Experimental Study on the Flexural Performance of Geogrid-Reinforced Foamed Lightweight Soil

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

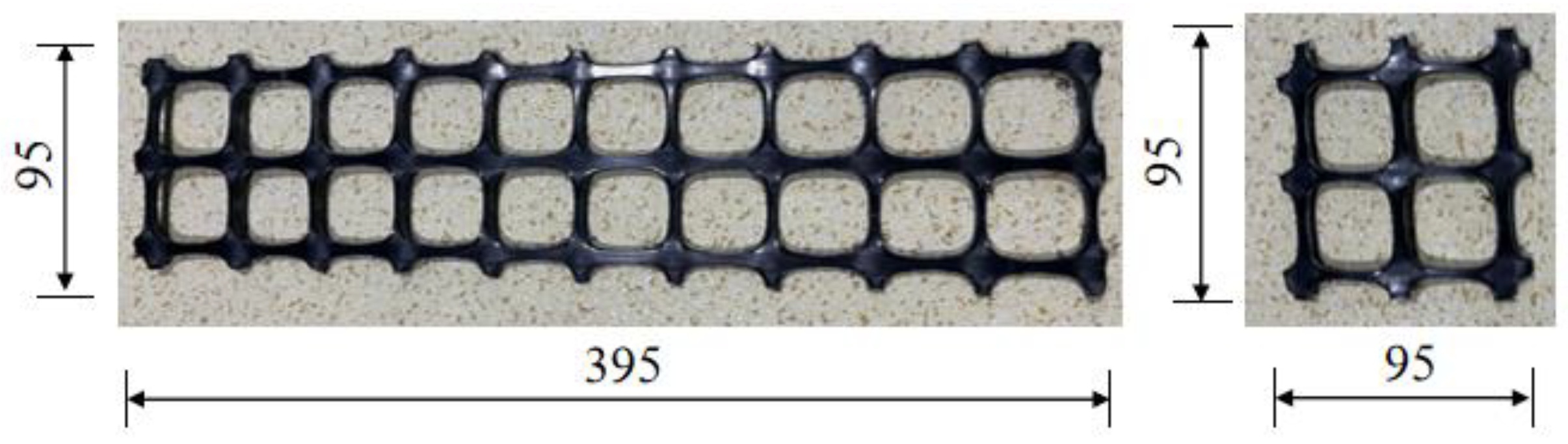

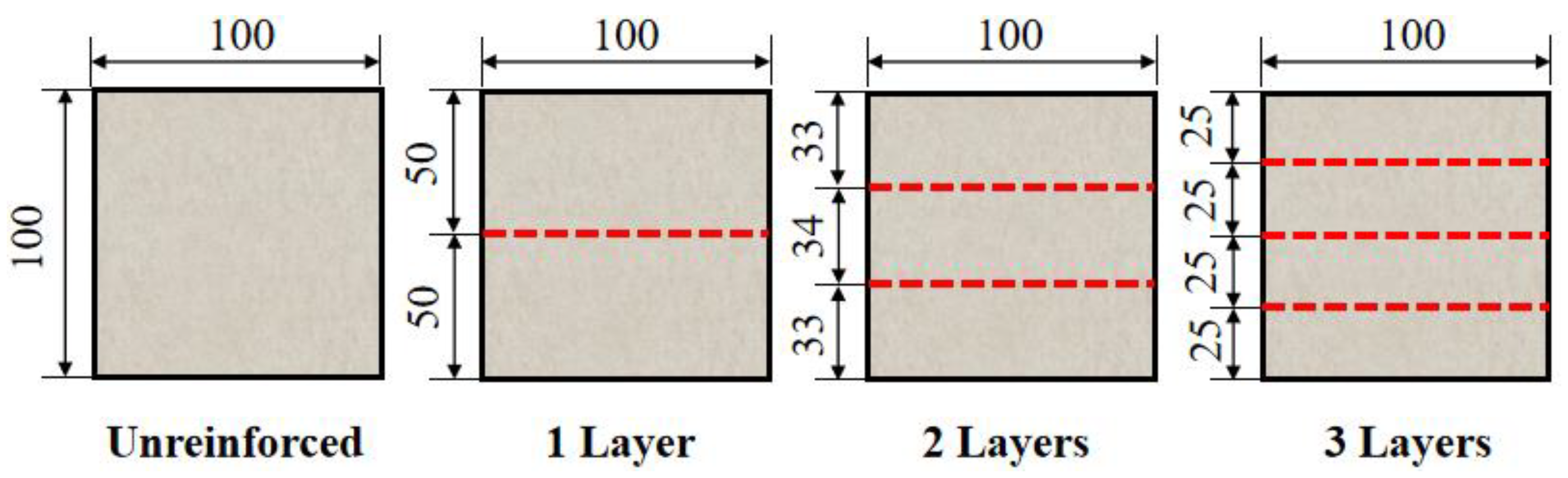

2.2. Experimental Design

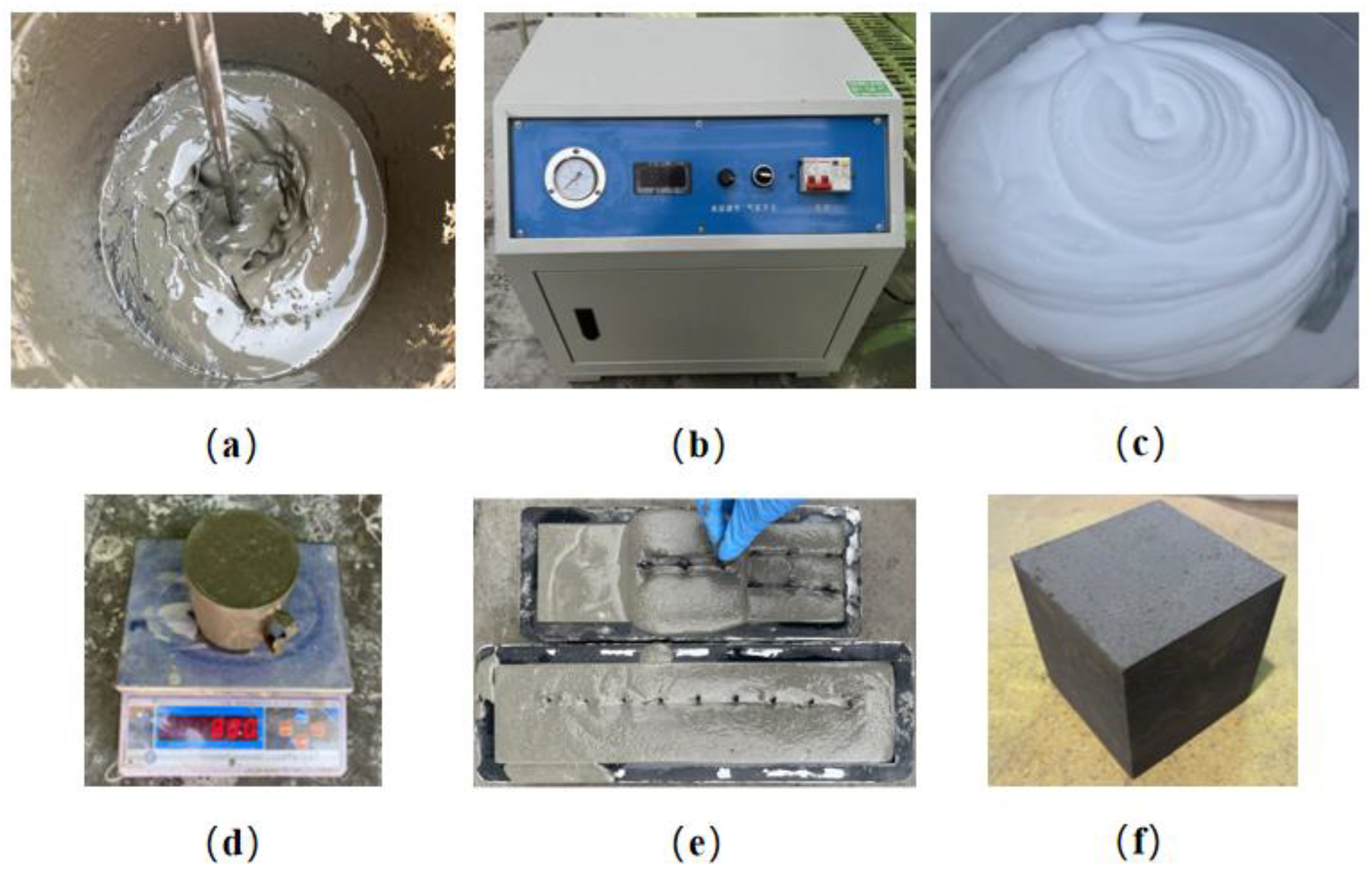

2.3. Specimen Preparation Method

2.4. Test Methods

3. Experimental Results and Discussion

3.1. Flexural Properties of GRFL Soil

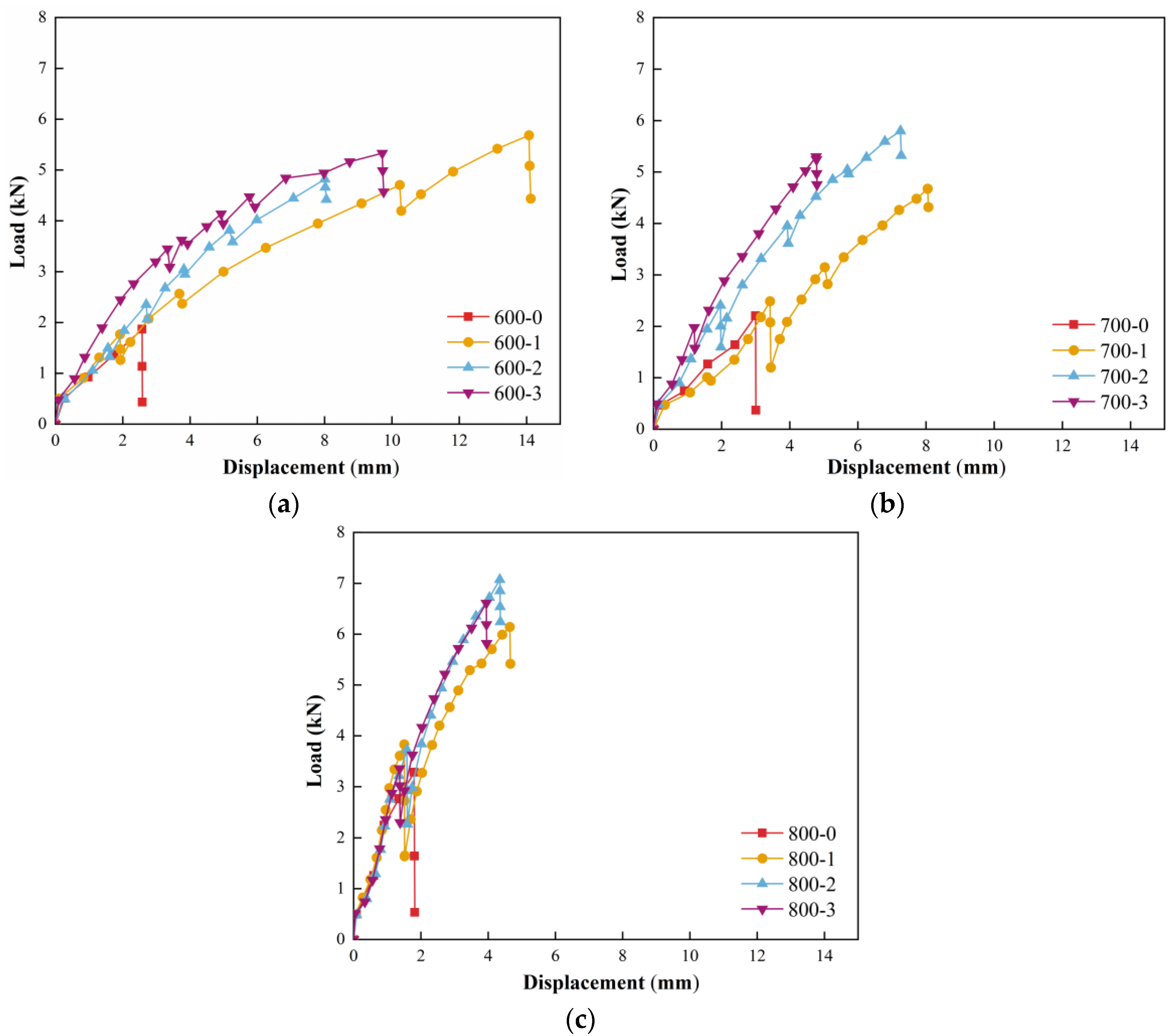

3.1.1. Load–Displacement Curves

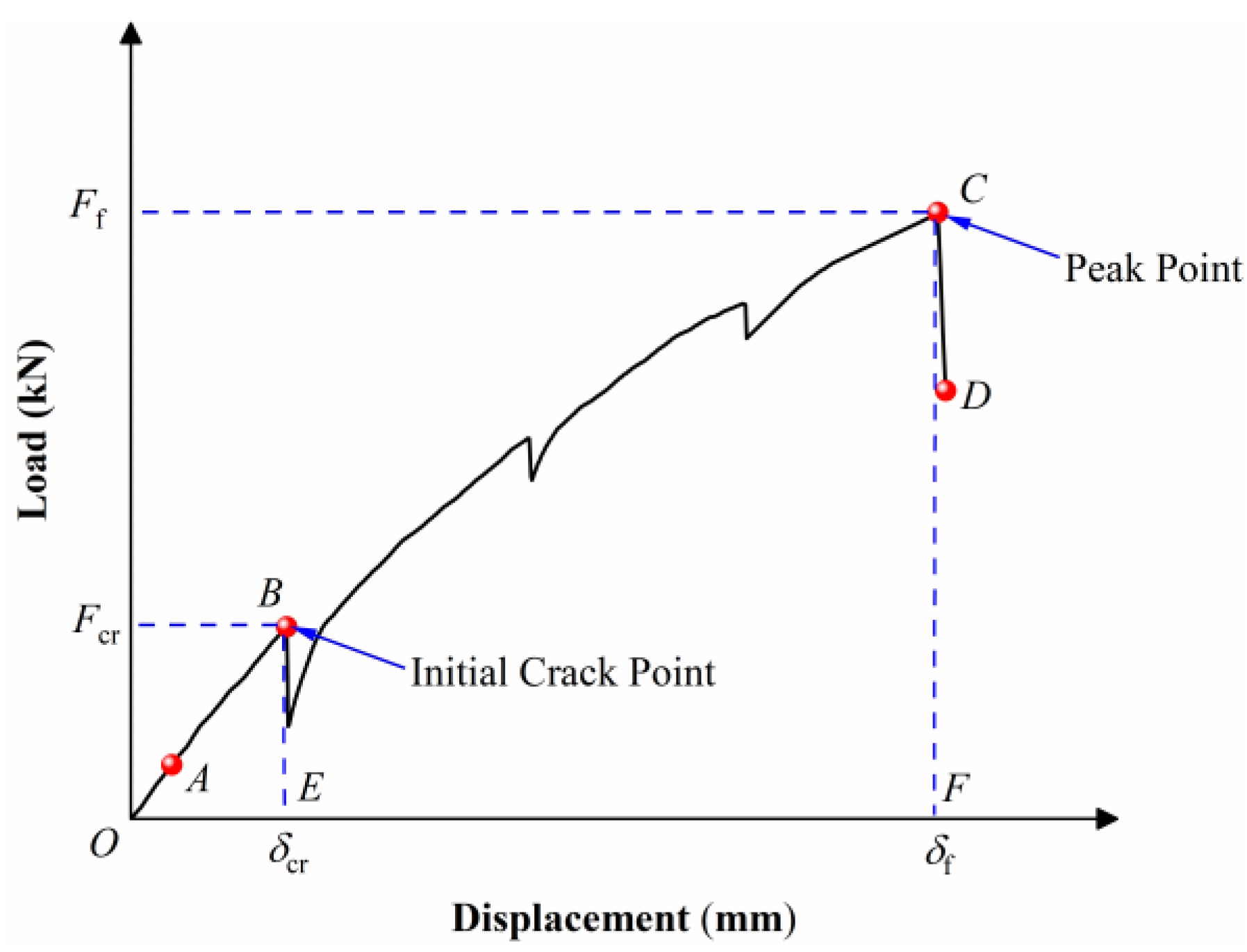

- During the linear phase (OA), loads are low and grow linearly with displacement due to the cementite crystals between discrete pores bearing the load, which exhibit linear behavior.

- The hardening phase (AB) is reached when the loads are slightly reduced relative to linearly increasing loads. The load–displacement curve shifts from linear to nonlinear, the internal self-structure’s microcracks start to develop new cracks, and the load continues to rise until it reaches the initial cracking load. The initial cracking load in this study is the load that corresponds to the first inflection point in the load–displacement curve’s rising portion.

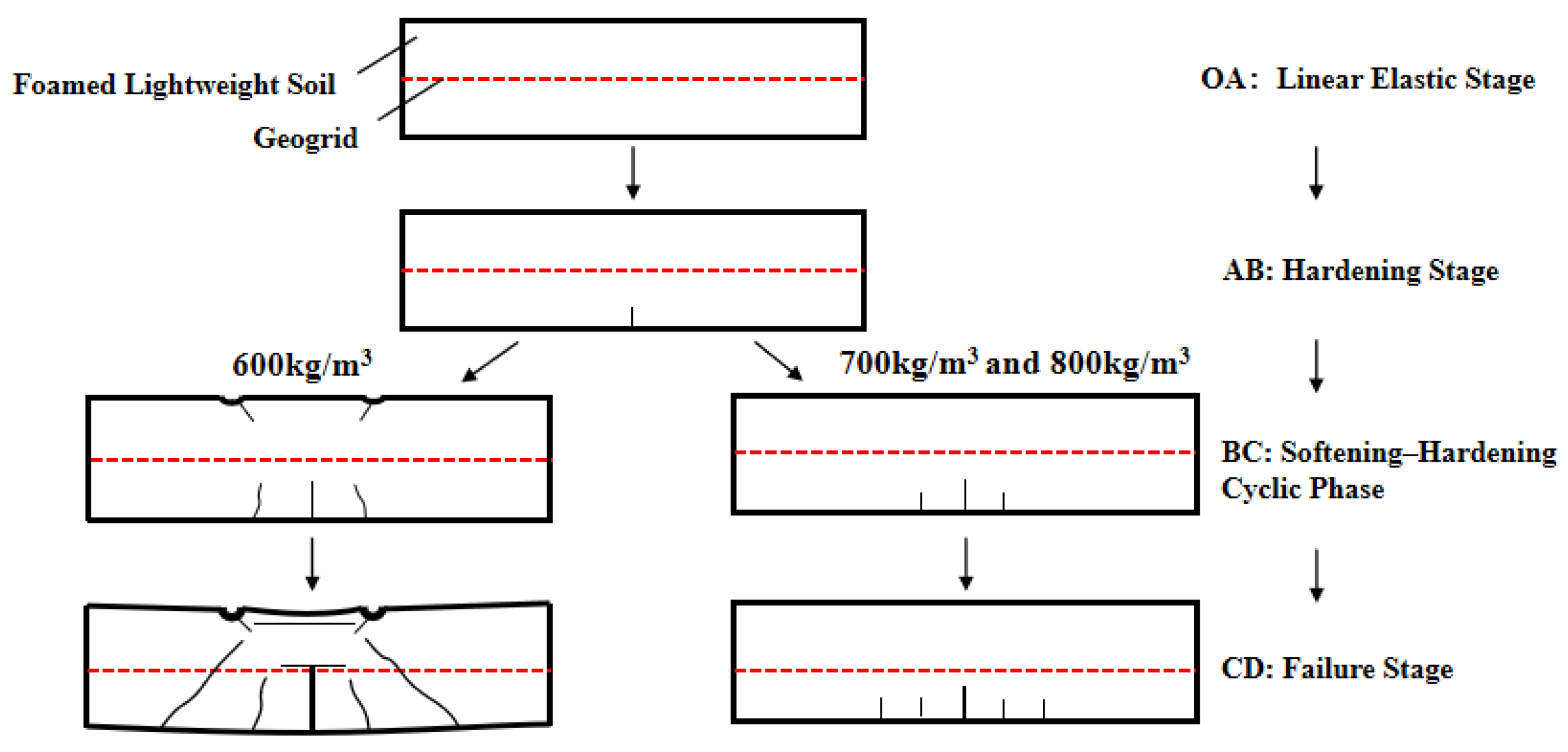

- The vertical load increases after a slight dip in the softening–hardening cycle phase (BC), which primarily affects foamed lightweight soils with wet densities of 600 kg/m3 and 700 kg/m3. The peak load is reached after multiple cycles, whereas the foamed lightweight soil with a wet density of 800 kg/m3 only goes through one cycle.

- The specimen enters the failure phase (CD) after achieving the peak load. When the vertical load drops linearly, the foamed lightweight soil becomes incapable of withstanding the load, and the specimen is destroyed.

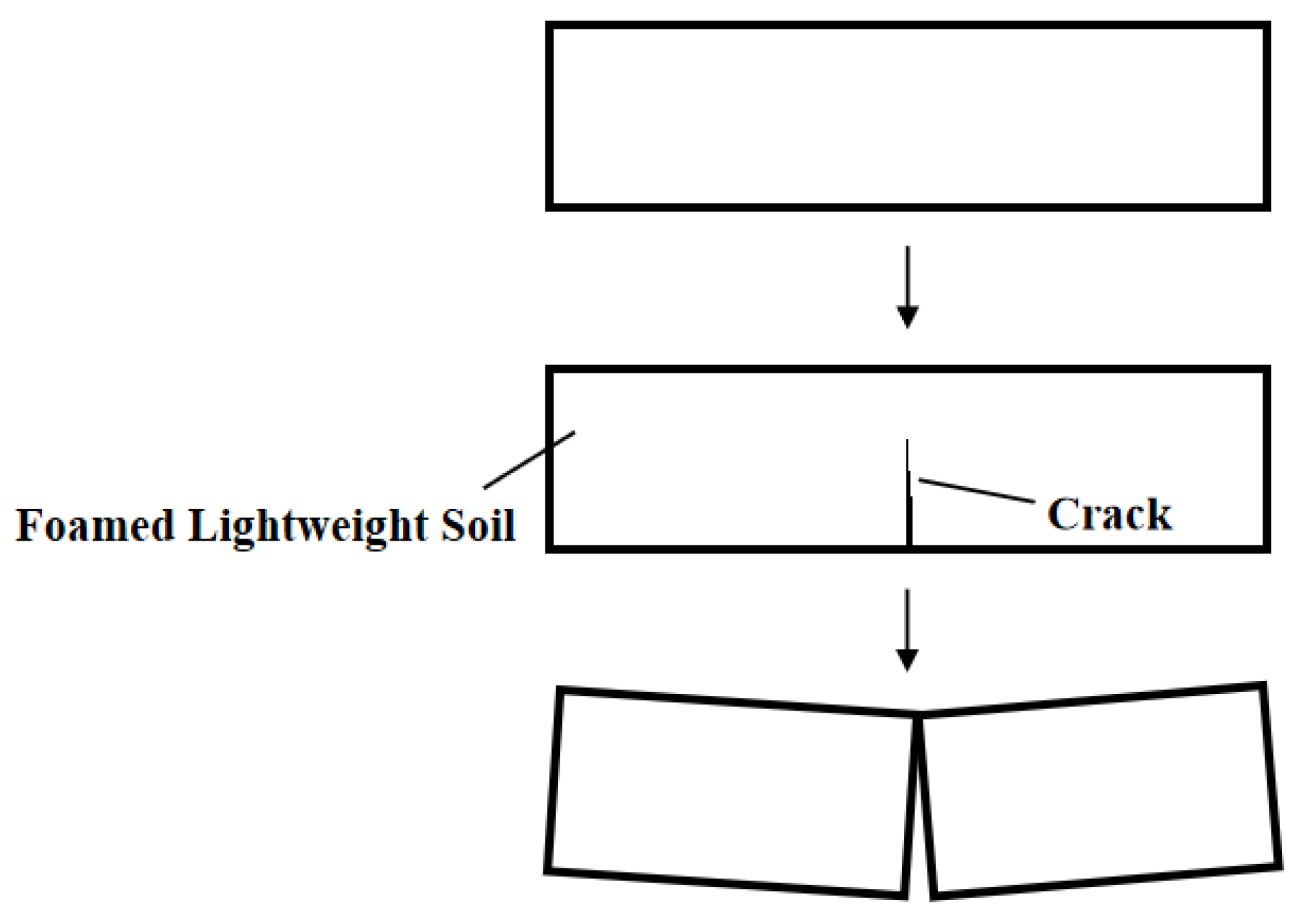

3.1.2. Damage Patterns

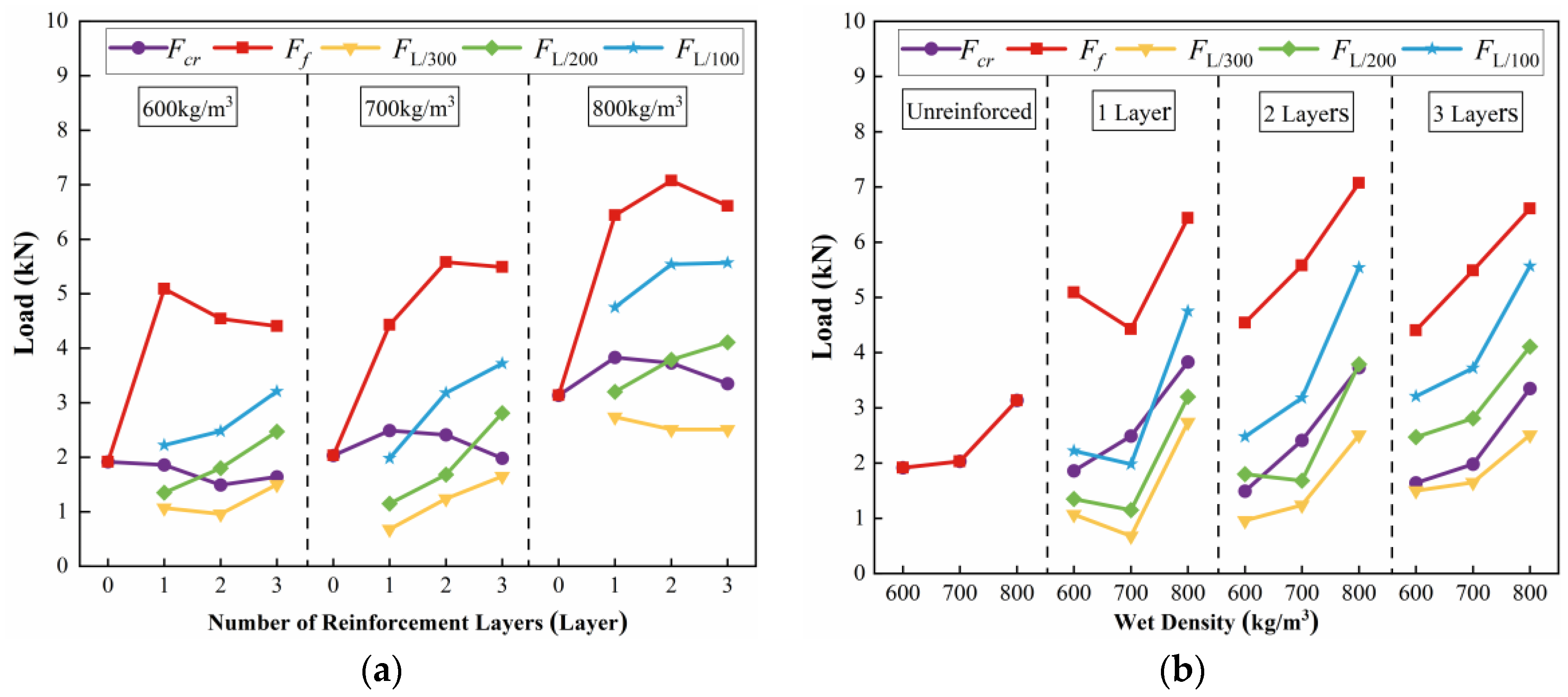

3.1.3. Characteristics of Load Changes at Different Stages

3.2. Strength Characteristics of GRFL Soil

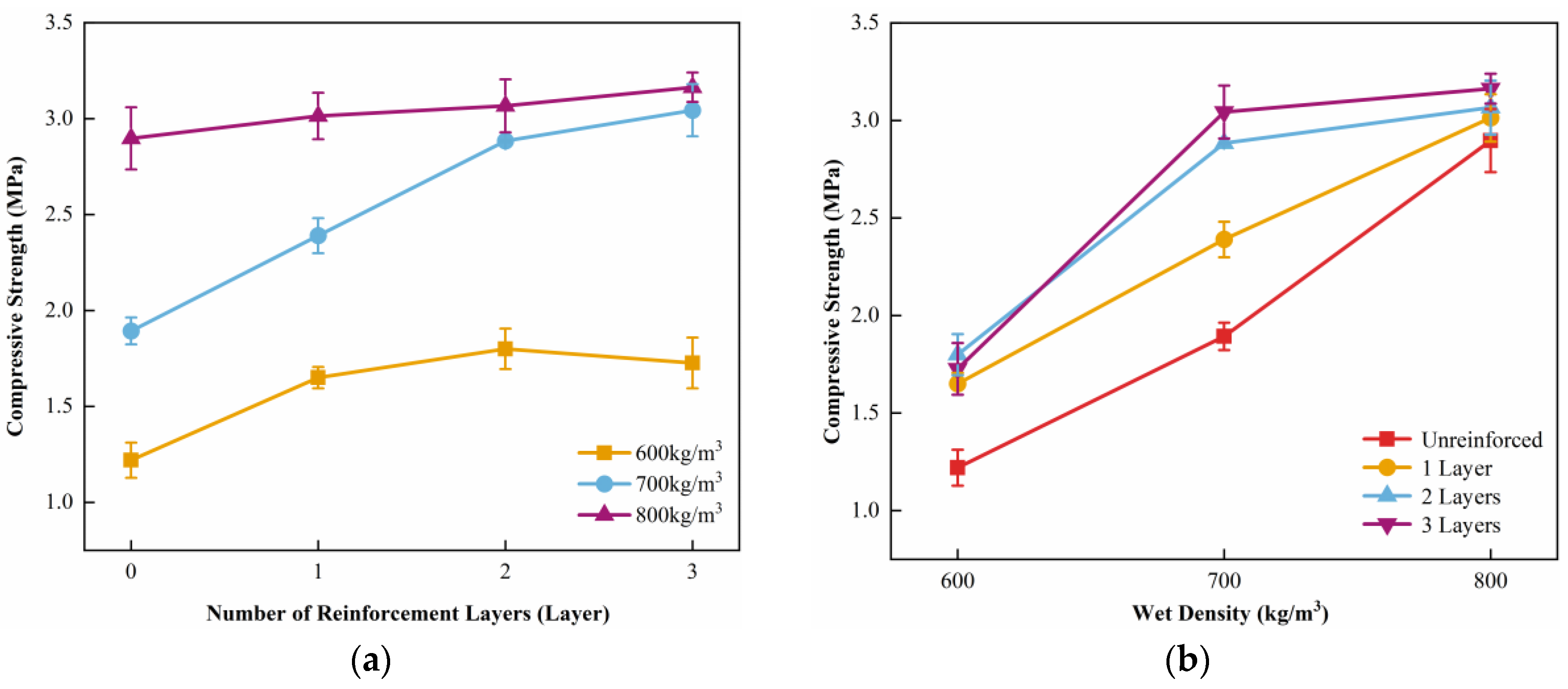

3.2.1. Unconfined Compressive Strength

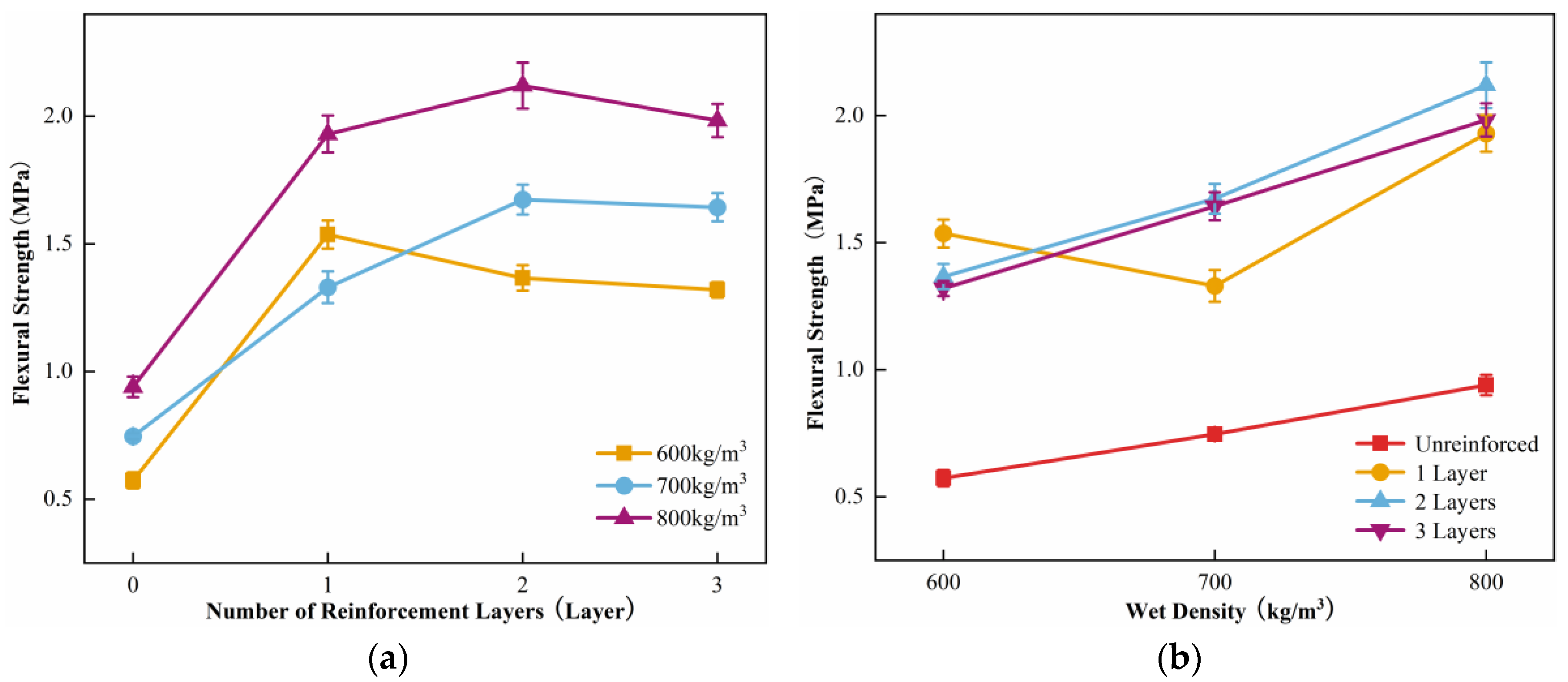

3.2.2. Flexural Strength

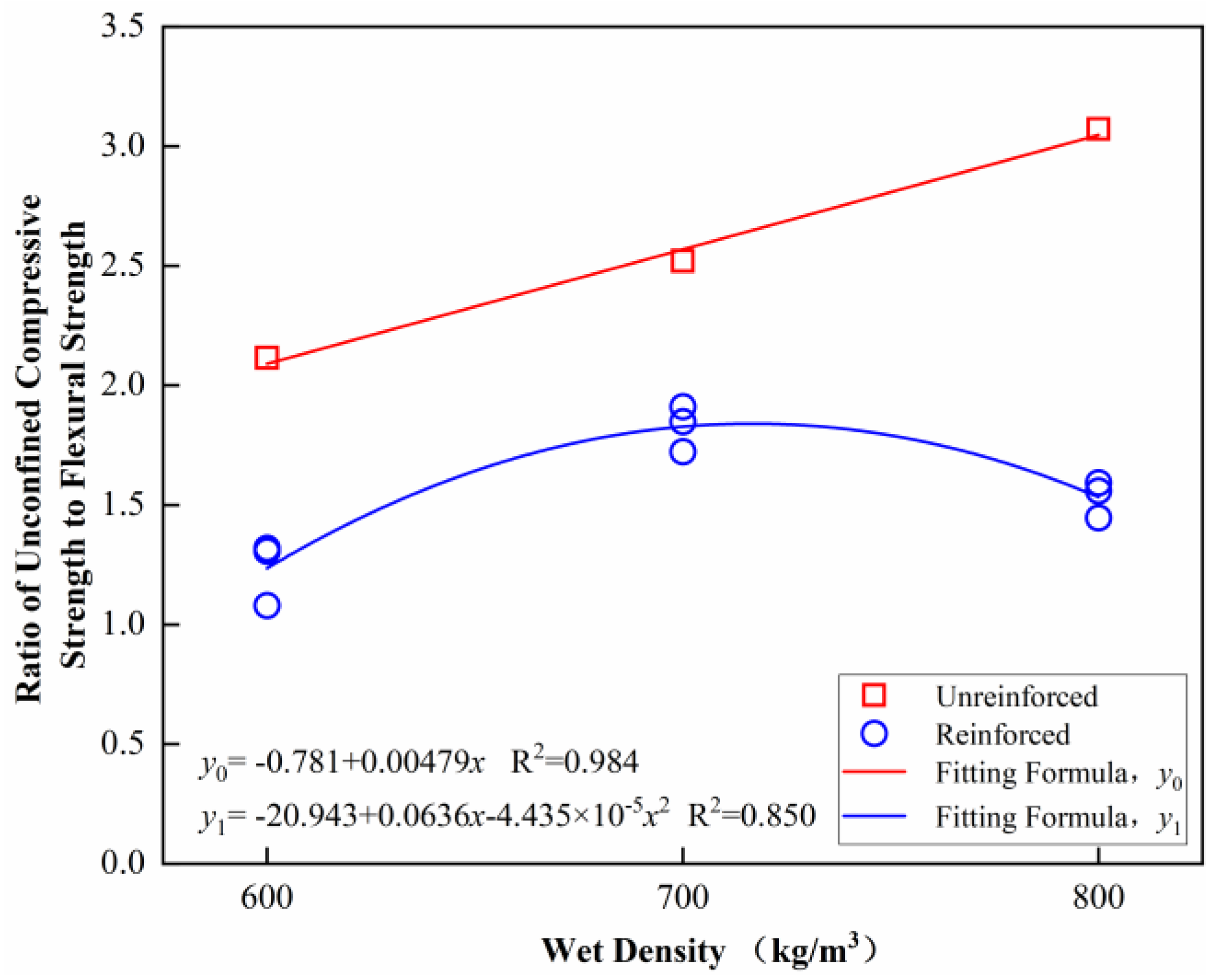

3.2.3. Relationship Between Unconfined Compressive Strength and Flexural Strength

3.3. Analysis of Variance

4. Conclusions and Future Work

- In order to properly avoid deflection, the geogrid is placed vertically at a predetermined location inside the test mold that is filled with a foamed lightweight soil slurry. GRFL soil’s load–displacement curve complies with the elastic–plastic deformation characteristics, which are separated into linear elastic, hardening, softening–hardening cyclic, and failure phases. After first breaking, the load continues to increase, consequently increasing the material’s ductility.

- When the wet density of the GRFL soil is 600 kg/m3, bond failure destruction usually occurs; however, when the wet densities are 700 kg/m3 and 800 kg/m3, the damage pattern is less noticeable and the stability is improved.

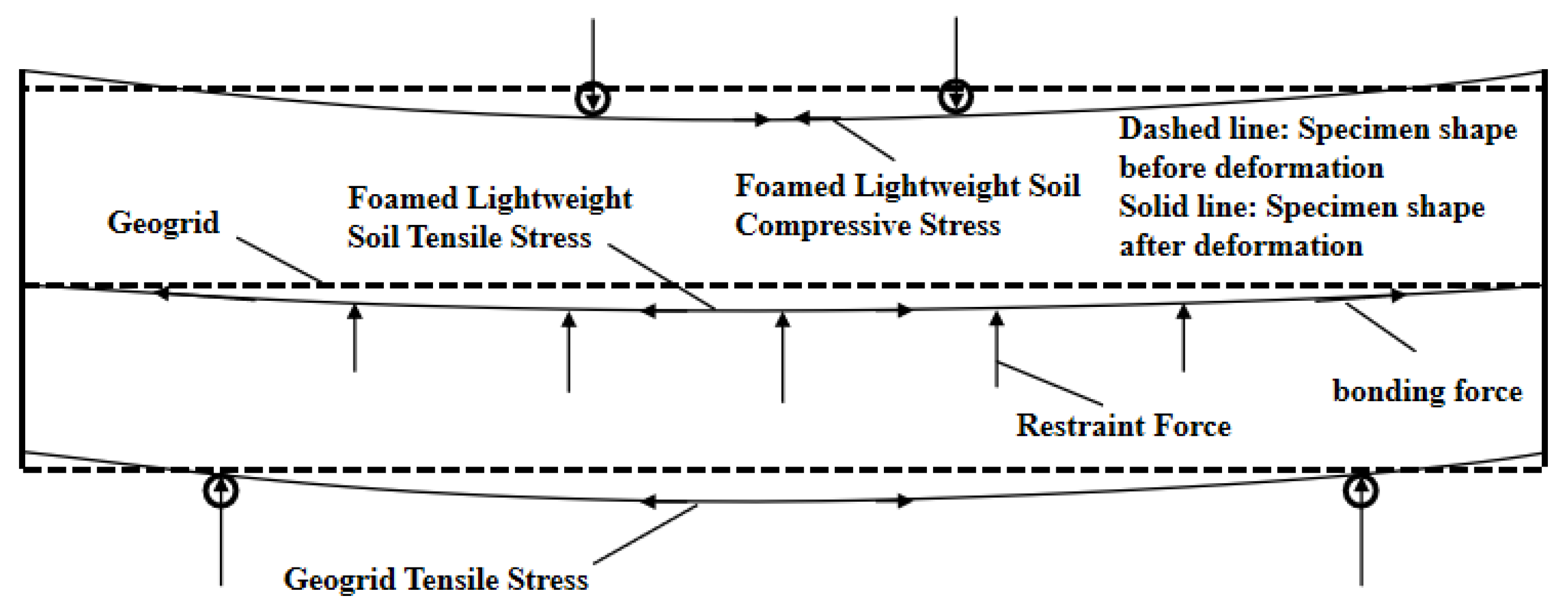

- The foamed lightweight soil itself bears the majority of the load in the early loading stage, while the geogrid bears the majority of the load in the late loading stage. The two share the load through cooperative action.

- The unconfined compressive strength and flexural strength of the foamed lightweight soil were considerably increased by the addition of the geogrid. A multiple nonlinear regression equation was used to create a prediction model for unconfined compressive strength based on the wet density and the number of reinforced layers. Wet density and the ratio of unconfined compressive strength to flexural strength were shown to be positively correlated.

- An analysis of variance revealed that the number of reinforced layers had the biggest impact on the flexural strength, while the wet density had the biggest impact on the unconfined compressive strength. The strength and ductility of GRFL soil may be efficiently managed to increase the applicability in road engineering by selecting the right wet density and number of reinforced layers.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jierula, A.; Li, H.; Chen, Y.; Wu, C.; Wu, X.; Yin, H. Study on the Influence of Density and Water–Cement Ratio on the Cement Utilization, Fluidity, Mechanical Properties, and Water Absorption of Foam Concrete. Buildings 2024, 14, 3550. [Google Scholar] [CrossRef]

- Gołaszewski, J.; Klemczak, B.; Smolana, A.; Gołaszewska, M.; Cygan, G.; Mankel, C.; Peralta, I.; Röser, F.; Koenders, E.A.B. Effect of Foaming Agent, Binder and Density on the Compressive Strength and Thermal Conductivity of Ultra-Light Foam Concrete. Buildings 2022, 12, 1176. [Google Scholar] [CrossRef]

- Mohtadi, A.; Ghomeishi, M.; Dehghanbanadaki, A. Towards Sustainable Construction: Evaluating Thermal Conductivity in Advanced Foam Concrete Mixtures. Buildings 2024, 14, 3636. [Google Scholar] [CrossRef]

- Bat-Erdene, P.-E.; Pareek, S.; Koenders, E.; Mankel, C.; Löher, M.; Xiao, P. Evaluation of the Thermal Performance of Fly Ash Foam Concrete Containing Phase Change Materials (PCMs). Buildings 2023, 13, 2481. [Google Scholar] [CrossRef]

- Liu, C.; Luan, K.; Su, J. Study on Post-Fire Resistance of Ceramsite Foamed Concrete Sandwich Composite Slabs. Structures 2023, 58, 105506. [Google Scholar] [CrossRef]

- Kou, R.; Guo, M.-Z.; Shi, Y.; Mei, M.; Jiang, L.; Chu, H.; Zhang, Y.; Shen, H.; Xue, L. Sound-Insulation and Photocatalytic Foamed Concrete Prepared with Dredged Sediment. J. Clean. Prod. 2022, 356, 131902. [Google Scholar] [CrossRef]

- Zhang, B.; Poon, C.S. Sound Insulation Properties of Rubberized Lightweight Aggregate Concrete. J. Clean. Prod. 2018, 172, 3176–3185. [Google Scholar] [CrossRef]

- Raj, A.; Sathyan, D.; Mini, K.M. Physical and Functional Characteristics of Foam Concrete: A Review. Constr. Build. Mater. 2019, 221, 787–799. [Google Scholar] [CrossRef]

- Amran, Y.H.M.; Farzadnia, N.; Abang Ali, A.A. Properties and Applications of Foamed Concrete; A Review. Constr. Build. Mater. 2015, 101, 990–1005. [Google Scholar] [CrossRef]

- Zhang, S. Research on Dynamic Characteristics of Subgrade and Dynamic Construction Control Index on Changsha Round-the-City Expressway. Master’s Thesis, Changsha University of Science & Technology, Changsha, China, 2013. [Google Scholar]

- Zhang, H.; Qi, X.; Wan, L.; Zuo, Z.; Ge, Z.; Wu, J.; Song, X. Properties of Silt-Based Foamed Concrete: A Type of Material for Use in Backfill behind an Abutment. Constr. Build. Mater. 2020, 261, 119966. [Google Scholar] [CrossRef]

- Chica, L.; Alzate, A. Cellular Concrete Review: New Trends for Application in Construction. Constr. Build. Mater. 2019, 200, 637–647. [Google Scholar] [CrossRef]

- Huang, J.; Su, Q.; Zhao, W.; Li, T.; Zhang, X. Experimental Study on Use of Lightweight Foam Concrete as Subgrade Bed Filler of Ballastless Track. Constr. Build. Mater. 2017, 149, 911–920. [Google Scholar] [CrossRef]

- Zhang, C.; Zhu, Z.; Zhang, Y.; Liu, F.; Yang, Y.; Wan, Y.; Huo, W.; Yang, L. Engineering Properties and Optimal Design of Foam Lightweight Soil Composite Fly Ash: An Eco-Friendly Subgrade Material. J. Clean. Prod. 2023, 429, 139631. [Google Scholar] [CrossRef]

- Shi, L.; Chen, H.; Dou, J.; Lv, Z.; Muo, S.; Chen, Y. Finite element simulation of thermal performance of medium lightweight foamed concrete self-insulating block wall. Brick-Tile 2024, 5, 18–23. [Google Scholar] [CrossRef]

- Shi, X.; Huang, J.; Su, Q. Experimental and Numerical Analyses of Lightweight Foamed Concrete as Filler for Widening Embankment. Constr. Build. Mater. 2020, 250, 118897. [Google Scholar] [CrossRef]

- Fang, C. Study on Deformation and Stability Characteristics of Foamed Lightweight Soil Reinforced Embankment. Master’s Thesis, Chongqing Jiaotong University, Chongqing, China, 2023. [Google Scholar] [CrossRef]

- Liu, X.; Liu, F.; Yin, Z.; Zhu, P.; Wang, M. Study on Crack Propagation Characteristics of Foam Concrete–Soil Composite with Different Height Ratios under Dynamic and Static Loading Conditions. J. Eng. Sci. Technol. Rev. 2024, 17, 131–139. [Google Scholar] [CrossRef]

- Falliano, D.; De Domenico, D.; Ricciardi, G.; Gugliandolo, E. Improving the Flexural Capacity of Extrudable Foamed Concrete with Glass-Fiber Bi-Directional Grid Reinforcement: An Experimental Study. Compos. Struct. 2019, 209, 45–59. [Google Scholar] [CrossRef]

- Yavuz Bayraktar, O.; Kaplan, G.; Gencel, O.; Benli, A.; Sutcu, M. Physico-Mechanical, Durability and Thermal Properties of Basalt Fiber Reinforced Foamed Concrete Containing Waste Marble Powder and Slag. Constr. Build. Mater. 2021, 288, 123128. [Google Scholar] [CrossRef]

- Shi, X.; Ning, B.; Wang, J.; Cui, T.; Zhong, M. Improving Flexural Toughness of Foamed Concrete by Mixing Polyvinyl Alcohol-Polypropylene Fibers: An Experimental Study. Constr. Build. Mater. 2023, 400, 132689. [Google Scholar] [CrossRef]

- Rao, D.; Wang, X.; Zhou, W.; Zheng, G.; Chu, Y.; Fang, C. Study on the deformation of reinforced lightweight soil embankments based on full-scale model tests. Drill. Eng. 2024, 51, 111–116. [Google Scholar]

- Tao, Y. Experimental Study on Pavement Performance of Geogrid-Reinforced Foamed Concrete. Master’s Thesis, Hunan University of Science and Technology, Xiangtan, China, 2023. [Google Scholar] [CrossRef]

- Hulimka, J.; Krzywoń, R.; Jędrzejewska, A. Laboratory Tests of Foam Concrete Slabs Reinforced with Composite Grid. Procedia Eng 2017, 193, 337–344. [Google Scholar] [CrossRef]

- Al-Barqawi, M.; Aqel, R.; Wayne, M.; Titi, H.; Elhajjar, R. Polymer Geogrids: A Review of Material, Design and Structure Relationships. Materials 2021, 14, 4745. [Google Scholar] [CrossRef] [PubMed]

- El Meski, F.; Chehab, G.R. Flexural Behavior of Concrete Beams Reinforced with Different Types of Geogrids. J. Mater. Civ. Eng. 2014, 26, 04014038. [Google Scholar] [CrossRef]

- Wang, Z.; Cai, Y.; Qi, Y.; Yang, G.; Ye, C. Large-scale triaxial tests of geogrid reinforced rubber gravel mixtures. J. Railw. Sci. Eng. 2023, 20, 2509–2520. [Google Scholar] [CrossRef]

- Wu, L.; Zhu, Y.; Xu, Q.; Chen, Q.; Wang, Y. Triaxial test study of geogrid reinforced sand. J. Hefei Univ. Technol. Nat. Sci. 2024, 47, 83–90. [Google Scholar]

- CJJ/T 177—2012; Technical Specification for Filling Engineering with Foamed Lightweight Soil. China Architecture & Building Press: Beijing, China, 2012. (In Chinese)

- Zhang, Q.; Zhang, K.; Yu, J.; Sun, R.; Song, X. Experimental Study of Geogrid Reinforced under Different Foundation Settlement Modes. Hans J. Civ. Eng. 2019, 8, 939–948. [Google Scholar] [CrossRef]

- GB/T 11969—2020; Test Methods for Properties of Autoclaved Aerated Concrete. Standards Press of China: Beijing, China, 2020. (In Chinese)

- Zhang, X. Research on Static and Dynamic Characteristics and Durability of Polypropylene Fiber-modified Rubber Foamed Concrete. Master’s Thesis, Shandong University, Jinan, China, 2024. [Google Scholar]

- Liu, J.; Li, H.; Zhang, B.; Liu, B.; Hao, B.; Jiang, N. Pore structure analysis of foamed lightweight soil based on X-CT scanning technology. J. Beijing Polytech. Univ. 2024, 50, 1228–1236. [Google Scholar]

- ASTM C1609/C1609M-24; Standard Test Method for Flexural Performance of Fiber-Reinforced Concrete (Using Beam with Third-Point Loading). ASTM International: West Conshohocken, PA, USA, 2024.

- Wang, T. Flexural Behavior and Calculation Method of Reinforced Concrete Short Beam Strengthened by CFRP Sheet. Ph.D. Thesis, Zhengzhou University, Zhengzhou, China, 2018. [Google Scholar]

- Li, B.; Chi, Y.; Xu, L.; Shi, Y.; Li, C. Experimental Investigation on the Flexural Behavior of Steel-Polypropylene Hybrid Fiber Reinforced Concrete. Constr. Build. Mater. 2018, 191, 80–94. [Google Scholar] [CrossRef]

- Decký, M.; Drusa, M.; Zgútová, K.; Blaško, M.; Hájek, M.; Scherfel, W. Foam Concrete as New Material in Road Constructions. Procedia Eng. 2016, 161, 428–433. [Google Scholar] [CrossRef]

- Liu, K.; Su, Q.; Ni, P.; Zhou, C.; Zhao, W.; Yue, F. Evaluation on the Dynamic Performance of Bridge Approach Backfilled with Fibre Reinforced Lightweight Concrete under High-Speed Train Loading. Comput Geotech. 2018, 104, 42–53. [Google Scholar] [CrossRef]

- Wu, J.; Wang, J.; Liu, M.; Zhuang, P.; Zhang, H.; Song, X. Dynamic Properties of Silt-Based Foamed Concrete as Filler in Subgrade. J. Mater. Civ. Eng. 2022, 34, 04022241. [Google Scholar] [CrossRef]

- Liu, H.; Han, J.; Parsons, R.L. Mitigation of Seasonal Temperature Change-Induced Problems with Integral Bridge Abutments Using EPS Foam and Geogrid. Geotext. Geomembr. 2021, 49, 1380–1392. [Google Scholar] [CrossRef]

- Amran, M.; Huei Lee, Y.; Vatin, N.; Fediuk, R.; Poi-Ngian, S.; Yong Lee, Y.; Murali, G. Design Efficiency, Characteristics, and Utilization of Reinforced Foamed Concrete: A Review. Crystals 2020, 10, 948. [Google Scholar] [CrossRef]

- Li, W.; Yang, J.; Sun, M.; Xu, F.; Zhao, Y.; Xia, H. A Sludge-Modified Foam Concrete for Road Fill Material: Performance Evaluation and Carbon Footprint Analysis. J. CO2 Util. 2025, 91, 103006. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, J.; Liu, Z.; Ma, C.; Song, Z.; Cui, F.; Wu, J.; Song, X. Strength Characteristics of Foamed Concrete under Coupling Effect of Constant Compressive Loading and Freeze-Thaw Cycles. Constr. Build. Mater. 2024, 411, 134565. [Google Scholar] [CrossRef]

| Model | Mesh Size/mm | Tensile Strength/(kN/m) | Elongation at Break/% | ||

|---|---|---|---|---|---|

| Longitudinal | Transverse | Longitudinal | Transverse | ||

| TGSG50-50 | 33 × 33 | 55.8 | 60.3 | 6.3 | 7.6 |

| Serial Number | Target Wet Density/ (kg/m3) | Number of Reinforcement Layers | Cement Content/ (kg/m3) | Water Content/ (kg/m3) | Foam Dosage/ (kg/m3) | Measured Wet Density/ (kg/m3) | Flow Value/ (mm) |

|---|---|---|---|---|---|---|---|

| 600-0 | 600 | 0 | 365 | 201 | 34 | 608 | 183 |

| 600-1 | 1 | 592 | 181 | ||||

| 600-2 | 2 | 605 | 184 | ||||

| 600-3 | 3 | 602 | 184 | ||||

| 700-0 | 700 | 0 | 432 | 237 | 31 | 697 | 181 |

| 700-1 | 1 | 705 | 185 | ||||

| 700-2 | 2 | 700 | 183 | ||||

| 700-3 | 3 | 710 | 191 | ||||

| 800-0 | 800 | 0 | 498 | 274 | 28 | 805 | 182 |

| 800-1 | 1 | 800 | 185 | ||||

| 800-2 | 2 | 802 | 190 | ||||

| 800-3 | 3 | 808 | 186 |

| Wet Density (kg/m3) | Reinforcement Layers | Measured Value (MPa) | Calculated Value (MPa) | Error (%) |

|---|---|---|---|---|

| 600 | 0 | 1.22 | 1.37 | 12.30 |

| 1 | 1.65 | 1.58 | 4.24 | |

| 2 | 1.80 | 1.79 | 0.56 | |

| 3 | 1.73 | 2.01 | 16.18 | |

| 700 | 0 | 1.89 | 2.09 | 10.58 |

| 1 | 2.54 | 2.30 | 9.45 | |

| 2 | 2.88 | 2.51 | 12.85 | |

| 3 | 3.04 | 2.72 | 10.53 | |

| 800 | 0 | 2.89 | 2.80 | 3.11 |

| 1 | 3.01 | 3.02 | 0.33 | |

| 2 | 3.07 | 3.23 | 5.21 | |

| 3 | 3.16 | 3.44 | 8.86 |

| F1–0.05(2,9) | Degree of Significance |

|---|---|

| >4.26 | Significant |

| <4.26 | Insignificant |

| Consideration Index | Item | Influencing Factors | |

|---|---|---|---|

| Wet Density | Number of Reinforcement Layers | ||

| Freedom df | 2 | 3 | |

| Unconfined Compressive Strength | Sum of Squares | 12.813 | 2.277 |

| Mean Square | 6.407 | 0.759 | |

| F1–0.05(2,9) | 166.802 | 19.763 | |

| Significance | Significant | Significant | |

| Contribution Rate | 89.41% | 10.59% | |

| Flexural Strength | Sum of Squares | 1.898 | 5.566 |

| Mean Square | 0.949 | 1.855 | |

| F1–0.05(2,9) | 62.283 | 121.787 | |

| Significance | Significant | Significant | |

| Contribution Rate | 33.84% | 66.16% | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Liu, Y.; Zhang, H.; An, N.; Fan, Z. Experimental Study on the Flexural Performance of Geogrid-Reinforced Foamed Lightweight Soil. Buildings 2025, 15, 461. https://doi.org/10.3390/buildings15030461

Li Y, Liu Y, Zhang H, An N, Fan Z. Experimental Study on the Flexural Performance of Geogrid-Reinforced Foamed Lightweight Soil. Buildings. 2025; 15(3):461. https://doi.org/10.3390/buildings15030461

Chicago/Turabian StyleLi, Yinhe, Yong Liu, Hongbo Zhang, Ning An, and Zuolin Fan. 2025. "Experimental Study on the Flexural Performance of Geogrid-Reinforced Foamed Lightweight Soil" Buildings 15, no. 3: 461. https://doi.org/10.3390/buildings15030461

APA StyleLi, Y., Liu, Y., Zhang, H., An, N., & Fan, Z. (2025). Experimental Study on the Flexural Performance of Geogrid-Reinforced Foamed Lightweight Soil. Buildings, 15(3), 461. https://doi.org/10.3390/buildings15030461