Adaptive Fuzzy Backstepping Sliding Mode Control for a 3-DOF Hydraulic Manipulator with Nonlinear Disturbance Observer for Large Payload Variation

Abstract

Featured Application

Abstract

1. Introduction

- -

- First, the dynamics of the 3-DOF hydraulic manipulator including actuator is derived.

- -

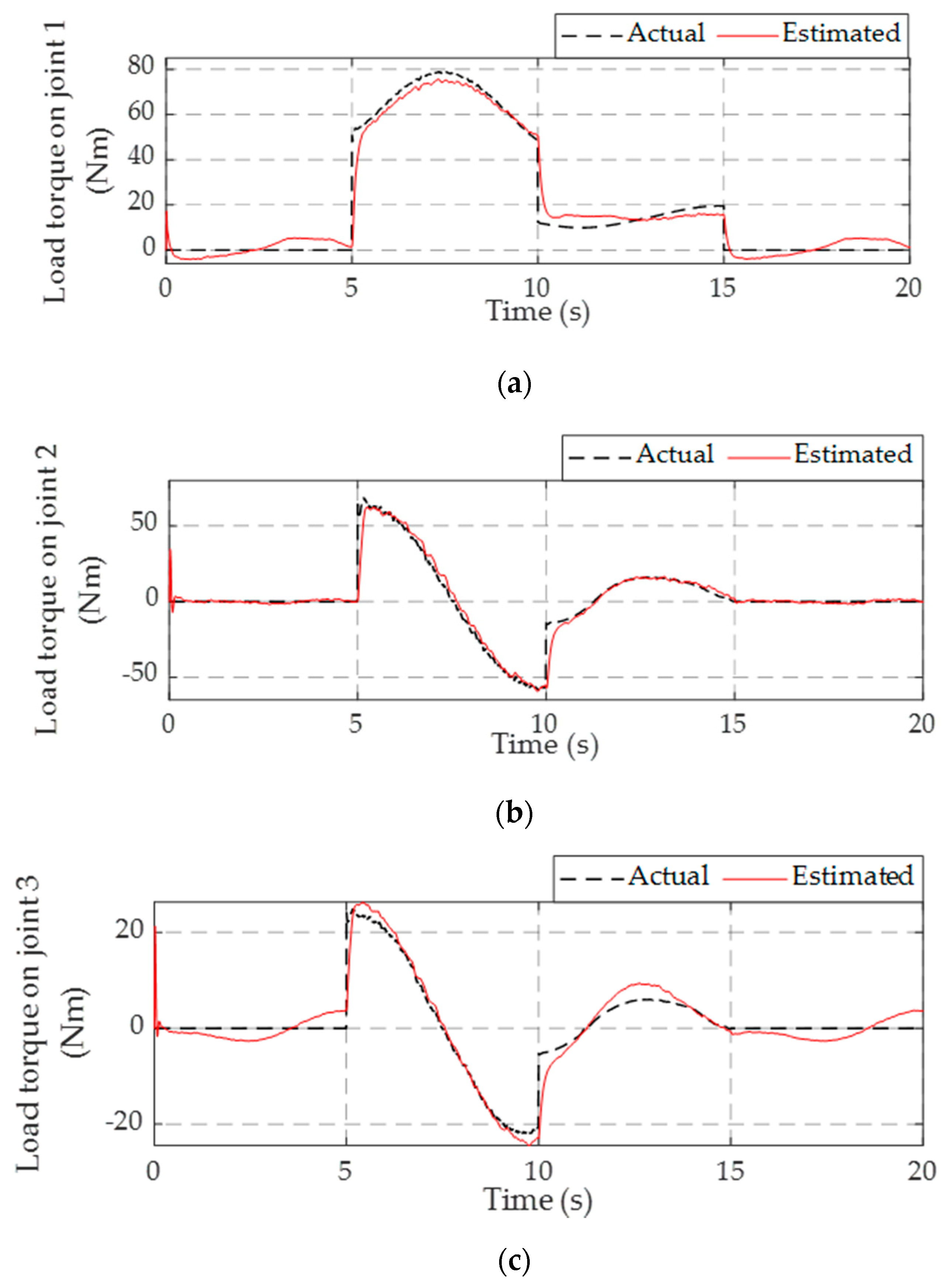

- Second, the backstepping sliding mode control is proposed for the tracking performance and the disturbance observer (DO) is utilized to observe the variation of the external payload torque.

- -

- Third, the two FLS is used to adopt the system performance. The first FLS is applied for tuning switching gain based on its tracking error and error changing rate. The other FLS is used to boost the controller gains with the input is the estimated load torque.

- -

- Finally, some simulated comparisons are given between the proposed controller scheme and the conventional controller to demonstrate the effectiveness of the proposed algorithm.

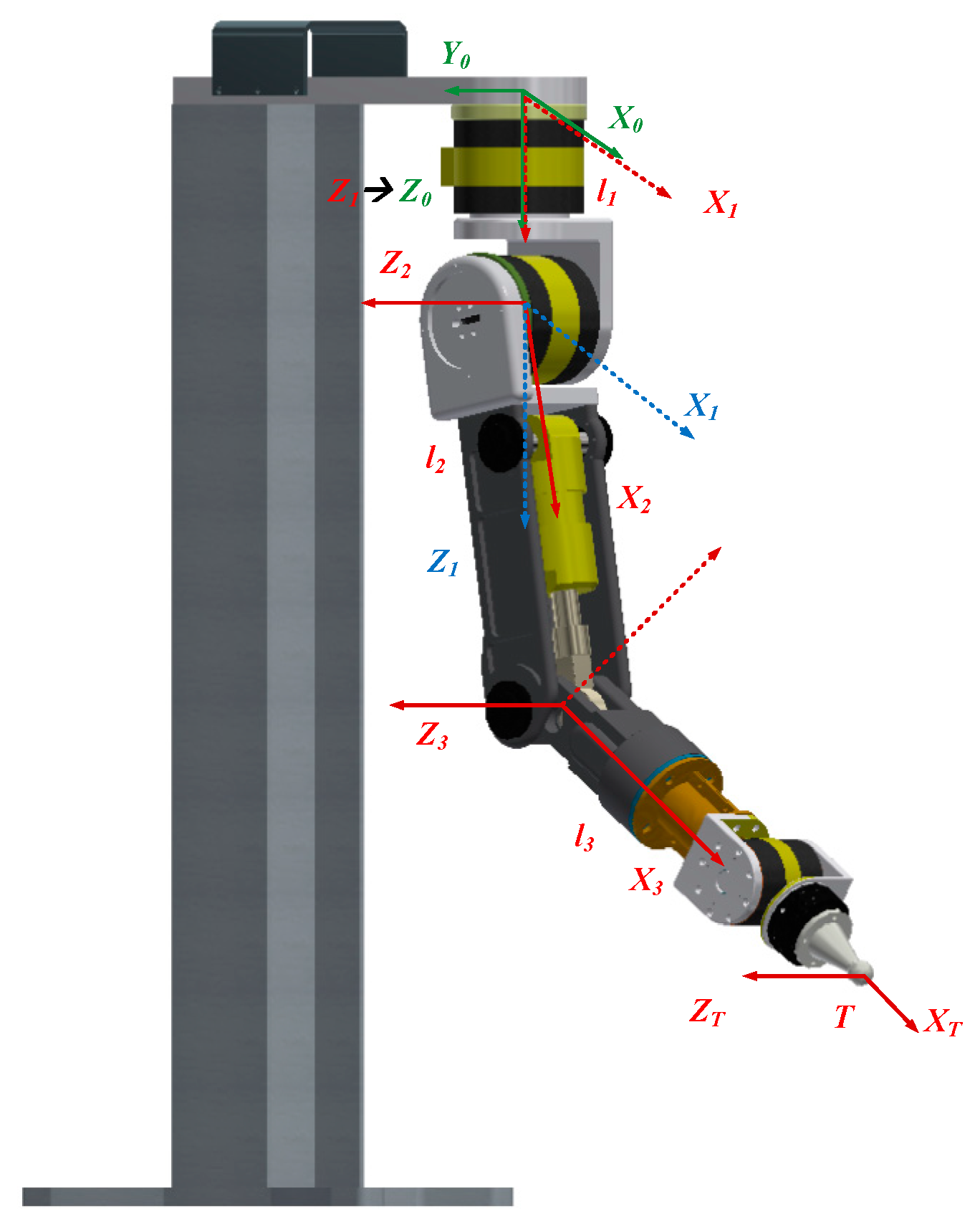

2. Manipulator Analysis

2.1. Dynamics Manipulator

2.2. The Dynamic of the Electro-Hydraulic Actuator

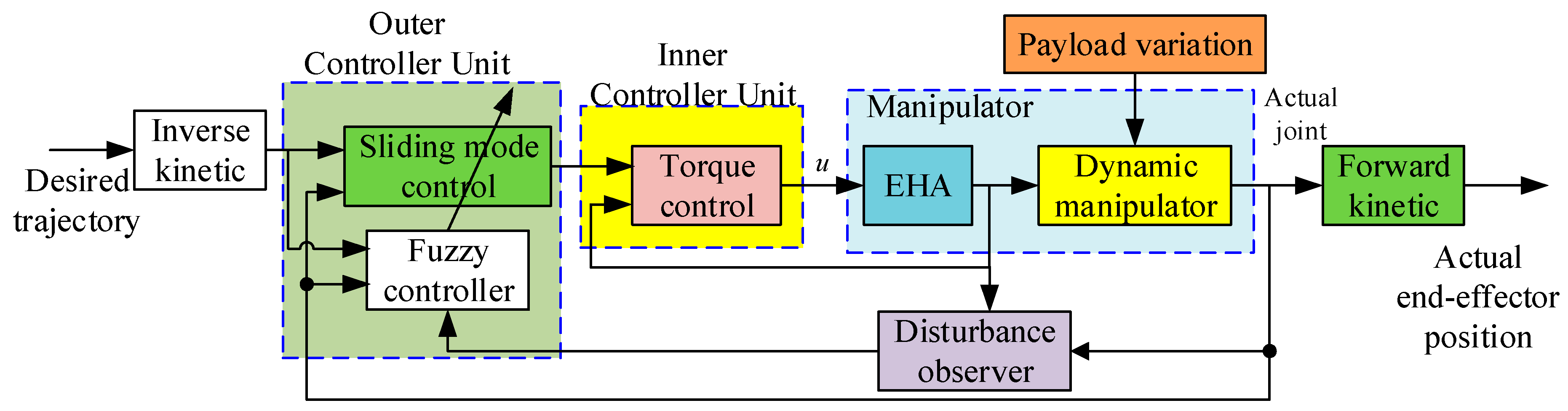

3. Adaptive Fuzzy Controller for the Hydraulic Manipulator

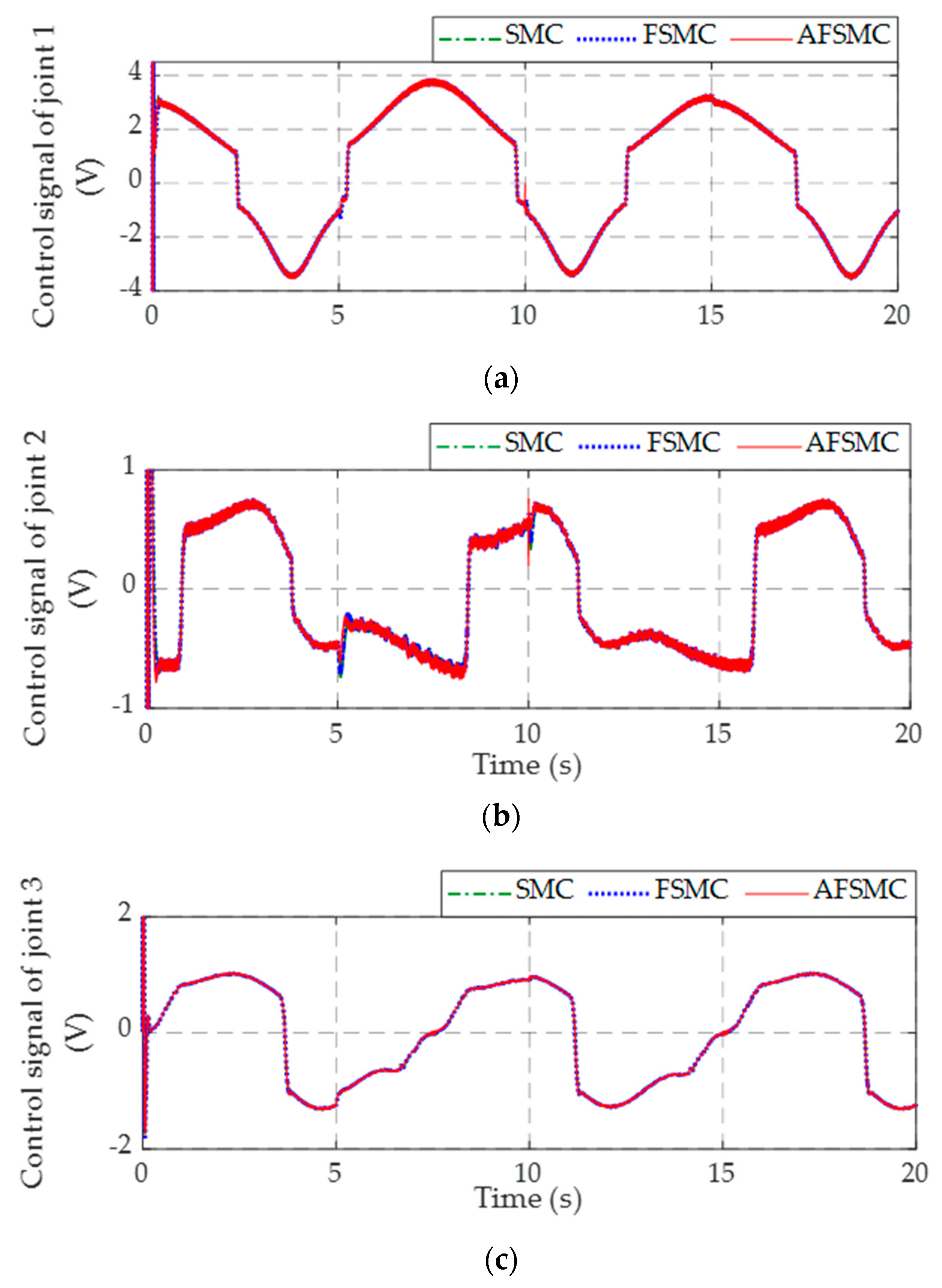

3.1. Cascade Control

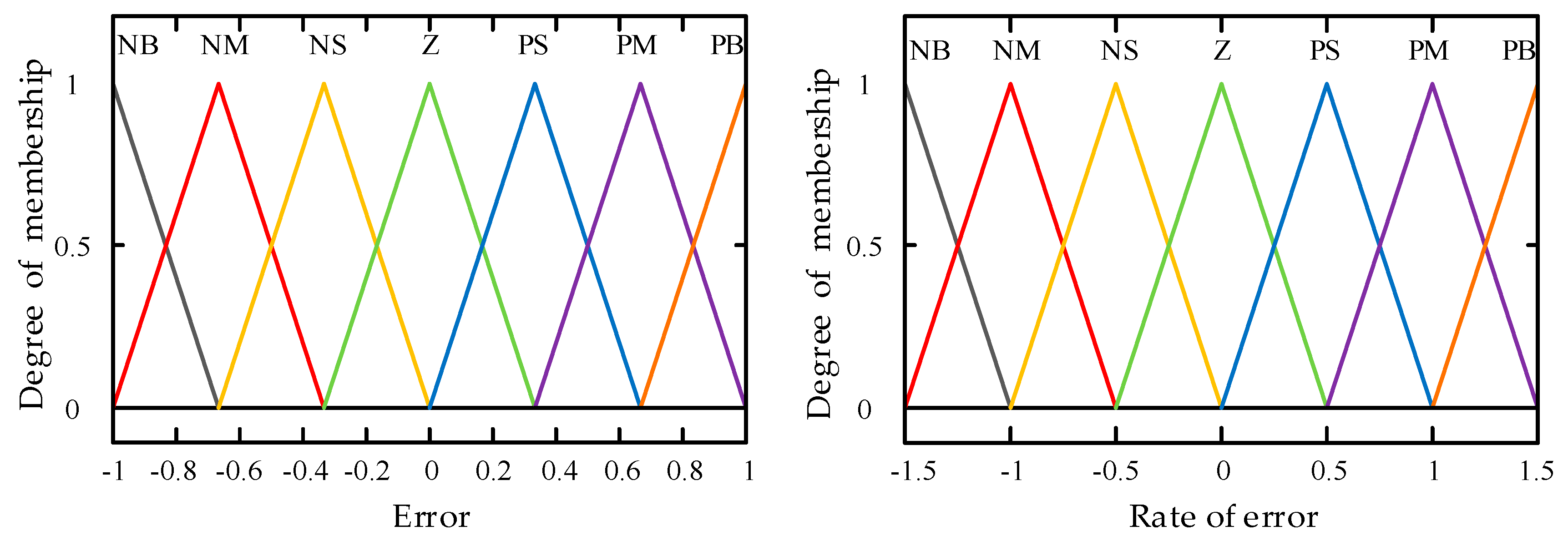

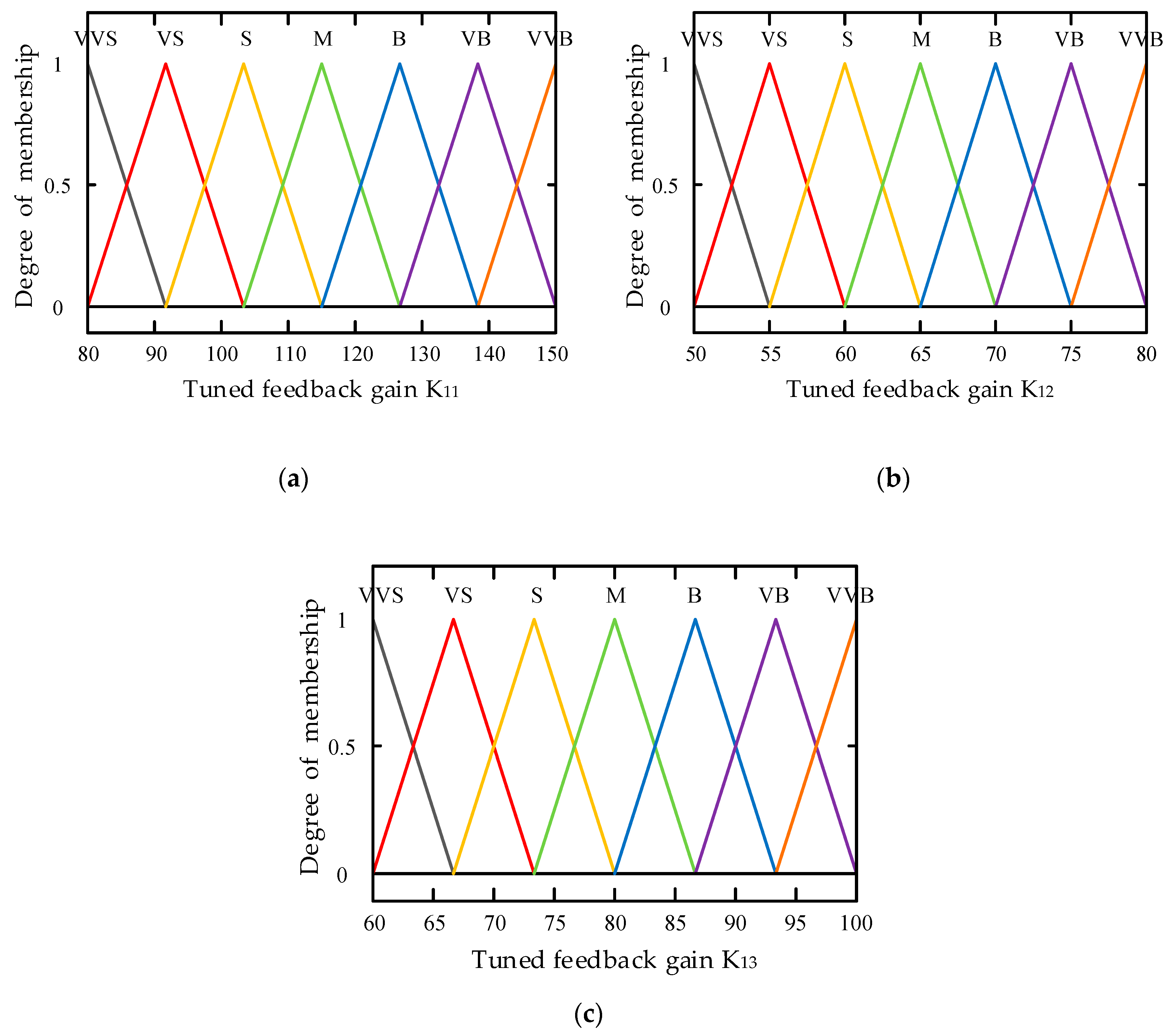

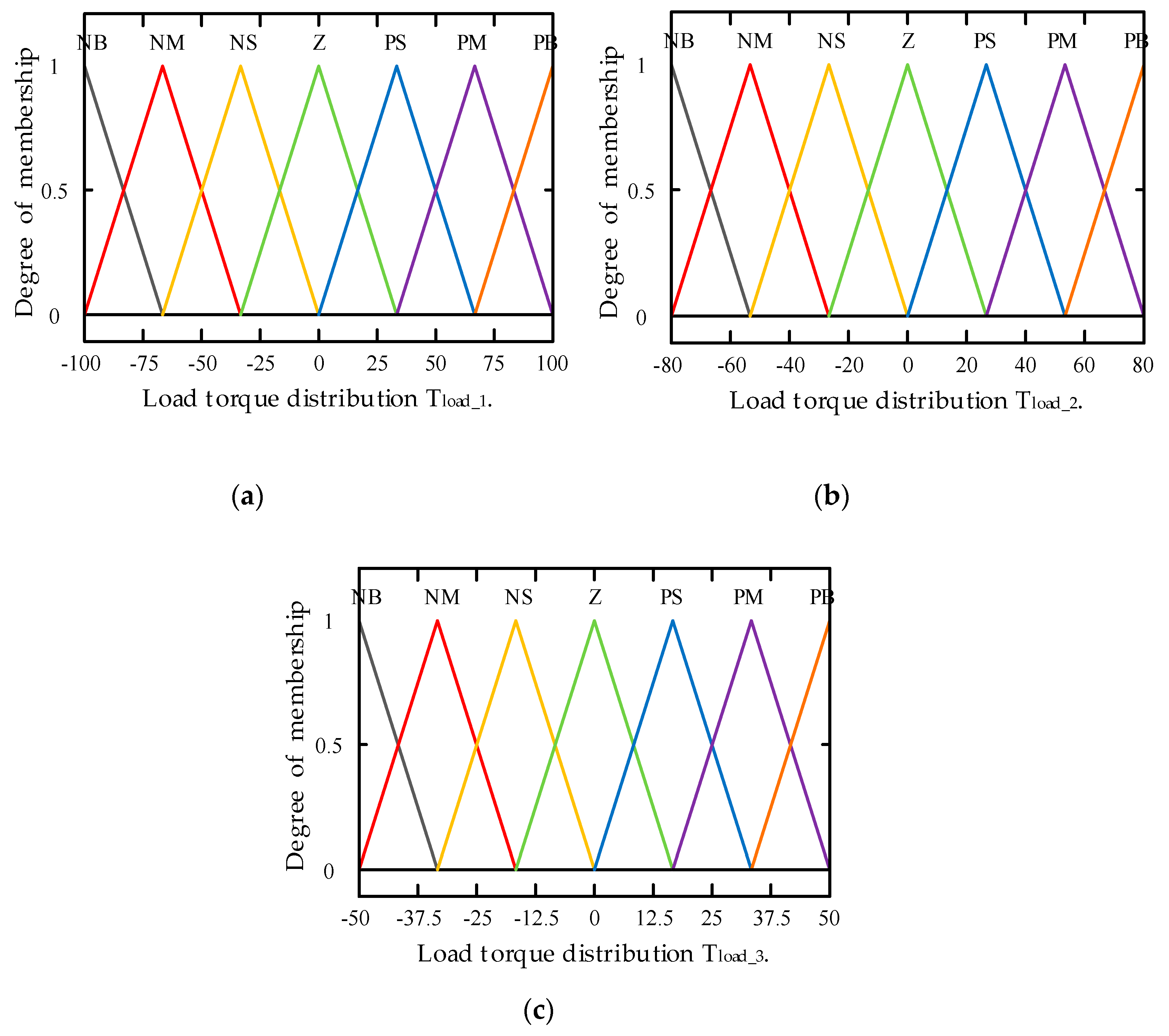

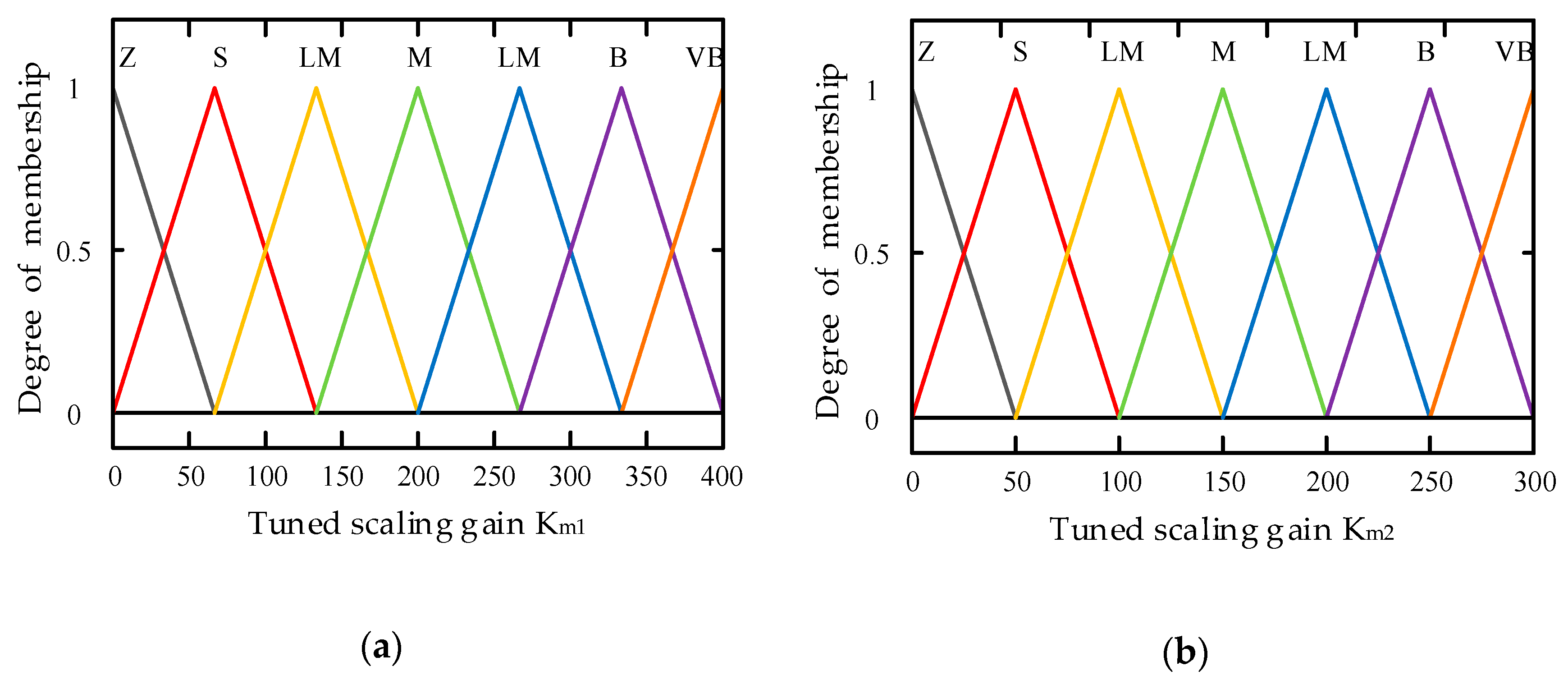

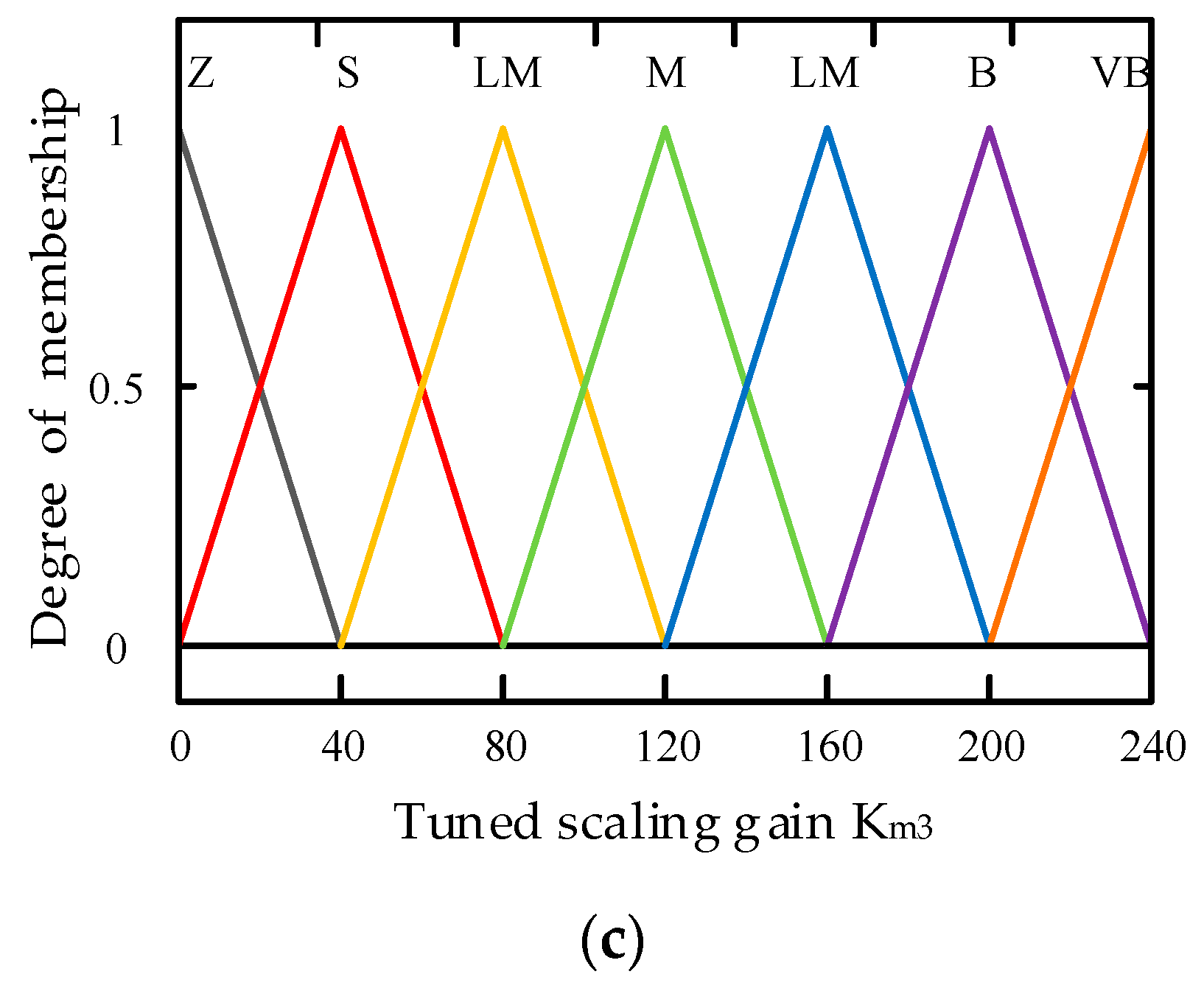

3.2. Adaptive Fuzzy Logic System

3.3. Nonlinear Disturbance Observer

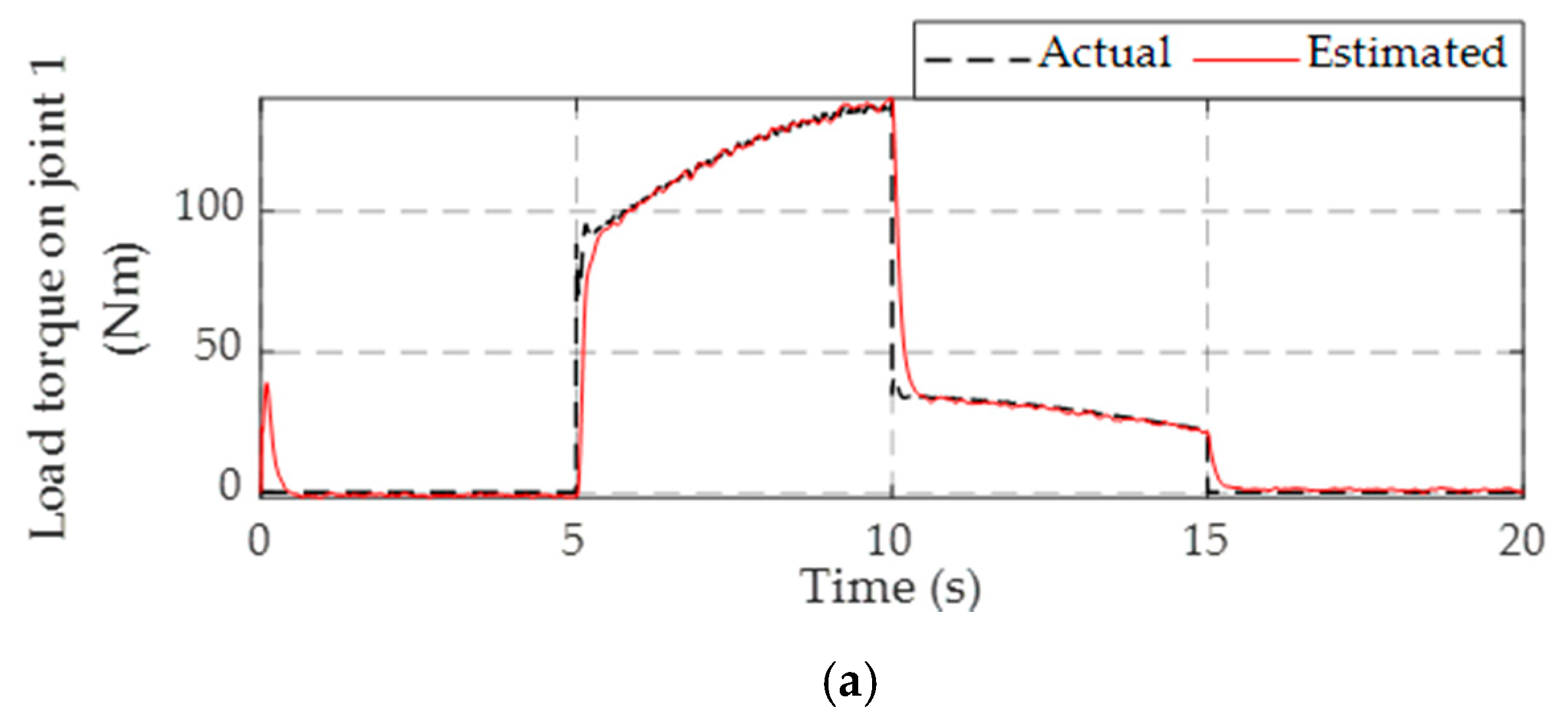

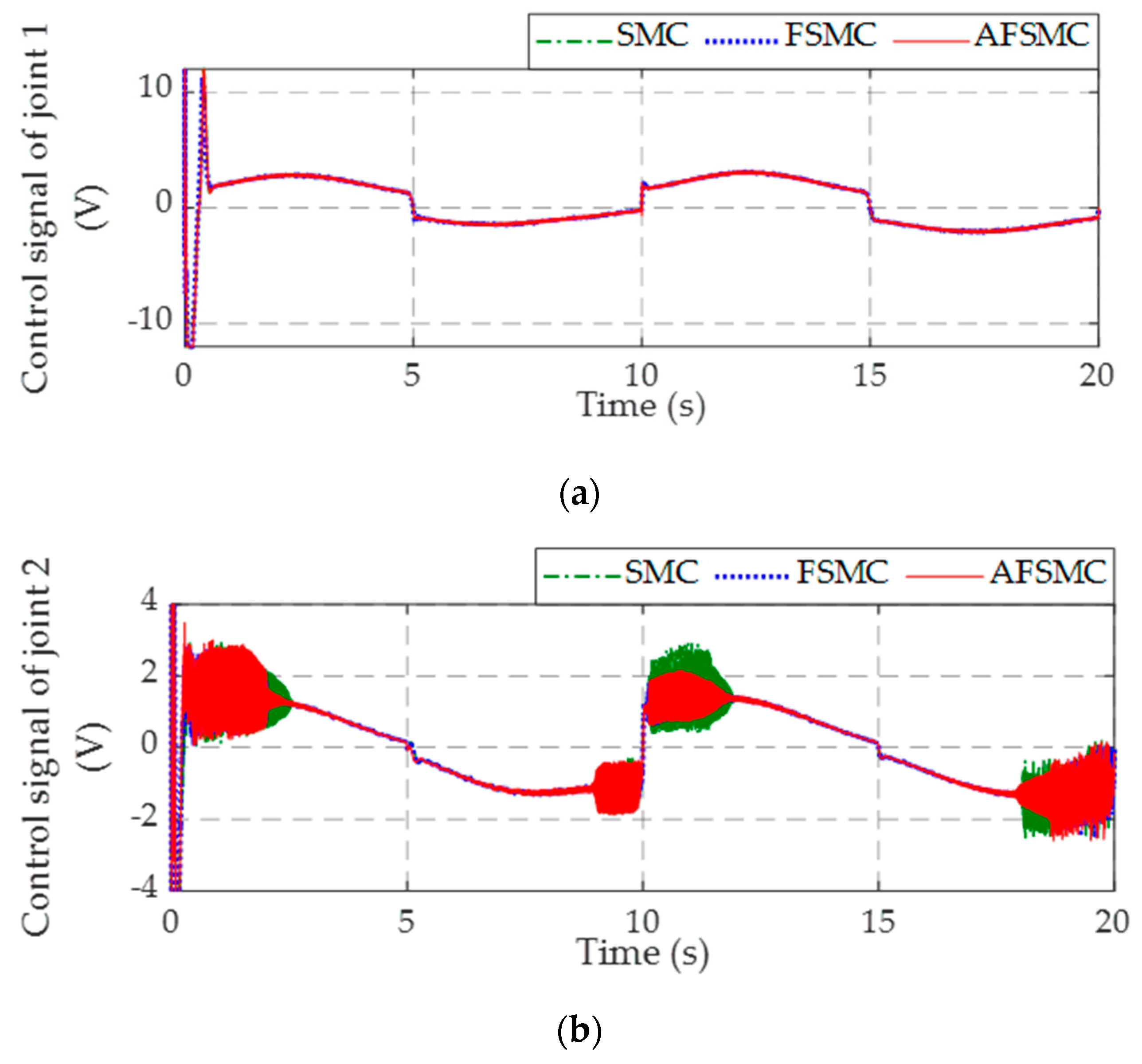

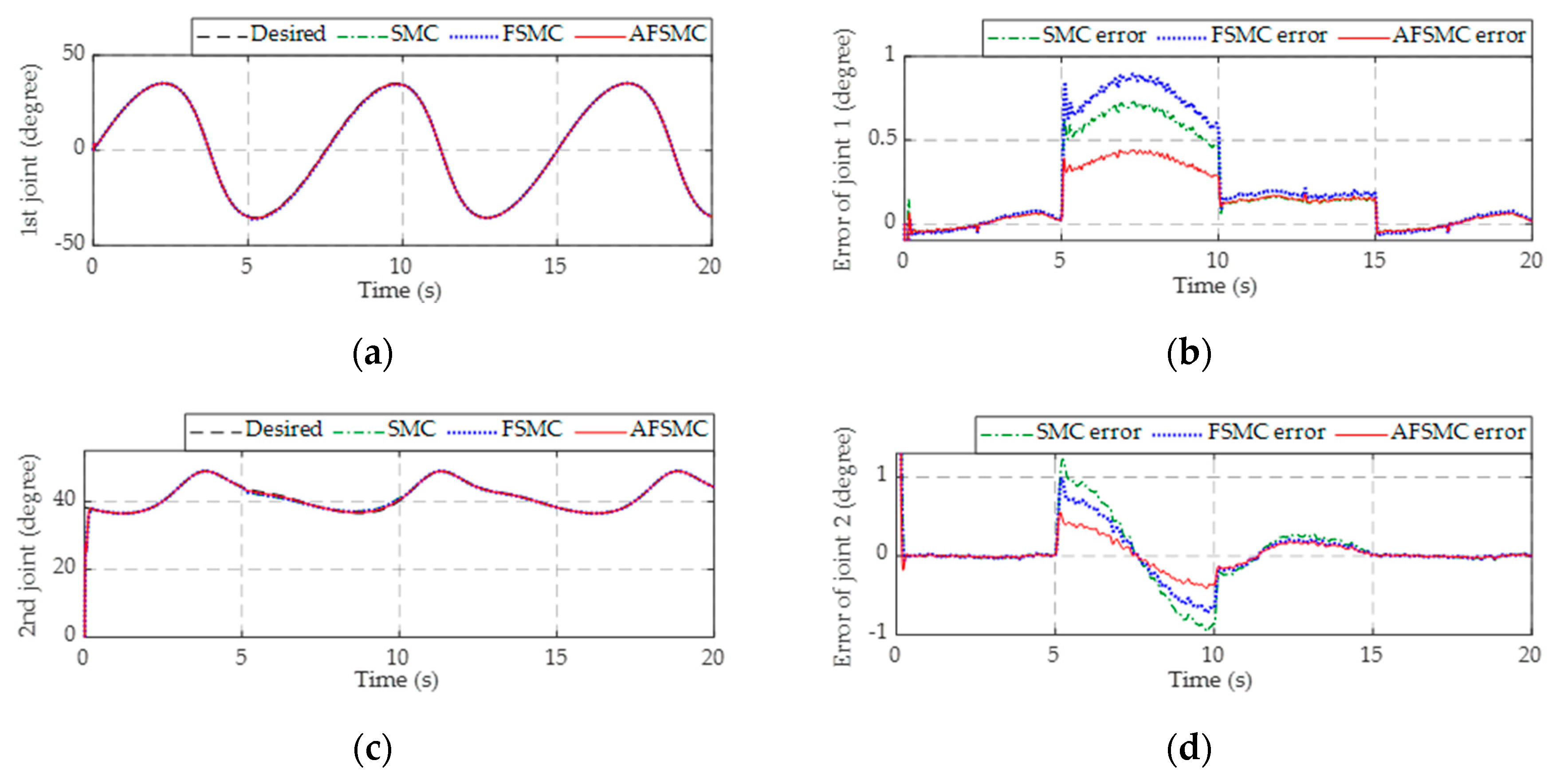

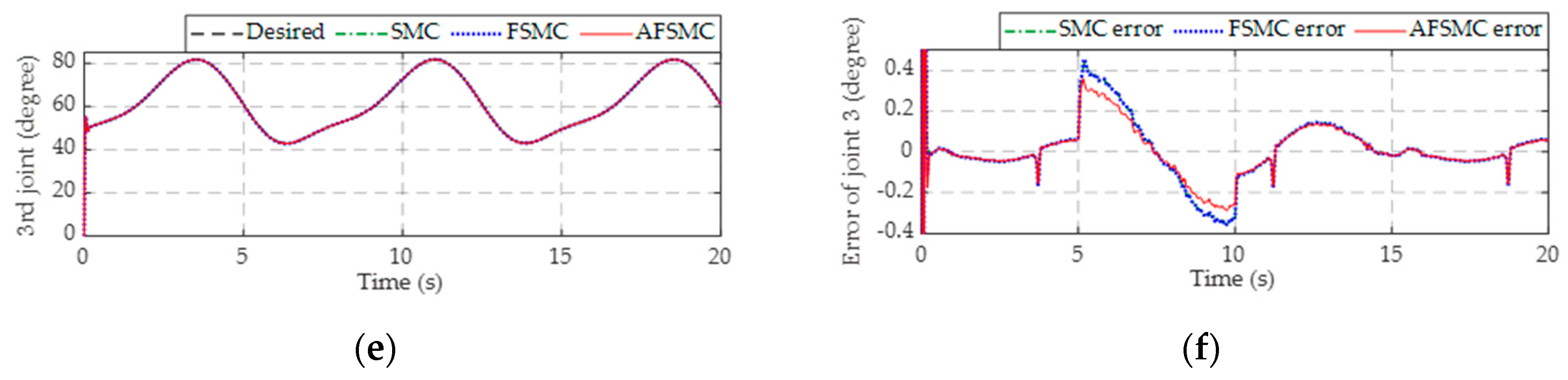

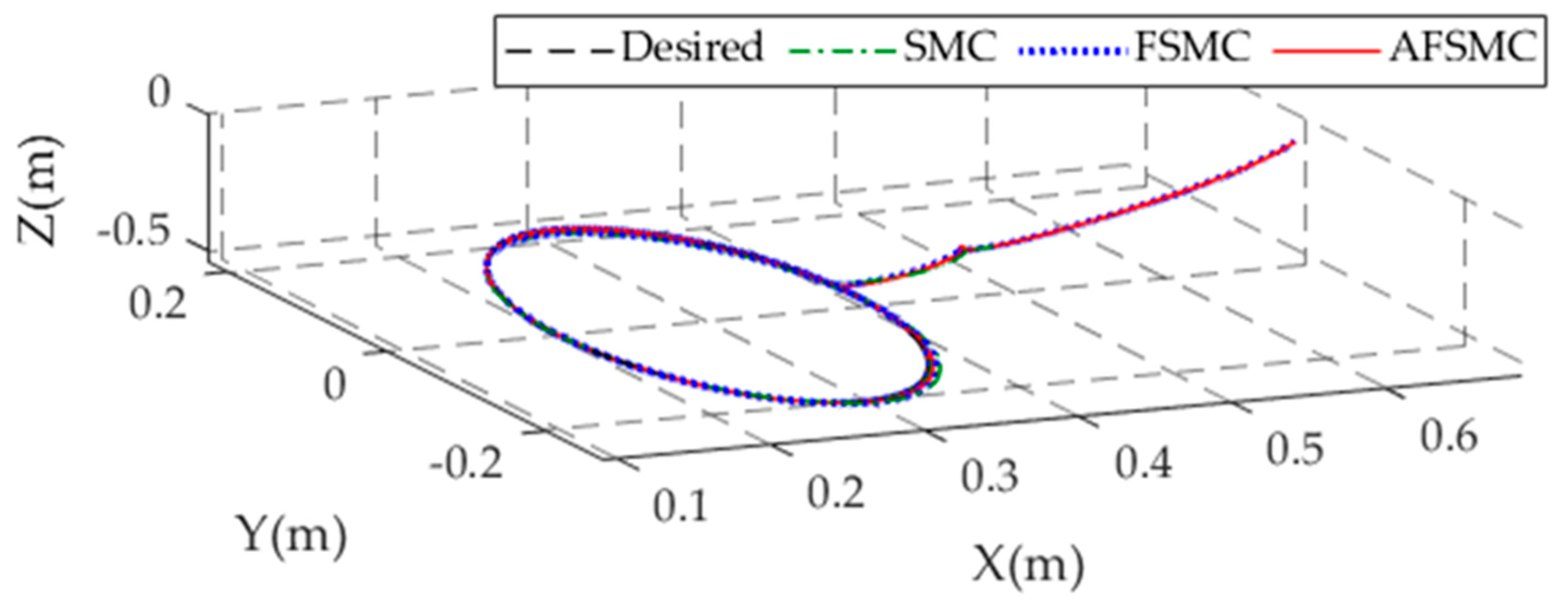

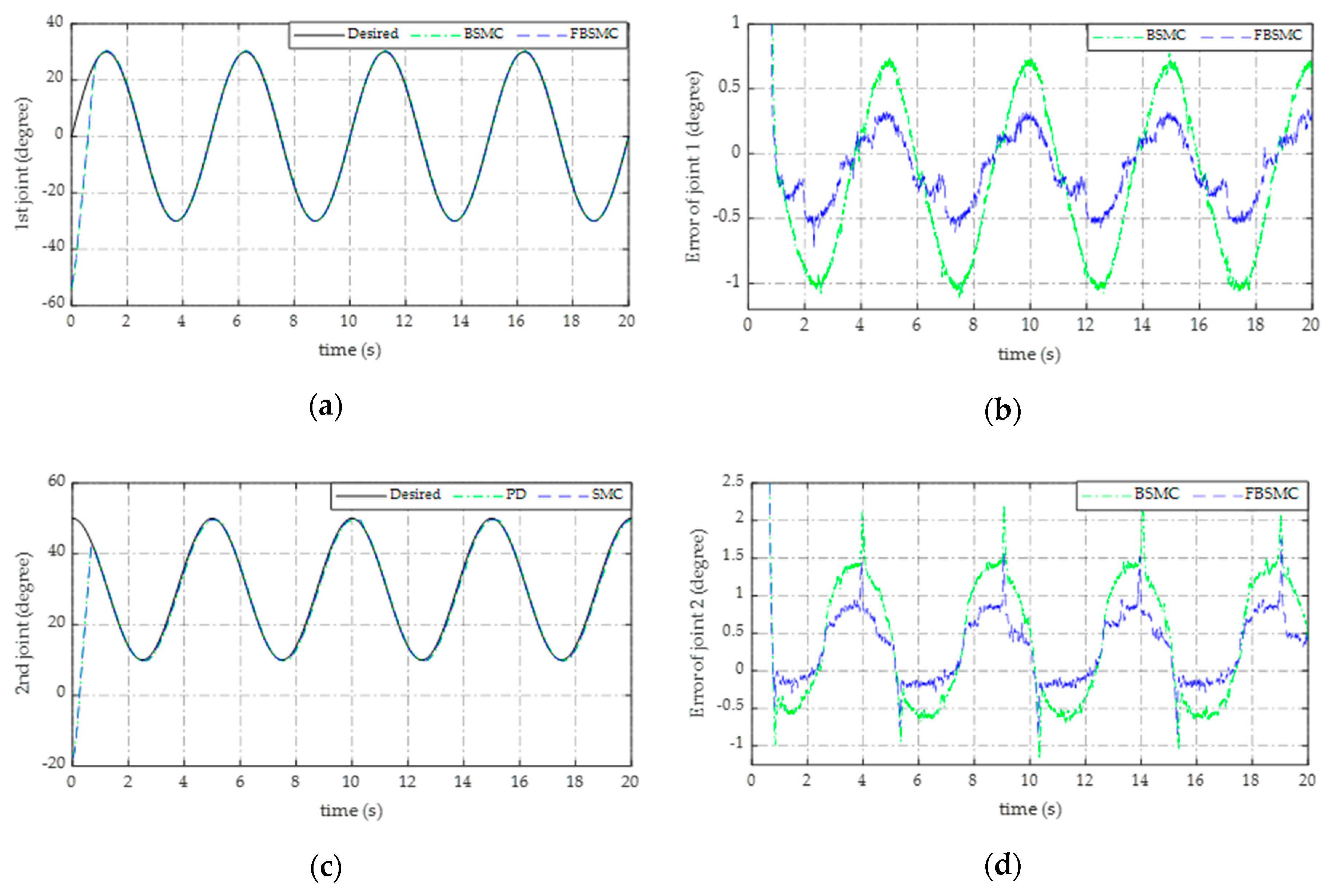

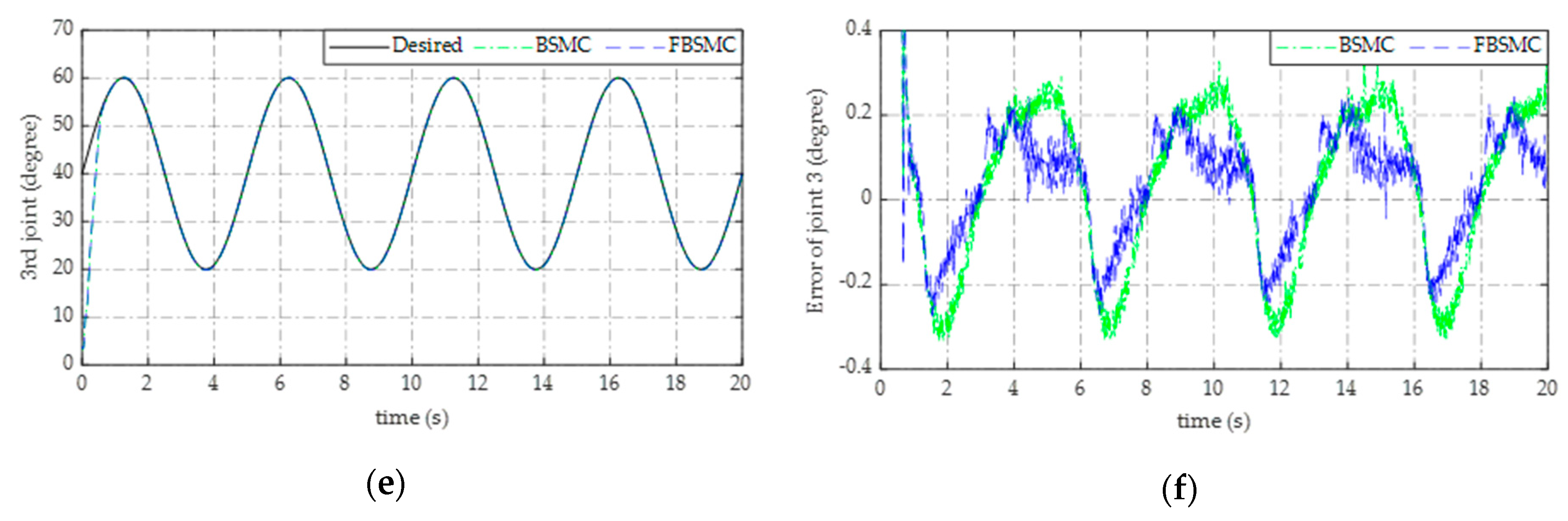

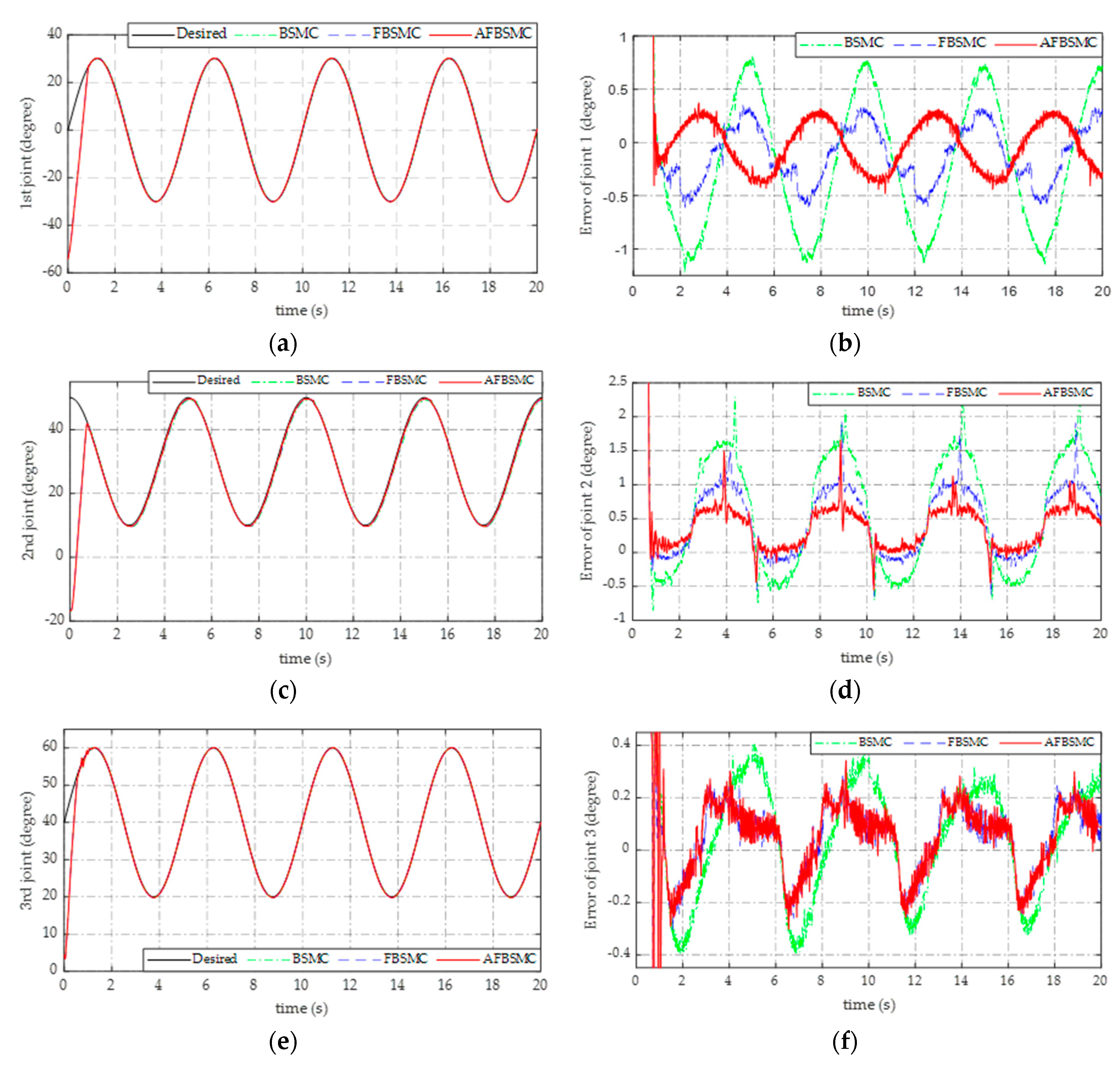

4. Simulations

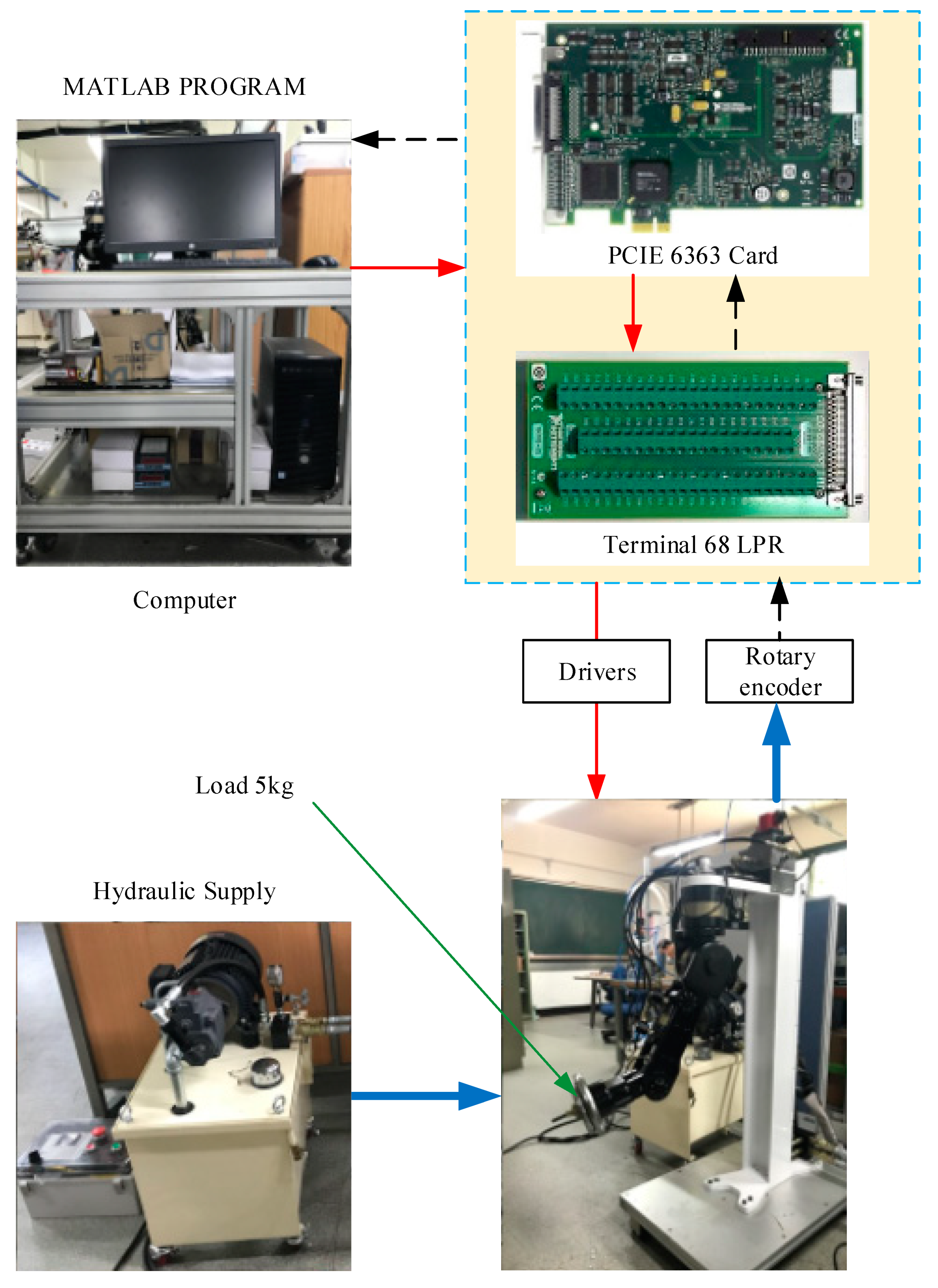

5. Experiments

5.1. Experimental Setup

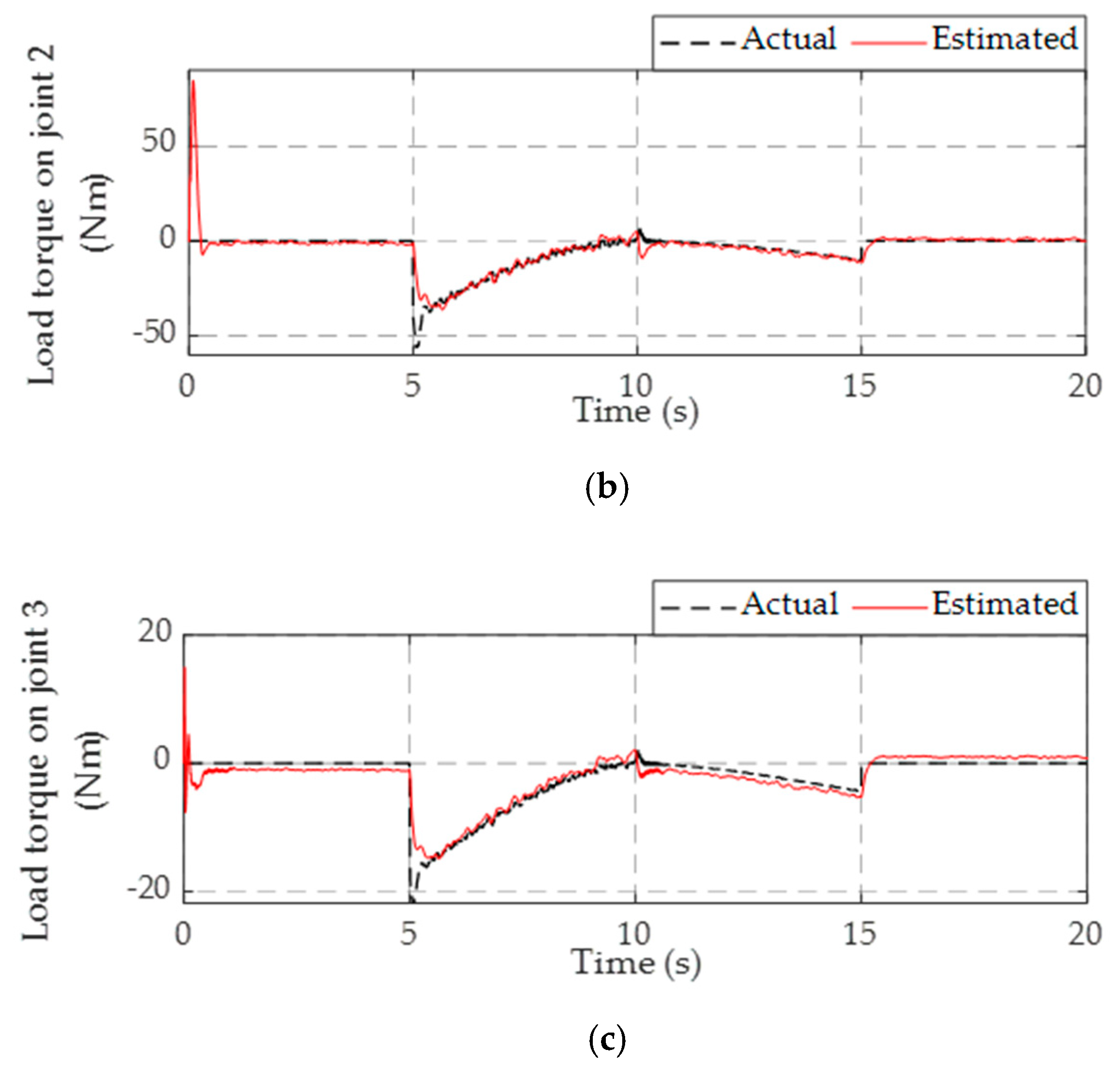

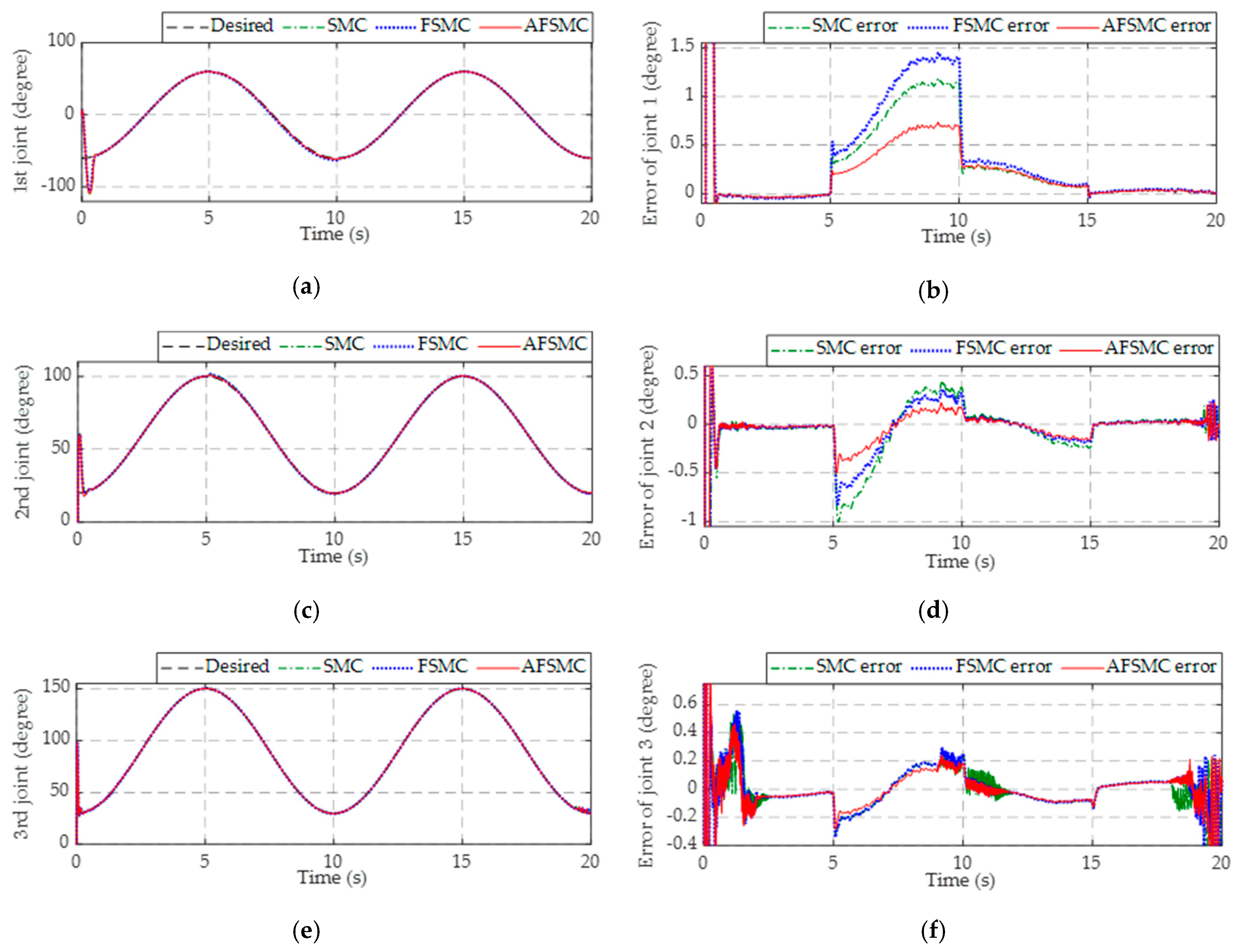

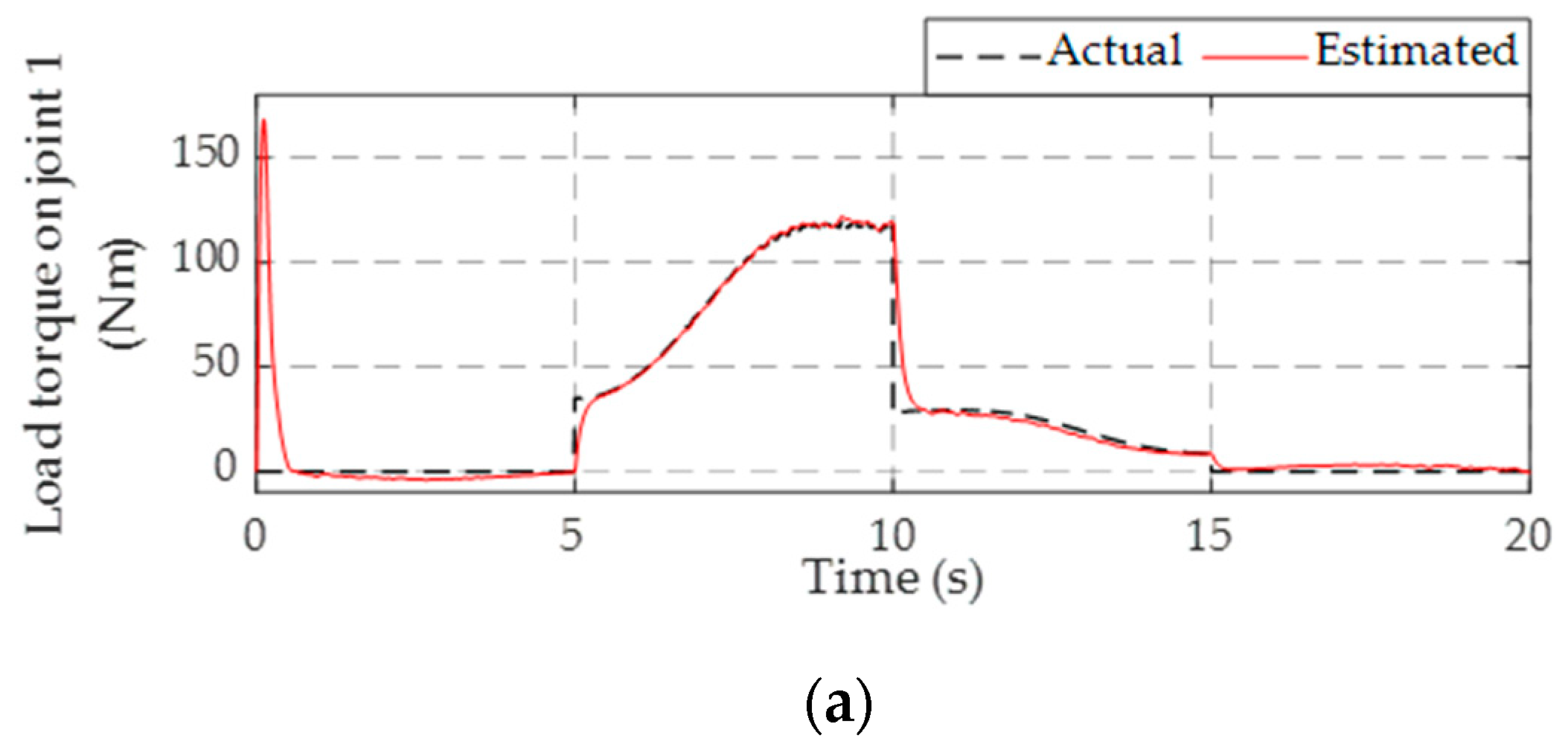

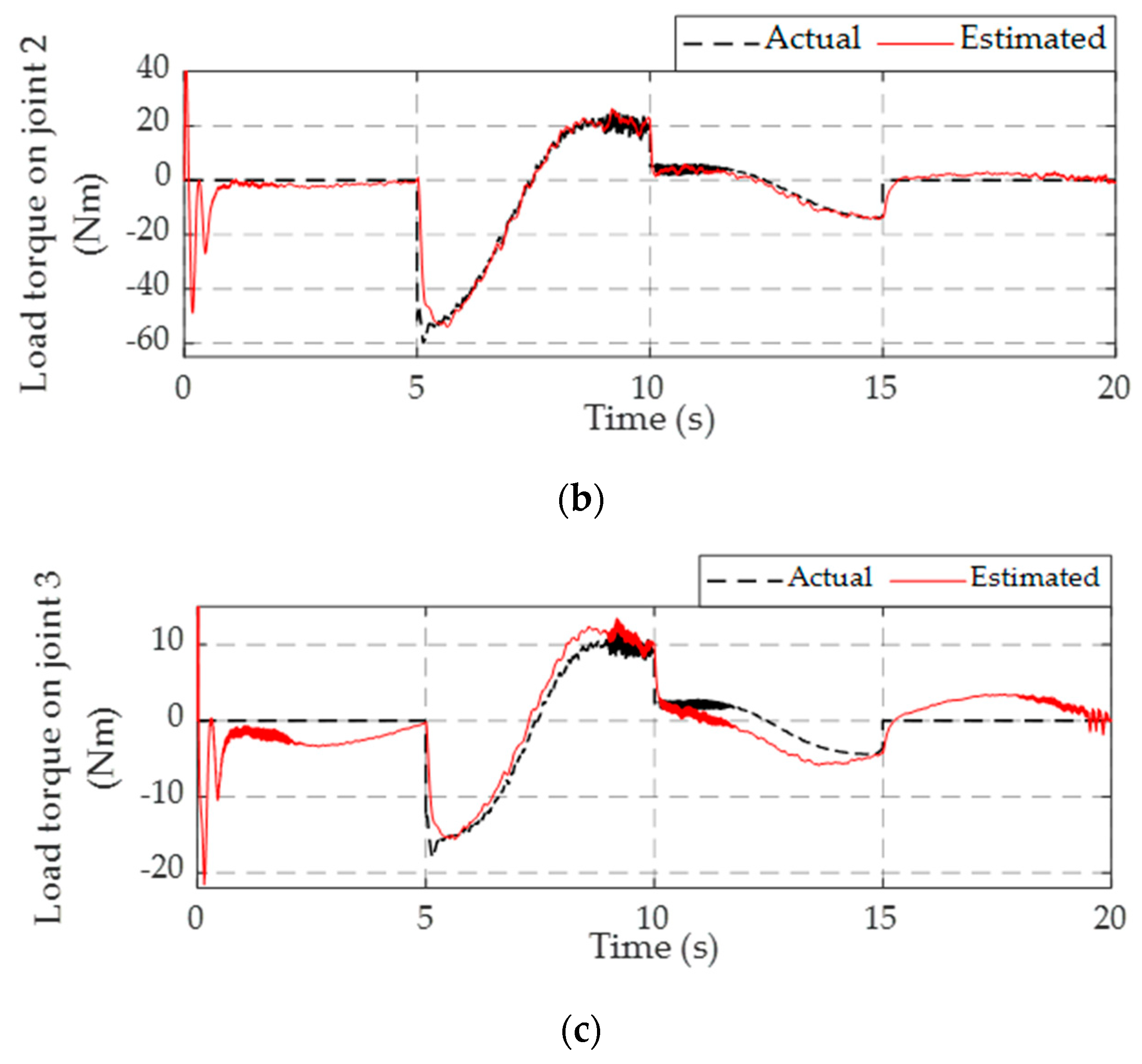

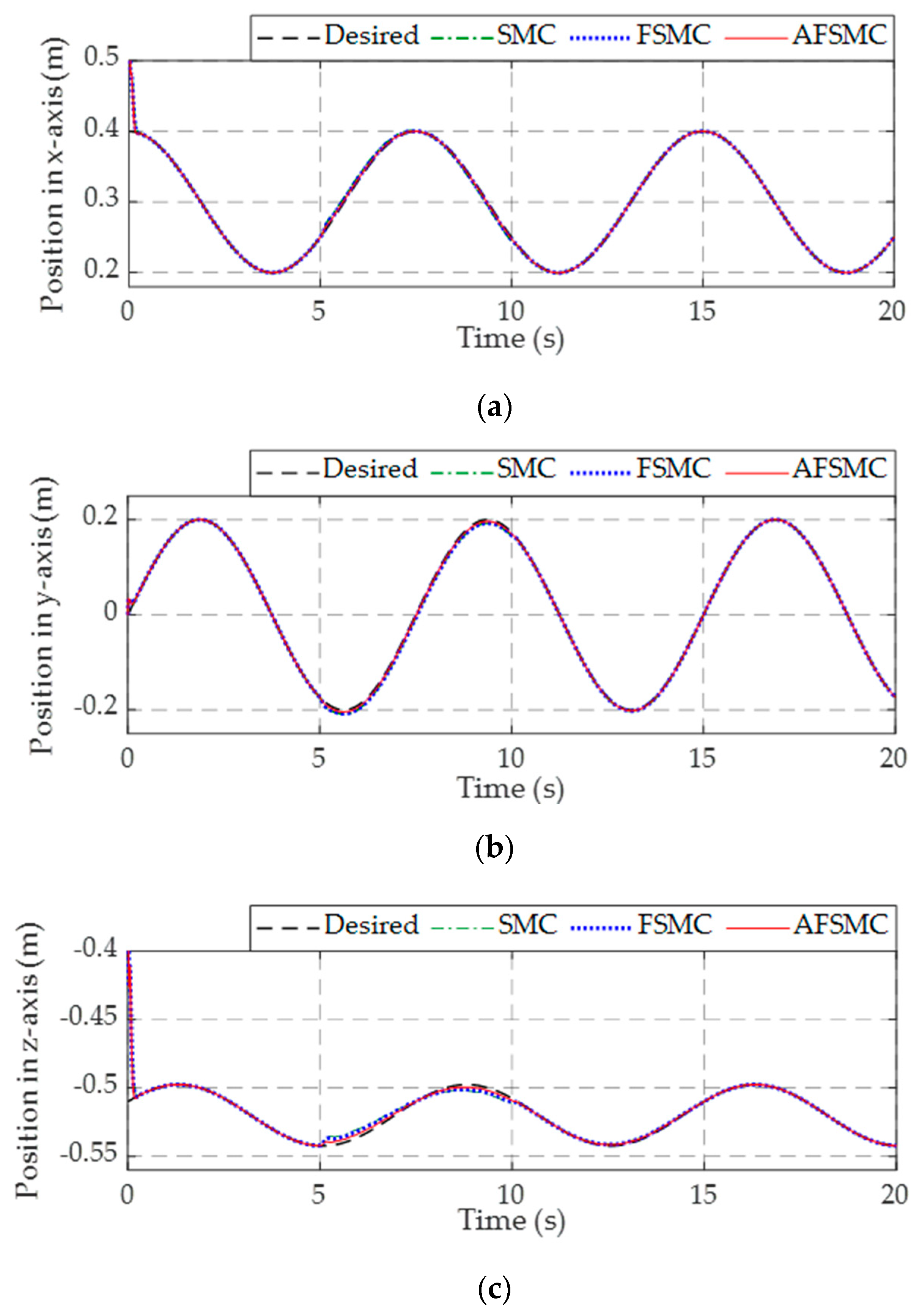

5.2. Experiment Results

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

Appendix B

References

- John, J.C. Introduction to Robotics Mechanics and Control, 3rd ed.; Addison-Wisley: Reading, PA, USA; Pearson Education Inc.: Upper Saddle River, NJ, USA, 1989. [Google Scholar]

- Su, Y.X.; Muller, P.C.; Zheng, C.H. Global Asymptotic Saturated PID Control for Robot Manipulators. IEEE Trans. Control Syst. Technol. 2010, 18, 1280–1288. [Google Scholar] [CrossRef]

- Li, S.; Ahmad, G.; Xie, W.; Gao, Y. An Enhanced IBVS Controller of a 6DOF Manipulator Using Hybrid PDSMC Method. Int. J. Control Autom. Syst. 2018, 16, 844–855. [Google Scholar] [CrossRef]

- Nikdel, N.; Badamchizadeh, M.A.; Azimirad, V.; Nazari, M.A. Adaptive backstepping control for an n-degree of freedom robotic manipulator based on combined state augmentation. Robot. Comput. Integr. Manuf. 2017, 44, 129–143. [Google Scholar] [CrossRef]

- Rong, J.W.; Rajkumar, M. Design of Fuzzy-Neural-Network-Inherited Backstepping Control for Robot Manipulator Including Actuator Dynamics. IEEE Trans. Fuzzy Syst. 2014, 22, 709–722. [Google Scholar]

- Lee, H.S.; Won, S.J.; Ahn, K.K. The Numerical Modeling and Sliding Mode Control of a New Submersible Fish Cage. J. Drive Control 2017, 14, 18–24. [Google Scholar]

- Baek, J.M.; Jin, M.L.; Han, S.H. A New Adaptive Sliding-Mode Control Scheme for Application to Robot Manipulators. IEEE Trans. Ind. Electron. 2016, 63, 3628–3637. [Google Scholar] [CrossRef]

- Ha, T.W.; Jun, K.H.; Nguyen, M.T.; Han, S.M.; Shin, J.W.; Ahn, K.K. Position control of an Electro-Hydrostatic Rotary Actuator using adaptive PID control. J. Drive Control 2017, 14, 37–44. [Google Scholar]

- Bo, Z.; Li, Y. Model-free Adaptive Dynamic Programming Based Near-optimal Decentralized Tracking Control of Reconfigurable Manipulators. Int. J. Control Autom. Syst. 2018, 16, 478–490. [Google Scholar]

- Lv, W.S.; Wang, F.; Zhang, L.L. Adaptive Fuzzy Finite-time Control for Uncertain Nonlinear Systems with Dead-zone Input. Int. J. Control Autom. Syst. 2018, 16, 2549–2558. [Google Scholar] [CrossRef]

- Ra, C.G.; Kim, S.K.; Suk, J.Y. Adaptive Sliding Mode Autopilot Design for Skid-to-turn Missile Model with Uncertainties. Int. J. Control Autom. Syst. 2017, 15, 2733–2743. [Google Scholar] [CrossRef]

- To, X.D.; Ahn, K.K. Radial Basis Function Neural Network based Adaptive Fast Nonsingular Terminal Sliding Mode Controller for Piezo Positioning Stage. Int. J. Control Autom. Syst. 2017, 15, 2733–2743. [Google Scholar]

- Vu, T.Y.; Wang, Y.N.; Pham, V.C.; Nguyen, X.Q.; Vu, H.T. Robust Adaptive Sliding Mode Control for Industrial Robot Manipulator Using Fuzzy Wavelet Neural Networks. Int. J. Control Autom. Syst. 2017, 15, 2930–2941. [Google Scholar]

- Kim, M.; Kuc, T.Y.; Kim, H.; Lee, J.S. Adaptive Iterative Learning Controller with Input Learning Technique for a Class of Uncertain MIMO Nonlinear Systems. Int. J. Control Autom. Syst. 2017, 15, 315–328. [Google Scholar] [CrossRef]

- Spong, M.W.; Seth, H.; Vidyasagar, M. Robot Dynamics and Control, 1st ed.; John Wiley & Sons, Inc.: New York, NY, USA, 2005. [Google Scholar]

- Yuan, J. Adaptive control of robotic manipulators including motor dynamics. IEEE Trans. Robot. Autom. 1995, 11, 612–617. [Google Scholar] [CrossRef]

- Tarn, T.J.; Bejczy, A.K.; Yun, X.; Li, Z. Effect of motor dynamics on nonlinear feedback robot arm control. IEEE Trans. Robot. Autom. 1991, 7, 114–122. [Google Scholar] [CrossRef]

- Chen, B.S.; Uang, H.J.; Tseng, C.S. Robust tracking enhancement of robot systems including motor dynamics: A fuzzy-based dynamic game approach. IEEE Trans. Fuzzy Syst. 1998, 6, 538–552. [Google Scholar] [CrossRef]

- Caldwell, D.G.; Medrano-Cerda, G.A.; Goodwin, M. Control of pneumatic muscle actuators. IEEE Control Syst. Mag. 1995, 15, 40–48. [Google Scholar]

- Papoutsidakis, M.; Chatzopoulos, A.; Tseles, D. Hydraulics and Pneumatics: A Brief Summary of their Operational Characteristics. J. Multidiscip. Eng. Sci. Technol. 2018, 5, 8973–8977. [Google Scholar]

- Chiag, C.J.; Chen, Y.C. Neural network fuzzy sliding mode control of pneumatic muscle actuators. Eng. Appl. Artif. Intell. 2017, 65, 68–86. [Google Scholar] [CrossRef]

- Tu, D.C.T.; Ahn, K.K. Intelligent phase plane switching control of pneumatic artificial muscle manipulators with magneto-rheological brake. Mechatronics 2006, 16, 85–95. [Google Scholar]

- Papoutsidakis, M.; Xatzopoulos, A.; Smyraiou, G.P.; Tseles, D. PLC Programming Case Study for Hydraulic Positioning Systems Implementations. Int. J. Comput. Appl. 2017, 167, 49–53. [Google Scholar] [CrossRef]

- Mostafa, T.; Yarmohammadi, M.J. Development of a Self-tuning PID Controller on Hydraulically Actuated Stewart Platform Stabilizer with Base Excitation. Int. J. Control Autom. Syst. 2018, 16, 2990–2999. [Google Scholar]

- Ilyas, E. Sliding mode control with PID sliding surface and experimental application to an electromechanical plant. ISA Trans. 2006, 45, 109–118. [Google Scholar]

- Van, M.; Mavrovouniotis, M.; Ge, S.S. An Adaptive Backstepping Nonsingular Fast Terminal Sliding Mode Control for Robust Fault Tolerant Control of Robot Manipulators. IEEE Trans. Syst. Man Cybern. Syst. 2017, 49, 1448–1458. [Google Scholar] [CrossRef]

- Singh, S.; Qureshi, M.S.; Swarnkar, P. Comparison of Conventional PID Controller with Sliding Mode Controller for a 2-Link Robotic Manipulator. In Proceedings of the International Conference on Electrical Power and Energy Systems (ICEPES), Bhopal, India, 14–16 December 2016. [Google Scholar]

- Ahn, K.K.; Doan, N.C.N.; Jin, M. Adaptive Backstepping Control of an Electrohydraulic Actuator. IEEE ASME Trans. Mechatron. 2014, 19, 987–995. [Google Scholar] [CrossRef]

- Nguyen, M.T.; Doan, N.C.N.; Park, H.G.; Ahn, K.K. Trajectory control of an electro hydraulic actuator using an iterative backstepping control scheme. Mechatronics 2015, 29, 96–102. [Google Scholar]

- Wu, S.F.; Zhang, J.W. A Terminal Sliding Mode Observer Based Robust Backstepping Sensorless Speed Control for Interior Permanent Magnet Synchronous Motor. Int. J. Control Autom. Syst. 2018, 16, 2743–2753. [Google Scholar] [CrossRef]

- Sharma, R.; Gaur, P.; Mittal, A.P. Design of two-layered fractional order fuzzy logic controllers applied to robotic manipulator with variable payload. Appl. Soft Comput. 2016, 47, 565–576. [Google Scholar] [CrossRef]

- Sharma, R.; Gaur, P.; Mittal, A.P. Performance analysis of two-degree of freedom fractional order PID controllers for robotic manipulator with payload. ISA Trans. 2015, 58, 279–291. [Google Scholar] [CrossRef]

- Sharma, R.; Kumar, V.; Gaur, P.; Mittal, A.P. An adaptive PID like controller using mix locally recurrent neural network for robotic manipulator with variable payload. ISA Trans. 2016, 62, 258–267. [Google Scholar] [CrossRef]

- Nho, H.C.; Meckl, P. Intelligent Feedforward Control and Payload Estimation for a Two-Link Robotic Manipulator. IEEE ASME Trans. Mechatron. 2003, 8, 277–283. [Google Scholar] [CrossRef]

- Khaled, E.; Muhammad, S.A.; Rizwan, U. Dynamic Stability Enhancement Using Fuzzy PID Control Technology for Power System. Int. J. Control Autom. Syst. 2019, 17, 234–242. [Google Scholar]

- Choi, H.D.; Lee, C.J.; Lim, M.T. Fuzzy Preview Control for Half-vehicle Electro-hydraulic Suspension System. Int. J. Control Autom. Syst. 2018, 16, 2489–2500. [Google Scholar] [CrossRef]

- Sharkawy, A.B.; Salman, S.A. An Adaptive Fuzzy Sliding Mode Control Scheme for Robotic Systems. Intell. Control Autom. 2011, 2, 299–309. [Google Scholar] [CrossRef]

- Amer, A.F.; Sallam, E.A.; Elawady, W.M. Adaptive fuzzy sliding mode control using supervisory fuzzy control for 3 DOF planar robot manipulators. Appl. Soft Comput. 2011, 11, 4943–4953. [Google Scholar] [CrossRef]

- He, J.; Luo, M.; Zhang, Q.; Zhao, J.; Xu, L. Adaptive Fuzzy Sliding Mode Controller with Nonlinear Observer for Redundant Manipulators Handling Varying External Force. J. Bionic Eng. 2016, 13, 600–611. [Google Scholar] [CrossRef]

- Guo, Y.; Woo, P.Y. An Adaptive Fuzzy Sliding Mode Controller for Robotic Manipulators. IEEE Trans. Syst. Man Cybern. Part A Syst. Hum. 2003, 33, 149–159. [Google Scholar]

- Chen, W.H.; Ballance, D.J.; Gawthrop, P.J.; O’Reilly, J. A Nonlinear Disturbance Observer for Robotic Manipulators. IEEE Trans. Ind. Electron. 2000, 47, 932–938. [Google Scholar] [CrossRef]

- Mohammadi, A.; Tavakoli, M.; Marquez, H.J.; Hashemzadeh, F. Nonlinear disturbance observer design for robotic manipulators. Control Eng. Pract. 2013, 21, 253–267. [Google Scholar] [CrossRef]

- Mohamadreza, H.; Amir, K. Disturbance Observer-based Trajectory Following Control of Robot Manipulators. Int. J. Control Autom. Syst. 2019, 17, 203–211. [Google Scholar]

- Elleuch, D.; Damak, T. Backstepping sliding mode controller coupled to adaptive sliding mode observer for interconnected fractional nonlinear system. Int. J. Mech. Mechatron. Eng. 2013, 7, 372–378. [Google Scholar]

- Merritt, H.E. Hydraulic Control Systems; John Wiley & Son, Inc.: New York, NY, USA, 1967; p. 134. [Google Scholar]

- Yao, I.; Jiao, Z.; Ma, D.; Tan, L. High-Accuracy Tracking Control of Hydraulic Rotary Actuators with Modeling Uncertainties. IEEE ASME Trans. Mechatron. 2014, 19, 633–641. [Google Scholar] [CrossRef]

- Jelali, M.; Kroll, A. Hydraulic Servo-Systems Modelling, Identification and Control, 2nd ed.; Springer-Verlag London Ltd.: Berlin/Heidelberg, Germany, 2004. [Google Scholar]

- Schkoda, R.F.; Hall, T. Hydraulic Spool Valve Modeling for System Level Analysis. In Proceedings of the 2014 American Control Conference, Portland, OR, USA, 4–6 June 2014. [Google Scholar]

- Kurode, S.; Desai, P.G.; Shiralkar, A. Modeling of electro-hydraulic servo valve and Robust Position Control using Sliding Mode Technique. In Proceedings of the 1st International and 16th National Conference on Machines and Mechanisms (iNaCoMM2013), Roorkee, India, 18–20 December 2013. [Google Scholar]

- Guan, C.; Pan, S. Adaptive sliding mode control of electro-hydraulic system with nonlinear unknown parameters. Control Eng. Pract. 2008, 16, 1275–1284. [Google Scholar] [CrossRef]

- Miroslav, K.; Ioannis, K.; Petar, K. Nonlinear and Adaptive Control Design; John Wiley & Sons. Inc.: New York, NY, USA, 1995; pp. 490–492. [Google Scholar]

- Perruquetti, W. Sliding Mode Control in Engineering; Marcel Dekker, Inc.: New York, NY, USA, 2002. [Google Scholar]

| NB | NM | NS | Z | PS | PM | PB | ||

|---|---|---|---|---|---|---|---|---|

| e(t) | NB | M | B | VB | VVB | VB | B | M |

| NM | S | M | B | VB | B | M | S | |

| NS | VS | S | M | B | M | S | VS | |

| Z | VVS | VS | S | M | S | VS | VVS | |

| PS | VS | S | M | B | M | S | VS | |

| PM | S | M | B | VB | B | M | S | |

| PB | M | B | VB | VVB | VB | B | M | |

| NB | NM | NS | Z | PS | PM | PB | ||

|---|---|---|---|---|---|---|---|---|

| NB | VB | B | LB | M | LB | B | VB | |

| NM | B | LB | M | LM | M | LB | B | |

| NS | LB | M | LM | S | LM | M | LB | |

| Z | M | LM | S | Z | S | LM | M | |

| PS | LB | M | LM | S | LM | M | LB | |

| PM | B | LB | M | LM | M | LB | B | |

| PB | VB | B | LB | M | LB | B | VB | |

| Parameter | Value (unit) |

|---|---|

| 5 (kg) | |

| 5 (kg) | |

| 5 (kg) | |

| 0.3 (m) | |

| 0.5 (m) | |

| 0.2 (m) | |

| g | 9.81 (m/s2) |

| Parameter | Value (Unit) |

|---|---|

| 1.15 10−4 (m3/rad) | |

| (m2) | |

| (m2) | |

| 870 (kg/m3) | |

| 100 (bar) | |

| 2 (bar) | |

| Effective Bulk modulus β | 1.25 109 (Pa) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Truong, H.V.A.; Tran, D.T.; To, X.D.; Ahn, K.K.; Jin, M. Adaptive Fuzzy Backstepping Sliding Mode Control for a 3-DOF Hydraulic Manipulator with Nonlinear Disturbance Observer for Large Payload Variation. Appl. Sci. 2019, 9, 3290. https://doi.org/10.3390/app9163290

Truong HVA, Tran DT, To XD, Ahn KK, Jin M. Adaptive Fuzzy Backstepping Sliding Mode Control for a 3-DOF Hydraulic Manipulator with Nonlinear Disturbance Observer for Large Payload Variation. Applied Sciences. 2019; 9(16):3290. https://doi.org/10.3390/app9163290

Chicago/Turabian StyleTruong, Hoai Vu Anh, Duc Thien Tran, Xuan Dinh To, Kyoung Kwan Ahn, and Maolin Jin. 2019. "Adaptive Fuzzy Backstepping Sliding Mode Control for a 3-DOF Hydraulic Manipulator with Nonlinear Disturbance Observer for Large Payload Variation" Applied Sciences 9, no. 16: 3290. https://doi.org/10.3390/app9163290

APA StyleTruong, H. V. A., Tran, D. T., To, X. D., Ahn, K. K., & Jin, M. (2019). Adaptive Fuzzy Backstepping Sliding Mode Control for a 3-DOF Hydraulic Manipulator with Nonlinear Disturbance Observer for Large Payload Variation. Applied Sciences, 9(16), 3290. https://doi.org/10.3390/app9163290