Abstract

This paper presents the results of a study on the influence of juice extraction and thermosonication methods on the content of microorganisms in juices stored under refrigeration and in ambient temperature. It was determined that the type of extraction device used influenced the content of microorganisms in juice. The lowest total content of mesophilic microorganisms was obtained in juice extracted on a piston press, and the highest was obtained using a centrifuge. The additional purpose was to evaluate the influence of ultrasonic treatment on selected parameters of apple juice quality: cloud value, antioxidant activity, total phenolic content, flavonoid content, and anthocyanin content. The ultrasound treatment of juice from the piston press was conducted at two levels of radiated sonic power so as to obtain sublethal and lethal temperatures of the juice. It was demonstrated that only ultrasound treatment within the range of lethal temperatures was sufficient to deactivate microorganisms. It was determined that thermosonication did not influence the deterioration of chemical properties of juices, with the exception of decreased anthocyanin content. The described method enables prolongation of the shelf life of fresh apple juice under refrigeration to 168 hours (7 days).

1. Introduction

Apples (Malus domestica) are a source of numerous valuable phenolic compounds with documented antioxidant, antibacterial, antiviral, anti-inflammatory, antiallergic, and even anticancer properties [1,2]. This fruit is typically consumed fresh or processed into juice. Under industrial conditions, juices are preserved primarily with the help of thermal methods. Research has demonstrated that the use of these method influences the degradation of polyphenols and reduces nutritional value [3]. An interest by consumers in high-quality foods with minimal processing has been observed in recent years. Juices with several-day best-before dates are an example of this kind of food. Eliminating microbial hazards creates an issue in the production of several-day juices. In order to preserve these juices, light pasteurization, a pulsed electric field, and combined methods are used [4]. Despite the systems of food safety assurance in use, cases of poisoning caused by juice consumption are still recorded around the world [5,6,7]. Considering the low degree of processing, juice can form reservoirs of natural microflora and be a carrier of undesirable microorganisms. Microbial contamination occurs at the raw material cultivation stage, where there is exposure to contamination from soil, water, and even air, as well as during transport and storage [8]. It has been proven that increased use of natural fertilizer, commonly in the cultivation of fruits and vegetables on organic farms, is the source of pathogens in numerous cases. The list of microorganisms present will differ depending on the season and climatic changes [9].

Ultrasound has been increasingly used in food processing in recent years [10,11]. High-intensity and high-power active ultrasound techniques have the capacity to interact with raw material (matter) and can modify the course of physical or chemical processes. Ultrasound can be used to increase pressing efficacy [11], to support the process of extracting different components (herb extracts, polyphenols, aromatic compounds, polysaccharides) [12,13,14], and to improve the quality of obtained products [15]. Some authors have studied the potential of ultrasound for use in the preservation of fruit juice [16,17]. However, some researchers have suggested that ultrasonic treatment at low temperatures is not very efficient for inactivation of some microorganisms [18]. Therefore, in many cases ultrasound is combined with moderate heat, a process known as thermosonication [19,20]. This method increases the inactivation of microorganisms by the combined effects of heat and cavitation [21,22,23,24]. The efficiency of sonication can also be enhanced through gamma irradiation [25], the use of high pressure [26], or the introduction of additional substances [25]. Despite numerous studies, knowledge on the application of active ultrasound (US) to preserve fresh juice is insufficient. From a practical standpoint, the method of thermosonication is rather expensive, and researchers have attempted to increase, reduce, or stabilize juice temperature by introducing an additional cooling–heating system [22,27]. In our study, we propose using the heat generated by ultrasound to heat tested juice samples, which in industrial practice would considerably reduce the costs associated with the energy consumption of the thermosonication process.

Another issue in the production of minimally processed fruit juices is selecting the method of obtaining them. Typical methods include pressing with the use of piston presses, cylinder presses, screw presses, or centrifuges (decanters). The obtained juice is characterized by variable physical and chemical properties, which may influence the presence and development of microflora. Thus far, no studies have been carried out on the influence of the extraction method on the microorganism content in juice.

The primary purpose of the study was to assess the influence of juice extraction and ultrasound treatment (thermosonication) methods on the content of microorganisms in juices stored under refrigeration and in ambient temperature. An additional purpose was to evaluate the influence of ultrasonic treatment on selected parameters of apple juice quality: cloud value, antioxidant activity, total phenolic content, flavonoid content, and anthocyanin content.

2. Materials and Methods

2.1. Chemicals

Methanol, Folin–Ciocalteu reagent, catechin, 2,2-diphenyl-1-picrylhydrazyl (DPPH), sodium nitrite, sodium carbonate, sodium hydroxide, aluminum trichloride, potassium chloride buffer, and sodium acetate buffer were purchased from Sigma-Aldrich (Darmstadt, Germany). All other chemicals used in the experiment were of analytical grade.

2.2. Apple Juice Preparation

The research was conducted with the use of Idared apples purchased from the Rylex Group (Błędów, Poland). The tests were conducted on healthy fruits without any mechanical damage. Prior to the tests, the fruits were washed, dried on blotting paper, and divided into portions of 500 g each. Before being pressed in a piston press, the apples were crushed using an MKJ250 shredding machine (Spomasz Nakło, Poland) with a standard grating disk with 8 mm holes. Juice was obtained using three devices: a self-made laboratory piston press [28], a double-screw press (Green Star Elite 3000, Tribest), and a decanter (Zelmer, Poland). Prior to starting the testing, the devices were carefully cleaned and disinfected. The extracted juice was collected in sterilized containers and stored in a cold place before the subsequent experiment stage.

2.3. Experimental Model

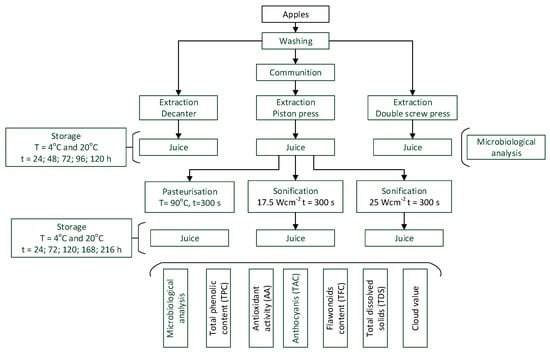

The experimental chart is presented in Figure 1.

Figure 1.

Experimental chart.

The first part of the experiment was carried out in the following model system. Juice was obtained using a piston press, a double-screw press, and a decanter. The obtained juice was collected in sterilized containers. Fresh juice as a control sample was immediately provided for microbiological testing. The remaining samples were stored for 120 hours (5 days) in closed containers at 4 °C in a refrigerator (Polar, Poland) and at 20 °C in a heat chamber (SUP-4, Wamed, Warsaw, Poland). On all samples, inoculation was performed six times: directly after extraction, and after 24 h, 48 h, 72 h, 96 h, and 120 h in three repetitions.

The second part of the experiment involved preserving the juice with the use of ultrasound treatment and pasteurization. Following the assumptions of the experiment, tests were performed on juice from the device on which the least microbial colonies were obtained. Juice was stored for 216 hours (9 days) in closed containers at 4 °C in a refrigerator (Polar, Poland) and at 20 °C in a heat chamber (SUP-4, Wamed, Warsaw, Poland). On all juice samples, inoculation was performed after 24 h, 72 h, 120 h, 168 h, and 216 h in three replicates.

2.4. Sonication and Thermal Treatment

Sonication was performed using an ultrasonic processor (Sonic VC 750, Sonics & Materials, Inc., USA) at a frequency of 20 kHz. The generator was a horn-type (19 mm diameter). All experiments were conducted on samples of 200 mL of juice without additional stirring. Two types of juice processing with ultrasound were used. The parameters of the first ultrasonic treatment (U1) were as follows: radiated sonic power: 17.5 W·cm−2, time of treatment: 300 s; second ultrasonic treatment (U2): 25 W·cm−2 and 300 s. During the sonication process, juice temperature was measured with the use of a thermocouple. In the first phase, testing was carried out to determine the sonication parameters so that the final juice temperature would remain in the sublethal and lethal thermosonication range.

The pasteurization process was carried out using a water bath; 200 mL portions of juice were pasteurized in water at 90 °C for 300 s. Pasteurized juice was treated as a control sample.

2.5. Chemical Testing

2.5.1. Total Phenolic Content (TPC)

Total phenolic content (TPC) of apple juice was determined according to the Folin–Ciocalteu (FC) method [29] with slight modification. Gallic acid was used as a standard, and methanol gallic acid solution (1 mg/1 mL) was diluted with methanol to give appropriate concentrations for a standard curve. Sample extract (0.2 mL) was mixed with 2 mL of methanol in a 25 mL volumetric flask. Then Folin–Ciocalteu reagent (2 mL, diluted 1:10) was added and allowed to react for 3 minutes. Next, 2 mL of Na2CO3 solution was added and the mixture was made up to 25 mL with distilled water. After 30 minutes at room temperature in a dark place, absorbance at 760 nm was measured using a spectrophotometer (UV-1800, Shimadzu, Japan). The results were expressed as mg gallic acid equivalent/100 mL fresh juice (mg GAE/100 mL).

2.5.2. Antioxidant Activity (AA)

The antioxidant activity of apple juice was evaluated using DPPH assay. For the analysis, 0.2 mL of apple juice was mixed with an aliquot of 5.8 mL of freshly prepared 6·10−5 M DPPH radical in methanol. After 30 minutes standing at room temperature, spectrophotometric absorbance at 516 nm was measured using methanol as a blank. Antioxidant activity was expressed as percentage inhibition of the DPPH radical from the equation [30]

2.5.3. Total Flavonoid Content (TFC)

The total flavonoid content was analyzed by the method presented in [31] with slight modification. The prepared apple juice (0.2 mL) was mixed with 4 mL of deionized water and subsequently with 0.3 mL of NaNO2 solution (5%). After 6 minutes, 0.3 mL of 10% methanolic solution of AlCl3 × 6H2O was added, then after 5 min, 2 mL of NaOH solution (4%) was added to the mixture. Next, water was added to bring the final volume to 10 mL, and the mixture was thoroughly mixed and allowed to stand for another 15 min. Absorbance was measured with a UV–VIS spectrophotometer (UV-1800, Shimadzu, Japan) at a wavelength of 510 nm. The results were expressed as mg catechin equivalent/100 mL fresh juice (mg CE/100 mL).

2.5.4. Total Anthocyanin Content (TAC)

The anthocyanin content was assayed with a method proposed by Wrolstade’a [32] using potassium chloride buffer (0.025 M, pH 1.0) and sodium acetate buffer (0.4 M, pH 4.5). Juice sample (0.5 mL) was mixed with 9.5 mL of each buffer solution, and absorbance (A) was measured at 520 and 700 nm. Then, the anthocyanin content was calculated with the equation

where

MW is molecular weight of malvidin-3-O-glucoside (493.2 g/mol), DF is dilution factor, 1 is path length (1 cm), ε is an extinction coefficient (28,000 L/mol/cm), and 1000 is conversion for mg/100 mL.

2.5.5. Total Dissolved Solids (TDS)

Total dissolved solids of apple juice were determined according to the method reported by Jaeger et al. [33] with slight modification. Juice samples were centrifuged at 6500 rpm for 20 min (Megafuge 1.0R, Heraeus, Hanau, Germany) to remove particles before measurement.

2.5.6. Cloud Value

The cloud value of apple juice was determined according to the method reported by Versteeg et al. [34] with slight modification. Apple juice samples (10 mL) were centrifuged at 6000 rpm for 10 min at room temperature (20 °C). Cloud value was measured as supernatant absorbance at 660 nm using a spectrophotometer (UV-1800, Shimadzu, Japan) with distilled water serving as a blank.

2.6. Microbial Test

The surface culture method was used to determine the total number of mesophilic microorganisms in 1 cm3. The cultures were made on biocrop PCA standardized medium, and 1 cm³ of sample was applied to Petri dishes with solidified support. The material was spread with a sterile pad on the entire surface of the substrate until dry. Plates were incubated at 30 °C for 72 h, after which colonies were counted. The results are presented as the arithmetic mean of three replicates. The total number of microorganisms was determined in line with ISO standards [35].

2.7. Statistical Analysis

Each measurement was made in three replicates. Statistical analysis was conducted in Statistica, using analysis of variance (ANOVA) [36]. The significance of differences was tested with the help of Tukey’s least significant difference (LSD) test at a significance level of P < 0.05. The results of the experiments are presented in tables and graphs. The tables present the mean values with standard deviations, while the graphs present mean values and whiskers representing standard deviations.

3. Results and Discussion

3.1. Determination of Final Juice Temperature

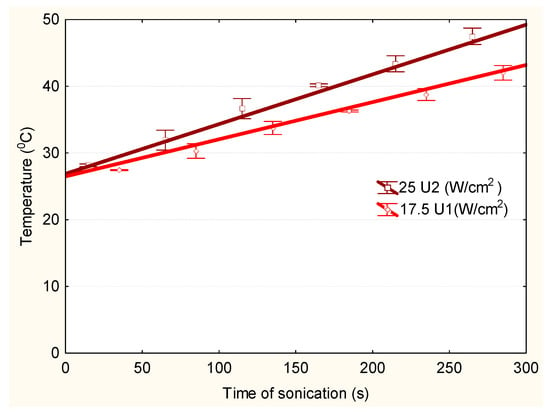

Thermosonication can be classified into two groups: sublethal (below 45 °C) and lethal (above 45 °C [17,37]. The purpose of the experiment was to select sonication parameters so that the final juice temperature remained in both the sublethal and lethal thermosonication range. The final juice temperature was the result of the combination of juice volume (200 mL), ultrasound intensity, and processing time (300 s), and was 42.5 °C and 48.5 °C for 17.5 W cm−2 (U1) and 25 W cm−2 (U2) intensity, respectively. Changes in juice temperature during ultrasound treatment are presented in Figure 2.

Figure 2.

Influence of sonication time on temperature of apple juice. Error bars represent standard deviations.

3.2. Influence of Device Type on Total Mesophilic Microorganism Content in Apple Juice

Results of testing of juices concerning the influence of device type and time and temperature of storage are presented in Table 1 and Table 2. Mean total microorganisms in the studied juices directly after production was low and ranged between 4 × 101 and 4 × 102 colony forming units (cfu)/mL. As demonstrated by research, the microbial content in fresh juice is variable and depends on the raw material state and production conditions. Results of the study conducted by Simforian et al. [38], carried out in several tens of samples, demonstrated that the total microorganism count in juice ranged between 3.65 and 9.31 × 102 cfu/mL. On the other hand, Gientka et al. [39] determined that the total microorganism content in one-day carrot juice was from 3.1 × 105 to 9.1 × 105 cfu/mL. The low microbial content found in our study is primarily associated with the experimental conditions, i.e., the fruits were carefully cleaned and the devices were disinfected. Thus far, no permissible level of microorganisms has been established for minimally processed products [40]. The applicable microbiological criterion determining the number of mesophilic microorganisms to be 103–104 cfu/mL only concerns pasteurized juices [41].

Table 1.

Total number of mesophilic microorganisms (colony forming units (cfu)/mL) in apple juice obtained with various devices stored at 4 °C. Different letters in the same column indicate values significantly different at P < 0.05.

Table 2.

Total number of mesophilic microorganisms (cfu/mL) in apple juice obtained with various devices stored at 20 °C. Different letters in the same column indicate values significantly different at P < 0.05.

Under experimental conditions, the lowest total microorganism content directly after extraction was recorded in the case of juice obtained using a piston press. Juice from the double-screw press was characterized by close to twofold higher total microorganism count. A very high, 10-fold higher total microorganism count as compared with the piston press was found for juice obtained using the decanter. A visual assessment of juice from the decanter indicated high pulp and skin content. It is possible that microorganisms inhabiting the surface of the skin were introduced with it to the juice, and the solids formed a medium for bacterial growth.

During juice storage, a significant increase of total mesophilic microorganism count occurred in all tested samples, and a clearly less pronounced increase was observed in samples stored in refrigeration conditions (Table 1 and Table 2). In the case of juice obtained with the use of the piston press and stored at 4 °C, a close to three-fold increase of total mesophilic microorganism count was observed after 96 hours (4 days), but the number was over three-fold lower than in juice obtained with the use of the decanter. After 120 hours (5 days), the total microorganism count in juice obtained using the basket, double-screw press, and decanter was nonquantifiable (nqf). In the case of juice stored at 20 °C after 72 hours (3 days), independent of the production method, a rapid decrease in quality was recorded associated with increased total microbial count, and the samples were characterized by nonquantifiable colony forming units or demonstrated spilled structure. The slowest growth of total mesophilic microbial count independent of storage conditions was observed in the case of juice from the piston press. Therefore, this juice underwent further detailed testing. As demonstrated by the experiments (Table 1), juice produced in accordance with our procedure should not be stored in refrigeration conditions for more than 96 hours (4 days).

3.3. Influence of Ultrasound Treatment on Microorganism Content in Apple Juice

Juice preservation with the use of pasteurization (P) resulted in complete destruction of mesophilic microorganisms. During storage of pasteurized juice independent of storage temperature, the total microbial count was 0 cfu/mL (Table 3 and Table 4). After treatment U1, i.e., at an intensity of 17.5 W cm−2, in freshly extracted juice the microorganisms were deactivated. During storage of juice at 4 °C for 72 hours (3 days) their growth was not observed. After 120 hours (5 days) the total microorganism count was nonquantifiable for juice stored at 4 °C and 20 °C. Applying treatment U2 at an intensity of 25 W cm−2 turned out to be efficient in terms of prolonging the shelf life of juice stored at 4 °C. Over 144 hours (7 days), the amount of microorganisms remained at a low acceptable level, and only after 216 hours (9 days) the quality of juice deteriorated drastically and the total microorganism count was nonquantifiable. The efficacy of ultrasound on microorganisms depends on the physicochemical properties of food, the volume of food being processed, the types of microorganisms, the treatment temperature, the power level, and the duration of ultrasound treatment [25,42,43]. The efficacy of treatment U2 (25 W cm−2) in the destruction of microorganisms in juice is associated with a synergistic effect. On the one hand, the microorganism destruction is associated with the phenomenon of cavitation and the effect of air bubbles on their cell walls (source); on the other hand, the juice temperature increased to 48.5 °C during sonication, above the lethal level [17]. This was confirmed by the study of Demirdöven and Baysal [44], who demonstrated that using only ultrasound to destroy microorganisms is insufficient and combined methods should be used for this purpose.

Table 3.

Total number of mesophilic microorganisms (cfu/mL) in apple juice from piston press after ultrasound treatment stored at 4 °C. Different letters in the same column indicate values significantly different at P < 0.05.

Table 4.

Total number of mesophilic microorganisms (cfu/mL) in apple juice from piston press after ultrasound treatment stored at 20 °C. Different letters in the same column indicate values significantly different at P < 0.05.

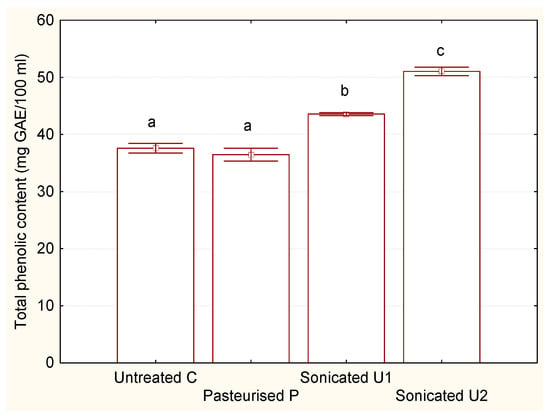

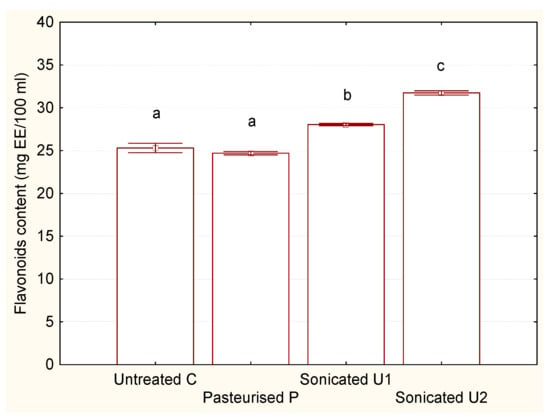

3.4. Total Phenolic and Flavonoid Content

Figure 3 and Figure 4 present the influence of various treatment methods on the polyphenol and flavonoid content in apple juice. Pasteurization did not influence the polyphenol content in comparison to control sample. In the case of samples subjected to the action of ultrasound, a statistically significant increase in the value of the tested parameter was observed. This change relative to control amounted to 16% for treatment U1 (17.5 W cm−2) and 36% for treatment U2 (25 W cm−2).

Figure 3.

Effect of preservation method on total phenolic content in apple juice. Error bars represent standard deviations. Values that share the same letter are not significantly different at P < 0.05.

Figure 4.

Effect of preservation method on flavonoid content in apple juice. Error bars represent standard deviations. Values that share the same letter are not significantly different at P < 0.05.

A similar tendency was seen for flavonoid content. Pasteurization did not result in changed flavonoid content in juice, but treatments U1 and U2 resulted in a statistically significant increase of flavonoid content. Increased flavonoid content in juice was observed after ultrasound treatment, from 28.04 to 31.74 mg CAE/100 mL. The flavonoid content in the control sample was 25.30 mg CAE/100 mL.

The obtained results are in line with data obtained by other authors. Bhat et al. [45] observed increased polyphenol and flavonoid content during ultrasound treatment of lime juice. Abid et al. [46] obtained higher content of tested substances during sonication of apple juice (cv. Fuji). Several theories arose, aiming to explain the possible cause of the higher amount of polyphenol compounds in juices processed with ultrasound. The first theory speaks to the formation of hydroxyl radicals due to the effect of ultrasound followed by their bonding with aromatic rings of phenolic compounds. The addition of a second hydroxyl group in the ortho- or para-position has been reported to enhance the antioxidant activity of phenolic compounds [47]. Another explanation is the change of polyphenol oxidase (PPO) activity post-sonication treatment [45].

The third theory explaining the cause of increased polyphenol content is that cell walls of solids in juice are disrupted due to cavitation. This process leads to the release of certain chemically bound polyphenols, resulting in their increased availability. In our opinion, the latter mechanism is the most likely and influences, to the greatest degree, the increased polyphenols detected in ultrasound-processed juice. This is confirmed by the differences seen between the content of solids in juice subjected to ultrasound treatment and non-processed juice.

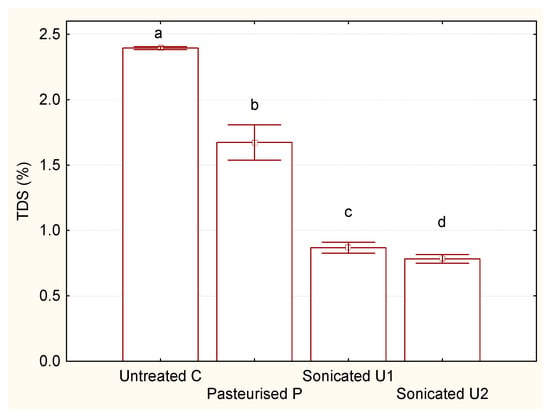

Changes in the content of solids due to ultrasound treatment are presented in Figure 5.

Figure 5.

Effect of preservation method on solids content in apple juice. Error bars represent standard deviations. Values that share the same letter are not significantly different at P < 0.05.

Ultrasound treatment resulted in a 63.4% decrease in the content of solids for U1 (17.5 W cm−2) and 67.2% for U2 (25 W cm−2). Disruption of solids resulted in increased availability of bioactive particles and thus increased detection of polyphenols in apple juice. We would like to clearly emphasize that ultrasound treatment does not increase the content of polyphenols and only increases their availability due to disintegration of solids contained in apple juice.

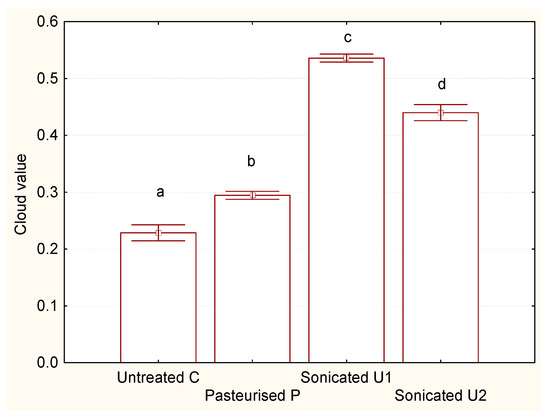

3.5. Cloud Value

Cloud value is related to particle suspensions, composed of a mixture of protein, pectin, lipids, and other minor components [48], and is an important parameter of apple juice quality. The influence of various treatment methods on cloud value is presented in Figure 6.

Figure 6.

Effect of preservation method on cloud value in apple juice. Error bars represent standard deviations. Values that share the same letter are not significantly different at P < 0.05.

The applied juice preservation methods (P, U1, and U2) increased the cloud value of apple juice by 28% for pasteurized juice as compared to the control sample. In the case of samples subjected to ultrasound, the change in cloud value depended on the intensity. Increased cloud value compared to control was 134% for juice sonicated at 17.5 W·cm−2 intensity (treatment U1) and 92% at 25 W·cm−2 intensity (treatment U2). A similar tendency was reported by other authors [46,49,50], who also observed increased cloud value of apple and acai juices after ultrasonic treatment.

The reason for the increased cloud value in sonicated apple juice is mechanisms induced by cavitation. These phenomena cause a breakdown of solid particles of juice and facilitate its homogenization. Seshadri et al. [51] suggested that ultrasound may break linear pectin molecules and reduce the molecular weight of complex compounds. Comparing treatments U1 and U2, it is worth noting that increased ultrasonic intensity caused a significant decrease (p < 0.05) in cloud value. This may be related to the increased sonic energy and further reduction of suspended particles, providing greater transparency of apple juice.

Decreased cloud value under the influence of ultrasound may also be caused by the disintegration of liquid molecules, including lipid molecules, contained in fruit juice. Dispersion system transparency depends on the degree of dispersion of molecules of the dispersed phase in the continuous phase. When the dispersed phase is sufficiently disintegrated, the whole system becomes transparent. The efficiency of ultrasound in creating transparent dispersion systems has been confirmed by numerous authors [52,53].

A similar tendency was observed by Tiwari et al. [54], who also reported an increased cloud value of orange juice after ultrasonic treatment and a slow decrease with increased ultrasound intensity. However, it should be emphasized that in each case of ultrasound treatment, the cloud value remained at a considerably higher level compared with control sample.

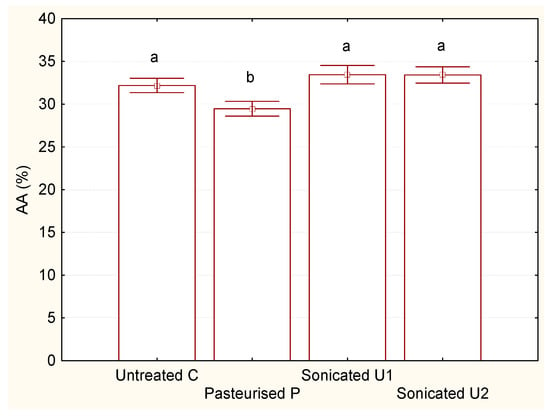

3.6. Antioxidant Activity of Apple Juice

The antioxidant activity of bioactive substances contained in apple juice is as significant a determinant of quality as the total polyphenol content. The influence of treatment type on the antioxidant activity of apple juice is presented in Figure 7. A minor though statistically significant reduction of antioxidant activity of apple juice was observed after pasteurization. In the case of ultrasound treatment, no statistically significant changes of antioxidant activity were observed.

Figure 7.

Effect of preservation method on antioxidant activity of apple juice. Error bars represent standard deviations. Values that share the same letter are not significantly different at P < 0.05.

In this field, our results differ from those obtained by other authors. Bhat et al. [45] found increased antioxidant activity during sonication of lime juice, and Abid et al. [46] during ultrasound treatment of apple juice.

Free radical scavenging capacity is typically closely correlated with polyphenol content in juice. Numerous studies have demonstrated a strong relationship between the polyphenol concentration and antioxidant capacity of foods [55,56,57,58,59].

On the other hand, Wolfe et al. [60] did not find any relationship between antioxidant capacity and total phenolic content in apple tissues. This lack of correlation could be due to the weakened antioxidant capacity of polyphenols as a result of the action of cavitation. Another cause may be the decomposition of other bioactive substances influencing the total capacity of juice to scavenge free radicals.

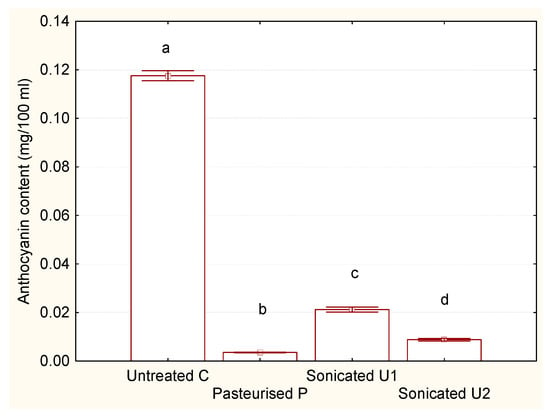

3.7. Anthocyanin Content

Anthocyanins are natural plant pigments widely distributed in the environment, classified among flavonoids [61]. Anthocyanin content is an important determinant of the color of various fruits. Cyanidin is one of the most common pigments found in apples and is primarily responsible for the red coloration of their skin [62,63]. Anthocyanins exhibit antioxidant properties through quenching of free oxygen radicals, including singlet oxygen, superoxide anion radical, and hydroxyl radical. They also exhibit detoxification, anti-angiogenic, and anti-inflammatory activity; they can also induce apoptosis and inhibit digestive enzymes [64].

Results concerning the influence of various types of treatment of apple juice on anthocyanin content are presented in Figure 8. All applied methods of juice preservation resulted in a considerable decrease of anthocyanin content. The most unfavorable influence was exhibited by pasteurization, which showed as much as a 97% decrease of anthocyanin content. In the case of ultrasound treatment, the decrease of anthocyanin content depended on the force of ultrasound and amounted to 92% for 17.5 W·cm−2 intensity (treatment U1) and 82% for 25 W·cm−2 intensity (treatment U2).

Figure 8.

Effect of preservation method on anthocyanin content in apple juice. Error bars represent standard deviations. Values that share the same letter are not significantly different at P < 0.05.

The process of anthocyanin degradation under the influence of heat treatment is widely known [65,66]. Anthocyanin breakdown is mainly caused by covalent bond cleavage or acceleration of the oxidation process as a result of increased temperature [66].

The results regarding the effect of ultrasonic treatment on the stability of anthocyanins in apple juice differ from those obtained by other authors. During ultrasound treatment of apple juice, Abid et al. [46] did not observe a statistically significant reduction of anthocyanin content. However, it should be noted that the authors used considerably lower intensity of the ultrasound field (2.0 W·cm−2). Moreover, the unfavorable influence of ultrasound on anthocyanin stability can also be partially explained by the lack of correlation between total polyphenol content and antioxidant activity.

On the other hand, Dubrović et al. [67] observed a statistically significant decrease in anthocyanin content in ultrasound processed strawberry juice. Degradation of anthocyanin during ultrasound treatment could be explained by oxidation reaction promoted by the interaction of free radicals, which leads to destruction by the opening of rings and formation of chalcone [68].

4. Conclusions

This study shows that the type of extraction device used influences the content of microorganisms in juice. Among the analyzed devices, the lowest total content of mesophilic microorganisms was obtained in juice extracted on a piston press and the highest using a centrifuge. The effect of ultrasonic treatment on the inactivation of microorganisms depends on the process parameters. We found that only ultrasound treatment within the range of lethal temperatures is sufficient to deactivate microorganisms.

The tested chemical properties depended significantly on the nature of juice treatment. The study confirms that sonication significantly improved polyphenol and flavonoid content. On the other hand, pasteurization did not have any influence on these components. Each pretreatment type resulted in a reduction of total dissolved solids in juice. Ultrasonic treatment did not have an impact on the antioxidant activity of juice, whereas it had a minor influence on decreasing this parameter. Both applied methods of juice preservation (sonication and pasteurization) resulted in a considerable decrease in the anthocyanin content.

The study indicates a need for appropriate selection of pressing devices for production of juices with a shelf life of several days. The results suggest that ultrasonic treatment may be successfully employed for the preservation of apple juice with improved microbial safety and quality.

Author Contributions

Conceptualization, Z.K. and R.N.; Methodology, Z.K., R.N., and W.Ż.-S.; Formal analysis, Z.K. and P.S.; Investigation, Z.K., K.W., W.Ż.-S., and M.P.; Data curation, A.S.; Writing—original draft preparation, Z.K. and R.N.; Writing—review and editing, Z.K., R.N., and A.S.; Visualization, Z.K.; Supervision, Z.K. and R.N.; Project administration, Z.K. and R.N.; Funding acquisition, Z.K. and R.N.

Funding

This research received no external funding.

Acknowledgments

The authors would like to thank the technical staff from Department of Food Engineering and Machines. Without their help, the present study would not have been performed.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Hyson, D.A. A comprehensive review of apples and apple components and their relationship to human health. Adv. Nutr. 2011, 2, 408–420. [Google Scholar] [CrossRef] [PubMed]

- Wootton-Beard, P.C.; Ryan, L. Improving public health? The role of antioxidant-rich fruit and vegetable beverages. Food Res. Int. 2011, 44, 3135–3148. [Google Scholar] [CrossRef]

- Markowski, J.; Baron, A.; Quéré, J.-M.L.; Płocharski, W. Composition of clear and cloudy juices from French and Polish apples in relations to processing technology. LWT-Food Sci. Technol. 2015, 62, 813–820. [Google Scholar] [CrossRef]

- Sulaiman, A.; Farid, M.; Silva, F.V. Quality stability and sensory attributes of apple juice processed by thermosonication, pulsed electric field and thermal processing. Food Sci. Technol. Int. 2017, 23, 265–276. [Google Scholar] [CrossRef] [PubMed]

- Parish, M.E. Public health and nonpasteurized fruit juices. Crit. Rev. Microbiol. 1997, 23, 109–119. [Google Scholar] [CrossRef] [PubMed]

- Foster, T.; Vasavada, P.C. Beverage Quality and Safety; CRC Press: Boca Raton, FL, USA, 2003. [Google Scholar]

- Dewanti-Hariyadi, R. Microbiological Quality and Safety of Fruit Juices. Food Rev. Int. 2013, 1, 54–57. [Google Scholar]

- Szwejda, J.; Czapski, J. Warzywa minimalnie przetworzone a skażenie mikrobiologiczne. Przem. Ferment. Owocowo Warzywny 2007, 51, 21–23. [Google Scholar]

- Libudzisz, Z.; Kowal, K.; Żakowska, Z. Mikrobiologia Techniczna Tom 1; Wydawnictwo Naukowe PWN: Warszawa, Poland, 2019. [Google Scholar]

- Chandrapala, J.; Oliver, C.; Kentish, S.; Ashokkumar, M. Ultrasonics in food processing—Food quality assurance and food safety. Trends Food Sci. Technol. 2012, 26, 88–98. [Google Scholar] [CrossRef]

- Knorr, D.; Zenker, M.; Heinz, V.; Lee, D.-U. Applications and potential of ultrasonics in food processing. Trends Food Sci. Technol. 2004, 15, 261–266. [Google Scholar] [CrossRef]

- Kobus, Z. Dry matter extraction from valerian roots (Valeriana officinalis L.) with the help of pulsed acoustic field. Int. Agrophys. 2008, 22, 133–137. [Google Scholar]

- Balachandran, S.; Kentish, S.E.; Mawson, R.; Ashokkumar, M. Ultrasonic enhancement of the supercritical extraction from ginger. Ultrason. Sonochem. 2006, 13, 471–479. [Google Scholar] [CrossRef] [PubMed]

- Kobus, Z.; Wilczyński, K.; Nadulski, R.; Rydzak, L.; Guz, T. Effect of Solvent Polarity on the Efficiency of Ultrasound-assisted Extraction of Polyphenols from Apple Pomace. In Farm Machinery and Processes Management in Sustainable Agriculture, Proceedings of the IX International Scientific Symposium Farm Machinery and Processes Management in Sustainable Agriculture, Lublin, Poland, 22–24 November 2017; Edmund, L., Jacek, U., Bruno, H., Eds.; Reprografic Centre: Lublin, Poland, 2017; pp. 158–163. [Google Scholar]

- Entezari, M.H.; Hagh Nazary, S.; Haddad Khodaparast, M.H. The direct effect of ultrasound on the extraction of date syrup and its micro-organisms. Ultrason. Sonochem. 2004, 11, 379–384. [Google Scholar] [CrossRef] [PubMed]

- Adekunte, A.; Valdramidis, V.P.; Tiwari, B.K.; Slone, N.; Cullen, P.J.; Donnell, C.P.O.; Scannell, A. Resistance of Cronobacter sakazakii in reconstituted powdered infant formula during ultrasound at controlled temperatures: A quantitative approach on microbial responses. Int. J. Food Microbiol. 2010, 142, 53–59. [Google Scholar] [CrossRef] [PubMed]

- Ugarte-Romero, E.; Feng, H.; Martin, S.E. Inactivation of Shigella boydii 18 IDPH and Listeria monocytogenes Scott A with power ultrasound at different acoustic energy densities and temperatures. J. Food Sci. 2007, 72, M103–M107. [Google Scholar] [CrossRef] [PubMed]

- Gabriel, A.A. Microbial inactivation in cloudy apple juice by multi-frequency Dynashock power ultrasound. Ultrason. Sonochem. 2012, 19, 346–351. [Google Scholar] [CrossRef] [PubMed]

- Soria, A.C.; Villamiel, M. Effect of ultrasound on the technological properties and bioactivity of food: A review. Trends Food Sci. Technol. 2010, 21, 323–331. [Google Scholar] [CrossRef]

- Anaya-Esparza, L.M.; Velázquez-Estrada, R.M.; Roig, A.X.; García-Galindo, H.S.; Sayago-Ayerdi, S.G.; Montalvo-González, E. Thermosonication: An alternative processing for fruit and vegetable juices. Trends Food Sci. Technol. 2017, 61, 26–37. [Google Scholar] [CrossRef]

- Evelyn; Silva, F.V.M. High pressure processing pretreatment enhanced the thermosonication inactivation of Alicyclobacillus acidoterrestris spores in orange juice. Food Control 2016, 62, 365–372. [Google Scholar] [CrossRef]

- Ferrario, M.; Alzamora, S.M.; Guerrero, S. Study of the inactivation of spoilage microorganisms in apple juice by pulsed light and ultrasound. Food Microbiol. 2015, 46, 635–642. [Google Scholar] [CrossRef]

- Arroyo, C.; Cebrián, G.; Pagán, R.; Condón, S. Synergistic combination of heat and ultrasonic waves under pressure for Cronobacter sakazakii inactivation in apple juice. Food Control 2012, 1, 342–348. [Google Scholar] [CrossRef]

- Muñoz, A.; Caminiti, I.M.; Palgan, I.; Pataro, G.; Noci, F.; Morgan, D.J.; Cronin, D.A.; Whyte, P.; Ferrari, G.; Lyng, J.G. Effects on Escherichia coli inactivation and quality attributes in apple juice treated by combinations of pulsed light and thermosonication. Food Res. Int. 2012, 45, 299–305. [Google Scholar] [CrossRef]

- Alighourchi, H.; Barzegar, M.; Sahari, M.A.; Abbasi, S. The effects of sonication and gamma irradiation on the inactivation of Escherichia coli and Saccharomyces cerevisiae in pomegranate juice. Iran. J. Microbiol. 2014, 6, 51–58. [Google Scholar]

- Abid, M.; Jabbar, S.; Hu, B.; Hashim, M.M.; Wu, T.; Wu, Z.; Khan, M.A.; Zeng, X. Synergistic impact of sonication and high hydrostatic pressure on microbial and enzymatic inactivation of apple juice. LWT-Food Sci. Technol. 2014, 59, 70–76. [Google Scholar] [CrossRef]

- Sanchez-Rubio, M.; Taboada-Rodríguez, A.; Cava-Roda, R.; López-Gómez, A.; Marín-Iniesta, F. Combined use of thermo-ultrasound and cinnamon leaf essential oil to inactivate Saccharomyces cerevisiae in natural orange and pomegranate juices. LWT-Food Sci. Technol. 2016, 73, 140–146. [Google Scholar] [CrossRef]

- Nadulski, R.; Kobus, Z.; Wilczyński, K.; Zawiślak, K.; Grochowicz, J.; Guz, T. Application of Freezing and Thawing in Apple (Malus domestica) Juice Extraction. J. Food Sci. 2016, 81, E2718–E2725. [Google Scholar] [CrossRef]

- Singleton, V.L.; Orthofer, R.; Lamuela-Raventós, R.M. Analysis of total phenols and other oxidation substrates and antioxidants by means of folin-ciocalteu reagent. Methods Enzymol. 1999, 299, 152–178. [Google Scholar]

- Sharma, S.; Kori, S.; Parmar, A. Surfactant mediated extraction of total phenolic contents (TPC) and antioxidants from fruits juices. Food Chem. 2015, 185, 284–288. [Google Scholar] [CrossRef]

- Zhishen, J.; Mengcheng, T.; Jianming, W. The determination of flavonoid contents in mulberry and their scavenging effects on superoxide radicals. Food Chem. 1999, 64, 555–559. [Google Scholar] [CrossRef]

- AOAC Official Methods of Analysis, 2019. Available online: http://www.aoac.org/aoac_prod_imis/AOAC/Publications/Official_Methods_of_Analysis/AOAC_Member/Publications/OMA/AOAC_Official_Methods_of_Analysis.aspx (accessed on 9 May 2019).

- Jaeger, H.; Schulz, M.; Lu, P.; Knorr, D. Adjustment of milling, mash electroporation and pressing for the development of a PEF assisted juice production in industrial scale. Innov. Food Sci. Emerg. Technol. 2012, 14, 46–60. [Google Scholar] [CrossRef]

- Versteeg, C.; Rombouts, F.M.; Spaansen, C.H.; Pilnik, W. Thermostability and Orange Juice Cloud Destabilizing Properties of Multiple Pectinesterases from Orange. J. Food Sci. 1980, 45, 969–971. [Google Scholar] [CrossRef]

- ISO 4833-1:2013, Microbiology of the Food Chain—Horizontal Method for the Enumeration of Microorganisms—Part 1: Colony Count at 30 Degrees C by the Pour Plate Technique. 2019. Available online: https://www.iso.org/obp/ui/#iso:std:iso:4833:-1:ed-1:v1:en (accessed on 9 May 2019).

- STATISTICA (Data Analysis Software System), V. 12, StatSoft, Inc.: Tulsa, OK, USA. Available online: http://www.statsoft.com (accessed on 2 May 2019).

- Ciccolini, L.; Taillandier, P.; Wilhem, A.M.; Delmas, H.; Strehaiano, P. Low frequency thermo-ultrasonication of Saccharomyces cerevisiae suspensions: Effect of temperature and of ultrasonic power. Chem. Eng. J. 1997, 65, 145–149. [Google Scholar] [CrossRef]

- Simforian, E.; Nonga, H.E.; Ndabikunze, B.K. Assessment of microbiological quality of raw fruit juice vended in Dar es Salaam city, Tanzania. Food Control 2015, 57, 302–307. [Google Scholar] [CrossRef]

- Gientka, I.; Chlebowska-Śmigiel, A.; Sawikowska, K. Zmiany jakości mikrobiologicznej soków marchwiowych podczas próby przechowalniczej. Bromatol. Chem. Toksykol. 2012, 45, 397–401. [Google Scholar]

- Aneja, K.R.; Dhiman, R.; Aggarwal, N.K.; Kumar, V.; Kaur, M. Microbes Associated with Freshly Prepared Juices of Citrus and Carrots, International. Int. J. Food Sci. 2014, 2014, 408085. [Google Scholar] [CrossRef]

- Ordinance of the Minister of Health of 13 January 2003 (Rozporządzenie Ministra Zdrowia z dnia 13 stycznia 2003 r. w sprawie maksymalnych poziomów zanieczyszczeń chemicznych i biologicznych, które mogą znajdować się w żywności, składnikach żywności, dozwolonych substancjach dodatkowych, substancjach pomagających w przetwarzaniu albo na powierzchni żywności). Available online: http://www2.mz.gov.pl/wwwmz/index?ml=pl&mx=0&ma=0901 (accessed on 2 July 2019).

- Lee, H.; Zhou, B.; Liang, W.; Feng, H.; Martin, S.E. Martin, Inactivation of Escherichia coli cells with sonication, manosonication, thermosonication, and manothermosonication: Microbial responses and kinetics modeling. J. Food Eng. 2009, 93, 354–364. [Google Scholar] [CrossRef]

- Piyasena, P.; Mohareb, E.; McKellar, R.C. Inactivation of microbes using ultrasound: A review. Int. J. Food Microbiol. 2003, 87, 207–216. [Google Scholar] [CrossRef]

- Demirdöven, A.; Baysal, T. The Use of Ultrasound and Combined Technologies in Food Preservation. Food Rev. Int. 2008, 25, 1–11. [Google Scholar] [CrossRef]

- Bhat, R.; Kamaruddin, N.S.B.C.; Min-Tze, L.; Karim, A.A. Sonication improves kasturi lime (Citrus microcarpa) juice quality. Ultrason. Sonochem. 2011, 18, 1295–1300. [Google Scholar] [CrossRef]

- Abid, M.; Jabbar, S.; Wu, T.; Hashim, M.M.; Hu, B.; Lei, S.; Zhang, X.; Zeng, X. Effect of ultrasound on different quality parameters of apple juice. Ultrason. Sonochem. 2013, 20, 1182–1187. [Google Scholar] [CrossRef]

- Ashokkumar, M.; Sunartio, D.; Kentish, S.; Mawson, R.; Simons, L.; Vilkhu, K.; Versteeg, C. Modification of food ingredients by ultrasound to improve functionality: A preliminary study on a model system. Innov. Food Sci. Emerg. Technol. 2008, 9, 155–160. [Google Scholar] [CrossRef]

- Baker, R.A.; Cameron, R.G. Clouds of citrus juices and juice drinks. Food Technol. 1999, 53, 64–69. [Google Scholar]

- Abid, M.; Jabbar, S.; Wu, T.; Hashim, M.M.; Hu, B.; Saeeduddin, M.; Zeng, X. Qualitative Assessment of Sonicated Apple Juice during Storage. J. Food Process. Preserv. 2015, 39, 1299–1308. [Google Scholar] [CrossRef]

- Oliveira, A.F.A.; Mar, J.M.; Santos, S.F.; da Silva Júnior, J.L.; Kluczkovski, A.M.; Bakry, A.M.; Bezerra, J.d.A.; Nunomura, R.d.C.S.; Sanches, E.A.; Campelo, P.H. Non-thermal combined treatments in the processing of açai (Euterpe oleracea) juice. Food Chem. 2018, 265, 57–63. [Google Scholar] [CrossRef]

- Seshadri, R.; Weiss, J.; Hulbert, G.J.; Mount, J. Ultrasonic processing influences rheological and optical properties of high-methoxyl pectin dispersions. Food Hydrocoll. 2003, 17, 191–197. [Google Scholar] [CrossRef]

- Leong, T.S.H.; Wooster, T.J.; Kentish, S.E.; Ashokkumar, M. Minimising oil droplet size using ultrasonic emulsification. Ultrason. Sonochem. 2009, 16, 721–727. [Google Scholar] [CrossRef]

- McClements, D.J. Edible nanoemulsions: Fabrication, properties, and functional performance. Soft Matter 2011, 7, 2297–2316. [Google Scholar] [CrossRef]

- Tiwari, B.K.; Muthukumarappan, K.; O’Donnell, C.P.; Cullen, P.J. Effects of sonication on the kinetics of orange juice quality parameters. J. Agric. Food Chem. 2008, 56, 2423–2428. [Google Scholar] [CrossRef]

- He, L.; Xu, H.; Liu, X.; He, W.; Yuan, F.; Hou, Z.; Gao, Y. Identification of phenolic compounds from pomegranate (Punica granatum L.) seed residues and investigation into their antioxidant capacities by HPLC–ABTS+ assay. Food Rev. Int. 2011, 44, 1161–1167. [Google Scholar] [CrossRef]

- Maria do Socorro, M.R.; Alves, R.E.; de Brito, E.S.; Pérez-Jiménez, J.; Saura-Calixto, F.; Mancini-Filho, J. Bioactive compounds and antioxidant capacities of 18 non-traditional tropical fruits from Brazil. Food Chem. 2010, 121, 996–1002. [Google Scholar] [CrossRef]

- Vieira, F.G.; Borges Gda, S.; Copetti, C.; Gonzaga, L.V.; Nunes Eda, C.; Fett, R. Activity and contents of polyphenolic antioxidants in the whole fruit, flesh and peel of three apple cultivars. Arch. Latinoam. Nutr. 2009, 59, 101–106. [Google Scholar]

- Chinnici, F.; Bendini, A.; Gaiani, A.; Riponi, C. Radical scavenging activities of peels and pulps from cv. Golden Delicious apples as related to their phenolic composition. J. Agric. Food Chem. 2004, 52, 4684–4689. [Google Scholar]

- Drogoudi, P.D.; Michailidis, Z.; Pantelidis, G. Peel and flesh antioxidant content and harvest quality characteristics of seven apple cultivars. Sci. Hortic. 2008, 115, 149–153. [Google Scholar] [CrossRef]

- Wolfe, K.; Wu, X.; Liu, R.H. Antioxidant activity of apple peels. J. Agric. Food Chem. 2003, 51, 609–614. [Google Scholar] [CrossRef]

- Cifford, M. Anthocyanins—Nature, occurrence and dietary burden. J. Sci. Food Agric. 2019, 80, 1063–1072. [Google Scholar] [CrossRef]

- Lancaster, J.E.; Dougall, D.D.K. Regulation of skin color in apples. Crit. Rev. Plant Sci. 1992, 10, 487–502. [Google Scholar] [CrossRef]

- Tsao, R.; Yang, R.; Young, J.C.; Zhu, H. Polyphenolic profiles in eight apple cultivars using high-performance liquid chromatography (HPLC). J. Agric. Food Chem. 2003, 51, 6347–6353. [Google Scholar] [CrossRef]

- Miguel, M. Anthocyanins: Antioxidant and/or anti-inflammatory activities. J. Appl. Pharm. Sci. 2011, 1, 7–15. [Google Scholar]

- Dobson, G.; McDougall, G.J.; Stewart, D.; Cubero, M.A.; Karjalainen, R.O. Effects of juice matrix and pasteurization on stability of black currant anthocyanins during storage. J. Food Sci. 2017, 82, 44–52. [Google Scholar] [CrossRef]

- Patras, A.; Brunton, N.P.; O’Donnell, C.; Tiwari, B.K. Effect of thermal processing on anthocyanin stability in foods; mechanisms and kinetics of degradation. Trends Food Sci. Technol. 2010, 21, 3–11. [Google Scholar] [CrossRef]

- Dubrović, I.; Herceg, Z.; Reżek Jambrak, A.; Badanjak, M.; Dragović-Uzelac, V. Effect of high intensity ultrasound and pasteurization on anthocyanin content in strawberry juice. Food Technol. Biotechnol. 2011, 49, 196–204. [Google Scholar]

- Sadilova, E.; Carle, R.; Stintzing, F.C. Thermal degradation of anthocyanins and its impact on color and in vitro antioxidant capacity. Mol. Nutr. Food Res. 2007, 51, 1461–1471. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).