Execution Plan Control in Dynamic Coalition of Robots with Smart Contracts and Blockchain

Abstract

1. Introduction

2. Problem Statement

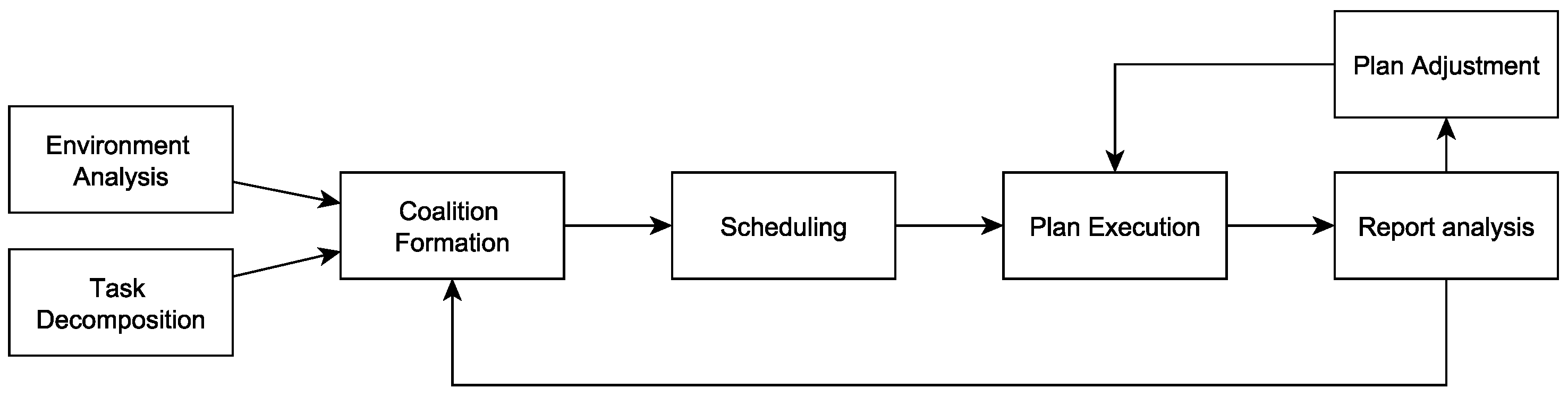

3. Task Scheduling for Coalition

3.1. Coalition Formation

3.2. Scheduling

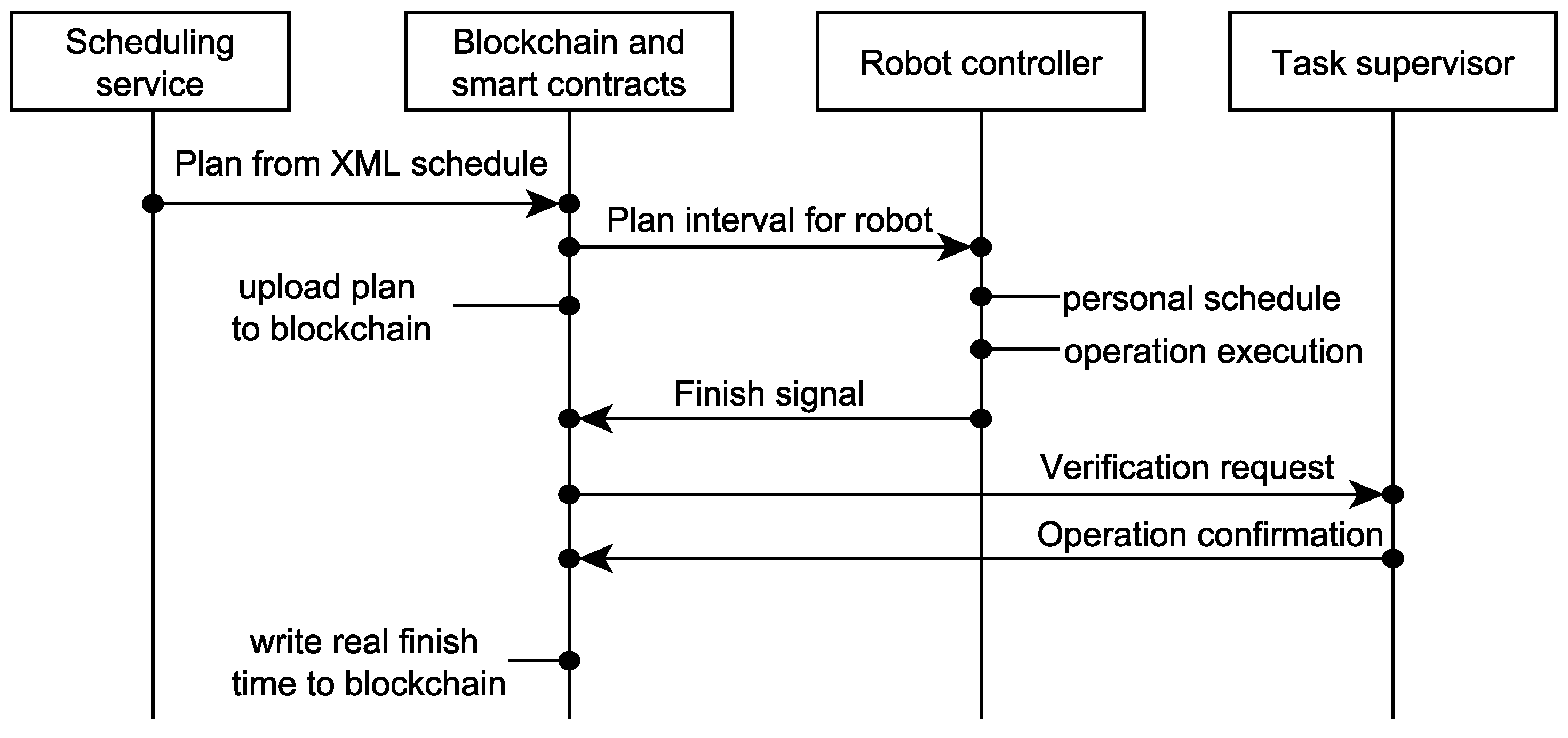

4. Plan Execution Control

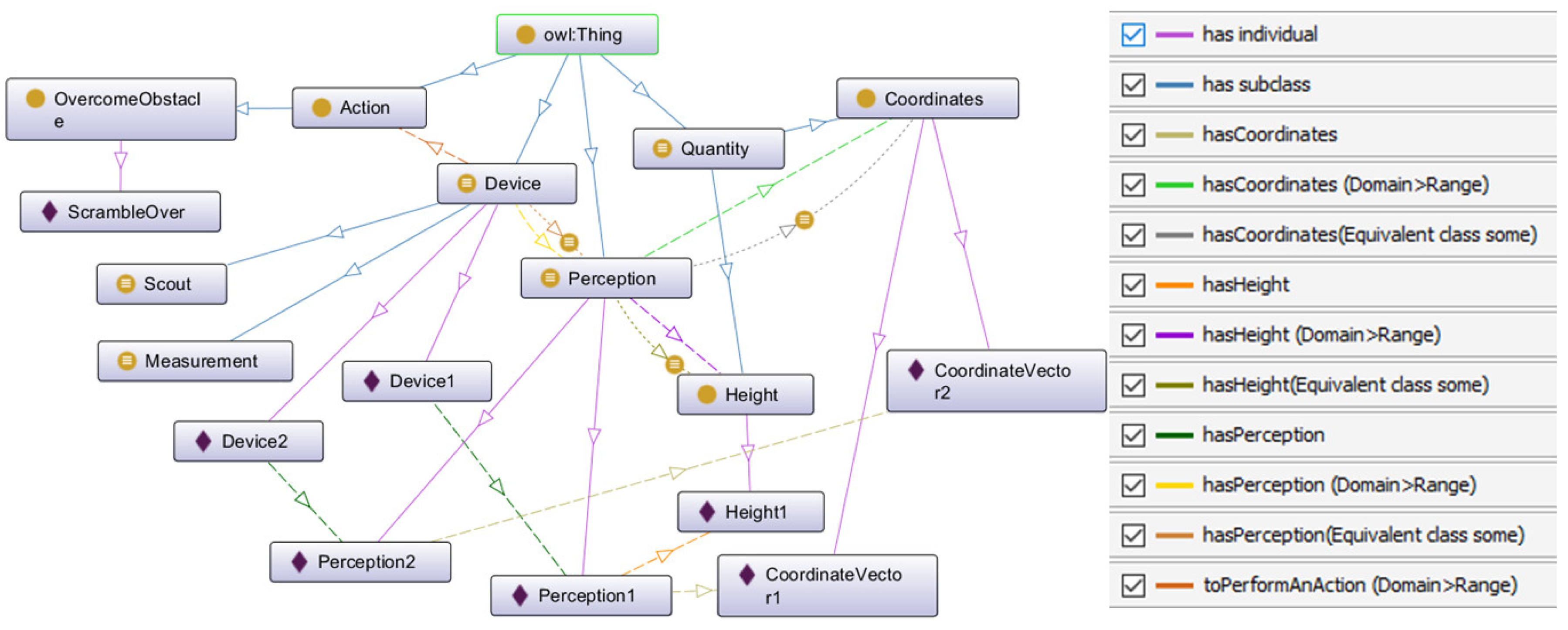

| Listing 1. Example of SWRL rules to select a quadcopter and a rover with defined requirements. |

| Device(?d2) ∧ Device(?d1) ∧ hasCoordinateX(?v1, ?vx1) ∧ hasCoordinateX(?v2, ?vx2) ∧ |

| hasCoordinateY(?v1, ?vy1) ∧ hasCoordinateY(?v2, ?vy2) ∧ Perception(?p1) ∧ |

| isQuadcopter(?d1, ?true) ∧ swrlb : equal(?vx1, ?vx2) ∧ swrlb : equal(?vy1, ?vy2) ∧ |

| isRover(?d2, true) ∧ hasHeight(?p1, ?h1) ∧ hasPerception(?d1, ?p1) ∧ OvercomeObstacle(?a) ∧ |

| hasCoordinates(?p1, ?v1) ∧ hasCoordinates(?p2, ?v2) → toPerformAnAction(?d2, ?a) |

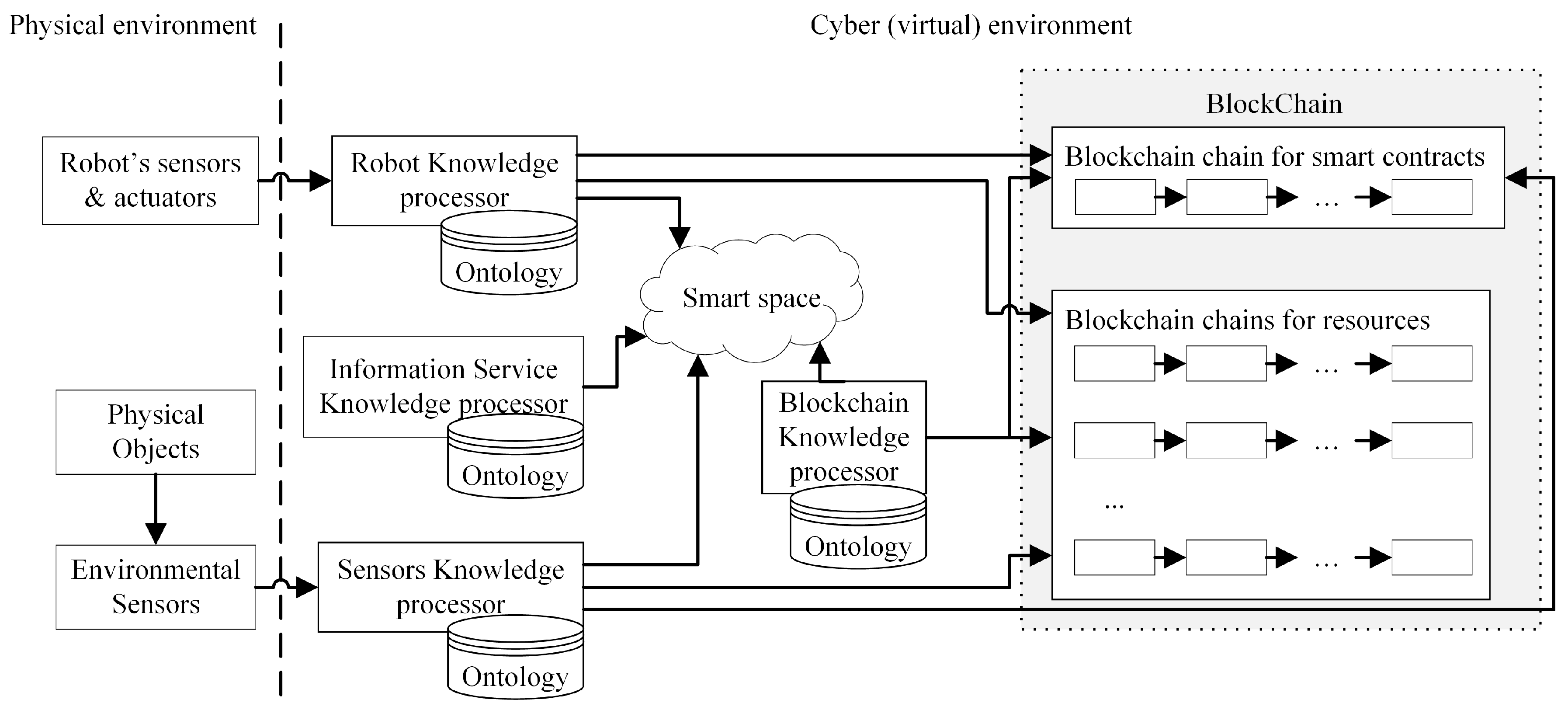

4.1. Blockchain Usage for Robot Coalition

4.2. Smart Contracts for Execution Control

- 1

- Schedule upload using XML format. It provides:

- (a)

- Receiving an execution plan in XML.

- (b)

- Parse it, extract the robots, tasks associated with robots, the order of execution, and the timing of tasks.

- (c)

- Generation entries from the blockchain from the extracted items. Each entry must contain one task, which is described by the robot responsible for its execution and the start and end dates of the execution.

- (d)

- Send on the blackboard a notice of the start of execution.

- 2

- Start the task. Accept a message from the robot about the start of the task, record the moment of the real start of execution in the blockchain, verify with the planned one, and record the fact in case of a strong deviation.

- 3

- Completion of the task. Same as with the start—get notification, check correctness and write to the ledger. In case of a strong deviation from the plan, write to the blockchain and notify others about the failure of the plan through the blackboard.

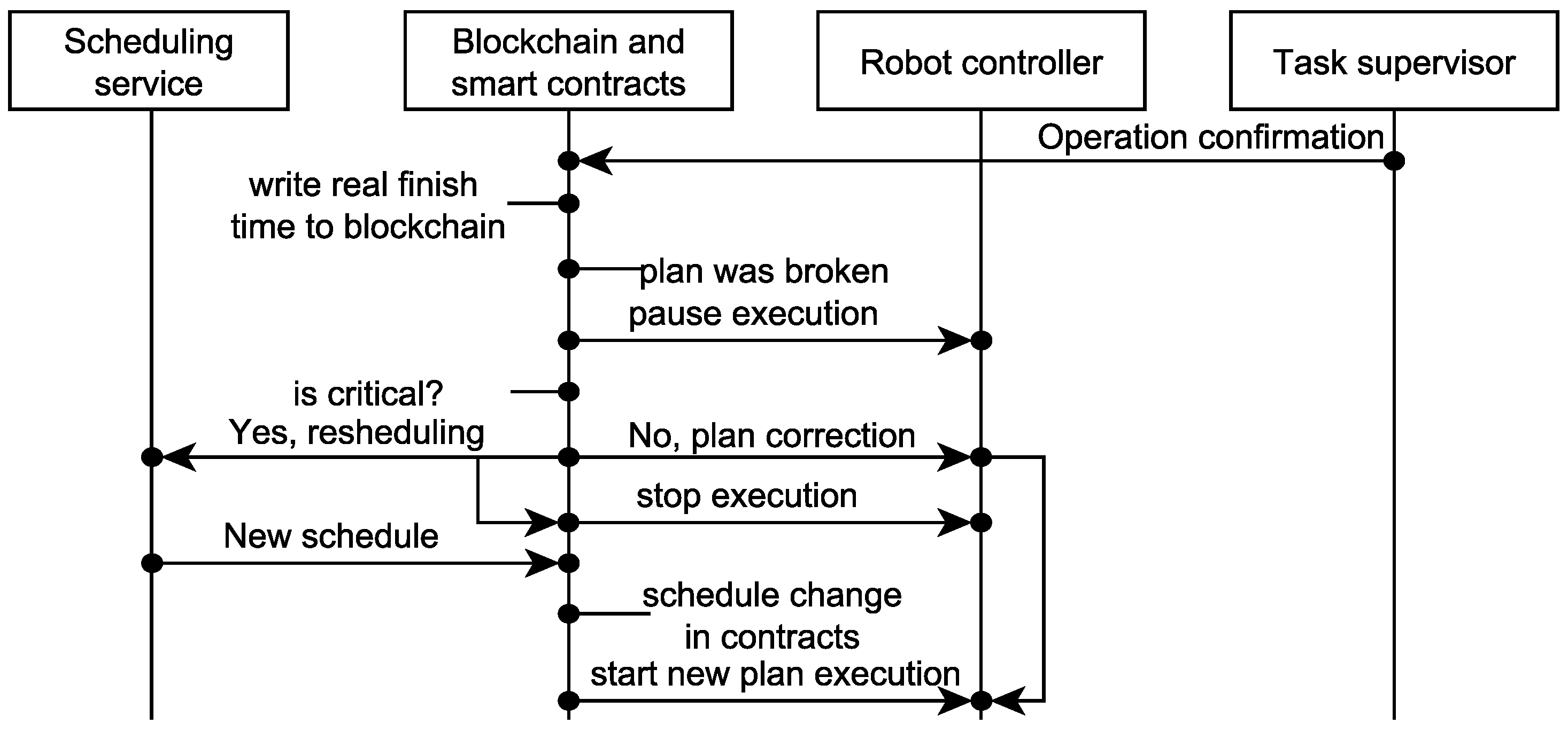

4.2.1. Dynamic Execution Adjustment

4.2.2. Rescheduling

5. Results

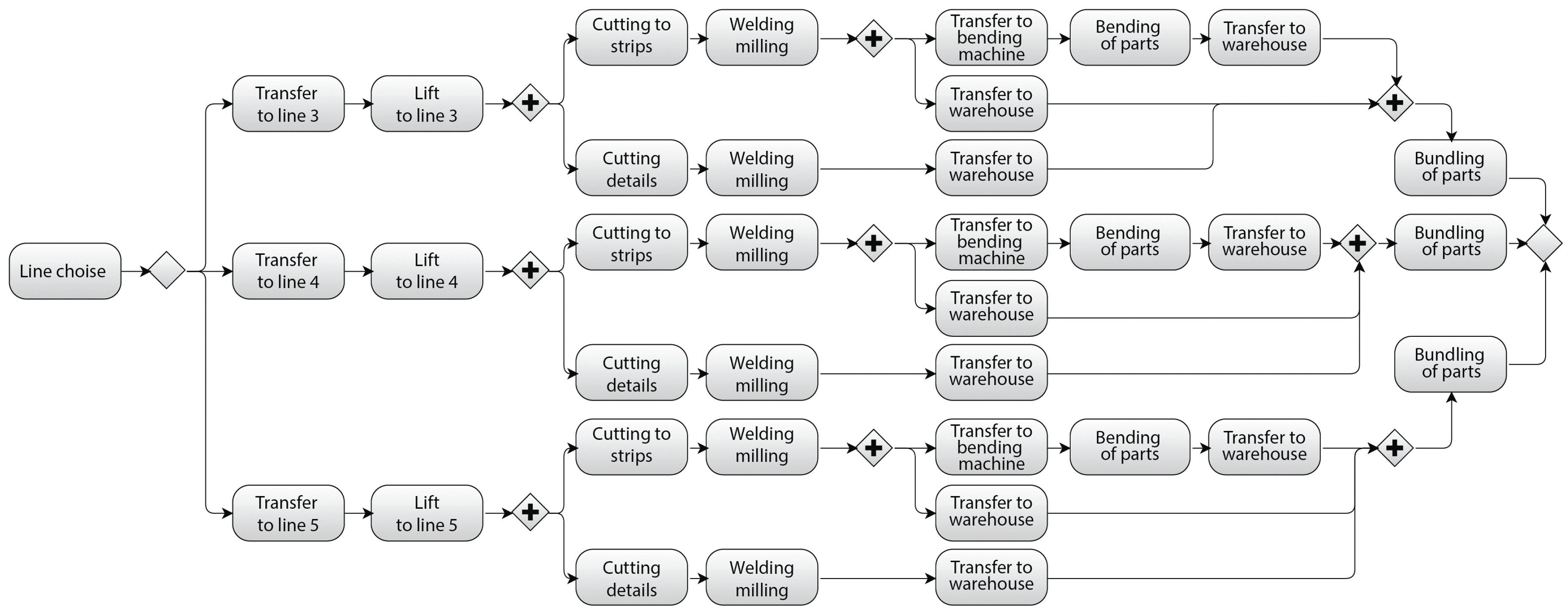

- 1

- The schedule object is a task. Combines processes, quality indicators, and resources. There are no special properties and identifiers.

- 2

- Array of processes. Each process contains its own identifier and an array of operations.

- 3

- Each operation in the array contains an identifier, name, priority, a link to the involved resource, and several possible moments of the beginning and end of the operation.

- 4

- An array of quality indicators, contains Pki objects. Each such object has an identifier and property generalized, weight, name, and value.

- 5

- Array of resources. Each resource contains an identifier (it is accessed from the operation, see above) and worktime.

| Listing 2. Example of BPMN file for the coalition process description. |

| <spy:schedule> |

| <spy:processes> |

| <spy:Process id="1"> |

| <spy:operations> |

| <spy:Operation id="1"> |

| <spy:name>Transfer to line #3</spy:name> |

| <spy:priority>0.3254</spy:priority> |

| <spy:resource>RS_2</spy:resource> |

| <spy:start> |

| <spy:StartTime intensity="5">12</spy:StartTime> |

| <spy:StartTime intensity="3">24</spy:StartTime> |

| </spy:start> |

| <spy:end> |

| <spy:EndTime>15</spy:EndTime> |

| <spy:EndTime>25</spy:EndTime> |

| </spy:end> |

| </spy:Operation> |

| .... |

| </spy:operations> |

| </spy:Process> |

| .... |

| </spy:processes> |

| <spy:quality> |

| <spy:Pki id="J1" generalized="False"> |

| <spy:weight>0.8</spy:weight> |

| <spy:name>Energy consumption</spy:name> |

| <spy:val>321</spy:val> |

| </spy:Pki> |

| <spy:Pki id="J2" generalized="False"> |

| <spy:weight>0.2</spy:weight> |

| <spy:name>Time consumption</spy:name> |

| <spy:val>31</spy:val> |

| </spy:Pki> |

| </spy:quality> |

| <spy:resources> |

| <spy:Resource id="RS_2"> |

| <spy:worktime>12</spy:worktime> |

| </spy:Resource> |

| <spy:Resource id="RS_3"> |

| <spy:worktime>16</spy:worktime> |

| </spy:Resource> |

| </spy:resources> |

| </spy:schedule> |

6. Discussion

7. Materials and Methods

8. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Panov, A.I.; Yakovlev, K. Behavior and Path Planning for the Coalition of Cognitive Robots in Smart Relocation Tasks. In Robot Intelligence Technology and Applications 4; Kim, J.H., Matson, E.T., Myung, H., Xu, P., Eds.; Springer: Berlin/Heidelberg, Germany, 2017; Volume 208, pp. 3–20. [Google Scholar] [CrossRef]

- Balta, E.C.; Jain, K.; Lin, Y.; Tilbury, D.; Barton, K.; Mao, Z.M. Production as a Service: A Centralized Framework for Small Batch Manufacturing. In Proceedings of the 2017 13th IEEE Conference on Automation Science and Engineering (CASE), Xi’an, China, 20–23 August 2017; pp. 382–389. [Google Scholar] [CrossRef]

- Shah, A. Robot Explorers. Mech. Eng. 2018, 140, 30–35. [Google Scholar] [CrossRef][Green Version]

- Khanna, A.; Kaur, S. Evolution of Internet of Things (IoT) and its significant impact in the field of Precision Agriculture. Comput. Electron. Agric. 2019, 157, 218–231. [Google Scholar] [CrossRef]

- Roldán, J.J.; del Cerro, J.; Garzón-Ramos, D.; Garcia-Aunon, P.; Garzón, M.; de León, J.; Barrientos, A. Robots in agriculture: State of art and practical experiences. In Service Robots; InTech: Rijeka, Croatia, 2018. [Google Scholar]

- Ferrer, E.C. The blockchain: A new framework for robotic swarm systems. In Proceedings of the Future Technologies Conference (FTC), Vancouver, BC, Canada, 15–16 November 2018. [Google Scholar]

- Kashevnik, A.; Teslya, N. Blockchain-Oriented Coalition Formation by CPS Resources: Ontological Approach and Case Study. Electronics 2018, 7, 66. [Google Scholar] [CrossRef]

- IEEE Robotics and Automation Society. IEEE Standard Ontologies for Robotics and Automation; IEEE: Piscataway, NJ, USA, 2015; p. 60. [Google Scholar] [CrossRef]

- Horrocks, I.; Patel-Schneider, P.F.; Boley, H.; Tabet, S.; Grosof, B.; Dean, M. SWRL: A Semantic Web Rule Language Combining OWL and RuleML. Available online: https://www.w3.org/Submission/2004/SUBM-SWRL-20040521/ (accessed on 4 January 2020).

- Hosam, H.; Khaldoun, Z. Planning coalition formation under uncertainty: Auction approach. In Proceedings of the 2006 International Conference on Information and Communication Technologies: From Theory to Applications (ICTTA 2006), Damascus, Syria, 23–28 April 2006; Volume 2, pp. 3013–3017. [Google Scholar] [CrossRef]

- Sheremetov, L.B.; Smirnov, A.V. Supply Chain Configuration as a Cooperative Game with Fuzzy Coalitions. In Supply Chain Management Under Fuzziness; Kahraman, C., Öztayşi, B., Eds.; Springer: Berlin/Heidelberg, Germany, 2014; Volume 313, pp. 293–314. [Google Scholar] [CrossRef]

- Ackoff, R.L. The Art of Problem Solving; Wiley: New York, NY, USA, 1998. [Google Scholar]

- Klir, G.J. Architecture of Systems Problem Solving; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Hanziverov, F.; Ostrouhov, V. Simulation of Space Systems for Natural Resources Research; Mashinostroenie: Moscow, Russia, 1989. [Google Scholar]

- Pereira, J.L.; Freitas, A.P. Simulation of BPMN process models: Current BPM tools capabilities. In New Advances in Information Systems and Technologies; Springer: Berlin/Heidelberg, Germany, 2016; pp. 557–566. [Google Scholar]

- Deeptimahanti, D.K.; Sanyal, R. An innovative approach for generating static UML models from natural language requirements. In Proceedings of the International Conference on Advanced Software Engineering and Its Applications, Sanya, China, 13–15 December 2008; Springer: Berlin/Heidelberg, Germany, 2008; pp. 147–163. [Google Scholar]

- Friedrich, F.; Mendling, J.; Puhlmann, F. Process model generation from natural language text. In Proceedings of the International Conference on Advanced Information Systems Engineering, London, UK, 20–24 June 2011; Springer: Berlin/Heidelberg, Germany, 2011; pp. 482–496. [Google Scholar]

- Leopold, H.; Mendling, J.; Polyvyanyy, A. Generating natural language texts from business process models. In Proceedings of the International Conference on Advanced Information Systems Engineering, Gdansk, Poland, 25–29 June 2012; Springer: Berlin/Heidelberg, Germany, 2012; pp. 64–79. [Google Scholar]

- Ivanov, D.; Sokolov, B.; Potryasaev, S. A dynamic model and an algorithm for supply Chain scheduling problem solving. In Proceedings of the 16th International Conference on Harbor, Maritime and Multimodal Logistics Modelling and Simulation, HMS 2014, Bordeaux, France, 10–12 September 2014; pp. 85–91. [Google Scholar]

- Potryasaev, S.A.; Sokolov, B.V.; Ivanov, D.A. Control theory application to spacecraft scheduling problem. In Proceedings of the 2014 International Conference on Computer Technologies in Physical and Engineering Applications (ICCTPEA), St. Petersburg, Russia, 30 June–4 July 2014; pp. 145–146. [Google Scholar] [CrossRef]

- Smirnov, A.; Teslya, N. Robot Interaction Through Smart Contract for Blockchain-Based Coalition Formation. In Proceedings of the IFIP International Conference on Product Lifecycle Management, Turin, Italy, 2–4 July 2018; Springer: Berlin/Heidelberg, Germany, 2018; pp. 611–620. [Google Scholar]

- Teslya, N. Industrial socio-cyberphysical system’s consumables tokenization for smart contracts in blockchain. In Proceedings of the International Conference on Business Information Systems, Berlin, Germany, 18–20 July 2018; Lecture Notes in Business Information Processing. Springer: Cham, Switzerland, 2019; Volume 339, pp. 344–355. [Google Scholar] [CrossRef]

- Androulaki, E.; Barger, A.; Bortnikov, V.; Cachin, C.; Christidis, K.; De Caro, A.; Enyeart, D.; Ferris, C.; Laventman, G.; Manevich, Y.; et al. Hyperledger Fabric: A Distributed Operating System for Permissioned Blockchains. In Proceedings of the Thirteenth EuroSys Conference, Porto, Portugal, 23–26 April 2018; p. 15. [Google Scholar]

- Szabo, N. Formalizing and Securing Relationships on Public Networks. First Monday 1997, 2, 9. [Google Scholar] [CrossRef]

- Bano, S.; Sonnino, A.; Al-Bassam, M.; Azouvi, S.; McCorry, P.; Meiklejohn, S.; Danezis, G. SoK: Consensus in the age of blockchains. In Proceedings of the 1st ACM Conference on Advances in Financial Technologies, Zurich, Switzerland, 21–23 October 2019; pp. 183–198. [Google Scholar]

- Sokolov, B.; Ushakov, V. Model-Algorithmic Support for Abilities Calculating of Control System Based on Projection Operators. In Proceedings of the Computer Science On-line Conference, Zlin, Czech Republic, 24–27 April 2019; Springer: Berlin/Heidelberg, Germany, 2019; pp. 342–348. [Google Scholar]

- Smirnov, A.; Sheremetov, L.; Teslya, N. Fuzzy cooperative games usage in smart contracts for dynamic robot coalition formation: Approach and use case description. In Proceedings of the 21st International Conference on Enterprise Information Systems, ICEIS 2019, Heraklion/Crete, Greece, 3–5 May 2019; Volume 1, pp. 361–370. [Google Scholar]

- Teslya, N.; Potryasaev, S. Project Repository. Available online: https://cais.iias.spb.su/gitlab/tnn/robot-coalition-blockchain (accessed on 4 January 2020).

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Teslya, N.; Potryasaev, S. Execution Plan Control in Dynamic Coalition of Robots with Smart Contracts and Blockchain. Information 2020, 11, 28. https://doi.org/10.3390/info11010028

Teslya N, Potryasaev S. Execution Plan Control in Dynamic Coalition of Robots with Smart Contracts and Blockchain. Information. 2020; 11(1):28. https://doi.org/10.3390/info11010028

Chicago/Turabian StyleTeslya, Nikolay, and Semyon Potryasaev. 2020. "Execution Plan Control in Dynamic Coalition of Robots with Smart Contracts and Blockchain" Information 11, no. 1: 28. https://doi.org/10.3390/info11010028

APA StyleTeslya, N., & Potryasaev, S. (2020). Execution Plan Control in Dynamic Coalition of Robots with Smart Contracts and Blockchain. Information, 11(1), 28. https://doi.org/10.3390/info11010028