Research on a Coordinated Control Method of Tractor Electro-Hydraulic Hitch Tillage Depth and Travel Speed Based on Optimal Overall Efficiency and Economic Performance

Abstract

1. Introduction

2. Materials and Methods

2.1. Theoretical Modeling

- (a)

- Only the linear motion of the tractor in the forward direction is considered;

- (b)

- The stiffness of the components of the three-point hitch is neglected, and the tractor and plow are regarded as a single rigid body;

- (c)

- Air resistance and gradient (slope) resistance during plowing are ignored;

- (d)

- The ground conditions under the left and right wheels of the tractor are assumed to be identical, and lateral tilting during forward motion is neglected;

- (e)

- The point of application of the plowing resistance is assumed to lie along the centroidal axis of the moldboard plow, and the vertical distance from this point to the ground is set as two-thirds of the tillage depth.

2.1.1. Tractor Dynamic Vertical Load Model

2.1.2. Tire-Soil Traction Model

2.1.3. Dynamic Model of the Tractor–Plow Tillage System

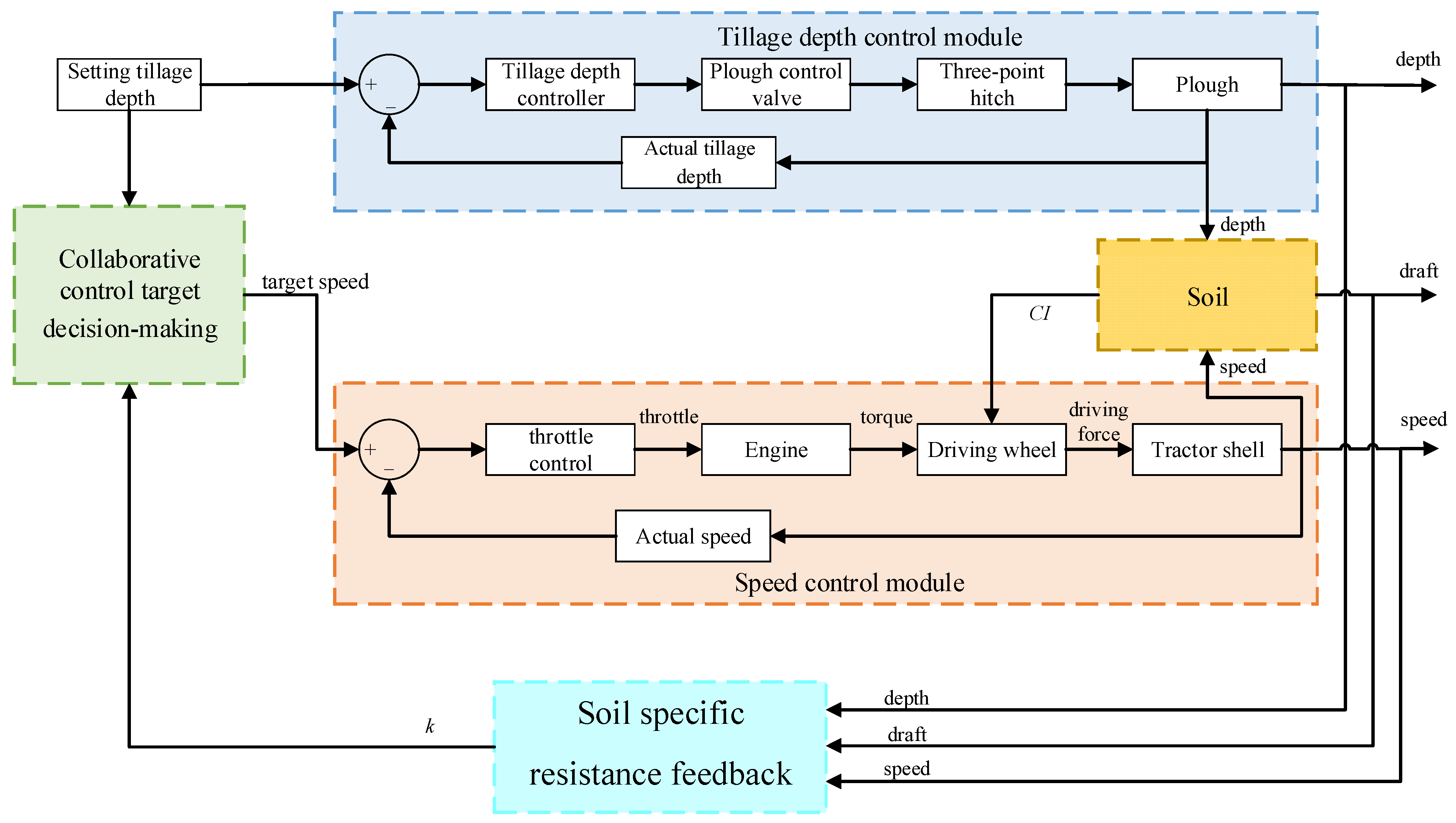

2.2. Design of a Coordinated Control System for Tillage Depth and Vehicle Speed

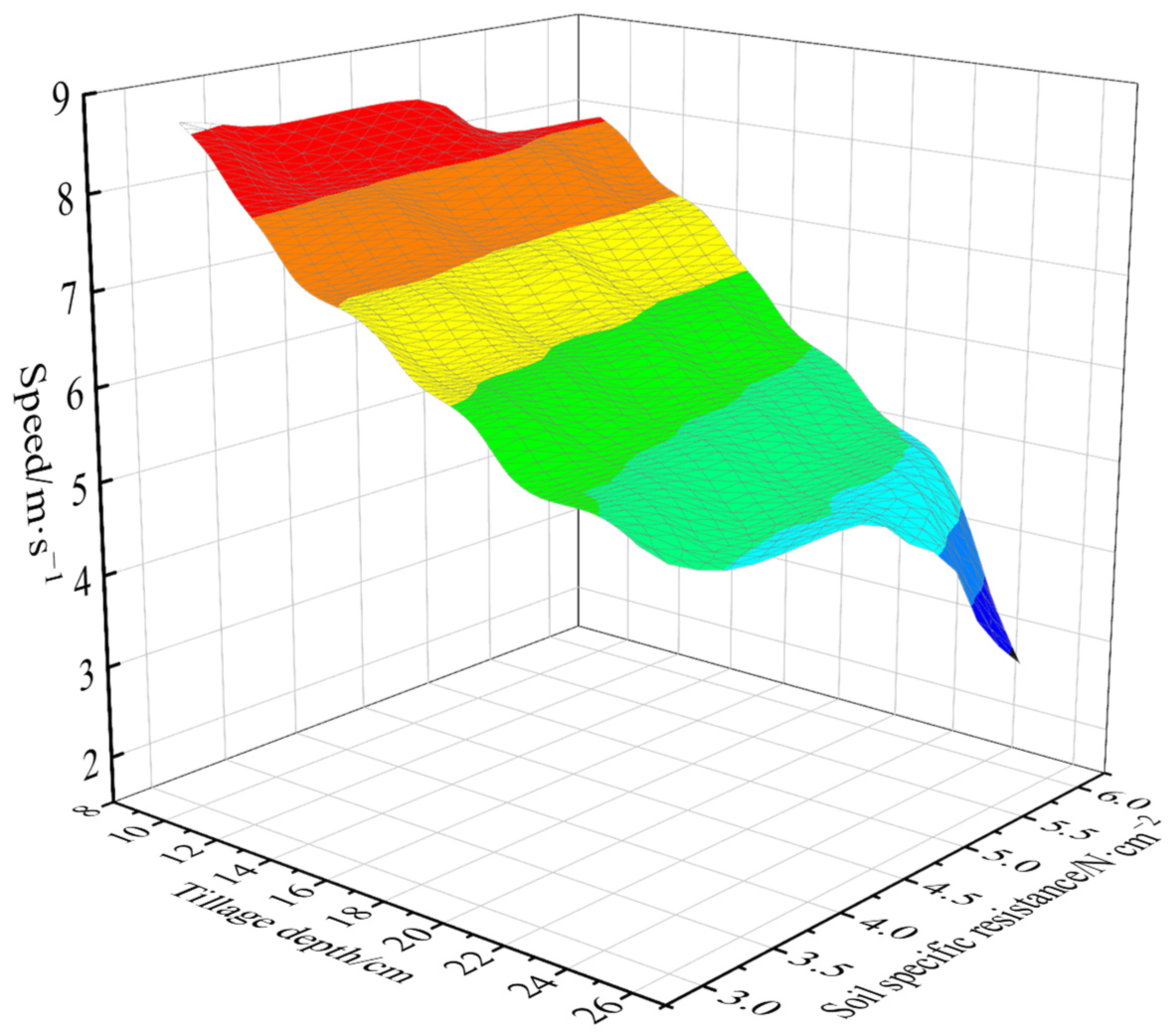

2.2.1. Optimization of Coordinated Control Objective Decision Based on Optimal Overall Efficiency and Economy

2.2.2. Principle of Coordinated Control

2.3. Controller Design

2.3.1. Design of Tillage Depth Controller Based on Global Sliding Mode

2.3.2. Design of a Sliding Mode Variable Structure Speed Controller

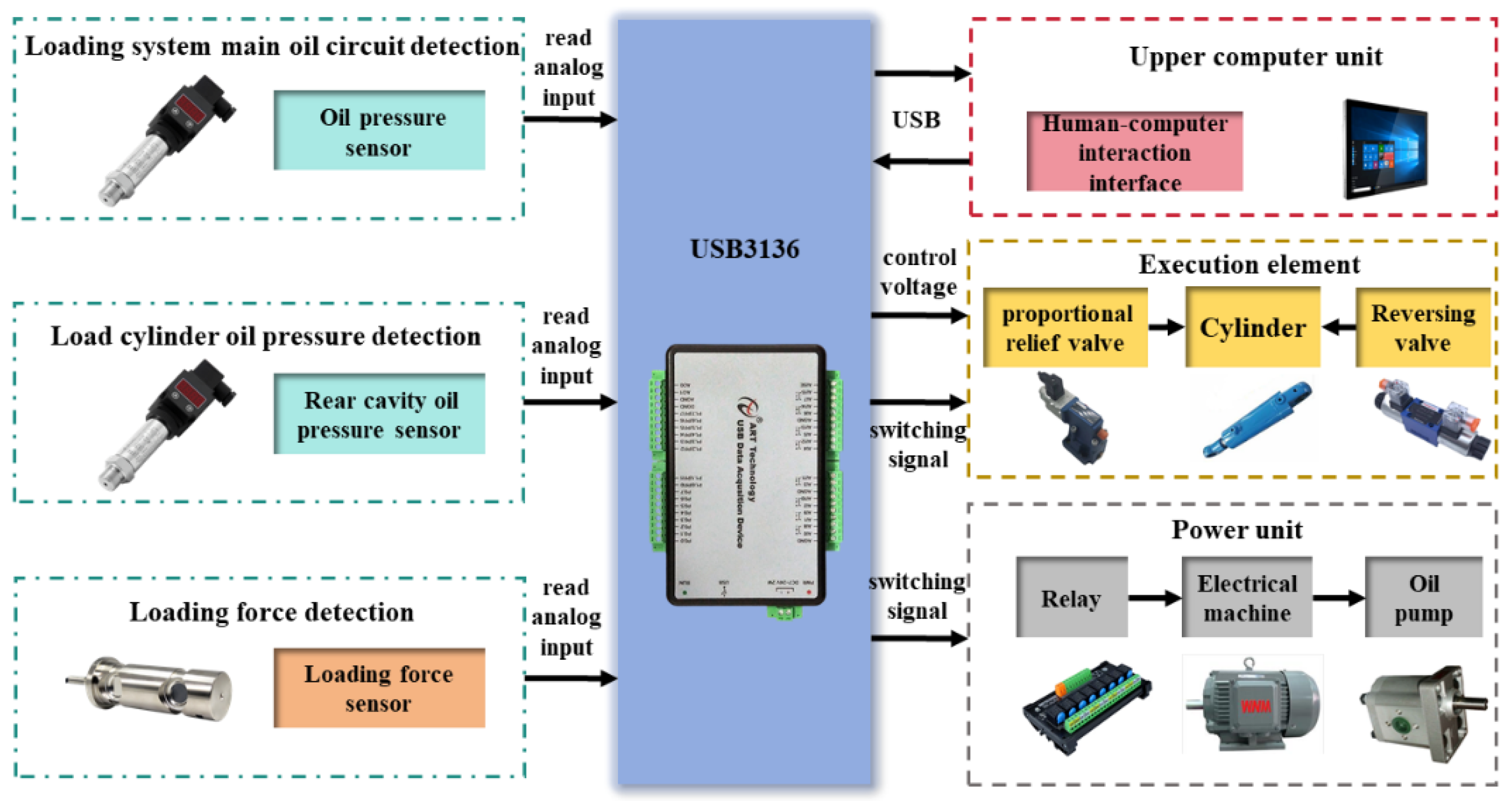

2.4. Construction of the Experimental Platform

2.4.1. Structure and Principle of the Electro-Hydraulic Suspension Test Bench

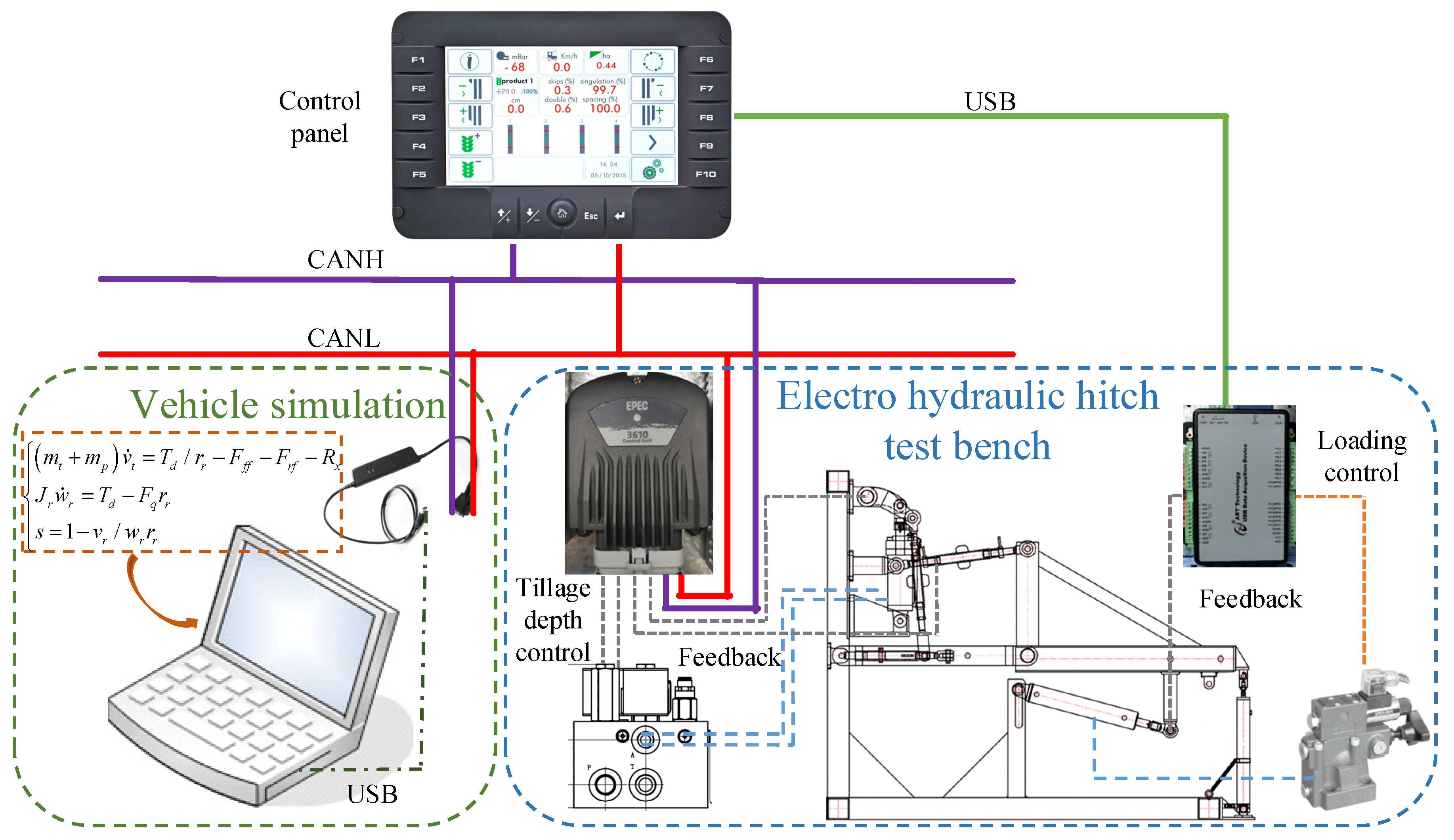

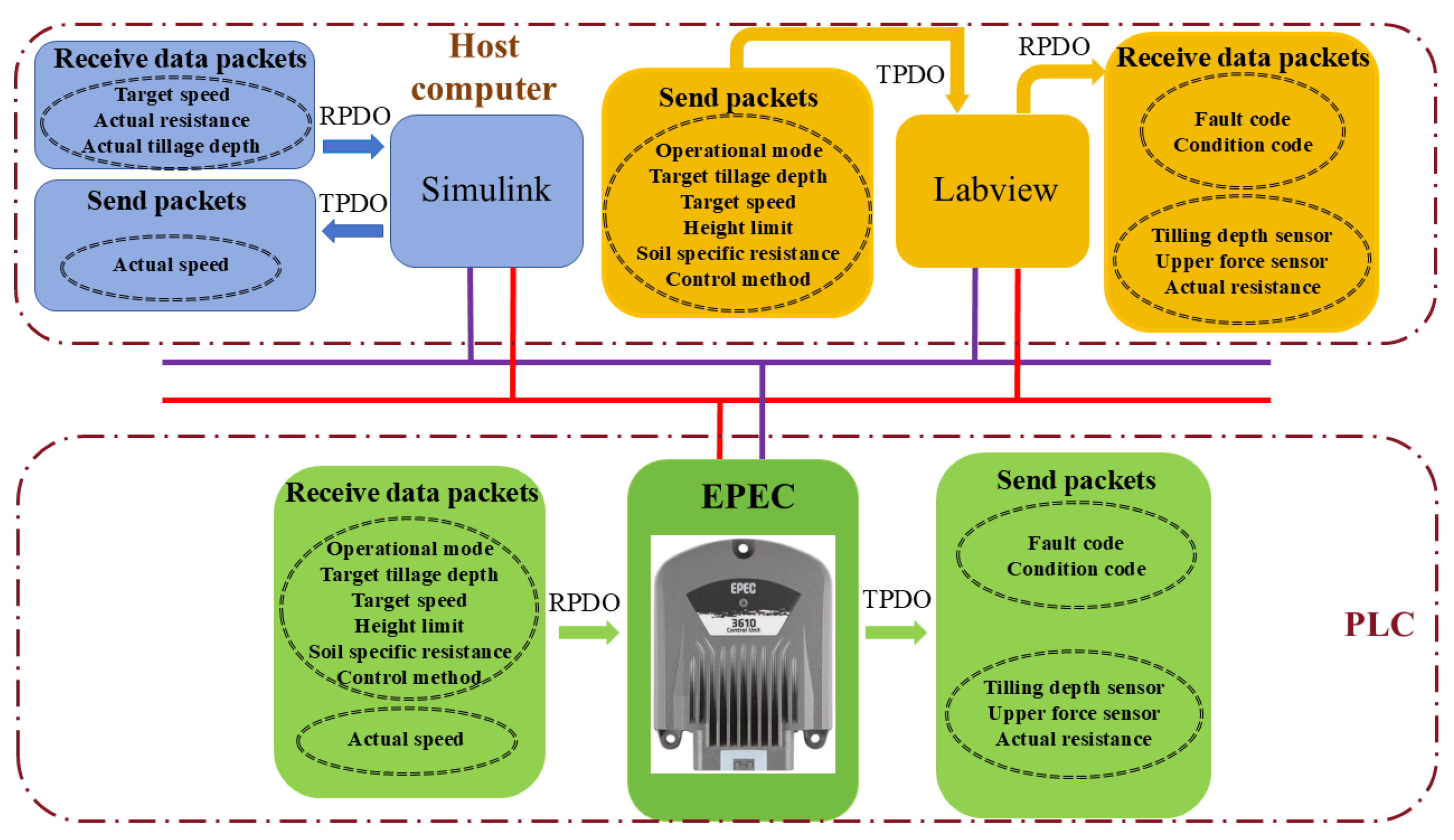

2.4.2. Construction of a Hardware-in-the-Loop Tillage Depth and Vehicle Speed Coordinated Control Platform Based on CAN Communication

2.4.3. CAN Communication Signal Verification

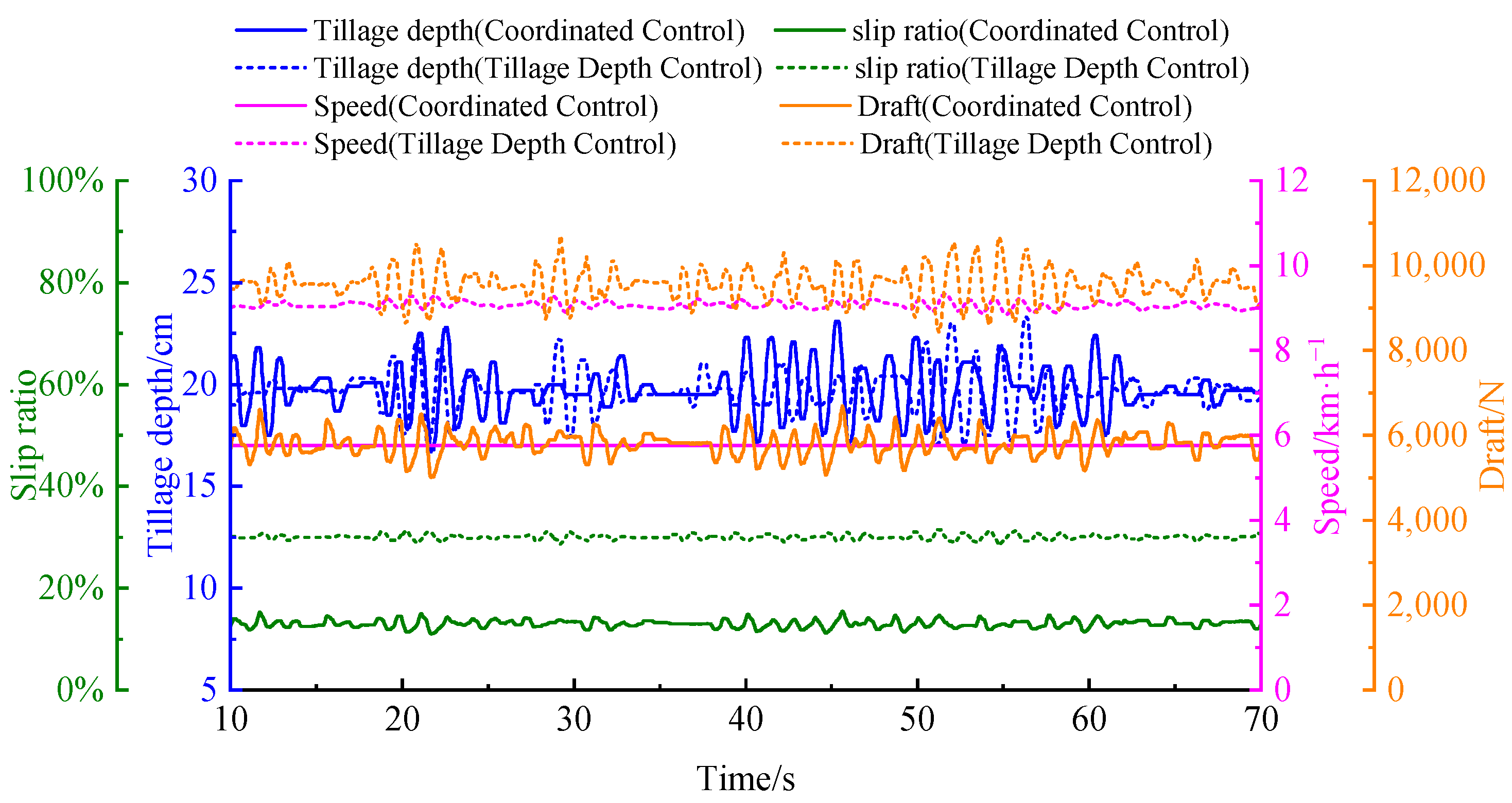

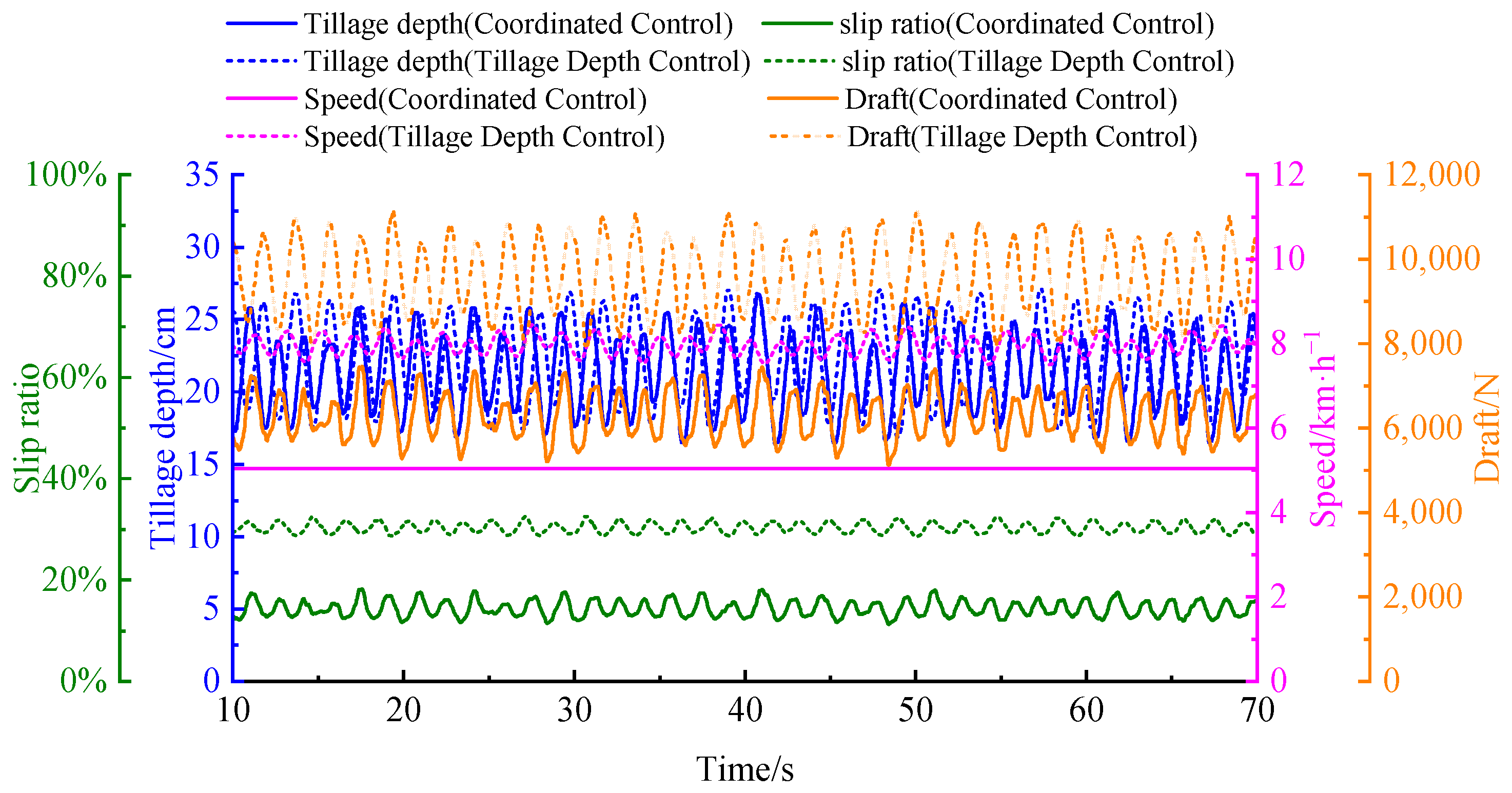

2.4.4. Comparison Between Tillage Depth–Vehicle Speed Coordinated Control and Tillage Depth Control Methods Under Different Operating Conditions

3. Results and Discussion

3.1. CAN Bus Test Results

3.2. Comparison of Results Under Different Control Methods

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mamkagh, A.M. Effect of soil moisture, tillage speed, depth, ballast weight and, used implement on wheel slippage of the tractor: A review. Asian J. Adv. Agric. Res. 2019, 9, 1–7. [Google Scholar] [CrossRef]

- Benkovic, R.; Sumanovac, L.; Jug, D.; Jug, I.; Japundzic-Palenkic, B.; Mirosavljevic, K.; Popijac, M.; Benkovic-Lacic, T. Influence of Aggregated Tillage Implements on Fuel Consumption and Wheel Slippage. Teh. Vjesn. Tech. Gaz. 2021, 28, 956–962. [Google Scholar]

- Anche, G.M.; Devika, K.B.; Subramanian, S.C. Robust Pitching Disturbance Force Attenuation for Tractor Considering Functional Constraints. IEEE Access 2020, 8, 86419–86432. [Google Scholar] [CrossRef]

- Shen, W.; Wang, J.H.; Huang, H.L.; He, J.Y. Fuzzy sliding mode control with state estimation for velocity control system of hydraulic cylinder using a new hydraulic transformer. Eur. J. Control 2019, 48, 104–114. [Google Scholar] [CrossRef]

- Singha, P.S.; Kumar, A.; Sarkar, S.; Baishya, S.; Kumar, P. Development of Electro-Hydraulic Hitch Control System through Lower Link Draft Sensing of a Tractor. J. Sci. Ind. Res. 2022, 81, 384–392. [Google Scholar] [CrossRef]

- Xu, J.K.; Li, R.C.; Li, Y.C.; Zhang, Y.S.; Sun, H.L.; Ding, X.K.; Ma, Y. Research on Variable-Universe Fuzzy Control Technology of an Electro-Hydraulic Hitch System. Processes 2021, 9, 1920. [Google Scholar] [CrossRef]

- Gupta, C.; Tewari, V.K.; Ashok Kumar, A.; Shrivastava, P. Automatic tractor slip-draft embedded control system. Comput. Electron. Agric. 2019, 165, 104947. [Google Scholar] [CrossRef]

- Zhang, S.; Wu, Z.B.; Chen, J.; Li, Z.; Zhu, Z.X.; Song, Z.H.; Mao, E.R. Control method of driving wheel slip rate of high-power tractor for ploughing operation. Trans. CSAE Trans. Chin. Soc. Agric. Eng. 2020, 36, 47–55. [Google Scholar]

- Zhao, G.Q.; Xia, Z.G. Research on Tractor Slip Rate Control Based on SimulationX. J. Agric. Mech. Res. 2021, 43, 240–245. [Google Scholar]

- Han, Z.R.; Yang, J.R.; Li, R.C.; Xu, X.Z.; Li, Y.C.; Li, N. Research on Tillage Depth Control Method of Double Parameters of Variable Target Slip Rate and Position. J. Agric. Mech. Res. 2023, 45, 246–252. [Google Scholar]

- Cui, D.D.; Cui, G.W.; Zhang, T. Research on adaptive variable weight factor of electric control hydraulic lifting system for agricultural machinery equipment. Mach. Tool Hydraul. 2024, 52, 115–122. [Google Scholar]

- Zhang, S.L.; Ren, W.; Xie, B.; Luo, Z.H.; Wen, C.K.; Chen, Z.J.; Zhu, Z.X.; Li, T.H. A combined control method of traction and ballast for an electric tractor in ploughing based on load transfer. Comput. Electron. Agric. 2023, 207, 107750. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, X.; Wang, W.; Song, Y.L.; Cui, Y.J. Joint control method based on speed and slip rate switching in plowing operation of wheeled electric. Comput. Electron. Agric. 2023, 215, 108426. [Google Scholar] [CrossRef]

- Kumari, A.; Raheman, H. Tillage operation with a tractor drawn rotavator using an embedded advisory system for minimizing fuel consumption. J. Biosyst. Eng. 2023, 48, 487–502. [Google Scholar] [CrossRef]

- Li, X.Z.; Xu, L.Y.; Liu, M.N.; Yan, X.H.; Zhang, M.Z. Research on torque cooperative control of distributed drive system for fuel cell electric tractor. Comput. Electron. Agric. 2024, 219, 108811. [Google Scholar] [CrossRef]

- Shao, X.D.; Yang, Z.H.; Mowafy, S.; Zheng, B.W.; Song, Z.H.; Luo, Z.H.; Guo, W.J. Load characteristics analysis of tractor drivetrain under field plowing operation considering tire-soil interaction. Soil Tillage Res. 2023, 227, 105620. [Google Scholar] [CrossRef]

- Moitzi, G.; Haas, M.; Wagentristl, H.; Boxberger, J.; Gronauer, A. Energy consumption in cultivating and ploughing with traction improvement system and consideration of the rear furrow wheel-load in ploughing. Soil Tillage Res. 2013, 134, 56–60. [Google Scholar] [CrossRef]

- Sunusi, I.I.; Zhou, J.; Wang, Z.Z.; Sun, C.Y.; Ibrahim, I.E.; Opiyo, S.; Korohou, T. Intelligent tractors: Review of online traction control process. Comput. Electron. Agric. 2020, 170, 105176. [Google Scholar] [CrossRef]

- Brixius, W.; Wismer, R.D. Traction prediction equations for wheeled vehicles. In Proceedings of the John Deere Technical Report Release Conference, Moline, IL, USA, 7 July 1975. [Google Scholar]

- Brixius, W. Traction prediction equations for bias ply tires. Am. Soc. Agric. Eng. 1987, 9, 87–98. [Google Scholar]

- Zhao, J.H.; Zhao, T.L.; Xu, L.Y.; Li, Y.Y.; Zhang, J.Y.; Liu, Y.H.; Sun, L. General model building and experiment on traction performance prediction based on APSO algorithm. Trans. Chin. Soc. Agric. Mach. 2024, 55, 519–529. [Google Scholar]

- Wang, Q.; Wang, X.D.; Wang, W.; Zhang, S.; Cui, Y.J. Resistance adaptive operation control of electric tractor ploughing unit. J. Agric. Mech. Res. 2025, 47, 224–229. [Google Scholar]

- Sun, X.; Song, Y.; Wang, Y.; Qian, J.; Lu, Z.; Wang, T. Design and test of a tractor electro-hydraulic-suspension tillage-depth and loading-control system test bench. Agriculture 2023, 13, 1884. [Google Scholar] [CrossRef]

- Wang, S.Y.; Liu, Z.; Li, R.C.; Xu, J.K.; Liu, Y.J. Variable Weight Force-Position Mixed Control of High-power Tractor Based on Soil Specific Resistnce. Trans. Chin. Soc. Agric. Mach. 2018, 49, 351–357. [Google Scholar]

- Liu, J.K. Matlab Simulation for Sliding Mode Control, 1st ed.; Tsinghua University Press: Beijing, China, 2005; pp. 417–422. [Google Scholar]

- Aravind, K.; Paja, P.; Manuel, P. Task-based agricultural mobile robots in arable farming: A review. Span. J. Agric. Res. 2017, 15, e02R01. [Google Scholar] [CrossRef]

- Cho, W.K.; Yoon, Y.G.; You, S.H. A Study on Sway Stability Control Methods for Tractor-Trailer System Using Rear Wheel Steering. IEEE Access 2024, 12, 66952–66963. [Google Scholar] [CrossRef]

- An, Y.H.; Wang, L.; Deng, X.T.; Chen, H.; Lu, Z.X.; Wang, T. Research on Differential Steering Dynamics Control of Four-Wheel Independent Drive Electric Tractor. Agriculture 2023, 13, 1758. [Google Scholar] [CrossRef]

- Sun, X.X.; Lu, Z.X.; Song, Y.; Cheng, Z.; Jiang, C.X.; Qian, J.; Lu, Y. Development Status and Research Progress of a Tractor Electro-Hydraulic Hitch System. Agriculture 2022, 12, 1547. [Google Scholar] [CrossRef]

- Han, J.; Yan, X.; Tang, H. Method of controlling tillage depth for agricultural tractors considering engine load characteristics. Biosyst. Eng. 2023, 227, 95–106. [Google Scholar] [CrossRef]

| Condition | Target Tillage Depth (cm) | Random Variation Interval of Soil Specific Resistance (N/cm2) |

|---|---|---|

| 1 | 16 | 2.5~3.5 |

| 2 | 20 | 3.5~4.5 |

| 3 | 25 | 4.5~5.5 |

| ID | Data | Signal | Value After Analytical Solution |

|---|---|---|---|

| 220 | 01 C8 00 02 32 32 23 41 | Operational mode | Automatic control |

| Target tillage depth | 200 | ||

| Target speed | 2 | ||

| Height limit | 50 | ||

| Falling speed | 50 | ||

| Soil specific resistance | 2 | ||

| Control method | Position control | ||

| 120 | 00 02 C8 00 B7 00 74 13 | Fault code | 0 |

| Condition code | Falling | ||

| Actual tillage depth | 200 | ||

| Tillage depth sensor | 183 | ||

| Draft sensor | 4980 | ||

| 78 | 02 | Actual speed | 2 |

| Working Condition | Method | Traction Efficiency | Fuel Consumption Rate (g·(kW·h)−1) | Overall Machine Efficiency–Economy |

|---|---|---|---|---|

| 1 | Tillage Depth Control | 61.2% | 399.1 | 0.14 |

| Coordinated Control | 75.3% | 357.8 | 0.21 | |

| 2 | Tillage Depth Control | 60.6% | 401.3 | 0.15 |

| Coordinated Control | 74.4% | 368.1 | 0.20 | |

| 3 | Tillage Depth Control | 60.1% | 404.1 | 0.15 |

| Coordinated Control | 73.4% | 375.4 | 0.19 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, X.; Song, Y.; Lu, Z.; Deng, X. Research on a Coordinated Control Method of Tractor Electro-Hydraulic Hitch Tillage Depth and Travel Speed Based on Optimal Overall Efficiency and Economic Performance. Agriculture 2025, 15, 2232. https://doi.org/10.3390/agriculture15212232

Sun X, Song Y, Lu Z, Deng X. Research on a Coordinated Control Method of Tractor Electro-Hydraulic Hitch Tillage Depth and Travel Speed Based on Optimal Overall Efficiency and Economic Performance. Agriculture. 2025; 15(21):2232. https://doi.org/10.3390/agriculture15212232

Chicago/Turabian StyleSun, Xiaoxu, Yue Song, Zhixiong Lu, and Xiaoting Deng. 2025. "Research on a Coordinated Control Method of Tractor Electro-Hydraulic Hitch Tillage Depth and Travel Speed Based on Optimal Overall Efficiency and Economic Performance" Agriculture 15, no. 21: 2232. https://doi.org/10.3390/agriculture15212232

APA StyleSun, X., Song, Y., Lu, Z., & Deng, X. (2025). Research on a Coordinated Control Method of Tractor Electro-Hydraulic Hitch Tillage Depth and Travel Speed Based on Optimal Overall Efficiency and Economic Performance. Agriculture, 15(21), 2232. https://doi.org/10.3390/agriculture15212232