Evaluating the Performance and Efficiency of Sandwich-Insulated Concrete Block Products in the Saudi Market

Abstract

1. Introduction

2. Experimental Procedures

2.1. Visual Inspection

2.2. Dry Density

2.3. Compressive Strength

2.4. Thermal Performance

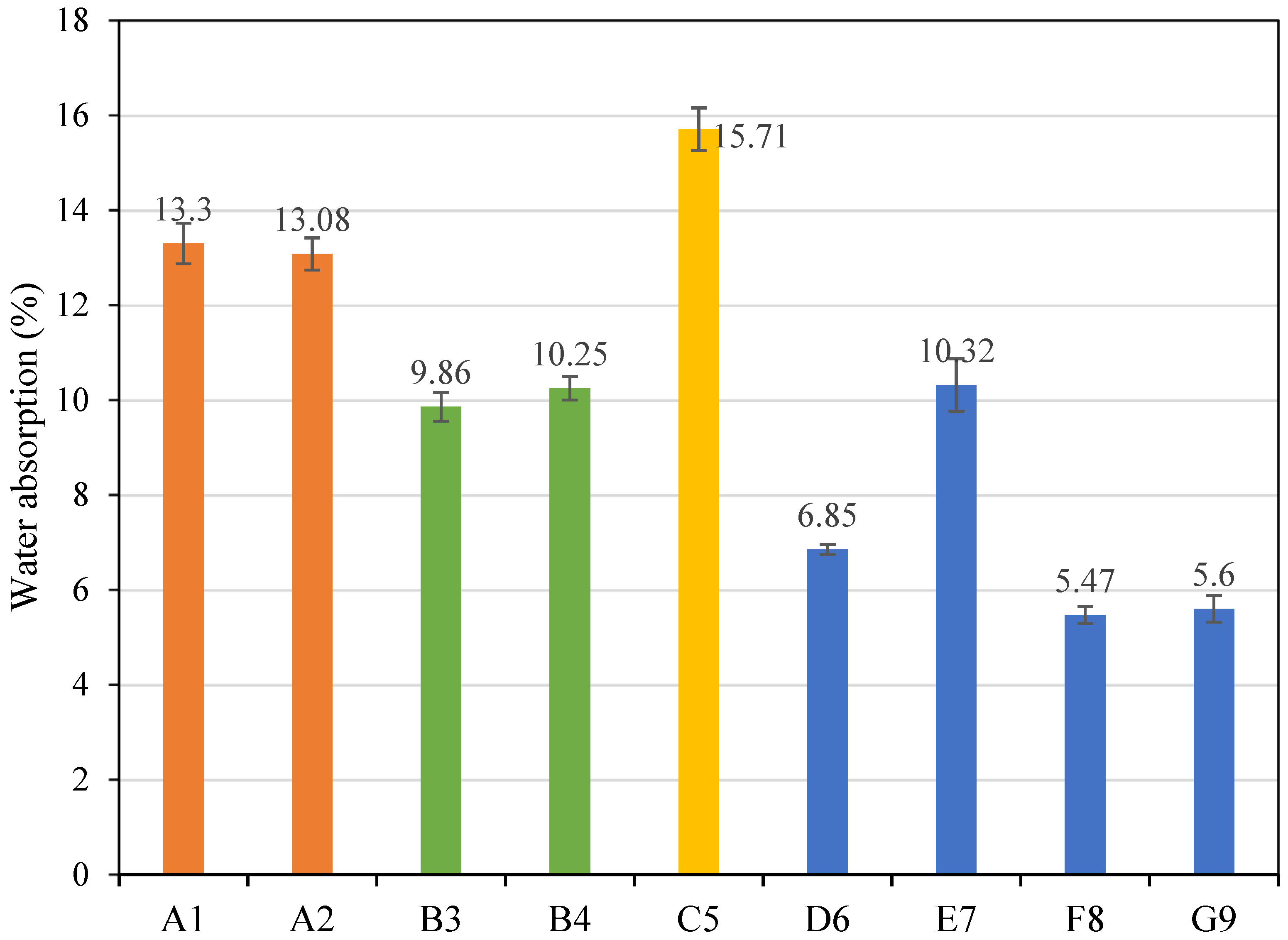

2.5. Water Absorption

2.6. Chloride and Sulfate Contents

2.7. Polystyrene Degradation Tests

2.7.1. Accelerated Weathering Test

2.7.2. Antibacterial Test

3. Results and Discussion

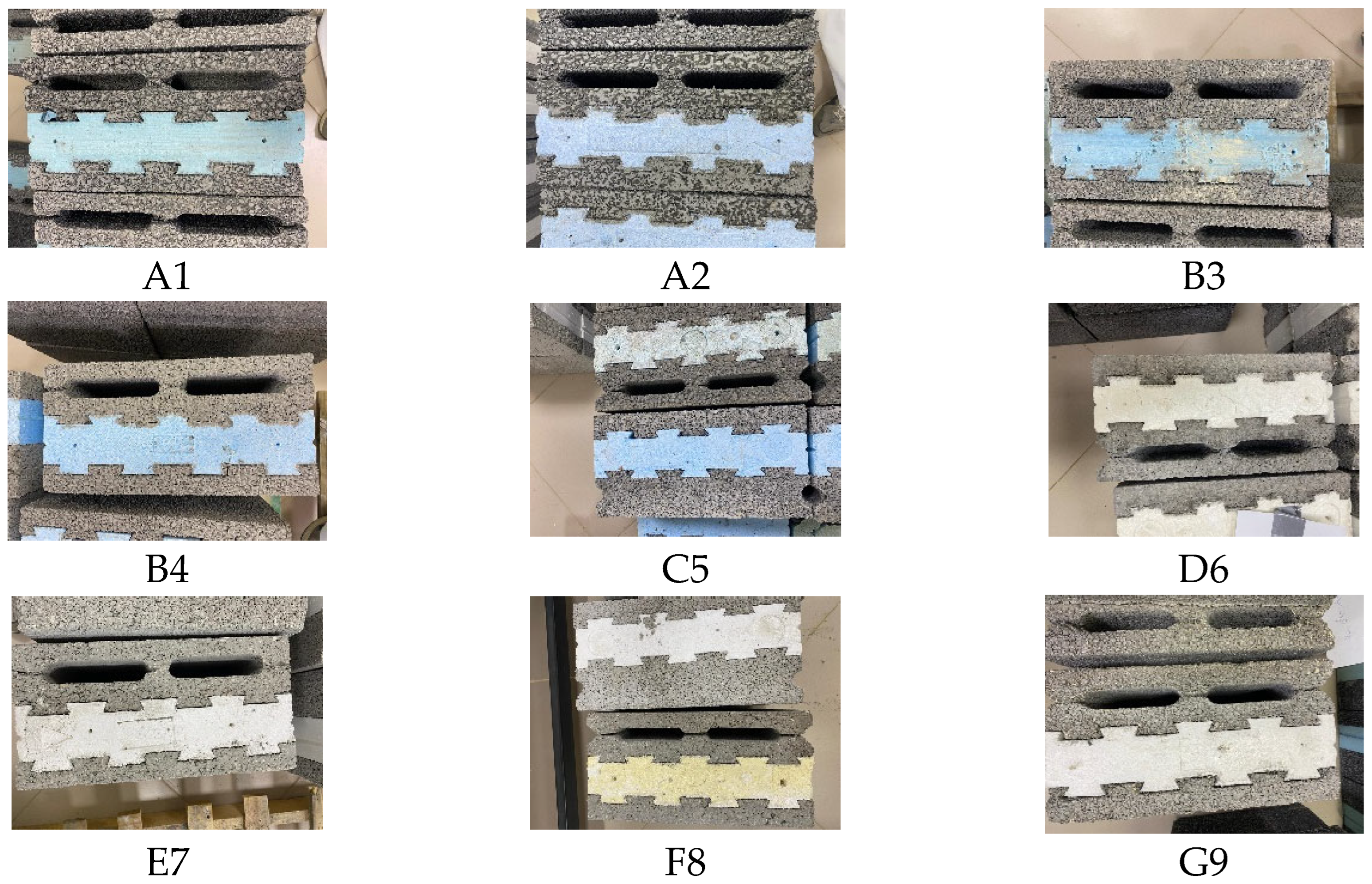

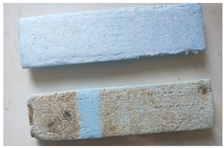

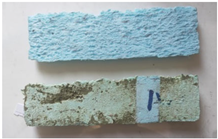

3.1. Appearance and Visual Inspection

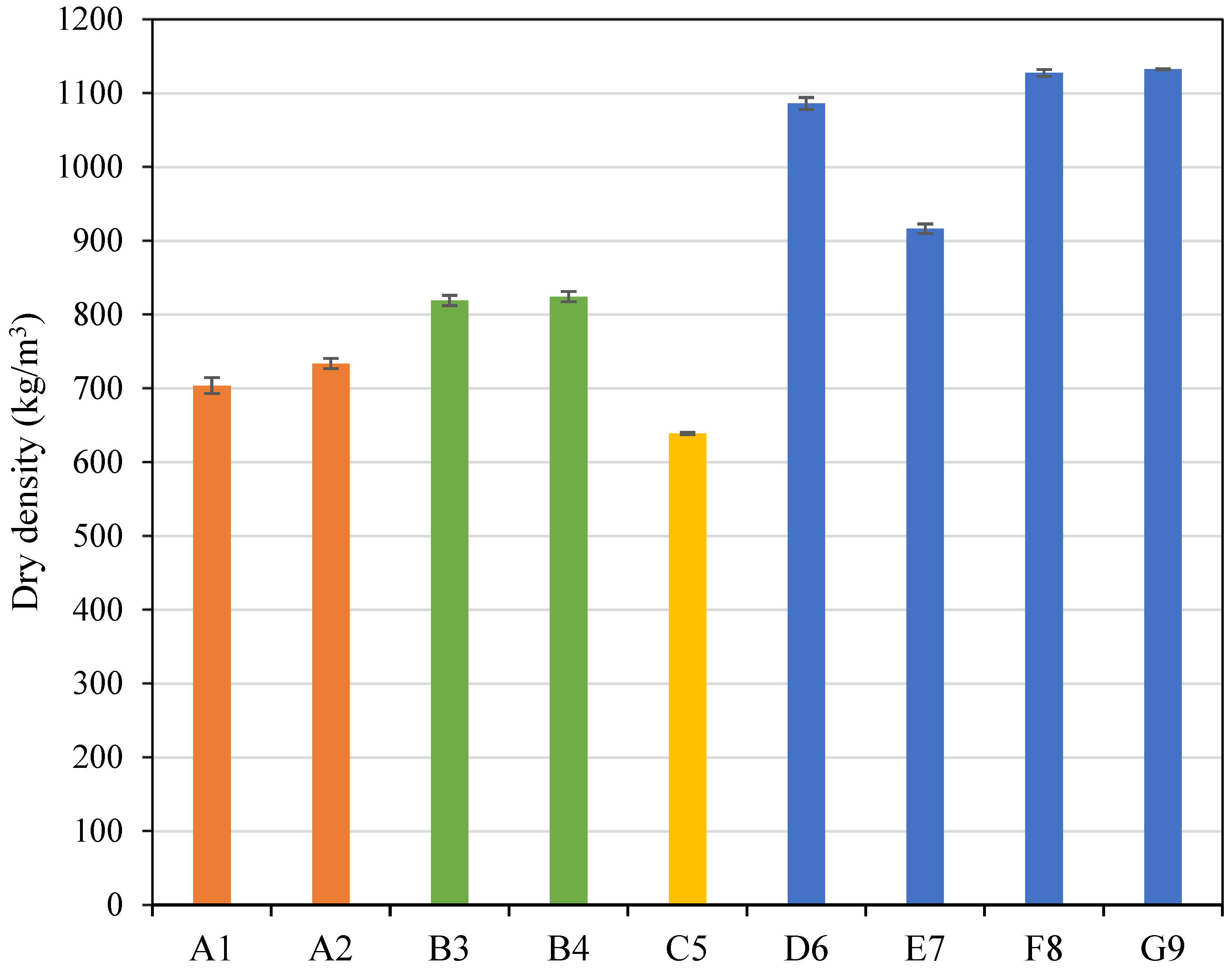

3.2. Dry Density

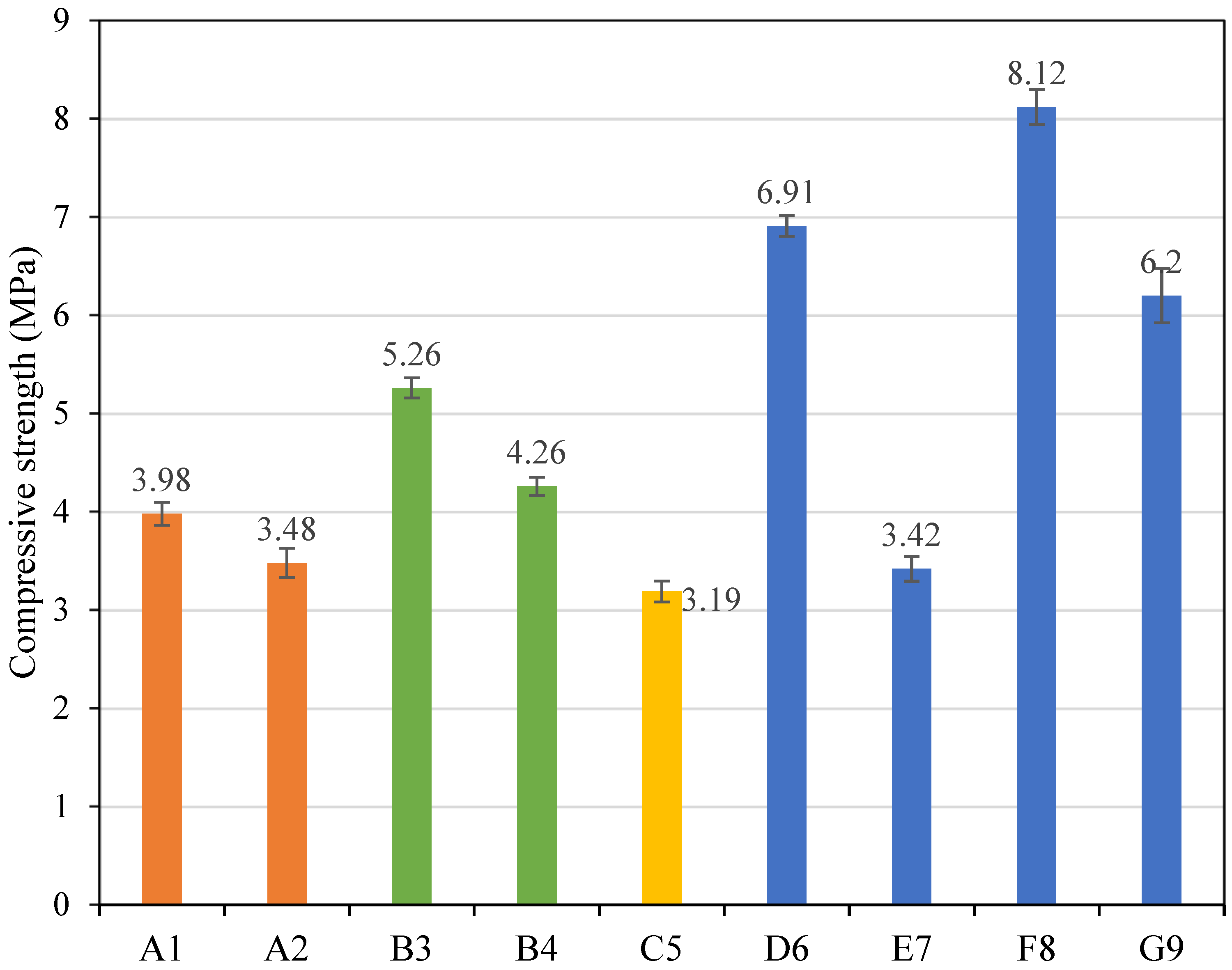

3.3. Mechanical Performance

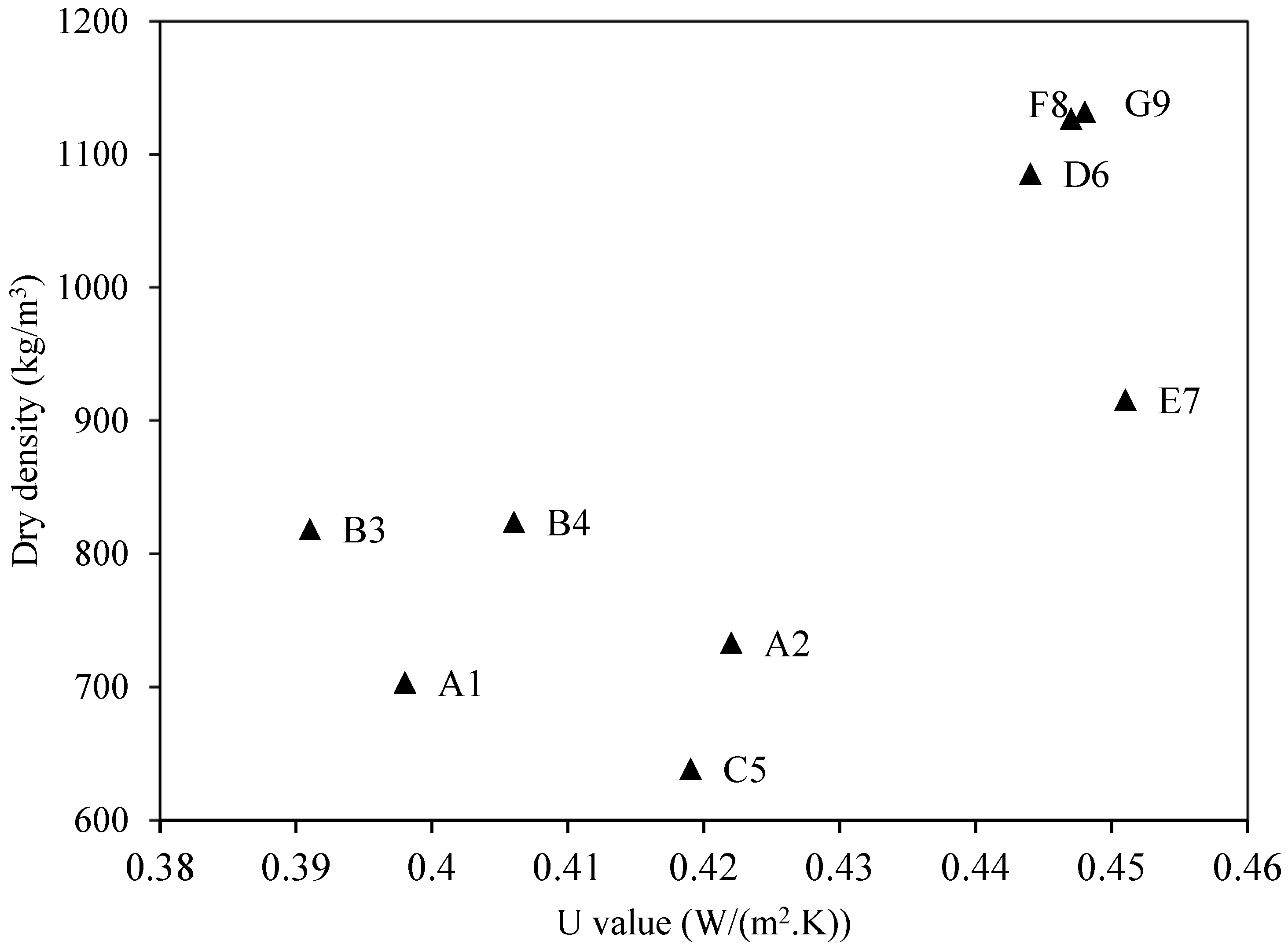

3.4. Thermal Performance

3.5. Cost-Effectiveness Analysis

3.6. Absorption Results

3.7. Durability of Outer Shell (Concrete) and Internal Insulating Layer (Polystyrene)

4. Conclusions

- The properties of aggregate and shell composition significantly influence the performance of sandwich-insulated concrete blocks. As the volcanic aggregates used to enhance the thermal insulation, they compromised the mechanical performance and durability by increasing the absorption and chloride content.

- Sandwich-insulated concrete blocks made with normal aggregates slightly reduce the thermal efficiency, while they exhibit superior mechanical strength, decreased absorption, and compliance with durability standards.

- The selection of internal core insulating material is critical. The XPS has better performance than EPS in terms of thermal performance, but showed the lowest antibacterial resistance. In contrast, EPS exhibited higher antibacterial activity but was more vulnerable to UV-induced degradation. Therefore, the outer concrete shell is essential for protecting the insulation layer from environmental exposure and ensuring its long-term functionality.

- To achieve the optimal performance and required standards of sandwich-insulated concrete blocks, the shell composition needs to be carefully designed and produced to make the sandwich-insulated concrete block a sustainable solution.

Limitations and Future Work

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Van De Walle, W.; Claes, S.; Janssen, H. Implementation and validation of a 3D image-based prediction model for the thermal conductivity of cellular and granular porous building blocks. Constr. Build. Mater. 2018, 182, 427–440. [Google Scholar] [CrossRef]

- Al-Tamimi, A.S.; Al-Amoudi, O.S.B.; Al-Osta, M.A.; Ali, M.R.; Ahmad, A. Effect of insulation materials and cavity layout on heat transfer of concrete masonry hollow blocks. Constr. Build. Mater. 2020, 254, 119300. [Google Scholar] [CrossRef]

- Pierzchlewicz, J. Modern concrete wall-units with improved thermal resistance for housing in hot climate. Sultan Qaboos Univ. J. Sci. 1996, 1, 69–80. [Google Scholar] [CrossRef]

- IECC. International Energy Conservation Code 2012; C403, 2; International Code Council: Washington, DC, USA, 2012. [Google Scholar]

- Solomon, A.; Latha, H. Inspection of properties of expanded polystyrene (EPS), compressive bhaviour, bond analytical examination of insulated concrete form (ICF) blocks using different densities of EPS. Int. J. Civ. Eng. Technol. 2017, 8, 209–221. [Google Scholar]

- Sariisik, A.; Sariisik, G. New production process for insulation blocks composed of EPS and lightweight concrete containing pumice aggregate. Mater. Struct. 2012, 45, 1345–1357. [Google Scholar] [CrossRef]

- Gencel, O.; del Coz Díaz, J.J.; Sutcu, M.; Kocyigit, F.; Álvarez Rabanal, F.P.; Alonso-Martínez, M.; Barrera, G.M. Thermal performance optimization of lightweight concrete/EPS layered composite building blocks. Int. J. Thermophys. 2021, 42, 52. [Google Scholar] [CrossRef]

- Tyagi, V.V.; Pandey, A.K.; Buddhi, D.; Kothari, R. Thermal performance assessment of encapsulated PCM based thermal management system to reduce peak energy demand in buildings. Energy Build. 2016, 117, 44–52. [Google Scholar] [CrossRef]

- Emadi, M.I. The role of thermal insulation in external walls for energy consumption in the case of Famagusta, North Cyprus. Adv. Environ. Technol. Biotechnol. 2014, 4, 81–90. [Google Scholar]

- Al-Naghi, A.A.A.; Rahman, M.K.; Al-Amoudi, O.S.B.; Gondal, M.A. Energy Conservation and Thermal Insulation Performance of Concrete Block Walls Incorporating Expanded Polystyrene Panels: Experimental and Simulation study. J. Arch. Eng. 2022, 28, 04022023. [Google Scholar] [CrossRef]

- Ismaiel, M.; Chen, Y.; Cruz-Noguez, C.; Hagel, M. Thermal resistance of masonry walls: A literature review on influence factors, evaluation, and improvement. J. Build. Phys. 2021, 45, 528–567. [Google Scholar] [CrossRef]

- Almujahid, A.; Kaneesamkandi, Z. Connstruction of a test room for evaluating thermal performance of building wall systems under real conditions. Int. J. Innov. Res. Sci. Eng. Technol. 2013, 2, 1333–1339. [Google Scholar]

- Al-Awsh, W.A.; Al-Amoudi, O.S.B.; Al-Osta, M.A.; Ahmad, A.; Saleh, T.A. Experimental assessment of the thermal and mechanical performance of insulated concrete blocks. J. Clean. Prod. 2021, 283, 124624. [Google Scholar] [CrossRef]

- Ramli Sulong, N.H.; Mustapa, S.A.S.; Abdul Rashid, M.K. Application of expanded polystyene (EPS) in buildings and constructions: A review. J. Appl. Polym. Sci. 2019, 136, 47529. [Google Scholar] [CrossRef]

- Dafalla, M.; Al Shuraim, M.; Shaker, A. Influence of density and thickness on polystyrene insulated concrete block walls. Int. J. Geomate 2019, 17, 62–67. [Google Scholar] [CrossRef]

- Shi, W.; Miao, L.; Luo, J.; Wang, J.; Chen, Y. Durability of Modified Expanded Polystyrene Concrete after Dynamic Cyclic Loading. Shock. Vib. 2016, 2016, 2391476. [Google Scholar] [CrossRef]

- Pavlík, Z.; Jerman, M.; Trník, A.; Kočí, V.; Černý, R. Effective thermal conductivity of hollow bricks with cavities filled by air and expanded polystyrene. J. Build. Phys. 2013, 37, 436–448. [Google Scholar] [CrossRef]

- Al-Jabri, K.; Hago, A.; Al-Nuaimi, A.; Al-Saidy, A. Concrete blocks for thermal insulation in hot climate. Cem. Concr. Res. 2005, 35, 1472–1479. [Google Scholar] [CrossRef]

- Makrygiannis, I.; Karalis, K. Optimizing building thermal insulation: The impact of brick geometry and thermal coefficient on energy efficiency and comfort. Ceramics 2023, 6, 1449–1466. [Google Scholar] [CrossRef]

- Moutassem, F.; Alamara, K. Design and production of sustainable lightweight concrete precast sandwich panels for non-load bearing partion walls. Cogent Eng. 2021, 8, 1993565. [Google Scholar] [CrossRef]

- Dinesh, W.G.; Pooj, M.K.; Shivali, R.K. Review paper on thermocol sandwich concrete bricks. Int. J. Grid Distrib. Comput. 2020, 13, 272–276. [Google Scholar]

- Taleb, H.M.; AlShuhail, K. Thermal performance of insulated concrete block in Sharjah, United Arab Emirates (UAE): Continuous monitoring and UR assessment. J. Asian Arch. Build. Eng. 2020, 20, 61–77. [Google Scholar] [CrossRef]

- Demirel, B. Optimization of the composite brick composed of expanded polystyrene and pumice blocks. Constr. Build. Mater. 2013, 40, 306–313. [Google Scholar] [CrossRef]

- Cai, S.; Zhang, B.; Cremaschi, L. Moisture behavior of polystyrene insulation in below-grade application. Energy Build. 2018, 159, 24–38. [Google Scholar] [CrossRef]

- Ali, Y.A.; Fahmy, E.H.; AbouZeid, M.N.; Shaheen, Y.B.; Mooty, M.N.A. Use of expanded polystyrene wastes in developing hollow block masonry units. Constr. Build. Mater. 2020, 241, 118149. [Google Scholar] [CrossRef]

- Murillo, A.M.; Abisambra, G.V.; Acosta, P.A.; Quesada, Q.C.; Tutikian, B.F.; Ehrenbring, H.Z. Comparison of the fire resistance behaviour of structural insulated panels with expanded polystyrene core treated with intumescent coating. J. Mater. Res. Technol. 2021, 12, 1958–1969. [Google Scholar] [CrossRef]

- Tang, W.; Huang, D.; Qiang, X.; Liu, W. Preparation of Hydrophilic and Fire-Resistant Phytic Acid/Chitosan/Polydopamine-Coated Expanded Polystyrene Particles by Using Coating Method. Coatings 2024, 14, 574. [Google Scholar] [CrossRef]

- Wang, Z.; Huang, Z.; Yang, T. Silica coated expandedn polystyrene/cement composites with improved fire resistance, smoke suppression and mechanical strength. Mater. Chem. Phys. 2020, 240, 122190. [Google Scholar] [CrossRef]

- Pereira, D.; Gago, A.; Proença, J.; Morgado, T. Fire performance of sandwich wall assemblies. Compos. Part B Eng. 2016, 93, 123–131. [Google Scholar] [CrossRef]

- Zhao, W.; Zhao, H.-B.; Cheng, J.-B.; Li, W.; Zhang, J.; Wang, Y.-Z. A green, durable and effective flame-retardant coating for expandable polystyrene foams. Chem. Eng. J. 2022, 440, 135807. [Google Scholar] [CrossRef]

- ASTM C62; Standard Specification for Building Bricks (Solid Masonry Units). ASTM International: West Conshohocken, PA, USA, 2005.

- BS EN-772-13:2000; Methods of Test for Masonry Units. Part 13: Determination of Net and Gross Dry Density of Masonry Units (Except for Natural Stone). British Standard Institution: Singapore, 2000.

- ASTM C140; Standard Test Methods for Sampling and Testing Concrete Masonry Units and Related Units. ASTM International (2013): West Conshohocken, PA, USA, 2018.

- ASTM C518-21; Standard Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus. ASTM International: West Conshohocken, PA, USA, 2021.

- BS 1881-124; Testing Concrete Part 122 Method for Determination of Water Absorption. British Standard Institution: Singapore, 2011.

- ASTM G154; Standard Practice for Operating Fluorescent Ultraviolet (UV) Lamp Apparatus for Exposure of Nonmetallic Materials. ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM E2149-20; Standard Test Method for Determining the Antimicrobial Activity of Immobilized Antimicrobial Agents Under Dynamic Contact Conditions. ASTM: Conshohocken, PA, USA, 2010.

- SASO 2875; Non-Load Bearing Lightweight Thermal Insulation Concrete Masonry Units of Foamed Concrete, Light Weight Aggregates or Made of a Mixture of Polystyrene Granules with Foam Concrete (Lightweight Aerated Concrete) or Sandwich Insulation Layer. Saudi Standards: Riyadh, Saudi Arabia, 2024.

- ASTM C126-14; Standard Specification for Ceramic Glazed Structural Clay Facing Tile, Facing Brick, and Solid Masonry Units. ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM C129; Standard Specification for Nonloadbearing Concrete Masonry Units. ASTM International: West Conshohocken, PA, USA, 2017.

- SBC 602; Saudi Building Energy Conservation Code-Residential. Saudi Building Code National Committee: Riyadh, Saudi Arabia, 2018; p. 64.

- Al-Hadhrami, L.M. Comprehensive review of cooling and heating degree days characteristics over Kingdom of Saudi Arabia. Renew. Sustain. Energy Rev. 2013, 27, 305–314. [Google Scholar] [CrossRef]

- Yu, J.; Dong, Y.; Wang, T.-H.; Chang, W.-S.; Park, J. U-values for building envelopes of different materials: A review. Buildings 2024, 14, 2434. [Google Scholar] [CrossRef]

- BS EN 206-1; Concrete. Part 1, Specification, Performance, Production and Conformity. British Standards Institution: Singapore, 2000.

- BS 8110-1; Structural Use of Concrete—Part 1: Code of Practice for Design and Construction. British Standards Institution: Singapore, 1997.

- ASTM G21; Standard Practice for Determining Resistance of Synthetic Polymeric Materials to Fungi. ASTM International: West Conshohocken, PA, USA, 2002.

| Block Dimensions | Polystyrene Properties | |||||||

|---|---|---|---|---|---|---|---|---|

| Group | No | Length (cm) | Width (cm) | Depth (cm) | Shell Aggregate | Type | Thickness (cm) | Density (kg/m3) |

| A | 1 | 40 | 20 | 20 | Volcanic | XPS | 7.5 | 35 |

| 2 | 40 | 20 | 20 | Volcanic | EPS | 7.5 | 16 | |

| B | 3 | 40 | 20 | 20 | Volcanic | XPS | 7.5 | 35 |

| 4 | 40 | 20 | 20 | Volcanic | EPS | 7.5 | 20 | |

| C | 5 | 40 | 20 | 20 | Volcanic | EPS | 7.5 | 16 |

| E | 6 | 40 | 20 | 20 | Normal | EPS | 7.5 | 16 |

| F | 7 | 40 | 20 | 20 | Normal | EPS | 7.5 | 16 |

| G | 8 | 40 | 20 | 20 | Normal | EPS | 7.5 | 16 |

| H | 9 | 40 | 20 | 20 | Normal | EPS | 7.5 | 16 |

| Group | No | Shell Aggregate | Block Density (kg/m3) | Measured K-Value W/m·K | Polystyrene Properties | Calculated U Value W/(m2·K) | |||

|---|---|---|---|---|---|---|---|---|---|

| Type | Thickness (cm) | Density (kg/m3) | Measured K-Value W/m·K | ||||||

| A | 1 | Volcanic | 703.8 | 0.2335 | XPS | 7.5 | 35 | 0.0387 | 0.398 |

| 2 | Volcanic | 733.6 | 0.2718 | EPS | 7.5 | 16 | 0.0446 | 0.422 | |

| B | 3 | Volcanic | 818.9 | 0.2726 | XPS | 7.5 | 35 | 0.0387 | 0.391 |

| 4 | Volcanic | 824.3 | 0.2725 | EPS | 7.5 | 20 | 0.0424 | 0.406 | |

| C | 5 | Volcanic | 638.9 | 0.2548 | EPS | 7.5 | 16 | 0.0442 | 0.419 |

| E | 6 | Normal | 1086.0 | 0.4336 | EPS | 7.5 | 16 | 0.0438 | 0.444 |

| E | 7 | Normal | 916.2 | 0.4262 | EPS | 7.5 | 16 | 0.0453 | 0.451 |

| F | 8 | Normal | 1127.2 | 0.4515 | EPS | 7.5 | 16 | 0.0442 | 0.447 |

| G | 9 | Normal | 1132.4 | 0.468 | EPS | 7.5 | 16 | 0.0435 | 0.448 |

| Scenario | ΔU (W/m2·K) | Cost Variation (SAR) | Additional Cost Per m2 |

|---|---|---|---|

| Normal-EPS block vs. Volcanic-EPS block | 0.0325 | −1.65 | −20.62 |

| Normal-EPS block vs. Volcanic-XPS block | 0.0535 | −5.15 | −64.37 |

| Volcanic-EPS block vs. Volcanic-XPS Block | 0.021 | −3.5 | −43.75 |

| Exposure | Scenario /Case | ΔU (W/m2·K) | Cost Variation (SAR) | Additional Cost Per m2 (SAR/m2) | Energy Saved (kWh/m2·y) | Money Saved (SAR/m2·y) | Simple Payback (Years) |

|---|---|---|---|---|---|---|---|

| Low Degree-hours = 75,168 °C·h/y | Normal EPS block vs. Volcanic EPS | 0.0325 | −1.65 | −20.62 | 2.443 | 0.440 | 46.863 |

| Normal EPS block vs. Volcanic XPS block | 0.0535 | −5.15 | −64.37 | 4.021 | 0.724 | 88.91 | |

| Volcanic EPS vs. Volcanic XPS Blocks | 0.021 | −3.5 | −43.75 | 1.579 | 0.284 | 154.05 | |

| Moderate Degree-hours = 136,512 °C·h/y | Normal EPS block vs. Volcanic EPS | 0.0325 | −1.65 | −20.62 | 4.437 | 0.799 | 25.81 |

| Normal EPS block vs. Volcanic XPS block | 0.0535 | −5.15 | −64.37 | 7.303 | 1.315 | 48.95 | |

| Volcanic EPS vs. Volcanic XPS Blocks | 0.021 | −3.5 | −43.75 | 2.867 | 0.516 | 84.79 | |

| High Degree-hours = 181,176 °C·h/y | Normal EPS block vs. Volcanic EPS | 0.0325 | −1.65 | −20.62 | 5.888 | 1.06 | 19.45 |

| Normal EPS block vs. Volcanic XPS block | 0.0535 | −5.15 | −64.37 | 9.693 | 1.745 | 36.89 | |

| Volcanic EPS vs. Volcanic XPS Blocks | 0.021 | −3.5 | −43.75 | 3.805 | 0.685 | 63.87 |

| Shell Material | Chlorides | Sulfates | Evaluation | Remarks |

|---|---|---|---|---|

| Volcanic (group A) | 1.6 | - | Not accepted | According to BS EN 206-1, Chlorides < 1% of cement mass |

| Volcanic (group B) | 1.5 | - | Not accepted | |

| Normal (group E) | 0.09 | - | Accepted | |

| Normal (group G) | 0.07 | - | Accepted | |

| Volcanic (group A) | - | 2.1 | Accepted | According to BS 8110-1 Sulfates < 4% Of cement mass |

| Volcanic (group B) | - | 2.1 | Accepted | |

| Normal (group D) | - | 0.66 | Accepted | |

| Normal (group G) | - | 0.42 | Accepted |

| Material | Density (kg/m3) | Thermal Conductivity (W/m·K) | Color and Shape Changes | ||

|---|---|---|---|---|---|

| EPS white | Before | 16 | 0.0446 |  |  |

| After | 18.1 | 0.0512 |  | ||

| EPS blue | Before | 20.6 | 0.0418 |  |  |

| After | 21.2 | 0.0436 |  | ||

| XPS | Before | 34.1 | 0.0385 |  |  |

| After | 37.3 | 0.0394 |  | ||

| Sample Name | Contact Time | No. of Tested Plates | Escherichia Coli (cgu/mL) | Escherichia Coli ATCC 25922 | Antibacterial Activity |

|---|---|---|---|---|---|

| Control sample | After 1 h | 1 | 15 × 102 | 15 × 102 | |

| 2 | 13.9 × 102 | ||||

| 3 | 16.1 × 102 | ||||

| EPS-blue 20 | After 1 h | 1 | 12 × 102 | 12 × 102 | 20% |

| 2 | 12.2 × 102 | ||||

| 3 | 11.8 × 102 | ||||

| EPS—white 16 | After 1 h | 1 | 9 × 102 | 9 × 102 | 40% |

| 2 | 9.2 × 102 | ||||

| 3 | 8.8 × 102 | ||||

| XPS-35 | After 1 hr | 1 | 13 × 102 | 13 × 102 | 13% |

| 2 | 13.3 × 102 | ||||

| 3 | 12.7 × 102 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alanazi, H.; Alzlfawi, A.; Albuaymi, M. Evaluating the Performance and Efficiency of Sandwich-Insulated Concrete Block Products in the Saudi Market. Buildings 2025, 15, 4172. https://doi.org/10.3390/buildings15224172

Alanazi H, Alzlfawi A, Albuaymi M. Evaluating the Performance and Efficiency of Sandwich-Insulated Concrete Block Products in the Saudi Market. Buildings. 2025; 15(22):4172. https://doi.org/10.3390/buildings15224172

Chicago/Turabian StyleAlanazi, Hani, Abdullah Alzlfawi, and Mohammed Albuaymi. 2025. "Evaluating the Performance and Efficiency of Sandwich-Insulated Concrete Block Products in the Saudi Market" Buildings 15, no. 22: 4172. https://doi.org/10.3390/buildings15224172

APA StyleAlanazi, H., Alzlfawi, A., & Albuaymi, M. (2025). Evaluating the Performance and Efficiency of Sandwich-Insulated Concrete Block Products in the Saudi Market. Buildings, 15(22), 4172. https://doi.org/10.3390/buildings15224172