1. Introduction

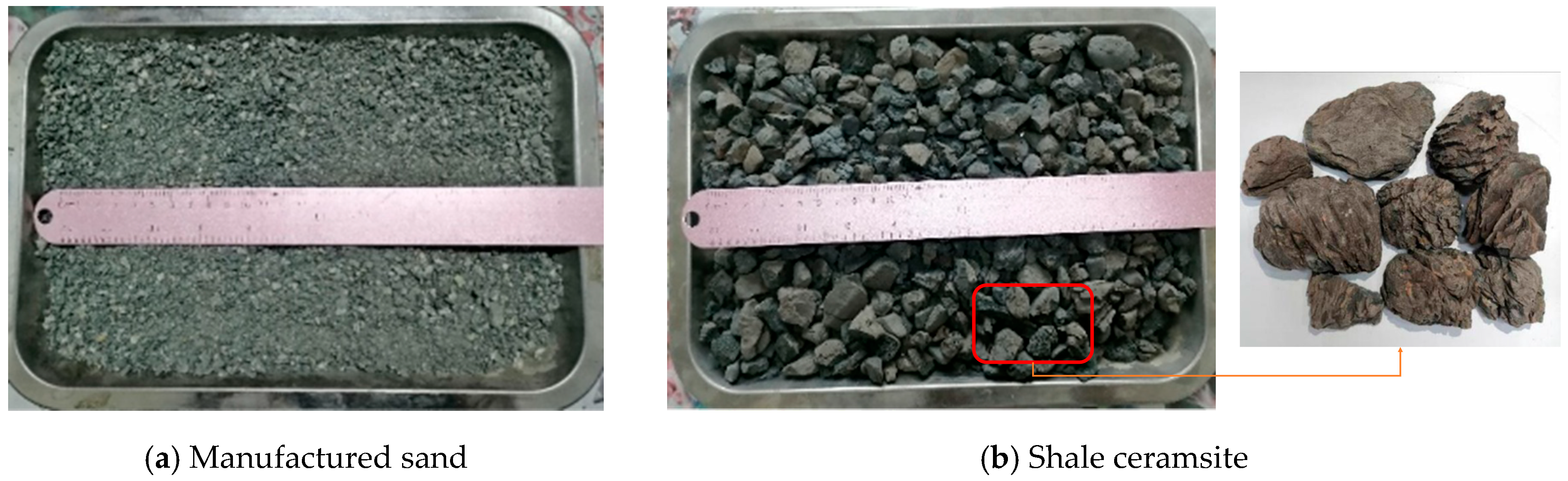

The expanding scarcity of natural river sand, accelerated by environmental regulations and finite resource availability, has promoted the widespread utilization of manufactured sand as an eco-friendly substitute in concrete manufacturing [

1,

2]. Self-compacting lightweight aggregate concrete (SCLC), valued for its vibration-free placement enhancing construction efficiency and structural quality, combined with reduced weight, offers significant advantages in demanding applications like high-rise buildings, large-span structures, and infrastructure projects [

3,

4]. However, many such projects are located in cold regions where concrete structures are critically vulnerable to damage from freeze–thaw cycles [

5,

6,

7]. During prolonged freeze–thaw cycles, cracks initiate within the concrete matrix and progressively expand, ultimately leading to significant structural deterioration. As a critical indicator of durability, this form of deterioration poses a principal threat to the service life of structures, particularly in regions with cold weather. Therefore, a significant international research priority is focused on improving the freeze–thaw durability of concrete, specifically mixtures containing Supplementary Materials such as MS. While MS offers a solution to river sand scarcity [

8,

9], its typical need for blending with river sand in SCLC and its potential impact on the crucial frost resistance in cold environments necessitate thorough investigation.

Current investigations into the factors influencing concrete’s frost resistance have become both extensive and varied. In their work, Guo et al. [

10] compiled a theoretical model for freeze–thaw damage designed to assess microstructural evolution. Their findings highlighted that the degradation of the concrete microstructure arises from a combined outcome of various factors during freeze–thaw cycles. Han [

11] studied the performance evolution mechanism of manufactured sand concrete with different morphological parameters from the microscopic point of view. The results indicate that micro-pores serve as the primary initiation sites for damage in manufactured sand concrete, where higher air content correlates with increased levels of both initial and cumulative damage. Chen et al. [

12] investigated the microstructural properties at the interfacial transition zone of manufactured sand mortar. Their analysis provides critical insights for enhancing both the mechanical strength and long-term durability of this material. Results demonstrate that the rough surface morphology of manufactured sand effectively minimizes interfacial cracking at the paste-aggregate boundary, thereby improving compactness and enhancing overall durability. Zhou et al. [

13] examined the influence of various parent rock lithologies on the freeze–thaw durability of concrete, concluding that granite represents the most suitable option for regions experiencing severe freeze–thaw conditions owing to its superior frost resistance. In a separate investigation, Tao et al. [

14] explored the synergistic effects of thermal variation and freeze–thaw cycles on concrete performance, establishing that the evolution of the dynamic modulus can serve as a quantitative indicator for strength degradation. In a related investigation, Cao et al. [

15] developed a freeze–thaw damage model for shale ceramsite lightweight aggregate concrete by establishing a functional correlation between the relative dynamic elastic modulus and freeze–thaw cycle count. Experimental data indicate that the freeze–thaw durability of shale ceramsite lightweight aggregate concrete exhibits a positive correlation with concrete strength grade. Luo et al. [

16] investigated the deterioration mechanisms and damage progression in dune sand concrete subjected to freeze–thaw cycles, formulating a corresponding damage model based on a microstructural degradation indicator. The results showed that the 30% sand dune replacement rate produced the best frost resistance. Zhao et al. [

17] examined the dynamic response and damage evolution of concrete under freeze–thaw conditions, revealing an initial mass increase followed by progressive loss, indicating a transition in damage mechanisms from internal microcracking to macroscopic surface spalling. Wang Zhixuan et al. [

18] established a predictive model of concrete deterioration under freeze–thaw cycles. The results indicate that the macroscopic model accurately characterizes global stiffness reduction and strength deterioration, whereas the mesoscopic simulation elucidates the underlying damage mechanisms, such as crack initiation and propagation. Ma et al. [

19] linked salt freeze damage, pore structure, and mechanical properties to establish a unilateral salt freeze damage model of manufactured sand concrete based on pore structure parameters. Wu Hairong et al. [

20] systematically reviewed the failure mechanism, constitutive model and numerical simulation methods for concrete subjected to the combined action of sulfate attack and freeze–thaw cycles. In contrast to the extensive research on frost resistance across various concrete types, limited investigation has been dedicated to studying the freeze–thaw durability of SCLC.

While numerous scholars have also investigated the properties of SCC with manufactured sand replacing natural river sand, their findings show significant variations. The research by Bhavanishankar et al. [

21] established that the addition of manufactured sand contributes to the enhancement of properties in SCC. Similarly, Suriya et al. [

22] observed fewer microcracks and voids in SCC containing manufactured sand, as evidenced by microscopic analysis. Research by Magudeaswaran et al. [

23] confirmed that the rheological performance and mechanical strength of SCC exhibit enhancement corresponding to higher proportions of manufactured sand. Contrary to these findings, the laboratory experiments conducted by Li et al. [

24] yielded divergent results. Their data revealed that the introduction of manufactured sand into SCC improves its mechanical performance and freeze–thaw durability, yet it reduces its workability. This conclusion aligns with Shen et al. [

25], who similarly reported that incorporating manufactured sand contributes to improved strength and frost resistance in concrete mixtures. This effect is mainly attributed to the stone powder within manufactured sand, which promotes the infiltration of cement paste into the aggregates and subsequently leads to the formation of a more compact concrete matrix. Therefore, both the workability and mechanical performance of concrete exhibit a strong dependence on the stone powder content within manufactured sand, with both properties reaching their peak when the stone powder content is 7.5%. These results collectively confirm the technical viability of substituting natural sand with manufactured sand in SCC applications.

Because lightweight aggregate can significantly reduce the weight of concrete members, it is also used in self-compacting concrete [

26,

27,

28]. To harmonize the workability and mechanical properties of SCLC, researchers have put forward multiple methodological approaches. Mazloom et al. [

29] found that adding a certain amount of silica fume to SCLC enhances its homogeneity. Consistent with this finding, Ting et al. [

4] confirmed that the synergistic combination of lightweight aggregates with supplementary cementitious materials like fly ash and silica fume effectively enhances the compressive strength of SCLC. Regarding the frost resistance of SCLC, Wang Lei [

30] demonstrated that C30 SCLC exhibits inferior frost resistance compared to C40 and C50 SCLC. Stratoura et al. [

31] determined that lightweight aggregate concrete incorporating manufactured sand exhibits heightened vulnerability to freeze–thaw damage, a characteristic primarily attributed to the intrinsic porosity of lightweight aggregates. Additionally, Adhikary et al. [

32] concluded through their research that SCLC possesses superior freeze–thaw resistance compared to SCC, attributed to its high porosity. Current literature reveals that the freeze–thaw durability of SCLC has not been extensively explored, highlighting the need for further detailed investigations.

In current research practices, river sand continues to serve as the primary fine aggregate in the majority of experimental work concerning SCLC fabrication. However, some scholars have explored alternatives such as crushed stone fines [

33], sintered fly-ash aggregate [

34], and rubber particles [

35] to replace river sand in SCLC preparation, demonstrating the feasibility of these materials. In light of the recent trend in manufactured sand development, it is also feasible to prepare SCLC using manufactured sand. Zhu et al. [

36] demonstrated that SCLC fully incorporating manufactured sand exhibits superior mechanical properties compared to conventional SCLC. Zhang et al. [

37] designed a C40 SCLC incorporating manufactured sand, which exhibited excellent compressive strength and workability. The studies demonstrated that SCLC with manufactured sand possesses favorable working and mechanical properties [

38]. Experimental observations indicate an inverse relationship between manufactured sand content and the workability of SCLC, whereas its mechanical properties and carbonation resistance enhancement with higher incorporation levels [

39]. Additionally, the optimal manufactured sand content for achieving the best overall performance in SCLC beam members was found to be 60–80% [

40]. However, most studies on the performance of SCLC incorporating manufactured sand primarily focus on its basic properties, with limited research on its frost resistance. Furthermore, studies from the perspectives of microscopic analysis and freeze–thaw damage modeling are even scarcer. Given that freeze–thaw cycles significantly contribute to concrete deterioration, the establishment of a freeze–thaw damage evolution model to quantitatively assess concrete durability and service life has become a key focus of current research [

41].

Current investigations into the role of manufactured sand content in SCLC have primarily centered on fundamental performance. However, comprehensive studies that systematically examine its effect on frost resistance from combined macroscopic, microscopic, and modeling perspectives remain notably limited. Therefore, this study uses the method of volume replacement to obtain SCLC groups with different manufactured sand contents. Four types of freeze–thaw evaluation indexes for the concrete in each group were tested. The changes in the microstructure and pore characteristics of MS-SCLC under freeze–thaw cycles were studied via scanning electron microscopy (SEM) and nuclear magnetic resonance (NMR), and the microscale mechanism of freeze–thaw damage of MS-SCLC was elucidated. Using the Weibull distribution’s probability density function, a freeze–thaw damage model for SCLC incorporating manufactured sand was established. The model correlates the damage degree with sand content, thereby providing a valuable framework for future research and engineering applications in this field.

3. Results and Analysis

3.1. Analysis of the Influence of Manufactured Sand Content on the Basic Properties of SCLC

The workability tested in this study includes filling, gap passing, and segregation resistance while the mechanical properties include cube compressive strength, splitting tensile strength, and elastic modulus.

3.1.1. Workability

The filling property of self-compacting concrete, referring to its capacity to achieve uniform flow under self-weight without external vibration, was tested by slump expansion and the expansion time T

500 test. The gap-passing ability, indicative of self-compacting concrete’s capacity to traverse reinforced sections and narrow openings without segregation or obstruction, was evaluated using J-ring and U-box test methods. The segregation resistance, which reflects the ability of self-compacting concrete to maintain a homogeneous mixture of all its components, was tested via the V-funnel test [

42].

Figure 4 presents the workability test diagram of SCLC with varying manufactured sand contents, with the corresponding quantitative data summarized in

Table 7.

According to

Table 7, compared with the slump expansion,

T500, J-ring extension, PA value, the height differential between the two compartments of the U-shaped box, and

TV for MS-SCLC-0, those for MS-SCLC-100 decrease by 14.4%, increase by 100%, decrease by 17.3%, increase by 135.7%, increase 4.6-fold, and increase by 13 s, respectively. It can be concluded that the workability of SCLC in each group gradually degrades with increasing manufactured sand content. In general, when the manufactured sand content is greater than 60%, although the workability of SCLC meets the specifications, it is considerably lower compared to SCLC with less than 60% manufactured sand content.

The observed deterioration in workability with increased manufactured sand content is consistent with the findings of reference [

24]. There are three main reasons: (1) The surface of the manufactured sand is rough and the edges and corners are sharp, increasing the friction between the mortar and the aggregate, thereby reducing workability [

1,

8]. (2) Furthermore, the stone powder content increases with the manufactured sand content. Its high specific surface area increases slurry viscosity, exhibiting a “viscosity-enhancing effect” that impairs workability [

50]. (3) Stone powder has an adsorption effect on the water reducer. Higher manufactured sand content means more stone powder, which adsorbs a greater amount of the admixture [

9]. This reduces the number of effective water-reducer molecules available to disperse cement particles, thus decreasing slurry fluidity and concrete workability.

3.1.2. Mechanical Properties

Following a 28-day standard curing period at approximately 20 °C and no less than 95% relative humidity, the cube compressive strength, splitting tensile strength, and elastic modulus were determined in accordance with GB/T 50081-2019 [

51].

Figure 5 illustrates the mechanical testing procedure, while

Table 8 summarizes the corresponding results for SCLC mixtures with varying manufactured sand contents.

According to

Table 8, the mechanical performance of SCLC exhibits a consistent enhancement with elevated proportions of manufactured sand across all mix groups. Compared with the cube compressive strength of SCLC containing 0% manufactured sand, that of SCLC containing 30%, 60%, 80%, and 100% manufactured sand increases by 1.71%, 4.89%, 5.87%, and 7.09%, respectively. Further, the splitting tensile strength increases by 1.59%, 3.17%, 4.13%, and 6.67%, respectively, and the elastic modulus increases by 3.32%, 8.53%, 10.90%, and 13.27%, respectively. In general, when the manufactured sand content is greater than 60%, the improvement in mechanical properties is apparent. The dry apparent density of SCLC in each group meets the requirements for the density grade of lightweight aggregate concrete [

43], indicating that SCLC exhibits low weight and high strength. Because the apparent density of manufactured sand is larger than that of river sand, the dry apparent density of concrete increases, reaching a maximum of 4.0% higher with increasing manufactured sand content. Owing to the inferior compressive strength of lightweight aggregate compared to conventional aggregate, the tension–compression ratio of SCLC is reduced across all test groups. This trend suggests that SCLC exhibits a more pronounced brittle failure behavior relative to ordinary concrete [

52]. The elastic modulus of SCLC in each group is lower than the corresponding requirements [

43]. The low elastic modulus of SCLC is primarily due to its high-volume cementitious material content and correspondingly low coarse aggregate proportion. This mix design results in a compromised granular skeleton, which directly leads to a reduction in the elastic modulus [

52].

The preceding analysis identifies three principal mechanisms through which the manufactured sand content influences the mechanical characteristics of SCLC: (1) The incorporation of stone powder in manufactured sand improves concrete performance through multiple mechanisms: it refines the pore structure, optimizes the bulk density of fine aggregates, and leads to a denser interfacial transition zone between the cement paste and aggregate [

53]. This effect becomes more pronounced with increasing manufactured sand content. (2) The manufactured sand used in this study is relatively rough, with sharp edges and corners, and many flakes. It can produce a large mechanical bite force with the cement gel to improve the bonding performance between the aggregate and the slurry [

50]; (3) During the concrete mixing process, stone powder adsorbs a portion of the free water, thereby effectively lowering the water-cementitious materials ratio. Consequently, the mechanical properties are improved [

9].

3.2. Analysis of Macroscopic Properties of SCLC Under Freeze–Thaw Environment by Manufactured Sand Content

This investigation employed apparent morphology, mass loss rate, relative dynamic elastic modulus and compressive strength loss rate as key indicators to assess frost resistance. Subsequently, the rapid freezing method was utilized to analyze the evolution of freeze–thaw damage in SCLC in correlation with its manufactured sand content.

In this rapid freezing method, the temperature of the freeze–thaw chamber is set between −18 °C and 7 °C, and the freezing process accounts for about half of the whole cycle time, that is, about 1–2 h. Based on the established standard, the frost resistance test can be concluded prior to completing the scheduled freeze–thaw cycles if the specimen’s mass loss rate reaches 5% or its relative dynamic elastic modulus drops to 60%, as either condition confirms a loss of frost durability.

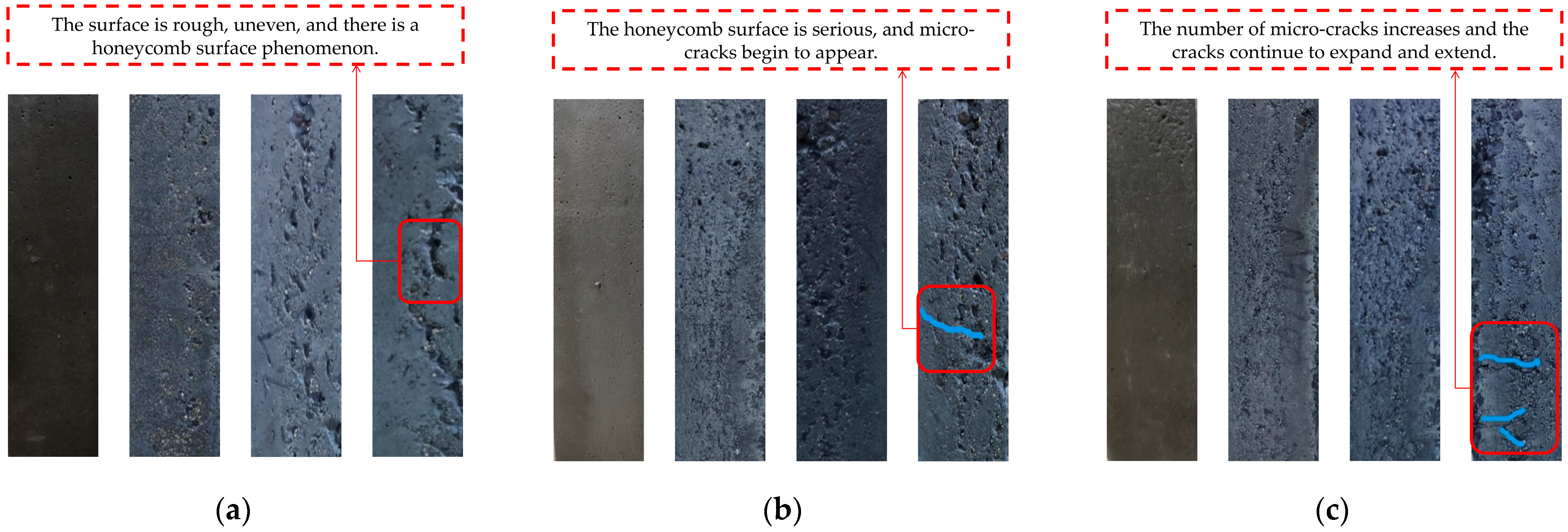

3.2.1. Apparent Morphology

Figure 6 presents changes in the apparent morphology of SCLC with 0%, 60%, and 100% manufactured sand after 0, 50, 125, and 175 or 200 freeze–thaw cycles. Apparent morphology describes the visual surface degradation of concrete following freeze–thaw cycles, including crack formation and propagation, edge spalling, breakage, the enlargement of surface cavities, and aggregate expo-sure, all of which offer a direct depiction of the material’s deterioration and are typically recorded photographically.

As the proportion of manufactured sand rises, the exterior material of SCLC shows degradation of surface integrity, as evidenced by crack expansion, surface spalling, and expansion of pores or cavities. Furthermore, the damaged area increases, the pockmarked surface becomes more severe, and freeze–thaw cracks are more likely to occur. This is because microcracks are produced by mechanical rolling during the production of manufactured sand, which increases water absorption; the higher the manufactured sand content, the more water the concrete absorbs and the greater the frost-heaving force generated when water freezes, causing the surrounding concrete to break. Moreover, the flaky shape of many manufactured sand particles leads to more severe pitting after freeze–thaw cycles.

Under prolonged freeze–thaw cycling, all SCLC mixtures exhibited a progressive deterioration in surface appearance: the outer surface of the test block transitions from being initially undamaged to gradually developing small pits. The pores then connect into a network, and the coarse aggregate becomes partially exposed. Finally, the surface is severely spalled, fine aggregate layers fall off, the coarse aggregate is exposed or falls off, and the internal damage becomes extreme. This is caused by the gradual loss of cementitious materials on the concrete surface.

3.2.2. Mass Loss Rate

Figure 7a demonstrates the combined impact of manufactured sand content and freeze–thaw cycles on the mass loss rate across all SCLC mixtures.

As depicted in

Figure 7a, a clear positive correlation exists between the mass loss rate of SCLC and its manufactured sand content. The mass loss rate of MS-SCLC-80 surpasses the 5% threshold following 200 freeze–thaw cycles, whereas MS-SCLC-100 exceeds this critical value after only 175 cycles. This result demonstrates that the frost resistance of MS-SCLC-100 becomes compromised after 175 cycles, leading to the termination of further freeze–thaw testing for this mixture. This phenomenon can be attributed to two primary factors: first, as indicated by the material parameters, the rough surface of manufactured sand and micro-cracks generated during its production [

11,

54] lead to the retention of frozen water on the surface of the test block. Second, the tiny open capillary pores within sand particles fail to enter the slurry, creating a “closed container effect” as water becomes trapped in these pores. When water saturation reaches a critical threshold, the surrounding concrete fractures during the freezing process [

55]. Notably, MS-SCLC-100 withstood 175 freeze–thaw cycles before its mass loss rate surpassed the 5% threshold, demonstrating the technical viability of employing manufactured sand in SCLC production for cold region applications.

With progressive freeze–thaw cycling, all SCLC mixtures demonstrated a gradual increase in mass loss rate. This trend is principally attributed to the physical detachment of cement paste and lightweight aggregate particles from the concrete surface. During the initial phase (25 freeze–thaw cycles), the extent of surface material exfoliation remained comparatively limited. Freeze–thaw action causes harmful closed pores on the test block surface to connect with the external environment, enhancing water absorption by the test block. This temporary water uptake leads to a slight increase in the specimen’s mass, resulting in a negative mass loss rate initially.

3.2.3. Relative Dynamic Elastic Modulus

Figure 7b illustrates the relative dynamic elastic modulus of the various SCLC mixtures is influenced by both manufactured sand content and the number of freeze–thaw cycles.

As revealed in

Figure 7b, higher proportions of manufactured sand correspond to a progressively smaller reduction in the relative dynamic elastic modulus across all SCLC groups. Following 50 freeze–thaw cycles, the relative dynamic elastic modulus across groups with different manufactured sand contents show little variation. After 100 cycles, the corresponding reductions reached 15.3% for MS-SCLC-0, 15.9% for MS-SCLC-30, 13.2% for MS-SCLC-60, 9.8% for MS-SCLC-80, and 8.3% for MS-SCLC-100. Upon completion of 200 cycles, both MS-SCLC-0 and MS-SCLC-30 demonstrated relative dynamic elastic modulus values falling below the specified 60% threshold, indicating that the specimens had failed. MS-SCLC-100 maintains a relative dynamic elastic modulus above 60% after 175 freeze–thaw cycles, attributable to the rough surface, angular particle morphology, and enhanced interfacial bonding characteristics of manufactured sand [

12]. Furthermore, the stone powder in manufactured sand reacts with cementitious components, forming products that interlock with other hydration phases, thereby densifying the cement matrix. Its simultaneous filling effect also contributes to a more refined pore structure in SCLC, improves uniformity, refines the capillary pores, and improves the interface transition zone between the cement stones [

56].

A consistent decline in the relative dynamic elastic modulus was observed across all SCLC groups as the number of freeze–thaw cycles increased. This is caused by the destruction of the internal structure and the increase in porosity.

3.2.4. Compressive Strength Loss Rate

Figure 7c presents the combined effects of manufactured sand content and freeze–thaw cycles on the compressive strength loss rate for all SCLC mixtures.

According to

Figure 7c, the loss rate for compressive strength decreases with increasing manufactured sand content: This trend, however, remains inconspicuous prior to 50 freeze–thaw cycles, which can be attributed to the concrete’s high intrinsic strength and minimal cumulative damage during the initial freezing and thawing stages. After 50 freeze–thaw cycles, this trend is apparent. This phenomenon can be attributed to the micro-filling effect of stone powder in manufactured sand, which diminishes the proportion of detrimental pores, refines the pore structure, and enhances overall compactness in SCLC. The rough surface and angular morphology of manufactured sand enhance the bonding performance at the aggregate-paste interface, thereby contributing to a denser microstructure in SCLC. Thus, the compressive strength loss rate after freezing and thawing is small.

The compressive strength loss rate of all SCLC groups exhibited a progressive increase with continuing freeze–thaw cycles. This deterioration stems from two primary mechanisms: the physical loss of cementitious material and spalling at the edges, which reduces the effective load-bearing cross-section; and the internal structural degradation characterized by pore enlargement, crack propagation, and a loosened matrix. Furthermore, the damage to the specimen’s edges diminishes the constraining “hoop effect”, collectively leading to the reduction in compressive strength.

3.3. Analysis of the Microscopic Properties of SCLC Under Freeze–Thaw Environment Based on Manufactured Sand Content

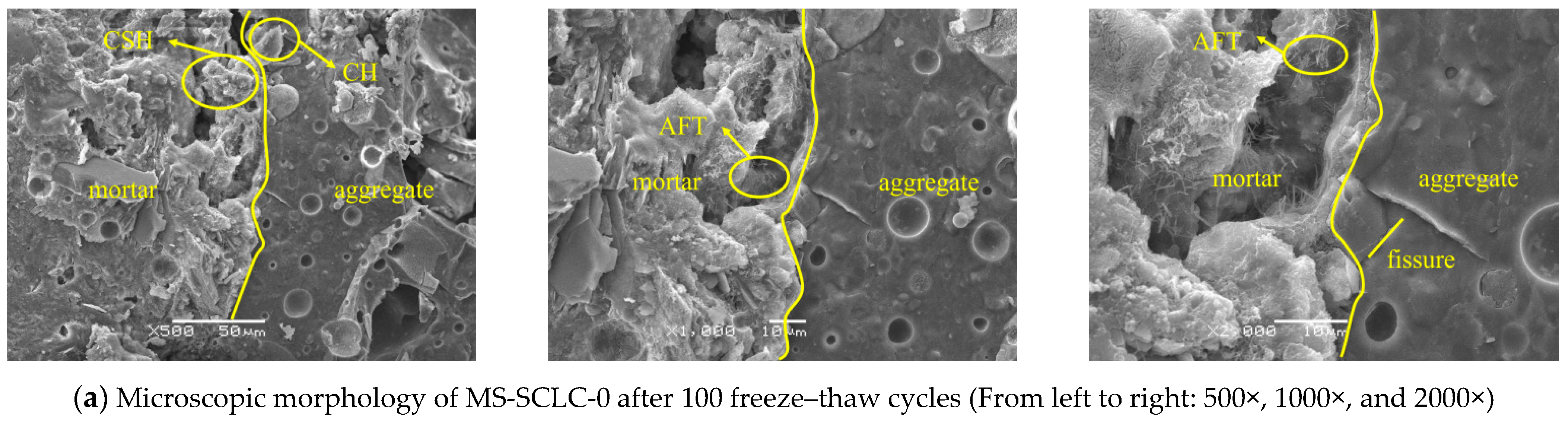

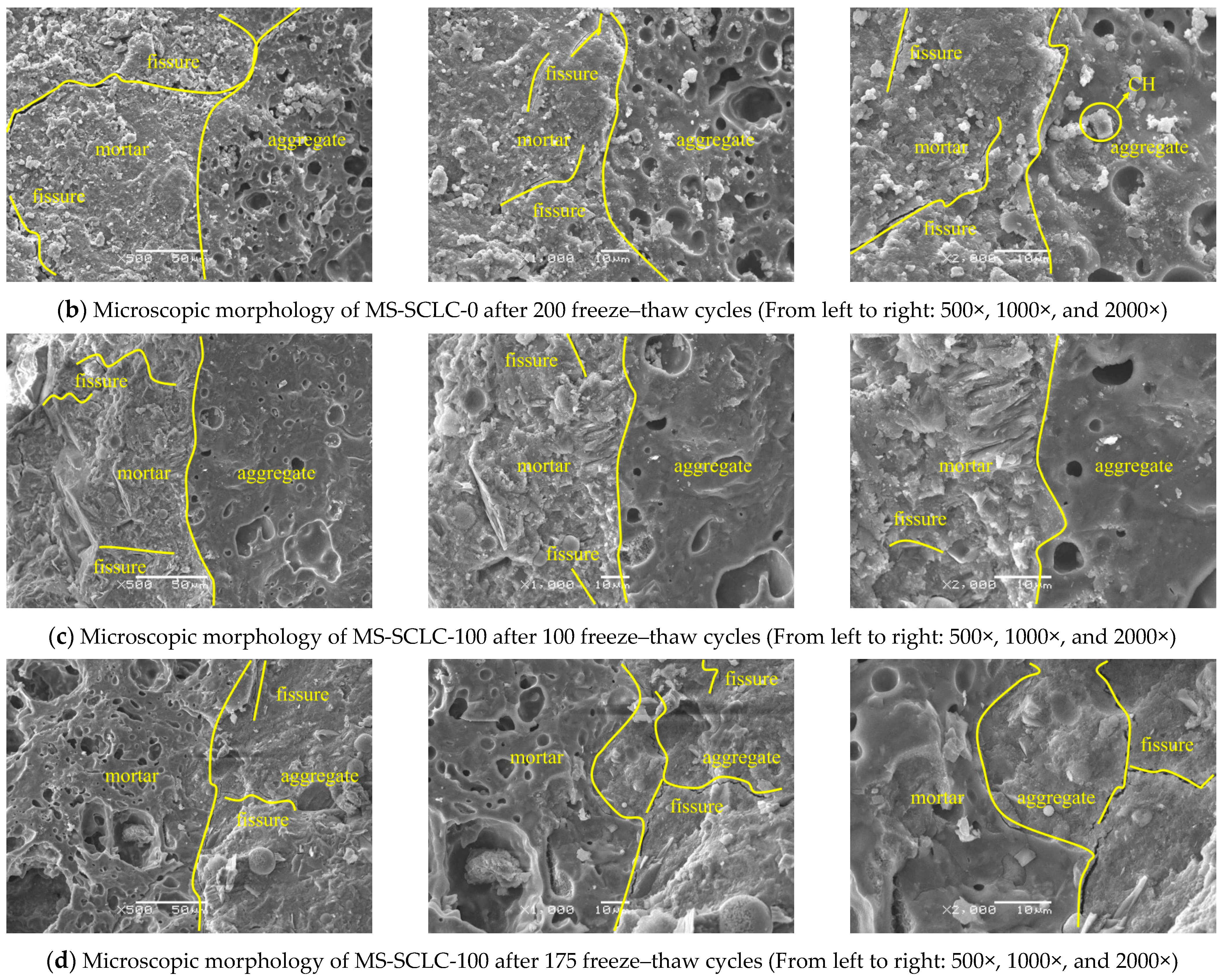

This research utilized SEM and NMR techniques to analyze microstructural evolution and pore structure alterations in SCLC subjected to freeze–thaw cycles, providing insights into the microscale damage mechanisms induced by freezing and thawing.

3.3.1. SEM Analysis of SCLC with Manufactured Sand Under Freeze–Thaw Environment

SEM utilizes electron lenses to focus an electron beam into a nanometer-scale spot. A deflection system then scans the beam across the sample surface in a raster pattern. During this scanning process, the electron beam excites secondary electrons and other physical signals from the sample. These signals are collected by a detector and converted into an image through signal processing. The final image is displayed by modulating the brightness of a synchronously scanned cathode ray tube. The microstructural analysis in this study was conducted using a JSM-7610F field emission scanning electron microscope (JEOL Ltd., Tokyo, Japan) with an operational magnification range from 25× to 1,000,000×.

Figure 8 shows the microstructures and mortar-aggregate transition interface zones of MS-SCLC-0 (after 100 and 200 freeze–thaw cycles) and MS-SCLC-100 (after 100 and 175 freeze–thaw cycles), imaged at different magnifications using SEM.

From a comparative analysis between

Figure 8a,b, as well as between

Figure 8c,d. Observations reveal that the quantity of fine cracks in both SCLC mixtures progressively rises with small and narrow cracks propagation leading to interconnection. This internal structural deterioration ultimately results in surface spalling of the concrete specimens. Throughout the freeze–thaw process, the cement within the concrete matrix continues to undergo hydration reactions. Compared with

Figure 8a, the amounts of hydrated calcium silicate gel and calcium hydroxide in

Figure 8b are considerably increased and the mortar–aggregate transition interface area is denser.

A comparative analysis of

Figure 8a,c reveals that MS-SCLC-100 possesses a significantly denser internal microstructure compared to MS-SCLC-0, which corresponds to its superior post-freeze–thaw compressive strength at the macroscopic level. In the context of hydration products, numerous needle-like ettringite crystals and reticular and fibrous hydrated calcium silicate gels as well as flake calcium hydroxide can be observed in

Figure 8a. Moreover, a large amount of hydrated calcium silicate gel and a small amount of calcium hydroxide can be observed in

Figure 8c. In general, the internal hydration of concrete is satisfactory. Compared with MS-SCLC-0, MS-SCLC-100 has more and wider cracks and most of these cracks extend along the transition interface area. Consequently, mixtures with higher manufactured sand content exhibit more pronounced surface spalling. Nevertheless, owing to the stone powder present in MS-SCLC-100, its micro-filling effect enhances pore structure refinement, which subsequently leads to improved retention of relative dynamic elastic modulus and reduced compressive strength loss with increasing manufactured sand proportions.

3.3.2. NMR Analysis of SCLC with Manufactured Sand Under Freeze–Thaw Environment

Before the NMR test, the specimen must be fully saturated with water. The pore structure characteristics of the concrete were then analyzed by assessing the flow of hydrogen atoms in water molecules within the pores.

- (1)

T2 spectrum test results and analysis.

The T

2 spectral distribution serves as an indicator of pore structure evolution in concrete, where pore sizes are proportional to the transverse relaxation time. The peak areas in the T

2 spectrum correspond to the number of pores, with the first, second, third, and fourth peaks representing progressively larger pore sizes.

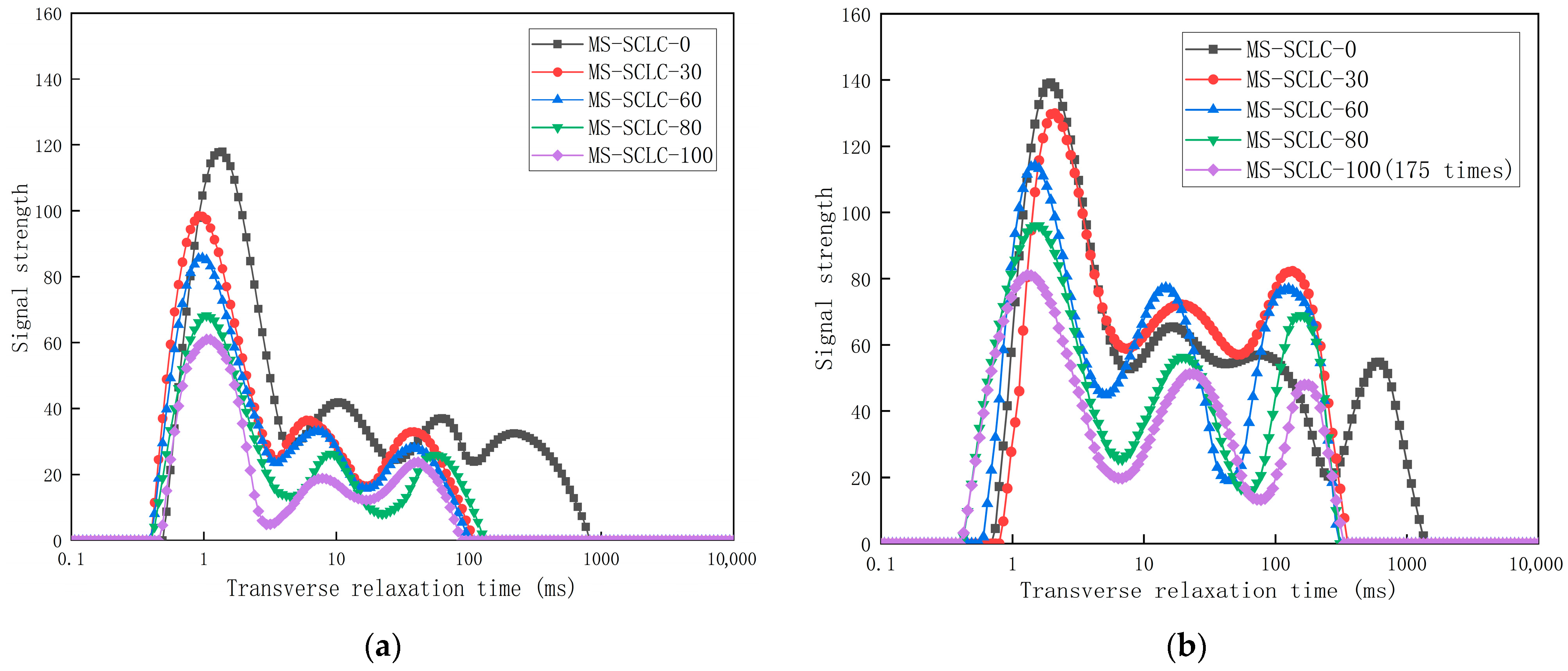

Figure 9 displays the T

2 spectrum distribution curves for SCLC mixtures with varying manufactured sand contents after being subjected to 100 and 200 freeze–thaw cycles.

As shown in

Figure 9, the T

2 spectrum distribution curve of the SCLC with 0% manufactured sand content has four peaks, and the other groups have three peaks. Furthermore, the larger the manufactured sand content, the smaller the peak area, which indicates that the internal pores of SCLC are reduced; the area of the first peak of each SCLC group still accounts for the majority of the peak area, implying that the content of small pores is high. Consequently, following 100 freeze–thaw cycles, SCLC mixtures incorporating manufactured sand exhibit a notably slower rate of reduction in their dynamic elastic modulus. After 200 freeze–thaw cycles, areas of the second and third characteristic peaks increase, indicating a rise in macropore content. Furthermore, as the manufactured sand content increases, the T

2 spectrum distribution curve shifts leftward, indicating a reduction in the number of internal pore structures within the SCLC, along with decreased signal intensity and pore content.

- (2)

Pore size distribution curve and classification.

The T

2 spectral distribution curve can be transformed to obtain the pore size distribution curve by Equation (1) [

57]. Following the pore classification system proposed by Academician Wu Zhongwei [

58], pores in concrete are classified into four categories based on their radii: harmless pores (below 0.02 μm), less harmful pores (ranging from 0.02 to 0.05 μm), harmful pores (between 0.05 and 0.2 μm), and multi-harmful pores (exceeding 0.2 μm).

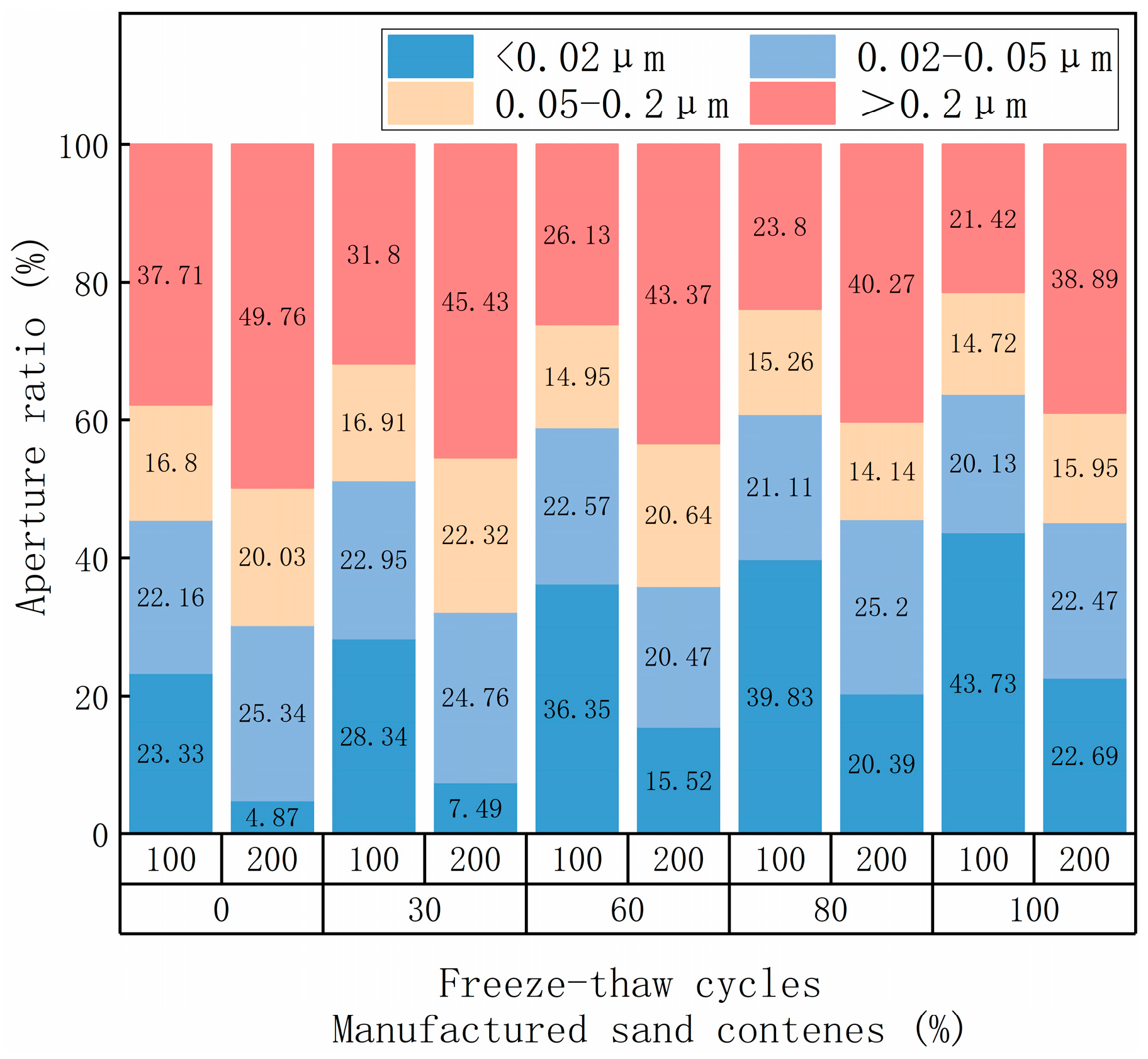

Figure 10 displays the pore size distribution patterns of different SCLC mixtures after undergoing 100 and 200 freeze–thaw cycles.

where

T2 is the T

2 spectrum area.

ρ2 is the T

2 surface relativity, typically ranging from 3 to 10 for concrete materials, and is taken as

ρ2 = 5 based on empirical data. The parameter

F represents a shape factor, with its numerical value being determined by pore geometry—specifically assigned as 1 for planar, 2 for cylindrical, and 3 for spherical pore structures. In this study, the pores in the concrete are assumed to be spherical; hence,

F = 3.

R is the pore radius.

According to

Figure 10, a higher proportion of manufactured sand correlates with an increased fraction of harmless pores and a corresponding decrease in multi-harmful pores. This is because the manufactured sand optimizes the pore structure evolution within the matrix under freeze–thaw action. This demonstrates that manufactured sand effectively refines the pore structure of SCLC during freeze–thaw exposure, inhibiting the development of larger pores and thereby mitigating the reduction in compressive strength.

A comparative analysis reveals that between 100 and 200 freeze–thaw cycles, all SCLC mixtures demonstrated a progressive transition in pore structure, characterized by a reduction in the proportion of harmless pores and a corresponding increase in the proportion of harmful pores. Compared with 100 freeze–thaw cycles, the proportion of harmless pores in the SCLC with 0%, 30%, 60%, 80%, and 100% of manufactured sand decreased by 18.46%, 20.85%, 20.83%, 19.44%, and 21.04% after 200 freeze–thaw cycles, respectively. Moreover, following 200 freeze–thaw cycles, the respective increases in harmful pore proportions measured 12.05%, 11.63%, 17.24%, 16.47%, and 17.47%. This progression indicates a continuous pore coarsening process where small pores inside the concrete are converted to medium pores and medium pores are converted to large pores. This is because water repeatedly enters and exits the pores of SCLC during freeze–thaw cycles. Under the action of osmotic pressure and hydrostatic pressure, the small pores inside SCLC become large pores and the dense structure inside SCLC is destroyed. Consequently, the compressive strength decreases macroscopically.

3.4. Freeze–Thaw Damage Prediction Model for Manufactured Sand SCLC Based on the Weibull Distribution

This investigation employed the relative dynamic elastic modulus as the key parameter for quantifying freeze–thaw damage in concrete. A deterioration model founded on the two-parameter Weibull distribution [

59] was subsequently developed to characterize the damage progression patterns of SCLC containing varying manufactured sand contents under cyclic freezing-thawing conditions.

The damage degree of concrete after

n freeze–thaw cycles, denoted as

D(

n), is defined as its failure probability

Pf (

n). This probability increases progressively with cycle count, reaching complete material failure when

Pf (

n) = 1. Quantified by the relative dynamic elastic modulus

Edx,

D(

n) serves as the damage indicator. The associated parameters

α and

β are determined by linearizing the two-parameter Weibull distribution-based evolution model, yielding Equation (2).

In the aforementioned equation, α represents the characteristic life parameter, β denotes the shape parameter of the Weibull distribution, and n corresponds to the number of freeze–thaw cycles.

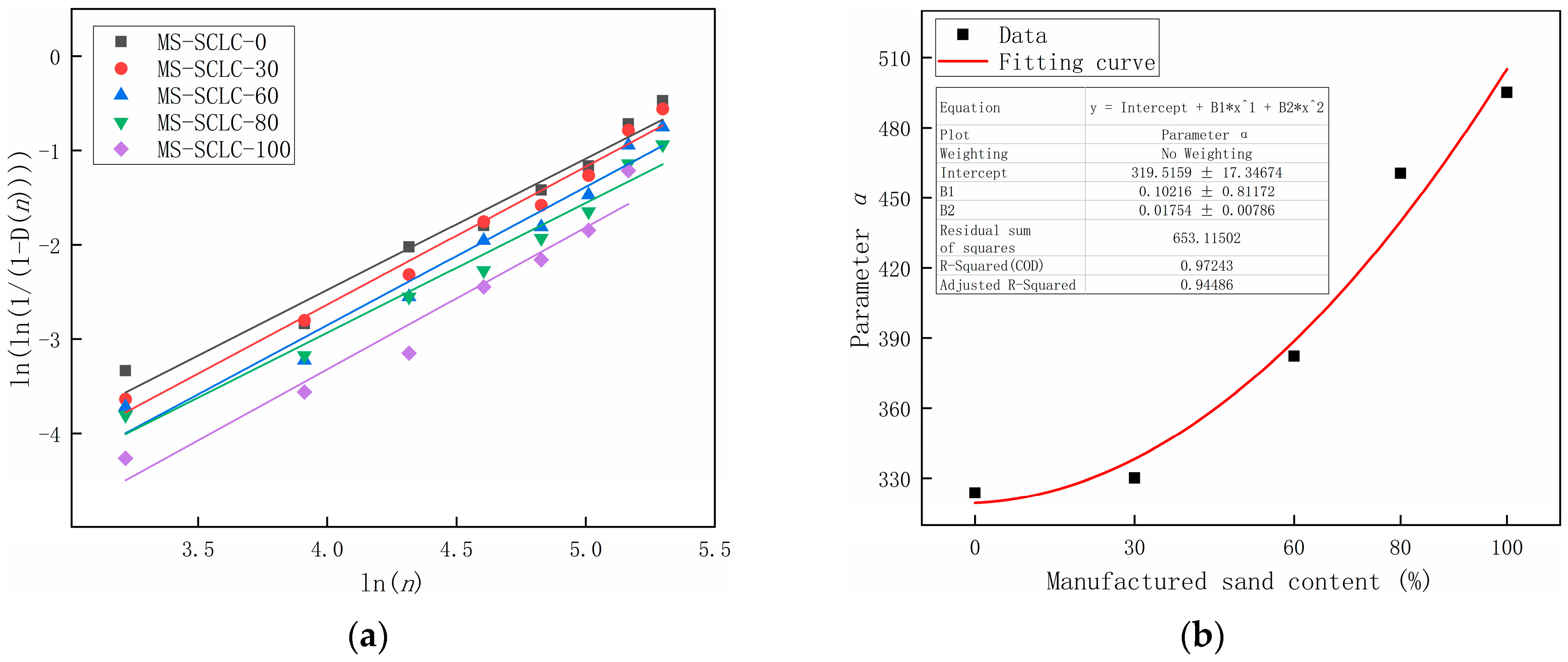

In this study, the loss rate of the dynamic elastic modulus was obtained, and the test results were fitted and regressed. The fitting function image is shown in

Figure 11a, where

,

,

,

.

Parameters

a and

b were determined through Origin software fitting, with the resulting values for

a,

b,

α, and

β comprehensively listed in

Table 9.

The parameter

α for each SCLC mix in

Table 6 exhibits a correlation with the manufactured sand content (

p). The correlation is represented by Equation (3), and the corresponding fitting curve is shown in

Figure 11b.

The parameter

β in

Table 6 is averaged to obtain

, and the calculated variance is 0.0023, which indicates that the parameter is stable.

In summary, Equation (3) is substituted into Equation (2), and the freeze–thaw damage evolution equation for SCLC with manufactured sand content is obtained as shown in Equation (4).

The loss rate of dynamic elastic modulus, derived from relative dynamic elastic modulus measurements, serves as a direct indicator of freeze–thaw damage. A damage evolution model for SCLC, incorporating manufactured sand content, was developed using the two-parameter Weibull distribution and demonstrates strong agreement with experimental results.

Equation (4) enables engineers to predict the relative dynamic elastic modulus (Edx) of SCLC after n freeze–thaw cycles by incorporating the target service environment’s anticipated cycle count (n) and the specific manufactured sand proportion (p), thereby allowing quantitative durability assessment across various service lifetimes.

Equation (3) and

Figure 11b clarify the quantitative relationship between the characteristic life parameter α and the manufactured sand content

p. In the design stage, the parameter

α can be optimized by adjusting the manufactured sand content (

p), so as to realize the quantitative design and pre-control of the target service life of concrete (i.e., frost resistance durability), thereby meeting the durability requirements of specific projects.

4. Discussion

The present investigation systematically examines the influence of manufactured sand content on the frost resistance characteristics of SCLC. An optimal manufactured sand content that enables MS-SCLC to exhibit satisfactory performance was determined. Moreover, the evolutions in the microstructure and pore characteristics of SCLC after freeze–thaw cycles were analyzed. A freeze–thaw damage model for MS-SCLC was subsequently developed utilizing the theoretical framework of the Weibull distribution.

With an increase in the manufactured sand content, the workability of SCLC deteriorates while its mechanical properties improve. Under the same number of freeze–thaw cycles, elevated manufactured sand content leads to increased mass loss in SCLC; however, it effectively mitigates the reduction in both relative dynamic elastic modulus and compressive strength loss rate. When the manufactured sand content is approximately 60%, the workability and mechanical properties of SCLC reach the best balance point, and the frost resistance is optimized. The results of microstructure analysis provide an explanation for this: Compared with MS-SCLC-0, MS-SCLC-100 has more and wider cracks. However, with increasing manufactured sand content, the internal pores of SCLC decrease in number and the maximum pore size becomes smaller. The higher the proportion of harmless pores, the lower the proportion of more harmful pores.

The freeze–thaw damage model for SCLC, formulated using the two-parameter Weibull distribution, demonstrates excellent consistency with the experimental data. However, although the parameters and suitability of the Weibull model (R2 values) are presented in this study, the lack of external data for model verification remains a key limitation. Therefore, an important direction for future research is to validate the model externally using a wider range of mix ratios or independent test data from different freeze–thaw conditions. In addition, the freeze–thaw damage model for SCLC with manufactured sand content established in this study is based on granite manufactured sand. Therefore, future work could involve studying and comparing manufactured sands derived from different parent rock types.