Spark Ignition (SI) Engine Energy and Ecological Performance Using Natural Gas and Late Intake Valve Close (LIVC)

Abstract

1. Introduction

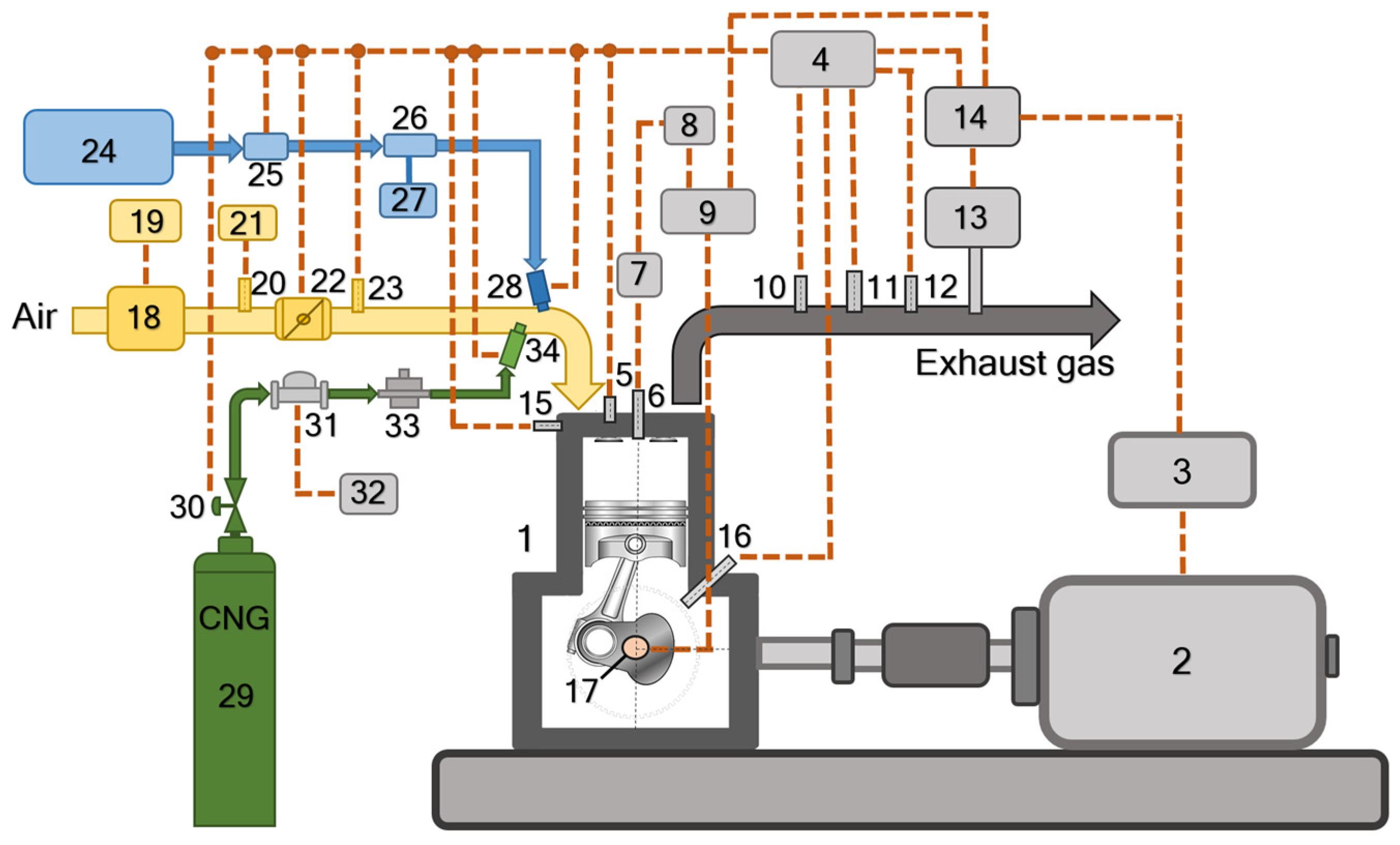

2. Materials and Methods

2.1. The Engine Test Bench, Equipment, and Specifications

2.2. Testing Conditions and Fuel Properties

2.3. The Methodology of the Combustion Process

2.4. Methodology for Calculating Energy and Environmental Performance

3. Results

3.1. Analysis of the Combustion Process

3.2. Analysis of Energy Indicators

3.3. Analysis of Ecological Indicators

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| aBDC | after bottom dead center |

| AFR | air fuel mass ratio |

| A/F | air fuel |

| Bair | air mass flow |

| Bf_g | gasoline mass flow |

| Bf_ng | natural gas mass flow |

| BMEP | break mean effective pressure |

| BSFC | brake-specific fuel consumption |

| BTE | brake thermal efficiency |

| bTDC | before top dead center |

| BDC | bottom dead center |

| CA | crankshaft angle |

| CAD | crankshaft angle degrees |

| CD | combustion duration |

| CH4 | methane |

| C2H6 | ethane |

| C3H8 | propane |

| C4H10 | butane |

| C5H12 | pentane |

| CNG | compressed natural gas |

| CO | carbon monoxide |

| COVIMEP | coefficient of variation of indicated mean effective pressure |

| CO2 | carbon dioxide |

| DOHC | double overhead camshaft |

| ECU | electronic control unit |

| ES | electrochemical sensor |

| EU | European Union |

| G | gasoline |

| ICE | internal combustion engine |

| ID | ignition delay |

| IMEP | indicated mean effective pressure |

| IT | ignition timing |

| IVC | intake valve closing |

| LHV | lower heating value |

| LIVC | late intake valve closing |

| NDIR | non-dispersive infrared technology |

| n | engine speed |

| NG | natural gas |

| NO | nitric oxide |

| NO2 | nitrogen dioxide |

| NOx | nitrogen oxides |

| N2 | nitrogen |

| m | shape parameter |

| MFB | mass fraction burned |

| MFB50 | 50% of the mass fraction burned |

| MFB90 | 90% of the mass fraction burned |

| MN | methane number |

| MON | motor octane number |

| O2 | oxygen |

| pcyl | in-cylinder pressure |

| pex | exhaust pressure |

| pin | intake pressure |

| PN | particle number |

| ROHR | rate of heat release |

| RON | research octane number |

| SI | spark ignition |

| SIE | spark ignition engine |

| SOC | start of combustion |

| TDC | top dead center |

| Tex | exhaust gas temperature |

| Tin | intake air temperature |

| VE | volumetric efficiency |

| VVT | variable valve timing |

| λ | excess air coefficient |

References

- Share of Global CO2 Emissions by Sector. 2023. Available online: https://www.statista.com/statistics/1129656/global-share-of-co2-emissions-from-fossil-fuel-and-cement/ (accessed on 2 February 2025).

- Dimaratos, A.; Kontses, D.; Kontses, A.; Saltas, E.; Raptopoulos-Chatzistefanou, A.; Andersson, J.; Aakko-Saksa, P.; Samaras, Z. Emissions of currently non-regulated gaseous pollutants from modern passenger cars. Transp. Res. Procedia 2023, 72, 3078–3085. [Google Scholar] [CrossRef]

- Fontaras, G.; Zacharof, N.-G.; Ciuffo, B. Fuel consumption and CO2 emissions from passenger cars in Europe—Laboratory versus real-world emissions. Prog. Energy Combust. Sci. 2017, 60, 97–131. [Google Scholar] [CrossRef]

- Greenhouse Gas Emissions from Transport in Europe. Available online: https://www.eea.europa.eu/en/analysis/indicators/greenhouse-gas-emissions-from-transport (accessed on 9 March 2025).

- European Commission. CO2 Emissions from New Cars and Vans Continued to Decrease in 2023 as Zero-Emission Vehicles Registrations Continued to Grow. Available online: https://climate.ec.europa.eu/news-your-voice/news/co2-emissions-new-cars-and-vans-continued-decrease-2023-zero-emission-vehicles-registrations-2024-06-10_en (accessed on 9 March 2025).

- Deal Confirms Zero-Emissions Target for New Cars and Vans in 2035 | News| European Parliament. Available online: https://www.europarl.europa.eu/news/lt/press-room/20221024IPR45734/deal-confirms-zero-emissions-target-for-new-cars-and-vans-in-2035 (accessed on 12 March 2025).

- European Commission. CO2 Emission Performance Standards for Cars and Vans. Available online: https://climate.ec.europa.eu/eu-action/transport/road-transport-reducing-co2-emissions-vehicles/co2-emission-performance-standards-cars-and-vans_en (accessed on 7 March 2025).

- Fan, F.; Dai, S.; Yang, B.; Ke, H. Urban density, directed technological change, and carbon intensity: An empirical study based on Chinese cities. Technol. Soc. 2023, 72, 102151. [Google Scholar] [CrossRef]

- Fan, J.; Meng, X.; Tian, J.; Xing, C.; Wang, C.; Wood, J. A review of transportation carbon emissions research using bibliometric analyses. J. Traffic Transp. Eng. (Engl. Ed.) 2023, 10, 878–899. [Google Scholar] [CrossRef]

- Abrar, I.; Arora, T.; Khandelwal, R. Bioalcohols as an alternative fuel for transportation: Cradle to grave analysis. Fuel Process. Technol. 2023, 242, 107646. [Google Scholar] [CrossRef]

- Tian, Z.; Zhen, X.; Wang, Y.; Liu, D.; Li, X. Comparative study on combustion and emission characteristics of methanol, ethanol and butanol fuel in TISI engine. Fuel 2020, 259, 116199. [Google Scholar] [CrossRef]

- Liu, Z.; Yu, X.; Sun, P.; Xu, S. Experimental investigation of the performance and emissions of a dual-injection SI engine with natural gas direct injection plus gasoline port injection under lean-burn conditions. Fuel 2021, 300, 120952. [Google Scholar] [CrossRef]

- Waseem, M.; Amir, M.; Lakshmi, G.S.; Harivardhagini, S.; Ahmad, M. Fuel cell-based hybrid electric vehicles: An integrated review of current status, key challenges, recommended policies, and future prospects. Green Energy Intell. Transp. 2023, 2, 100121. [Google Scholar] [CrossRef]

- Ghersi, D.E.; Loubar, K.; Amoura, M.; Tazerout, M. Multi-objective optimization of micro co-generation spark-ignition engine fueled by biogas with various CH4/CO2 content based on GA-ANN and decision-making approaches. J. Clean. Prod. 2021, 329, 129739. [Google Scholar] [CrossRef]

- Meng, X.; Xie, F.; Li, X.; Han, L.; Duan, J.; Gong, Y.; Zhou, Y. Study on the effects of intake valve timing and lift on the combustion and emission performance of ethanol, N-butanol, and gasoline engine under stoichiometric combustion and lean burn conditions. Energy 2024, 300, 131385. [Google Scholar] [CrossRef]

- Shi, H.; Jiang, W.; Shen, T. Lyapunov Function based Nonlinear Control of EGR-VVT Dual Loop in IC Engines. In Proceedings of the 2019 IEEE International Conference on Cybernetics and Intelligent Systems (CIS) and IEEE Conference on Robotics, Automation and Mechatronics (RAM), Bangkok, Thailand, 18–20 November 2019; pp. 239–244. [Google Scholar]

- Li, J.; Yu, X.; Xie, J.; Yang, W. Mitigation of high pressure rise rate by varying IVC timing and EGR rate in an RCCI engine with high premixed fuel ratio. Energy 2020, 192, 116659. [Google Scholar] [CrossRef]

- Shin, J.Y.; Lee, S.; Bae, C.; Jung, J.; Son, Y.; Heo, H.; Lee, J. Effect of late intake valve closing on the particle number emissions of a turbocharged gasoline direct injection engine. Fuel Process. Technol. 2022, 230, 107209. [Google Scholar] [CrossRef]

- Kontses, A.; Ntziachristos, L.; Zardini, A.A.; Papadopoulos, G.; Giechaskiel, B. Particulate emissions from L-Category vehicles towards Euro 5. Environ. Res. 2020, 182, 109071. [Google Scholar] [CrossRef]

- Kim, S.; Park, C.; Jang, H.; Kim, C.; Kim, Y. Effect of boosting on a performance and emissions in a port fuel injection natural gas engine with variable intake and exhaust valve timing. Energy Rep. 2021, 7, 4941–4950. [Google Scholar] [CrossRef]

- Wang, R.; Qiao, J.; Jia, D.; Shen, D.; Duan, X.; Liu, J. Effects of asynchronous late intake valve closing combined with high geometric compression ratio and exhaust gas recirculation on combustion and fuel consumption in a turbocharged SI engine:An experimental study. Energy 2024, 290, 130058. [Google Scholar] [CrossRef]

- Prajapati, L.K.; Tirkey, J.V.; Jena, P.; Giri, A. Parametric performance evaluation of SI engine using producer gas-biogas-hydrogen blend as a fuel: A thermodynamic modeling and optimization approach. Int. J. Hydrogen Energy 2024, 72, 268–287. [Google Scholar] [CrossRef]

- Zhu, K.; Lou, D.; Zhang, Y.; Ren, Y.; Fan, L. Effect of Atkinson cycle coupling compression ratio on the combustion characteristics of natural gas engines. Energy 2024, 309, 133111. [Google Scholar] [CrossRef]

- Jia, D.; Qiao, J.; Wang, S.; Guan, J.; Liu, J.; Fu, J.; Li, Y.; Wang, R. Influence of variable enhanced LIVC miller cycle coupled with high compression ratio on the performance and combustion of a supercharged spark ignition engine. Energy 2024, 309, 133214. [Google Scholar] [CrossRef]

- Gong, Z.; Feng, L.; Wang, Z. Experimental and numerical study of the effect of injection strategy and intake valve lift on super-knock and engine performance in a boosted GDI engine. Fuel 2019, 249, 309–325. [Google Scholar] [CrossRef]

- Sirna, A.; Hassan, A.; Ristow Hadlich, R.; Loprete, J.; Trelles, J.P.; Van Dam, N.; Mack, J.H.; Assanis, D. Understanding Diesel-Pilot Assisted Methane Combustion in a Compression Ignition Engine. In Proceedings of the ASME 2023 ICE Forward Conference, Pittsburgh, PA, USA, 8–11 October 2023; American Society of Mechanical Engineers: Pittsburgh, PA, USA, 2023; p. V001T02A003. [Google Scholar]

- Pamminger, M.; Sevik, J.; Scarcelli, R.; Wallner, T.; Hall, C. Influence of Compression Ratio on High Load Performance and Knock Behavior for Gasoline Port-Fuel Injection, Natural Gas Direct Injection and Blended Operation in a Spark Ignition Engine. In Proceedings of the WCXTM 17: SAE World Congress Experience, Detroit, MI, USA, 4–6 April 2017. SAE Technical Paper 2017-01-0661. [Google Scholar] [CrossRef]

- Li, X.; Zhen, X.; Wang, Y.; Tian, Z. Numerical comparative study on performance and emissions characteristics fueled with methanol, ethanol and methane in high compression spark ignition engine. Energy 2022, 254, 124374. [Google Scholar] [CrossRef]

- Karagöz, Y.; Balcı, Ö.; Gezer, O.; Köten, H.; Işın, Ö. Performance and emissions of spark-ignition engines fuelled with petrol and methane. Proc. Inst. Civ. Eng. Energy 2021, 174, 156–169. [Google Scholar] [CrossRef]

- Oh, J.; Noh, K.; Lee, C. A Theoretical Study on the Thermodynamic Cycle of Concept Engine with Miller Cycle. Processes 2021, 9, 1051. [Google Scholar] [CrossRef]

- Murtaza, G.; Bhatti, A.I.; Ahmed, Q. Design, Development, and Evaluation of a Control Framework for an Atkinson Cycle Engine. J. Dyn. Syst. Meas. Control 2018, 140, 051005. [Google Scholar] [CrossRef]

- Shojaeefard, M.H.; Keshavarz, M. Mathematical modeling of the complete thermodynamic cycle of a new Atkinson cycle gas engine. Appl. Therm. Eng. 2015, 91, 866–874. [Google Scholar] [CrossRef]

- Murtaza, G.; Bhatti, A.I.; Ahmed, Q. Control-Oriented Model of Atkinson Cycle Engine With Variable Intake Valve Actuation. J. Dyn. Syst. Meas. Control 2016, 138, 061001. [Google Scholar] [CrossRef]

- Niu, Q.; Sun, B.; Zhang, D.; Luo, Q. Research on performance optimization and fuel-saving mechanism of an Atkinson cycle gasoline engine at low speed and part load. Fuel 2020, 265, 117010. [Google Scholar] [CrossRef]

- Sun, X.; Fu, J.; Zhou, F.; Luo, B.; Liu, J. Performance prediction and multi-objective optimization for the Atkinson cycle engine using eXtreme Gradient Boosting. Therm. Sci. Eng. Prog. 2024, 48, 102402. [Google Scholar] [CrossRef]

- Kurien, C.; Varma, P.S.; Mittal, M. Effect of ammonia energy fractions on combustion stability and engine characteristics of gaseous (ammonia/methane) fuelled spark ignition engine. Int. J. Hydrogen Energy 2023, 48, 1391–1400. [Google Scholar] [CrossRef]

- Yang, S.; Yang, X.; Liu, H.; Feng, Z.; Li, X. Simulation Analysis of Early and Late Miller Cycle Strategies Influence on Diesel Engine Combustion and Emissions. In Proceedings of the WCX SAE World Congress Experience, Detroit, MI, USA, 21–23 April 2020. SAE Technical Paper 2020-01-0662. [Google Scholar] [CrossRef]

- Hanipah, M.R.; Rosli, M.H.A.; Razali, A.R. Flexible valve timing strategies for boosting a small four-stroke spark ignition engine performance. In Proceedings of the Small Engine Technology Conference & Exposition, Hiroshima, Japan, 19–21 November 2019. SAE Technical Paper 2019-32-0591. [Google Scholar] [CrossRef]

- Allawi, M.K.; Mejbel, M.K.; Oudah, M.H. Variable Valve Timing (VVT) Modelling by Lotus Engine Simulation Software. Int. J. Automot. Mech. Eng. 2021, 17, 8397–8410. [Google Scholar] [CrossRef]

- Zibani, I.; Marumo, R.; Chuma, J.; Ngebani, I.; Tsamaase, K. Variable Valve Timing for a Camless Stepping Valve Engine. Procedia Manuf. 2020, 43, 590–597. [Google Scholar] [CrossRef]

- Millo, F.; Mirzaeian, M.; Luisi, S.; Doria, V.; Stroppiana, A. Engine displacement modularity for enhancing automotive s.i. engines efficiency at part load. Fuel 2016, 180, 645–652. [Google Scholar] [CrossRef]

- Dev, S.; Guo, H.; Lafrance, S.; Liko, B. An Experimental Study on the Effect of Exhaust Gas Recirculation on a Natural Gas-Diesel Dual-Fuel Engine. In Proceedings of the WCX SAE World Congress Experience, Detroit, MI, USA, 21–23 April 2020. SAE Technical Paper 2020-01-0310. [Google Scholar] [CrossRef]

- Park, S.; Song, S. Model-based multi-objective Pareto optimization of the BSFC and NO x emission of a dual-fuel engine using a variable valve strategy. J. Nat. Gas Sci. Eng. 2017, 39, 161–172. [Google Scholar] [CrossRef]

- Fairbrother, R.; Leifert, T.; Gande, R.; Salentinig, G. Accurate Gas Exchange and Combustion Analysis Directly at the Test Bed. In Proceedings of the ASME 2012 Internal Combustion Engine Division Fall Technical Conference, Vancouver, BC, Canada, 23–26 September 2012; American Society of Mechanical Engineers: Vancouver, BC, Canada, 2012; pp. 667–676. [Google Scholar]

- Rimkus, A.; Vipartas, T.; Kriaučiūnas, D.; Matijošius, J.; Ragauskas, T. The Effect of Intake Valve Timing on Spark-Ignition Engine Performances Fueled by Natural Gas at Low Power. Energies 2022, 15, 398. [Google Scholar] [CrossRef]

- Sankesh, D.; Edsell, J.; Mazlan, S.; Lappas, P. Comparative Study between Early and Late Injection in a Natural-gas Fuelled Spark-ignited Direct-injection Engine. Energy Procedia 2017, 110, 275–280. [Google Scholar] [CrossRef]

- Bozza, F.; De Bellis, V.; Teodosio, L. A numerical procedure for the calibration of a turbocharged spark-ignition variable valve actuation engine at part load. Int. J. Engine Res. 2017, 18, 810–823. [Google Scholar] [CrossRef]

- Kumar Singotia, P.; Saraswati, S. Cycle-by-cycle variations in a spark ignition engine fueled with gasoline and natural gas. IOP Conf. Ser. Mater. Sci. Eng. 2019, 691, 012061. [Google Scholar] [CrossRef]

- Duan, X.; Deng, B.; Liu, Y.; Li, Y.; Liu, J. Experimental study the impacts of the key operating and design parameters on the cycle-to-cycle variations of the natural gas SI engine. Fuel 2021, 290, 119976. [Google Scholar] [CrossRef]

- Jahirul, M.I.; Masjuki, H.H.; Saidur, R.; Kalam, M.A.; Jayed, M.H.; Wazed, M.A. Comparative engine performance and emission analysis of CNG and gasoline in a retrofitted car engine. Appl. Therm. Eng. 2010, 30, 2219–2226. [Google Scholar] [CrossRef]

- Heoy Geok, H.; Mohamad, T.; Abdullah, S.; Yusoff, A.; Shamsudeen, A.; Adril, E. Experimental investigation of performance and emission of a sequential port injection natural gas engine. Eur. J. Sci. Res. 2009, 30, 204–214. [Google Scholar]

- Yan, B.; Wang, H.; Zheng, Z.; Qin, Y.; Yao, M. The effects of LIVC Miller cycle on the combustion characteristics and thermal efficiency in a stoichiometric operation natural gas engine with EGR. Appl. Therm. Eng. 2017, 122, 439–450. [Google Scholar] [CrossRef]

- Tirkey, J.V. Thermodynamic performance analysis of over-expansion stroke and late inlet valve close on hcng-si engine. Int. J. Power Energy Syst. 2018, 38. [Google Scholar] [CrossRef]

- Wang, J.; Duan, X.; Wang, W.; Guan, J.; Li, Y.; Liu, J. Effects of the continuous variable valve lift system and Miller cycle strategy on the performance behavior of the lean-burn natural gas spark ignition engine. Fuel 2021, 297, 120762. [Google Scholar] [CrossRef]

- Garlet, R.A.; Fagundez, J.L.S.; Hausen, R.B.; Roso, V.R.; Lanzanova, T.D.M.; Salau, N.P.G.; Martins, M.E.S. Prospects of performance, emissions and cost of methane-based fuels in a spark-ignition engine compared to conventional Brazilian fuels. Fuel 2024, 357, 129788. [Google Scholar] [CrossRef]

- Bohon, S.; Fang, T. Performance and emission testing of a bi-fuel outboard spark-ignition engine. Int. J. Engine Res. 2016, 17, 576–592. [Google Scholar] [CrossRef]

- Kim, J.; Park, S.S.; Bae, C. The effects of late intake valve closing and different cam profiles on the in-cylinder flow field and the combustion characteristics of a compression ignition engine. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2018, 232, 853–865. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Engine type/code | Naturally aspirated, four-stroke/HR16DE |

| No. of cylinders/valves | 4/16 |

| Cylinder arrangement | In-line |

| Injection type | Port fuel injection |

| Gas distribution system | Double overhead camshaft (DOHC) |

| Displacement/firing order | 1.598 dm3/1-3-4-2 |

| Bore/stroke | 78.0 mm/83.6 mm |

| Compression ratio | 10.7 |

| Max. engine power | 84 kW at 6000 rpm |

| Max. engine torque | 156 Nm at 4400 rpm |

| Intake valve open/close | 24°–−11° before TDC 1/24°–59° after BDC 2 |

| Exhaust valve open/close | 24° before BDC/4° after TDC |

| Intake and exhaust valve duration | 228°, 208° |

| Fuel type | Gasoline, compressed natural gas |

| Gas | Measuring Principle | Resolution | Measurement Reliability | Measuring Range |

|---|---|---|---|---|

| CO2 | NDIR 1 | 0.01% vol. | 0.2% vol. 2 | 0–50% vol. |

| CO | NDIR | 0.1 ppm | 2 ppm 2 | 0–10,000 ppm |

| NO | NDIR | 0.1 ppm | 2 ppm 2 | 0–4000 ppm |

| NO2 | NDIR | 0.1 ppm | 1 ppm 2 | 0–1000 ppm |

| CH4 | NDIR | 0.1 ppm | 10 ppm 2 | 0–10,000 ppm |

| C3H8 | NDIR | 0.1 ppm | 2 ppm 2 | 0–5000 ppm |

| O2 | ES 4 | 0.01% vol. | ±0.25% vol. 3 | 0–25% vol. |

| Properties | Gasoline (E10) | Natural Gas |

|---|---|---|

| Density, [kg/m3] | 753.7 * | 0.7609 |

| Lower heating value, [MJ/kg] | 41.79 | 49.22 ** |

| Research octane number (RON) | 97.1 | ~120 |

| Methane number (MN) | - | ~77 |

| Stoichiometric A/F ratio, [kg/kg] | 14.24 | ~17.1 |

| Fuel composition, [%Vol.] | Gasoline 90.3 | Methane (CH4) 94.3124 |

| Ethanol 9.7 | Ethane (C2H6) 4.2309 | |

| Propane (C3H8) 0.6631 | ||

| i-Butane (C4H10) 0.0766 | ||

| n-Butane (C4H10) 0.1405 | ||

| neo-Pentane (C5H12) 0.0015 | ||

| i-Pentane (C5H12) 0.0098 | ||

| n-Pentane (C5H12) 0.0043 | ||

| C6 plus (C6+) 0.0015 | ||

| Nitrogen (N2) 0.4446 | ||

| Carbon dioxide (CO2) 0.1155 | ||

| Hydrogen (H), [%Mass] | 13.89 | 24.34 |

| Carbon (C), [%Mass] | 82.5 | 74.69 |

| Oxygen (O), [%Mass] | 3.61 | - |

| H/C ratio | 1.87/1 | 3.88/1 |

| Physical state | Liquid | Compressed gas |

| Object | Input Data |

|---|---|

| Fuel properties | Fuel type, stoichiometric air-to-fuel ratio (AFR), lower heating value (LHV). |

| Engine values | Number of cylinders, engine cycle, bore, stroke, compression ratio, connecting rod length, piston top surface area, cylinder head and liner, pressure in cylinder pcyl. |

| Operation point | Engine speed n, break mean effective pressure BMEP, start and end of high pressure, air mass flow Bair, mass flow of gasoline Bf_g and natural gas Bf_ng, residual gas content, piston and cylinder head wall temperature, liner temperature when piston at top and bottom dead center. |

| Test Conditions | Combustion Phase | IVC, 24° aBDC | IVC, 38° aBDC | IVC, 52° aBDC | IVC, 59° aBDC | ||||

|---|---|---|---|---|---|---|---|---|---|

| G | NG | G | NG | G | NG | G | NG | ||

| n = 2000 rpm BMEP = 0.31 MPa | ID | 14.3 | 13.6 | 13.7 | 13.2 | 12.8 | 12.2 | 10.8 | 10.1 |

| MFB50 | 17.3 | 18.5 | 13.4 | 14.2 | 10.1 | 10.7 | 7.6 | 8.3 | |

| MFB90 | 32.9 | 38.0 | 31.2 | 34.7 | 28.0 | 29.3 | 21.1 | 21.4 | |

| n = 2000 rpm BMEP = 0.79 MPa | ID | 9.6 | 8.9 | 8.7 | 8.4 | 8.1 | 7.8 | 7.4 | 7.3 |

| MFB50 | 8.9 | 10.3 | 7.5 | 8.8 | 5.9 | 7.1 | 4.3 | 5.4 | |

| MFB90 | 19.0 | 23.3 | 18.2 | 22.1 | 16.9 | 20.2 | 14.2 | 17.0 | |

| n = 3000 rpm BMEP = 0.31 MPa | ID | 11.7 | 7.8 | 11.4 | 10.3 | 11.2 | 10.7 | 11.0 | 10.9 |

| MFB50 | 5.7 | 5.3 | 5.7 | 5.6 | 5.8 | 5.6 | 5.7 | 5.5 | |

| MFB90 | 19.4 | 18.8 | 20.0 | 19.6 | 20.7 | 20.5 | 21.7 | 21.6 | |

| n = 3000 rpm BMEP = 0.79 MPa | ID | 7.8 | 6.7 | 7.4 | 6.5 | 6.5 | 6.2 | 6.8 | 5.8 |

| MFB50 | 5.0 | 6.8 | 4.3 | 6.2 | 3.7 | 5.3 | 2.8 | 4.8 | |

| MFB90 | 17.4 | 19.6 | 16.5 | 19.0 | 15.6 | 18.2 | 14.7 | 17.4 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vipartas, T.; Rimkus, A.; Stravinskas, S.; Pitrėnas, A.; Matulis, A. Spark Ignition (SI) Engine Energy and Ecological Performance Using Natural Gas and Late Intake Valve Close (LIVC). Appl. Sci. 2025, 15, 6185. https://doi.org/10.3390/app15116185

Vipartas T, Rimkus A, Stravinskas S, Pitrėnas A, Matulis A. Spark Ignition (SI) Engine Energy and Ecological Performance Using Natural Gas and Late Intake Valve Close (LIVC). Applied Sciences. 2025; 15(11):6185. https://doi.org/10.3390/app15116185

Chicago/Turabian StyleVipartas, Tadas, Alfredas Rimkus, Saulius Stravinskas, Aurelijus Pitrėnas, and Audrius Matulis. 2025. "Spark Ignition (SI) Engine Energy and Ecological Performance Using Natural Gas and Late Intake Valve Close (LIVC)" Applied Sciences 15, no. 11: 6185. https://doi.org/10.3390/app15116185

APA StyleVipartas, T., Rimkus, A., Stravinskas, S., Pitrėnas, A., & Matulis, A. (2025). Spark Ignition (SI) Engine Energy and Ecological Performance Using Natural Gas and Late Intake Valve Close (LIVC). Applied Sciences, 15(11), 6185. https://doi.org/10.3390/app15116185