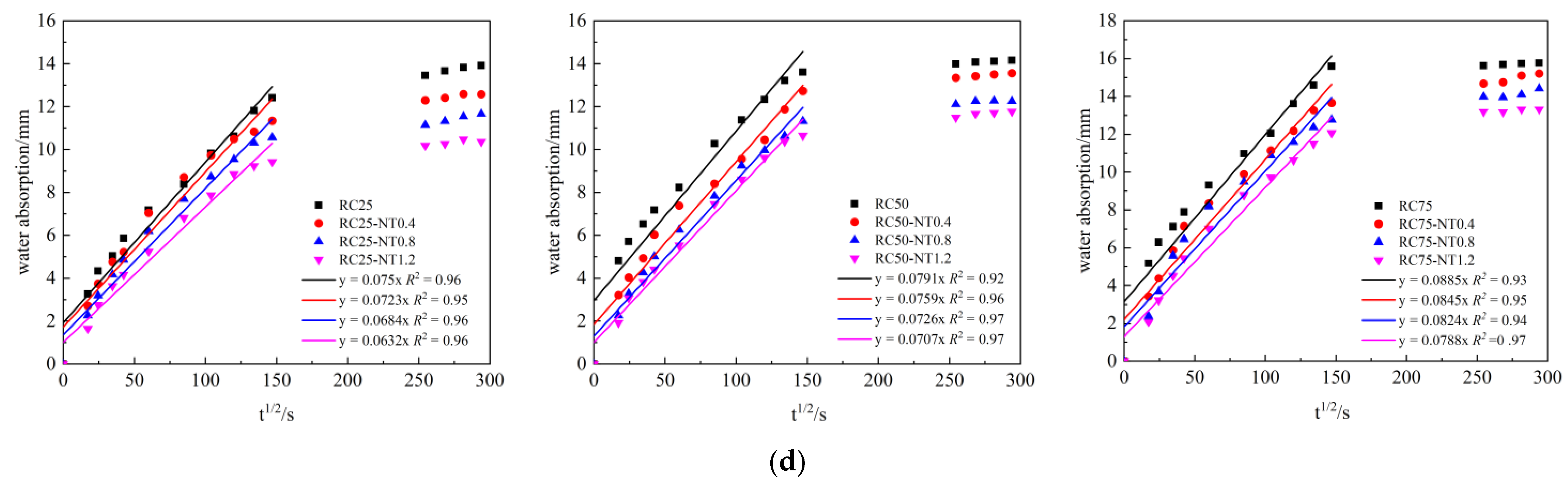

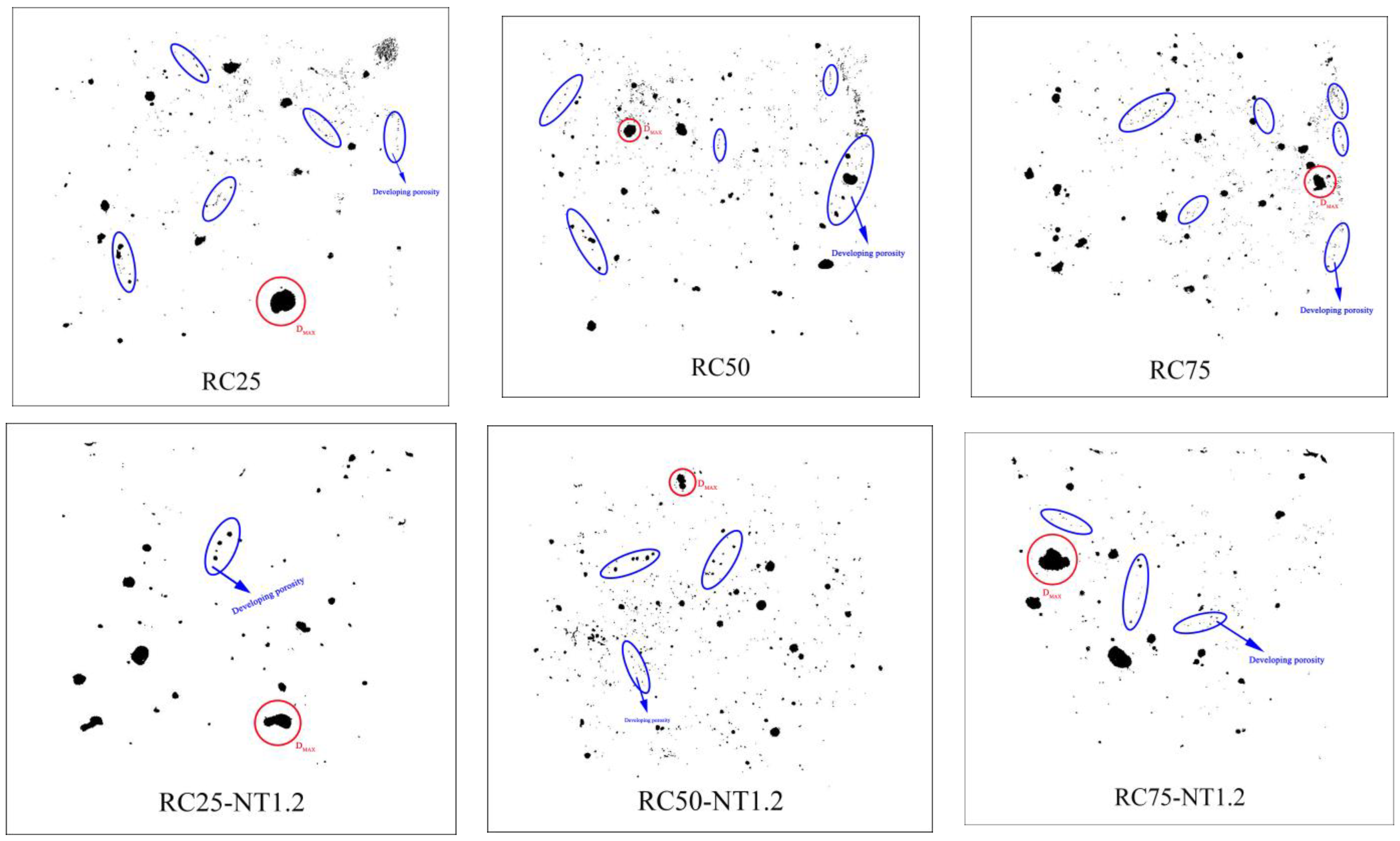

Figure 6 shows the relationship between the initial capillary-water-absorption rate

S1 and the number of freeze–thaw cycles

n. According to the diagram, the initial capillary-water-absorption rate

S1 of the three groups of recycled aggregate concrete shows an upward trend, the growth rate is faster with time, and the water absorption is more.

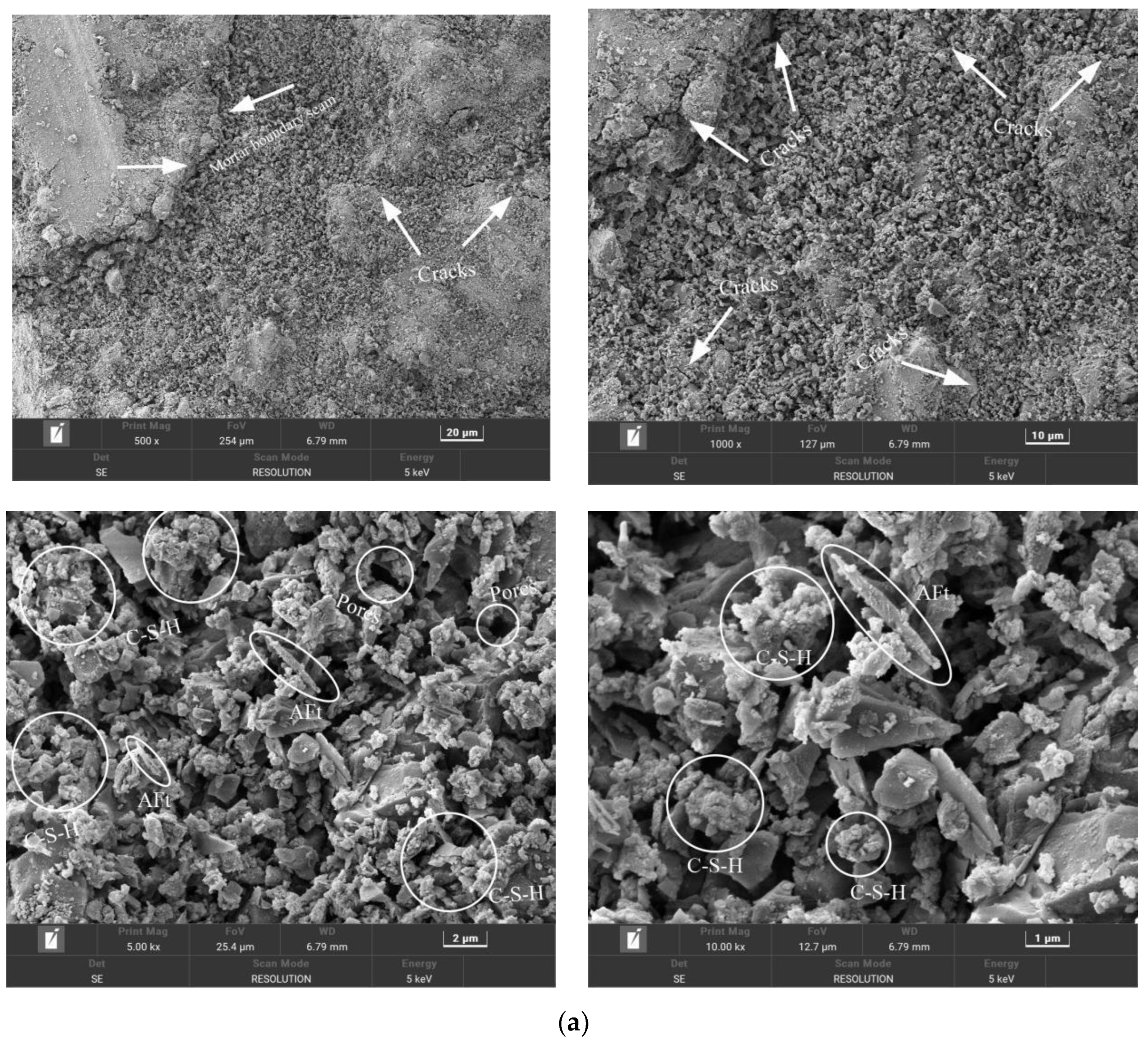

Under the condition of no nanomaterials, the maximum differences in

S1 of RC25, RC50, and RC75 reached 39.73%, 42.1%, and 44.75%, respectively, when the freeze–thaw cycle was 0 and 150 times. It can be seen that the freeze–thaw cycle has a direct impact on the water absorption of recycled aggregate concrete. This is because when RCA is recycled, a large amount of residual original cement mortar will form an interface transition zone (ITZ) with high porosity and a large number of microcracks on the aggregate surface. ITZs can easily weaken the bearing capacity and stability of concrete. When the test block is in a freeze–thaw environment, the seepage pressure and hydrostatic pressure make the water in the ITZ continue to move [

27,

28]. When the pressure reaches a certain level, the fine cracks contained in the RCA are expanded, increased, and connected, resulting in the generation of new cracks driven by the original cracks. Under the action of capillary force, the water invades rapidly, and

S1 rises sharply. Therefore, the

S1 of R75 is higher than that of the other two groups.

After adding nanomaterials, the water absorption of recycled aggregate concrete decreased significantly. Before freezing and thawing, the water-absorption rate of the three groups of specimens with 1.2% nano-TiO

2 content was reduced by 28.76%, 21.62%, and 13.9%, respectively, compared with those without nanomaterials. When the freeze–thaw cycle was 150 times, it was reduced by 15.73%, 10.62%, and 10.96%, respectively. It can be seen that the incorporation of nano-TiO

2 can reduce the water absorption of recycled aggregate concrete to varying degrees, and the less the RCA content, the better the effect. Because nano-TiO

2 is a “zero-dimensional structure” nanoparticle with a size much smaller than cement particles, it can accelerate CA(OH)

2 formation as a nucleation site of CA(OH)

2 crystals, promote cement hydration, affect the microporous structure of cementitious composites, and can fill and repair the pores and cracks of recycled concrete ITZs (to some extent), and improve their physical properties [

29,

30]. Secondly, nano-TiO

2 is a kind of nonreactive fine filler without doping activity. It has stability and inertia, which can accelerate the hydration rate of cement, increase the reaction area between RCA and cement paste, and produce more C–S–H gel [

31]. The photocatalytic effect makes nano-TiO

2 have strong cohesiveness in cement-based composites. With the increase in dosage, the filling effect of the cement mixture is more sufficient, the channel of water entering the concrete is reduced, and the compactness of the recycled aggregate concrete is improved.

Macroscopically, the density of the

S1 curve of the three groups of recycled aggregate concrete is R75 > R50 > R25. This is because the higher the RCA content, the lower the internal compactness of the concrete, and the same amount of nano-TiO

2 cannot be filled. If the content of nano-TiO

2 is too high, the material will gather due to the agglomeration effect, reduce the average spacing between particles, and limit the formation of Ca(OH)

2 [

32]. Overall, among the three groups of different nano-TiO

2 recycled aggregate concrete, the combination of 25% RCA and 1.2% nano-TiO

2 is the best.

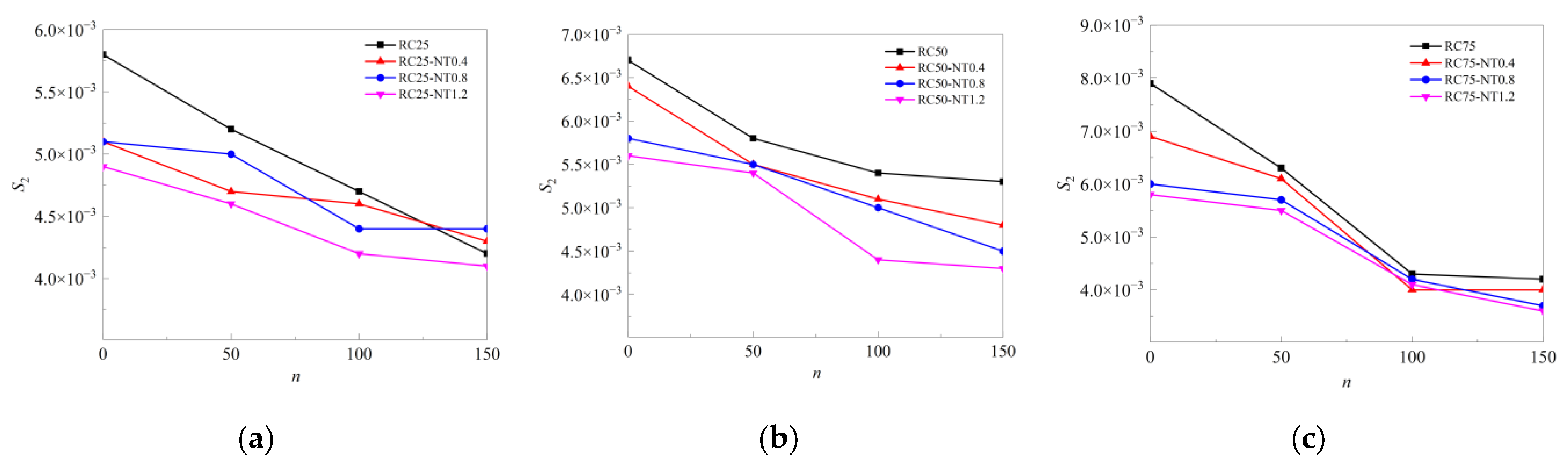

Figure 7 is the relationship between the secondary capillary-water-absorption rate

S2 and the number of freeze–thaw cycles n of nano-TiO

2 recycled aggregate concrete with different dosages. Different from

S1, with the increase in freeze–thaw cycles, the growth rate of

S2 slowed down, the water absorption changed little, and the numerical change trend between groups was very small. This is because the recycled aggregate concrete in the early capillary-water-absorption rate is relatively fast; with the extension of time, the natural water absorption of the test block gradually reached a saturated state, resulting in the test block’s later water-absorption rate being relatively slow, and the water absorption being greatly reduced.

It can be analysed from the change curves of S1 and S2 that the water-absorption index can fully reflect the water-absorption performance of recycled aggregate concrete. The incorporation of nano-TiO2 can reduce the water-absorption performance of recycled aggregate concrete and effectively improve the freeze–thaw resistance. Therefore, the use of recycled aggregate concrete in severe cold regions can fully consider the superiority of nano-TiO2.