Facile Synthesis of Copper(I) Oxide Nanochains and the Photo-Thermal Conversion Performance of Its Nanofluids

Abstract

:1. Introduction

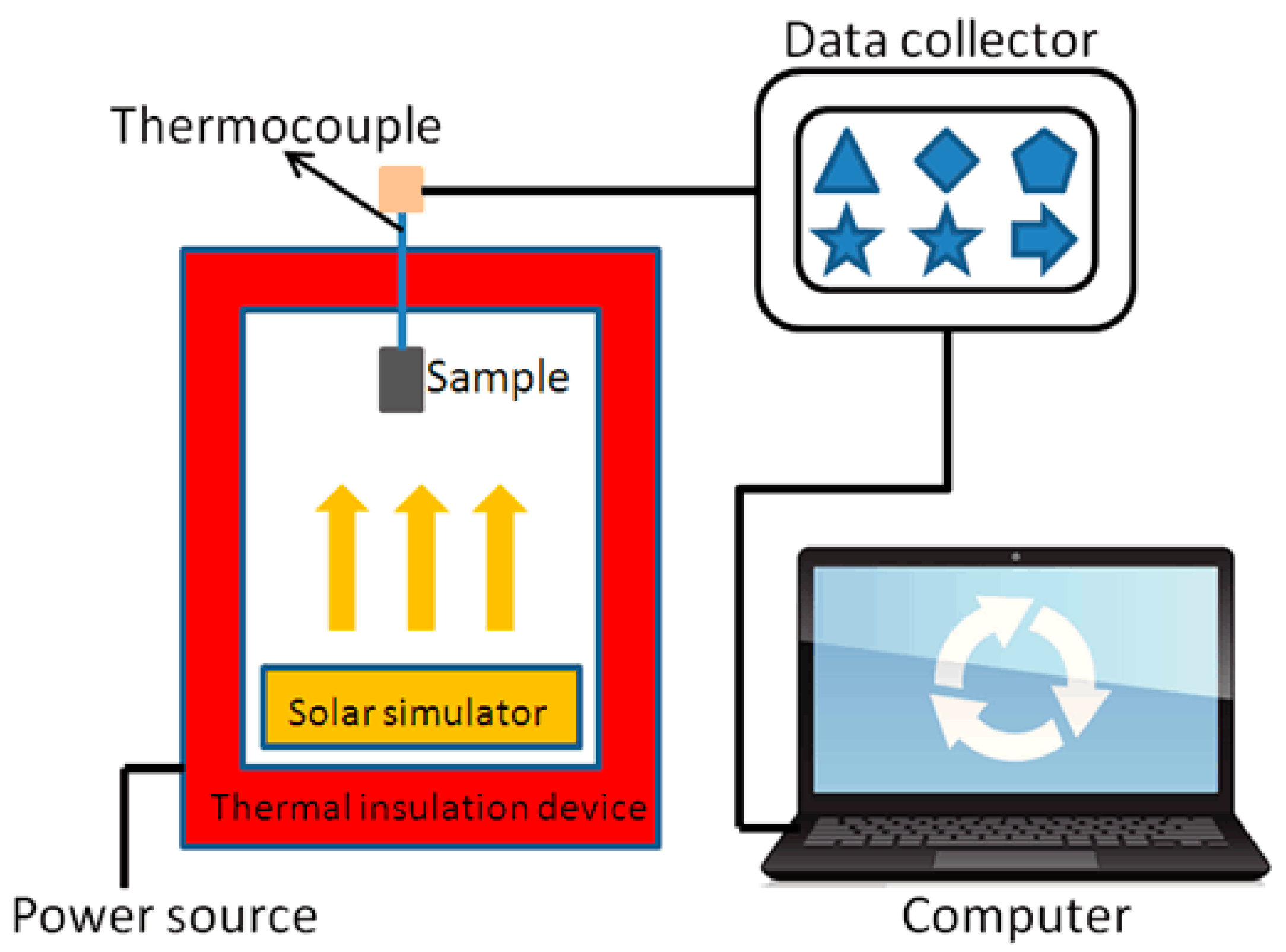

2. Materials and Methods

2.1. Materials and Reagents

2.2. Synthesis

2.3. Characterization

3. Results and Discussion

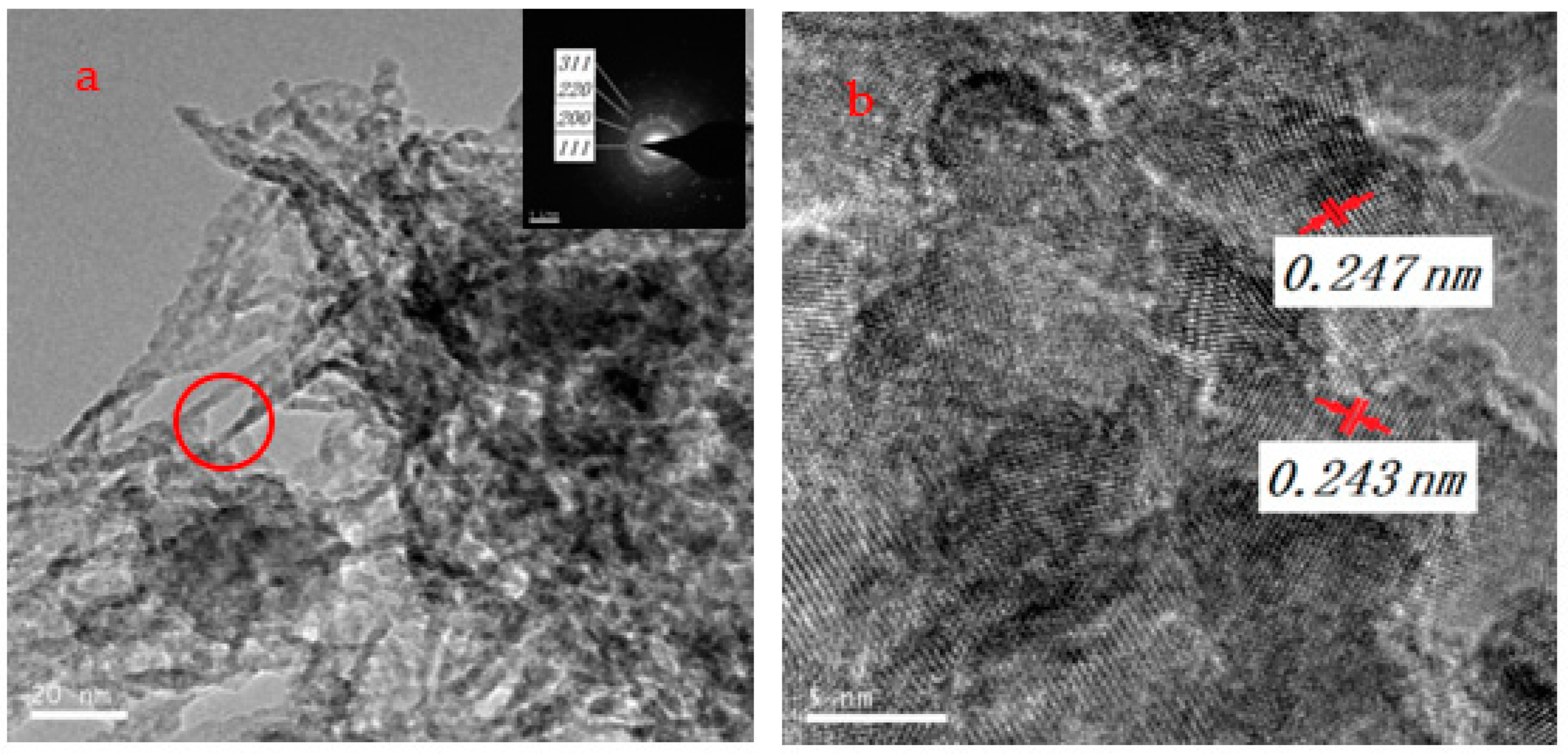

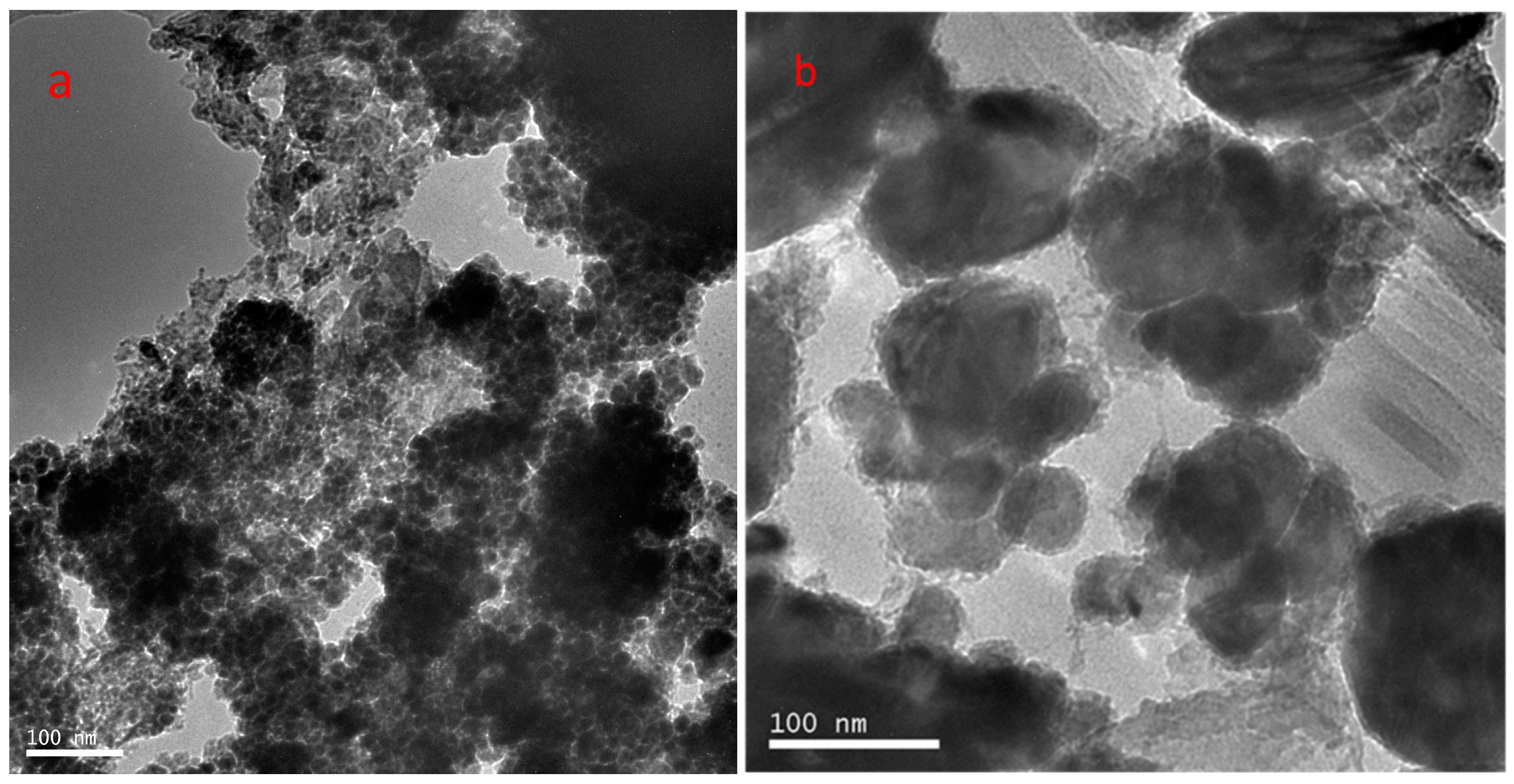

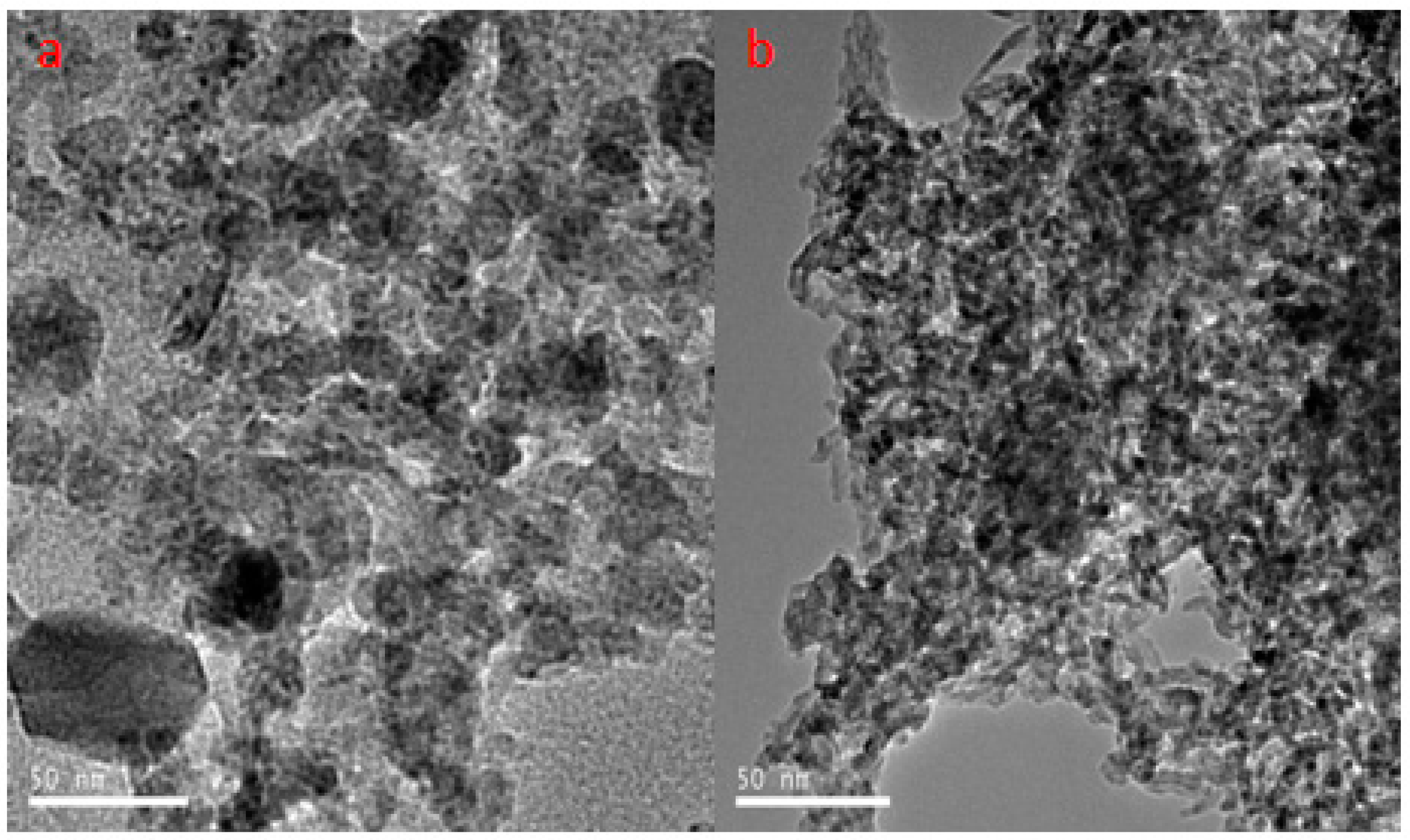

3.1. The Characterization of Cu2O Nanochains

3.2. The Effect Factors of the Formation of Cu2O Nanochains

3.2.1. The Effect of Reaction Time on the Morphology of the Product

3.2.2. The Effect of Precursor Concentration on the Morphology of the Product

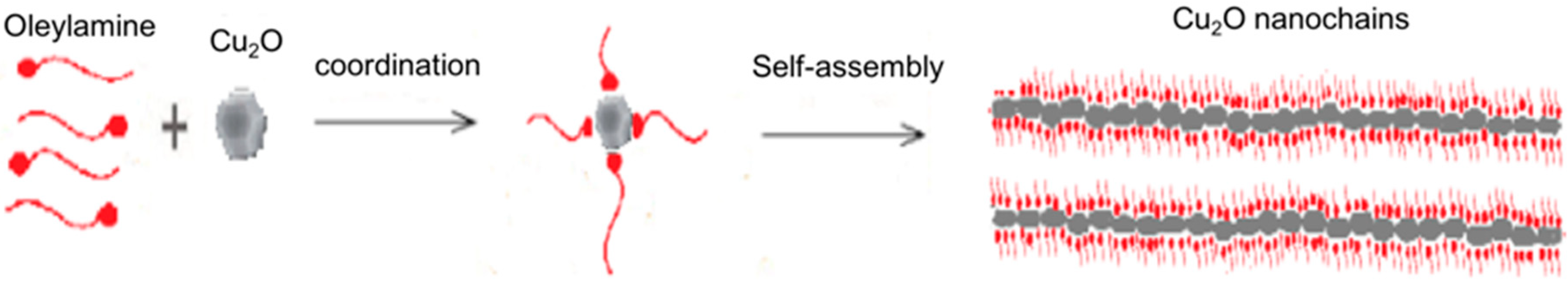

3.3. The Formation Mechanism of Cu2O Nanochains

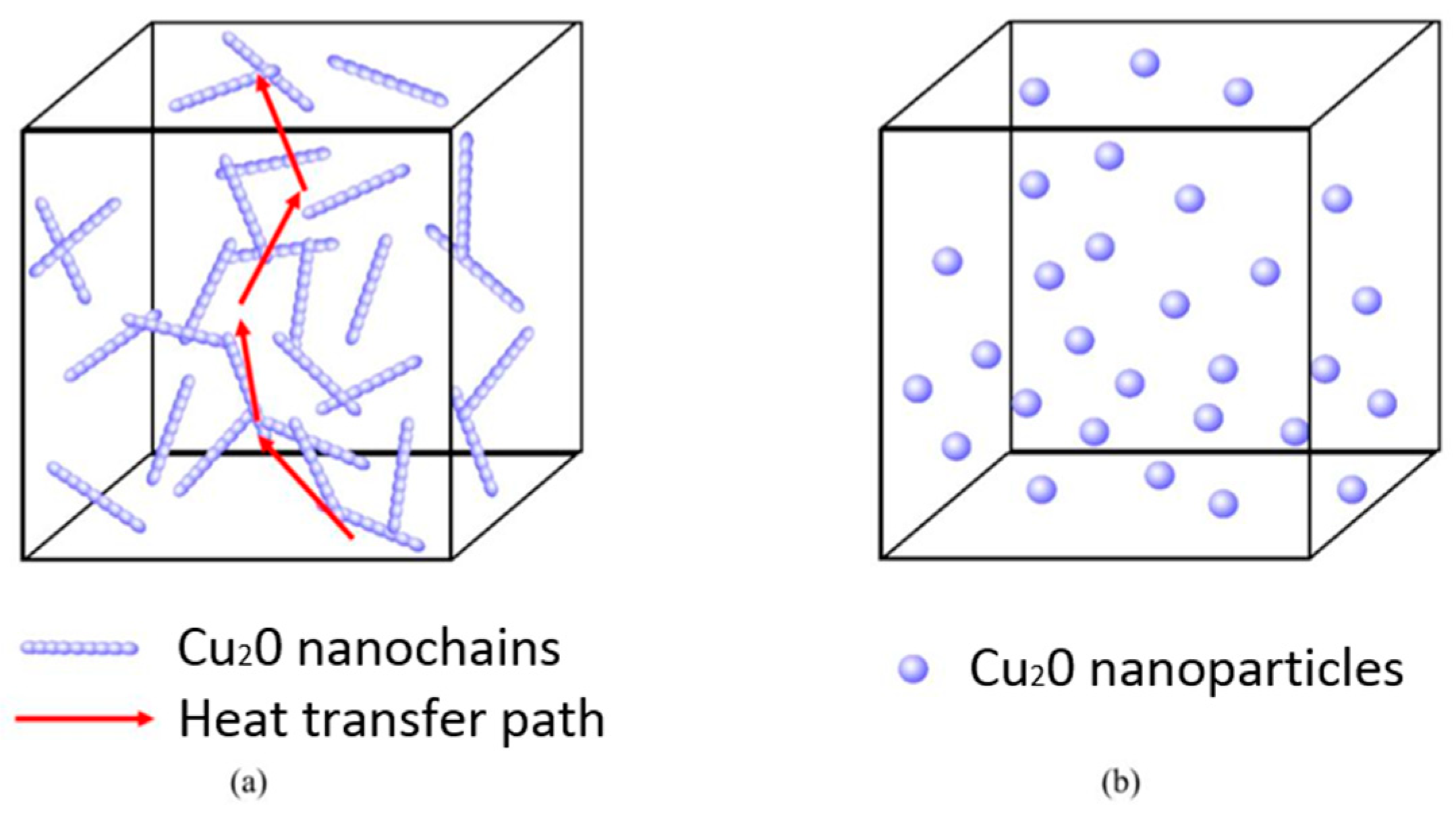

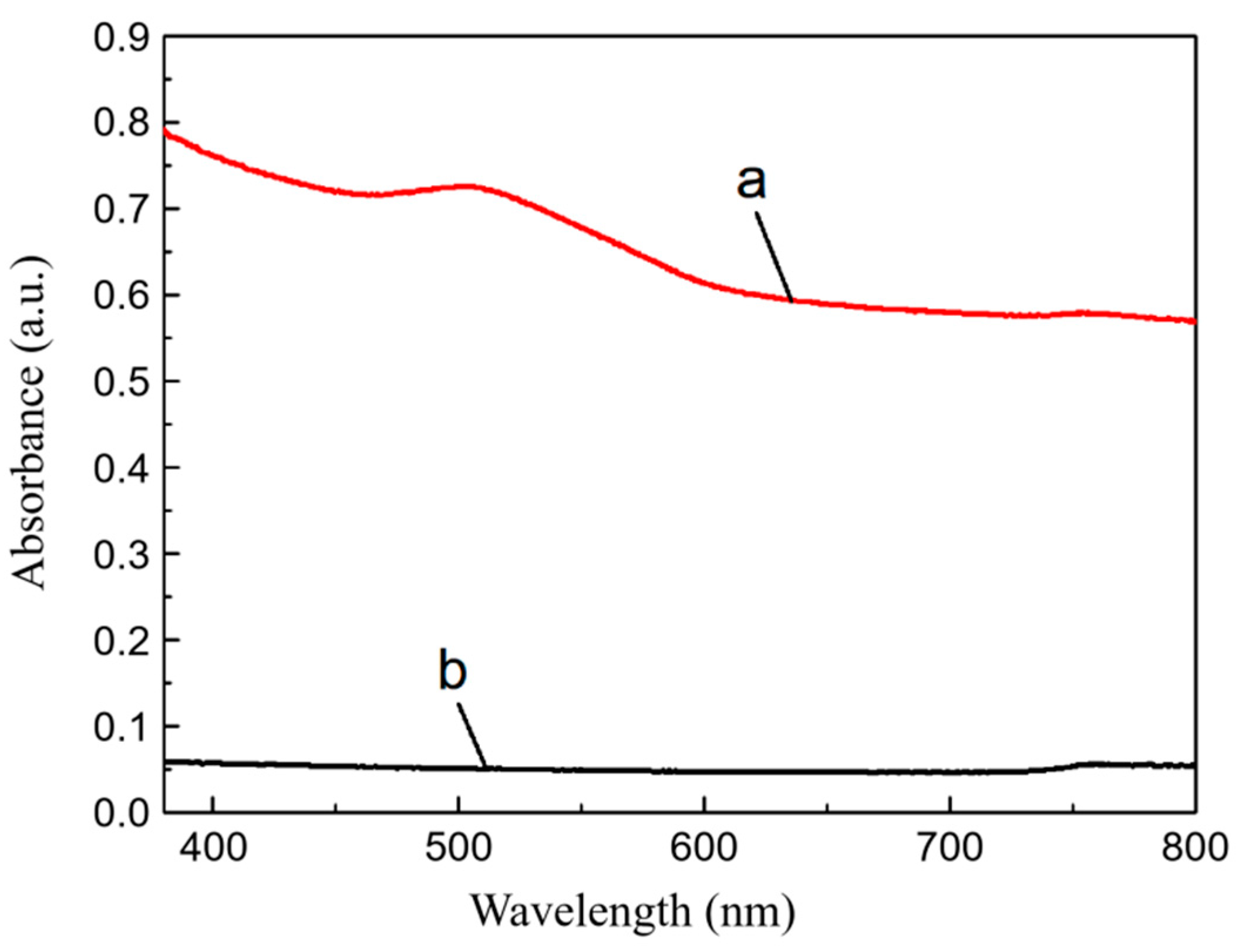

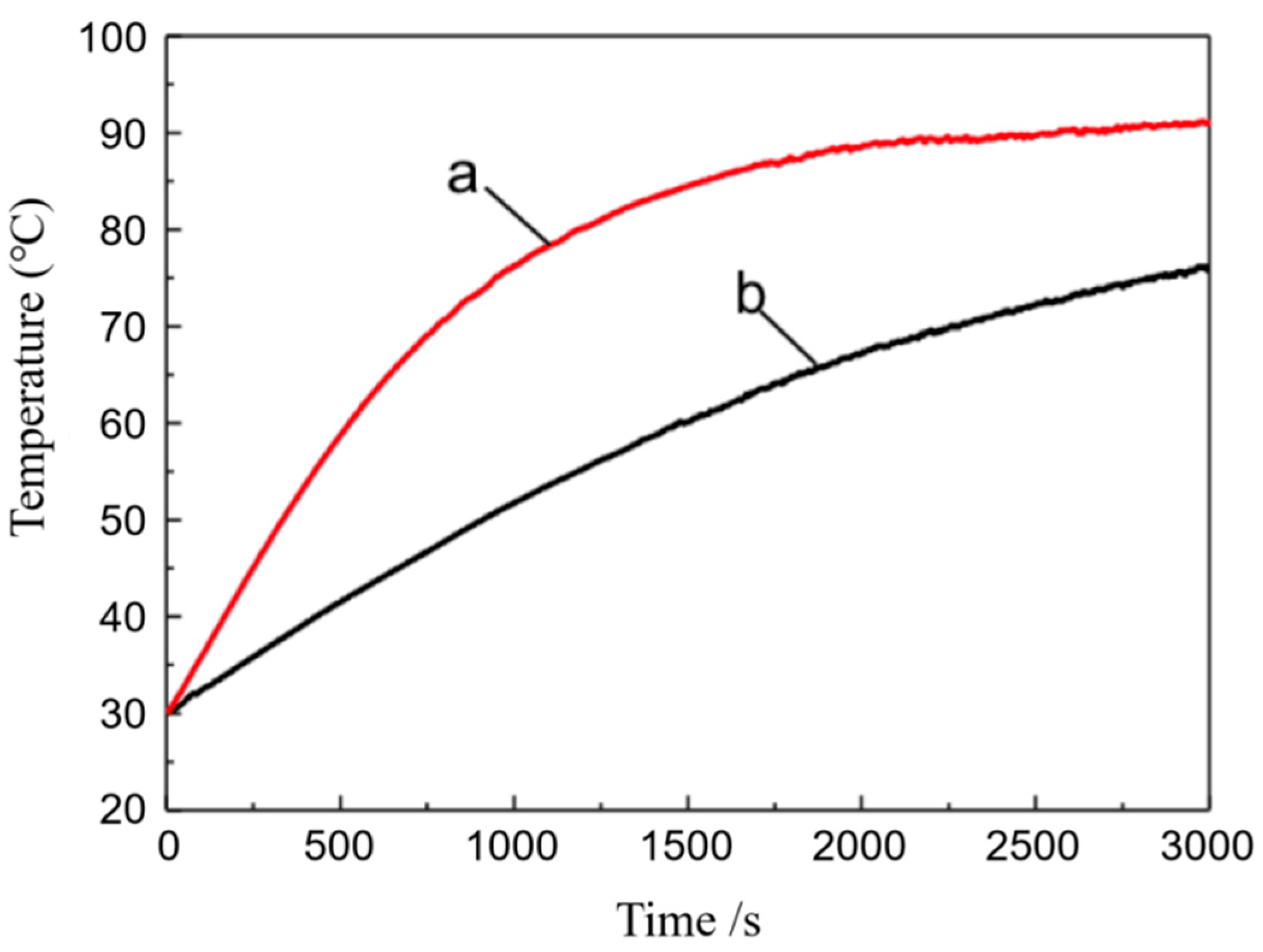

3.4. Thermo-Physical Properties and Photo-Thermal Performance of Nanofluids

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Goel, N.; Taylor, R.A.; Otanicar, T. A review of nanofluid-based direct absorption solar collectors: Design considerations and experiments with hybrid PV/Thermal and direct steam generation collectors. Renew. Energy 2020, 145, 903–913. [Google Scholar] [CrossRef]

- Wang, K.; He, Y.; Liu, P.; Kan, A.; Yu, W. Highly-efficient nanofluid-based direct absorption solar collector enhanced by re-verse-irradiation for medium temperature applications. Renew. Energy 2020, 159, 652–662. [Google Scholar] [CrossRef]

- Hong, S.W.; Kang, Y.-T.; Kleinstreuer, C.; Koo, J. Impact analysis of natural convection on thermal conductivity measurements of nanofluids using the transient hot-wire method. Int. J. Heat Mass Transf. 2011, 54, 3448–3456. [Google Scholar] [CrossRef]

- Saidur, R.; Leong, K.; Mohammed, H. A review on applications and challenges of nanofluids. Renew. Sustain. Energy Rev. 2011, 15, 1646–1668. [Google Scholar] [CrossRef]

- Fang, J.; Xuan, Y. Investigation of optical absorption and photothermal conversion characteristics of binary CuO/ZnO nanofluids. RSC Adv. 2017, 7, 56023–56033. [Google Scholar] [CrossRef] [Green Version]

- Lenert, A.; Wang, E.N. Optimization of nanofluid volumetric receivers for solar thermal energy conversion. Sol. Energy 2012, 86, 253–265. [Google Scholar] [CrossRef] [Green Version]

- Otanicar, T.P.; Phelan, P.E.; Prasher, R.S.; Rosengarten, G.; Taylor, R.A. Nanofluid-based direct absorption solar collector. J. Renew. Sustain. Energy 2010, 2, 033102. [Google Scholar] [CrossRef] [Green Version]

- Saidur, R.; Meng, T.C.; Said, Z.; Hasanuzzaman, M.; Kamyar, A. Evaluation of the effect of nanofluid-based absorbers on direct solar collector. Int. J. Heat Mass Transf. 2012, 55, 5899–5907. [Google Scholar] [CrossRef]

- Tyagi, H.; Phelan, P.; Prasher, R. Predicted Efficiency of a Low-Temperature Nanofluid-Based Direct Absorption Solar Col-lector. J. Sol. Energy Eng. 2009, 131, 143–155. [Google Scholar] [CrossRef]

- Xu, B.; Chen, C.; Zhou, J.; Ni, Z.; Ma, X. Preparation of novel microencapsulated phase change material with Cu-Cu2O/CNTs as the shell and their dispersed slurry for direct absorption solar collectors. Sol. Energy Mater. Sol. Cells 2019, 200, 109980. [Google Scholar] [CrossRef]

- Dai, P.; Li, W.; Xie, J.; He, Y.; Thorne, J.; McMahon, G.; Zhan, J.; Wang, D. Forming buried junctions to enhance the photovoltage generated by cuprous oxide in aqueous solutions. Angew. Chem. Int. Ed. 2014, 53, 13493–13497. [Google Scholar] [CrossRef]

- Wang, J.; Ma, J.; Li, X.; Li, Y.; Zhang, G.; Zhang, F.; Fan, X. Cu2O mesoporous spheres with a high internal diffusion capacity and improved catalytic ability for the aza-Henry reaction driven by visible light. Chem. Commun. 2014, 50, 14237–14240. [Google Scholar] [CrossRef] [PubMed]

- Shah, J.; Kumar, S.; Ranjan, M.; Sonvane, Y.; Thareja, P.; Gupta, S.K. The effect of filler geometry on thermo-optical and rheo-logical properties of CuO nanofluid. J. Mol. Liq. 2018, 272, 668–675. [Google Scholar] [CrossRef]

- Hacialioglu, S.; Meng, F.; Jin, S. Facile and mild solution synthesis of Cu2O nanochains and nanotubes driven by screw dis-locations. Caryologia 2012, 31, 449–456. [Google Scholar]

- Zhao, L.; Dong, W.; Zheng, F.; Fang, L.; Shen, M. Interrupted growth and photoelectrochemistry of Cu2O and Cu particles on TiO2. Electrochim. Acta 2012, 80, 354–361. [Google Scholar] [CrossRef]

- Zhang, D. Synergetic effects of Cu2O photocatalyst with titania and enhanced photoactivity under visible irradiation. Acta Chim. Slovaca 2013, 6, 141–149. [Google Scholar] [CrossRef]

- Tran, P.D.; Batabyal, S.K.; Pramana, S.S.; Barber, J.; Wong, L.H.; Loo, S.C. A cuprous oxide-reduced graphene oxide (Cu2O-rGO) composite photocatalyst for hydrogen generation: Employing rGO as an electron acceptor to enhance the photocatalytic ac-tivity and stability of Cu2O. Nanoscale 2012, 4, 3875–3878. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Dua, R.; Zhang, L.; Zhu, H.; Zhang, H.; Wang, P. Carbon-layer-protected cuprous oxide nanowire arrays for efficient water reduction. ACS Nano 2013, 7, 1709–1717. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Wang, W.; Li, Y.; Zhang, Y.; Yan, Z.; Huo, Z. Hierarchical branched Cu2O nanochains with enhanced photocatalytic activity and stability for H2 production. Nanoscale 2014, 6, 195–198. [Google Scholar] [CrossRef]

- Zhu, H.; Zhang, C.; Liu, S.; Tang, Y.; Yin, Y. Effects of nanoparticle clustering and alignment on thermal conductivities of Fe3O4 aqueous nanofluids. Appl. Phys. Lett. 2006, 89, 023123. [Google Scholar] [CrossRef]

- Zeiny, A.; Jin, H.; Bai, L.; Lin, G.; Wen, D. A comparative study of direct absorption nanofluids for solar thermal applications. Sol. Energy 2018, 161, 74–82. [Google Scholar] [CrossRef]

- Chen, W.; Zou, C.; Li, X. An investigation into the thermophysical and optical properties of SiC/ionic liquid nanofluid for direct absorption solar collector. Sol. Energy Mater. Sol. Cells 2017, 163, 157–163. [Google Scholar] [CrossRef]

- Wang, M.; Shan, X.; Yang, N. Understanding length dependences of effective thermal conductivity of nanochains. Phys. Lett. A 2012, 376, 3514–3517. [Google Scholar] [CrossRef]

- Zhu, D.H.; Yu, W.; Du, H.X.; Chen, L.F.; Li, Y.; Xie, H.Q. Thermal conductivity of composite materials containing copper nanochains. J. Nanomater. 2016, 2016, 3089716. [Google Scholar] [CrossRef] [Green Version]

- Hochbaum, A.; Yang, P. Semiconductor nanowires for energy conversion. Chem. Rev. 2010, 110, 527–546. [Google Scholar] [CrossRef] [PubMed]

- Elisa, S.; Vallejo, J.P.; David, C.; Luis, L. Functionalized graphene nanoplatelet-nanofluids for solar thermal collectors. Sol. Energy Mater. Sol. Cells 2018, 185, 205–209. [Google Scholar]

- Xu, B.; Zhou, J.; Ni, Z.; Zhang, C.; Lu, C. Synthesis of novel microencapsulated phase change materials with copper and copper oxide for solar energy storage and photo-thermal conversion. Sol. Energy Mater. Sol. Cells 2018, 179, 87–94. [Google Scholar] [CrossRef]

- Xia, H.; Zinke-Allmang, M. Rate equation approach to the late stages of cluster ripening. Phys. A Stat. Mech. Appl. 1998, 261, 176–187. [Google Scholar] [CrossRef]

- LaMer, V.K.; Dinegar, R.H. Theory, Production and mechanism of formation of monodispersed hydrosols. J. Am. Chem. Soc. 1950, 72, 4847–4854. [Google Scholar] [CrossRef]

- Yabuki, A.; Tanaka, S. Electrically conductive copper film prepared at low temperature by thermal decomposition of copper amine complexes with various amines. Mater. Res. Bull. 2012, 47, 4107–4111. [Google Scholar] [CrossRef]

- Chen, Z.-Z.; Shi, E.-W.; Zheng, Y.-Q.; Li, W.-J.; Xiao, B.; Zhuang, J.-Y. Growth of hex-pod-like Cu2O whisker under hydrothermal conditions. J. Cryst. Growth 2003, 249, 294–300. [Google Scholar] [CrossRef]

- Galwey, A.K.; Jamieson, D.; Brown, M.E. Thermal decomposition of three crystalline modifications of anhydrous copper(II) formate. J. Phys. Chem. 1974, 78, 2664–2670. [Google Scholar] [CrossRef]

- Behura, A.K.; Gupta, H.K. Efficient direct absorption solar collector using nanomaterial suspended heat transfer fluid. Mater. Today Proc. 2020, 22, 1664–1668. [Google Scholar] [CrossRef]

- Zeng, J.; Xuan, Y. Tunable full-spectrum photo-thermal conversion features of magnetic-plasmonic Fe3O4/TiN nanofluid. Nano Energy 2018, 51, 754–763. [Google Scholar] [CrossRef]

- Fang, X.P. Research on Heat and Mass Transfer Mechanisms and Optical Character of Nanofluids; Nanjing University of Science and Technology: Nanjing, China, 2013. [Google Scholar]

- Tajik Jamal-Abad, M. Thermal conductivity of Cu and Al-Water nanofluids. Int. J. Eng. 2013, 26, 821–828. [Google Scholar]

- Sadri, R.; Ahmadi, G.; Togun, H.; Dahari, M.; Kazi, S.N.; Sadeghinezhad, E.; Zubir, N. An experimental study on thermal con-ductivity and viscosity of nanofluids containing carbon nanotubes. Nanoscale Res. Lett. 2014, 9, 151. [Google Scholar] [CrossRef] [Green Version]

- Nabil, M.; Azmi, W.; Hamid, K.A.; Zawawi, N.; Priyandoko, G.; Mamat, R. Thermo-physical properties of hybrid nanofluids and hybrid nanolubricants: A comprehensive review on performance. Int. Commun. Heat Mass Transf. 2017, 83, 30–39. [Google Scholar] [CrossRef]

- Daviran, S.; Kasaeian, A.; Tahmooressi, H. Evaluation of clustering role versus brownian motion effect on the heat conduc-tion in nanofluids: A novel approach. Int. J. Heat Mass Transf. 2017, 108, 822–829. [Google Scholar] [CrossRef]

- Song, D.; Hatami, M.; Wang, Y.; Jing, D.; Yang, Y. Prediction of hydrodynamic and optical properties of TiO2/water suspen-sion considering particle size distribution. Int. J. Heat Mass Transf. 2016, 92, 864–876. [Google Scholar] [CrossRef]

- Lin, J.; Cai, X.; Liu, Z.; Liu, N.; Xie, M.; Zhou, B.; Wang, H.; Guo, Z. Anti-liquid-interfering and bacterially antiadhesive strategy for highly stretchable and ultrasensitive strain sensors based on cassie-baxter wetting state. Adv. Funct. Mater. 2020, 30, 2000398. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ni, Z.; Cao, X.; Wang, X.; Zhou, S.; Zhang, C.; Xu, B.; Ni, Y. Facile Synthesis of Copper(I) Oxide Nanochains and the Photo-Thermal Conversion Performance of Its Nanofluids. Coatings 2021, 11, 749. https://doi.org/10.3390/coatings11070749

Ni Z, Cao X, Wang X, Zhou S, Zhang C, Xu B, Ni Y. Facile Synthesis of Copper(I) Oxide Nanochains and the Photo-Thermal Conversion Performance of Its Nanofluids. Coatings. 2021; 11(7):749. https://doi.org/10.3390/coatings11070749

Chicago/Turabian StyleNi, Zhongjin, Xiaohai Cao, Xinyi Wang, Shiyu Zhou, Caixia Zhang, Bin Xu, and Yihua Ni. 2021. "Facile Synthesis of Copper(I) Oxide Nanochains and the Photo-Thermal Conversion Performance of Its Nanofluids" Coatings 11, no. 7: 749. https://doi.org/10.3390/coatings11070749

APA StyleNi, Z., Cao, X., Wang, X., Zhou, S., Zhang, C., Xu, B., & Ni, Y. (2021). Facile Synthesis of Copper(I) Oxide Nanochains and the Photo-Thermal Conversion Performance of Its Nanofluids. Coatings, 11(7), 749. https://doi.org/10.3390/coatings11070749