Abstract

Sesame oil has been widely used for centuries. It is not only used as a kitchen ingredient, but it is also used to apply to the skin. Sesame oil contains natural compounds such as sesamol, sesamolin and sesamide, which have the ability to reflect or absorb certain UV rays. These substances can act as UV filters, helping to minimize the effects of harmful UV radiation on the skin. The aim of the study was to investigate the radioprotective/sun protection properties of sesame oil. The influence of sesame oils from different manufacturers on the directional reflectance of the skin was analyzed at various time intervals. To assess the sunscreen properties of the oil, a new technique was used: the 410-Solar hemispherical directional reflectometer. Sesame oil can be used in sunscreen preparations, but only when combined with other, more powerful ingredients. The oil itself is not sufficient protection against solar radiation. The study revealed no significant disparities in performance between the tested sesame oils from diverse manufacturers.

1. Introduction

Sesame oil has accompanied humans for thousands of years. It is obtained from the seeds of the oil plant Sesamum indicum L. in the process of cold pressing or refining. It is widely used in the cosmetics industry due to its anti-inflammatory, antioxidative, and emollient properties. As an emollient, it is used in lubricating preparations to alleviate the symptoms of diseases resulting from damage to the protective barrier of the skin and also in products for the care of the delicate skin of infants and children. Applied to the face as the last stage of care, it creates an occlusive layer on the skin surface, so the active ingredients from preparations applied under the oil can penetrate deeper and remain on the skin longer. An oil coating also inhibits excessive water loss from the epidermis [1,2,3,4]. Since ancient times, this oil has been used for hair care to add shine and to protect the hair against external factors. Pure sesame oil, in mixtures with other oils or with essential oils, is used in massage and in the art of Ayurveda. Due to the high content of fatty acids, the extracted oil is also used to make high-quality soaps [1,2,3].

Sesame oil is recommended for use on burns, including sunburns, due to its regenerative properties. It enables faster wound healing. It is also considered a natural UV filter and is added to sunscreen preparations [2,4,5]. Its ingredients, such as sesamol, sesamolin, sesamide, and lecithin can reflect or absorb certain UV rays. Sesamol, a 5-hydroxy-1,3-benzodioxole, can be formed as a result of the thermal reduction of sesamolin. This compound has an antioxidative effect that helps protect the skin from UVB damage. UVB radiation leads to the formation of reactive oxygen species (ROS), which can damage DNA and contribute to skin cancer and photoaging. Sesamol neutralizes free radicals and reduces the risk of such damage. Sesamol increases the activity of several antioxidative enzymes, such as superoxide dismutase, catalase, glutathione peroxidase, and glutathione. Sesamol decreases cytotoxicity, ROS levels, lipid peroxidation, and oxidative DNA damage in skin fibroblasts. Sesamol also reduces the expression of TRP-1 and TRP-2 proteins, which are involved in melanin synthesis, and inhibits the expression of MITF, the main regulator of melanogenesis. This leads to a reduction in skin hyperpigmentation induced by UV [6,7,8].

Like sesamol, sesamolin has antioxidative properties, neutralizes free radicals, and boosts the activity of antioxidative enzymes, which are crucial in neutralizing reactive oxygen species caused by UVB radiation [6,8,9].

Lecithin is a component of cell membranes that helps to maintain the integrity and stability of skin lipids. UV radiation can lead to lipid peroxidation, which destabilizes cell membranes. Lecithin is an antioxidant that helps protect skin cells [9].

The growing awareness of the risks of solar radiation on the skin is having an impact on the cosmetics industry, especially the tanning products segment. Recently, natural products have gained interest. Sunscreen manufacturers have added natural raw materials with a sun-protective effect, such as vegetable oils, to cosmetic formulas. Oils have a low sun protection factor, so they cannot be used alone. Most are often combined with substances with higher photoprotective properties, such as physical or chemical filters. Due to their antioxidative and anti-inflammatory properties, vegetable oils aid in minimizing the effects of UV exposure and have a beneficial impact on the skin’s condition [10].

Photoprotection is crucial in preventing the consequences of long-term exposure to solar radiation, which causes visible deterioration in the structure and function of the skin. More serious effects include an increased risk of carcinogenesis and the development of skin cancer. Topical application of photoprotective preparations that contain active molecules that absorb or reflect UV radiation on the skin is the most common method for reducing the penetration of UV radiation on the skin.

The aim of this study was to evaluate the sun protection properties of sesame oil when applied to the skin. Currently, efforts are underway to find substances that can absorb or reflect UV radiation without affecting the skin. However, the literature lacks in vivo studies. Such research is necessary to objectively assess how effectively the oil provides protection against radiation when applied to the skin. The study was performed in vivo using a non-invasive hemispherical directional reflectance method.

The use of hemispherical directional reflection to examine skin and cosmetic products has recently been demonstrated to be an effective method for assessing their quantitative and qualitative interactions with electromagnetic radiation in the spectral range from 335 to 2500 nm [11,12,13]. The directional reflectance of a surface is defined as the ratio of the total energy reflected into the subtending hemisphere to the energy incident on the studied surface [11,14]. Reflectance, or the light reflection coefficient, is expressed as the ratio of the power of the reflected beam to the power incident on the boundary of two media with different refractive indices. The energy value of electromagnetic radiation reflected by the body ranges from 0 to 1. The greater the reflectance value, the more electromagnetic radiation is reflected from the body surface [12].

2. Materials and Methods

The research was conducted in accordance with the Helsinki Declaration [15] on a group of 20 healthy women, aged 20–60, with phototypes I–III according to Fitzpatrick [16]. There were no visible blood vessels, pigmented moles, or other lesions or dermatoses in the examined areas.

A 410-Solar directional reflectometer (Surface Optics Corporation, San Diego, CA, USA) was used for the measurements. The reflectometer measures reflectance at a near-normal incidence at an angle of incidence 20° for seven spectral bands encompassing ultraviolet, visible light, and infrared: 335–380 nm, 400–540 nm, 480–600 nm, 590–720 nm, 700–1100 nm, 1000–1700 nm, and 1700–2500 nm. The component of the apparatus that performs the measurement is the hemispherical directional measurement head [11].

Before applying the products to the skin, a first measurement was performed. Then, four different sesame oils, in an amount of 2 mg/cm2, were applied to the skin on a previously marked, hairless 30 × 30 mm area on the inside of the forearm.

There were four cold-pressed sesame oils from four different producers, marked as oils A, B, C, and D. Three measurements were performed for each site, and then the results were averaged. The subsequent measurements were performed 20 min, 60 min, and 120 min after applying the oil to the skin.

The obtained dataset was entered into an Excel v. 2019 spreadsheet, and then its completeness was assessed. In the next stage, the verified database was implemented into licensed statistical packages such as Statistica V.7.1. pl by StatSoft, the PQ-Stat Software package, v. 1.6.6.204 (2018), and MedCalc Statistical Software v. 20.019 (MedCalc Software bvba, Ostend, Belgium; 2021), which were used to perform the statistical calculations and evaluations [17,18,19].

In the statistical evaluation, the level of significance (the probability of making a type I error) was p(α) < 0.05. The compliance of the distribution of the tested feature (reflectance level) with the normal distribution was verified using the Shapiro–Wilk test. To statistically evaluate differences in reflectance levels at subsequent time points (before application, after 20 min, after 60 min, after 120 min), the non-parametric Friedman ANOVA test for repeated (dependent) measurements was used. The use of the test does not require a normal distribution. Since it was found that the Friedman statistic is often too conservative, in addition to the traditional Friedman ANOVA test, its modification proposed by Iman and Davenport, which additionally includes corrections for tied ranks, was used. Conover–Iman post hoc tests for repeated measurements were used directly in the ANOVA tests for simple (multiple) comparisons. The non-parametric Kruskal–Wallis ANOVA test was used to statistically evaluate differences in reflectance levels at selected time points between groups using different types of oils (Oil A, Oil B, Oil C, Oil D). To use the test, the distribution of the tested variable does not require compliance with a normal distribution. If a statistically significant relation was found, the Kruskal–Wallis ANOVA test was supplemented with Dunn–Bonferoni post hoc tests [17,18,19].

3. Results

3.1. Reflectance Values at a Wavelength of 335–380 nm

Table 1 presents selected descriptive statistics of the reflectance at a wavelength of 335–380 nm.

Table 1.

Selected descriptive statistics of the reflectance values at a wavelength of 335–380 nm, along with a statistical assessment of the normality of distribution.

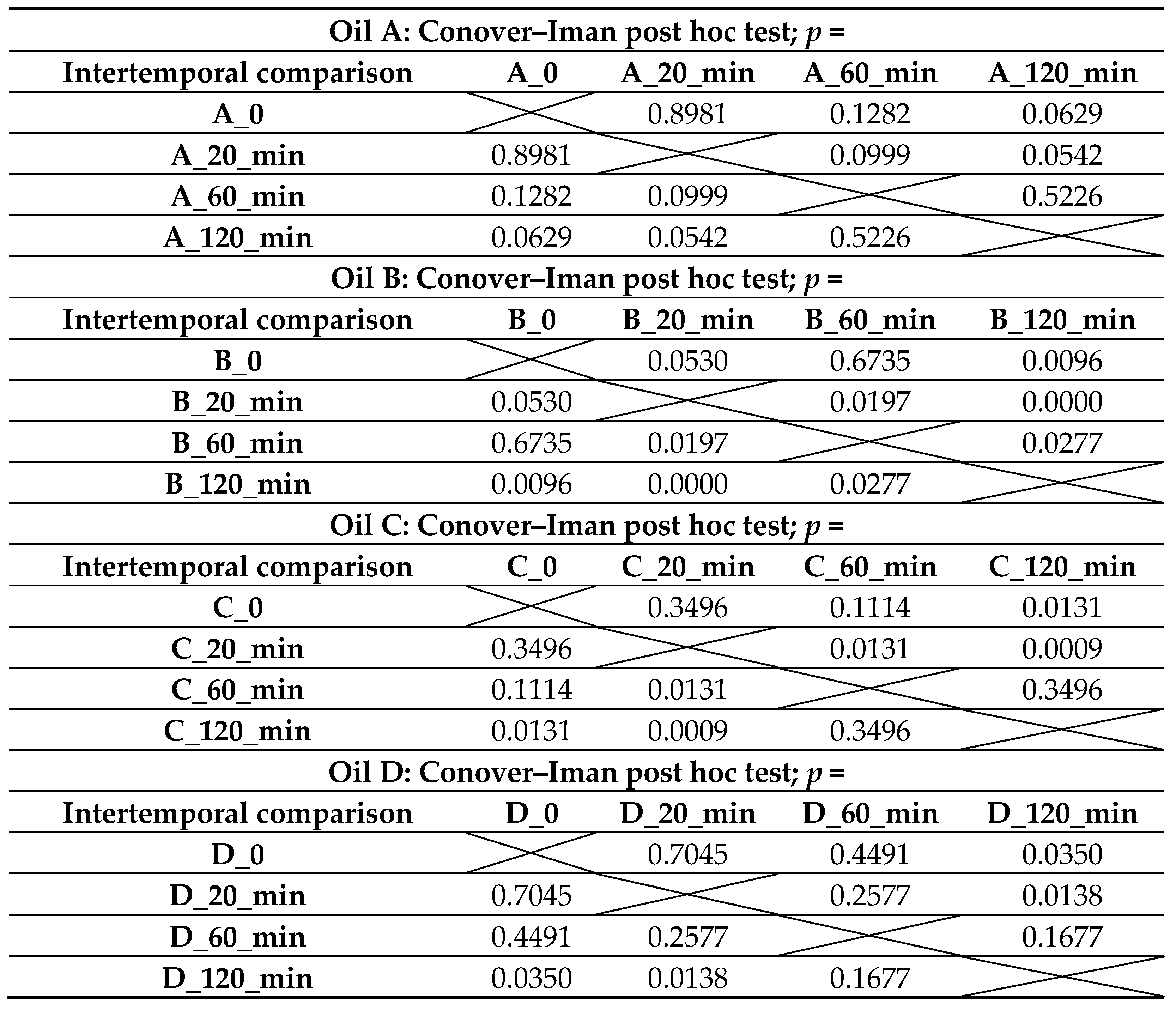

In assessing the differences in reflectance values at various time points (before oil application, after 20 min, and after 60 min), there was no statistically significant difference (p = 0.4443) between particular time points for the reflectance at a wavelength of 335–380 nm after the application of Oil A. The results of repeated tests (Table 2) confirm the lack of differences at all time points of the reflectance assessment at a wavelength of 335–380 nm after the use of Oil A.

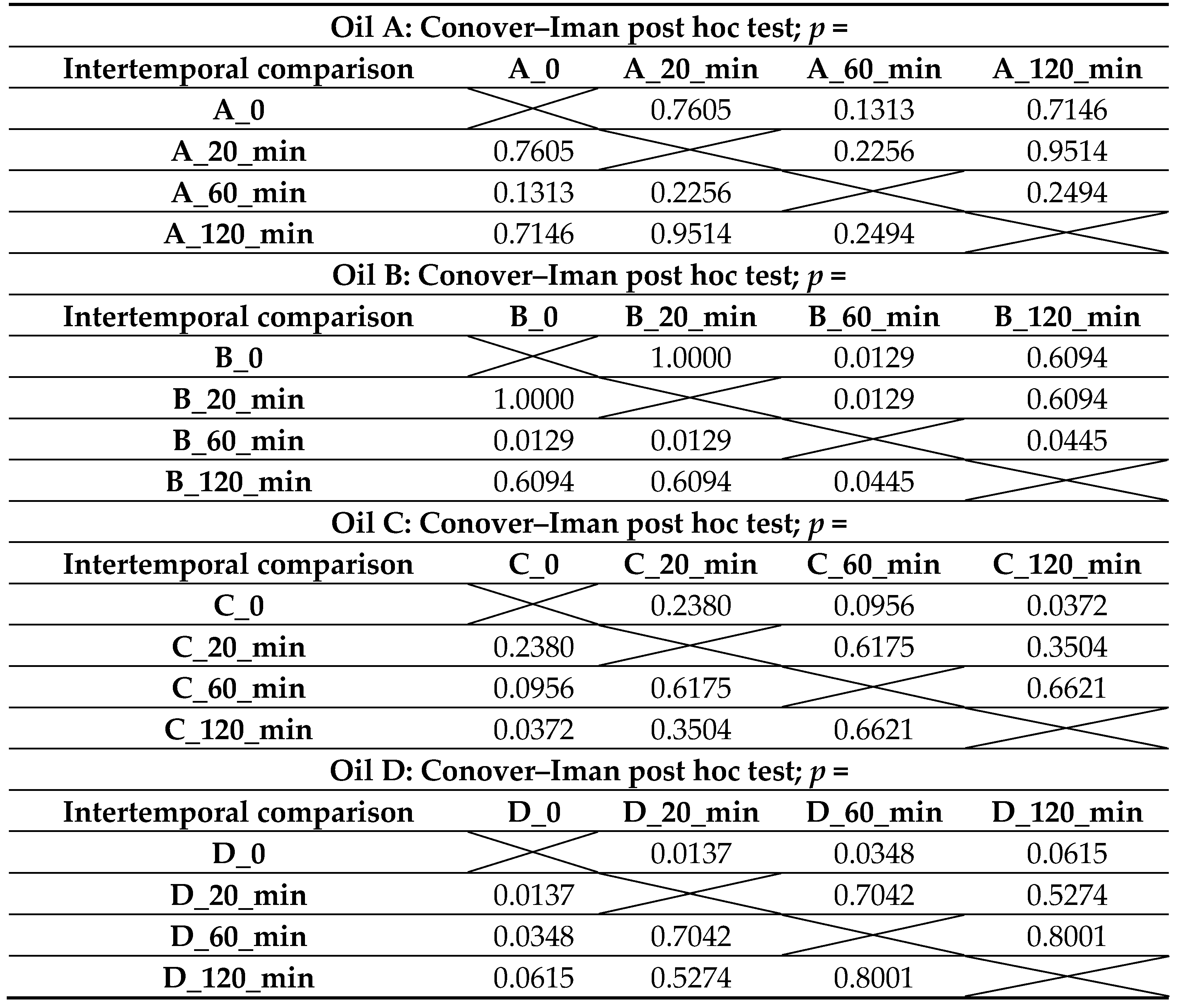

Table 2.

Results of post hoc tests on the reflectance at a wavelength of 335–380 nm after the application of Oils A, B, C, and D.

In the assessment of differences in reflectance values at subsequent time points (before oil application, after 20 min, and after 60 min), a statistically significant difference (p = 0.0348) was found between particular time points for the reflectance at a wavelength of 335–380 nm after the application of Oil B.

Moreover, it was found that at a wavelength of 335–380 nm after the application of Oil B (Table 2), the reflectance value after 60 min of exposure was statistically significantly higher compared with the value before and after 20 min of exposure, while the reflectance value after 120 min of exposure was statistically significantly lower compared with the value after 60 min of exposure.

In the assessment of differences in reflectance values at subsequent time points (before oil application, after 20 min, and after 60 min), there was no statistically significant difference (p = 0.1779) between particular time points for the reflectance at a wavelength of 335–380 nm after the application of Oil C.

However, it was found that at a wavelength of 335–380 nm after the application of Oil C (Table 2), the reflectance value after 120 min of exposure was statistically significantly higher compared with the value right before exposure.

In the assessment of differences in reflectance values at subsequent time points (before oil application, after 20 min, and after 60 min), there was no statistically significant difference (p = 0.0634) between particular time points for the reflectance at a wavelength of 335–380 nm after the application of Oil D.

However, it was found that at a wavelength of 335–380 nm after the application of Oil D (Table 2), the reflectance values after 20 min and 60 min of exposure were statistically significantly higher compared with the value right before exposure.

Comparing the type of oil, there was no statistically significant difference in the reflectance values at a wavelength of 335–380 nm before exposure (p = 0.9473), after 20 min of exposure (p = 0.8877), after 60 min of exposure (p = 0.7580), and after 120 min of exposure (p = 0.8877) between the type of oil used.

3.2. Reflectance Values at a Wavelength of 400–540 nm

Table 3 presents selected descriptive statistics of the reflectance at a wavelength of 400–540 nm.

Table 3.

Selected descriptive statistics of the reflectance value at a wavelength of 400–540 nm, along with a statistical assessment of the normality of distribution.

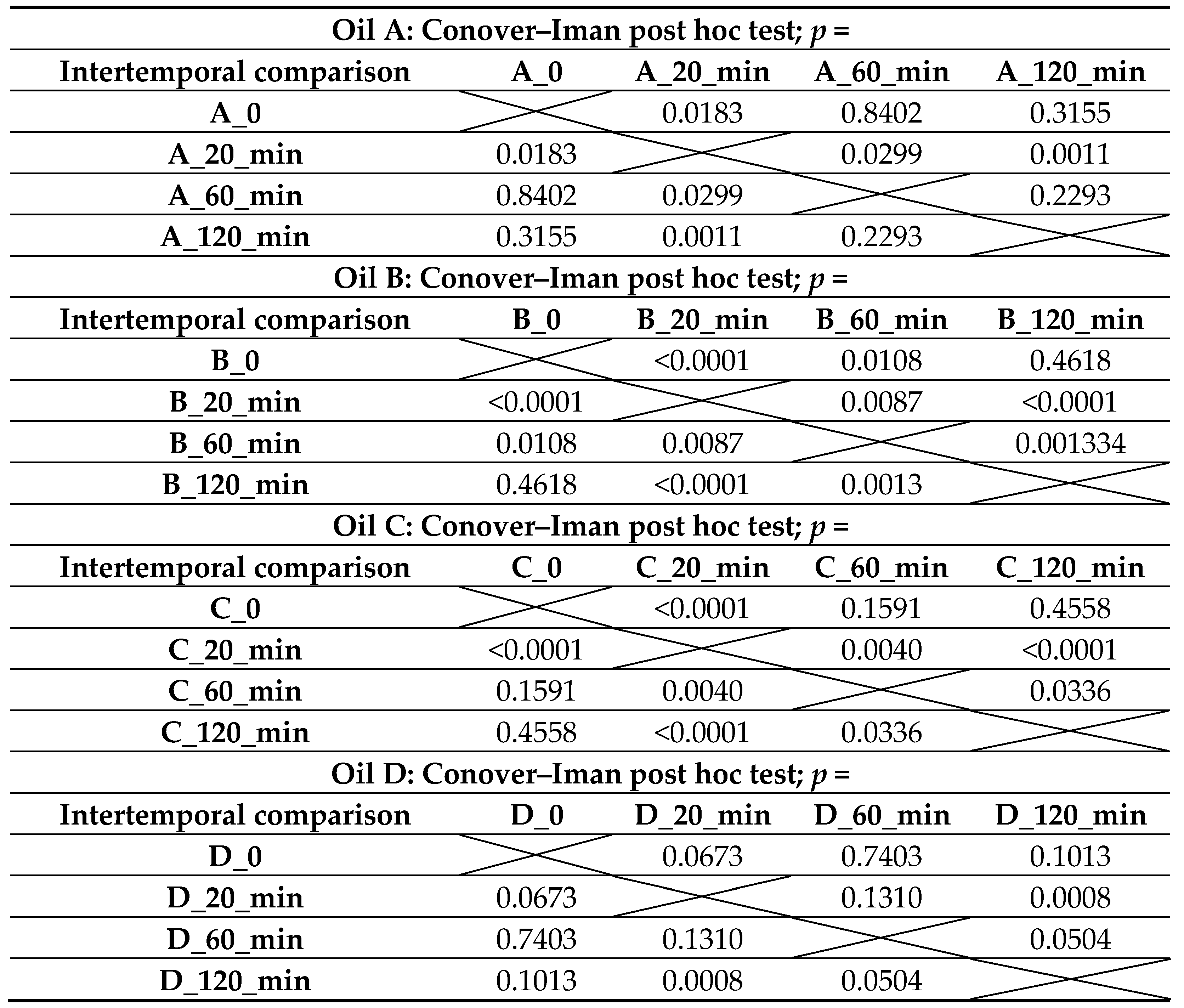

In the assessment of differences in reflectance values at subsequent time points (before oil application, after 20 min, and after 60 min), a statistically significant difference (p = 0.0108) was found between particular time points for the reflectance value at a wavelength of 400–540 nm after the application of Oil A.

Moreover, it was found that at a wavelength of 400–540 nm after the application of Oil A (Table 4), the reflectance values after 60 min and 120 min of exposure were statistically significantly higher compared with the value after 20 min of exposure.

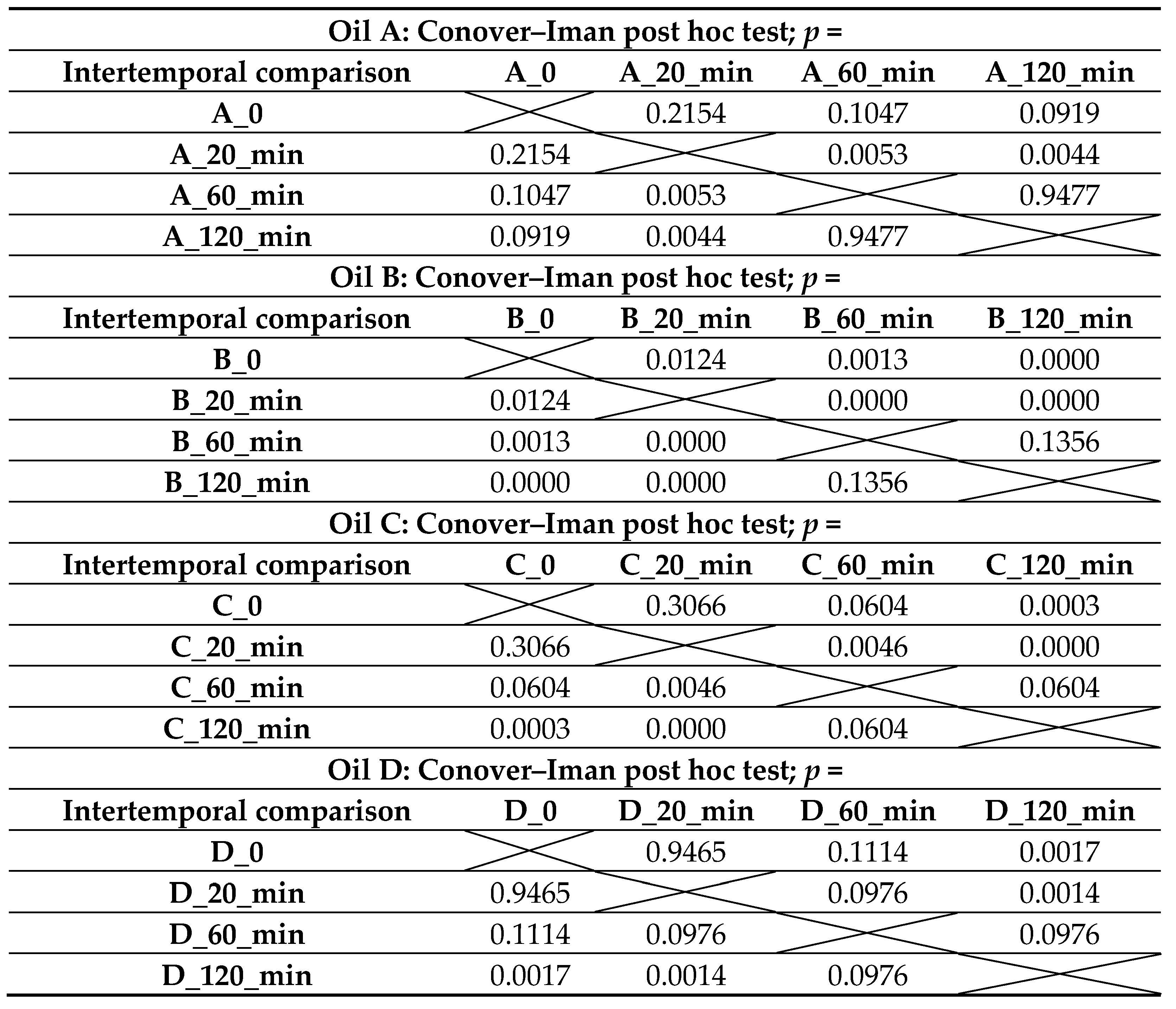

Table 4.

Results of post hoc tests on the reflectance at a wavelength of 400–540 nm after the application of Oils A, B, C, and D.

In the assessment of differences in reflectance values at subsequent time points (before oil application, after 20 min, and after 60 min), a statistically significant difference (p < 0.0001) was found between particular time points for the reflectance at a wavelength of 400–540 nm after the application of Oil B.

It was shown that at a wavelength of 400–540 nm after the application of Oil B (Table 4), the reflectance value before exposure was statistically significantly higher compared with the value after 20 min of exposure, and after 60 min and 120 min of exposure, it was statistically significantly lower. Moreover, the reflectance value after 20 min of exposure was statistically significantly lower than the value after 60 and 120 min of exposure.

In the assessment of differences in reflectance values at subsequent time points (before oil application, after 20 min, and after 60 min), a statistically significant difference (p < 0.0001) was found between particular time points for the reflectance at a wavelength of 400–540 nm after the application of Oil C.

It was found that at a wavelength of 400–540 nm after the application of Oil C (Table 4), the reflectance value after 120 min of exposure was statistically significantly higher compared with the value before and after 20 min of exposure, and that the reflectance value after 60 min of exposure was statistically significantly higher compared with the value after 20 min of exposure.

In the assessment of differences in reflectance values at subsequent time points (before oil application, after 20 min, and after 60 min), a statistically significant difference (p = 0.0034) was found between particular time points for the reflectance at a wavelength of 400–540 nm after the application of Oil D.

Moreover, it was found that at a wavelength of 400–540 nm after the application of Oil D (Table 4), the reflectance value after 120 min of exposure was statistically significantly higher compared with the value before and after 20 min of exposure.

Comparing the type of oil, there was no statistically significant difference in the reflectance values at a wavelength of 400–540 nm before exposure (p = 0.8076), after 20 min of exposure (p = 0.8822), after 60 min of exposure (p = 0.8331), and after 120 min of exposure (p = 0.7438) between the type of oil used.

3.3. Reflectance Values at a Wavelength of 480–600 nm

Table 5 presents selected descriptive statistics of the reflectance at a wavelength of 480–600 nm.

Table 5.

Selected descriptive statistics of the reflectance value at a wavelength of 480–600 nm, along with a statistical assessment of the normality of distribution.

In the assessment of differences in reflectance values at subsequent time points (before oil application, after 20 min, and after 60 min), there was no statistically significant difference (p = 0.1678) between particular time points for the reflectance at a wavelength of 480–600 nm after the application of Oil A.

In the assessment of differences in reflectance values at subsequent time points (before oil application, after 20 min, and after 60 min), a statistically significant difference (p = 0.0059) was found between particular time points for the reflectance at a wavelength of 480–600 nm after the application of Oil B.

Moreover, it was found that at a wavelength of 480–600 nm after the application of Oil B (Table 6), the reflectance values after 60 min and 120 min of exposure were statistically significantly higher compared with the value after 20 min of exposure.

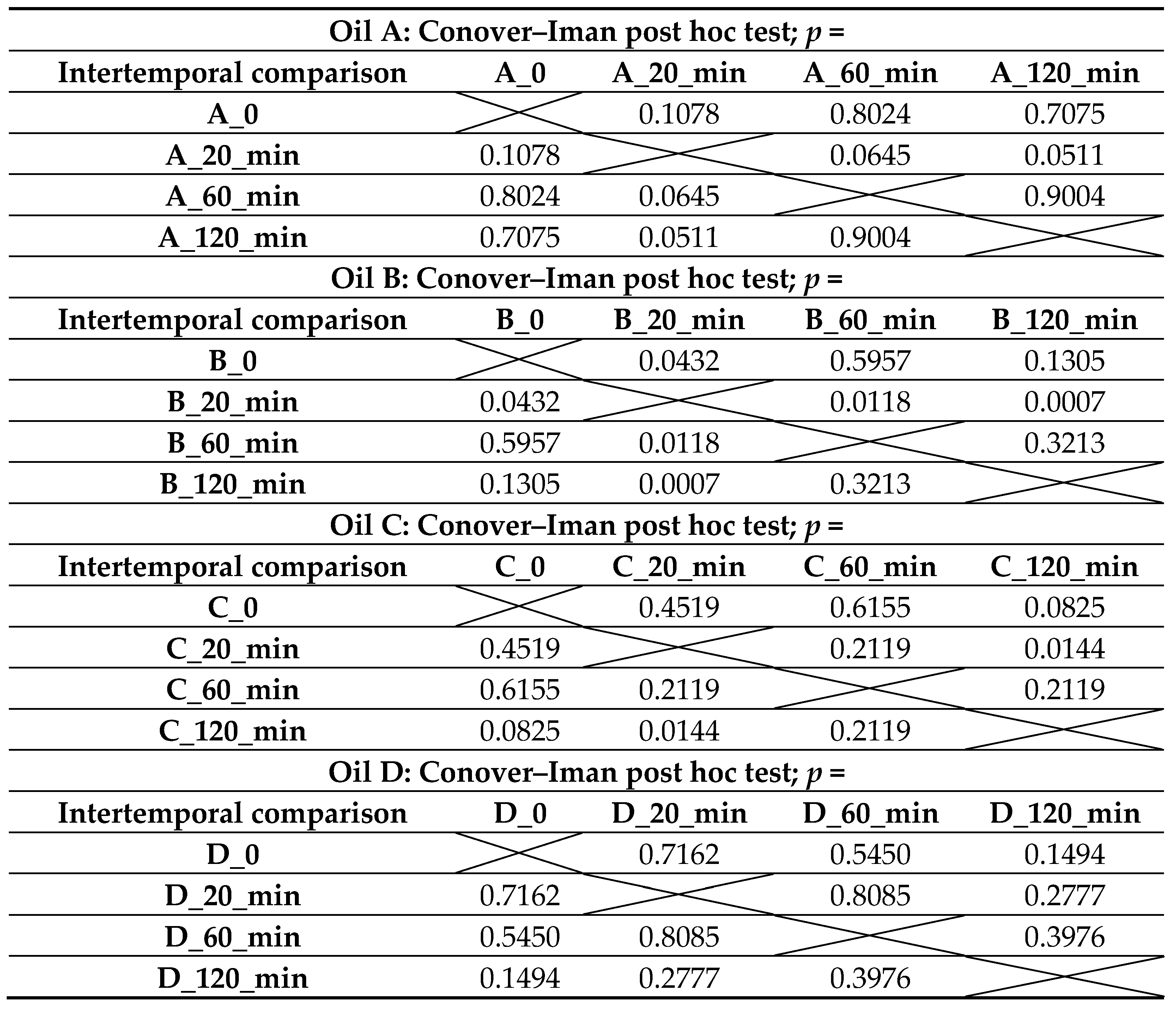

Table 6.

Results of post hoc tests of the reflectance at a wavelength of 480–600 nm after the application of Oils A, B, C, and D.

In the assessment of differences in reflectance values at subsequent time points (before oil application, after 20 min, and after 60 min), there was no statistically significant difference (p = 0.0920) between particular time points for the reflectance at a wavelength of 480–600 nm after the application of Oil C.

However, it was found that at a wavelength of 480–600 nm after the application of Oil C (Table 6), the reflectance value after 120 min of exposure was statistically significantly higher compared with the value after 20 min of exposure.

In the assessment of differences in reflectance values at subsequent time points (before oil application, after 20 min, and after 60 min), there was no statistically significant difference (p = 0.5150) between particular time points for the reflectance at a wavelength of 480–600 nm after the application of Oil D.

Comparing the type of oil, there was no statistically significant difference in the reflectance values at a wavelength of 480–600 nm before exposure (p = 0.9758), after 20 min of exposure (p = 0.8646), after 60 min of exposure (p = 0.7580), and after 120 min of exposure (p = 0.8302) between the type of oil used.

3.4. Reflectance Values at a Wavelength of 590–720 nm

Table 7 presents selected descriptive statistics of the reflectance at a wavelength of 590–720 nm.

Table 7.

Selected descriptive statistics of the reflectance value at a wavelength of 590–720 nm, along with a statistical assessment of the normality of distribution.

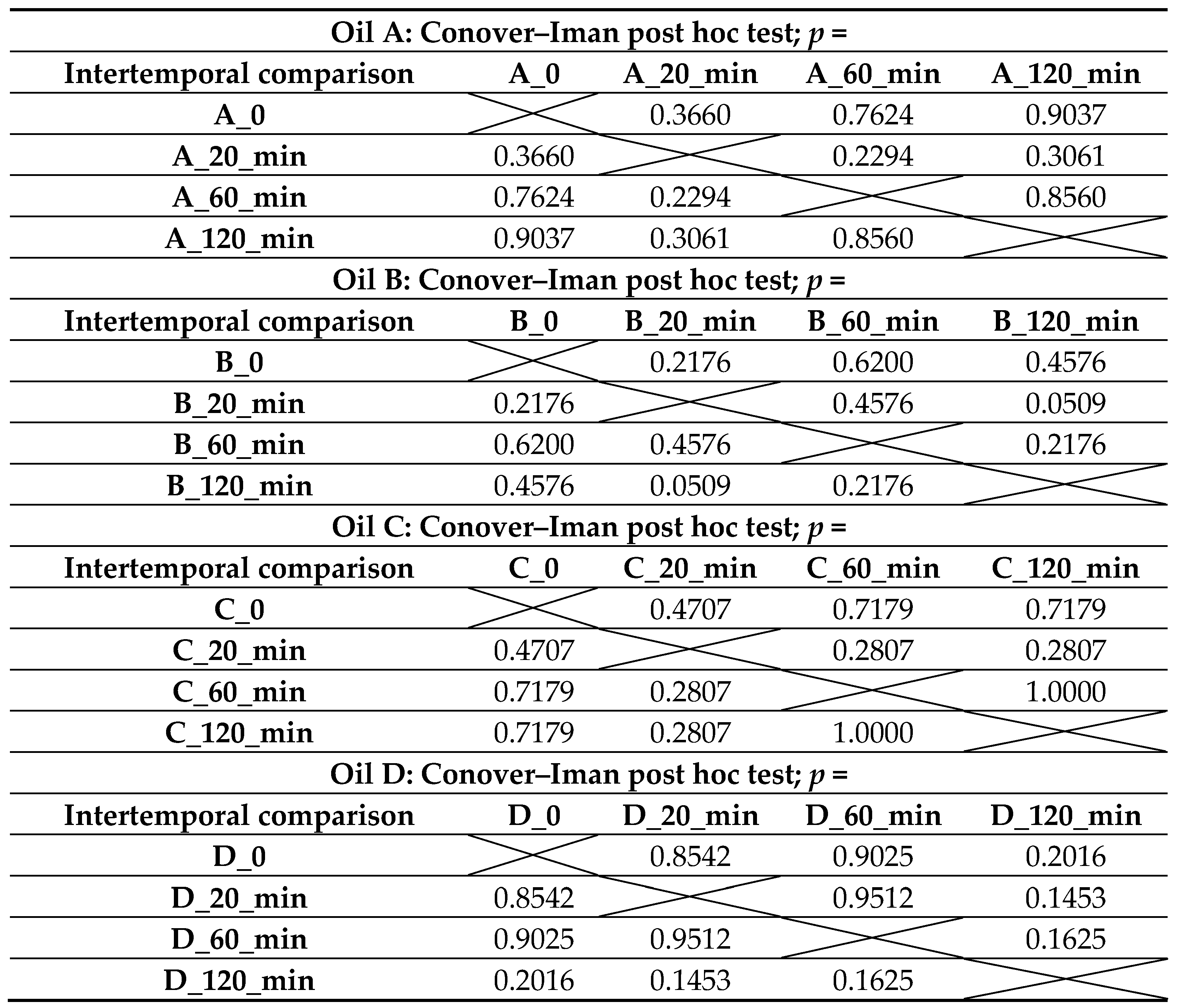

In the assessment of differences in reflectance values at subsequent time points (before oil application, after 20 min, and after 60 min), there was no statistically significant difference between particular time points for the reflectance at a wavelength of 590–720 nm after the application of Oil A (p = 0.6269), Oil B (p = 0.2495), Oil C (p = 0.6654), or Oil D (p = 0.4068).

The results of multiple tests (Table 8) confirm the absence of differences at all the time points of reflectance assessment at a wavelength of 590–720 nm after the application of each tested oil.

Table 8.

Results of post hoc tests of the reflectance at a wavelength of 590–720 nm after the application of Oils A, B, C, and D.

Comparing the type of oil, there was no statistically significant difference in the reflectance values at a wavelength of 590–720 nm before exposure (p = 0.9473), after 20 min of exposure (p = 0.9871), after 60 min of exposure (p = 0.9940), and after 120 min of exposure (p = 0.87876) between the type of oil used.

3.5. Reflectance Values at a Wavelength of 700–1100 nm

Table 9 presents selected descriptive statistics of the reflectance at a wavelength of 700–1100 nm.

Table 9.

Selected descriptive statistics of the reflectance value at a wavelength of 700–1100 nm, along with a statistical assessment of the normality of distribution.

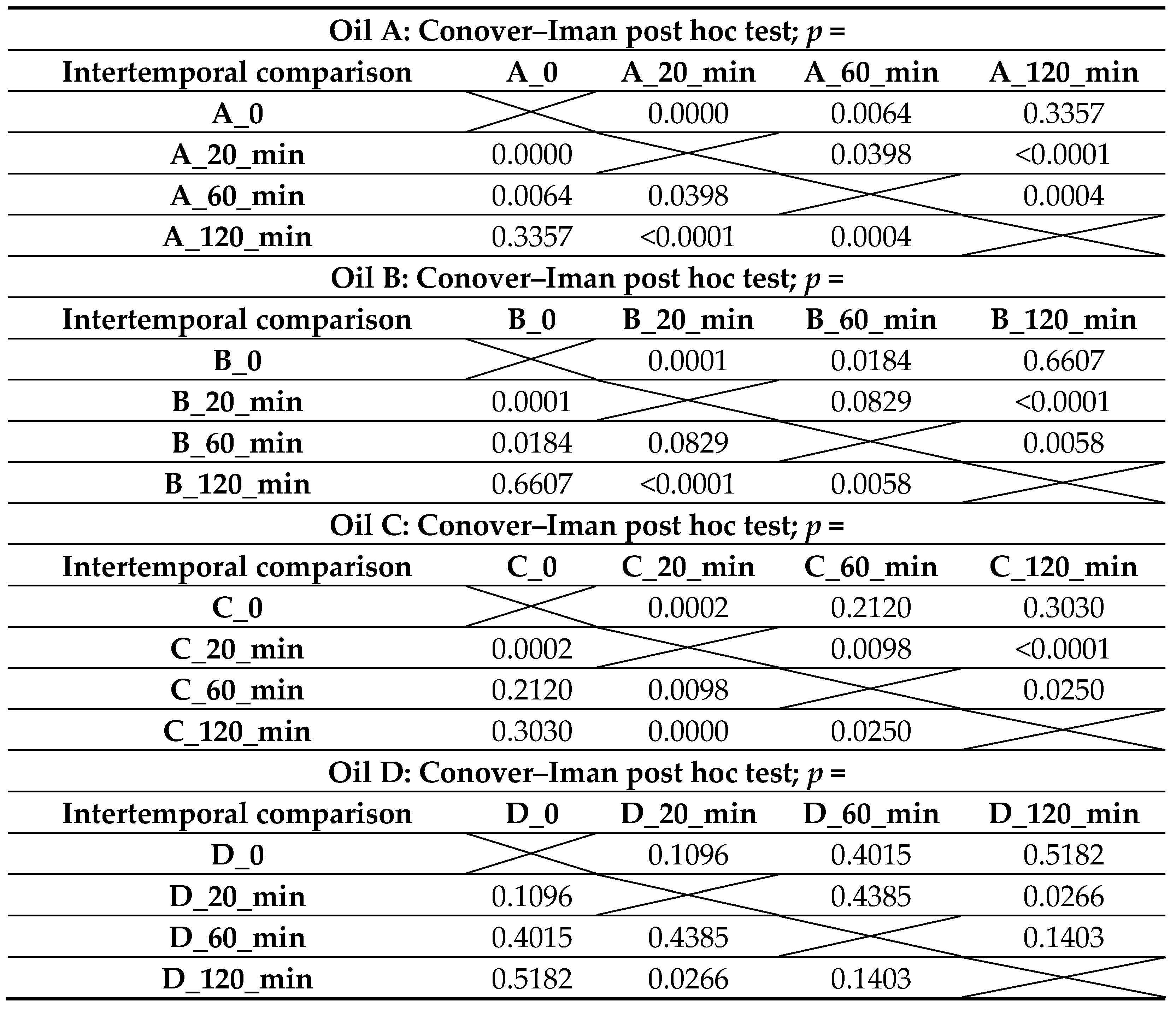

In the assessment of differences in reflectance values at subsequent time points (before oil application, after 20 min, and after 60 min), there was no statistically significant difference (p = 0.0591) between particular time points for the reflectance at a wavelength of 700–1100 nm after the application of Oil A. The results of multiple tests (Table 10) confirm the absence of differences at all time points of the reflectance assessment at a wavelength of 700–1100 nm after the application of Oil A.

Table 10.

Results of post hoc tests of the reflectance at a wavelength of 700–1100 nm after the application of Oils A, B, C, and D.

In the assessment of differences in reflectance values at subsequent time points (before oil application, after 20 min, and after 60 min), a statistically significant difference (p = 0.0003) was found between particular time points for the reflectance at a wavelength of 700–1100 nm after the application of Oil B.

It was found that at a wavelength of 700–1100 nm after the application of Oil B (Table 10), the value of the reflectance after 120 min of exposure was statistically significantly higher compared with the value before, after 20 min, and after 60 min of exposure, and the value of reflectance after 60 min of exposure was statistically significantly higher compared with the value after 20 min of exposure.

In the assessment of differences in reflectance values at subsequent time points (before oil application, after 20 min, and after 60 min), a statistically significant difference (p = 0.0040) was found between particular time points for the reflectance at a wavelength of 700–1100 nm after the application of Oil C.

It was found that at a wavelength of 700–1100 nm after the application of Oil C (Table 10), the reflectance value after 60 min of exposure was statistically significantly higher compared with the value after 20 min of exposure and, moreover, the reflectance value after 120 min of exposure was statistically significantly higher compared with the value before exposure and after 20 min of exposure.

In the assessment of differences in reflectance values at subsequent time points (before oil application, after 20 min, and after 60 min), there was no statistically significant difference (p = 0.0671) between particular time points for the reflectance at a wavelength of 700–1100 nm after the application of Oil D.

However, it was found that at a wavelength of 700–1100 nm after the application of Oil D (Table 10), the reflectance value after 120 min of exposure was statistically significantly higher compared with the value before exposure and after 20 min of exposure.

Comparing the type of oil, there was no statistically significant difference in the reflectance values at a wavelength of 700–1100 nm before exposure (p = 0.9938), after 20 min of exposure (p = 0.9662), after 60 min of exposure (p = 0.9754), and after 120 min of exposure (p = 0.9942) between the type of oil used.

3.6. Reflectance Values at a Wavelength of 1000–1700 nm

Table 11 presents selected descriptive statistics of the reflectance at a wavelength of 1000–1700 nm.

Table 11.

Selected descriptive statistics of the reflectance value at a wavelength of 1000–1700 nm, along with a statistical assessment of the normality of distribution.

In the assessment of differences in reflectance values at subsequent time points (before oil application, after 20 min, and after 60 min) a statistically significant difference (p = 0.0093) was found between particular time points for the reflectance at a wavelength of 1000–1700 nm after the application of Oil A.

It was found that at a wavelength of 1000–1700 nm after the application of Oil A (Table 12), the reflectance value after 20 min of exposure was statistically significantly lower compared with the value before exposure, and the reflectance values after 60 min and 120 min of exposure were statistically significantly higher compared with the value after 20 min of exposure.

Table 12.

Results of post hoc tests of the reflectance at a wavelength of 1000–1700 nm after the application of Oils A, B, C, and D.

In the assessment of differences in reflectance values at subsequent time points (before oil application, after 20 min, and after 60 min), a statistically significant difference (p < 0.0001) was found between particular time points for the reflectance at a wavelength of 1000–1700 nm after the application of Oil B.

It was found that at a wavelength of 1000–1700 nm after the application of Oil B (Table 12), the reflectance value after 20 min of exposure was statistically significantly lower compared with the values before exposure and after 60 min and 120 min of exposure. Also, the reflectance value after 60 min of exposure was statistically significantly higher compared with the value before exposure and statistically significantly lower compared with the value after 120 min of exposure.

In the assessment of differences in reflectance values at subsequent time points (before oil application, after 20 min, and after 60 min), a statistically significant difference (p < 0.0001) was found between particular time points for the reflectance at a wavelength of 1000–1700 nm after the application of Oil C.

It was found that at a wavelength of 1000–1700 nm after the application of Oil C (Table 12), the reflectance value after 20 min of exposure was statistically significantly lower compared with the value before exposure and with the values after 60 min and 120 min of exposure, and the reflectance value after 120 min of exposure was statistically significantly higher compared with the value after 20 min and 60 min of exposure.

In the assessment of differences in reflectance values at subsequent time points (before oil application, after 20 min, and after 60 min), a statistically significant difference (p = 0.0094) was found between particular time points for the reflectance at a wavelength of 1000–1700 nm after the application of Oil D.

It was found that at a wavelength of 1000–1700 nm after the application of Oil D (Table 12), the reflectance value after 120 min of exposure was statistically significantly higher compared with the value after 20 min of exposure.

Comparing the type of oil, there was no statistically significant difference in the values of reflectance at a wavelength of 1000–1700 nm before exposure (p = 0.9319), after 20 min of exposure (p = 0.5504), after 60 min of exposure (p = 0.7551), and after 120 min of exposure (p = 0.8877) between the type of oil used.

3.7. Reflectance Values at a Wavelength of 1700–2500 nm

Table 13 presents selected descriptive statistics of the reflectance at a wavelength of 1700–2500 nm.

Table 13.

Selected descriptive statistics of the reflectance value at a wavelength of 1700–2500 nm, along with a statistical assessment of the normality of distribution.

In the assessment of differences in reflectance values at subsequent time points (before oil application, after 20 min, and after 60 min), a statistically significant difference (p < 0.0001) was found between particular time points for the reflectance at a wavelength of 1700–2500 nm after the application of Oil A.

It was found that at a wavelength of 1700–2500 nm after the application of Oil A (Table 14), the reflectance value after 20 min of exposure was statistically significantly lower compared with the value before exposure and with the values after 60 min and 120 min of exposure; as well, the reflectance value after 120 min of exposure was statistically significantly higher compared with the values after 20 min and 60 min of exposure.

Table 14.

Results of post hoc tests of the reflectance at a wavelength of 1700–2500 nm after the application of Oils A, B, C, and D.

In the assessment of differences in reflectance values at subsequent time points (before oil application, after 20 min, and after 60 min), a statistically significant difference (p < 0.0001) was found between particular time points for the reflectance at a wavelength of 1700–2500 nm after the application of Oil B.

It was found that at a wavelength of 1700–2500 nm after the application of Oil B (Table 14), the reflectance value after 20 min of exposure was statistically significantly lower compared with the value before exposure and with the values after 60 min and 120 min of exposure, and the reflectance value after 120 min exposure was statistically significantly higher compared with the values after 20 min and 60 min of exposure.

In the assessment of differences in reflectance values at subsequent time points (before oil application, after 20 min, and after 60 min), a statistically significant difference (p < 0.0001) was found between particular time points for the reflectance at a wavelength of 1700–2500 nm after the application of Oil C.

It was found that at a wavelength of 1700–2500 nm after the application of Oil C (Table 14), the reflectance value after 20 min of exposure was statistically significantly lower compared with the value before exposure and with the values after 60 min and 120 min of exposure, and the reflectance value after 120 min exposure was statistically significantly higher compared with the values after 20 min and 60 min of exposure.

In the assessment of differences in reflectance values at subsequent time points (before oil application, after 20 min, and after 60 min), there was no statistically significant difference (p = 0.1292) between particular time points for the reflectance at a wavelength of 1700–2500 nm after the application of Oil D.

However, it was found that at a wavelength of 1700–2500 nm after the application of Oil D (Table 14), the reflectance value after 120 min was statistically significantly higher compared with the value after 20 min of exposure.

Comparing the type of oil, there was no statistically significant difference in the reflectance values at a wavelength of 1700–2500 nm before exposure (p = 0.8052), after 20 min of exposure (p = 0.0763), after 60 min of exposure (p = 0.4944), and after 120 min of exposure (p = 0.9740) between the type of oil used.

4. Discussion

Over the last few years, awareness of the harmful effects of solar radiation on the human body has significantly increased. Society is increasingly using photoprotective preparations to protect itself from the negative effects of excessive sun exposure. Human skin is chronically exposed to sunlight from an early age, as some ranges of radiation can also penetrate glass and materials. In creating cosmetic recipes, more attention is being paid to the origin of raw materials and to the creation of natural cosmetics that contain more plant ingredients and fewer artificially obtained substances. Currently, the formulas of sunscreen preparations are being improved with substances that can absorb or reflect UV radiation without negatively affecting the skin [20].

Sesame oil is a rich source of unsaturated fatty acids, polyphenols, vitamins, and amino acids, which is why it has been used for centuries in nutrition and also in cosmetics to improve the appearance of skin, hair, and nails. It protects the skin against premature aging caused by several factors, including solar radiation, thanks to its antioxidative and anti-inflammatory properties [1,2,10].

There are many products on the cosmetic market that contain sunscreen. Unfortunately, most sunscreens only protect against UVB and less often against UVA. Depending on their composition, UV filters may either absorb (chemical filters) or reflect radiation (physical filters). Recently, many scientific publications have reported the harmfulness of other ranges of solar radiation, including infrared and blue light (HEV), which is also emitted by electronic devices [21,22,23].

The range of the solar radiation spectrum includes ultraviolet radiation (UVB (290–320 nm) and UVA (320–400 nm)) as well as visible light (400–770 nm) and infrared light (700–3000 nm). Ultraviolet radiation, which constitutes only 8% of this spectrum, is the most researched and understood. In comparison, visible light makes up 39%, while infrared radiation makes up 53% of the total [23]. Ultraviolet radiation has mutagenic and carcinogenic effects. As a result of excessive and long-term exposure to ultraviolet rays, skin burns, erythema, and hyperpigmentation can occur, which can lead to the development of skin cancers, including melanoma. However, UV radiation is not the only type of radiation that has harmful effects on the skin. Infrared radiation (IR) and blue visible light (HEV) may also contribute to the acceleration of skin aging and the formation of skin defects, such as hyperpigmentation. Infrared radiation can penetrate the deeper layers of the skin, reaching the subcutaneous tissue, while ultraviolet radiation can penetrate the epidermis. IR rays are strongly absorbed by water in the tissues, causing them to heat up, which may lead to the rupture of capillaries in the skin, the formation of erythema, and the intensification of rosacea. Therefore, sunscreen cosmetics should contain substances that also protect against the harmful effects of other types of solar radiation [21,22].

The study of the hemispherical reflectance of the skin before and after the use of sesame oil showed the lowest reflection value in the range of 335–380 nm, which corresponds to the range of ultraviolet radiation. According to the literature, the level of anti-UVB protection offered by sesame oil is defined as SPF 2 [9]. Therefore, we can clearly conclude that sesame oil does not provide significant protection against ultraviolet radiation. Since there were no significant differences in performance between the tested sesame oils, it is not possible to determine which preparation had the strongest effect on the directional reflectance of the skin. The tested sesame oils showed the greatest increase in reflectance in visible light ranges (400–540 nm, 480–600 nm, 590–720 nm) and near-infrared light (700–1100 nm, 1000–1700 nm, 1700–2500 nm). However, the differences in reflectance values between the oils before and after application were small, allowing us to conclude that this oil has a protective effect against infrared and visible radiation. It is important to note that no previous publication has proposed the use of hemispherical directional reflectance to assess the sun protection properties of sesame oil. The absence of scientific reports in this area categorizes this study as pioneering. However, the 410-Solar reflectometer has already been used for cosmetic testing. Wilczyński et al. [11] performed an experiment in which filters protecting against infrared radiation were analyzed. The findings of the study indicate that popular care creams, UV filters, and products containing colloidal silica failed to provide effective protection against infrared radiation [11].

The 410-Solar device is safe and simple to use. It involves placing the measuring port of the device on the skin, pressing the trigger, and making a measurement within a few seconds. The reflectometer device allows for the quick and precise monitoring of changes in skin reflectance. This study analyzed data from 20 volunteers. At intervals of 20, 60, and 120 min, skin reflectance measurements were made before and after applying the oils to the skin of the forearm. The results obtained in the study indicate that sesame oil can be used in sunscreen products, but only when combined with other, more powerful ingredients. The oil itself is not sufficient protection against solar radiation. As an abundant source of nutrients, it has a beneficial effect on the condition of the skin. Therefore, in sunscreen formulations, it has the potential to enhance sun protection and primarily enhances the care capabilities of such cosmetics.

5. Conclusions

When analyzing the tests performed using a reflectometer, the following conclusions can be drawn:

- The 410-Solar reflectometer allows for a quantitative assessment of the sun protection properties of sesame oil within the spectrum of solar radiation in in vivo conditions.

- Oil A enhances the reflectance in the near-infrared and visible light ranges, including blue HEV light. For significant protection against blue light, you must wait 60 min after applying the oil to the skin. Even 120 min later, it still retains its protective properties. In the near-infrared spectrum, significant protection is achieved within a period of 120 min.

- Oil B caused an increase in reflectance in the largest number of analyzed ranges when compared with the other tested oils. In the ultraviolet range, the reflectance value decreases 60 min after applying the oil to the skin. In the near-infrared range, it continues to increase.

- During the tests, the effects of Oil C were seen in one range of visible light and in all ranges of near-infrared light. This oil is at its highest reflectance value 120 min after application to the skin.

- Oil D caused an increase in reflectance in the smallest number of analyzed ranges when compared with the other tested oils. Achieving the highest level of reflectance measured in this study took approximately 120 min after application to the skin. There was an impact on the reflectance in one of the visible and one of the infrared light ranges.

- Sesame oil has photoprotective properties; however, due to its relatively low protection factor, it should not be treated as an equivalent to sunscreen preparations.

Author Contributions

Conceptualization, M.B. and S.W.; methodology, M.B.; software, S.W.; validation, J.T., A.L. and A.S.-W.; formal analysis, M.B.; investigation, J.T., P.B. and A.L.; resources, S.W.; data curation, M.B.; writing—original draft preparation, A.S.-W. and A.L.; writing—review and editing, J.T.; visualization, A.S.-W. and J.T.; supervision, S.W.; project administration, M.B.; funding acquisition, S.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Medical University of Silesia, grant number PCN-CBN-640-2-1-1005/22/23.

Institutional Review Board Statement

The study was conducted in accordance with the Declaration of Helsinki and approved by the Bioethics Committee of the Medical University of Silesia on 29 June 2021 (PCN/CBN/0022/KB1/27/III/16/17/21).

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The datasets used and analyzed during the current study are available from the corresponding author on reasonable request. The data are not publicly available due to privacy reasons.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Shah, N.C. Sesamum indicum (sesame or til): Seeds & oil—An historical and scientific evaluation from Indian perspective. Indian J. Hist. Sci. 2013, 48, 151–174. [Google Scholar]

- Shasmitha, R. Health benefits of Sesamum indicum: A short review. Asian J. Pharm. Clin. Res. 2015, 8, 1–3. [Google Scholar]

- Zaid, A.N.; Jaradat, N.; Malkieh, N.; Al-Rimawi, S.; Hussein, F.; Isa, L.; Ali, I.; Manasra, R.; Silwadi, G.; Sadder, O.; et al. Impact of sesame oil source: A quality assessment for cosmeceutical and pharmaceutical use. J. Pharm. Sci. 2019, 44, 189–196. [Google Scholar]

- Wei, P.; Zhao, F.; Wang, Z.; Wang, Q.; Chai, X.; Hou, G.; Meng, Q. Sesame (Sesamum indicum L.): A comprehensive review of nutritional value, phytochemical composition, health benefits, development of food, and industrial applications. Nutrients 2022, 14, 4079. [Google Scholar] [CrossRef]

- Pathak, N.; Rai, A.K.; Kumari, R.; Bhat, K.V. Value addition in sesame: A perspective on bioactive components for enhancing utility and profitability. Pharmacogn. Rev. 2014, 8, 147–155. [Google Scholar]

- Joshi, R.; Kumar, M.S.; Satyamoorthy, K.; Unnikrisnan, M.K.; Mukherjee, T. Free radical reactions and antioxidant activities of sesamol: Pulse radiolytic and biochemical studies. J. Agric. Food Chem. 2005, 53, 696–703. [Google Scholar] [CrossRef] [PubMed]

- You, Y.J.; Wu, P.Y.; Liu, Y.J.; Hou, C.W.; Wu, C.S.; Wen, K.C.; Lin, C.Y.; Chiang, H.M. Sesamol Inhibited Ultraviolet Radiation-Induced Hyperpigmentation and Damage in C57BL/6 Mouse Skin. Antioxidants 2019, 8, 207. [Google Scholar] [CrossRef] [PubMed]

- Gharby, S.; Harhar, H.; Bouzoubaa, Z.; Asdadi, A.; El Yadini, A.; Charrouf, Z. Chemical characterization and oxidative stability of seeds and oil of sesame grown in Morocco. J. Saudi Soc. Agric. Sci. 2017, 16, 105–111. [Google Scholar] [CrossRef]

- Ácsová, A.; Hojerová, J.; Janotková, L.; Bendová, H.; Jedličková, L.; Hamranová, V.; Martiniaková, S. The real UVB photoprotective efficacy of vegetable oils: In vitro and in vivo studies. Photochem. Photobiol. Sci. 2021, 20, 139–151. [Google Scholar] [CrossRef]

- Jesus, A.; Sousa, E.; Cruz, M.T.; Cidade, H.; Lobo, J.M.S.; Almeida, I.F. Uv filters: Challenges and prospects. Pharmaceuticals 2022, 15, 263. [Google Scholar] [CrossRef]

- Wilczyński, S.; Deda, A.; Koprowski, R.; Banyś, A.; Błońska-Fajfrowska, B. The use of directional reflectance measurement for in vivo assessment of protective properties of cosmetics in the infrared radiation range. Photochem. Photobiol. 2017, 93, 1303–1311. [Google Scholar] [CrossRef]

- Stolecka-Warzecha, A.; Wilczyński, S.; Pawlus, A.; Lebiedowska, A.; Chmielewski, Ł.; Niezgoda, Z. The use of hemispheric directional reflectance method to verify the usefulness of filters protecting the skin against infrared radiation. Clin. Cosmet. Investig. Dermatol. 2023, 16, 2663–2675. [Google Scholar] [CrossRef]

- Stolecka-Warzecha, A.; Brandys, A.; Bożek, M.; Lebiedowska, A.; Błońska-Fajfrowska, B.; Wilczyński, S. Use Directional-Hemispherical Reflectance to Identify Female Skin Features in Response of Microdermabrasion Treatment. Appl. Sci. 2022, 12, 12087. [Google Scholar] [CrossRef]

- Nicodemus, F.E. Reflectance nomenclature and directional reflectance and emissivity. Appl. Opt. 1970, 9, 1474. [Google Scholar] [CrossRef]

- World Medical Association. World Medical Association Declaration of Helsinki: Ethical principles for medical research involving human subjects. JAMA 2013, 310, 2191–2194. [Google Scholar] [CrossRef]

- Fitzpatrick, T.B. The validity and practicality of sun-reactive skin types I through VI. Arch. Dermatol. 1988, 124, 869–871. [Google Scholar] [CrossRef] [PubMed]

- Conover, W.J. Practical Nonparametric Statistics, 3rd ed.; John Wiley & Sons: New York, NY, USA, 1999. [Google Scholar]

- Altman, D.G. Practical Statistics for Medical Research; Chapman and Hall: London, UK, 1991. [Google Scholar]

- Bewick, V.; Cheek, L.; Ball, J. Statistics review 10: Further nonparametric methods. Crit. Care 2004, 8, 196–199. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Pawlik, A.; Niewęgłowska-Wilk, M.; Kalicińska, J.; Śpiewak, R. „Natural”, „bio-” and „eco-” cosmetics. Security guarantee or marketing? Aesthetic Cosmetol. 2017, 2, 125–127. (In Polish) [Google Scholar]

- Bernstein, E.; Sarkas, H.; Boland, P. Iron oxides in novel skin care formulations attenuate blue light for enhanced protection against skin damage. J. Cosmet. Dermatol. 2021, 20, 532–537. [Google Scholar] [CrossRef]

- Barolet, D.; Christiaens, F.; Hamblin, M. Infrared and skin: Friend or foe. J. Photochem. Photobiol. B 2016, 166, 78–85. [Google Scholar] [CrossRef]

- Skórska, E. The impact of the solar ultraviolet radiation on the human body. Kosmos 2016, 65, 657–667. (In Polish) [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).