Abstract

This review will focus on advances in electronic and optoelectronic technologies by through the analysis of a full research and industrial application scenario. Starting with the analysis of nanocomposite sensors, and electronic/optoelectronic/mechatronic systems, the review describes in detail the principles and the models for finding possible implementations of Industry 5.0 applications. The study then addresses production processes and advanced detection systems integrating Artificial Intelligence (AI) algorithms. Specifically, the review introduces new research topics in Industry 5.0 about AI self-adaptive systems and processes in electronics, robotics and production management. The paper proposes also new Business Process Modelling and Notation (BPMN) Process Mining (PM) workflows, and a simulation of a complex Industry 5.0 manufacturing framework. The performed simulation estimates the diffusion heat parameters of a hypothesized production-line layout, describing the information flux of the whole framework. The simulation enhances the technological key elements, enabling an industrial upscale in the next digital revolution. The discussed models are usable in management engineering and informatics engineering, as they merge the perspectives of advanced sensors with Industry 5.0 requirements. The goal of the paper is to provide concepts, research topics and elements to design advanced production network in manufacturing industry.

1. Introduction

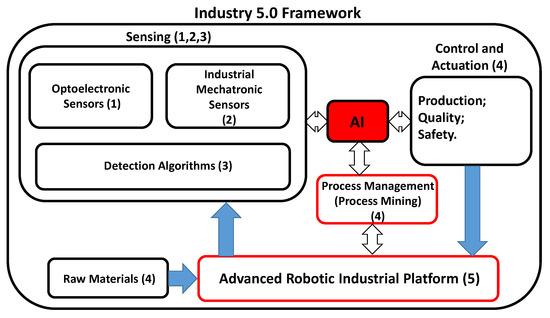

Technological advances in industry are in different production sectors of the supply chain. Today, many optical, electronic, and mechatronic technologies can be applied to the industrial scenario, improving the Industry 4.0 framework based on the digital transformation process. Some recently advanced technologies are in metastructures oriented to optical computing [1], nanoparticles in metasurface applications [2], Epsilon–Near-zero (ENZ) metamaterials [3,4], graphene-based transistors for biomedical applications [5], plasmonic devices [6,7], and deep learning that supports decision-making, as seen in COVID-19 risk management processes [8,9]. These technologies could be integrated into industrial processes or considered as innovative products for manufacturing industries. An upscale in production was gained by Industry 4.0 and by innovative facilities of Industry 5.0. The Industry 5.0 era has been characterized by a full digitalization and transformation process which contributed to fully changing organizational and production processes. This change is mainly focused on the implementation of Artificial Intelligence (AI) algorithms, which tailor production and processes in a self-adaptive modality. Specifically, the new advances in optoelectronic and mechatronic technologies show a possible evolution in the management of industrial processes, thus optimizing resources according to the dynamic market. Today, a strategic market plan should be designed first in the short term, to follow better the market’s trends and trajectories. The goal of this proposed short review is then to define production models based on advanced technology discussed in the paper, and offer an approach to designing a possible future framework which includes Industry 5.0 facilities that can start an analysis of the scientific state of the art profiled here to serve actual industry technology needs, and to orient further research. Figure 1 illustrates a block diagram sketching a basic Industry 5.0 framework, which will be discussed in this paper. The diagram, deduced from the analysis of the state of the art and from emergent topics in research, consists of the following blocks or grouped modules:

Figure 1.

Industry 5.0 framework of the topics of this review structured in five main different blocks.

- -

- A sensing module composed of innovative optoelectronic sensors (block 1), industrial mechatronic sensors (block 2), and detection algorithms (block 3);

- -

- Control and actuation facilities (block 4) which address production, quality, safety, process management, raw materials management, and Process Mining (PM);

- -

- An AI engine managing production line actions (blocks 1, 2, 3, 4, 5);

- -

- An Advanced robotic industrial platform (block 5).

The proposed auto-consistent framework of Figure 1 highlights the relationships between all mentioned blocks. Particular attention is given to new advanced sensors such as optoelectronic sensors suitable for high-velocity data transfer, industrial mechatronic sensors supporting the control and actuation mechanisms of advanced production machines and industrial robots, and engineered intelligent processes requiring AI decision-making procedures. The proposed work is structured as follows:

- -

- Discussion of the adopted methodology of the searching approach of the state of the art;

- -

- Discussion of the blocks of the framework of Figure 1, which will by provide a perspective of the implementation of each framework in a future Industry 5.0 scenario for each topic;

- -

- Description of a complex model of an Industry 5.0 framework defined by the topics found in the state of the art (framework constructed by supposing possible evolutions/implementations of the analyzed technologies and by hypothesizing a production line in the manufacturing sector);

- -

- Simulation of the information flux of the designed framework by means of the estimation of the diffusion heat parameters;

- -

- Design of Business Process Modeling and Notation (BPMN) workflows applied to this example of the Industry 5.0 framework, which will be useful for enhancing the different technological levels that will upgrade the production;

- -

- A BPMN model explaining, with more details, the processes of the robotic and machine control exploiting predictive maintenance and quality assessment processes designed with the Industry 5.0 framework.

Methodology

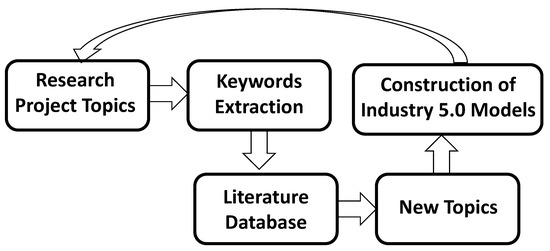

The method of searching for works in the literature is based on the scheme of Figure 2, and is defined by the following main steps:

Figure 2.

Block diagram of the adopted methodology followed to construct the proposed work.

- -

- The topics found in the literature are related to the requirements of the industry research projects (regional, national and European research topics) outlining the following macro-topics: Mechatronic Systems, Industry 4.0, Digital Transformation, Agriculture 4.0, Internet of Things (IoT), Human & Machine Interfaces (HMI), Quantum Computing, Energy, Edge Computing, Artificial Intelligence, Dynamic Business and Strategic Marketing, Additive Manufacturing, Key Enabling Technologies (KET), Photonics, Micro-Technologies, Nano-Technologies, Advanced Materials, Smart Materials, Technologies and Advanced Production Systems, Innovative Management Frameworks, Change Management, Product Quality Assessment, etc.;

- -

- Different keywords matching with specific industrial application fields (papers found in literature) are extracted, such as: Micro-Sensors, Nano-Sensors, Optoelectronic Sensors, Image Vision Techniques, Leakage Detection, Sensing and Actuation AI Systems, Nanocomposite Sensors, Defect Detection, Defect Prediction, Embedded Electronic Devices and Systems for the Automatic Control of Assembly Processes, Embedded Microelectronics, Integrated Systems for Applications of Remote Control, Multi-Sector Environment, Soft Robotics, Infrared Thermography, Multi-Spectral Analysis, AI Control and Actuation, etc.;

- -

- New research topics following the correlations between the different extracted keywords are defined, such as: rapid prototyping, reverse engineering, Industry 5.0, process mining applied to industrial production processes and on quality assessment, electronic assisted production management, etc.;

The proposed models integrate innovative Industry 5.0 topics found in litterature, are designed by the draw.io open source tool (BPMN standard), and are simulated by the Cytoscape tool (simulation of a complex Industry 5.0 framework which estimates the diffusion heat parameter).

The next sessions discuss the papers selected from literature about the topics and the keywords matching with the framework of Figure 1. For each topic found in these works, possible implementations in Industry 5.0 scenarios are proposed, and innovative aspects of perspectives in possible implementations are discussed.

2. Sensing Field

Many works found in literature address the sensing field in industrial environments (blocks 1, 2, and 3 of Figure 1). Innovative sensors such as optoelectronic sensors are a part of the sensing field and of innovative electronic/mechatronic systems that are interconnected to detection algorithms (see Figure 1). Specifically, Complementary Metal-Oxide Semiconductor (CMOS) and laser-based technologies [10,11,12] are typically applied to implement and to improve image vision techniques detecting colors, temperatures, and defects in manufacturing production processes. Looking forward-, advanced systems could include cameras integrated to other sensor systems, switching automatically in cases of defective cameras and detecting intelligently specific defect regions. For example, the scanning of small regions could be performed by means of intelligent algorithms controlling zooming. Nanocomposite optoelectronic sensors [13,14,15,16,17,18,19,20,21,22,23,24,25] are characterized by a fast detection response and by a high sensitivity, and are suitable for the detection of gases, energy-harvesting applications, pressure sensing, detection of notches and surface defects such as cracks, and three dimensional (3D) object morphologies and colors. High sensitivity and a fast response rate are very important in workpiece processing requiring a micrometric manipulation and very low processing tolerances (high-precision workstations), and for fully optical systems requiring a working frequency in the THz band. Advanced solutions could be implemented in worker security systems that detect small quantities of gases or liquids, thus enabling automatically alerting systems and security procedures. Concerning the robotic handling process, a high sensitivity pressure response allows the use of nanocomposite sensors for soft handling or for production systems characterized simultaneously by both hard and soft pressure forces; an intelligent system could calibrate the robotic handling by reading simultaneously strong and soft pressure forces to accurately control the product’s handling, and to detect possible millimeter-sized defects on the surface. The possibility of controlling the chemical composition of polymeric materials would allow tuning of the sensitivity of the optical response, which would allow the design of sensors which have different pressure working ranges that can adapt to the system of control. The control logic to be implemented could be improved by an auto-adaptive feedback control system which could intelligently drive robotic motors. An advanced nanocomposite sensor system could include both touch and no-touching sensors that detect 3D object morphology and other parameters such as colors and temperatures.

The research topics give particular attention to the leakage detection of oil, water and gases, including pipeline and electrical leakages [26,27,28,29,30,31,32,33,34,35,36,37,38]. Advanced solutions could include the adoption of AI tools for the pollution and leakage detections (as for production processes using liquids), and the integration of different technologies interconnected to renewable energy routing systems (sustainable production systems).

Finally, optoelectronic and fiberoptic systems are applied in manufacturing processes by controlling cutting machines, assessing the quality of surfaces of processed workpieces, and in additive manufacturing processes [39,40,41,42,43,44]. Advanced Industry 5.0 solutions could be addressed on reverse engineering approaches that automatically optimize laser cutting operations, that also integrate image vision techniques, or AI data driven systems that enable self-adaptive manufacturing processes. Specifically, additive manufacturing processes could be controlled intelligently with an AI self-tuning the machine parameters.

Table 1 reports more details about the optoelectronic systems and their possible implementation in an Industry 5.0 framework.

Table 1.

State of the art: some advanced optoelectronic sensors adaptable for industrial applications in Industry 5.0 scenario.

Our selected state of the art discussion of electronic and mechatronic sensors is about optomechatronic systems [45,46,47,48], printed and flexible electronics [49,50,51,52], gas sensors [53,54], sensor network systems [55,56,57,58,59,60], and other sensors applied in different production processes such as food and agriculture; and manufacturing processes such as drilling, milling and cutting [61,62,63,64,65,66,67,68,69,70,71]. Perspectives in Industry 5.0 frameworks involve the possibility of integrating different technologies into a unique platform, and adopting spatially adaptable electronic components for specific production plants. Furthermore, the evolution of production processes requires advanced diagnostic to be implemented by AI predicting risks and by applying PM models, auto-calibration of the manufacturing machine parameters, and auto-adaptive control systems monitoring tool wear. Table 2 lists more information about some electronic and mechatronic sensors and their possible implementation in an Industry 5.0 framework.

Table 2.

State of the art: some electronic and mechatronic sensors adaptable for industrial applications in Industry 5.0 scenario.

Concerning the industry sensing field, the analyzed state of the art finally addresses the important topics of algorithms supporting leakage detection [72,73,74,75,76,77,78,79,80,81], the digital transformation process of Industry 4.0 [82,83,84,85,86,87,88,89,90,91,92,93,94,95,96], and the data processing regarding energetic consumption in production processes [97,98,99,100,101,102,103]. Possible improvements to integrate into an Industry 5.0 framework relate to automated AI decision-making processes which enable interventions and procedures, production simulation setting machine parameters, and auto-calibration of the machines used in manufacturing processes. In the proposed scenario, an important role is assigned to big data systems interconnected to AI engines and to data-fusion approaches. The AI-based detection algorithms could provide an important contribution to managing complex production systems by estimating many variables such as energy required for the machined production, product defects, machine failure features, and more. Some efficient AI algorithms are Artificial Neural Network (ANN), and Long Short-Term Memory (LSTM). Other useful algorithms are Discrete Fourier Transform (DFT), and K-Means clustering algorithm (machine learning unsupervised algorithm). Two possible upgraded systems are in the management of energy used in production, and in energy digital twins using quantum computing. A possible future professional skill would be an energy manager that optimizes electrical consumption in industrial processes. Machine learning algorithms are also suitable for defect classification and defect prediction. Table 3 discusses some topics about detection algorithms and their possible implementation in an Industry 5.0 framework.

Table 3.

State of the art: detection algorithms and possible implementation of processes in an Industry 5.0 scenario.

3. Supply Chain Processes and Advances

The research topics in industrial production mainly address an intelligent way to manage raw materials [104,105,106,107,108,109,110,111], new models of AI decision-making in processes controlling production [112,113,114,115,116,117,118,119,120,121,122,123], and new procedures/methods oriented to control and actuation actions [124,125,126,127,128,129,130,131,132]. The topics are indicated in block 4 of Figure 1. Possible implementations of the analyzed topics in Industry 5.0 perspectives are mainly in process automation and in processes controlled by AI decision model engines that improve production, security, and quality. Other important aspects of industry upgrades are in the integration of different technologies and in intelligent machine reconfiguration systems. The integration of AI in the decision-making processes allow to the implementation of PM models; AI data driven by production phases is a new advance for process switching and process management, which includes new organizational models. Image vision techniques based on infrared thermography technologies are important for improving inline monitoring processes controlling defects and automatically reconfiguring machines and robots. Table 4 has the works found regarding the state of the art around raw materials management, PM models, control and actuation processes, and provides possible implementations in an Industry 5.0 framework.

Table 4.

State of the art: raw materials management advanced approaches, process mining, control/actuation methods and possible implementations of processes in Industry 5.0 scenarios.

4. Advanced Robotic Industrial Platforms

Many developments in research fields are in robotic platforms [133,134,135,136,137,138,139,140,141,142,143,144,145,146,147,148,149,150,151] (see block 5 of Figure 1). Collaborative robot (Cobot), soft robot, robot agents, and industrial robots are today controlled by innovative sensors and techniques (as for writing 3D processes in additive manufacturing). Neural networks, reinforcement learning methods, and AI algorithms are possible new solutions for improving the handling and object manipulation of robots. Possible projections in Industry 5.0 scenarios are in synchronization of the whole supply chain’s machinery, in self-adaptive robot control systems, in the use of quantum computing to increase AI efficiency, and in the digital twin models assisting production and marketing strategies. AI data processing could be processed into an Industry 5.0 framework by edge computing systems. Advanced technological platforms are also platforms that accurately control motion tracking, information systems suitable for integration of heterogeneous data from different technologies such as the Enterprise Service Bus (ESB), and the Supervisory Control and Data Acquisition (SCADA) system. All the systems could be integrated into a unique one controlling and synchronizing a whole production. In Table 5, we discuss the works found in the state of the art about advanced robotic platforms and possible improvements in an Industry 5.0 framework.

Table 5.

State of the art: advanced robotic systems and technological platforms, and Industry 5.0 perspectives.

5. Discussion: Industry 5.0 Framework and Complex Systems Simulations

This section designed and simulated an advanced Industry 5.0 framework integrating different advanced technologies. The discussion is completed by a description of the limitations and perspectives related the analyzed layout, by through a description of examples of applications matching with the Industry 5.0 scenario.

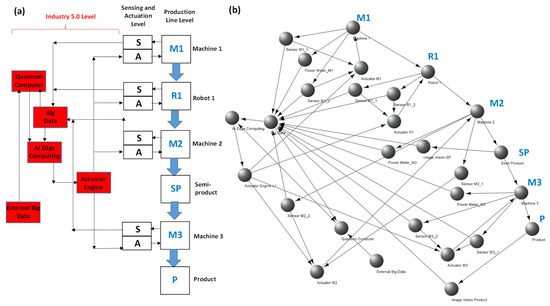

5.1. Industry 5.0 Workflow Design and Process Simulation

The works selected from the state of the art literature allow us to define a possible framework of how Industry 5.0 could involve a lot of previously mentioned technologies. The hypotheses of possible improvements of processes in Industry 5.0 frameworks allowed us to design the production layout, while including the main important variables found in the literature. A modern framework is characterized by a large number of variables, so we structured a complex system characterized by a “capillary” information flux between all the variables named nodes. An approach used to simulate complex models [103] is the calculation of the diffusion heat parameter [152,153,154]. The diffusion heat parameter is a probabilistic definition of the information flux distribution flowing between all nodes. Diffusion is typically a phenomenon associated to “particles” moving in an environment. In the specified case, the environment is modelled by nodes, and edges connecting all the nodes of the complex model. The probability of the distribution of the diffusion heat parameter is the position distribution of particles, which simulates the information flux, after a time t. In the analyzed model, a parameter of t = 0.038 s is enough for the transient calculation of the simulated complex Industry 5.0 manufacturing network. The hypothesized network is assumed to be a single production line consisting of three production machines and a robot, connected in a series configuration as illustrated in Figure 3a. The raw materials are processed by a first machine (Machine 1 node indicated by M1), then the workpiece is handled by a robot (Robot 1 node indicated by R1), sent to be processed by a second machine (Machine 2 node indicated by M2), which realizes a semi-product, which is then processed by a final, third machine (Machine 3 node indicated by M3), which produces the final product. As illustrated in Figure 3a, the machines define a first operating level named Production Line Level which is interconnected to a second one associated to sensing and actuation processes (Sensing and Actuator Level made up of sensors S and actuators A). A third level, named Industry 5.0 Level, represents the upgrade from Industry 4.0 to the Industry 5.0 scenario, and is consists of the following main elements (nodes): Quantum Computer, Big Data, External Big Data, AI Edge Computing, and an Actuator Engine (all the elements suggested for an upscale in production). The simulated network is better modelled by the graph of Figure 3b, which indicates nodes and edges. The simulated nodes are:

Figure 3.

(a) Simplified Industry 5.0 framework differentiating three main levels of the processing of a manufacturing workpiece: production line level, sensing and actuation level, and Industry 5.0 level. (b) Cytoscape complex model simulating the Industry 5.0 framework.

- Machine 1 (M1): the first machine, processing raw materials loaded at the input of the production line.

- Sensor M1_1: sensor monitoring Machine 1.

- Sensor M1_2: sensor monitoring Machine 1.

- Actuator M1: actuator that relays the sensing and actuation processing of from Machine 1.

- Power Meter_M1: power meter reading the electrical power of Machine 1.

- Robot 1 (R1): robot handling the workpiece processed by Machine 1.

- Sensor R1_1: first sensor monitoring Robot 1.

- Sensor R1_2: second sensor monitoring Robot 1.

- Actuator R1: actuator which relays sensing and actuation processing from Robot 1 (includes sensing of from both the sensors Sensor R1_1 and Sensor R1_2).

- Machine 2 (M2): second machine processing the workpiece after robotic manipulation.

- Sensor M2_1: sensor monitoring Machine 2.

- Sensor M2_2: sensor monitoring Machine 2.

- Actuator M2: actuator relaying sensing and actuation processing from Machine 2.

- Power Meter_M2: power meter reading the electrical power of Machine 2.

- Semi-Product (SP): semi-product output of Machine 2.

- Image Vision SP: camera implementing image vision algorithms to detect the defects of the Semi-Product.

- Machine 3 (M3): third machine processing the semi-product.

- Sensor M3_1: sensor monitoring Machine 3.

- Sensor M3_2: sensor monitoring Machine 3.

- Actuator M3: actuator relaying the sensing and actuation processing of Machine 3.

- Power Meter_M3: power meter reading electrical power of Machine 3.

- Product (P): final product of the whole production line (output of Machine 3).

- Image Vision Product: camera implementing image vision algorithms for detecting defects of in the final product;

- Big Data: internal big data collecting all production data (data from the whole production line).

- AI Edge Computing: edge computing nodes processing all data collected into the internal big data system by AI algorithms; the AI algorithms are optimized by quantum calculus (Quantum Computer).

- Quantum Computer: the quantum computer processing data collected in Big Data and External Big Data.

- External Big Data: dataset collected from the cloud by other third parties related to this specific production (external backend systems).

- Actuator Engine L1: engine synchronizing all the actuators: Actuator M1, Actuator R1, Actuator M2, Actuator M3 (with synchronization supported by the AI algorithms).

Table 6.

Summary statistics concerning the parameters of the complex network of Figure 3b.

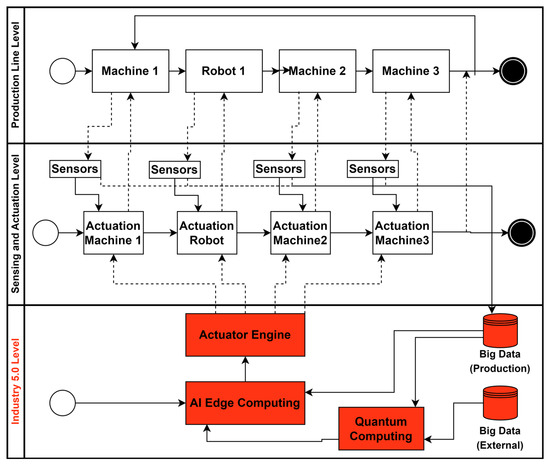

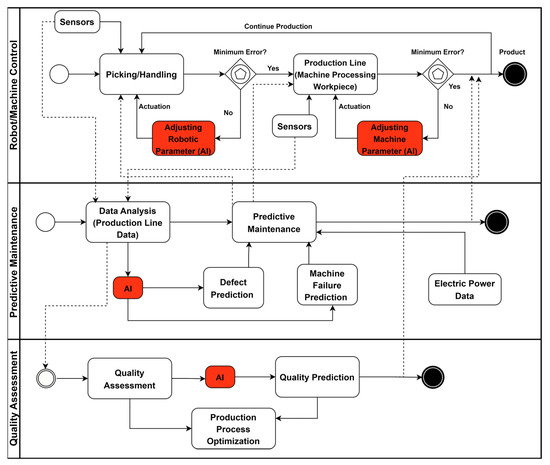

The complexity of the operations of the network of Figure 3b can be simplified by the workflow of Figure 4, which sketches all the operations of the simulated Industry 5.0 framework and facilitates comprehension of the information flux trajectories. The workflow is sketched by a standard BPMN (standard ISO/IEC 19510:2013 [155]), typically adopted for process mapping in industrial applications such as predictive maintenance [156] and security [157]. The BPMN workflow of the analyzed model is structured into three pools (representing the three levels indicated in Figure 3a), and highlighted in red are the data processes of the Industry 5.0 level, which upgraded production processes. The BPMNs model integrating AI decision-making procedures are named BPMN Process Mining (PM) models. The adopted BPMN tool was illustrated with the open-source program, draw.io [158].

Figure 4.

BPMN process modelling a simplification of the complex network of Figure 3b.

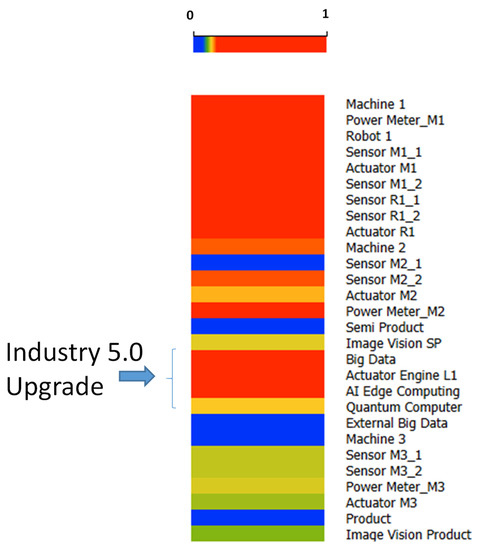

Figure 5 illustrates the result of the simulation of the complex Industry 5.0 network of Figure 3b: the calculation of the diffusion heat parameters of the whole information flux is summarized by the heat map in Figure 5. In this map, it is possible to observe that the elements that majorly upgrade the industrial production processes are: Big Data, Actuator Engine L1, Ai Edge Computing, and Quantum Computer, which are all the elements highlighted in red in the BPMN workflow of Figure 4, which confirms these nodes belong to the Industry 5.0 level (upgrading level). The simulation was performed by the open source Cytoscape tool [159].

Figure 5.

Heat map: diffusion heat simulation of the complex Industry 5.0 model enhancing central elements of the industry upgrade (Big Data, Actuator Engine L1, AI Edge Computing, Quantum Computer).

The BPMN approach is then adopted to “explode” in detail the processes involving robot/machine control, predictive maintenance, and quality assessment. By hypothesizing a production line constituted by a single robot that handles a workpiece that will be processed successively by a machine (simplification of the production line layout of Figure 3a), the BPMN workflow of Figure 6 illustrates the interaction between the three processes that integrate the AI facilities (highlighted in red). The main process is represented by the first pool, which describes the robot and machine control flux performed by sensors, and actuation actions performed by the AI by adjusting by according to feedback systems from the robot and machine parameters during the continuous production. Digital production data are transferred to a data analysis engine able to activate predictive maintenance interventions by adopting AI based decisions (AI predicting product defects and machine failure) and processing simultaneously the electrical power data of machines. An anomalous electric load could represent a machine start failure. The data, stored in a big data system, are also processed for quality assessment processes. Also, in this case, the AI algorithms could improve the whole production process by using its quality prediction.

Figure 6.

BPMN model “exploding” Industry 5.0 processes and correlations between robot/machine control, predictive maintenance, and quality assessment.

The proposed approach is based on the Industry 5.0 framework design and simulation. The framework conceptualization was extracted by analyzing the state of the art concerning the specific application field and technologies associated to an industry in the high-tech manufacturing sector. The limitations of the framework are mainly in the interoperability between all sub-processes. Table 7 lists some important limitations and the associated perspectives as possible solutions.

Table 7.

Framework limitations and perspectives to overcome these limitations.

5.2. Examples of Applications Matching with Industry 5.0 Framework

Table 8 indicates some examples of potential application fields and possible solutions for integrating the associated technologies into an Industry 5.0 scenario.

Table 8.

Examples of application fields matching with the Industry 5.0 framework.

6. Conclusions

The goal of this paper was to provide an overview of possible technologies and approaches that could potentially be adopted to construct an advanced production framework which included the main important variables and topics found in the cited literature. Some technologies analyzed in the state of the art were selected to construct an Industry 5.0 framework, while defining possible variables used to model and simulate a high-tech manufacturing layout. Specifically, we defined a large number of variables that allowed us to design a complex Industry 5.0 production layout by creating a manufacturing production line composed of three machines and a robot. A simulation of the diffusion heat parameter has defined the information flux of the whole complex network, and we highlighted some innovative elements, such as edge computing, quantum computing, big data and AI data processing, which improved production processes and quality. Finally, the paper discussed an approach to model Industry 5.0 processes by means of graphs constructed using nodes and edges and BPMN workflows, and described in detail the interaction between these processes. The processes highlighted in the Industry 5.0 model are predictive maintenance, machine control and actuation, and quality assessment. The selected literature is useful for constructing industrial research projects. The discussed models could support scientists in finding possible solutions for the design of Industry 5.0 frameworks using some tools suitable for designing a complex network and defining information fluxes of the main processes, thereby improving production.

Funding

This research received no external funding.

Conflicts of Interest

The author declares no conflict of interest.

References

- Mohammadi Estakhri, N.; Edwards, B.; Engheta, N. Inverse-Designed Metastructures That Solve Equations. Science 2019, 363, 1333–1338. [Google Scholar] [CrossRef]

- Lalegani, Z.; Seyyed Ebrahimi, S.A.; Hamawandi, B.; La Spada, L.; Batili, H.; Toprak, M.S. Targeted Dielectric Coating of Silver Nanoparticles with Silica to Manipulate Optical Properties for Metasurface Applications. Mater. Chem. Phys. 2022, 287, 126250. [Google Scholar] [CrossRef]

- Pacheco-Peña, V.; Beruete, M.; Rodríguez-Ulibarri, P.; Engheta, N. On the Performance of an ENZ-Based Sensor Using Transmission Line Theory and Effective Medium Approach. New J. Phys. 2019, 21, 043056. [Google Scholar] [CrossRef]

- Lincoln, R.L.; Scarpa, F.; Ting, V.P.; Trask, R.S. Multifunctional Composites: A Metamaterial Perspective. Multifunct. Mater. 2019, 2, 043001. [Google Scholar] [CrossRef]

- Akbari, M.; Shahbazzadeh, M.J.; La Spada, L.; Khajehzadeh, A. The Graphene Field Effect Transistor Modeling Based on an Optimized Ambipolar Virtual Source Model for DNA Detection. Appl. Sci. 2021, 11, 8114. [Google Scholar] [CrossRef]

- Greybush, N.J.; Pacheco-Peña, V.; Engheta, N.; Murray, C.B.; Kagan, C.R. Plasmonic Optical and Chiroptical Response of Self-Assembled Au Nanorod Equilateral Trimers. ACS Nano 2019, 13, 1617–1624. [Google Scholar] [CrossRef]

- Massaro, A.; Caratelli, D.; Yarovoy, A.; Cingolani, R. Analytical Approaches for Nano-Plasmonic and Micro-Millimetric Antennas. IET Microw. Antennas Propag. 2011, 5, 349. [Google Scholar] [CrossRef]

- Jamshidi, M.B.; Lalbakhsh, A.; Talla, J.; Peroutka, Z.; Roshani, S.; Matousek, V.; Roshani, S.; Mirmozafari, M.; Malek, Z.; La Spada, L.; et al. Deep Learning Techniques and COVID-19 Drug Discovery: Fundamentals, State-of-the-Art and Future Directions. In Studies in Systems, Decision and Control; Springer International Publishing: Cham, Switzerland, 2021; pp. 9–31. [Google Scholar]

- Elia, G.; Margherita, A.; Massaro, A.; Vacca, A. Adoption of Open Innovation in the COVID-19 Emergency: Developing a Process-Based Information Coordination System. Bus. Proc. Manag. J. 2022, 28, 419–441. [Google Scholar] [CrossRef]

- Wójcik, W.; Firago, V.; Smolarz, A.; Shedreyeva, I.; Yeraliyeva, B. Multispectral High Temperature Thermography. Sensors 2022, 22, 742. [Google Scholar] [CrossRef]

- Roales, J.; Moscoso, F.G.; Vargas, A.P.; Lopes-Costa, T.; Pedrosa, J.M. Colorimetric Gas Detection Using Molecular Devices and an RGB Sensor. Chemosensors 2023, 11, 92. [Google Scholar] [CrossRef]

- Ko, K.W.; Kim, D.H.; Kim, M.Y.; Kim, J.H. An Automatic Optical Inspection System for Inspection of CMOS Compact Camera Module Assembly. Int. J. Precis. Eng. Manuf. 2009, 10, 67–72. [Google Scholar] [CrossRef]

- Morganti, D.; Faro, M.J.L.; Leonardi, A.A.; Fazio, B.; Conoci, S.; Irrera, A. Luminescent Silicon Nanowires as Novel Sensor for Environmental Air Quality Control. Sensors 2022, 22, 8755. [Google Scholar] [CrossRef] [PubMed]

- Akbari-Saatlu, M.; Procek, M.; Mattsson, C.; Thungström, G.; Nilsson, H.-E.; Xiong, W.; Xu, B.; Li, Y.; Radamson, H.H. Silicon Nanowires for Gas Sensing: A Review. Nanomaterials 2020, 10, 2215. [Google Scholar] [CrossRef] [PubMed]

- Zappi, D.; Ramma, M.M.; Scognamiglio, V.; Antonacci, A.; Varani, G.; Giardi, M.T. High-Tech and Nature-Made Nanocomposites and Their Applications in the Field of Sensors and Biosensors for Gas Detection. Biosensors 2020, 10, 176. [Google Scholar] [CrossRef] [PubMed]

- Jeong, C.; Joung, C.; Lee, S.; Feng, M.Q.; Park, Y.B. Carbon nanocomposite based mechanical sensing and energy harvesting. Int. J. Precis. Eng. Manuf.-Green Technol. 2020, 7, 247–267. [Google Scholar] [CrossRef]

- Kanoun, O.; Khriji, S.; Naifar, S.; Bradai, S.; Bouattour, G.; Bouhamed, A.; El Houssaini, D.; Viehweger, C. Prospects of Wireless Energy-Aware Sensors for Smart Factories in the Industry 4.0 Era. Electronics 2021, 10, 2929. [Google Scholar] [CrossRef]

- Massaro, A.; Spano, F.; Cingolani, R.; Athanassiou, A. Experimental Optical Characterization and Polymeric Layouts of Gold PDMS Nanocomposite Sensor for Liquid Detection. IEEE Sens. J. 2011, 11, 1780–1786. [Google Scholar] [CrossRef]

- Massaro, A.; Spano, F.; Cazzato, P.; La Tegola, C.; Cingolani, R.; Athanassiou, A. Robot Tactile Sensing: Gold Nanocomposites as Highly Sensitive Real-Time Optical Pressure Sensors. IEEE Robot. Autom. Mag. 2013, 20, 82–90. [Google Scholar] [CrossRef]

- Lay-Ekuakille, A.; Massaro, A.; Singh, S.P.; Jablonski, I.; Rahman, M.Z.U.; Spano, F. Optoelectronic and Nanosensors Detection Systems: A Review. IEEE Sens. J. 2021, 21, 12645–12653. [Google Scholar] [CrossRef]

- Massaro, A.; Spano, F.; Missori, M.; Malvindi, M.A.; Cazzato, P.; Cingolani, R.; Athanassiou, A. Flexible Nanocomposites with All-Optical Tactile Sensing Capability. RSC Adv. 2013, 4, 2820–2825. [Google Scholar] [CrossRef]

- Giannoccaro, N.I.; Massaro, A.; Spedicato, L.; Lay-Ekuakille, A. Detection Analysis of Small Notches Damages Using a New Tactile Optical Device. IEEE ASME Trans. Mechatron. 2015, 20, 313–320. [Google Scholar] [CrossRef]

- Massaro, A.; Troia, M.; Spano, F.; Carbone, G. Friction in Totally Optical Robotic Finger Oriented on Shear Force Measurement. IEEE Sens. J. 2013, 13, 548–555. [Google Scholar] [CrossRef]

- Giannoccaro, N.I.; Lay-Ekuakille, A.; Spedicato, L.; Massaro, A.; Velazquez, R. An Innovative Tool for Detection of Small Notches Using a Nanocomposite Optical Sensor. IEEE Sens. J. 2016, 16, 5029–5036. [Google Scholar] [CrossRef]

- Massaro, A.; Giannoccaro, N.I.; Spedicato, L.; Lay-Ekuakille, A.; Missori, M.; Malvindi, M.A. Characterization of an Innovative Like-Eye Sensor for Feature Detection and Robot Sensing. Measurement 2014, 55, 153–167. [Google Scholar] [CrossRef]

- Moodie, D.; Costello, L.; McStay, D. Optoelectronic Leak Detection System for Monitoring Subsea Structures. In Optical Sensing and Detection; Berghmans, F., Mignani, A.G., van Hoof, C.A., Eds.; SPIE: Bellingham, WA, USA, 2010. [Google Scholar]

- McStay, D.; Shiach, G.; Nolan, A.; McAvoy, S. Optoelectronic Sensors for Subsea Oil and Gas Production. J. Phys. Conf. Ser. 2007, 76, 012065. [Google Scholar] [CrossRef]

- Ashry, I.; Mao, Y.; Wang, B.; Hveding, F.; Bukhamsin, A.; Ng, T.K.; Ooi, B.S. A Review of Distributed Fiber–Optic Sensing in the Oil and Gas Industry. J. Light. Technol. 2022, 40, 1407–1431. [Google Scholar] [CrossRef]

- Attivissimo, F.; Carducci, C.G.C.; Lanzolla, A.M.L.; Massaro, A.; Vadrucci, M.R. A Portable Optical Sensor for Sea Quality Monitoring. IEEE Sens. J. 2015, 15, 146–153. [Google Scholar] [CrossRef]

- Lay-Ekuakille, A.; Durickovic, I.; Lanzolla, A.; Morello, R.; De Capua, C.; Girão, P.S.; Postolache, O.; Massaro, A.; Van Biesen, L. Effluents, Surface and Subterranean Waters Monitoring: Review and Advances. Measurement 2019, 137, 566–579. [Google Scholar] [CrossRef]

- Prauzek, M.; Hercik, R.; Konecny, J.; Mikolajek, M.; Stankus, M.; Koziorek, J.; Martinek, R. An Optical-Based Sensor for Automotive Exhaust Gas Temperature Measurement. IEEE Trans. Instrum. Meas. 2022, 71, 1–11. [Google Scholar] [CrossRef]

- Werneck, M.M.; dos Santos, D.M.; de Carvalho, C.C.; de Nazare, F.V.B.; da Silva Barros Allil, R.C. Detection and Monitoring of Leakage Currents in Power Transmission Insulators. IEEE Sens. J. 2015, 15, 1338–1346. [Google Scholar] [CrossRef]

- Werneck, M.M.; Pinto, P.H.S.; Bellini, R.T.; Allil, R.C.S.B. Optical Sensor for Monitoring Leakage Current and Weather Conditions in a 500-KV Transmission Line. Sensors 2022, 22, 5034. [Google Scholar] [CrossRef] [PubMed]

- Raju, A.; Prakash, A.; Upadhyaya, A.M.; Sharan, P. Design and Analysis of Pipeline Leakage Detection Using Fibre Bragg Grating Sensor. In Proceedings of the 2018 3rd International Conference on Communication and Electronics Systems (ICCES), Coimbatore, India, 15–16 October 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 114–120. [Google Scholar]

- Abrar, U.; Yousaf, A.; Jaffri, N.R.; Rehman, A.U.; Ahmad, A.; Gardezi, A.A.; Naseer, S.; Shafiq, M.; Choi, J.-G. Analysis of Complex Solid-Gas Flow under the Influence of Gravity through Inclined Channel and Comparison with Real-Time Dual-Sensor System. Electronics 2021, 10, 2849. [Google Scholar] [CrossRef]

- Baroudi, U.; Al-Roubaiey, A.A.; Devendiran, A. Pipeline Leak Detection Systems and Data Fusion: A Survey. IEEE Access 2019, 7, 97426–97439. [Google Scholar] [CrossRef]

- Mohd Yussof, N.A.; Ho, H.W. Review of Water Leak Detection Methods in Smart Building Applications. Buildings 2022, 12, 1535. [Google Scholar] [CrossRef]

- Soldevila, A.; Boracchi, G.; Roveri, M.; Tornil-Sin, S.; Puig, V. Leak Detection and Localization in Water Distribution Networks by Combining Expert Knowledge and Data-Driven Models. Neural Comput. Appl. 2022, 34, 4759–4779. [Google Scholar] [CrossRef]

- Hung, S.-K.; Chung, Y.-H.; Chen, C.-L.; Chang, K.-H. Optoelectronic Angular Displacement Measurement Technology for 2-Dimensional Mirror Galvanometer. Sensors 2022, 22, 872. [Google Scholar] [CrossRef]

- Santos, J.L. Optical Sensors for Industry 4.0. IEEE J. Sel. Top. Quantum Electron. 2021, 27, 1–11. [Google Scholar] [CrossRef]

- Poprawe, R.; Hinke, C.; Meiners, W.; Eibl, F.; Zarei, O.; Voshage, M.; Ziegler, S.; Schleifenbaum, J.H.; Gasser, A.; Schopphoven, T.; et al. Digital Photonic Production along the Lines of Industry 4.0. In Laser Applications in Microelectronic and Optoelectronic Manufacturing (LAMOM) XXIII; Neuenschwander, B., Račiukaitis, G., Makimura, T., Grigoropoulos, C.P., Eds.; SPIE: Bellingham, WA, USA, 2018. [Google Scholar]

- Sioma, A.; Lenty, B. Detection of Fungal Infections on the Wood Surface Using LTM Imaging. Appl. Sci. 2022, 13, 490. [Google Scholar] [CrossRef]

- Ebayyeh, A.A.R.M.A.; Mousavi, A. A Review and Analysis of Automatic Optical Inspection and Quality Monitoring Methods in Electronics Industry. IEEE Access 2020, 8, 183192–183271. [Google Scholar] [CrossRef]

- Surdo, S.; Zunino, A.; Diaspro, A.; Duocastella, M. Acoustically Shaped Laser Light as an Enabling Technology for Industry 4.0. In Proceedings of the 2019 II Workshop on Metrology for Industry 4.0 and IoT (MetroInd4.0 & IoT), Naples, Italy, 4–6 June 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 360–364. [Google Scholar]

- Cho, H. (Ed.) Opto-Mechatronic Systems Handbook: Techniques and Applications; The Mechanical Engineering Handbook Series; CRC Press: Boca Raton, FL, USA, 2003. [Google Scholar]

- Ley, P.-P.; Knöchelmann, M.; Wolf, A.; Lachmayer, R. Tailoring the V-Model for Optics: A Methodology for Optomechatronic Systems. Appl. Sci. 2022, 12, 7798. [Google Scholar] [CrossRef]

- Knöchelmann, M. Prozess zur Entwicklung Optomechatronischer Systeme. Ph.D. Thesis, Leibniz Universität Hannover, Hannover, Germany, 2021. (In German). [Google Scholar]

- VDI, version 2206; Development of Mechatronic and Cyber-Physical Systems. Beuth Verlag GmbH: Berlin, Germany, 2021.

- Borghetti, M.; Cantù, E.; Sardini, E.; Serpelloni, M. Future Sensors for Smart Objects by Printing Technologies in Industry 4.0 Scenario. Energies 2020, 13, 5916. [Google Scholar] [CrossRef]

- Almuslem, A.; Shaikh, S.F.; Hussain, M.M. Flexible and Stretchable Electronics for Harsh-Environmental Applications. Adv. Mater. Technol. 2019, 4, 1900145. [Google Scholar] [CrossRef]

- Verma, A.; Goos, R.; Weerdt, J.D.; Pelgrims, P.; Ferraris, E. Design, Fabrication, and Testing of a Fully 3D-Printed Pressure Sensor Using a Hybrid Printing Approach. Sensors 2022, 22, 7531. [Google Scholar] [CrossRef]

- Cruz, S.M.F.; Rocha, L.A.; Viana, J.C. Printing Technologies on Flexible Substrates for Printed Electronics. In Flexible Electronics; InTech: London, UK, 2018. [Google Scholar]

- Khajavizadeh, L.; Andersson, M. MOSFET-Based Gas Sensors for Process Industry IoT Applications. In Proceedings of the 2022 International Conference on Electrical, Computer, Communications and Mechatronics Engineering (ICECCME), Maldives, Maldives, 16–18 November 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 1–5. [Google Scholar]

- Di Franco, C.; Elia, A.; Spagnolo, V.; Scamarcio, G.; Lugarà, P.M.; Ieva, E.; Cioffi, N.; Torsi, L.; Bruno, G.; Losurdo, M.; et al. Optical and Electronic NO(x) Sensors for Applications in Mechatronics. Sensors 2009, 9, 3337–3356. [Google Scholar] [CrossRef]

- Shao, Y.; Li, X.; Zhang, T.; Chu, S.; Liu, X. Time-Series-Based Leakage Detection Using Multiple Pressure Sensors in Water Distribution Systems. Sensors 2019, 19, 3070. [Google Scholar] [CrossRef]

- Laiton-Bonadiez, C.; Branch-Bedoya, J.W.; Zapata-Cortes, J.; Paipa-Sanabria, E.; Arango-Serna, M. Industry 4.0 Technologies Applied to the Rail Transportation Industry: A Systematic Review. Sensors 2022, 22, 2491. [Google Scholar] [CrossRef]

- Massaro, A.; Dipierro, G.; Selicato, S.; Cannella, E.; Galiano, A.; Saponaro, A. Intelligent Inspection of Railways Infrastructure and Risks Estimation by Artificial Intelligence Applied on Noninvasive Diagnostic Systems. In Proceedings of the 2021 IEEE International Workshop on Metrology for Industry 4.0 & IoT (MetroInd4.0 & IoT), Rome, Italy, 7–9 June 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 231–236. [Google Scholar]

- Gogolák, L.; Fürstner, I. Wireless Sensor Network Aided Assembly Line Monitoring According to Expectations of Industry 4.0. Appl. Sci. 2021, 11, 25. [Google Scholar] [CrossRef]

- Kalsoom, T.; Ramzan, N.; Ahmed, S.; Ur-Rehman, M. Advances in Sensor Technologies in the Era of Smart Factory and Industry 4.0. Sensors 2020, 20, 6783. [Google Scholar] [CrossRef] [PubMed]

- Javaid, M.; Haleem, A.; Singh, R.P.; Rab, S.; Suman, R. Significance of Sensors for Industry 4.0: Roles, Capabilities, and Applications. Sens. Int. 2021, 2, 100110. [Google Scholar] [CrossRef]

- Saloko, S.; Sulastri, Y.; Murad; Rinjani, M.A. The Effects of Temperature and Roasting Time on the Quality of Ground Robusta Coffee (Coffea Rabusta) Using Gene Café Roaster. In Proceedings of the 2nd International Conference on Bioscience, Biotechnology, and Biometrics 2019, Lombok, Indonesia, 13–14 August 2019; AIP Publishing: Melville, NY, USA, 2019. [Google Scholar]

- Catelani, T.A.; Páscoa, R.N.M.J.; Santos, J.R.; Pezza, L.; Pezza, H.R.; Lima, J.L.F.C.; Lopes, J.A. A Non-Invasive Real-Time Methodology for the Quantification of Antioxidant Properties in Coffee during the Roasting Process Based on near-Infrared Spectroscopy. Food Bioprocess Technol. 2017, 10, 630–638. [Google Scholar] [CrossRef]

- Navia, J.; Mondragon, I.; Patino, D.; Colorado, J. Multispectral Mapping in Agriculture: Terrain Mosaic Using an Autonomous Quadcopter UAV. In Proceedings of the 2016 International Conference on Unmanned Aircraft Systems (ICUAS), Arlington, VA, USA, 7–10 June 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 1351–1358. [Google Scholar]

- Sona, G.; Passoni, D.; Pinto, L.; Pagliari, D.; Masseroni, D.; Ortuani, B.; Facchi, A. Uav Multispectral Survey to Map Soil and Crop for Precision Farming Applications. ISPRS-Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2016, XLI-B1, 1023–1029. [Google Scholar] [CrossRef]

- Omia, E.; Bae, H.; Park, E.; Kim, M.S.; Baek, I.; Kabenge, I.; Cho, B.-K. Remote Sensing in Field Crop Monitoring: A Comprehensive Review of Sensor Systems, Data Analyses and Recent Advances. Remote Sens. 2023, 15, 354. [Google Scholar] [CrossRef]

- Ryalat, M.; ElMoaqet, H.; AlFaouri, M. Design of a Smart Factory Based on Cyber-Physical Systems and Internet of Things towards Industry 4.0. Appl. Sci. 2023, 13, 2156. [Google Scholar] [CrossRef]

- Jegorowa, A.; Kurek, J.; Antoniuk, I.; Krupa, A.; Wieczorek, G.; Świderski, B.; Bukowski, M.; Kruk, M. Automatic Estimation of Drill Wear Based on Images of Holes Drilled in Melamine Faced Chipboard with Machine Learning Algorithms. Forests 2023, 14, 205. [Google Scholar] [CrossRef]

- Massaro, A.; Galiano, A. Re-Engineering Process in a Food Factory: An Overview of Technologies and Approaches for the Design of Pasta Production Processes. Prod. Manuf. Res. 2020, 8, 80–100. [Google Scholar] [CrossRef]

- Binali, R.; Kuntoğlu, M.; Pimenov, D.Y.; Ali Usca, Ü.; Kumar Gupta, M.; Erdi Korkmaz, M. Advance Monitoring of Hole Machining Operations via Intelligent Measurement Systems: A Critical Review and Future Trends. Measurement 2022, 201, 111757. [Google Scholar] [CrossRef]

- Liang, Q.; Zhang, D.; Coppola, G.; Mao, J.; Sun, W.; Wang, Y.; Ge, Y. Design and Analysis of a Sensor System for Cutting Force Measurement in Machining Processes. Sensors 2016, 16, 70. [Google Scholar] [CrossRef]

- Kandavalli, S.R.; Khan, A.M.; Iqbal, A.; Jamil, M.; Abbas, S.; Laghari, R.A.; Cheok, Q. Application of Sophisticated Sensors to Advance the Monitoring of Machining Processes: Analysis and Holistic Review. Int. J. Adv. Manuf. Technol. 2023, 125, 989–1014. [Google Scholar] [CrossRef]

- Jafari, R.; Razvarz, S.; Vargas-Jarillo, C.; Gegov, A.; Arabikhan, F. Pipeline Leak Detection and Estimation Using Fuzzy PID Observer. Electronics 2022, 11, 152. [Google Scholar] [CrossRef]

- Spatafora, M.A.N.; Allegra, D.; Giudice, O.; Stanco, F.; Battiato, S. Natural Gas Leakage Detection: A Deep Learning Framework on IR Video Data. In Proceedings of the 2022 26th International Conference on Pattern Recognition (ICPR), Montreal, QC, Canada, 21–25 August 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 636–642. [Google Scholar]

- Xiong, K.; Jiang, J.; Pan, Y.; Yang, Y.; Chen, X.; Yu, Z. Deep Learning Approach for Detection of Underground Natural Gas Micro-Leakage Using Infrared Thermal Images. Sensors 2022, 22, 5322. [Google Scholar] [CrossRef]

- Kopbayev, A.; Khan, F.; Yang, M.; Halim, S.Z. Gas Leakage Detection Using Spatial and Temporal Neural Network Model. Process Saf. Environ. Prot. 2022, 160, 968–975. [Google Scholar] [CrossRef]

- Zhao, Q.; Nie, X.; Luo, D.; Wang, J.; Li, Q.; Chen, W. An Effective Method for Gas-Leak Area Detection and Gas Identification with Mid-Infrared Image. Photonics 2022, 9, 992. [Google Scholar] [CrossRef]

- Massaro, A.; Panarese, A.; Galiano, A. Technological Platform for Hydrogeological Risk Computation and Water Leakage Detection Based on a Convolutional Neural Network. In Proceedings of the 2021 IEEE International Workshop on Metrology for Industry 4.0 & IoT (MetroInd4.0 & IoT), Rome, Italy, 7–9 June 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 225–230. [Google Scholar]

- Adedeji, K.; Hamam, Y.; Abe, B.; Abu-Mahfouz, A. Leakage Detection and Estimation Algorithm for Loss Reduction in Water Piping Networks. Water 2017, 9, 773. [Google Scholar] [CrossRef]

- Guo, D.; Cui, Z.; Liu, C.; Li, Y. Analysis of the Influencing Factors of the Leak Detection Method Based on the Disturbance-Reflected Signal. Energies 2023, 16, 572. [Google Scholar] [CrossRef]

- Zhang, Y.; Jiang, Z.; Lu, J. Research on Leakage Location of Pipeline Based on Module Maximum Denoising. Appl. Sci. 2023, 13, 340. [Google Scholar] [CrossRef]

- Navarro-Díaz, A.; Delgado-Aguiñaga, J.A.; Santos-Ruiz, I.; Puig, V. Real-Time Leak Diagnosis in Water Distribution Systems Based on a Bank of Observers and a Genetic Algorithm. Water 2022, 14, 3289. [Google Scholar] [CrossRef]

- Xu, K.; Li, Y.; Liu, C.; Liu, X.; Hao, X.; Gao, J.; Maropoulos, P.G. Advanced Data Collection and Analysis in Data-Driven Manufacturing Process. Chin. J. Mech. Eng. 2020, 33, 43. [Google Scholar] [CrossRef]

- Jan, Z.; Ahamed, F.; Mayer, W.; Patel, N.; Grossmann, G.; Stumptner, M.; Kuusk, A. Artificial Intelligence for Industry 4.0: Systematic Review of Applications, Challenges, and Opportunities. Expert Syst. Appl. 2023, 216, 119456. [Google Scholar] [CrossRef]

- Peres, R.S.; Jia, X.; Lee, J.; Sun, K.; Colombo, A.W.; Barata, J. Industrial Artificial Intelligence in Industry 4.0—Systematic Review, Challenges and Outlook. IEEE Access 2020, 8, 220121–220139. [Google Scholar] [CrossRef]

- Janík, S.; Szabó, P.; Mĺkva, M.; Mareček-Kolibiský, M. Effective Data Utilization in the Context of Industry 4.0 Technology Integration. Appl. Sci. 2022, 12, 10517. [Google Scholar] [CrossRef]

- Gölzer, P.; Cato, P.; Amberg, M. Data Processing Requirements of Industry 4.0—Use Cases for Big Data Applications. In Proceedings of the European Conference on Information Systems, Münster, Germany, 26–29 May 2015; pp. 1–13. [Google Scholar]

- Raja Santhi, A.; Muthuswamy, P. Industry 5.0 or Industry 4.0S? Introduction to Industry 4.0 and a Peek into the Prospective Industry 5.0 Technologies. Int. J. Interact. Des. Manuf. 2023. [Google Scholar] [CrossRef]

- Bousdekis, A.; Lepenioti, K.; Apostolou, D.; Mentzas, G. Data Analytics in Quality 4.0: Literature Review and Future Research Directions. Int. J. Comput. Integr. Manuf. 2022, 1–24. [Google Scholar] [CrossRef]

- Massaro, A.; Manfredonia, I.; Galiano, A.; Pellicani, L.; Birardi, V. Sensing and Quality Monitoring Facilities Designed for Pasta Industry Including Traceability, Image Vision and Predictive Maintenance. In Proceedings of the 2019 II Workshop on Metrology for Industry 4.0 and IoT (MetroInd4.0 & IoT), Naples, Italy, 4–6 June 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 68–72. [Google Scholar]

- del Real Torres, A.; Andreiana, D.S.; Ojeda Roldán, Á.; Hernández Bustos, A.; Acevedo Galicia, L.E. A Review of Deep Reinforcement Learning Approaches for Smart Manufacturing in Industry 4.0 and 5.0 Framework. Appl. Sci. 2022, 12, 12377. [Google Scholar] [CrossRef]

- Wahid, A.; Breslin, J.G.; Intizar, M.A. Prediction of Machine Failure in Industry 4.0: A Hybrid CNN-LSTM Framework. Appl. Sci. 2022, 12, 4221. [Google Scholar] [CrossRef]

- Massaro, A.; Dipierro, G.; Cannella, E.; Galiano, A.M. Comparative Analysis among Discrete Fourier Transform, K-Means and Artificial Neural Networks Image Processing Techniques Oriented on Quality Control of Assembled Tires. Information 2020, 11, 257. [Google Scholar] [CrossRef]

- Massaro, A.; Manfredonia, I.; Galiano, A.; Xhahysa, B. Advanced Process Defect Monitoring Model and Prediction Improvement by Artificial Neural Network in Kitchen Manufacturing Industry: A Case of Study. In Proceedings of the 2019 II Workshop on Metrology for Industry 4.0 and IoT (MetroInd4.0 & IoT), Naples, Italy, 4–6 June 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 64–67. [Google Scholar]

- Khan, M.A.; Elmitwally, N.S.; Abbas, S.; Aftab, S.; Ahmad, M.; Fayaz, M.; Khan, F. Software Defect Prediction Using Artificial Neural Networks: A Systematic Literature Review. Sci. Program. 2022, 2022, 2117339. [Google Scholar] [CrossRef]

- Sethi, T.; Gagandeep. Improved Approach for Software Defect Prediction Using Artificial Neural Networks. In Proceedings of the 2016 5th International Conference on Reliability, Infocom Technologies and Optimization (Trends and Future Directions) (ICRITO), Noida, India, 7–9 September 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 480–485. [Google Scholar]

- Maarif, M.R.; Listyanda, R.F.; Kang, Y.-S.; Syafrudin, M. Artificial Neural Network Training Using Structural Learning with Forgetting for Parameter Analysis of Injection Molding Quality Prediction. Information 2022, 13, 488. [Google Scholar] [CrossRef]

- Tancredi, G.P.; Vignali, G.; Bottani, E. Integration of Digital Twin, Machine-Learning and Industry 4.0 Tools for Anomaly Detection: An Application to a Food Plant. Sensors 2022, 22, 4143. [Google Scholar] [CrossRef]

- Sleiti, A.K.; Kapat, J.S.; Vesely, L. Digital Twin in Energy Industry: Proposed Robust Digital Twin for Power Plant and Other Complex Capital-Intensive Large Engineering Systems. Energy Rep. 2022, 8, 3704–3726. [Google Scholar] [CrossRef]

- Paudel, H.P.; Syamlal, M.; Crawford, S.E.; Lee, Y.-L.; Shugayev, R.A.; Lu, P.; Ohodnicki, P.R.; Mollot, D.; Duan, Y. Quantum Computing and Simulations for Energy Applications: Review and Perspective. ACS Eng. Au 2022, 2, 151–196. [Google Scholar] [CrossRef]

- Ahn, J.; Kwon, H.-Y.; Ahn, B.; Park, K.; Kim, T.; Lee, M.-K.; Kim, J.; Chung, J. Toward Quantum Secured Distributed Energy Resources: Adoption of Post-Quantum Cryptography (PQC) and Quantum Key Distribution (QKD). Energies 2022, 15, 714. [Google Scholar] [CrossRef]

- Giani, A. Quantum computing opportunities in renewable energy. Nat. Comput. Sci. 2021, 1, 90–91. [Google Scholar] [CrossRef]

- Starace, G.; Tiwari, G.; Colangelo, C.; Massaro, A. Advanced Data Systems for Energy Consumption Optimization and Air Quality Control in Smart Public Buildings Using a Versatile Open Source Approach. Electronics 2022, 11, 3904. [Google Scholar] [CrossRef]

- Massaro, A.; Starace, G. Advanced and Complex Energy Systems Monitoring and Control: A Review on Available Technologies and Their Application Criteria. Sensors 2022, 22, 4929. [Google Scholar] [CrossRef]

- Toscano, G.; Maceratesi, V.; Leoni, E.; Stipa, P.; Laudadio, E.; Sabbatini, S. FTIR Spectroscopy for Determination of the Raw Materials Used in Wood Pellet Production. Fuel 2022, 313, 123017. [Google Scholar] [CrossRef]

- Rodionova, O.Y.; Sokovikov, Y.V.; Pomerantsev, A.L. Quality Control of Packed Raw Materials in Pharmaceutical Industry. Anal. Chim. Acta 2009, 642, 222–227. [Google Scholar] [CrossRef] [PubMed]

- Benabdellah, N.; Bourhaleb, M.; Nasri, M.; Benazzi, N.; Dahbi, S. Design of Temperature and Humidity Sensors for an Electronic Nose Used in Rotten Food. In Proceedings of the 2016 International Conference on Electrical and Information Technologies (ICEIT), Tangiers, Morocco, 4–7 May 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 505–509. [Google Scholar]

- Mamasadikov, Y.; Alikhonov, E.J. An Optoelectronic Device That Controls the Linear Density of Cotton Tape during Quality Processing of Cotton Raw Materials. SciEdu 2022, 3, 168–177. [Google Scholar]

- Darmawan, A.; Bahri, S.; Putra, A.T.B. Six Sigma Implementation in Quality Evaluation of Raw Material: A Case Study. IOP Conf. Ser. Mater. Sci. Eng. 2020, 875, 012065. [Google Scholar] [CrossRef]

- Strzałkowski, P. Characteristics of Waste Generated in Dimension Stone Processing. Energies 2021, 14, 7232. [Google Scholar] [CrossRef]

- You, J.; Wang, Z. Control of Raw Materials Releasing for a Manufacturing System with Product Quality Downgrade. In Proceedings of the 2021 China Automation Congress (CAC), Beijing, China, 22–24 October 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 1991–1996. [Google Scholar]

- Bartnitzki, T. Mining 4.0-Importance of Industry 4.0 for the RAW Materials Sector. Artif. Intell. 2017, 2, M2M. [Google Scholar]

- Md, A.Q.; Jha, K.; Haneef, S.; Sivaraman, A.K.; Tee, K.F. A Review on Data-Driven Quality Prediction in the Production Process with Machine Learning for Industry 4.0. Processes 2022, 10, 1966. [Google Scholar] [CrossRef]

- Tercan, H.; Meisen, T. Machine Learning and Deep Learning Based Predictive Quality in Manufacturing: A Systematic Review. J. Intell. Manuf. 2022, 33, 1879–1905. [Google Scholar] [CrossRef]

- Massaro, A. Advanced Control Systems in Industry 5.0 Enabling Process Mining. Sensors 2022, 22, 8677. [Google Scholar] [CrossRef] [PubMed]

- Massaro, A. Multi-Level Decision Support System in Production and Safety Management. Knowledge 2022, 2, 682–701. [Google Scholar] [CrossRef]

- Pech, M.; Vrchota, J.; Bednář, J. Predictive Maintenance and Intelligent Sensors in Smart Factory: Review. Sensors 2021, 21, 1470. [Google Scholar] [CrossRef] [PubMed]

- Angelopoulos, A.; Michailidis, E.T.; Nomikos, N.; Trakadas, P.; Hatziefremidis, A.; Voliotis, S.; Zahariadis, T. Tackling Faults in the Industry 4.0 Era-A Survey of Machine-Learning Solutions and Key Aspects. Sensors 2019, 20, 109. [Google Scholar] [CrossRef]

- Teh, H.Y.; Kempa-Liehr, A.W.; Wang, K.I.-K. Sensor Data Quality: A Systematic Review. J. Big Data 2020, 7. [Google Scholar] [CrossRef]

- Yurtay, Y. Process Mining in Manufacturing: A Literature Review. Sak. Univ. J. Comput. Inf. Sci. 2022, 5, 341–355. [Google Scholar] [CrossRef]

- Halaska, M.; Sperka, R. Process Mining—The Enhancement of Elements Industry 4.0. In Proceedings of the 2018 4th International Conference on Computer and Information Sciences (ICCOINS), Kuala Lumpur, Malaysia, 13–14 August 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1–6. [Google Scholar]

- Kamala, B.; Latha, B. Process Mining and Deep Neural Network Approach for the Prediction of Business Process Outcome. In Proceedings of the 2022 International Conference on Communication, Computing and Internet of Things (IC3IoT), Chennai, India, 10–11 March 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 1–4. [Google Scholar]

- Xavier, M.; Dubinin, V.; Patil, S.; Vyatkin, V. Process Mining in Industrial Control Systems. In Proceedings of the 2022 IEEE 20th International Conference on Industrial Informatics (INDIN), Perth, Australia, 25–28 July 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 1–6. [Google Scholar]

- Abonyi, J.; Dorgo, G. Process Mining in Production Systems. In Proceedings of the 2019 IEEE 23rd International Conference on Intelligent Engineering Systems (INES), Hungary, 25–27 April 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 000267–000270. [Google Scholar]

- Garcia, M.M.; Sattar, M.A.; Atmani, H.; Legendre, D.; Babout, L.; Schleicher, E.; Hampel, U.; Portela, L.M. Towards Tomography-Based Real-Time Control of Multiphase Flows: A Proof of Concept in Inline Fluid Separation. Sensors 2022, 22, 4443. [Google Scholar] [CrossRef]

- Schlicht, S.; Jaksch, A.; Drummer, D. Inline Quality Control through Optical Deep Learning-Based Porosity Determination for Powder Bed Fusion of Polymers. Polymers 2022, 14, 885. [Google Scholar] [CrossRef]

- Burmistrov, D.E.; Pavkin, D.Y.; Khakimov, A.R.; Ignatenko, D.N.; Nikitin, E.A.; Lednev, V.N.; Lobachevsky, Y.P.; Gudkov, S.V.; Zvyagin, A.V. Application of Optical Quality Control Technologies in the Dairy Industry: An Overview. Photonics 2021, 8, 551. [Google Scholar] [CrossRef]

- Sioma, A. Vision System in Product Quality Control Systems. Appl. Sci. 2023, 13, 751. [Google Scholar] [CrossRef]

- Mbodj, N.G.; Abuabiah, M.; Plapper, P.; El Kandaoui, M.; Yaacoubi, S. Modeling and Control of Layer Height in Laser Wire Additive Manufacturing. Materials 2022, 15, 4479. [Google Scholar] [CrossRef] [PubMed]

- Budzik, G.; Woźniak, J.; Paszkiewicz, A.; Przeszłowski, Ł.; Dziubek, T.; Dębski, M. Methodology for the Quality Control Process of Additive Manufacturing Products Made of Polymer Materials. Materials 2021, 14, 2202. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.; Park, H.J.; Chai, S.; Kim, G.R.; Yong, H.; Bae, S.J.; Kwon, D. Review on Quality Control Methods in Metal Additive Manufacturing. Appl. Sci. 2021, 11, 1966. [Google Scholar] [CrossRef]

- El-Mahdy, M.H.; Maged, S.A.; Awad, M.I. End-to-End Fault Tolerant Control of Discrete Event System Using Recurrent Neural Networks. In Proceedings of the 2022 2nd International Mobile, Intelligent, and Ubiquitous Computing Conference (MIUCC), Cairo, Egypt, 8–9 May 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 266–271. [Google Scholar]

- Karagiannis, P.; Michalos, G.; Andronas, D.; Matthaiakis, A.-S.; Giannoulis, C.; Makris, S. Cognitive Mechatronic Devices for Reconfigurable Production of Complex Parts. Appl. Sci. 2021, 11, 5034. [Google Scholar] [CrossRef]

- Low, J.H.; Khin, P.M.; Han, Q.Q.; Yao, H.; Teoh, Y.S.; Zeng, Y.; Li, S.; Liu, J.; Liu, Z.; Valdivia y Alvarado, P.; et al. Sensorized Reconfigurable Soft Robotic Gripper System for Automated Food Handling. IEEE ASME Trans. Mechatron. 2022, 27, 3232–3243. [Google Scholar] [CrossRef]

- Paul, N.; Tasgaonkar, V.; Walambe, R.; Kotecha, K. Integrating the Generative Adversarial Network for Decision Making in Reinforcement Learning for Industrial Robot Agents. Robotics 2022, 11, 150. [Google Scholar] [CrossRef]

- Chen, S.; Wen, J.T. Industrial Robot Trajectory Tracking Control Using Multi-Layer Neural Networks Trained by Iterative Learning Control. Robotics 2021, 10, 50. [Google Scholar] [CrossRef]

- Borboni, A.; Reddy, K.V.V.; Elamvazuthi, I.; AL-Quraishi, M.S.; Natarajan, E.; Azhar Ali, S.S. The Expanding Role of Artificial Intelligence in Collaborative Robots for Industrial Applications: A Systematic Review of Recent Works. Machines 2023, 11, 111. [Google Scholar] [CrossRef]

- Silva, G.; Rekik, K.; Kanso, A.; Schnitman, L. Multi-perspective human robot interaction through an augmented video interface supported by deep learning. In Proceedings of the 2022 31st IEEE International Conference on Robot and Human Interactive Communication (RO-MAN), Napoli, Italy, 29 August–2 September 2022; pp. 1168–1173. [Google Scholar]

- Buerkle, A.; Eaton, W.; Lohse, N.; Bamber, T.; Ferreira, P. EEG based arm movement intention recognition towards enhanced safety in symbiotic Human-Robot Collaboration. Robot. Comput. Integr. Manuf. 2021, 70, 102137. [Google Scholar] [CrossRef]

- Ghadirzadeh, A.; Chen, X.; Yin, W.; Yi, Z.; Bjorkman, M.; Kragic, D. Human-Centered Collaborative Robots with Deep Reinforcement Learning. IEEE Robot. Autom. Lett. 2020, 6, 566–571. [Google Scholar] [CrossRef]

- Gomes, N.M.; Martins, F.N.; Lima, J.; Wörtche, H. Reinforcement Learning for Collaborative Robots Pick-and-Place Applications: A Case Study. Automation 2022, 3, 223–241. [Google Scholar] [CrossRef]

- Koo, S. Advanced Micro-Actuator/Robot Fabrication Using Ultrafast Laser Direct Writing and Its Remote Control. Appl. Sci. 2020, 10, 8563. [Google Scholar] [CrossRef]

- Lyu, C.; Li, P.; Wang, D.; Yang, S.; Lai, Y.; Sui, C. High-Speed Optical 3D Measurement Sensor for Industrial Application. IEEE Sens. J. 2021, 21, 11253–11261. [Google Scholar] [CrossRef]

- Galdelli, A.; Pagnotta, D.P.; Mancini, A.; Freddi, A.; Monteriu, A.; Frontoni, E. Empowered Optical Inspection by Using Robotic Manipulator in Industrial Applications. In Proceedings of the 2019 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Macau, China, 3–8 November 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 2006–2013. [Google Scholar]

- Nabil, M.; Mahfouz, D.M.; Shehata, O.M. Development and Evaluation of a Control Architecture for Human-Collaborative Robotic Manipulator in Industrial Application. In Proceedings of the 2022 14th International Conference on Computer and Automation Engineering (ICCAE), Brisbane, Australia, 25–27 March 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 38–43. [Google Scholar]

- Wu, J.; Wang, M.; Jiang, Y.; Yi, B.; Fan, R.; Liu, M. Simultaneous Hand–Eye/Robot–World/Camera–IMU Calibration. IEEE ASME Trans. Mechatron. 2022, 27, 2278–2289. [Google Scholar] [CrossRef]

- Pizoń, J.; Gola, A. Human–Machine Relationship—Perspective and Future Roadmap for Industry 5.0 Solutions. Machines 2023, 11, 203. [Google Scholar] [CrossRef]

- Lu, Y.; Xu, X.; Wang, L. Smart manufacturing process and system automation—A critical review of the standards and envisioned scenarios. J. Manuf. Syst. 2020, 56, 312–325. [Google Scholar] [CrossRef]

- Abdelsattar, A.; Park, E.J.; Marzouk, A. An OPC UA Client/Gateway-Based Digital Twin Architecture of a SCADA System with Embedded System Connections. In Proceedings of the 2022 IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM), Sapporo, Japan, 11–15 July 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 798–803. [Google Scholar]

- Li, W.; Fan, Y.; Liu, W.; Xin, M.; Wang, H.; Jin, Q. A Self-Adaptive Process Mining Algorithm Based on Information Entropy to Deal with Uncertain Data. IEEE Access 2019, 7, 131681–131691. [Google Scholar] [CrossRef]

- Khorasani, M.; Loy, J.; Ghasemi, A.H.; Sharabian, E.; Leary, M.; Mirafzal, H.; Cochrane, P.; Rolfe, B.; Gibson, I. A Review of Industry 4.0 and Additive Manufacturing Synergy. Rapid Prototyp. J. 2022, 28, 1462–1475. [Google Scholar] [CrossRef]

- Massaro, A.; Selicato, S.; Miraglia, R.; Panarese, A.; Calicchio, A.; Galiano, A. Production Optimization Monitoring System Implementing Artificial Intelligence and Big Data. In Proceedings of the 2020 IEEE International Workshop on Metrology for Industry 4.0 & IoT., Roma, Italy, 3–5 June 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 570–575. [Google Scholar]

- Carlin, D.E.; Demchak, B.; Pratt, D.; Sage, E.; Ideker, T. Network Propagation in the Cytoscape Cyberinfrastructure. PLoS Comput. Biol. 2017, 13, e1005598. [Google Scholar] [CrossRef] [PubMed]

- Shannon, P.; Markiel, A.; Ozier, O.; Baliga, N.S.; Wang, J.T.; Ramage, D.; Amin, N.; Schwikowski, B.; Ideker, T. Cytoscape: A Software Environment for Integrated Models of Biomolecular Interaction Networks. Genome Res. 2003, 13, 2498–2504. [Google Scholar] [CrossRef] [PubMed]

- Otasek, D.; Morris, J.H.; Bouças, J.; Pico, A.R.; Demchak, B. Cytoscape Automation: Empowering Workflow-Based Network Analysis. Genome Biol. 2019, 20. [Google Scholar] [CrossRef] [PubMed]

- ISO/IEC 19510; Information technology—Object Management Group Business Process Model and Notation. 2013. Available online: https://www.iso.org/standard/62652.html (accessed on 7 March 2023).

- Fernandes, J.; Reis, J.; Melão, N.; Teixeira, L.; Amorim, M. The Role of Industry 4.0 and BPMN in the Arise of Condition-Based and Predictive Maintenance: A Case Study in the Automotive Industry. Appl. Sci. 2021, 11, 3438. [Google Scholar] [CrossRef]

- Zareen, S.; Akram, A.; Ahmad Khan, S. Security Requirements Engineering Framework with BPMN 2.0.2 Extension Model for Development of Information Systems. Appl. Sci. 2020, 10, 4981. [Google Scholar] [CrossRef]

- Draw.io. Available online: https://app.diagrams.net/ (accessed on 7 March 2023).

- Cytoscape. Available online: https://cytoscape.org/ (accessed on 7 March 2023).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).