Study on Mechanical Properties of Coarse-Fine Polypropylene Fiber Blended Concrete

Abstract

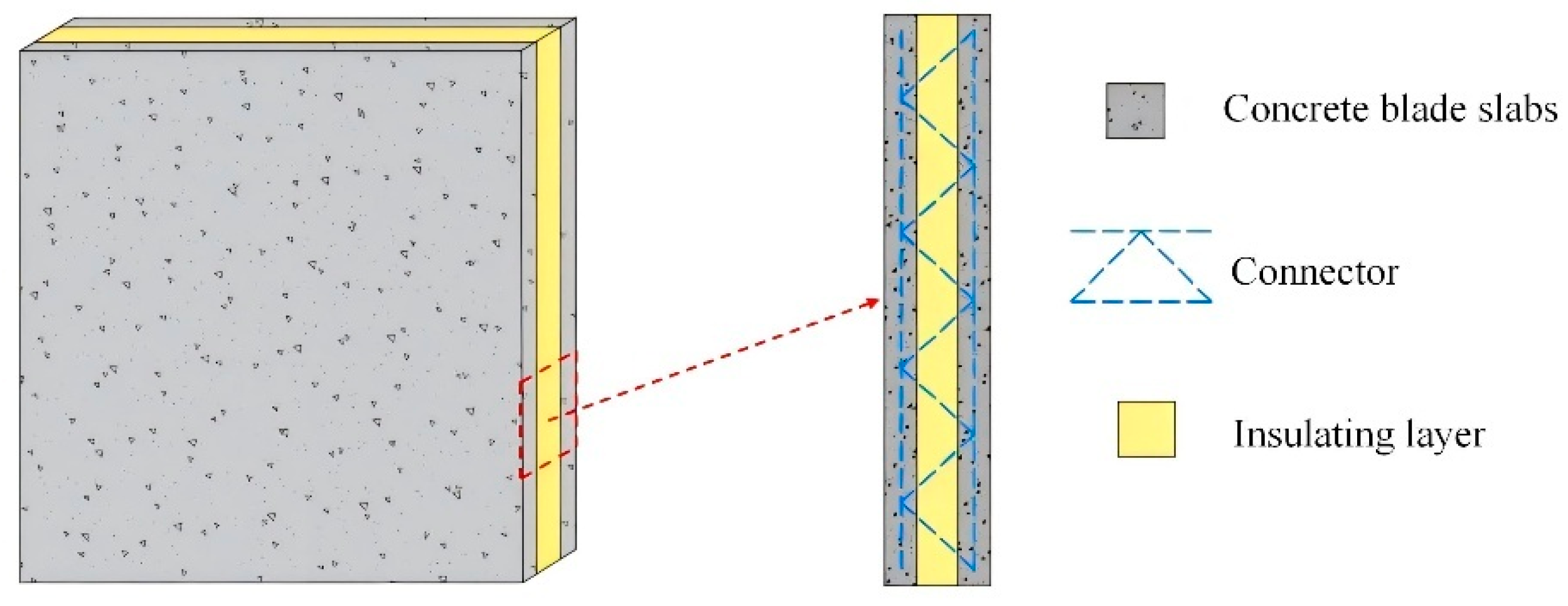

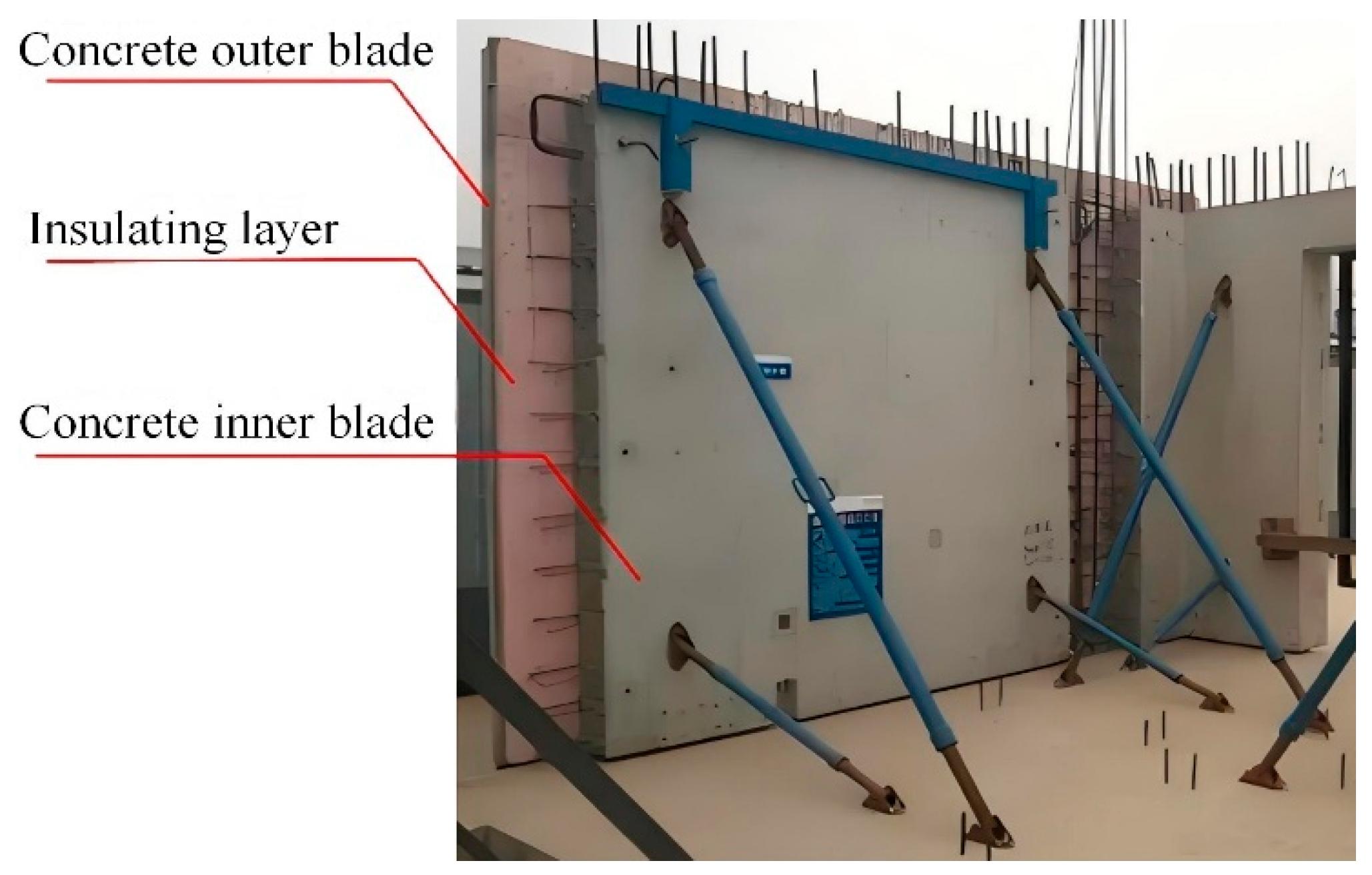

1. Introduction

2. Specimen Design and Grouping

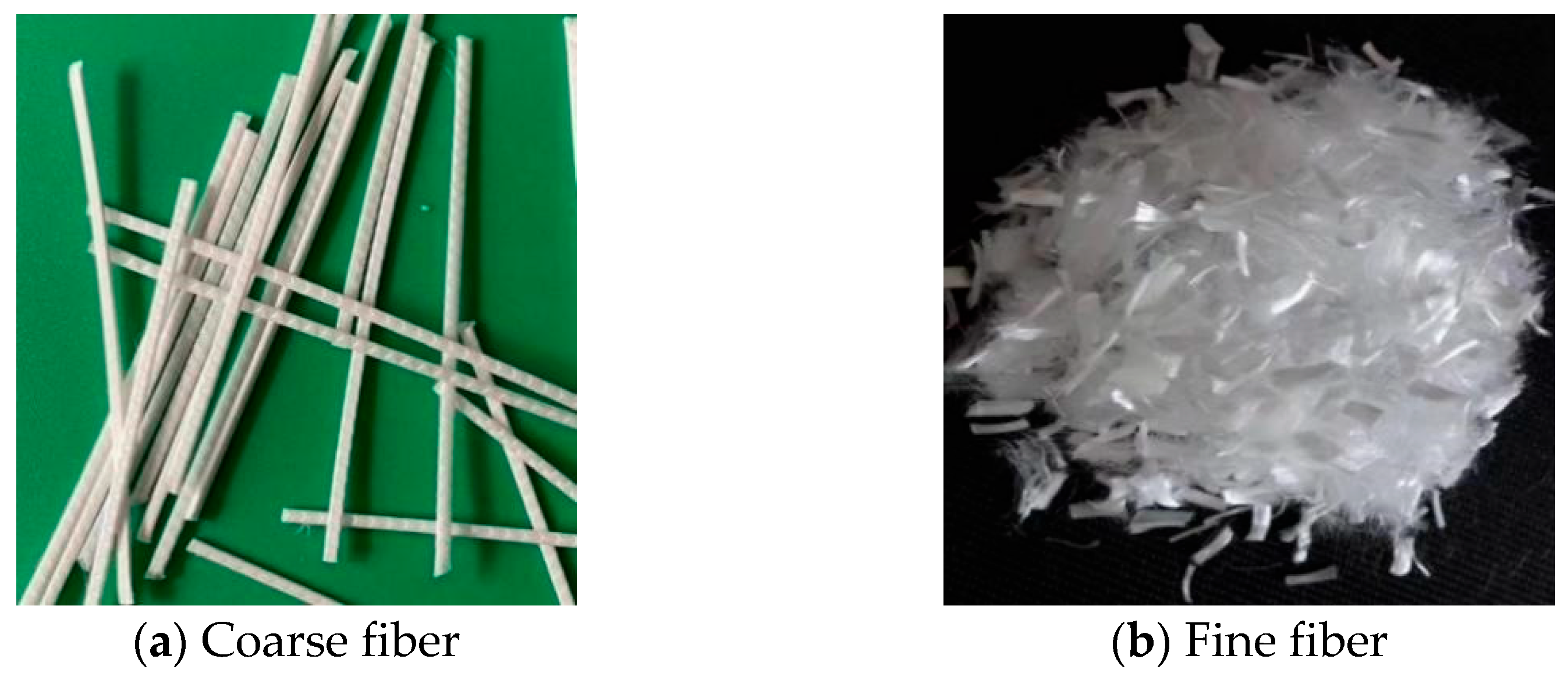

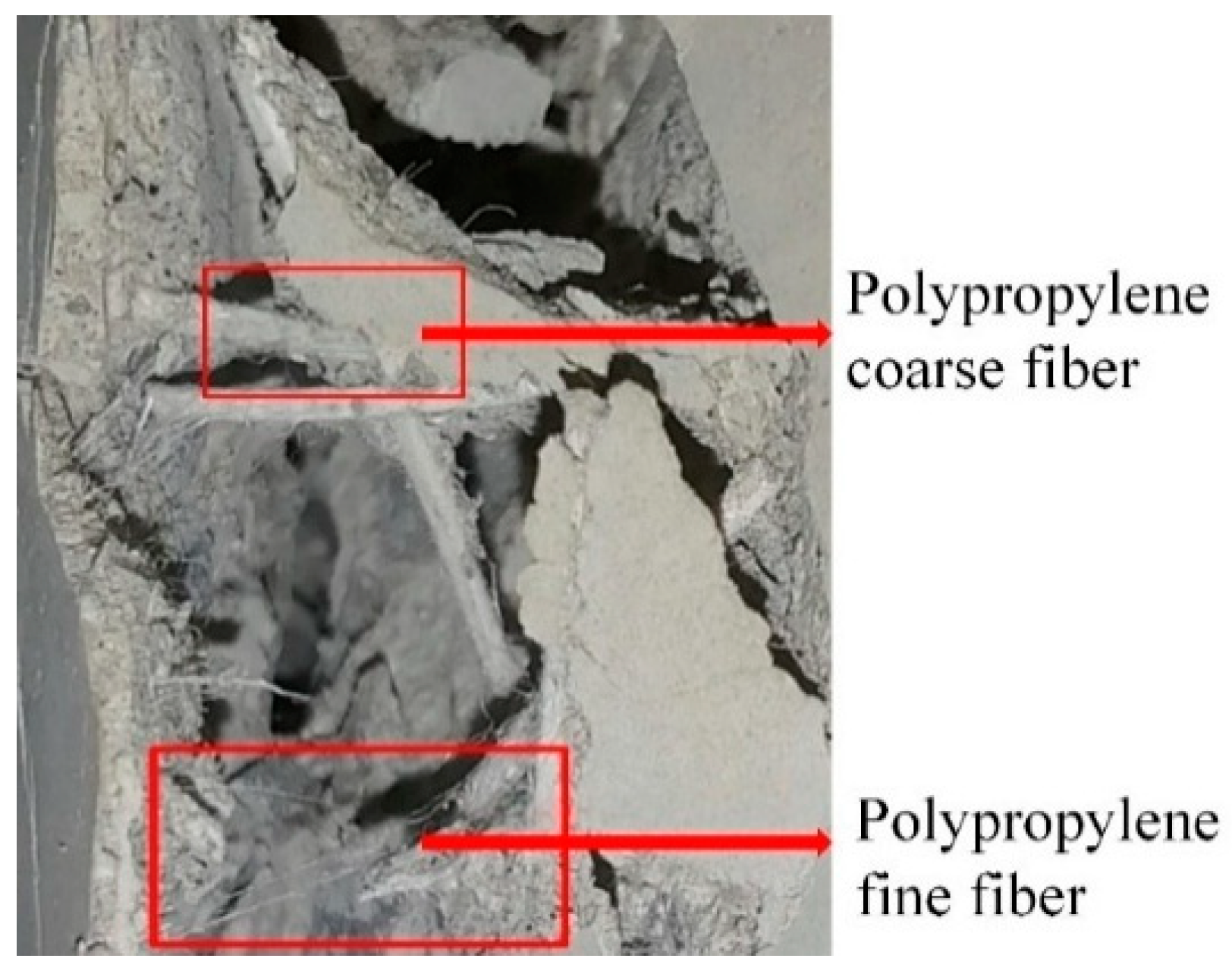

2.1. Fiber and Concrete

2.2. Sample Design

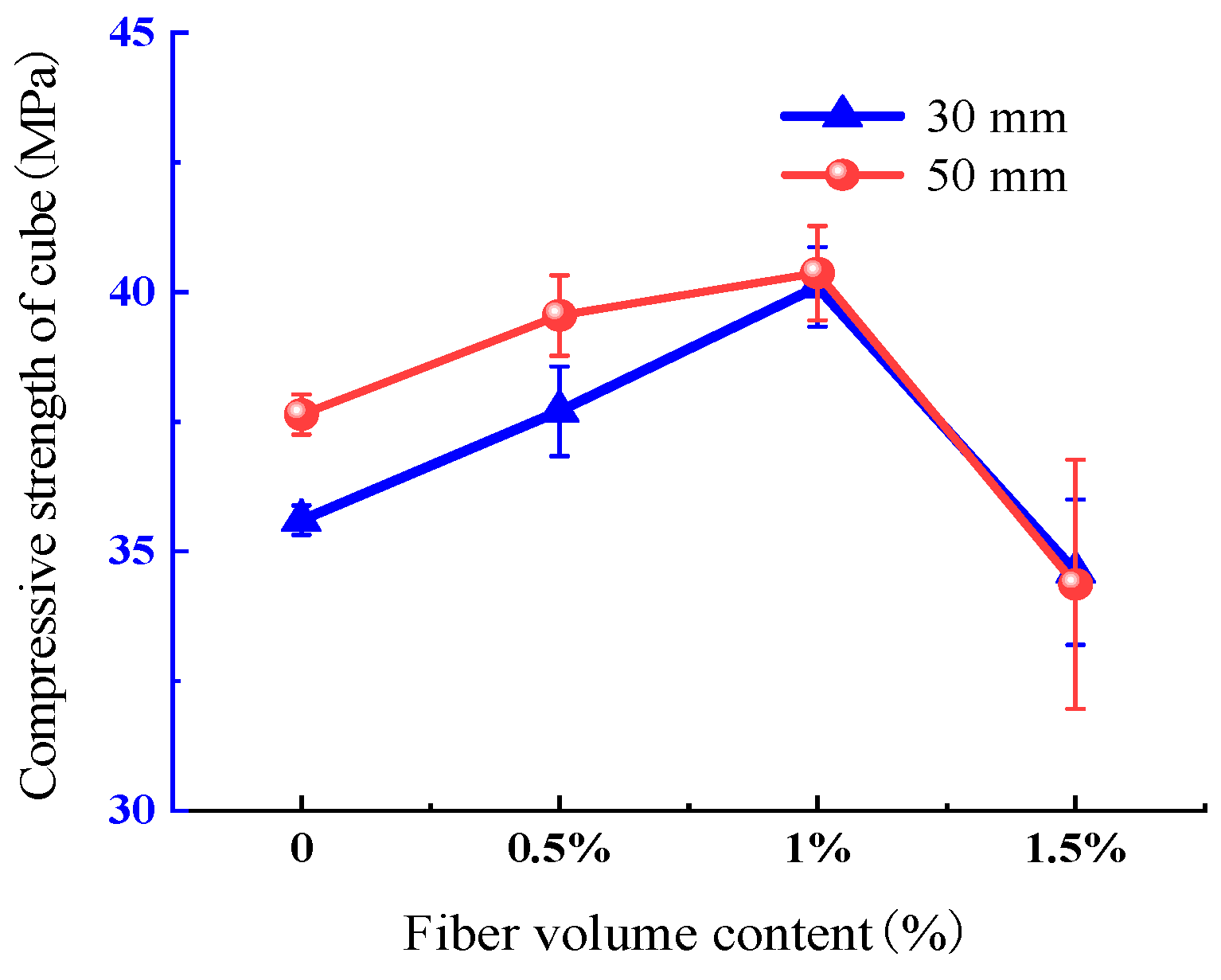

3. Cube Compressive Strength Test

3.1. Cube Compression Test Procedure

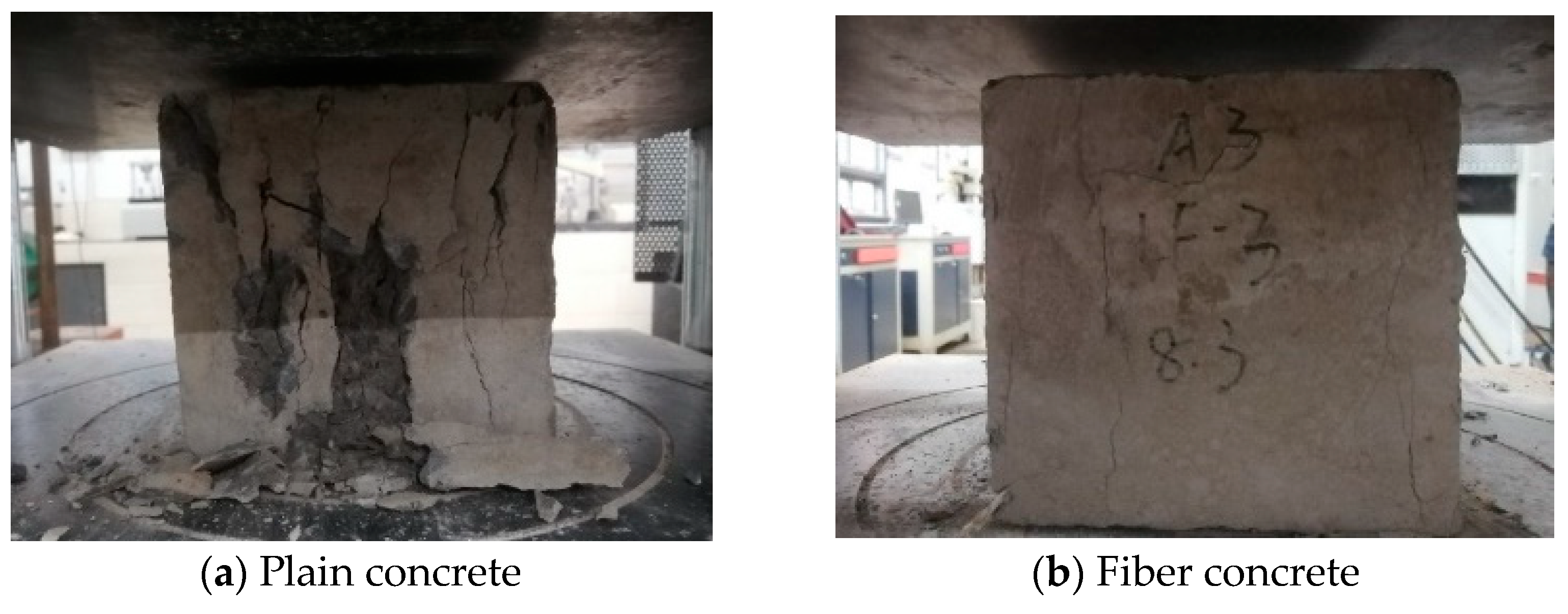

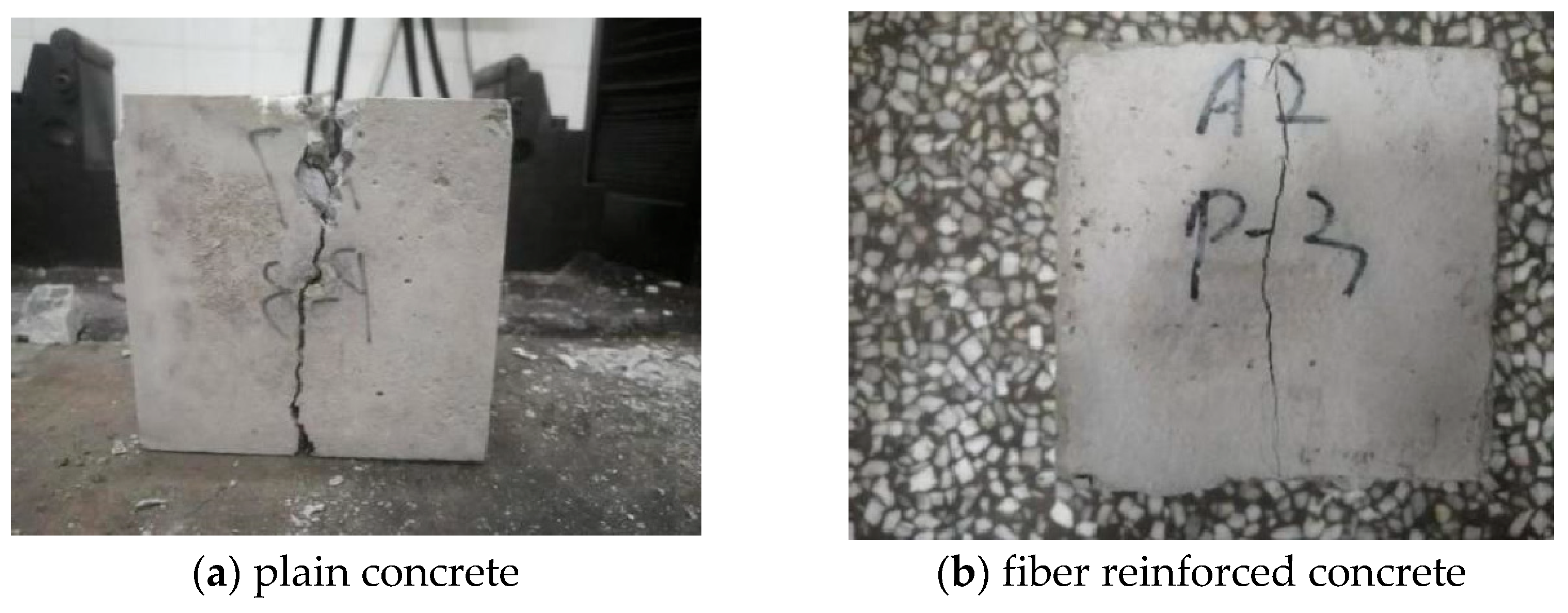

3.2. Cube Compression Failure Pattern

3.3. Cube Compression Test Results

4. Splitting Tensile Strength Test

4.1. Splitting Test Procedure

4.2. Splitting Failure Pattern

4.3. Splitting Test Results

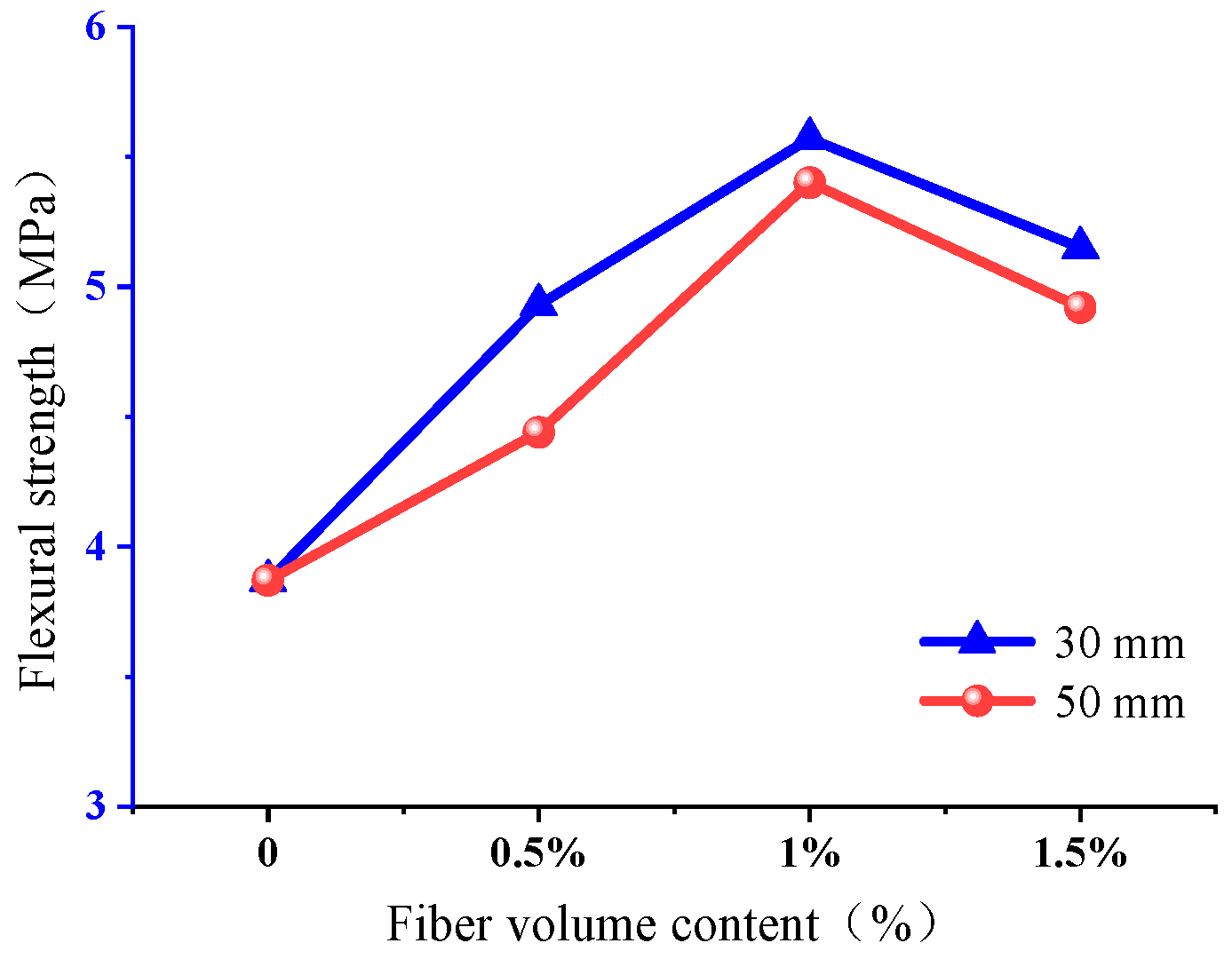

5. Flexural Strength Test

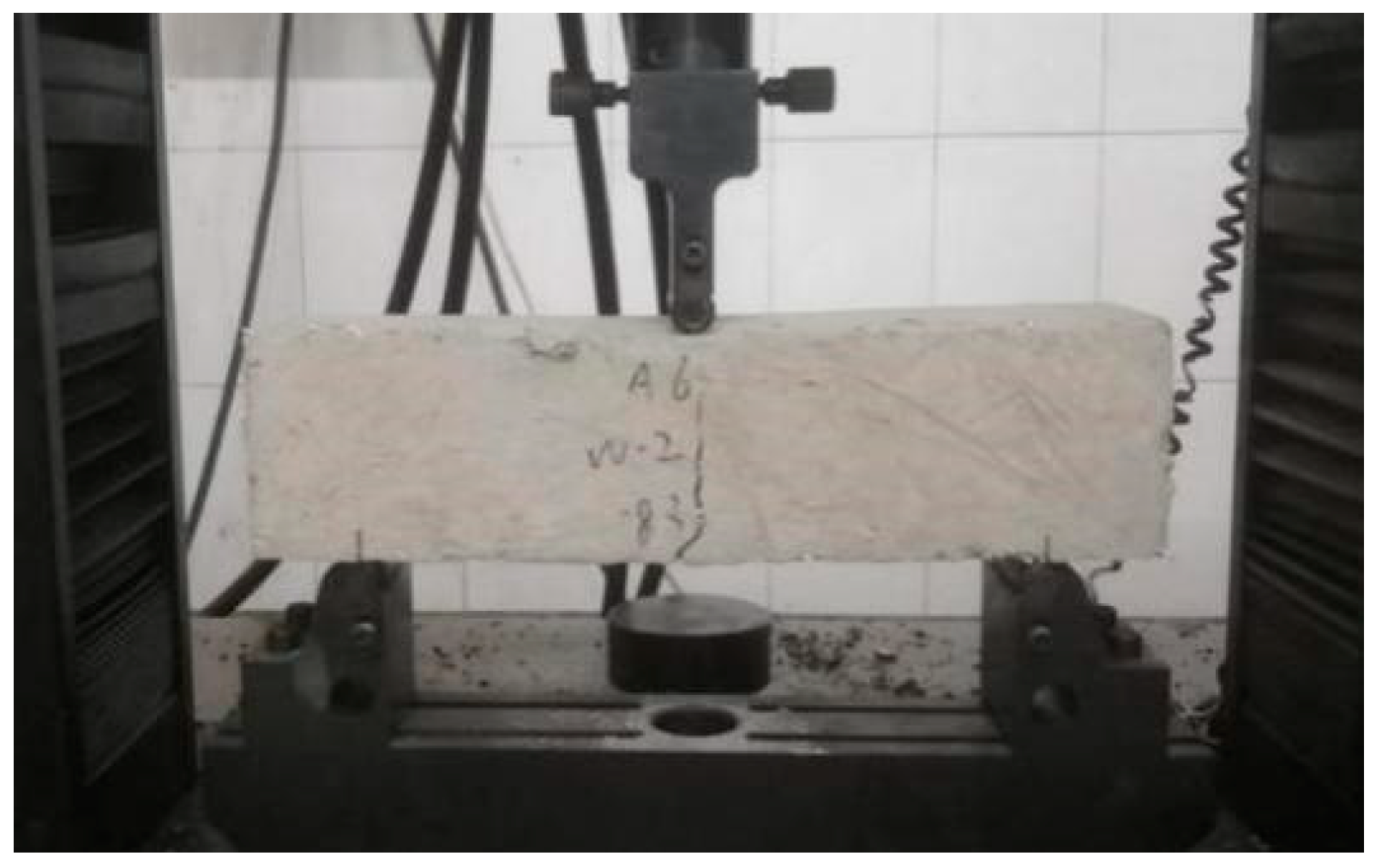

5.1. Flexural Test Procedure

5.2. Flexural Failure Pattern

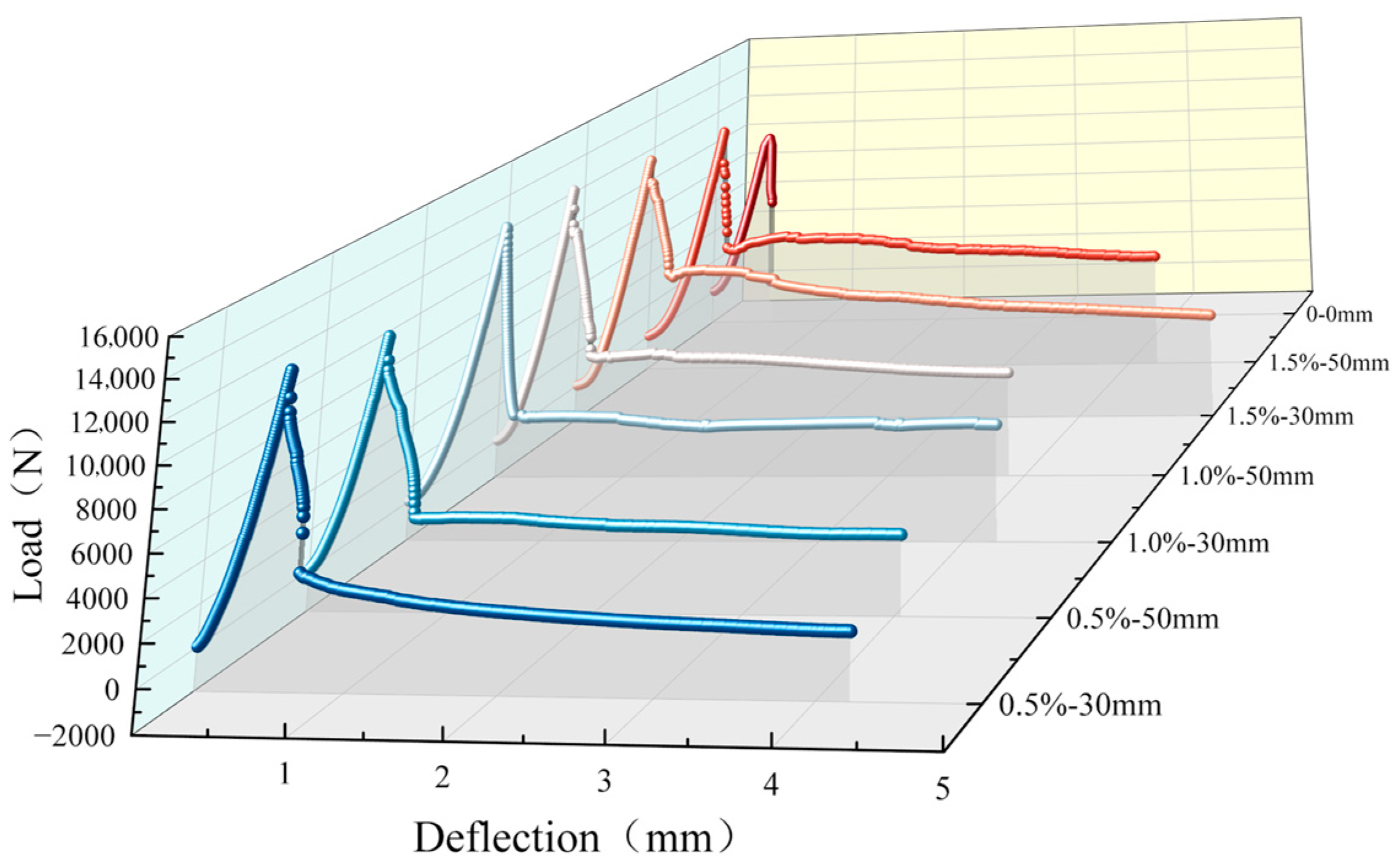

5.3. Load-Deflection Curve

5.4. Flexural Test Results

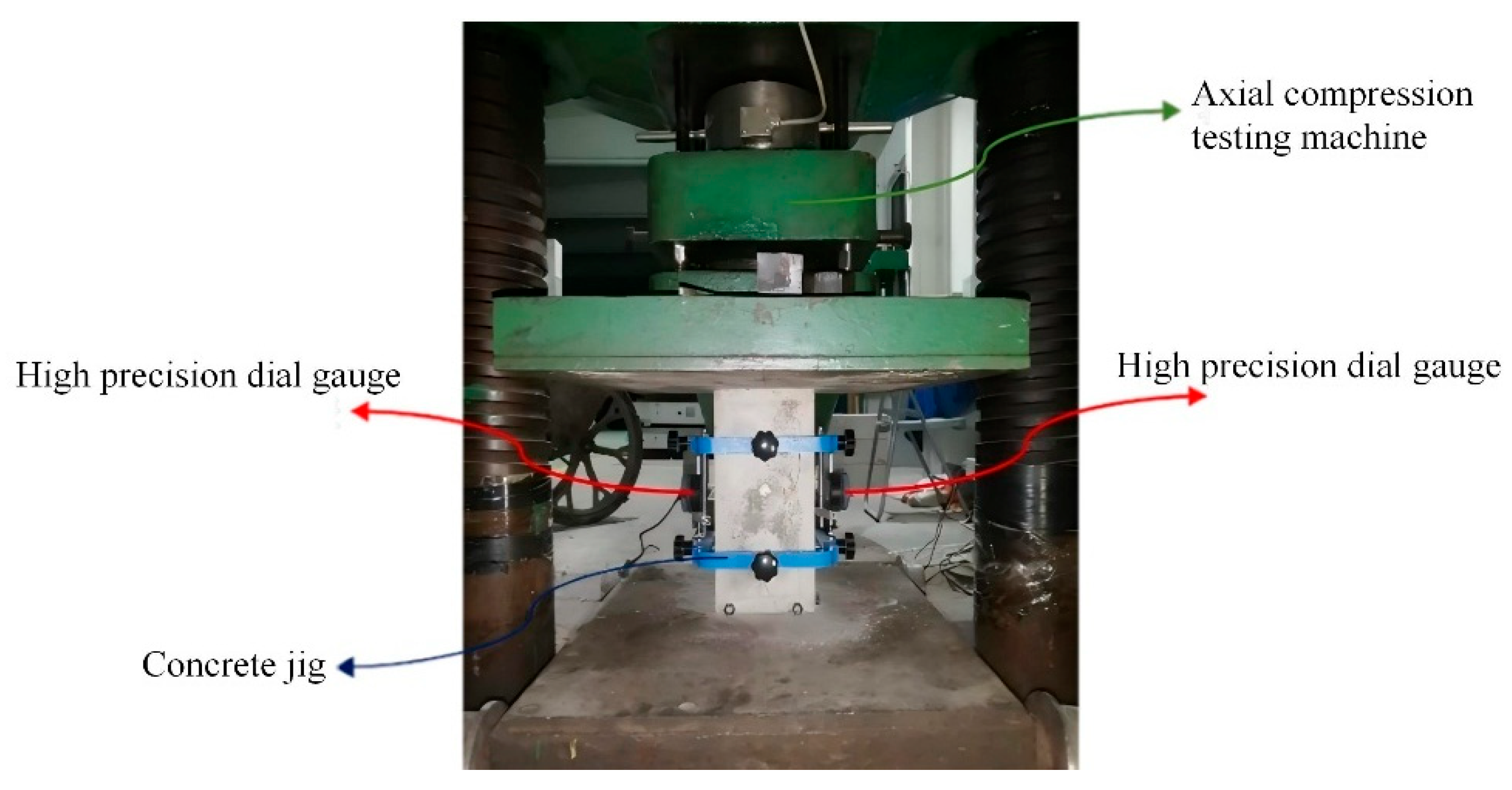

6. Axial Compressive Stress-Strain Curve Test

6.1. Test Procedure

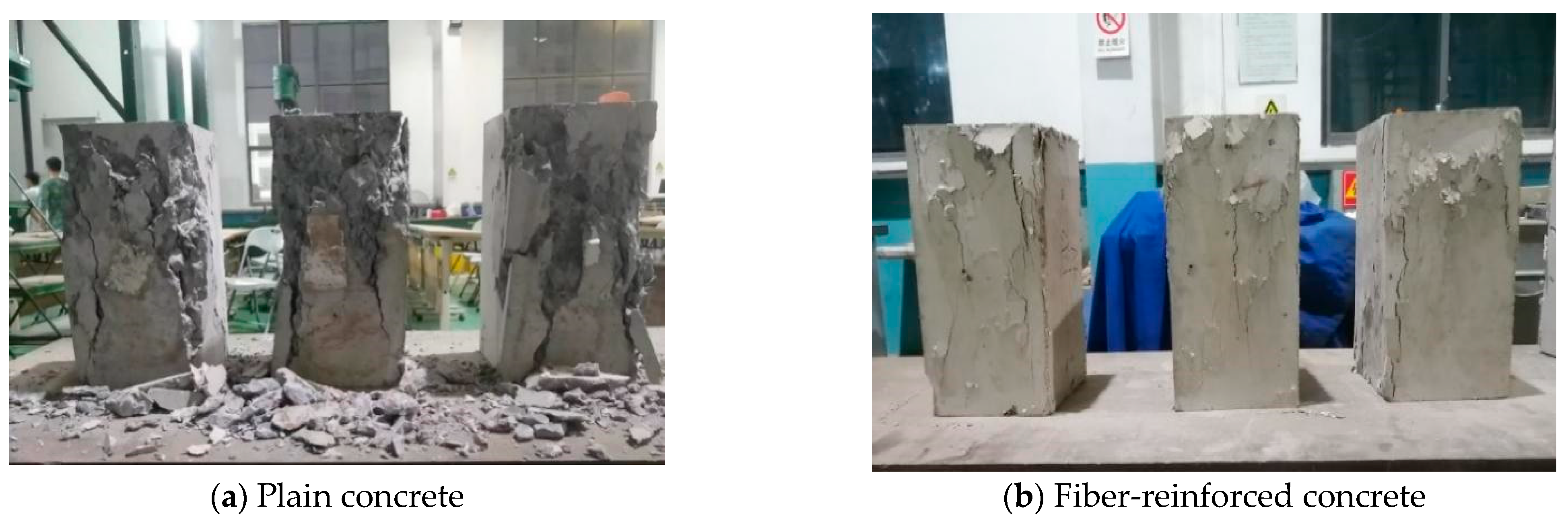

6.2. Failure Pattern Under Axial Compression

6.3. Test Results

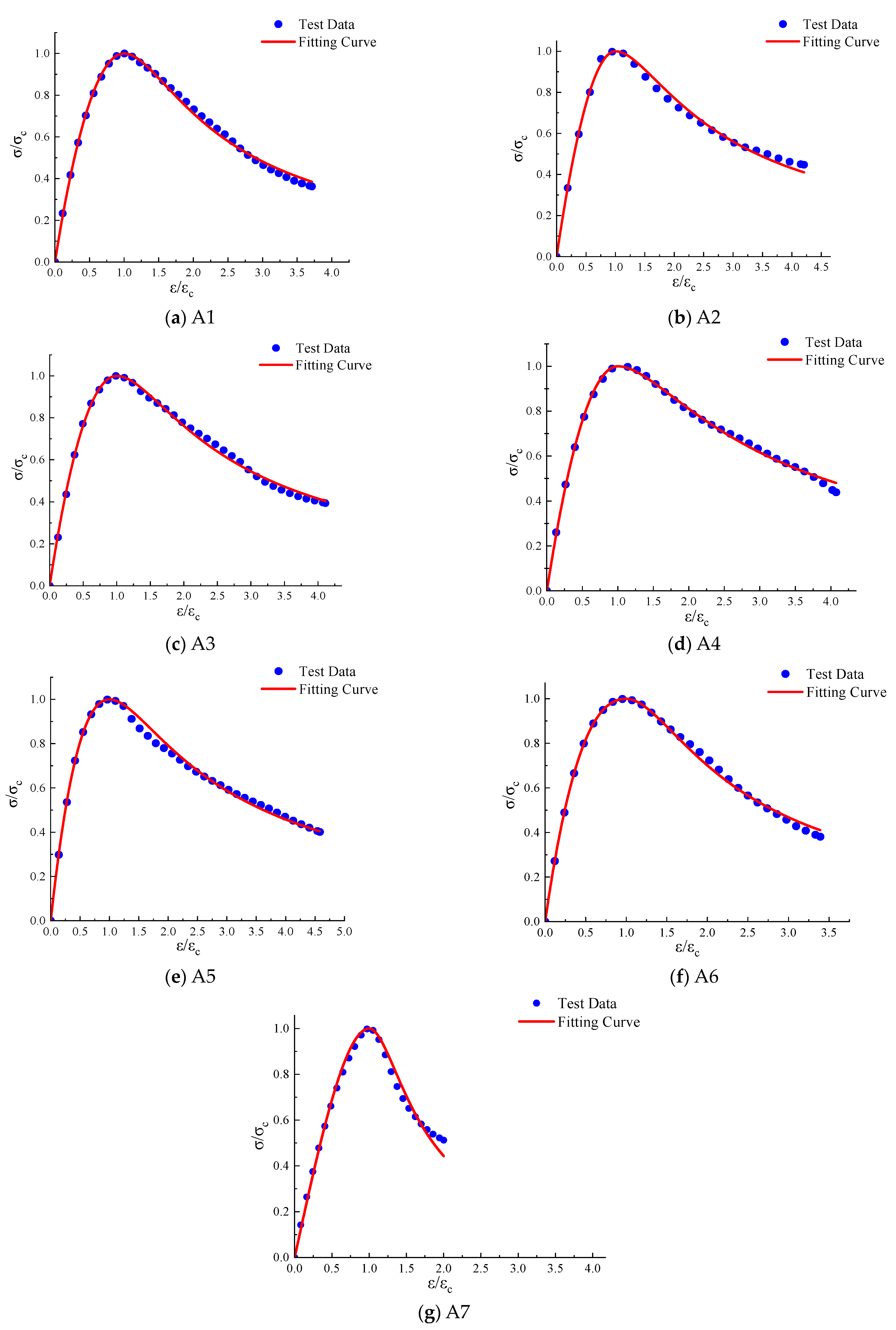

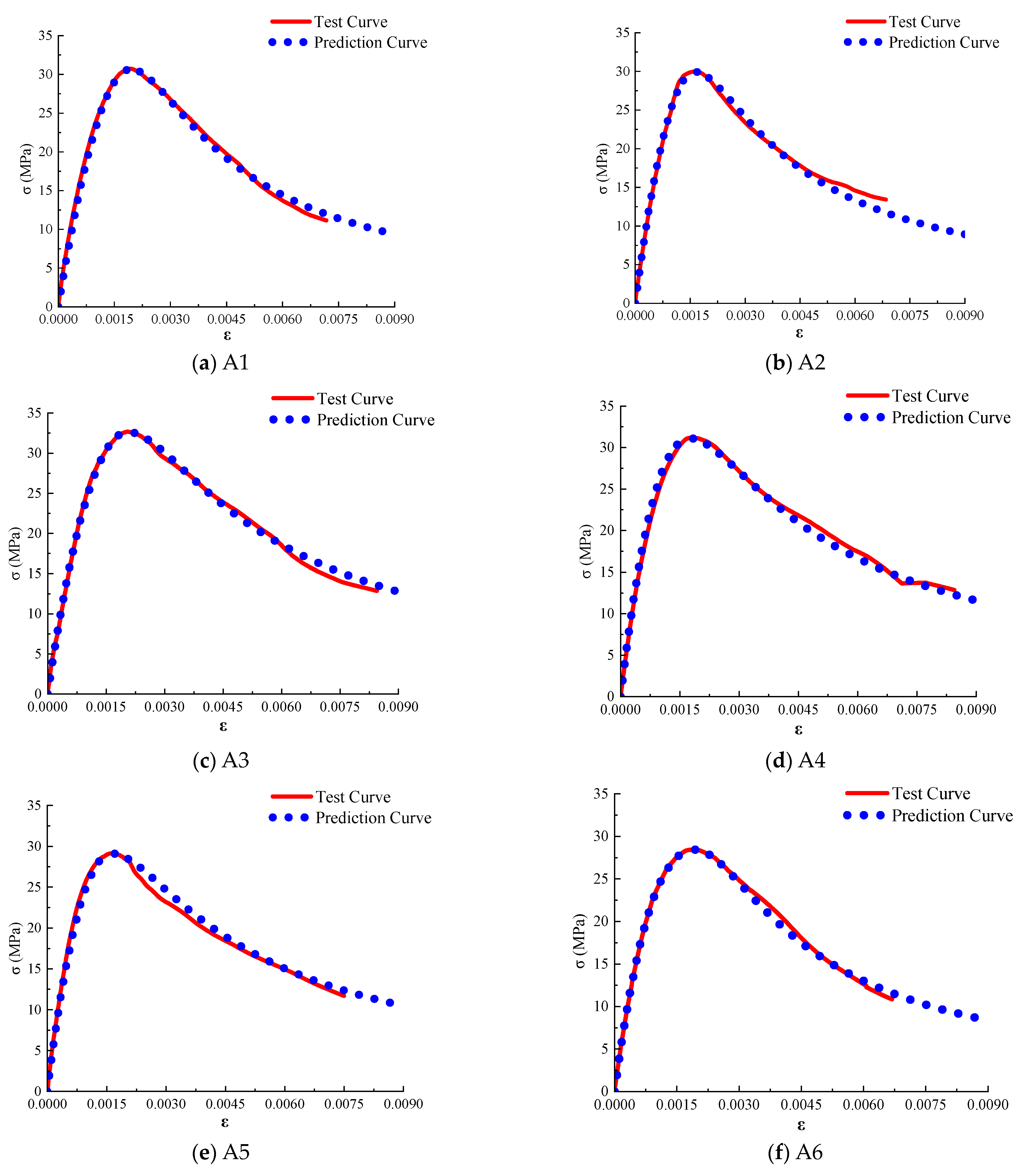

6.4. Fitting of the Axial Compressive Stress–Strain Curve

7. Conclusions

- (1)

- Under uniaxial loading, plain concrete specimens exhibited typical brittle failure characterized by rapid crack propagation and significant spalling. In contrast, fiber-reinforced concrete specimens maintain integrity due to the crack-bridging effect of the fibers, which effectively controls the crack width and results in a “cracked but not crushed” failure mode, thereby achieving notable crack resistance and toughness enhancement.

- (2)

- The experimental results indicate that the mechanical properties of concrete initially increase and then decrease with increasing fiber content. Within the range studied, when the coarse fiber content was 1% and the fiber length was 30 mm, the compressive strength, splitting tensile strength, and flexural strength of the specimens increased by 12.6%, 29.8%, and 44.5%, and each index of concrete specimen reached its best. Respectively, compared to plain concrete. However, when the fiber content was increased to 1.5%, agglomeration phenomena occurred, leading to a marked deterioration in the overall performance.

- (3)

- In flexural tests, plain concrete specimens exhibited sudden brittle fracture, whereas fiber-reinforced specimens were able to maintain structural continuity after the appearance of mid-span cracks due to the bridging action of the fibers. The residual strength increased with fiber content, which clearly demonstrates the significant improvement in ductility and crack resistance imparted by the fibers, thereby verifying the potential application of polypropylene fiber-reinforced concrete in sandwich wall panels and similar structures.

- (4)

- Based on existing segmented stress–strain equations for concrete, a model for the axial compression curve of polypropylene fiber-reinforced concrete was developed. Using the least-squares method, the relationship between the shape parameter, axial compressive strength, and fiber characteristic value was established. The model predictions, when compared with experimental data, showed excellent agreement, indicating that the proposed shape parameter formulation and corresponding curve model can accurately predict the axial stress–strain behavior of polypropylene fiber-reinforced concrete.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Correction Statement

References

- Song, S.; Chen, G.; Li, P.; Zhao, Y.; Zhang, T.; Bao, H.; Xiong, G.; Zhao, X. Investigation into wind resistance performance of cable-stiffened spherical latticed shells. J. Constr. Steel Res. 2025, 229, 109507. [Google Scholar] [CrossRef]

- Liu, G.; Gu, T.; Xu, P.; Hong, J.; Shrestha, A.; Martek, I. A production line–based carbon emission assessment model for prefabricated components in China. J. Clean. Prod. 2019, 212, 123–134. [Google Scholar] [CrossRef]

- General Office of the State Council of China. Guiding Opinions on Vigorously Developing Prefabricated Buildings; [State Council Document No. 71, 2016]; General Office of the State Council: Beijing, China, 2016. [Google Scholar]

- Mustafaraj, E.; Yardim, Y.; Corradi, M.; Perenchio, W.R. Polypropylene as a retrofitting material for shear walls. Materials 2020, 13, 2503. [Google Scholar] [CrossRef]

- Salmon, D.; Einea, A. Partially composite sandwich panel deflections. J. Struct. Eng. 1995, 121, 778–783. [Google Scholar] [CrossRef]

- Joseph, J.; Prabakar, J. Insulated precast concrete sandwich panels under punching and flexural actions. PCI J. 2019, 64, 68–79. [Google Scholar] [CrossRef]

- Ashraf, A.; Nibras, M. Reactive powder concrete sandwich panels with mechanical connection approach. In Proceedings of the 2018 International Conference on Advance of Sustainable Engineering and its Application, Wasit, Iraq, 14–15 March 2018; pp. 121–125. [Google Scholar]

- Benayoune, A.; Aziz, A.; Samad, A.; Trikha, D.; Ali, A.A.A. Structural behaviour of eccentrically loaded precast sandwich panels. Constr. Build. Mater. 2005, 20, 647–656. [Google Scholar] [CrossRef]

- Benayoune, A.; Samad, A.A.; Trikha, D.; Ali, A.A.; Ellinna, S. Flexural behaviour of precast concrete sandwich composite panels: Experimental and theoretical investigations. Constr. Build. Mater. 2008, 22, 580–592. [Google Scholar] [CrossRef]

- Li, X.W. Experimental study on basic and early mechanical properties of different fiber-reinforced concrete. J. Anhui Univ. Sci. Technol. 2017, 32, 45–52. [Google Scholar]

- Yang, X.; Liang, N.; Hu, Y.; Feng, R. An experimental study of shear resistance for multisize polypropylene fiber concrete beams. Int. J. Concr. Struct. Mater. 2021, 15, 52. [Google Scholar] [CrossRef]

- Hameed, R.; Turatsinze, A.; Duprat, F.; Sellier, A. A study on the reinforced fibrous concrete elements subjected to uniaxial tensile loading. KSCE J. Civ. Eng. 2010, 14, 547–556. [Google Scholar] [CrossRef]

- Kim, D.J.; Park, S.H.; Ryu, G.S.; Koh, K.T. Comparative flexural behavior of hybrid ultra high performance fiber reinforced concrete with different macro fibers. Constr. Build. Mater. 2011, 25, 4144–4152. [Google Scholar] [CrossRef]

- Dawood, E.T.; Ramli, M. High strength characteristics of cement mortar reinforced with hybrid fibres. Constr. Build. Mater. 2011, 25, 2240–2247. [Google Scholar] [CrossRef]

- Dawood, E.T.; Ramli, M. Durability of high strength flowing concrete with hybrid fibres. Constr. Build. Mater. 2012, 35, 521–530. [Google Scholar] [CrossRef]

- Ahmad, H.; Sheikh, M.N.S.; Hadi, M. Behaviour of GFRP bar-reinforced hollow-core polypropylene fiber and glass fiber concrete columns under axial compression. J. Build. Eng. 2021, 44, 103245. [Google Scholar] [CrossRef]

- Cui, K.; Xu, L.; Li, X.; Hu, X.; Huang, L.; Deng, F.; Chi, Y. Fatigue life analysis of polypropylene fiber reinforced concrete under axial constant-amplitude cyclic compression. J. Clean. Prod. 2021, 319, 128610. [Google Scholar] [CrossRef]

- Zhou, X.; Zeng, Y.; Chen, P.; Jiao, Z.; Zheng, W. Mechanical properties of basalt and polypropylene fibre-reinforced alkali-activated slag concrete. Constr. Build. Mater. 2021, 269, 121284. [Google Scholar] [CrossRef]

- Liu, J.; Jia, Y.; Wang, J. Experimental study on mechanical and durability properties of glass and polypropylene fiber reinforced concrete. Fibers Polym. 2019, 20, 1928–1936. [Google Scholar] [CrossRef]

- Wang, H.; He, X.; Zhou, M.; Wei, B.; Wu, W.; Zhou, G.; He, J. A study on the tensile fracture behavior of polypropylene fiber reinforced concrete based on a microscale model. Constr. Build. Mater. 2024, 417, 135291. [Google Scholar] [CrossRef]

- Song, P.S.; Hwang, S.; Sheu, B.C. Strength properties of nylon- and polypropylene-fiber-reinforced concretes. Cem. Concr. Res. 2005, 35, 1546–1550. [Google Scholar] [CrossRef]

- Kakooei, S.; Akil, H.M.; Jamshidi, M.; Soroushian, P. The effects of polypropylene fibers on the properties of reinforced concrete structures. Constr. Build. Mater. 2012, 30, 814–825. [Google Scholar] [CrossRef]

- Ministry of Industry and Information Technology of China. GB 175-2023; Common Portland Cement. China Standards Press: Beijing, China, 2023.

- Ministry of Housing and Urban-Rural Development of China. JGJ/T 221-2010; Technical Specification for Application of Fiber Reinforced Concrete. China Architecture & Building Press: Beijing, China, 2011.

- China Association for Engineering Construction Standardization. CECS 13:2009; Standard Test Methods for Fiber Reinforced Concrete. China Planning Press: Beijing, China, 2009.

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. GB/T 50081-2019; Standard for Test Methods of Concrete Physical Andmechanical Properties. China Planning Press: Beijing, China, 2009.

- Zhou, L.J.; Ren, X.D.; Li, J. Experimental technique for uniaxial tensile dynamic constitutive relation of concrete. Struct. Eng. 2016, 32, 163–168. [Google Scholar]

- Zhang, Y. Study on Mechanical Properties and Damage Failure Modes of Polypropylene Fiber Reinforced Concrete. Master’s Thesis, Xi’an University of Technology, Xi’an, China, 2019. [Google Scholar]

- China Association for Engineering Construction Standardization. CECS 38:2004; Technical Specification for Fiber Reinforced Concrete Structures. China Planning Press: Beijing, China, 2004.

- Li, L.; Li, X.Z.; Wang, B.Y.; Tao, J.C.; Shi, K. A review on interfacial bonding behavior between fiber and concrete. J. Build. Eng. 2025, 105, 112455. [Google Scholar] [CrossRef]

- Lan, F. Study on the Influence of Coarse Polypropylene-Basalt Fiber on Bearing Capacity of Concrete Pipes. Master’s Thesis, Chongqing University: Chongqing, China, 2021. [Google Scholar]

- Hao, Y.F.; Yang, G.Z.; Liang, K.K. Development of fly ash and slag based high-strength alkali-activated foam concrete. Cem. Concr. Compos. 2022, 128, 104447. [Google Scholar] [CrossRef]

- Guo, Z.H. Strength and Constitutive Relationship of Concrete: Principles and Applications; China Architecture & Building Press: Beijing, China, 2004. [Google Scholar]

- Liu, Y.; Chen, B.; Liu, X.; Liu, C.; Miao, J.; Weng, C.; Luo, Y. Experimental study on bond performance between corroded reinforcement and basalt-polypropylene fiber reinforced concrete after high temperature. Constr. Build. Mater. 2025, 474, 140944. [Google Scholar] [CrossRef]

| Fiber Type | Length/mm | Diameter/μm | Density/(g·cm−3) | Fusing Point/°C | Tensile Strength/MPa | Modulus of Elasticity/GPa | Elongation at Break/% | Alkali Resistance/% |

|---|---|---|---|---|---|---|---|---|

| Coarse fiber | 30/50 | 1000 | 0.91 | 174 | 627.9 | 10 | 6.3 | 98.9 |

| Fine fiber | 12 | 27 | 0.91 | 168 | 625 | 5.2 | 22 | 99 |

| Specific Surface Area/(m2·kg−1) | Setting Time/min | Compressive Strength/MPa | Flexural Strength/MPa | |||

|---|---|---|---|---|---|---|

| Initial Set | Final Set | 3d | 28d | 3d | 28d | |

| 350 | 95 | 150 | 28.5 | 49.3 | 5.6 | 7.9 |

| Experimental Group | Water | Cement | Sand | Gravel | Coarse and Fine Fiber Content Volume Rate/(%) | Coarse and Fine Fibers Length/(mm) |

|---|---|---|---|---|---|---|

| 1 | 240 | 453 | 553 | 1124 | 0.5% + 0.1% | 30 + 12 |

| 2 | 240 | 453 | 553 | 1124 | 0.5% + 0.1% | 50 + 12 |

| 3 | 240 | 453 | 553 | 1124 | 1% + 0.1% | 30 + 12 |

| 4 | 240 | 453 | 553 | 1124 | 1% + 0.1% | 50 + 12 |

| 5 | 240 | 453 | 553 | 1124 | 1.5% + 0.1% | 30 + 12 |

| 6 | 240 | 453 | 553 | 1124 | 1.5% + 0.1% | 50 + 12 |

| 7 | 240 | 453 | 553 | 1124 | — | — |

| Test | Specimen Size/(mm) | Sample | Curing Method | Maintenance Completed or Not |

|---|---|---|---|---|

| Cube Compressive Strength | 150 × 150 × 150 | 3 | Natural curing | Yes |

| Axial Compressive Stress–Strain Curve | 150 × 150 × 300 | 3 | Natural curing | Yes |

| Splitting Tensile Strength | 100 × 100 × 100 | 3 | Natural curing | Yes |

| Flexural Strength | 100 × 100 × 400 | 3 | Natural curing | Yes |

| Sample Number | Fiber Content and Length (%-mm) | Compressive Strength (MPa) | Effective Compressive Strength (MPa) | Strength Growth Rate (%) |

|---|---|---|---|---|

| A1-1 | 0.5%-30 mm | 37.5 | 37.7 | 5.9 |

| A1-2 | 38.6 | |||

| A1-3 | 36.9 | |||

| A2-1 | 0.5%-50 mm | 37.6 | 37.0 | 3.9 |

| A2-2 | 36.5 | |||

| A2-3 | 36.8 | |||

| A3-1 | 1.0%-30 mm | 40.0 | 40.1 | 12.6 |

| A3-2 | 39.0 | |||

| A3-3 | 40.5 | |||

| A4-1 | 1.0%-50 mm | 38.0 | 37.6 | 5.6 |

| A4-2 | 37.9 | |||

| A4-3 | 36.8 | |||

| A5-1 | 1.5%-30 mm | 33.2 | 34.6 | −2.8 |

| A5-2 | 34.5 | |||

| A5-3 | 36.0 | |||

| A6-1 | 1.5%-50 mm | 31.6 | 33.2 | −6.7 |

| A6-2 | 33.0 | |||

| A6-3 | 35.1 | |||

| A7-1 | —— | 35.6 | 35.6 | — |

| A7-2 | 36.0 | |||

| A7-3 | 25.2 * |

| Sample Number | Fiber Content and Length (%-mm) | Tensile Strength (MPa) | Effective Tensile Strength (MPa) | Strength Growth Rate (%) |

|---|---|---|---|---|

| A1-1 | 0.5%-30 mm | 2.16 | 2.20 | 15.2 |

| A1-2 | 2.27 | |||

| A1-3 | 2.16 | |||

| A2-1 | 0.5%-50 mm | 2.00 | 2.04 | 6.8 |

| A2-2 | 2.07 | |||

| A2-3 | 2.47 | |||

| A3-1 | 1.0%-30 mm | 2.71 | 2.48 | 29.8 |

| A3-2 | 2.35 | |||

| A3-3 | 2.37 | |||

| A4-1 | 1.0%-50 mm | 2.23 | 2.20 | 15.2 |

| A4-2 | 2.21 | |||

| A4-3 | 2.15 | |||

| A5-1 | 1.5%-30 mm | 2.30 | 2.24 | 17.3 |

| A5-2 | 2.09 | |||

| A5-3 | 2.34 | |||

| A6-1 | 1.5%-50 mm | 1.98 | 1.94 | 1.6 |

| A6-2 | 1.71 | |||

| A6-3 | 2.14 | |||

| A7-1 | —— | 1.91 | 1.91 | — |

| A7-2 | 1.20 | |||

| A7-3 | 2.19 |

| Sample Number | Fiber Content and Length (%-mm) | Bending Strength (MPa) | Effective Bending Strength (MPa) | Strength Growth Rate (%) |

|---|---|---|---|---|

| A1-1 | 0.5%-30 mm | 3.19 | 3.39 | |

| A1-2 | 3.68 | 27.9 | ||

| A1-3 | 3.29 | |||

| A2-1 | 0.5%-50 mm | 3.15 | 3.05 | |

| A2-2 | 2.80 | 15.1 | ||

| A2-3 | 3.21 | |||

| A3-1 | 1.0%-30 mm | 3.94 | 3.83 | |

| A3-2 | 3.87 | 44.5 | ||

| A3-3 | 3.68 | |||

| A4-1 | 1.0%-50 mm | 3.65 | 3.71 | |

| A4-2 | 3.63 | 40 | ||

| A4-3 | 3.85 | |||

| A5-1 | 1.5%-30 mm | 3.43 | 3.54 | |

| A5-2 | 3.42 | 33.6 | ||

| A5-3 | 3.76 | |||

| A6-1 | 1.5%-50 mm | 3.23 | 3.38 | |

| A6-2 | 3.60 | 27.5 | ||

| A6-3 | 3.31 | |||

| A7-1 | —— | 2.75 | 2.65 | |

| A7-2 | 2.84 | |||

| A7-3 | 2.37 |

| Sample Number | Fiber Content and Length (%-mm) | Compressive Strength (MPa) | Strain at Peak Stress | Strength Growth Rate (%) |

|---|---|---|---|---|

| A1 | 0.5%-30 mm | 30.74 | 0.0019 | 8.1 |

| A2 | 0.5%-50 mm | 29.99 | 0.0016 | 5.3 |

| A3 | 1.0%-30 mm | 32.66 | 0.002 | 14.7 |

| A4 | 1.0%-50 mm | 31.15 | 0.0018 | 9.3 |

| A5 | 1.5%-30 mm | 29.15 | 0.0017 | 2.4 |

| A6 | 1.5%-50 mm | 28.44 | 0.0019 | −0.1 |

| A7 | —— | 28.48 | 0.0013 | — |

| A1 | A2 | A3 | A4 | A5 | A6 | A7 | |

|---|---|---|---|---|---|---|---|

| a | 2.10107 | 1.94614 | 2.11396 | 2.05696 | 2.45862 | 2.53379 | 1.50728 |

| b | 0.80674 | 0.58838 | 0.62717 | 0.46748 | 0.52681 | 0.85210 | 2.51253 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, P.; Huang, M.; Shang, Y.; Kuang, Y.; Xiong, G.; Tang, X. Study on Mechanical Properties of Coarse-Fine Polypropylene Fiber Blended Concrete. Buildings 2025, 15, 2971. https://doi.org/10.3390/buildings15162971

Li P, Huang M, Shang Y, Kuang Y, Xiong G, Tang X. Study on Mechanical Properties of Coarse-Fine Polypropylene Fiber Blended Concrete. Buildings. 2025; 15(16):2971. https://doi.org/10.3390/buildings15162971

Chicago/Turabian StyleLi, Pengcheng, Mingyao Huang, Yingying Shang, Yanwen Kuang, Gang Xiong, and Xinyi Tang. 2025. "Study on Mechanical Properties of Coarse-Fine Polypropylene Fiber Blended Concrete" Buildings 15, no. 16: 2971. https://doi.org/10.3390/buildings15162971

APA StyleLi, P., Huang, M., Shang, Y., Kuang, Y., Xiong, G., & Tang, X. (2025). Study on Mechanical Properties of Coarse-Fine Polypropylene Fiber Blended Concrete. Buildings, 15(16), 2971. https://doi.org/10.3390/buildings15162971