Abstract

The bonding interface between repair materials and concrete substrate is the weakest link in the entire repair structure. If the interface bonding performance is insufficient, the repair material is prone to cracking or falling off, leading to repair failure. The shrinkage of repair materials is one of the primary factors affecting the bonding performance of these interfaces. In this study, sulphoaluminate cement (SAC) was used to improve the repair performance of ordinary Portland cement (OPC)–granulated blast furnace slag (GGBS) composite repair materials. The influence of SAC on the mechanical properties, bonding performance, expansion behavior, impermeability, and hydration heat of OPC-GGBS-SAC composite repair materials was investigated. The results demonstrate that the rapid hydration of SAC significantly improved the early strength and mechanical properties of the composite system at negative temperatures. The hydration products filled the pores within the concrete matrix, thereby enhancing the mechanical meshing effect at the interface. The early expansion effect of SAC formed a pre-stressor at the interface, which not only strengthened the bonding force between repair materials and the substrate, but also effectively inhibited the shrinkage of the composite system and prevented crack formation, thus significantly promoting the long-term reliability of the bonding interface. An appropriate amount of SAC can accelerate the hydration process of OPC-GGBS system, advance the exothermic peak, and promote the development of early strength. However, excessive incorporation will inhibit the later hydration of the composite system due to the way in which the hydration products wrap the cement particles. When the content of SAC was 5–10%, optimal comprehensive properties of the OPC-GGBS-SAC composite system were attained.

1. Introduction

The bond interface between the repair material and the substrate to be repaired is a weak link in the repair system. Due to the prolonged natural aging of the substrate, the volume deformation stabilizes. However, repair materials often undergo long-term shrinkage during hydration, which can easily cause cracking at the bonding interface, thereby leading to a decrease in bonding strength or repair failure [1,2]. Therefore, the interfacial bonding performance between repair materials and the repair substrate is a key issue affecting the repair and reinforcement of concrete structures.

The composition and ratio of the repair material, the strength and surface cleanliness of the matrix concrete, the roughness of the matrix surface, the initial moisture content of the matrix, and the interface agent will affect the interfacial bonding performance of bonds between repair materials and the pre-existing concrete substrate [3,4,5]. Promoting the surface treatment quality of substrate, brushing interface agents, and moisturizing curing can improve the mechanical meshing force between a repair material and a concrete matrix to a certain extent [6,7,8,9]. The interfacial bonding performance can be essentially improved by enhancing the compatibility between repair materials and the established concrete [10,11]. Research has shown that chemical shrinkage, drying shrinkage, and temperature shrinkage of cement-based repair materials during the hardening process are the main causes of interface cracking [12,13,14]. Secondly, when the repair material is poured onto the substrate, moisture will migrate to the surface of the substrate, resulting in an increase in the water–binder ratio in the interface area. The crystals will be oriented and arranged at the interface, forming a coarse and loose crystalline structure [15]. At the same time, water accumulation can easily form defects such as micro-cracks and holes at the interface [16]. Consequently, in an attempt to enhance the interface performance of cement-based repair materials, the shrinkage performance and the content of the calcium hydroxide in the repair material should be reduced, the crystal size should be refined, the crystal orientation should be decreased, and the compactness of the interface area should be improved [17,18].

Mineral admixtures are modified materials that are commonly used in cement-based materials. The filling effect and pozzolanic reaction can refine the pore size of cementitious materials and form a denser microstructure [19,20,21,22]. Furthermore, adding ground granulated blast furnace slag (GGBS), silica fume, and fly ash can decrease the content of calcium hydroxide and the porosity of the interface region, thereby promoting the interfacial bonding strength [23,24,25]. The addition of GGBS can generate more C-(A)-S-H gel, which contributes to the continuous densification of the microstructure of the system and reduces the chloride ion diffusion coefficient by 20~60% [26,27]. Research indicates that expansive agents can be employed to reduce the drying shrinkage of cement-based materials and have potential applications in enhancing the bond strength of repair materials [28,29,30]. Calcium-oxide-based expansive agents and ettringite-based expansive agents react to produce a large number of expansive crystals, exhibiting high early expansion rates and significant total expansion amounts [31]. However, due to the lack of effective constraints in the early stages of repair materials, the higher expansion stresses in the early stages can cause the pore structure of the repair material to become loose, resulting in a decrease in the compressive strength of the repair mortar. The expansion ability of magnesium-oxide-based expansion agents is controllable, providing long-term stable shrinkage compensation effects [32]. However, it can retard the early hydration rate of cement, and delayed expansion may cause cracking in the hardened paste [33].

Sulphoaluminate cement (SAC) has the characteristics of fast setting speed, high early strength, and micro-expansion. Haijun Zhou [34] found that SAC-based repair materials exhibited excellent compatibility with the concrete matrix. The hydration products of SAC filled the cracks and pores in the bonding interface region, forming a dense overall structure, resulting in high interfacial bonding strength. Therefore, the introduction of an appropriate amount of SAC into OPC can promote the hydration process, shorten the setting time, decrease porosity, and improve the early strength of the system [35]. In the composite system, Ye’elimite can hydrate to form a large amount of ettringite (AFt) within 5 min. Before 7 d of hydration, the strength of the system mainly comes from AFt. After 7 d, C3S became the main hydration phase, thus ensuring the stable development of the later strength of the system [36]. The addition of SAC can shorten the final setting time of OPC from 320 min to 50 min, increase the 3 d compressive strength from 13.6 MPa to 27.7 MPa, and reduce the drying shrinkage rate from 600 με to 222 με, which improves the efficiency and effectiveness of repairs [37]. Compared with OPC, OPC-GGBS-SAC ternary repair material exhibits the advantages of denser microstructure, rapid hardening, early strength, and micro-expansion [38], which can be applied in emergency repair engineering. In summary, extensive research has thoroughly investigated the workability, mechanical properties, and hydration mechanisms of the OPC-GGBS-SAC composite system. However, the development of interfacial bond strength in the OPC-GGBS-SAC composite system as a repair material and the existing concrete substrate remains unclear. It is necessary to conduct further research to determine whether the micro-expansion characteristics of SAC can enhance the interfacial bonding capacity of the OPC-GGBS system.

In this study, SAC was used to improve the OPC-GGBS composite system to achieve two goals: (1) Through the early strength characteristics of SAC, the early strength of the composite system was improved in order to meet the goal of rapid repair of repair materials in different environments. (2) By utilizing the micro-expansion properties of SAC, the composite system produced micro-expansion during the hydration at early stage, and the bonding force of the repair interface is stronger under the constraint of the concrete substrate. Meanwhile, it can compensate for the drying shrinkage in the later stage, maintain the volume stability of the repair system, and avoid cracks at the bonding interface. Based on this, the effects of SAC on the mechanical properties, bonding properties, expansion properties, penetration resistance, and hydration heat-release characteristics of OPC-GGBS-SAC composite repair materials were systematically studied in this paper. The influence and mechanism of SAC on the shrinkage compensation and interface bonding ability of the composite system was explored.

2. Materials and Methods

2.1. Materials

Grade 52.5R ordinary Portland cement (OPC) was produced by Shaanxi Jidong Cement Shield Engineering Co., Ltd. (Xianyang, China). Grade 42.5 fast-hardening sulfoaluminate cement (SAC) was obtained from Tangshan Polar Bear Building Materials Co., Ltd. (Tangshan, China). Grade S95 ground granulated blast slag (GGBS) was produced by Shaanxi Delong Powder Engineering Material Co., Ltd. (Hancheng, China). The specific surface area and the 28 d activity index were 516 m2/kg and 102%, respectively. The chemical components of cementitious materials are listed in Table 1, and the physical properties are shown in Table 2. The polycarboxylate superplasticizer (PCE) produced by Sika (Suzhou, China) Co., Ltd. was selected. The product model is 540P, which is white powder, and the water reduction rate is 25%. Quartz sand (S) with size ranges of 20~40 mesh and 40~70 mesh was selected as fine aggregate, which was mixed at a ratio of 6:4 and used. Crushed gravel (G) with a 5~10 mm particle size was used as the coarse aggregate.

Table 1.

The chemical composition of cementitious materials (wt.%).

Table 2.

The physical properties of cement.

2.2. Preparation of Samples

2.2.1. Preparation of the Repair Substrate

The repair substrate used for testing bonding performance was prefabricated using mortar and C50 fine aggregate concrete. The cement used was 42.5 grade ordinary Portland cement, the mineral admixture was grade I fly ash (FA) and S95 grade slag powder, the sand was quartz sand (S), and fine stones with a particle size of 5–10 mm were selected, and the mixture ratio is shown in Table 3. The 28 d compressive strengths of mortar and concrete were 63.2 MPa and 58.8 MPa, respectively. The mortar substrate was used to form shear bonded and flexural bonded specimens, and the concrete substrate was used for the formation of tensile-bonded and truncated-cone-bonded specimens. All substrates were used after standard curing for 90 d.

Table 3.

Mix ratio of repair substrate (kg/m3).

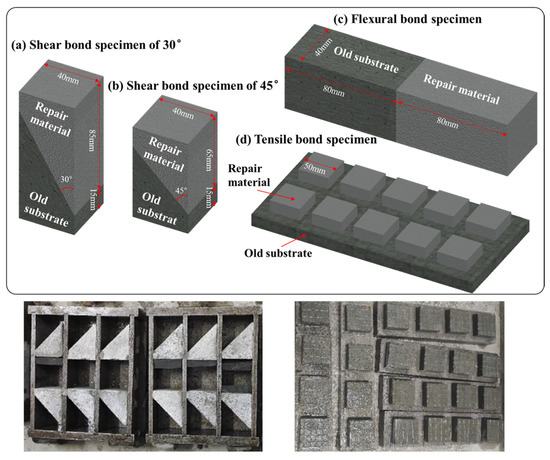

2.2.2. Preparation of Bonded Specimens

The schematic and physical image of the bonded specimen are shown in Figure 1. Before the specimen was prepared, the surface of the repaired substrates needed to be rough and cleaned to ensure that the bonding surface of all the repaired substrates had basically the same surface roughness. For the mortar substrates used for the shear bond tests, the samples were demolded after 1 d, and then the bonding surface was polished with 80 mesh sandpaper. When the cement paste on the bonding surface was removed and the sand particles were exposed, the grinding was stopped. Subsequently, the repair mortar substrates were cured to 90 d, and a brush was used to remove the precipitated materials attached to the bonding surface before the test. For the concrete substrates used for the tensile bond tests, before the final setting of the concrete (approximately 5 h), the bonding surface of the concrete slab was roughened using a steel wire brush in both horizontal and vertical directions. After demolding, grooves with a depth of approximately 1 mm were cut in the concrete slab along the edge of the specimen after demolding to avoid the influence of the surrounding matrix on the bond strength. The specimens were then cured, and the sediment attached to the bonding surface was removed using a brush before testing.

Figure 1.

Bonding specimens.

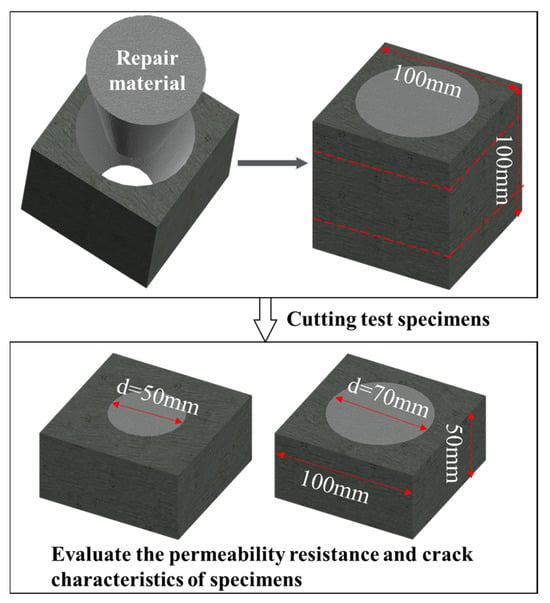

The truncated-cone-bonded specimen was used to test the bonding properties of the repair system under the constraint of the substrate and the effect of interface cracks on the permeability [39]. The bevel design of the truncated cone is more conducive to macroscopically reflecting the compression effect of the repair materials on the substrates when the repair materials expand, so that the repair materials are in closer direct contact with the substrates. Firstly, the hollow concrete matrix was prefabricated using an acrylic mold, and then the cement paste on the inner wall of the matrix was polished with sandpaper to ensure that the bonding surface of each specimen had the same roughness. After pouring the repair material, the specimens were cured for 90 d under standard curing conditions (20 ± 2 °C, RH ≥ 95%) and dry conditions (20 ± 2 °C, RH = 60 ± 5%), respectively. Then, the specimens were cut to a height of 50 mm to test the impermeability of the repair system and observe the crack width at the repair interface. The schematic diagram of the preparation of the truncated-cone-bonded specimen is displayed in Figure 2.

Figure 2.

Preparation process of truncated-cone-bonded specimen.

2.2.3. Preparation of OPC-GGBS-SAC Composite Repair Mortars

Since Ca(OH)2 in the system can be consumed by both GGBS and SAC, a significant reduction in the amount of OPC will not be conducive to maintaining the alkalinity of the OPC-GGBS-SAC composite system, thus affecting the reinforcement properties of the repair material. According to the previous test results, when the GGBS content was 30%, the mechanical properties of OPC-GGBS composite system were the best [40]. Therefore, based on 70% OPC and 30% GGBS, SAC was selected for modification, and SAC was replaced with OPC and GGBS in a ratio of 7:3 to add to the OPC-GGBS composite system. The mix of OPC-GGBS-SAC repair mortar is illustrated in Table 4.

Table 4.

Mix proportion of OPC-GGBS-SAC mortars.

2.3. Measurement Method

2.3.1. Mechanical Properties and Setting Time

As per the standard GB/T 1346-2024 [41], the setting time was measured using a Vicat apparatus. Following the standard GB/T 17671-2021 [42], the compressive and flexural strength were measured using an automatic universal testing apparatus.

The negative temperature environment was achieved through the “air freezing method” test chamber, and the temperature was precisely controlled at 10 ± 2 °C via an internal temperature sensor to ensure the uniformity of the temperature in the test chamber. After the pouring is completed, the entire test mold was wrapped in cling film and then placed onto the test specimen rack within the test chamber. It should be noted that all test specimens were positioned on the middle shelf of the specimen rack, maintaining a distance of over 20 cm from the chamber walls. Two hours before the test, the specimens were taken out from the test chamber, demolded, and placed in 20 °C water for thawing.

2.3.2. Bond Strength

- (1)

- Shear bonding strength

Shear bonding strength refers to compressive shear, tested using a compression testing machine and calculated according to Equation (1).

In the equation, σ (MPa) represents nominal shear bonding strength; P (N) represents the failure load; A (mm2) represents the bonding interface area, for 45° shear bonding specimens, A = 40 mm × 40 mm, for 30° shear bonding specimens, A = 2 × 40 mm × 40 mm.

- (2)

- Flexural bonding strength

Flexural bonding strength tests were conducted using a flexural testing machine, and the loading was carried out by using the three-point bending force form. The span was 100 ± 5 mm, and the loading rate was 50 N/s. The flexural bonding strength was calculated according to Equation (2).

In the equation, F (MPa) is the flexural bond strength; P (N) is the failure load; L (mm) is the length between two support points; b and h (mm) represent the width and height of the sample section, respectively.

- (3)

- Tensile bonding strength

Tensile bonding strength refers to the tensile force per unit area that the bond can withstand before failure occurs. In accordance with the JGJ/T 299-2013 standard [43], the tensile bonding strength was tested using a digital bond strength tester and calculated according to Equation (3).

In the equation, R (MPa) is the tensile bonding strength; Ft (N) is the value of the breaking tensile force; S (mm2) is the bonding area, S = 50 mm × 50 mm.

2.3.3. Expansion Properties

According to the standard GB 23439-2017 [44], the restrained expansion rates were determined with a specimen dimension of 40 mm × 40 mm × 140 mm, and 6 specimens were prepared for each group. Three of the samples were continuously cured in water, while the other three samples were cured in water for 14 days and then moved to an air-conditioned space (20 ± 2 °C, RH = 60 ± 5%) for continued curing. The deformation of the sample at a fixed age was measured with a specific length meter and a dial indicator, with a measurement accuracy of 0.001 mm.

2.3.4. Heat of Hydration

According to the ‘direct method’ specified in the standard GB/T 12959-2024 [45], the heat of hydration of samples was determined.

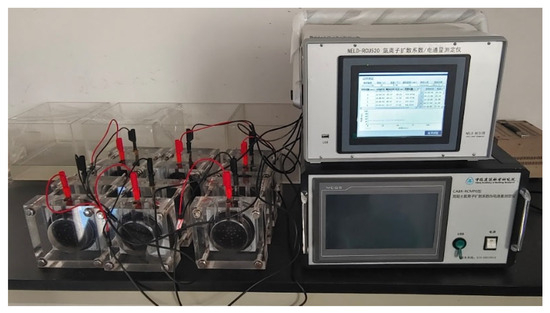

2.3.5. Electric Flux

After the specimens were cured to 28 d, the electric flux of the specimens was tested based on the standard GB/T 50082-2024 [46]. The average value of 3 samples in each group was taken as the final electric flux. The electric flux test device is displayed in Figure 3.

Figure 3.

Electric flux test device.

3. Results and Discussion

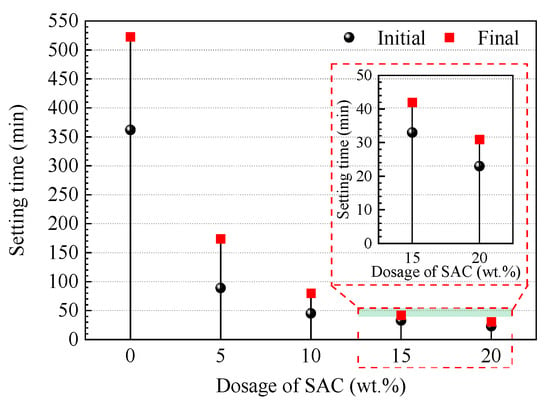

3.1. Setting Time

The influence of SAC on the setting time of OPC-GGBS-SAC composite system is exhibited in Figure 4. With the addition of SAC, the initial and final setting times of the OPC-GGBS-SAC composite system were greatly shortened, and the interval between the initial setting time and the final setting time was also greatly reduced. The initial setting time and final setting time of OPC-GGBS were 362 min and 523 min, respectively. After adding 5%, 10%, 15%, and 20% SAC, the initial setting times were shortened to 89 min, 45 min, 33 min, and 23 min, respectively, and the final setting times were shortened to 174 min, 80 min, 42 min, and 31 min, respectively. Even if a small amount of SAC was added, it was found to significantly promote setting and early strength. This is because SAC can rapidly hydrate and generate a large amount of AFt after contact with water, thereby quickly forming a network structure in the cement paste and promoting the increase in viscosity of the paste, causing the cement paste to lose its plasticity and develop its strength. When the amount of gypsum carried by SAC was insufficient, it will still react with the gypsum carried by the OPC, thus accelerating the time in which the OPC starts the reaction.

Figure 4.

Influence of SAC on setting time of OPC-GGBS-SAC.

3.2. Mechanical Properties at Room Temperature

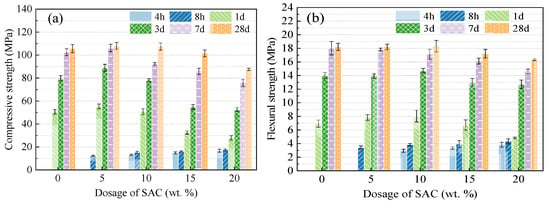

The mechanical performance of OPC-GGBS-SAC mortar under standard curing conditions is illustrated in Figure 5. When the SAC content exceeded 5%, the composite system hardened and had strength within 8 h. When the content exceeded 10%, the composite system began to have strength within 4 h. At 4 h and 8 h, with the increase in SAC content, the compressive strength and flexural strengths of OPC-GGBS-SAC system continued to increase. At 1 d, 3 d, 7 d, and 28 d, with the increase in SAC dosage, the compressive strength and flexural strength of the OPC-GGBS-SAC composite system showed a trend of first increase followed by decrease. Among them, when the SAC content was between 5% and 10%, the compressive and flexural strength reached the maximum at 1 d. When the SAC content was 5%, the compressive strength of 3 d, 7 d, and 28 d was highest. When the SAC content was 10%, the flexural strength reached the maximum at 28 d. For the mechanical properties before 1 d, the higher the amount of SAC, the higher the strength. For the mechanical properties of 1 d to 28 d, the optimal content of SAC was maintained between 5% and 10%.

Figure 5.

The (a) compressive strength and (b) flexural strength mechanical properties of OPC-GGBS-SAC mortars under standard curing conditions.

Through the rapid hydration of SAC, the early mechanical properties of the composite system were greatly improved. With the hydration reaction, OPC and GGBS in the composite system began to participate in the reaction, and the generated C-S-H gel was filled in the pores of the matrix, so that the strength of the mortar was enhanced. After adding an appropriate quantity of SAC, AFt, and C-S-H interpenetrated and interlocked, which helps to optimize the pore structure and improve the compactness of the samples. Moreover, the rapid hydration heat release of SAC and the consumption of Ca(OH)2 promoted the dissolution and hydration processes of OPC. However, when the SAC dosage was too high, the early strength developed rapidly, and the migration of hydration products in the pore solution and the filling and compaction of pores were affected by the fast generation of hydration production. In the early stage, the primary hydration product of SAC was AFt, which exists in a disordered and overlapping state, leaving many pores in the cement stone. Therefore, excessive SAC may cause an increase in porosity and defects in the composite system. When the SAC content was in the range of 5~15%, the difference between the compressive strength and flexural strength of the mortar at 28 d was small. This indicates that the later hydration of OPC and GGBS can fill the pores and defects mentioned above, and promote the compactness of the composite system, thus compensating for some of the negative effects on strength caused by the rapid hydration of SAC.

3.3. Mechanical Properties Under Negative Temperature

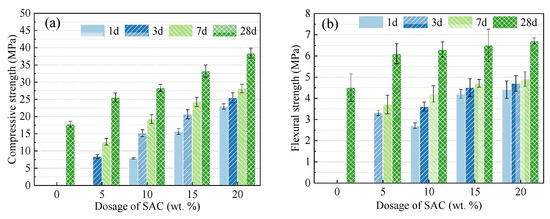

Figure 6 shows the mechanical properties of OPC-GGBS-SAC mortar under −10 °C curing conditions. The addition of SAC can enhance the performance of OPC at negative temperatures by rapidly consuming free water, reducing the content of frozen water and promoting the formation of early structure [47]. Therefore, the OPC-GGBS-SAC repair material can be used in winter construction. Under negative temperature conditions, mortars without SAC began to produce strength until 28 d, while mortars with 5% and 10% SAC began to produce strength at 3 d and 1 d, respectively. As the increase in SAC content, the compressive and flexural strengths of the mortars continued to increase at all ages. When the SAC contents were 5%, 10%, 15%, and 20%, the compressive strengths at 28 d at the low temperatures increased by 44.1%, 60.0%, 87.6%, and 116.9%, respectively, compared to the blank group. This demonstrates that the addition of SAC can greatly promote the development of mechanical properties of OPC-GGBS-SAC composite system in negative temperature environment and improve the limitation that most repair materials can only be used at room temperature environment.

Figure 6.

The (a) compressive strength and (b) flexural strength mechanical properties of OPC-GGBS-SAC mortars under −10 °C curing condition.

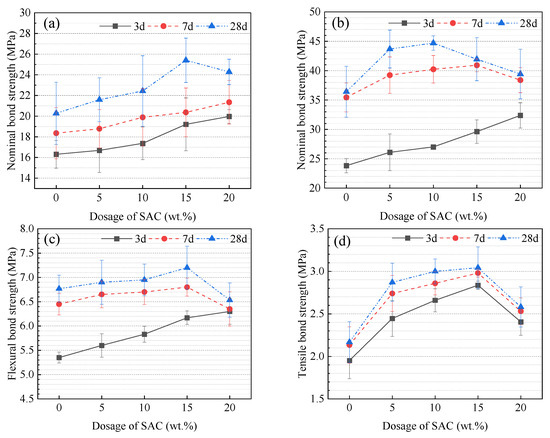

3.4. Bond Performance

The bond strength of OPC-GGBS-SAC mortar under different stress forms is shown in Figure 7. In Figure 7a,b, the inclination angle significantly affected the shear bond strength, and the ultimate vertical load that the 45° shear-bonded specimen can withstand when it fails was greater than 30° shear-bonded specimen. This indicates that the bond interface was more prone to be affected by sliding failure, that is, it was more sensitive to tangential stress. The shear stress applied at a steeper angle increased, thereby increasing the measurement of bond strength. Moreover, steeper angles facilitated a more uniform stress distribution at the interface, thus improving the accuracy and reliability of the bond strength measurement [48]. As the SAC content increases, the nominal bond strength of 30 ° shear bond specimens gradually increased at 3 d and 7 d. The maximum value at 28 d was reached when the SAC content was 15%. For 45° shear-bonded specimens, the optimal content of SAC was 20%, 15%, and 10% at 3 d, 7 d, and 28 d, respectively. SAC accelerated the hydration process, enhanced the amount of hydration products at early stage, and can rapidly fill pores in the interface to make the bond strength develop rapidly. Furthermore, the hydration products were filled into the holes of the bonded matrix, thereby improving the mechanical bonding force between the substrate and the repair material. When the content of SAC is too high, it will interfere with the microstructure at the interface, which is basically consistent with the effect of SAC on compressive strength.

Figure 7.

The bond strength of OPC-GGBS-SAC mortar under different stress forms: (a) 30° shear; (b) 45° shear; (c) flexural; (d) tensile.

Figure 7c,d reflect the bonding ability of the bonding interface under flexural failure and tensile failure. These two forms of force actually reflect the strength of van der Waals force, mechanical meshing force and chemical bonding force at the bonding interface. For the bonding interface of cement-based materials, mechanical meshing force plays a major role. According to the data of flexural bonding, with increasing SAC content, the bonding strength of 3 d gradually increased, while the bonding strength of 7 d and 28 d reached the highest when the SAC content was 15%. For the tensile bonding specimens, the bonding strength of 3 d, 7 d, and 28 d also reached the highest when the SAC content was 15%. When the SAC content increased to 20%, the tensile bond strength of each age decreased significantly. Based on the results of different stress forms, when the SAC content was 10~15%, the improvement in the bonding strength of the composite material is optimal. Compared with the blank group, under four different stress forms, the growth rates of 28 d bond strength were 10.6%, 22.7%, 2.8%, and 38.9%, respectively, when the SAC content was 10%, and the growth rates of 28 d bond strength were 25.2%, 15.2%, 6.5%, and 40.7%, respectively, when the SAC content was 15%.

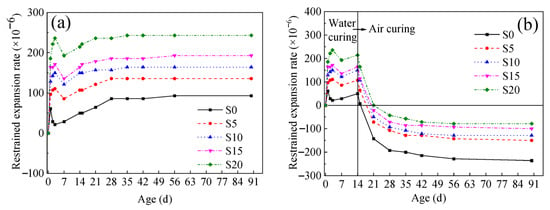

3.5. Compensation Shrinkage Performance

Figure 8 shows the restrained expansion rate of OPC-GGBS-SAC mortar cured in water and air. In Figure 8a, after the specimens containing SAC were placed in water for curing, the expansion phenomenon occurred in the first 3 d, followed by a brief shrinkage. After 7 d, it continued to expand and gradually stabilized at 28 d of curing. The early expansion of OPC-GGBS-SAC composite system was mainly attributed to the expansion effect of a large amount of AFt generated by SAC hydration. On the other hand, the ‘wet expansion’ of the specimen occurred after water absorption. The expansion of the specimen without SAC ended after 1 d, and then the volume shrank under the action of chemical shrinkage. The early expansion duration and expansion amount of the specimens without SAC were lower than those with SAC. In fact, in the process of curing the whole specimen in water, the shrinkage caused by the hydration of the specimen itself, the expansion of the hydration products and the “wet expansion” of water absorption occurred simultaneously. With the increase in SAC content, the expansion rate of mortar specimens increased significantly before 3 d, and with the increase in curing age, the expansion rate also improved slightly. It demonstrates that the hydration expansion of SAC mainly occurred in the early stage and can well compensate for the early shrinkage of the composite system. Due to the expansion of all mortar samples during 3 d~28 d was basically the same, the expansion amount generated during this period was considered to be as the hydration reaction in the system progresses. The specimen underwent ‘wet expansion’ due to continuous water absorption and the newly generated hydration products squeezed the pore wall in the pore’s water-filled state. Compared with the samples without SAC, after adding 5%, 10%, 15%, and 20% SAC, the restrained expansion rate of mortar specimens at 90 d increased by 46.1%, 76.9%, 107.7%, and 161.5%, respectively.

Figure 8.

Restrained expansion rate of OPC-GGBS-SAC mortars: (a) curing in water; (b) curing in air after 14 d.

In Figure 8b, after 14 d of water-curing, the mortar specimens were moved to air-curing conditions, and the free water in the mortar continued to evaporate under the drying effect. With the evaporation of moisture, the humidity inside the mortar decreased continuously, and the specimen shrank greatly and tended to be stable after 42 d. After adding SAC, the shrinkage of mortar specimens was greatly alleviated during the entire curing process. Compared with the samples without SAC, after adding 5%, 10%, 15%, and 20% SAC, the shrinkage of mortar specimens at 90 d was reduced by 36.4%, 45.5%, 57.6%, and 66.7%, respectively. The above results indicate that, under early water-curing conditions, the restrained expansion rate of the OPC-GGBS-SAC composite system was effectively improved by the addition of SAC, and the expansion amount was positively correlated with the amount of SAC. This means that the expansion performance of the repair material can be controlled by the amount of SAC, and the repair material with micro-expansion characteristics can be prepared. This material can generate expansion stress between the repair material and the damaged substrate, thereby ensuring a stronger bond at the repair bonding interface. In practical engineering, when the early maintenance was completed, the volume shrinkage of the repair material began to occur. The repair material modified by SAC can produce lower shrinkage, thus ensuring the volume stability of the repair system during long-term service.

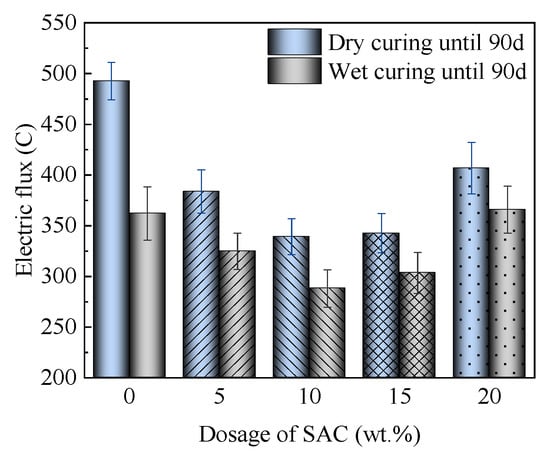

3.6. Resistance to Chloride Ion Permeability

In order to evaluate the impact of SAC on the chloride ion permeability resistance of the repair system formed by the repair materials and the damaged substrate, the truncated-cone-bonded specimens were prepared according to the steps outlined in Figure 2. The samples were subjected to dry curing and wet curing for 90 d, and the electric flux was tested. The results are presented in Figure 9. The electric flux of the dry-cured specimen was higher than that of the wet-cured specimen. This is because in a long-term drying environment, some cracks and defects may be produced at the adhesive interface between the repair materials and the cone substrate due to shrinkage. During the wet curing process, the unhydrated cement particles and GGBS in the repair material continued to undergo hydration reaction, which promoted higher density in both the repair material itself and the bonding interface. As the SAC content increases, the electric flux of the truncated-cone-bonded specimens under different curing conditions decreased first and then increased. When the SAC content was 10%, the electric flux of the cone-bonded specimen was the lowest. Compared with the blank group, the electric flux values of the specimens under dry curing and wet curing were reduced by 31.2% and 20.4%, respectively. This indicates that the resistance to chloride ion penetration of the bonding interface was promoted by the addition of SAC.

Figure 9.

Influence of SAC on electric flux of OPC-GGBS-SAC truncated-cone-bonded specimen.

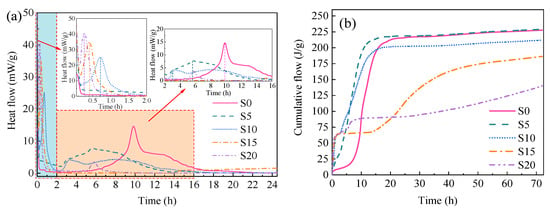

3.7. Heat of Hydration

The impact of SAC on the hydration heat-release rate and cumulative heat release of composite system is displayed in Figure 10. In Figure 10a, with the addition of SAC, the appearance time of the hydration heat-release peak of the composite system was significantly advanced, and the heat-release rate of the first hydration heat-release peak was also greatly increased. When the SAC content was 5%, 10%, 15%, and 20%, the time of the first hydration heat-release peak was advanced from 9.80 h (blank group) to 3.00 h, 0.71 h, 0.42 h, and 0.26 h, respectively. Moreover, after the addition of SAC, an obvious second heat-release peak appeared, which was caused by the hydration of OPC in the composite system. The second heat-release peak of the OPC-GGBS-SAC composite system appeared earlier than the first heat-release peak of the blank group. This indicates that the rapid hydration of SAC not only helps to shorten the setting time of the composite system and promote the rapid development of early strength, but it also accelerates the hydration process of OPC in the composite system.

Figure 10.

Effect of SAC on hydration heat of OPC-GGBS-SAC: (a) heat flow; (b) cumulative heat.

In Figure 10b, we can see that, with the addition of SAC, the cumulative heat release of the composite system increased rapidly. There are obvious “steps” that appear in the cumulative hydration heat-release curves of S15 and S20. This is because, when the SAC content was high, the concentrated heat-release period generated by rapid hydration of SAC was earlier and the heat-release rate was higher. Due to the rapid hydration heat-release process, the concentrated heat-release period was shorter. When the concentrated heat-release period of SAC ended, the OPC in the system still did not start to hydrate, resulting in a slow growth of accumulated heat release over a period. This phenomenon can also be illustrated in Figure 10a. After about 10 h of hydration, the cumulative heat release of S0 gradually exceeded that of S15 and S20, and, at around 6 h of hydration, S5 gradually exceeded S10. At 72 h of hydration, the cumulative hydration heat of each group, in descending order, is S5, S0, S10, S15, and S20. SAC can greatly accelerate the hydration reaction process of the system and promote the hydration reaction of the OPC in the system. This has great advantages in improving the early mechanical properties of repair materials, and at the appropriate SAC dosage, it can also enhance the hydration degree of the entire system. However, when the SAC content was 10%, the cumulative heat release and hydration degree of the composite system slightly decreased. The ettringite and AH3 gel formed by SAC hydration reaction filled the internal voids of the system, making the microstructure more compact, thus enhancing the mechanical properties of the composite system [49]. Furthermore, the hydration of SAC consumed calcium hydroxide of the system, which further promoted the hydration of OPC and ensured the subsequent development of the mechanical properties in the later stage of system [50]. When the SAC dosage exceeded 10%, the cumulative heat release at 72 h was greatly reduced. The reason is that the hydration products produced by the rapid hydration of SAC will wrap around some unhydrated cement particles, causing a decrease in the overall hydration degree of the composite system [35]. Meanwhile, the amount of water available for OPC hydration reactions was reduced by the rapid hydration of SAC, resulting in insufficient hydration of OPC. The higher the dosage of SAC, the greater the reduction in water content [51]. This is also the reason why the mechanical properties and bonding performance of the composite system were significantly reduced when the SAC content was too high.

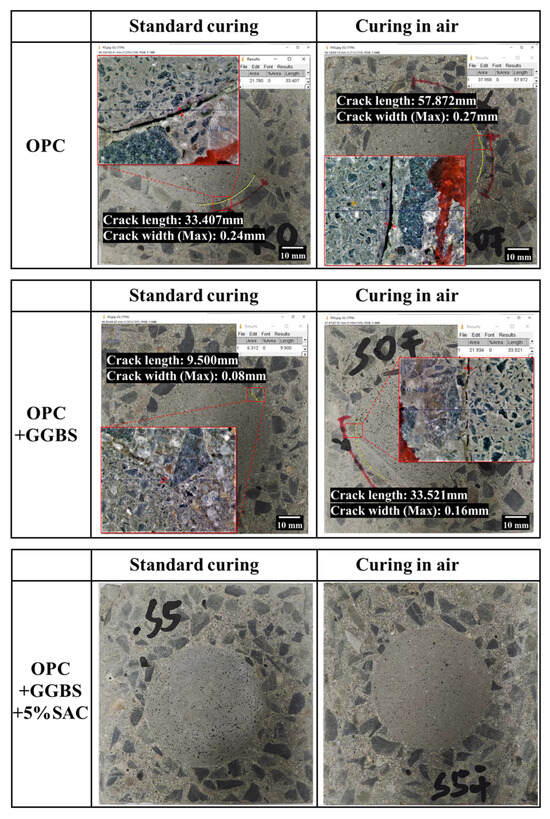

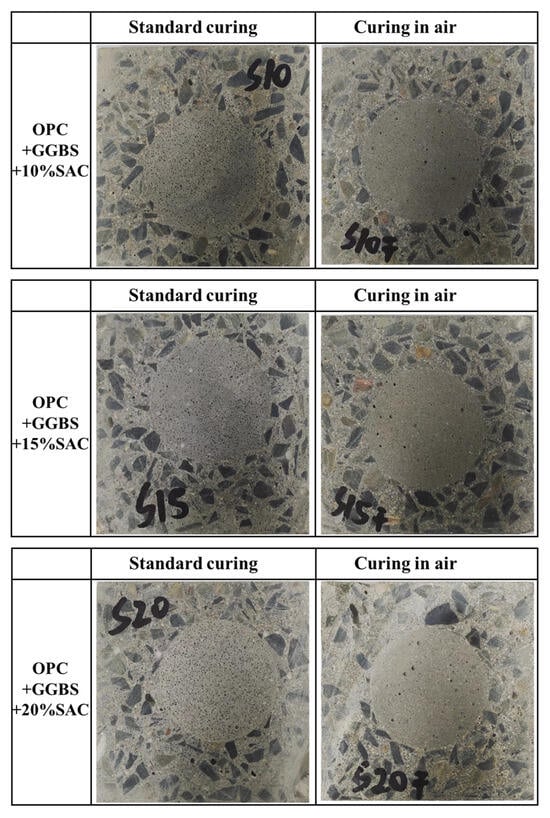

3.8. Reliability Evaluation of Bonding Interface

After standard curing and air curing for 90 d, the cracking at the bond interfaces were observed via the macro imaging equipment of the crack width tester. Figure 11 shows the reliability verification of the bonding interface of different repair systems. No cracks were found at the interface of the truncated-cone-bonded specimens with SAC, indicating that the bonding reliability was better. However, both OPC and OPC-GGBS specimens exhibited interface cracking under standard curing and air curing. In contrast, the crack width of the OPC-GGBS composite system was smaller than that of the pure OPC specimen, which indicates that the crack width of the bonding interface can be reduced to a certain extent by GGBS. In addition, even under standard curing, both OPC and OPC-GGBS also appeared cracking phenomenon. This indicates that the drying effect of the environment was not the only factor causing interface cracking, and the reason for cracking was more likely to be caused by the early shrinkage of the repair material. Therefore, it is particularly important to compensate for the early shrinkage of the repair material, and the addition of SAC just makes up for this defect. From the data of the restrained expansion rate, compared with the OPC-GGBS composite system, even if 5% SAC was added, the restrained expansion rate of the specimen increased from 60.7 × 10−6 to 110.7 × 10−6 at 3 d, and the restrained shrinkage rate decreased from 235.7 × 10−6 to 150.3 × 10−6 at 90 d after long-term air curing. When the SAC content was higher, the restrained expansion rate was higher, and the final shrinkage rate was lower. The addition of SAC can significantly alleviate the shrinkage of the OPC-GGBS composite system and avoid the cracking of the bonding interface. At the same time, the higher early expansion amount can produce expansion stress at the bonding interface to ensure the close combination between the repair material and the substrate. Therefore, SAC can effectively improve the reliability of the bonding interface.

Figure 11.

Bonding interface reliability verification of different repair systems.

3.9. Discussion

Based on the above research, it can be concluded that, as the proportion content of SAC increased, the setting time of the OPC-GGBS system gradually shortened, the restrained expansion rate continuously increased, and both compressive strength and bond strength exhibited a trend of initially increasing before subsequently declining. Specifically, the order of compressive strength was S5 > S10 > S0 > S15 > S20; the order of bonding performance was S15 > S10 > S5 > S20 > S0; the ranking of resistance to chloride ion penetration is S10 > S15 > S20 > S5 > S0. When the content of SAC was 15%, the bond strength of OPC-GGBS-SAC system reached the maximum. However, at this dosage level, the hydration rate of the composite system was excessively rapid, resulting in a setting time of merely 33 min. The construction operation window was limited, which may lead to the loss of fluidity of the repair material before pouring was completed, thereby compromising construction quality. Moreover, the compressive strength of the system with 15% SAC was significantly lower than that of the control group. Compressive strength was the core indicator for repairing materials to resist external loads and structural damage during long-term service. If only bonding strength was pursued, then the compressive strength would be neglected, and the repaired area may be destroyed due to insufficient overall mechanical properties following long-term use. Therefore, to achieve a comprehensive balance between the workability, mechanical properties, and bonding interface reliability of repair materials, it is recommended that the optimal dosage of SAC be 5~10%.

4. Conclusions

(1) The early strength and mechanical properties of OPC-GGBS-SAC composite system at negative temperatures was significantly improved by the fast hydration of SAC. SAC increased the generation of early hydration production, which infiltrated the cracks and pores of the bonding substrate, thereby strengthening the mechanical meshing between the substrate and the repair material. When the SAC content was 10~15%, the best effect on improving the bonding strength was achieved.

(2) SAC can effectively improve the restrained expansion rate of OPC-GGBS-SAC composite system, and the expansion amount was positively correlated with the amount of SAC. When the SAC content was 10%, the electric flux reached the lowest, which was 28.9% lower than that of the control group.

(3) A small amount of SAC can significantly accelerate the hydration process of OPC-GGBS system, advance the heat-release peak, and promote the development of early strength. However, when the content of SAC exceeded 10%, the cement particle was wrapped by the hydration products, which reduced the degree of hydration and the cumulative heat release in the later stage. Therefore, it is recommended that, when the content of SAC was controlled within 5~10%, the performance optimization effect of the composite system can be achieved best.

(4) The incorporation of SAC can effectively inhibit the shrinkage of the OPC-GGBS system. The early expansion effect not only generated pre-compression stress at the interface and promoted the strong bonding between the repair material and the substrate, it also prevented cracks, thereby significantly enhancing the reliability of the bonding interface.

Author Contributions

Conceptualization, G.L.; methodology, X.H., Y.Z. and M.N.; investigation, X.H., W.Z. and Y.L.; resources, G.L.; data curation, X.H., Y.Y. and M.N.; writing—original draft preparation, X.H. and M.N.; writing—review and editing, X.H., M.N. and G.L.; funding acquisition, M.N. and G.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by National Natural Science Foundation of China, grant number 52408291; China Postdoctoral Science Foundation, grant number 2024MD753966; Young Talent Fund of Xi’an Association for Science and Technology, grant number 0959202513133; National Natural Science Foundation from Shaanxi province, China, grant number 2025JC-YBMS-549.

Data Availability Statement

The general data are included in the article. Additional data are available on request.

Conflicts of Interest

The authors Xiang He, Wei Zhang, Yong Zhang, and Yang Yu were employed by POWERCHINA Northwest Engineering Co., Ltd. The remaining authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this article.

References

- Li, G.; Zhou, Q.; Wang, W.; Lu, C.; Chen, C.; Guo, Z.; Lu, C. Chloride diffusion along the interface between concrete matrix and repair materials under flexural loading. Constr. Build. Mater. 2023, 372, 130829. [Google Scholar] [CrossRef]

- Niu, M.; He, X.; Wang, Y.; Shen, Y.; Zhang, W.; Li, G. Performance degradation and chloride ion migration behavior of repaired bonding interfaces in seawater-freeze-thaw environment. Buildings 2025, 15, 2431. [Google Scholar] [CrossRef]

- Jia, L.; Jia, W.; Guo, J.; Sun, Y. Nano-silica-enhanced high-performance magnesium phosphate cement repair mortars: Optimization of interfacial bonding. Constr. Build. Mater. 2025, 490, 142447. [Google Scholar] [CrossRef]

- Semendary, A.; Dagmar, S. Factors affecting bond between precast concrete and cast in place ultra high performance concrete (UHPC). Eng. Struct. 2020, 216, 110746. [Google Scholar] [CrossRef]

- Lyu, J.; Feng, S.; Zhang, Q.; Xiao, H. Review of factors affecting bond strength between ultra-high-performance concrete and normal strength substrate. Constr. Build. Mater. 2024, 439, 137416. [Google Scholar] [CrossRef]

- Chen, P.; Li, Y.; Zhang, J.; Zhang, Z.; Wang, D. Influence of interface agent and form on the bonding performance and impermeability of ordinary concrete repaired with alkali-activated slag cementitious material. J. Build. Eng. 2024, 94, 110043. [Google Scholar] [CrossRef]

- Snoeck, D.; Wang, J.; Bentz, D.; De Belie, N. Applying a biodeposition layer to increase the bond of a repair mortar on a mortar substrate. Cem. Concr. Compos. 2018, 86, 30–39. [Google Scholar] [CrossRef]

- Mohammad, A.; Elke, G.; Kim, V.; Nico, B.; Nele, D. Treatment with nano-silica and bacteria to restore the reduced bond strength between concrete and repair mortar caused by aggressive removal techniques. Cem. Concr. Compos. 2021, 120, 104064. [Google Scholar] [CrossRef]

- Ummin, O.; Li, Y.; Li, K.; Chen, Y.; Jia, H.; Zuo, J. Influence of surface roughness and interfacial agent on the interface bonding characteristics of polyurethane concrete and cement concrete. J. Build. Eng. 2024, 91, 109596. [Google Scholar] [CrossRef]

- Zheng, H.; Pang, B.; Jin, Z.; Zhang, Y.; Hou, D.; Bi, J.; Zhang, W.; Yuan, L. Durability enhancement of cement-based repair mortars through waterborne polyurethane modification: Experimental characterization and molecular dynamics simulations. Constr. Build. Mater. 2024, 438, 137204. [Google Scholar] [CrossRef]

- Jia, L.; Zhao, F.; Yao, K.; Du, H. Bond performance of repair mortar made with magnesium phosphate cement and ferroaluminate cement. Constr. Build. Mater. 2021, 279, 122398. [Google Scholar] [CrossRef]

- Jin, Z.; Jing, S.; Pang, B.; Wang, P.; Chen, J.; Yang, C.; Song, X.; Liu, L. Sustainable infrastructure repair materials: Self-emulsifying waterborne epoxy enhanced CSA cement with superior shrinkage mitigation properties. Constr. Build. Mater. 2025, 490, 142432. [Google Scholar] [CrossRef]

- Hassan, B.; Steffen, G.; Stijn, M. Assessment of shrinkage and bond behaviour of high performance cement-based composites as a repair mortar. Dev. Built Environ. 2023, 15, 100203. [Google Scholar] [CrossRef]

- Hans, B.; Björn, H.; Marco, T. The influence of substrate moisture preparation on bond strength of concrete overlays and the microstructure of the OTZ. Cem. Concr. Res. 2017, 92, 84–91. [Google Scholar] [CrossRef]

- Momayez, A.; Ehsani, M.R.; Ramezanianpour, A.; Rajaie, H. Comparison of methods for evaluating bond strength between concrete substrate and repair materials. Cem. Concr. Res. 2005, 35, 748–757. [Google Scholar] [CrossRef]

- Zhang, S.; Yuan, Q.; Li, Q.; Zhang, F.; Xie, Z. Microstructural characteristics of bonding interfacial transition zone of concrete and magnesium ammonium phosphate cement. J. Build. Eng. 2023, 76, 107208. [Google Scholar] [CrossRef]

- Song, X.; Song, X.; Liu, H.; Huang, H.; Anvarovna, K.; Ugli, N.; Huang, Y.; Hu, J.; Wei, J.; Yu, Q. Cement-based repair materials and the interface with concrete substrates: Characterization, evaluation and improvement. Polymers 2022, 14, 1485. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, Z.; Zhou, D.; Yuan, B.; Liu, S.; Luo, Z.; Li, X.; Jin, D.; Xu, F. Improving interfacial bonding between ordinary Portland cement and geopolymer concrete using acid/alkaline-catalyzed nano-SiO2 sols: Insights into performance and mechanisms. Constr. Build. Mater. 2025, 490, 142537. [Google Scholar] [CrossRef]

- Zhao, F.; Li, H.; Liu, S.; Chen, J. Preparation and properties of an environment friendly polymer-modified waterproof mortar. Constr. Build. Mater. 2011, 25, 2635–2638. [Google Scholar] [CrossRef]

- Gao, Y.; Luo, J.; Yuan, S.; Zhang, J.; Gao, S.; Zhu, M.; Li, Z.; Zhou, X. Fabrication of graphene oxide/fiber reinforced polymer cement mortar with remarkable repair and bonding properties. J. Mater. Res. Technol. 2023, 24, 9413–9433. [Google Scholar] [CrossRef]

- Zhang, P.; Du, M.; Fang, H.; Shi, M.; Zhang, C.; Wang, F. Polymer-modified cement mortars: Their enhanced properties, applications, prospects, and challenges. Constr. Build. Mater. 2021, 299, 124290. [Google Scholar] [CrossRef]

- Abdulrahman, P.; Bzeni, D. Bond strength evaluation of polymer modified cement mortar incorporated with polypropylene fibers. Case Stud. Constr. Mater. 2022, 17, e01387. [Google Scholar] [CrossRef]

- Li, Y.; Wang, J.; Gao, S.; Zheng, Y. Improvement effects of nano-silica on bonding performance of polymer concrete for repairing damaged concrete. Constr. Build. Mater. 2023, 409, 133768. [Google Scholar] [CrossRef]

- Chen, H.; Fan, Y.; Li, Q.; Luan, H. Effect of nano-metakaolin modified cement mortar binder on the bond performance and failure behavior of new-old concrete. J. Build. Eng. 2024, 98, 111426. [Google Scholar] [CrossRef]

- Masao, K.; Tomohide, W.; Nariaki, T. Increase of bond strength at interfacial transition zone by the use of fly ash. Cem. Concr. Res. 2000, 30, 253–258. [Google Scholar] [CrossRef]

- Zhang, T.; Tian, W.; Guo, Y.; Bogush, A.; Khayrulina, E.; Wei, J.; Yu, Q. The volumetric stability, chloride binding capacity and stability of the Portland cement-GBFS pastes: An approach from the viewpoint of hydration products. Constr. Build. Mater. 2019, 205, 357–367. [Google Scholar] [CrossRef]

- Juang, C.; Kuo, W. Properties and Mechanical Strength Analysis of Concrete Using Fly Ash, Ground Granulated Blast Furnace Slag and Various Superplasticizers. Buildings 2023, 13, 1644. [Google Scholar] [CrossRef]

- Han, J.; Jia, D.; Yan, P. Understanding the shrinkage compensating ability of type K expansive agent in concrete. Constr. Build. Mater. 2016, 116, 36–44. [Google Scholar] [CrossRef]

- Guo, X.; Liao, L.; Xie, K.; Xu, W.; Lu, L.; Huang, K. Early-age mechanical and shrinkage performance of CaO-MgO expansive agent self-compacting concrete. J. Build. Eng. 2025, 111, 113165. [Google Scholar] [CrossRef]

- Xiong, G.; Liu, J.; Li, G.; Xie, H. A way for improving interfacial transition zone between concrete substrate and repair materials. Cem. Concr. Res. 2002, 32, 1877–1881. [Google Scholar] [CrossRef]

- Niu, M.; He, X.; Zhang, X.; Liu, Z.; Shen, Y.; Li, G. The coordination effect of expansive agent and fly ash on the hydration behavior and expansion performance of cement-based grouting materials. Case Stud. Constr. Mater. 2025, 23, e05067. [Google Scholar] [CrossRef]

- Cao, F.; Yan, P. The influence of the hydration procedure of MgO expansive agent on the expansive behavior of shrinkage-compensating mortar. Constr. Build. Mater. 2019, 202, 162–168. [Google Scholar] [CrossRef]

- Feng, J.; Wang, K.; Ma, H.; Song, J.; Wang, J.; Sui, G.; Gu, L. Study on hydration characteristics of composite cementitious system with MgO expansion agent. Mater. Today Commun. 2025, 48, 113571. [Google Scholar] [CrossRef]

- Zhou, H.; Li, Y.; Ma, C.; Zhou, Z.; Fang, Z.; Lou, J.; Liu, Y. Bond performance and mechanisms of sulphoaluminate cement-based UHPC for reinforcing old concrete substrate. Constr. Build. Mater. 2023, 366, 130233. [Google Scholar] [CrossRef]

- Guo, C.; Wang, R. Using sulphoaluminate cement and calcium sulfate to modify the physical-chemical properties of Portland cement mortar for mechanized construction. Constr. Build. Mater. 2023, 367, 130252. [Google Scholar] [CrossRef]

- Afroughsabet, V.; Biolzi, L.; Monteiro, P.J.M.; Gastaldi, M.M. Investigation of the mechanical and durability properties of sustainable high performance concrete based on calcium sulfoaluminate cement. J. Build. Eng. 2021, 43, 102656. [Google Scholar] [CrossRef]

- Luo, W.; Liu, Y.; Lv, J.; Liu, H.; Li, H.; Chen, W. Mechanical and shrinkage properties of engineered cementitious composites with blended use of high-belite sulphoaluminate cement and ordinary Portland cement. J. Build. Eng. 2025, 106, 112551. [Google Scholar] [CrossRef]

- He, X.; Yang, J.; Niu, M.; Hanif, A.; Li, G. Contribution of layered double hydroxides to hydration and chloride binding capacity of OPC-SAC-GGBS repair materials. Constr. Build. Mater. 2024, 416, 135203. [Google Scholar] [CrossRef]

- Qian, J.; You, C.; Wang, Q.; Wang, H.; Jia, X. A method for assessing bond performance of cement-based repair materials. Constr. Build. Mater. 2014, 68, 307–313. [Google Scholar] [CrossRef]

- He, X.; Zhang, Y.; Hu, W.; Zhang, W.; Niu, M.; Li, G. Chloride Ion Binding Capacity and Mechanistic Study of OPC-GGBS Cement-Based Repair Materials. Mater. Repor. 2025, 1–12. Available online: https://link.cnki.net/urlid/50.1078.TB.20250520.1110.016 (accessed on 20 May 2025). (In Chinese).

- GB/T 1346-2024; Test Methods for Water Requirement of Standard Consistency, Setting Time and Soundness of the Portland Cement. Standards Press of China: Beijing, China, 2024.

- GB/T 17671-2021; Test Method of Cement Mortar Strength (ISO Method). Standards Press of China: Beijing, China, 2021.

- JGJ/T 299-2013; Technical Code for In-Site Testing of Building Waterproof Engineering. China Architecture & Building Press: Beijing, China, 2013.

- GB 23439-2017; Expansive Agents for Concrete. Standards Press of China: Beijing, China, 2017.

- GB/T 12959-2024; Test Methods for Heat of Hydration of Cement. Standards Press of China: Beijing, China, 2024.

- GB/T 50082-2024; Standard for Test Methods of Long-Term Performance and Durability of Concrete. China Architecture & Building Press: Beijing, China, 2024.

- Zhang, G.; Yang, Y.; Yang, H.; Li, H. Calcium sulphoaluminate cement used as mineral accelerator to improve the property of Portland cement at sub-zero temperature. Cem. Concr. Compos. 2020, 106, 103452. [Google Scholar] [CrossRef]

- Vahid, S.; Oveys, G.; Amin, G.; Mahdi, H.; Majid, M. Slant shear tests and fuzzy logic integration for evaluating shear bond strength in SCC and FRSCC repair applications. Case Stud. Constr. Mater. 2025, 22, e04176. [Google Scholar] [CrossRef]

- Liu, L.; Liu, Y.; Luo, Q.; Wang, J.; Yi, P.; Xie, X.; Xing, F. Investigation into the effect of sulfoaluminate cement on compressive strength and impermeability of Portland cement with alkali-free accelerator at low temperatures. J. Build. Eng. 2025, 101, 111948. [Google Scholar] [CrossRef]

- Zhang, J.; Li, G.; Yang, X.; Ren, S.; Song, Z. Study on a high strength ternary blend containing calcium sulfoaluminate cement/calcium aluminate cement/ordinary Portland cement. Constr. Build. Mater. 2018, 191, 544–553. [Google Scholar] [CrossRef]

- Xu, Y.; He, T.; Ma, X.; Luo, R. The influence of calcium sulphoaluminate cement on the hydration process of cement paste mixed with alkali free liquid accelerator. Mater. Today Commun. 2022, 33, 104622. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).