A Review on the Applications of Basalt Fibers and Their Composites in Infrastructures

Abstract

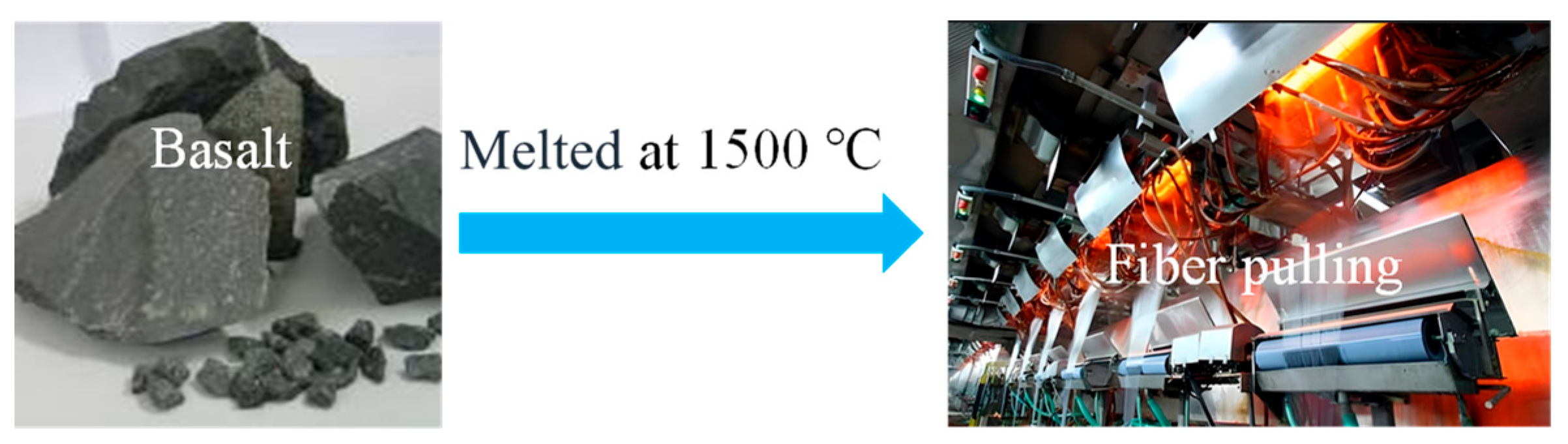

1. Introduction

- (1)

- BFRP has a fatigue strength ranging from 0.6 to 0.85 fu (fu is the static tensile strength) [4], which is slightly lower than CFRP (0.7 to 0.95 fu). It can be used to withstand dynamic loads, effectively improving the fatigue life of engineering structures.

- (2)

- BFRP has a creep rate of merely 3% when sustaining a 0.5 fu stress for 1000 h, and a one-million-hour creep rupture stress of 0.54 fu [5]. This creep rupture stress largely exceeds that of GFRP (0.29 fu). The one-thousand-hour relaxation rate of BFRP bars under an initial stress of 0.5 fu is only 2.6% [6], which is close to the corresponding value of ordinary steel strands.

- (3)

- BFRP has corrosion resistance, and high- and low-temperature resistance. Its strength and elastic modulus under ultraviolet irradiation change within 10%, and the predicted strength degradation in a marine environment for 100 years does not exceed 15% [7]. The strength retention rate reaches 50% at 500 °C [8], and the maximum working temperature of the composites made of specially developed basalt fibers can reach up to 1200 °C. In addition, the minimum working temperature ranges from −200 to −100 °C, depending on the resin matrix type. Furthermore, after 300 freeze–thaw cycles, the strength retention rate approximates 96% [9].

- (4)

- Similar to other types of FRP, BFRP has strong designability, which fulfills different engineering structural requirements through hybridization design with other fibers or steels.

- (5)

- The multi-function is also an attractive point of BFRP. It has a thermal conductivity of only 0.04 W/(m·K) [10], which is much lower than the value of steel equaling 48 W/(m·K). Thus, BFRP can be used as insulation building material. Additionally, the volume resistivity of BFRP is 1.5 × 1013 Ω·m, which realizes structural insulation without electromagnetic induction. The dielectric constant/dielectric loss is 2.61/0.0068, which can be used for transparent structures. Moreover, BFRP possesses low magnetic permeability equaling 4π × 10−8 H/m, which is only 1/10 of the value of low magnetic steel. Therefore, BFRP has potential in the application as electromagnetic interference (EMI) shielding. To sum up, BFRP can also be used as a functional material in non-structural members.

2. Applications of Basalt Fibers and Their Composites in Infrastructures

2.1. Concrete Structures Strengthened by BFRP Composites

2.1.1. Strengthening of Beams or Slabs Using Basalt Fiber Sheets or BFRP Laminates

2.1.2. Confinement of Columns

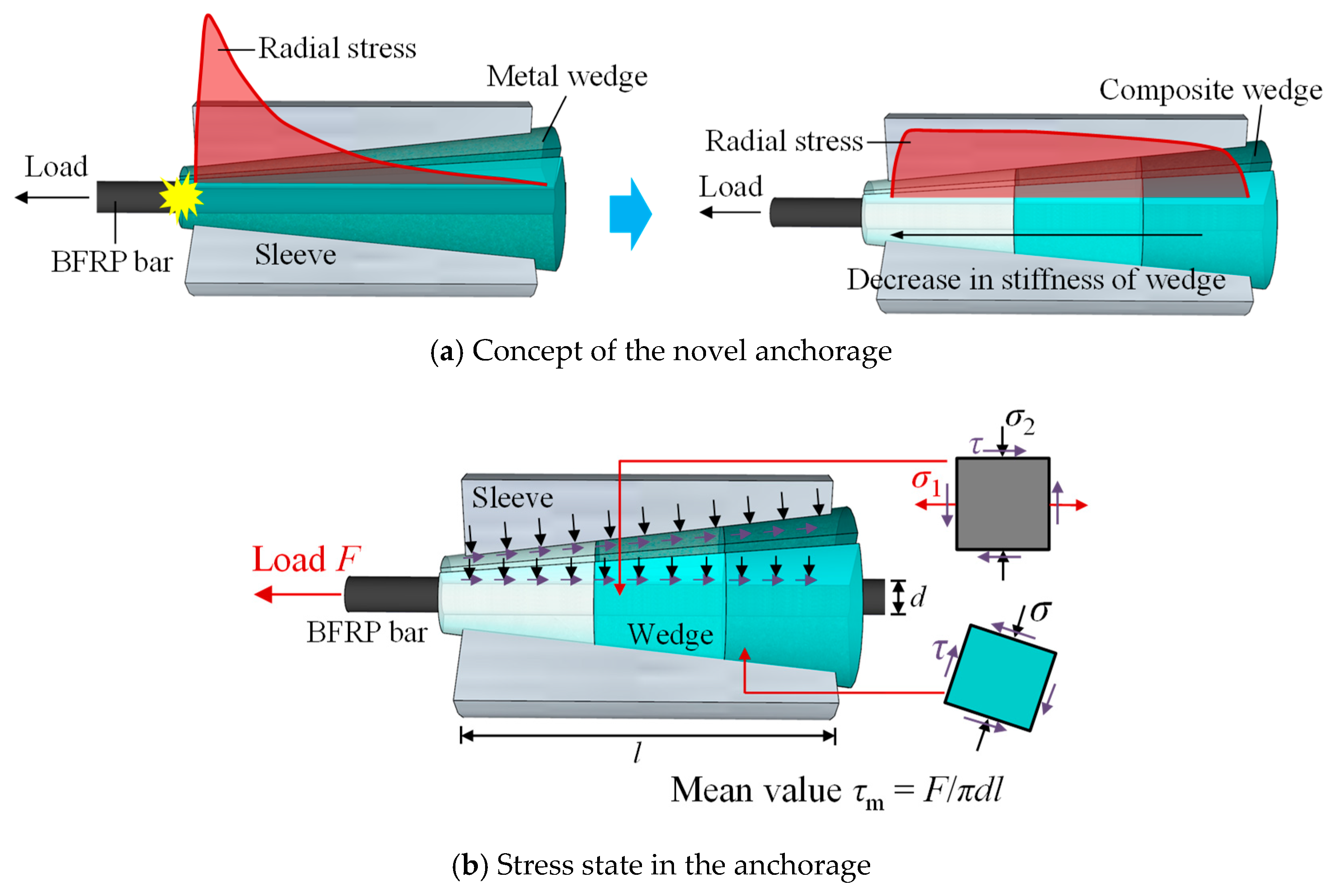

2.1.3. Strengthening via Prestressing BFRP Bars

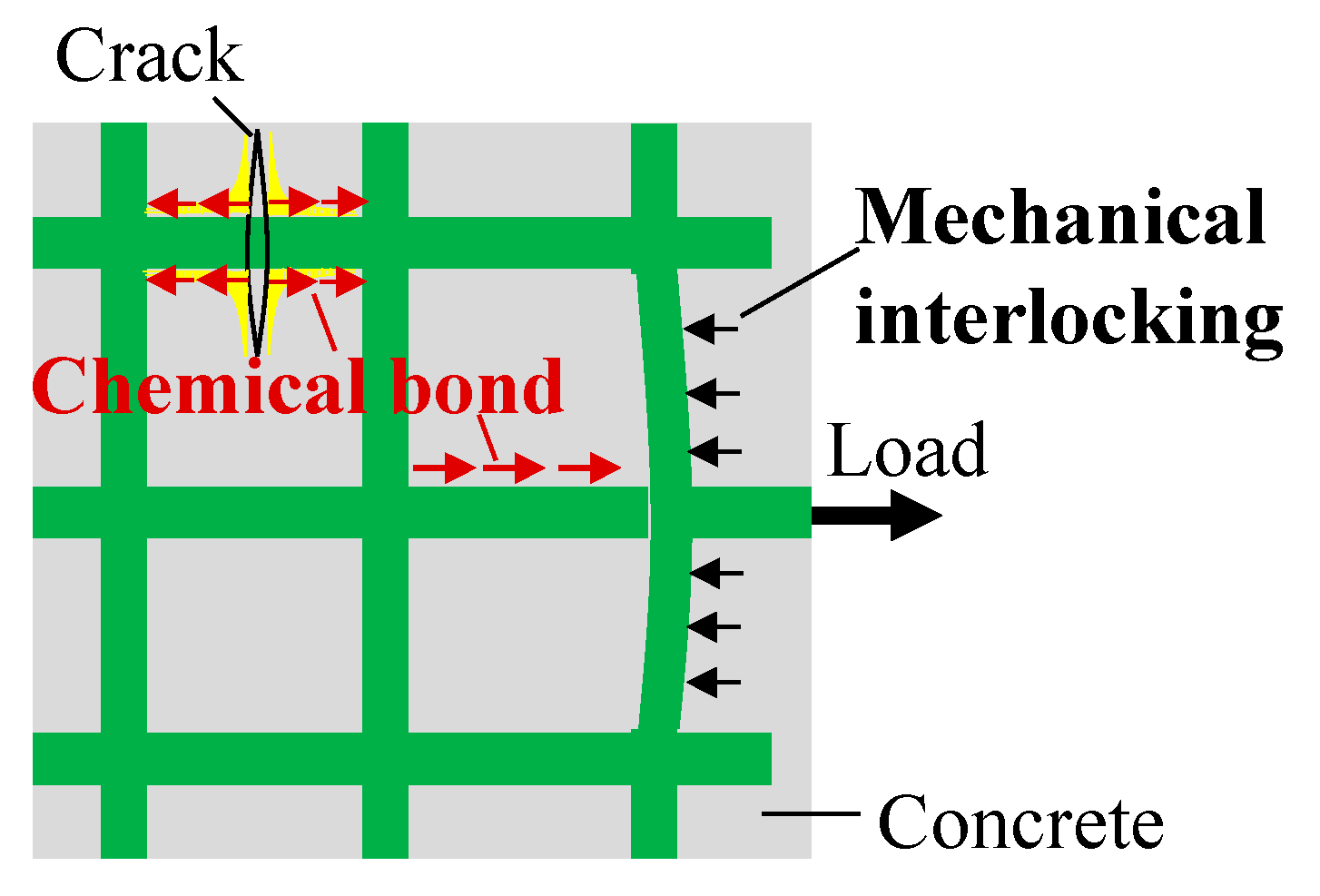

2.1.4. Strengthening via BFRP Grids

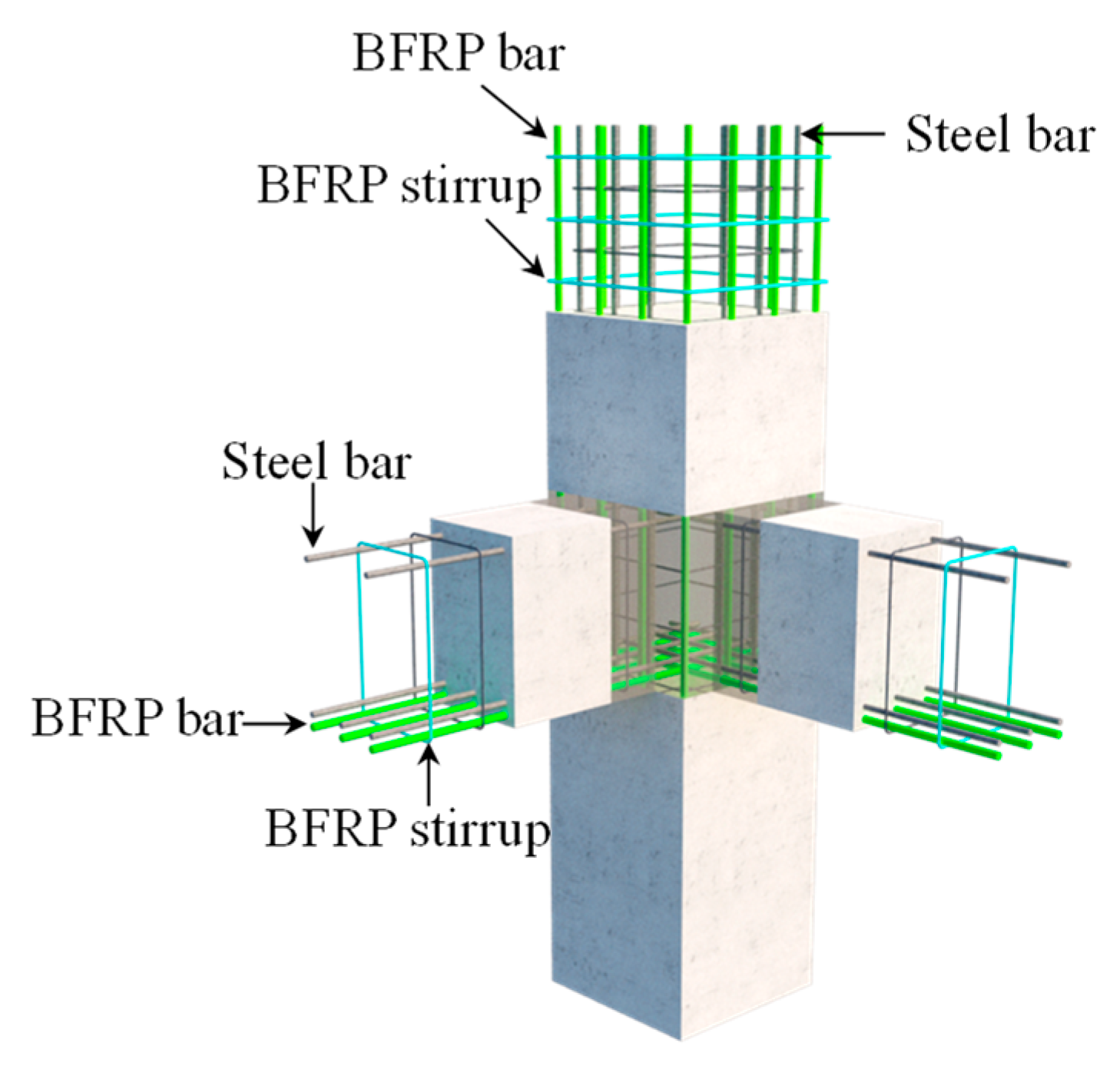

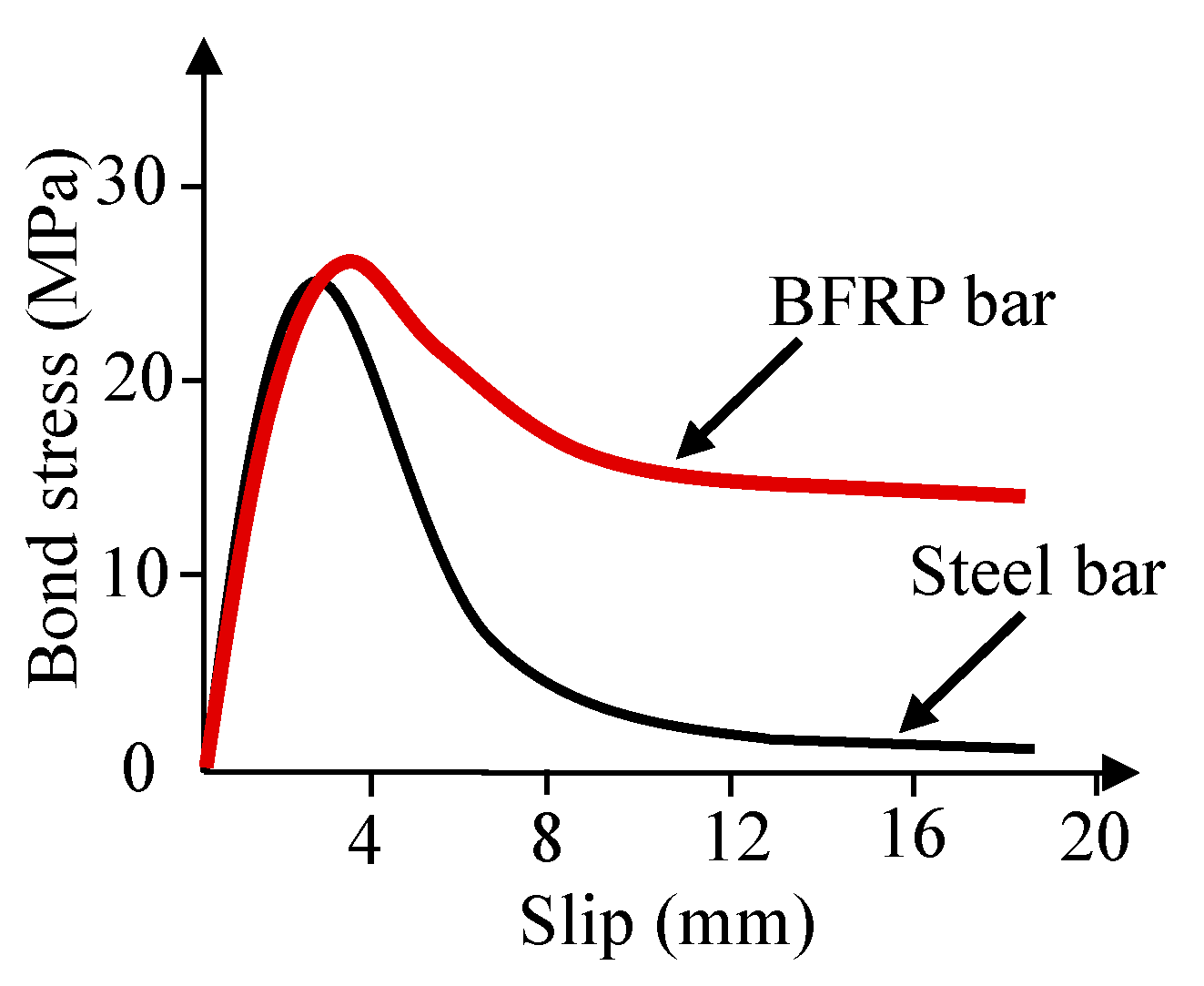

2.2. Concrete Structures Reinforced with BFRP Bars

2.3. Pavement Reinforced with Basalt Fibers and BFRP Bars

2.3.1. Asphalt Pavement Reinforced with Basalt Fibers

2.3.2. Pavements Reinforced with BFRP Bars

2.4. Cementitious Composites Reinforced with Basalt Fibers

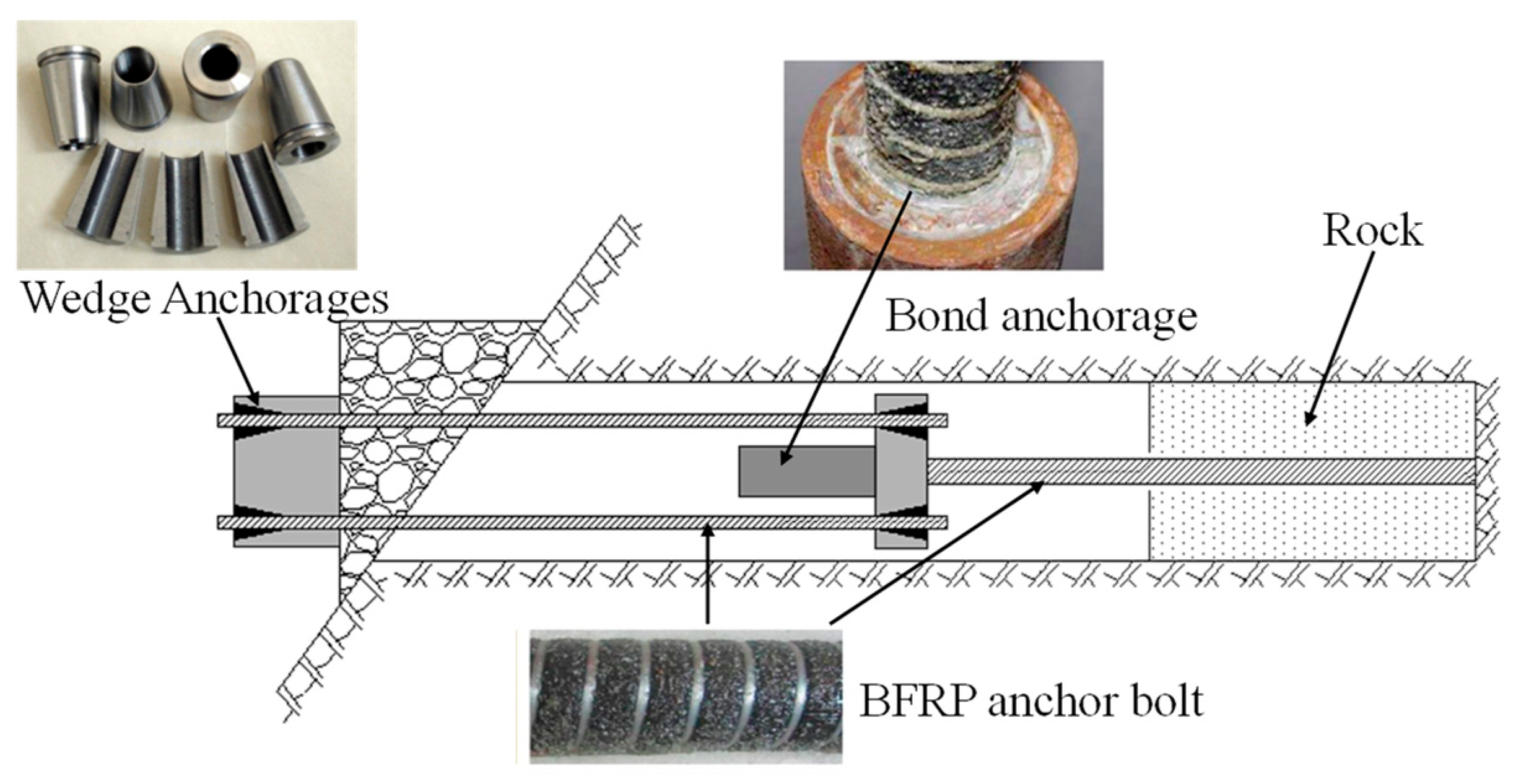

2.5. BFRP Anchor Bolt

2.6. Smart Structures with BFRP

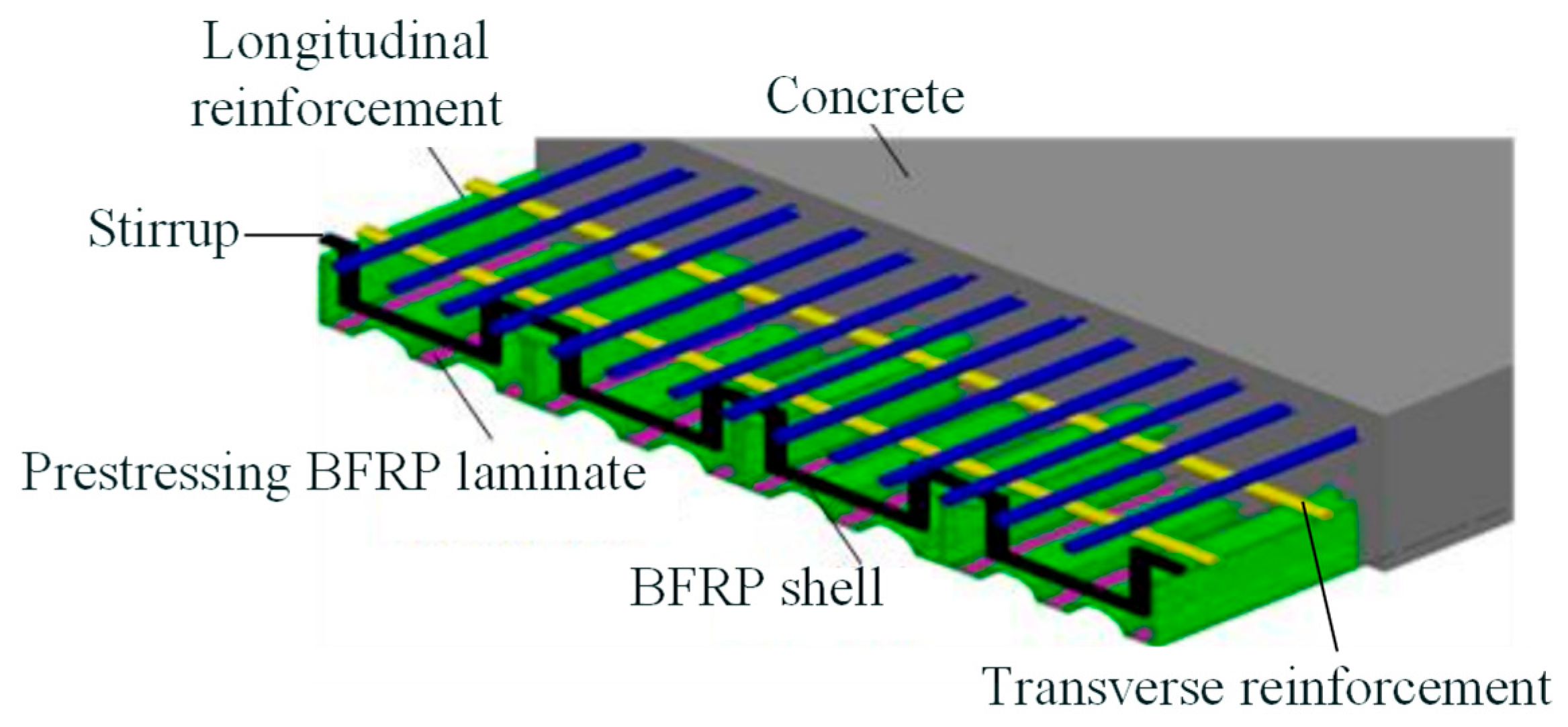

2.7. Composite Structures with BFRP Profiles and Concrete

3. Prospect of Future Studies

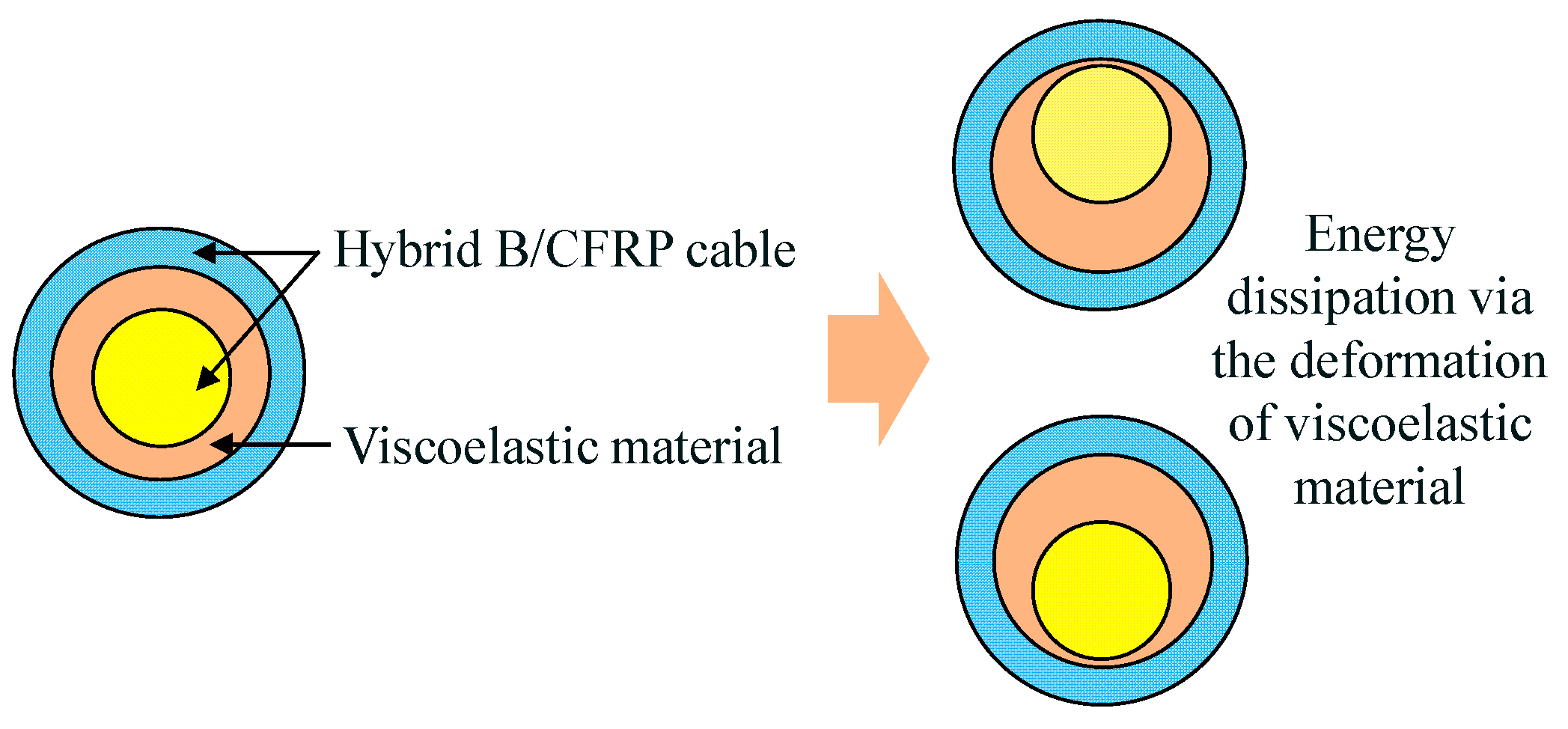

3.1. BFRP Cables

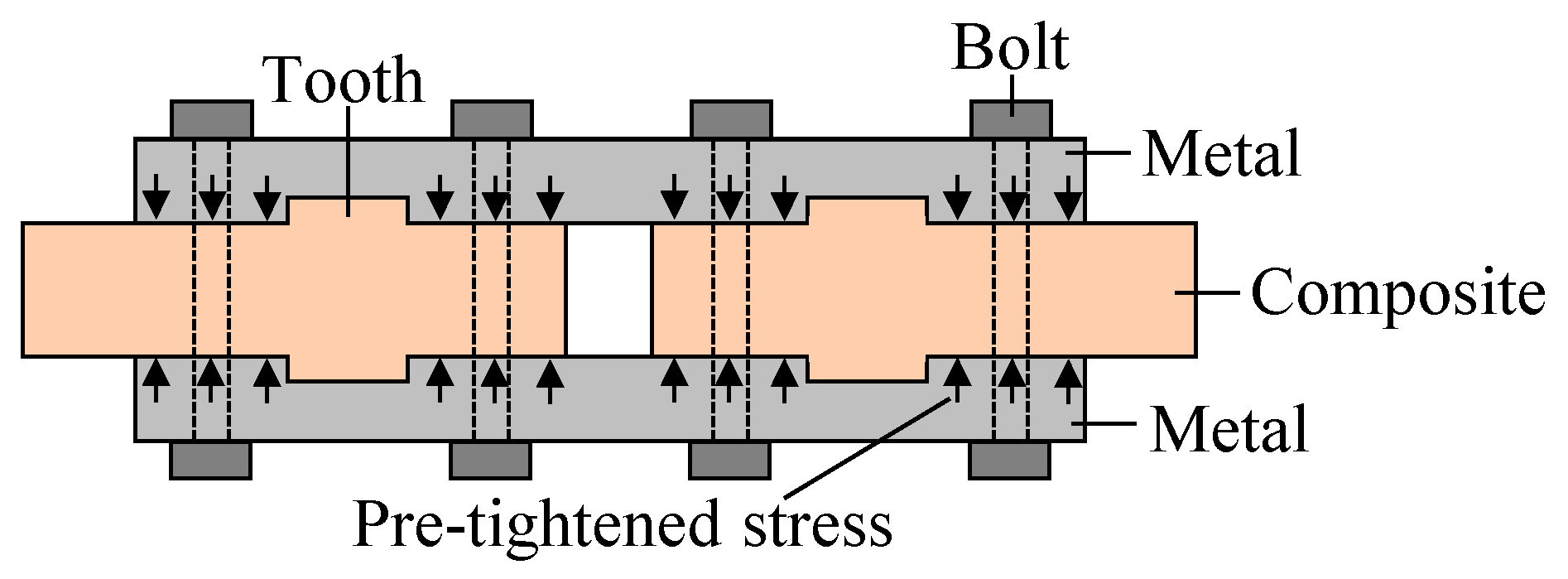

3.2. BFRP Truss Structures

3.3. BFRP with Thermoplastic Resin Matrix

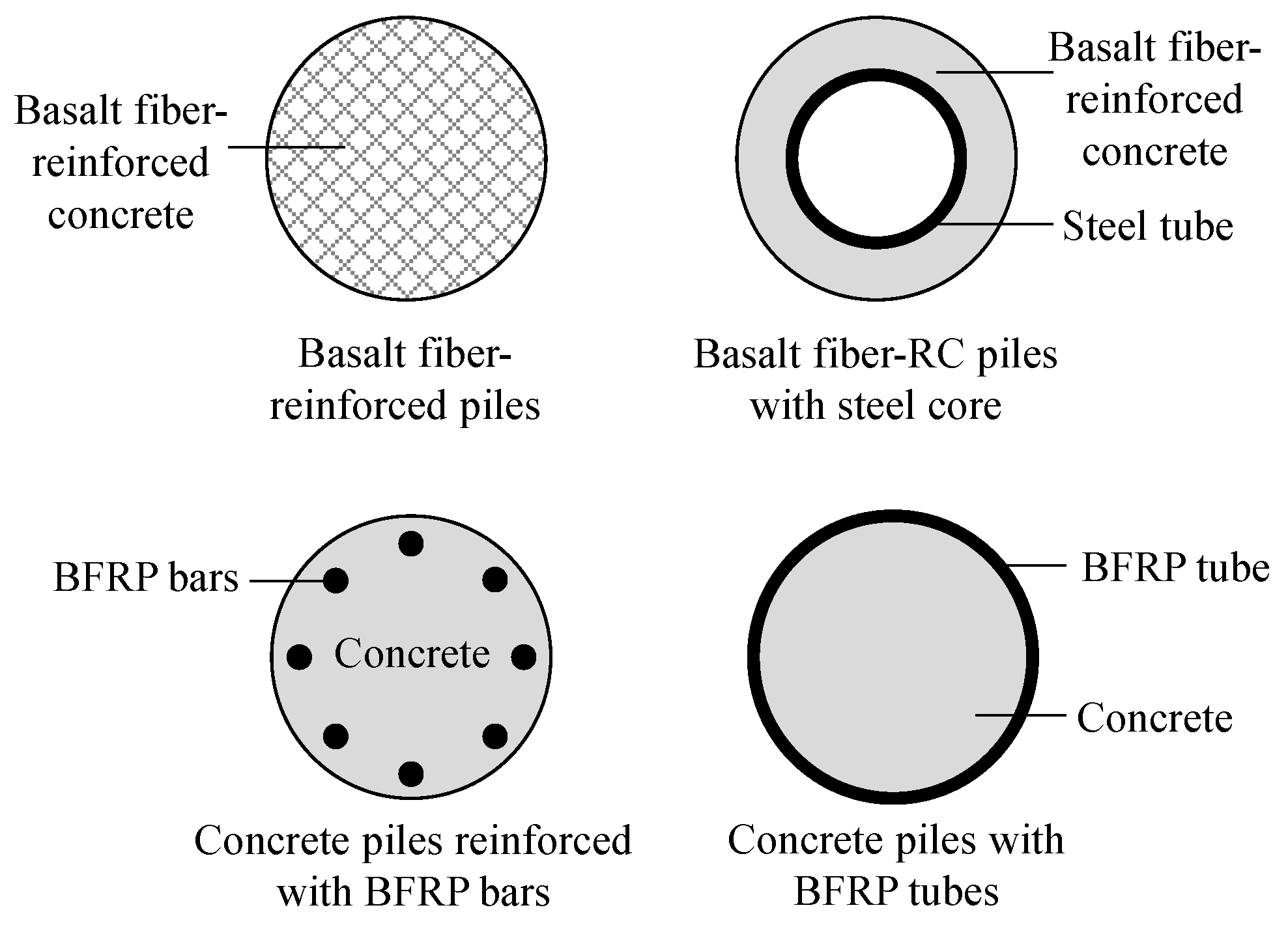

3.4. Composite Piles with Basalt Fibers and Their Composites

4. Comparative Limitations

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shi, J.; Wu, Q.; Li, B.; Liu, Y.; Cao, W.; Wang, H. Fatigue bond behavior of FRP-to-concrete joints with various bonding adhesives. Eng. Struct. 2024, 301, 117311. [Google Scholar] [CrossRef]

- Shi, J.; Li, H.; Cao, W.; Wang, H. Fatigue behavior and bond improvement of the FRP-to-concrete interface after marine corrosion. Eng. Struct. 2025, 332, 120043. [Google Scholar] [CrossRef]

- Cao, X.; Shi, J.; Xu, J.; Ji, E.; She, Y.; Wang, Z. The combined influence of bond–slip and joint-shear in the seismic upgrading via externally-attached BFRP-bar reinforced precast sub-frames. J. Build. Eng. 2023, 80, 107984. [Google Scholar] [CrossRef]

- Zhao, X.; Wang, X.; Wu, Z.; Zhu, Z. Fatigue behavior and failure mechanism of basalt FRP composites under long-term cyclic loads. Int. J. Fatigue 2016, 88, 58–67. [Google Scholar] [CrossRef]

- Shi, J.; Wang, X.; Wu, Z.; Zhu, Z. Creep behavior enhancement of a basalt fiber-reinforced polymer tendon. Constr. Build. Mater. 2015, 94, 750–757. [Google Scholar] [CrossRef]

- Shi, J.; Wang, X.; Huang, H.; Wu, Z. Relaxation behavior of prestressing basalt fiber-reinforced polymer tendons considering anchorage slippage. J. Compos. Mater. 2017, 51, 1275–1284. [Google Scholar] [CrossRef]

- Wu, G.; Dong, Z.; Wang, X.; Zhu, Y.; Wu, Z. Prediction of long-term performance and durability of BFRP bars under the combined effect of sustained load and corrosive solutions. J. Compos. Constr. 2015, 19, 04014058. [Google Scholar] [CrossRef]

- Li, T.; Zhu, H.; Shen, J.; Keller, T. Thermophysical and thermomechanical properties of basalt-phenolic FRP rebars under high temperature. Constr. Build. Mater. 2022, 342, 127983. [Google Scholar] [CrossRef]

- Shi, J.; Zhu, H.; Wu, G.; Wu, Z. Tensile behavior of FRP and hybrid FRP sheets in freeze-thaw cycling environments. Compos. Part B Eng. 2014, 60, 239–247. [Google Scholar] [CrossRef]

- Vankov, Y.; Bazukova, E.; Emelyanov, D.; Fedyukhin, A.; Afanaseva, O.; Akhmetova, I.; Berardi, U. Experimental assessment of the thermal conductivity of basalt fibres at high temperatures. Energies 2022, 15, 2784. [Google Scholar] [CrossRef]

- Wu, Z.; Iwashita, K.; Hayashi, K.; Higuchi, T.; Murakami, S. Development of continuous fiber sheets as a prestressing material and externally bonded upgrading technique. Jpn. Soc. Compos. 2007, 33, 72–75. [Google Scholar] [CrossRef]

- Sayed, A.; Wang, X.; Wu, Z. Modeling of shear capacity of RC beams strengthened with FRP sheets based on FE simulation. J. Compos. Constr. 2013, 17, 687–701. [Google Scholar] [CrossRef]

- Wu, Z.; Zhang, D.; Karbhari, V. Numerical simulation on seismic retrofitting performance of RC columns strengthened with fibre reinforced polymer sheets. Struct. Infrastruct. Eng. 2010, 6, 481–496. [Google Scholar] [CrossRef]

- Wu, Z.; Yuan, H.; Asakura, T.; Yoshizawa, H.; Kobayashi, A.; Kojima, Y.; Ahmed, E. Peeling behavior and spalling resistance of bonded bidirectional fiber reinforced polymer sheets. J. Compos. Constr. 2005, 9, 214–226. [Google Scholar] [CrossRef]

- Campione, G.; La Mendola, L.; Monaco, A.; Valenza, A.; Fiore, V. Behavior in compression of concrete cylinders externally wrapped with basalt fibers. Compos. Part B Eng. 2015, 69, 576–586. [Google Scholar] [CrossRef]

- Long, Y.; Zhu, J. Experimental study on concrete columns with various sizes confined by BFRP and hybrid FRP under axial compression. Adv. Mater. Res. 2014, 838, 407–411. [Google Scholar] [CrossRef]

- Lu, Z.; Su, L.; Yu, J. Experimental study on the seismic behaviour of strengthened concrete column-beam joints by simulated earthquake. Procedia Eng. 2011, 14, 1871–1878. [Google Scholar] [CrossRef]

- Yu, J.; Shang, X.; Lu, Z. Efficiency of externally bonded L-shaped FRP laminates in strengthening reinforced-concrete interior beam-column joints. J. Compos. Constr. 2015, 20, 04015064. [Google Scholar] [CrossRef]

- Wang, X.; Shi, J.; Wu, G.; Yang, L.; Wu, Z. Effectiveness of basalt FRP tendons for strengthening of RC beams through the external prestressing technique. Eng. Struct. 2015, 101, 34–44. [Google Scholar] [CrossRef]

- Shi, J.; Wang, X.; Wu, Z.; Wei, X.; Ma, X. Long-term mechanical behaviors of uncracked concrete beams prestressed with external basalt fiber-reinforced polymer tendons. Eng. Struct. 2022, 262, 114309. [Google Scholar] [CrossRef]

- Shi, J.; Wang, X.; Zhang, L.; Wu, Z.; Zhu, Z. Composite-wedge anchorage for fiber-reinforced polymer tendons. J. Compos. Constr. 2022, 26, 04022005. [Google Scholar] [CrossRef]

- Sokairge, H.; Elgabbas, F.; Elshafie, H. Structural behavior of RC beams strengthened with prestressed near surface mounted technique using basalt FRP bars. Eng. Struct. 2022, 250, 113489. [Google Scholar] [CrossRef]

- Hu, J.; Wei, Y.; Yi, J.; Zhang, Y.; Zhao, K. Axial compression performance of underwater columns reinforced with stainless steel tube-FRP grids. J. Constr. Steel Res. 2024, 218, 108721. [Google Scholar] [CrossRef]

- He, W.; Wang, X.; Wu, Z. Flexural behavior of RC beams strengthened with prestressed and non-prestressed BFRP grids. Compos. Struct. 2020, 246, 112381. [Google Scholar] [CrossRef]

- Gopinath, S.; Murthy, A.; Iyer, N.; Prabha, M. Behaviour of RC beams strengthened with basalt textile RC. J. Ind. Text. 2015, 44, 924–933. [Google Scholar] [CrossRef]

- Elsanadedy, H.; Almusallam, T.; Alsayed, S.; Al-Salloum, Y.A. Flexural strengthening of RC beams using textile reinforced mortar—Experimental and numerical study. Compos. Struct. 2013, 97, 40–55. [Google Scholar] [CrossRef]

- Al-Salloum, Y.; Elsanadedy, H.; Alsayed, S.; Iqbal, R. Experimental and numerical study for the shear strengthening of RC beams using textile-reinforced mortar. J. Compos. Constr. 2011, 16, 74–90. [Google Scholar] [CrossRef]

- Di Ludovico, M.; Prota, A.; Manfredi, G. Structural upgrade using basalt fibers for concrete confinement. J. Compos. Constr. 2010, 14, 541–552. [Google Scholar] [CrossRef]

- Elgabbas, F.; Ahmed, E.; Benmokrane, B. Flexural behavior of concrete beams reinforced with ribbed basalt-FRP bars under static loads. J. Compos. Constr. 2016, 21, 04016098. [Google Scholar] [CrossRef]

- Wang, X.; Liu, S.; Shi, Y.; Wu, Z.; He, W. Integrated high-performance concrete beams reinforced with hybrid BFRP and steel bars. J. Struct. Eng. 2022, 148, 04021235. [Google Scholar] [CrossRef]

- Ibrahim, A.; Wu, Z.; Fahmy, M.; Kamal, D. Experimental study on cyclic response of concrete bridge columns reinforced by steel and basalt FRP reinforcements. J. Compos. Constr. 2015, 20, 04015062. [Google Scholar] [CrossRef]

- GB/T 45019-2024; Basalt Fiber Modified Asphalt Mixture for Road Engineering. Standard Press of China: Beijing, China, 2024. (In Chinese)

- Qin, X.; Shen, A.; Guo, Y.; Li, Z.; Lv, Z. Characterization of asphalt mastics reinforced with basalt fibers. Constr. Build. Mater. 2018, 159, 508–516. [Google Scholar] [CrossRef]

- Liu, Q.; He, M. Research of the properties of basalt fiber reinforced polymer bar for continuously RC pavement. In Proceedings of the 3rd International Conference on Civil Engineering and Transportation (ICCET 2013), Kunming, China, 14–15 December 2013. [Google Scholar]

- Lipatov, Y.; Gutnikov, S.; Manylov, M.; Zhukovskaya, E.; Lazoryak, B. High alkali-resistant basalt fiber for reinforcing concrete. Mater. Des. 2015, 73, 60–66. [Google Scholar] [CrossRef]

- Sun, X.; Gao, Z.; Cao, P.; Zhou, C. Mechanical properties tests and multiscale numerical simulations for basalt fiber RC. Constr. Build. Mater. 2019, 202, 58–72. [Google Scholar] [CrossRef]

- Shaikh, F. Review of mechanical properties of short fibre reinforced geopolymer composites. Constr. Build. Mater. 2013, 43, 37–49. [Google Scholar] [CrossRef]

- Dias, D.; Thaumaturgo, C. Fracture toughness of geopolymeric concretes reinforced with basalt fibers. Cem. Concr. Compos. 2005, 27, 49–54. [Google Scholar] [CrossRef]

- Peng, Z.; Wang, X.; Wu, W.; Ding, L.; Liu, L.; Wu, Z.; Zhu, Z. Mechanical behavior of BFRP cable rock bolts: Experimental and analytical study. J. Compos. Constr. 2024, 28, 04024046. [Google Scholar] [CrossRef]

- Tang, Y.; Wu, Z.; Yang, C.; Wu, G.; Shen, S. A new type of smart basalt fiber-reinforced polymer bars as both reinforcements and sensors for civil engineering application. Smart Mater. Struct. 2010, 19, 115001. [Google Scholar] [CrossRef]

- Peng, Z.; Wang, X.; Ding, L.; Yang, Y.; Wu, Z.; Zhu, Z. Static and sustained loading behavior of a basalt FRP shell–concrete composite bridge deck: An experimental and numerical study. Eng. Struct. 2020, 230, 111689. [Google Scholar] [CrossRef]

- Wang, X.; Peng, Z.; Deng, W.; Wu, Z. Fatigue behavior of a composite bridge deck with prestressed basalt fiber-reinforced polymer shell and concrete. J. Bridge Eng. 2020, 25, 04020088. [Google Scholar] [CrossRef]

- Wang, X.; Xu, P.; Wu, Z.; Shi, J. A novel anchor method for multi-tendon FRP cable: Concept and FE study. Compos. Struct. 2015, 120, 552–564. [Google Scholar] [CrossRef]

- Wang, X.; Xu, P.; Wu, Z.; Shi, J. A novel anchor method for multi-tendon FRP cable: Manufacturing and experimental study. J. Compos. Constr. 2015, 19, 04015010. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, X.; Wu, Z. Damping behavior of hybrid fiber-reinforced polymer cable with self-damping for long-span bridges. J. Bridge Eng. 2017, 22, 05017005. [Google Scholar] [CrossRef]

- Zhang, D.; Zhao, Q.; Huang, Y.; Li, F.; Chen, H.; Miao, D. Flexural properties of a lightweight hybrid FRP-aluminum modular space truss bridge system. Compos. Struct. 2014, 108, 600–615. [Google Scholar] [CrossRef]

- Liu, L.; Wang, X.; Wu, Z.; Keller, T. Tension-tension fatigue behavior of ductile adhesively-bonded FRP joints. Compos. Struct. 2021, 268, 113925. [Google Scholar] [CrossRef]

- Li, F.; Zhao, Q.; Gao, Y.; Xu, L.; Chen, H. A prediction method of the failure load and failure mode for composite pre-tightened tooth connections based on the characteristic lengths. Compos. Struct. 2016, 154, 684–693. [Google Scholar] [CrossRef]

- Wang, X.; Zhao, X.; Chen, S.; Wu, Z. Static and fatigue behavior of basalt fiber-reinforced thermoplastic epoxy composites. J. Compos. Mater. 2020, 54, 2389–2398. [Google Scholar] [CrossRef]

- Salah-Eldin, A.; Mohamed, H.; Benmokrane, B. Axial-flexural performance of high-strength-concrete bridge compression members reinforced with basalt-FRP bars and ties: Experimental and theoretical investigation. J. Bridge Eng. 2019, 24, 04019069. [Google Scholar] [CrossRef]

- Cao, X.; Dai, G.; Gong, W.; Zhu, M.; Tang, J. Experimental study on the seismic behavior of new PHC piles. Arab. J. Geosci. 2020, 13, 778. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, X.; Wu, Z. Life cycle cost analysis of FRP cables for long-span cable supported bridges. Structures 2020, 25, 24–34. [Google Scholar] [CrossRef]

| Type of FRP | BFRP | CFRP | GFRP |

|---|---|---|---|

| Mechanical properties | Strength: 1000 to 1800 MPa Elastic modulus: 50 to 70 GPa Elongation: 2.0% to 2.8% | Strength: 1800 to 3000 MPa Elastic modulus: 140 to 230 GPa Elongation: about 1.5% | Strength: 800 to 1700 MPa Elastic modulus: 40 to 60 GPa Elongation: 2.0% to 3.0% |

| Functional properties | Insulation, non-magnetism | Conductivity, non-magnetism | Insulation, non-magnetism |

| Lifecycle cost [52] | Relatively low construction and maintenance cost, especially when hybridizing with steel | High construction cost, but low maintenance cost | Low construction cost, but high maintenance cost due to insufficient durability |

| Strengthening on beam or slab | Improvement in cracking and yielding moment and load-bearing capacity; Relatively high ductility | Significant improvement in cracking and yielding moment and load-bearing capacity; Relatively low ductility | Improvement in cracking and yielding moment and load-bearing capacity; Relatively high ductility |

| Confinement on column | Softening stage in constitutive curve | Linear constitutive curve | Softening stage in constitutive curve |

| Concrete structure or pavement reinforced with FRP bars | Applicable | Not applicable due to large difference in coefficient of thermal expansion | Applicable |

| Asphalt or cementitious composites reinforced with chopped fibers | Applicable | Not applicable due to insufficient oil absorption and high price | Not applicable due to vulnerability in an alkaline environment |

| Prestressing anchor bolt | Applicable | Applicable despite of relatively high prestress loss due to solid shrinkage | Not applicable due to low creep rupture stress |

| Self-sensing material | Compatible with fiber optic | Self-sensing nature due to conductivity | Compatible with fiber optic |

| Composite structures | Relatively large deformation during construction | Relatively small deformation during construction | Relatively large deformation during construction |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, W.; Shi, J.; Cao, X.; Zhang, M.; Li, L.; Jiang, J. A Review on the Applications of Basalt Fibers and Their Composites in Infrastructures. Buildings 2025, 15, 2525. https://doi.org/10.3390/buildings15142525

Yan W, Shi J, Cao X, Zhang M, Li L, Jiang J. A Review on the Applications of Basalt Fibers and Their Composites in Infrastructures. Buildings. 2025; 15(14):2525. https://doi.org/10.3390/buildings15142525

Chicago/Turabian StyleYan, Wenlong, Jianzhe Shi, Xuyang Cao, Meng Zhang, Lei Li, and Jingyi Jiang. 2025. "A Review on the Applications of Basalt Fibers and Their Composites in Infrastructures" Buildings 15, no. 14: 2525. https://doi.org/10.3390/buildings15142525

APA StyleYan, W., Shi, J., Cao, X., Zhang, M., Li, L., & Jiang, J. (2025). A Review on the Applications of Basalt Fibers and Their Composites in Infrastructures. Buildings, 15(14), 2525. https://doi.org/10.3390/buildings15142525