Effect of Rapid Thermal Annealing on the Characteristics of Micro Zn-Doped Ga2O3 Films by Using Mixed Atomic Layer Deposition

Abstract

1. Introduction

2. Materials and Methods

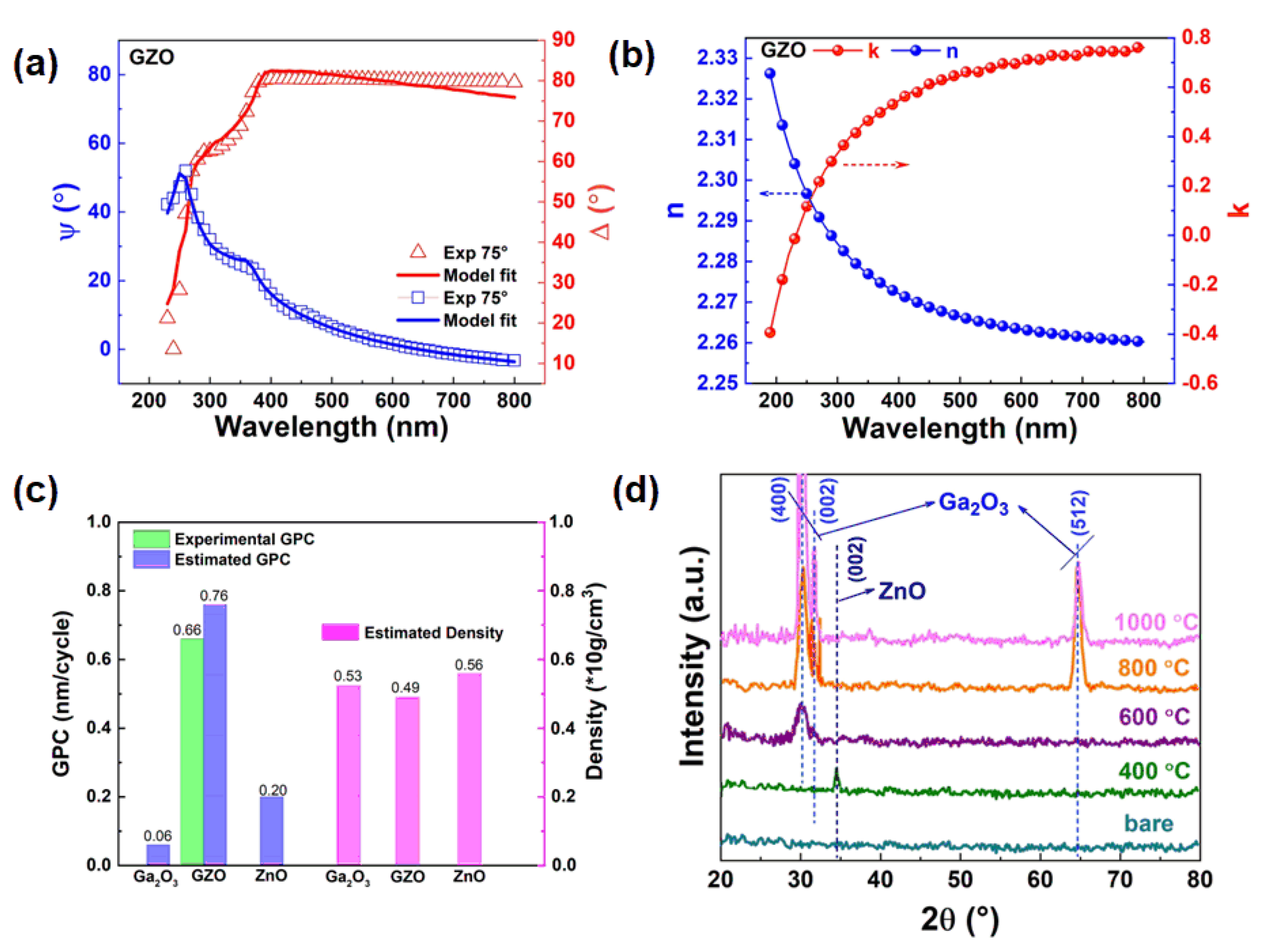

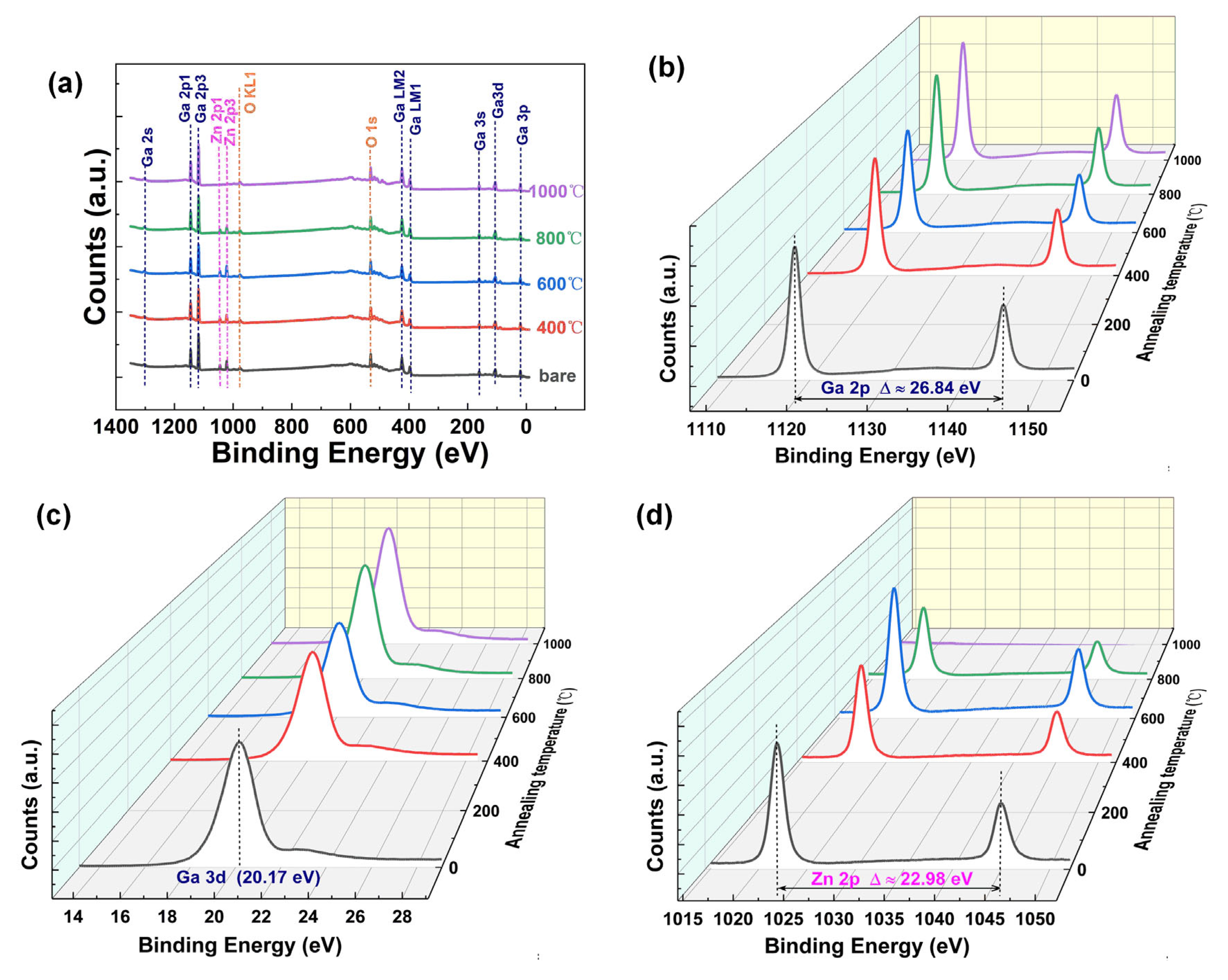

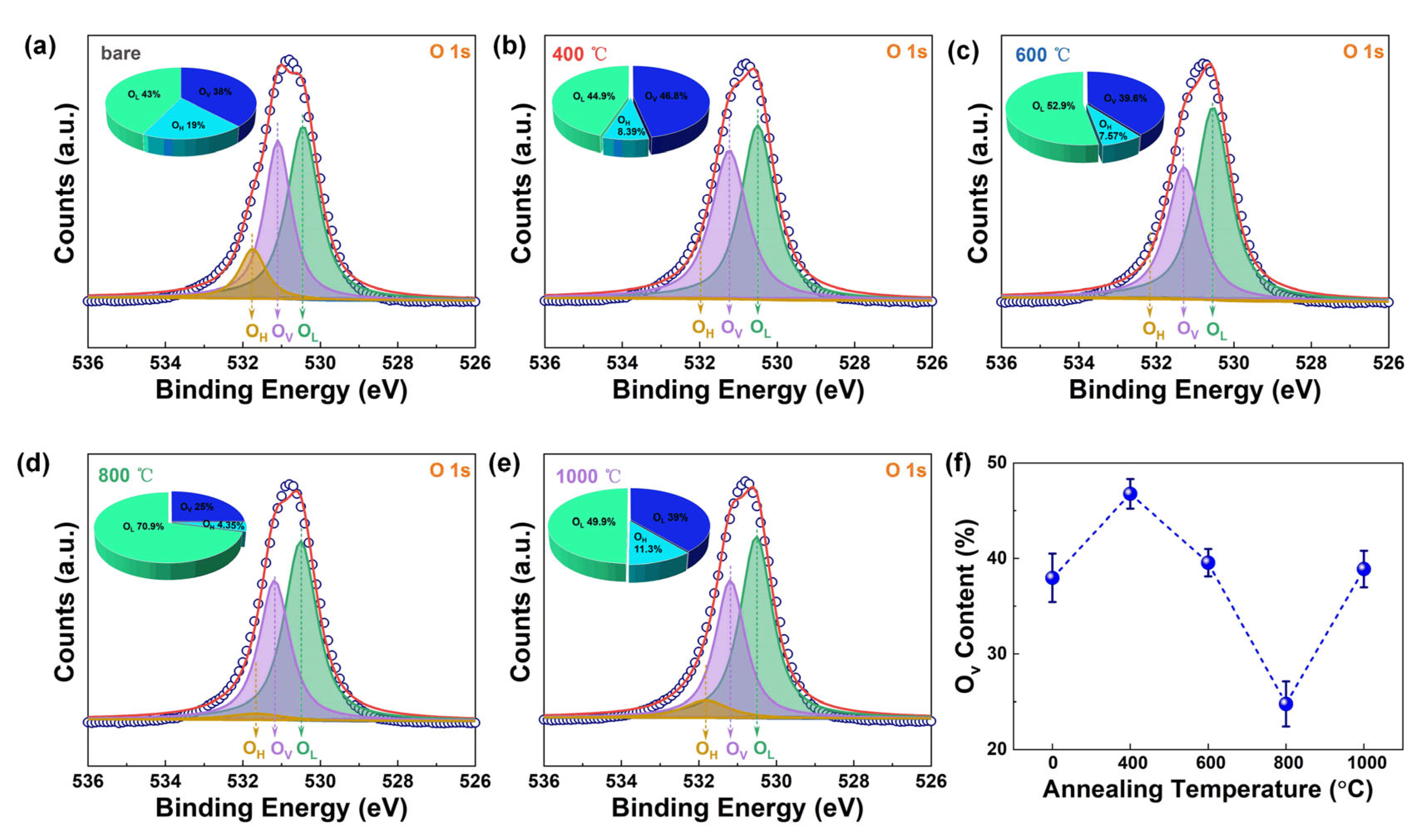

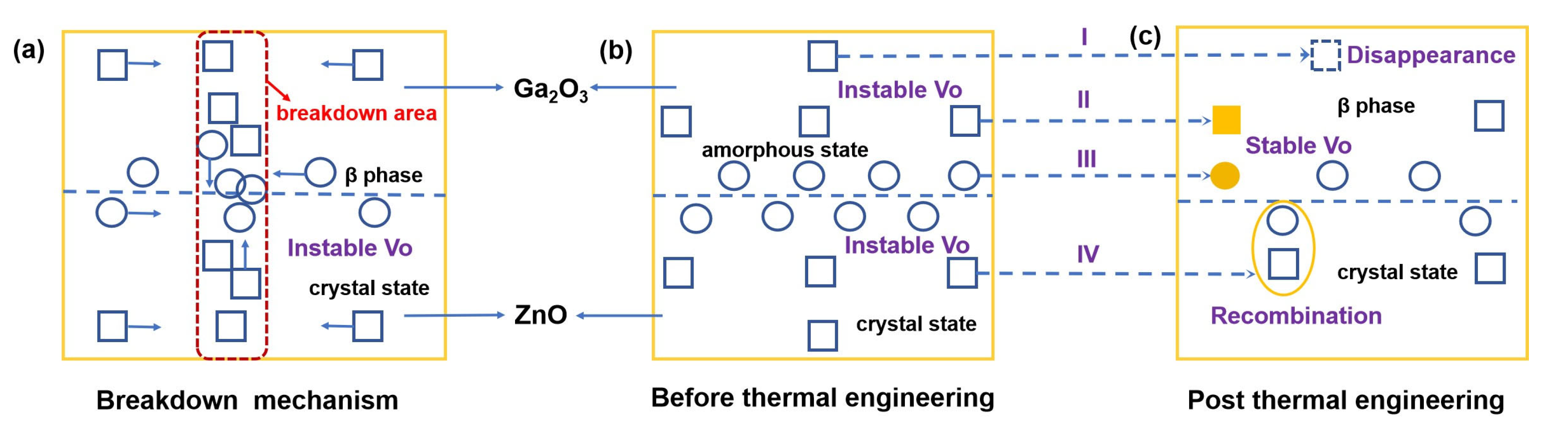

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mazumder, S.K.; Voss, L.F.; Dowling, K.M.; Conway, A.; Hall, D.; Kaplar, R.J.; Pickrell, G.W.; Flicker, J.; Binder, A.T.; Chowdhury, S.; et al. Overview of Wide/Ultrawide Bandgap Power Semiconductor Devices for Distributed Energy Resources. IEEE J. Emerg. Sel. Top. Power Electron. 2023, 11, 3957–3982. [Google Scholar] [CrossRef]

- Huang, Z.; Zhou, S.; Chen, L.; Zheng, Q.; Li, H.; Xiong, Y.; Ye, L.; Kong, C.; Fan, S.; Zhang, H.; et al. Fully Transparent Amorphous Ga2O3-Based Solar-Blind Ultraviolet Photodetector with Graphitic Carbon Electrodes. Crystals 2022, 12, 1427. [Google Scholar] [CrossRef]

- Lee, D.Y.; Jeong, S.; Moon, S.; Yang, M.; Kim, S.H.; Kim, D.; Lee, S.Y.; Lee, I.S.; Jeon, D.W.; Park, J.H.; et al. Giant Colloidal Quantum Dot/α-Ga2O3 Heterojunction for High Performance UV-Vis-IR Broadband Photodetector. ACS Nano 2024, 18, 34741–34749. [Google Scholar] [CrossRef]

- Lee, S.; Bielinski, A.R.; Fahrenkrug, E.; Dasgupta, N.P.; Maldonado, S. Macroporous p-GaP Photocathodes Prepared by Anodic Etching and Atomic Layer Deposition Doping. ACS Appl. Mater. Interfaces 2016, 8, 16178–16185. [Google Scholar] [CrossRef]

- Hernandeza, A.; Islama, M.M.; Saddatkiaa, P.; Codding, C.; Dulal, P.; Agarwal, S.; Janover, A.; Novak, S.; Huang, M.B.; Dang, T.; et al. MOCVD growth and characterization of conductive homoepitaxial Si-doped Ga2O3. Result Phys. 2021, 25, 104167. [Google Scholar] [CrossRef]

- Roy, S.; Mallesham, B.; Zade, V.B.; Martinez, A.; Shutthanandan, V.; Thevuthasan, S.; Ramana, C.V. Correlation between Structure, Chemistry, and Dielectric Properties of Iron-Doped Gallium Oxide (Ga2−xFexO3). J. Phys. Chem. C 2018, 122, 27597–27607. [Google Scholar] [CrossRef]

- Jiang, J.; Wu, S.M.; Li, X.Y.; Xin, Q.; Tian, Y. Zr-Doping Strategy of High-Quality Cu2O/β-Ga2O3 Heterojunctionfor Ultrahigh-Performance Solar-Blind Ultraviolet Photodetection. ACS Appl. Mater. Interfaces 2024, 16, 64136–64145. [Google Scholar] [CrossRef]

- Comstock, D.J.; Elam, J.W. Atomic Layer Deposition of Ga2O3 Films Using Trimethylgallium and Ozone. Chem. Mater. 2012, 24, 4011–4018. [Google Scholar] [CrossRef]

- Gebert, M.; Bhattacharyya, S.; Bounds, C.C.; Syed, N.; Daeneke, T.; Fuhrer, M.S. Passivating Graphene and Suppressing Interfacial Phonon Scattering with Mechanically Transferred Large-Area Ga2O3. Nano Lett. 2023, 23, 363–370. [Google Scholar] [CrossRef]

- Cheng, Z.; Shi, J.J.; Yuan, C.; Kim, S.; Graham, S. Chapter Four-Thermal science and engineering of β-Ga2O3 materials and devices. Semicond. Semimet. 2021, 107, 77–99. [Google Scholar]

- Fan, H.C.; Wang, C.; Ruan, Y.J.; Shen, K.C.; Wu, W.Y.; Wuu, D.S.; Lai, F.M.; Lien, S.Y.; Zhu, W.Z. Enhanced responsivity of solar blind ultraviolet photodetector by PEALD deposited Zn-doped Ga2O3 thin films. IEEE Trans. Electron. Dev. 2024, 71, 664–669. [Google Scholar] [CrossRef]

- Tao, J.J.; Lu, H.L.; Gu, Y.; Ma, H.P.; Li, X.; Chen, J.X.; Liu, W.J.; Zhang, H.; Feng, J.J. Investigation of growth characteristics, compositions, and properties of atomic layer deposited amorphous Zn-doped Ga2O3 films. Appl. Surf. Sci. 2019, 476, 733–740. [Google Scholar]

- Singh, A.K.; Yen, C.C.; Chang, K.P.; Wuu, D.S. Structural and photoluminescence properties of co-sputtered p-type Zn-doped β-Ga2O3 thin films on sapphire substrates. J. Lumin. 2023, 260, 119836. [Google Scholar]

- Hsu, C.H.; Wu, W.B.; Yue, X.X.; Wu, W.Y.; Gao, P.; Wuu, D.S.; Cho, Y.S.; Huang, C.J.; Lien, S.Y. Improved performance of solar blind ultraviolet photodetectors by spatial ALD Zn-doped Ga2O3 film and post-annealing. Surf. Coat. Technol. 2025, 497, 131798. [Google Scholar]

- Lee, S.H.; Lee, J.H.; Choi, S.J.; Park, J.S. Studies of thermoelectric transport properties of atomic layer deposited gallium-doped ZnO. Ceram. Int. 2017, 43, 7784–7788. [Google Scholar] [CrossRef]

- Lee, Y.L.; Chen, S.F.; Ho, C.L.; Wu, M.C. Effects of oxygen plasma post-treatment on Ga-doped ZnO films grown by thermal-mode ALD. ECS J. Solid State Sci. Technol. 2013, 2, 316–320. [Google Scholar]

- Dasgupta, N.P.; Neubert, S.; Lee, W.; Trejo, O.; Lee, J.R.; Prinz, F.B. Atomic layer deposition of Al-doped ZnO films: Effect of grain orientation on conductivity. Chem. Mater. 2010, 22, 4769–4775. [Google Scholar]

- Yuan, N.Y.; Wang, S.Y.; Tan, C.B.; Wang, X.Q.; Chen, G.G.; Ding, J.N. The influence of deposition temperature on growth mode, optical and mechanical properties of ZnO films prepared by the ALD method. J. Cryst. Growth 2013, 366, 43–46. [Google Scholar] [CrossRef]

- Lung, C.; Toma, M.; Pop, M.; Pop, A. Characterization of the structural and optical properties of ZnO thin films doped with Ga, Al and (Al plus Ga). J. Alloys Compd. 2017, 725, 1238–1243. [Google Scholar]

- Dong, L.P.; Jia, R.X.; Xin, B.; Zhang, Y.M. Effects of post-annealing temperature and oxygen concentration during sputtering on the structural and optical properties of β-Ga2O3 films. J. Vac. Sci. Technol. A 2016, 34, 060602. [Google Scholar] [CrossRef]

- Liu, X.J.; Sun, H.F.; Wu, Y.Z.; Sun, S.Y.; Ren, Y.; Tan, X.; Jia, H.L. Theoretical Study of Sulphur Atoms’ Adsorption and Migration Behaviors on Diamond (001) Surface. Coatings 2019, 9, 184. [Google Scholar] [CrossRef]

- Zheng, H.; Zhang, R.J.; Xu, J.P.; Wang, S.X.; Zhang, T.N.; Sun, Y.; Zheng, Y.X.; Wang, S.Y.; Chen, X.; Chen, L.Y.; et al. Thickness-Dependent Optical Constants and Annealed Phase Transitions of Ultrathin ZnO Films. J. Phys. Chem. C 2016, 120, 22532–22538. [Google Scholar]

- Ramachandran, R.K.; Dendooven, J.; Botterman, J.; Pulinthanathu Sree, S.; Poelman, D.; Martens, J.A.; Poelman, H.; Detavernier, C. Plasma enhanced atomic layer deposition of Ga2O3 thin films. J. Mater. Chem. A 2014, 2, 19232–19238. [Google Scholar]

- Yu, C.F.; Chen, S.H.; Sun, S.J.; Chou, H. Influence of the grain boundary barrier height on the electrical properties of Gallium doped ZnO thin films. Appl. Surf. Sci. 2011, 257, 6498–6502. [Google Scholar]

- Chandiran, A.K.; Tetreault, N.; Humphry-Baker, R.; Kessler, F.; Baranoff, E.; Yi, C.; Nazeeruddin, M.K.; Grätzel, M. Subnanometer Ga2O3 tunnelling layer by atomic layer deposition to achieve 1.1 V open-circuit potential in dye-sensitized solar cells. Nano Lett. 2012, 12, 3941–3947. [Google Scholar] [CrossRef]

- Guziewicz, E.; Krajewski, T.A.; Przezdziecka, E.; Korona, K.P.; Czechowski, N.; Klopotowski, L.; Terziyska, P. Zinc Oxide Grown by Atomic Layer Deposition: From Heavily n-Type to p-Type Material. Phys. Status Solidi B 2019, 257, 1900472. [Google Scholar]

- Suhariadi, I.; Itagaki, N.; Shiratani, M. Improved Nanoscale Al-Doped ZnO with a ZnO Buffer Layer Fabricated by Nitrogen-Mediated Crystallization for Flexible Optoelectronic Devices. ACS Appl. Nano Mater. 2020, 3, 2480–2490. [Google Scholar]

- Gao, Z.; Banerjee, P. Review Article: Atomic layer deposition of doped ZnO films. J. Vacuum Sci. Technol. A 2019, 37, 050802. [Google Scholar]

- Jiao, S.; Lu, H.; Wang, X.; Nie, Y.; Wang, D.; Gao, S.; Wang, J. The structural and photoelectrical properties of gallium oxide thin film grown by radio frequency magnetron sputtering. ECS J. Solid State Sci. Technol. 2019, 8, Q3086–Q3090. [Google Scholar]

- Jeong, S.W.; Lee, H.J.; Kim, K.S.; You, M.T.; Roh, Y.; Noguchi, T.; Xianyu, W.; Jung, J. Effects of annealing temperature on the characteristics of ALD-deposited HfO2 in MIM capacitors. Thin Solid Films 2006, 515, 526–530. [Google Scholar]

- Ylivaara, O.; Langner, A.; Ek, S.; Malm, J.; Julin, J.; Laitinen, M.; Ali, S.; Sintonen, S.; Lipsanen, H.; Sajavaara, T.; et al. Thermomechanical properties of aluminum oxide thin films made by atomic layer deposition. J. Vac. Sci. Technol. A 2022, 40, 062414. [Google Scholar]

- Shen, Y.; Ma, H.P.; Gu, L.; Zhang, J.; Huang, W.; Zhu, J.T.; Zhang, Q.C. Atomic-Level Sn Doping Effect in Ga2O3 Films Using Plasma-Enhanced Atomic Layer Deposition. Nanomaterials 2022, 12, 4256. [Google Scholar] [CrossRef] [PubMed]

- Shen, Y.; Ma, H.P.; Wang, Z.Y.; Gu, L.; Zhang, J.; Li, A.; Yang, M.; Zhang, Q.C. Influence of Rapid Thermal Annealing on the Characteristics of Sn-Doped Ga2O3 Films Fabricated Using Plasma-Enhanced Atomic Layer Deposition. Crystals 2023, 13, 301. [Google Scholar] [CrossRef]

- Mohamed, H.F.; Xia, C.; Sai, Q.; Cui, H.; Pan, M.; Qi, H. Growth and fundamentals of bulk β-Ga2O3 single crystals. J. Semicond. 2019, 40, 011801. [Google Scholar]

- Liu, S.Y.; Liu, S.; Zhou, Y.Y.; Piao, Y.J.; Li, G.J.; Wang, Q. Transparent ZnO: Al2O3 films with high breakdown voltage and resistivity. Appl. Phys. Lett. 2018, 113, 032102. [Google Scholar] [CrossRef]

- Dong, L.P.; Jia, R.X.; Xin, B.; Peng, B.; Zhang, Y.M. Effects of oxygen vacancies on the structural and optical properties of β-Ga2O3. Sci. Rep. 2017, 7, 40160. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tao, J.; Jiang, X.; Fan, A.; Hu, X.; Wang, P.; Dong, Z.; Wu, Y. Effect of Rapid Thermal Annealing on the Characteristics of Micro Zn-Doped Ga2O3 Films by Using Mixed Atomic Layer Deposition. Nanomaterials 2025, 15, 499. https://doi.org/10.3390/nano15070499

Tao J, Jiang X, Fan A, Hu X, Wang P, Dong Z, Wu Y. Effect of Rapid Thermal Annealing on the Characteristics of Micro Zn-Doped Ga2O3 Films by Using Mixed Atomic Layer Deposition. Nanomaterials. 2025; 15(7):499. https://doi.org/10.3390/nano15070499

Chicago/Turabian StyleTao, Jiajia, Xishun Jiang, Aijie Fan, Xianyu Hu, Ping Wang, Zuoru Dong, and Yingjie Wu. 2025. "Effect of Rapid Thermal Annealing on the Characteristics of Micro Zn-Doped Ga2O3 Films by Using Mixed Atomic Layer Deposition" Nanomaterials 15, no. 7: 499. https://doi.org/10.3390/nano15070499

APA StyleTao, J., Jiang, X., Fan, A., Hu, X., Wang, P., Dong, Z., & Wu, Y. (2025). Effect of Rapid Thermal Annealing on the Characteristics of Micro Zn-Doped Ga2O3 Films by Using Mixed Atomic Layer Deposition. Nanomaterials, 15(7), 499. https://doi.org/10.3390/nano15070499