Annealing Studies of Copper Indium Oxide (Cu2In2O5) Thin Films Prepared by RF Magnetron Sputtering

Abstract

:1. Introduction

2. Experimental Details

2.1. Deposition of Copper Indium Oxide Thin Films

2.2. Characterization of Copper Indium Oxide Thin Films

3. Results and Discussions

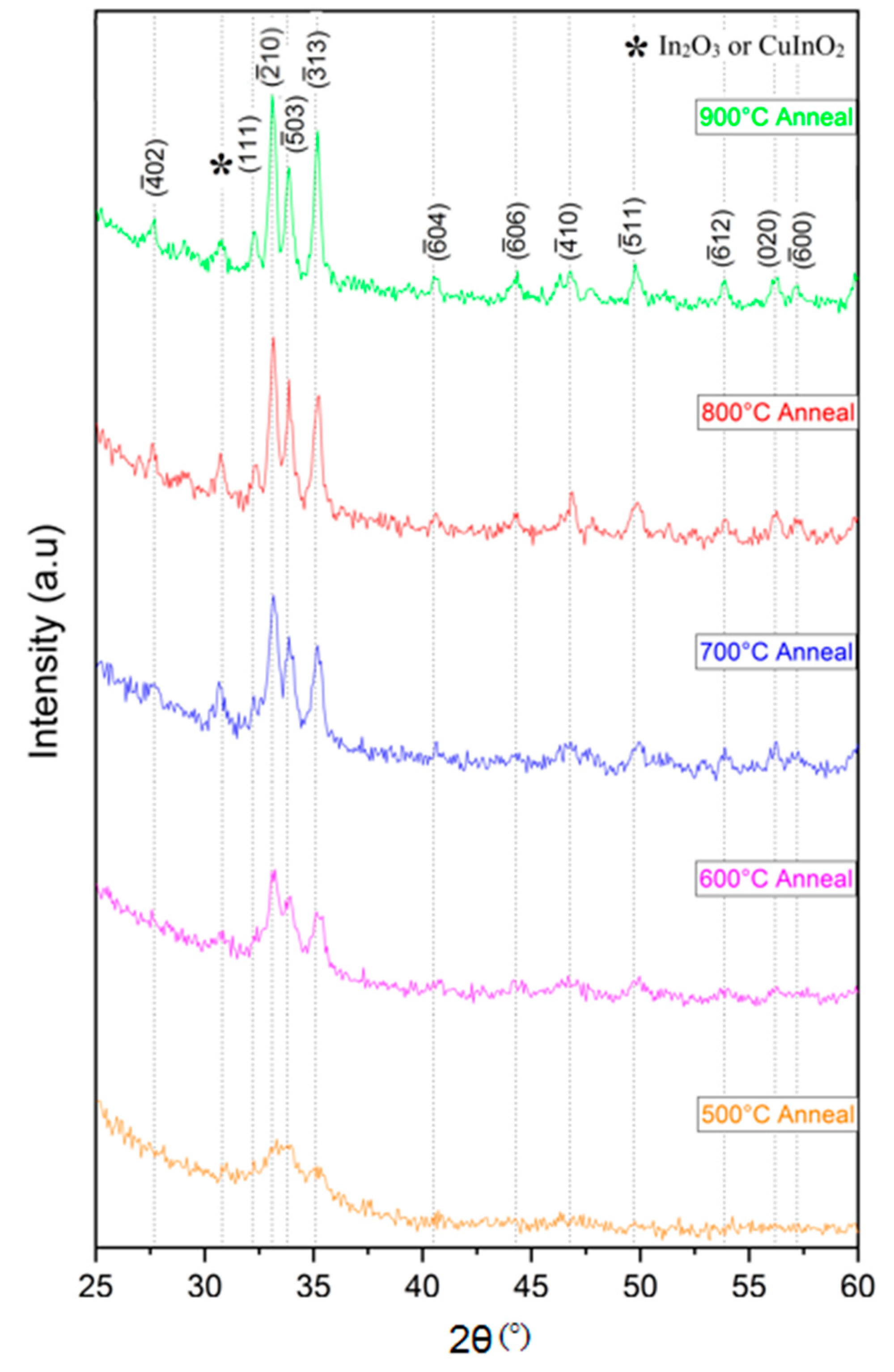

3.1. XRD Analysis

3.2. Morphology Studies

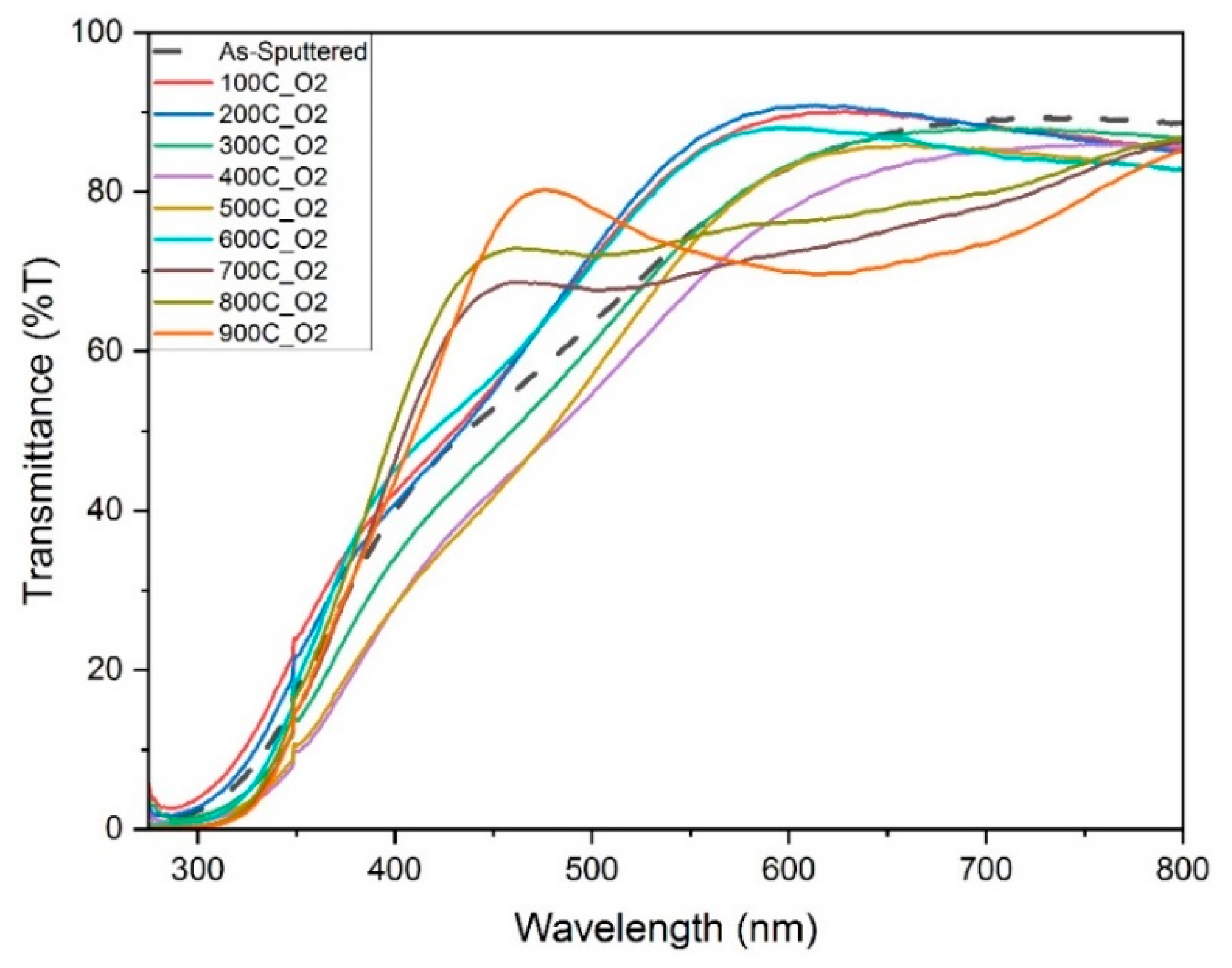

3.3. Optical Studies

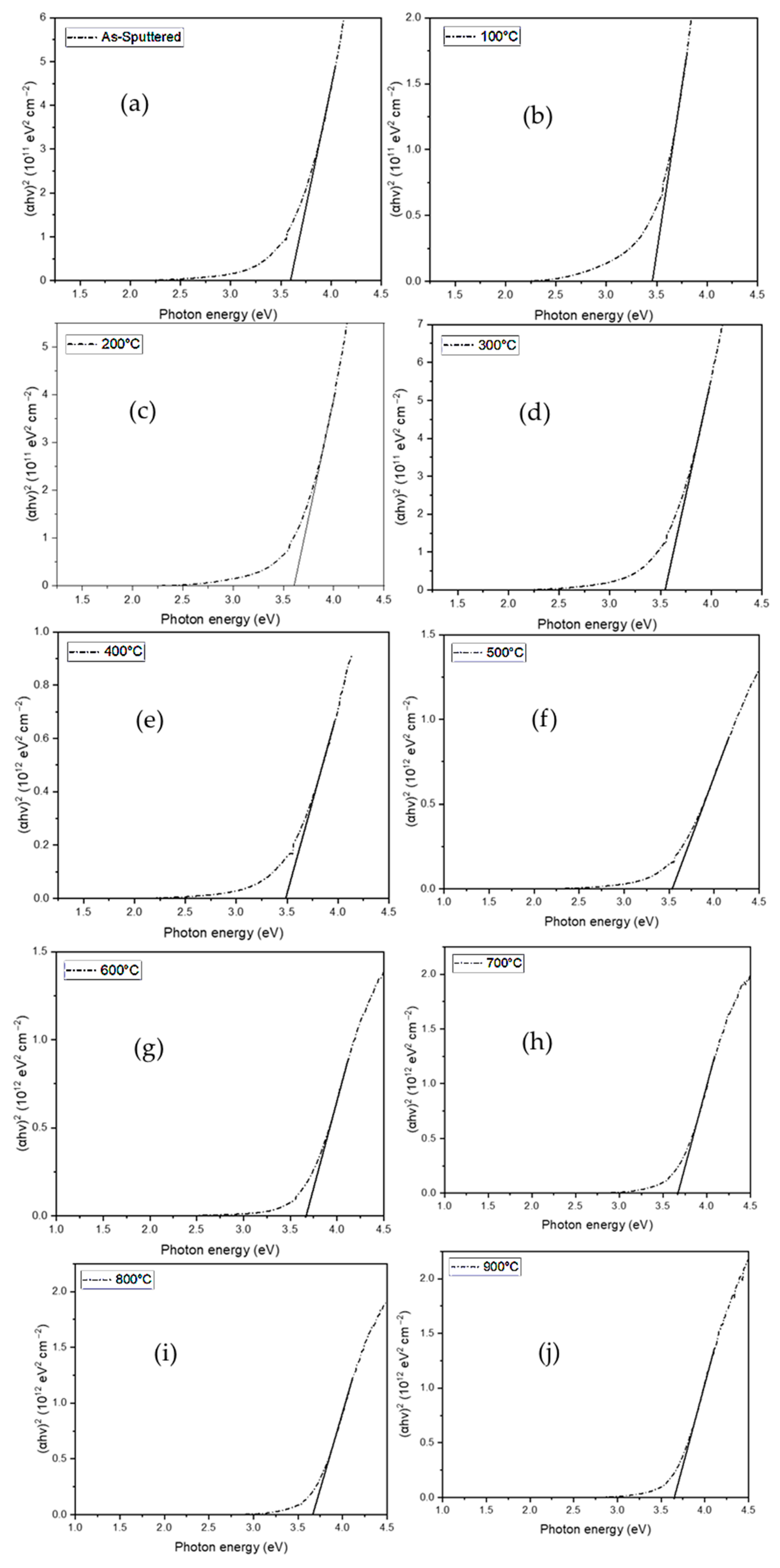

3.4. Optical Bandgap

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chopra, K.; Major, S.; Pandya, D. Transparent conductors—A status review. Thin Solid Film. 1983, 102, 1–46. [Google Scholar] [CrossRef]

- Dawar, A.; Joshi, J. Semiconducting transparent thin films: Their properties and applications. J. Mater. Sci. 1984, 19, 1–23. [Google Scholar] [CrossRef]

- Gordon, R.G. Criteria for choosing transparent conductors. MRS Bull. 2000, 25, 52–57. [Google Scholar] [CrossRef] [Green Version]

- Saikumar, A.K.; Skaria, G.; Sundaram, K.B. ZnO gate based MOSFETs for sensor applications. ECS Trans. 2014, 61, 65. [Google Scholar] [CrossRef]

- Szyszka, B.; Loebmann, P.; Georg, A.; May, C.; Elsaesser, C. Development of new transparent conductors and device applications utilizing a multidisciplinary approach. Thin Solid Film. 2010, 518, 3109–3114. [Google Scholar] [CrossRef]

- Zhang, B.; Yu, B.; Jin, J.; Ge, B.; Yin, R. Performance of InSnZrO as transparent conductive oxides. Phys. Status Solidi 2010, 207, 955–962. [Google Scholar] [CrossRef]

- Khan, A.; Rahman, F. Study of microstructural and optical properties of nanocrystalline indium oxide: A transparent conducting oxide (TCO). AIP Conf. Proc. 2019, 2115, 030091. [Google Scholar]

- Nehate, S.D.; Prakash, A.; Mani, P.D.; Sundaram, K.B. Work function extraction of indium tin oxide films from MOSFET devices. ECS J. Solid State Sci. Technol. 2018, 7, P87. [Google Scholar] [CrossRef]

- Sundaram, K.; Khan, A. Work function determination of zinc oxide films. J. Vac. Sci. Technol. A Vac. Surf. Film. 1997, 15, 428–430. [Google Scholar] [CrossRef]

- Sundaram, K.; Khan, A.J.T.S.F. Characterization and optimization of zinc oxide films by RF magnetron sputtering. Thin Solid Film. 1997, 295, 87–91. [Google Scholar] [CrossRef]

- Sundaresh, S.; Nehate, S.D.; Sundaram, K.B. Electrical and optical studies of reactively sputtered indium oxide thin films. ECS J. Solid State Sci. Technol. 2021, 10, 065016. [Google Scholar] [CrossRef]

- Noh, J.H.; Ryu, S.Y.; Jo, S.J.; Kim, C.S.; Sohn, S.-W.; Rack, P.D.; Kim, D.-J.; Baik, H.K. Indium oxide thin-film transistors fabricated by RF sputtering at room temperature. IEEE Electron. Device Lett. 2010, 31, 567–569. [Google Scholar] [CrossRef]

- Kawazoe, H.; Yasukawa, M.; Hyodo, H.; Kurita, M.; Yanagi, H.; Hosono, H.J.N. P-type electrical conduction in transparent thin films of CuAlO2. Nat. Cell Biol. 1997, 389, 939–942. [Google Scholar] [CrossRef]

- Biswas, S.K.; Sarkar, A.; Pathak, A.; Pramanik, P.J.T. Studies on the sensing behaviour of nanocrystalline CuGa2O4 towards hydrogen, liquefied petroleum gas and ammonia. Talanta 2010, 81, 1607–1612. [Google Scholar] [CrossRef]

- Fenner, L.; Wills, A.; Bramwell, S.; Dahlberg, M.; Schiffer, P. Zero-point entropy of the spinel spin glasses CuGa2O4 and CuAl2O4. J. Phys. Conf. Ser. 2008, 145, 012029. [Google Scholar] [CrossRef] [Green Version]

- Makhova, L.; Wett, D.; Lorenz, M.; Konovalov, I. X-ray spectroscopic investigation of forbidden direct transitions in CuGaO2 and CuInO2. Phys. Status 2006, 203, 2861–2866. [Google Scholar] [CrossRef]

- Pilliadugula, R.; Nithya, C.; Krishnan, N.G.; Nammalwar, G. Influence of Ga2O3, CuGa2O4 and Cu4O3 phases on the sodium-ion storage behaviour of CuO and its gallium composites. Nanoscale Adv. 2020, 2, 1269–1281. [Google Scholar] [CrossRef] [Green Version]

- Saikumar, A.K.; Sundaresh, S.; Nehate, S.D.; Sundaram, K.B.J.C. Properties of RF magnetron-sputtered copper gallium oxide (CuGa2O4). Thin Film. 2021, 11, 921. [Google Scholar]

- Shi, J.; Liang, H.; Xia, X.; Li, Z.; Long, Z.; Zhang, H.; Liu, Y. Preparation of high-quality CuGa2O4 film via annealing process of Cu/β-Ga2O3. J. Mater. Sci. 2019, 54, 11111–11116. [Google Scholar] [CrossRef]

- Su, C.-Y.; Chiu, C.-Y.; Chang, C.-H.; Ting, J.-M. Synthesis of Cu2In2O5 and CuInGaO4 nanoparticles. Thin Solid Film. 2013, 531, 42–48. [Google Scholar] [CrossRef]

- Su, C.-Y.; Mishra, D.K.; Chiu, C.-Y.; Ting, J.-M. Effects of Cu2S sintering aid on the formation of CuInS2 coatings from single crystal Cu2In2O5 nanoparticles. Surf. Coat. Technol. 2013, 231, 517–520. [Google Scholar] [CrossRef]

- Wang, J.; Ibarra, V.; Barrera, D.; Xu, L.; Lee, Y.-J.; Hsu, J.W.P. Solution synthesized p-type copper gallium oxide nanoplates as hole transport layer for organic photovoltaic devices. J. Phys. Chem. Lett. 2015, 6, 1071–1075. [Google Scholar] [CrossRef] [PubMed]

- Wei, H.; Chen, Z.; Wu, Z.; Cui, W.; Huang, Y.; Tang, W. Epitaxial growth and characterization of CuGa2O4 films by laser molecular beam epitaxy. AIP Adv. 2017, 7, 115216. [Google Scholar] [CrossRef] [Green Version]

- Yin, H.; Shi, Y.; Dong, Y.; Chu, X. Synthesis of spinel-type CuGa2O4 nanoparticles as a sensitive non-enzymatic electrochemical sensor for hydrogen peroxide and glucose detection. J. Electroanal. Chem. 2021, 885, 115100. [Google Scholar] [CrossRef]

- Zardkhoshoui, A.M.; Davarani, S.S. Designing a flexible all-solid-state supercapacitor based on CuGa2O4 and FeP-rGO electrodes. J. Alloys Compd. 2019, 773, 527–536. [Google Scholar] [CrossRef]

- Zhang, K.H.L.; Xi, K.; Blamire, M.; Egdell, R.G. P-type transparent conducting oxides. J. Phys. Condens. Mater. 2016, 28, 383002. [Google Scholar] [CrossRef]

- Singh, M.; Singh, V.N.; Mehta, B.R. Synthesis and properties of nanocrystalline copper indium oxide thin films deposited by RF magnetron sputtering. J. Nanosci. Nanotechnol. 2008, 8, 3889–3894. [Google Scholar] [CrossRef] [PubMed]

- Nair, B.G.; Rahman, H.; Aijo, J.K.; Keerthi, K.; Shaji, G.S.O.; Sharma, V.; Philip, R.R. Calcium incorporated copper indium oxide thin films—A promising candidate for transparent electronic applications. Thin Solid Film. 2019, 693, 137673. [Google Scholar] [CrossRef]

- Nair, B.G.; Okram, G.S.; Naduvath, J.; Shripathi, T.; Fatima, A.; Patel, T.; Jacob, R.; Keerthi, K.; Remillard, S.K.; Philip, R.R. Low temperature thermopower and electrical conductivity in highly conductive CuInO2 thin films. J. Mater. Chem. C 2014, 2, 6765–6772. [Google Scholar] [CrossRef]

- Saikumar, A.K.; Nehate, S.D.; Sundaram, K.B. Review—RF sputtered films of Ga2O3. ECS J. Solid State Sci. Technol. 2019, 8, Q3064–Q3078. [Google Scholar] [CrossRef]

- Yang, B.; He, Y.; Polity, A.; Meyer, B.K. Structural, optical and electrical properties of transparent conducting CuInO2 thin films prepared by RF sputtering. MRS Proc. 2005, 865, 865. [Google Scholar] [CrossRef]

- Holzwarth, U.; Gibson, N. The Scherrer equation versus the ‘Debye-Scherrer equation’. Nat. Nanotechnol. 2011, 6, 534. [Google Scholar] [CrossRef] [PubMed]

- Ramana, C.V.; Smith, R.J.; Hussain, O.M. Grain size effects on the optical characteristics of pulsed-laser deposited vanadium oxide thin films. Phys. Status 2003, 199, R4–R6. [Google Scholar] [CrossRef]

- Shakti, N.; Gupta, P. Structural and optical properties of sol-gel prepared ZnO thin film. Appl. Phys. Res. 2010, 2, 19. [Google Scholar] [CrossRef] [Green Version]

- Duta, M.; Anastasescu, M.; Calderon-Moreno, J.M.; Predoana, L.; Preda, S.; Nicolescu, M.; Stroescu, H.; Bratan, V.; Dascalu, I.; Aperathitis, E.; et al. Sol–gel versus sputtering indium tin oxide films as transparent conducting oxide materials. J. Mater. Sci. Mater. Electron. 2016, 27, 4913–4922. [Google Scholar] [CrossRef]

- Spence, W. The UV absorption edge of tin oxide thin films. J. Appl. Phys. 1967, 38, 3767–3770. [Google Scholar] [CrossRef]

- Lv, J.; Huang, K.; Chen, X.; Zhu, J.; Cao, C.; Song, X.; Sun, Z. Optical constants of Na-doped ZnO thin films by sol-gel method. Opt. Commun. 2011, 284, 2905–2908. [Google Scholar] [CrossRef]

| Annealing Temperature ( °C) | Bandgap (eV) |

|---|---|

| As deposited | 3.59 |

| 100 | 3.45 |

| 200 | 3.6 |

| 300 | 3.54 |

| 400 | 3.48 |

| 500 | 3.53 |

| 600 | 3.66 |

| 700 | 3.66 |

| 800 | 3.66 |

| 900 | 3.64 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Skaria, G.; Saikumar, A.K.; Shivprasad, A.D.; Sundaram, K.B. Annealing Studies of Copper Indium Oxide (Cu2In2O5) Thin Films Prepared by RF Magnetron Sputtering. Coatings 2021, 11, 1290. https://doi.org/10.3390/coatings11111290

Skaria G, Saikumar AK, Shivprasad AD, Sundaram KB. Annealing Studies of Copper Indium Oxide (Cu2In2O5) Thin Films Prepared by RF Magnetron Sputtering. Coatings. 2021; 11(11):1290. https://doi.org/10.3390/coatings11111290

Chicago/Turabian StyleSkaria, Giji, Ashwin Kumar Saikumar, Akshaya D. Shivprasad, and Kalpathy B. Sundaram. 2021. "Annealing Studies of Copper Indium Oxide (Cu2In2O5) Thin Films Prepared by RF Magnetron Sputtering" Coatings 11, no. 11: 1290. https://doi.org/10.3390/coatings11111290

APA StyleSkaria, G., Saikumar, A. K., Shivprasad, A. D., & Sundaram, K. B. (2021). Annealing Studies of Copper Indium Oxide (Cu2In2O5) Thin Films Prepared by RF Magnetron Sputtering. Coatings, 11(11), 1290. https://doi.org/10.3390/coatings11111290