1. Introduction

Pumice, known by various names across different languages, is a porous, volcanic rock. Its finer powdered form is often referred to as pumicite. In Turkish, it is commonly known as “sponge stone,” “foam stone,” or “callus stone” [

1]. Turkey holds approximately 15% of the world’s pumice reserves, with nearly 45% located in the Bitlis province.

Pumice is a glassy volcanic rock with a highly porous structure, formed by rapid cooling and degassing during volcanic eruptions. Its micro- and macroporous structure—composed mostly of isolated pores—results in low permeability and provides excellent thermal and acoustic insulation. Compared to other volcanic rocks such as perlite, obsidian, and tuff, pumice is distinguished by its high porosity, lighter color, and absence of crystalline water [

1].

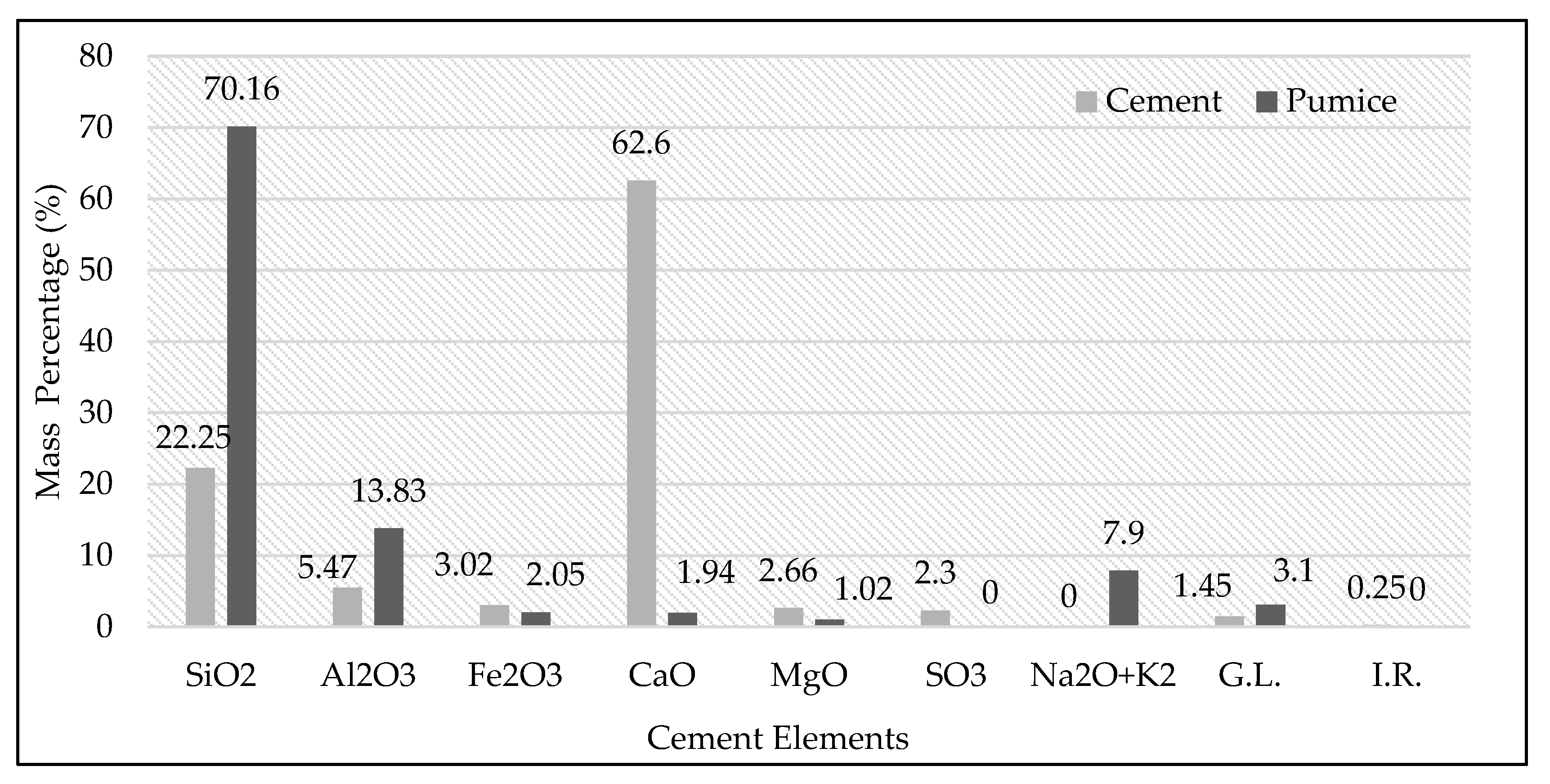

According to the Mohs hardness scale, pumice has a hardness of 5 to 6 and contains up to 75% silica (SiO2). Its typical chemical composition includes 60–75% SiO2, 13–17% Al2O3, 1–3% Fe2O3, 1–2% CaO, 7–8% Na2O–K2O, and trace amounts of TiO2 and SO3. The high silica content contributes to its abrasiveness, allowing it to abrade even steel surfaces, while Al2O3 enhances fire and heat resistance. The presence of Na2O and K2O imparts chemical reactivity, making pumice particularly valuable in textile applications.

Volcanic activity produces two main types of pumice: acidic and basic. Basic pumice (also known as basaltic pumice or scoria) is typically dark brown to black and has a density of approximately 1–2 g/cm

3. It is widely used in fertilizers and soil conditioning due to its higher content of aluminum, iron, calcium, and magnesium. In contrast, acidic pumice—off-white in color and rich in silica—is the more prevalent type and is extensively used in construction [

2,

3].

Extensive research has been conducted on lightweight concrete incorporating pumice as aggregate. For instance, Yildirim [

4] evaluated pumice- and fly ash-based concretes with cement contents of 350 and 450 kg/m

3 under different curing conditions, reporting compressive strength reductions of 12% and 17% in saline and acidic environments, respectively. Jianming et al. [

5] found that the addition of steel fibers significantly improves flexural strength and fracture toughness, with moderate increases in compressive strength. Similarly, Ahn et al. [

6] reported enhanced thermal resistance in lightweight concretes containing coal and fly ash. Badogiannis et al. [

7] demonstrated that fiber reinforcement improves both flexural strength and fracture behavior. Wongsa et al. [

8] investigated the fire resistance of pumice-reinforced lightweight concrete at 400 °C, 600 °C, and 800 °C, concluding that pumice and crushed clay brick aggregates offer better thermal insulation than conventional aggregates, especially when combined with geopolymer binders.

Further notable studies include Liu et al. [

9], who explored the use of pumice as a substitute for river sand in Ultra-High-Performance Concrete (UHPC), showing its capacity for internal curing without compromising strength. Top and Vapur [

10] produced fly ash-based geopolymer concrete using basaltic pumice, achieving compressive strengths between 20 and 55 MPa and water absorption rates from 1.05% to 17%. Turker and Kadiroglu [

11] demonstrated that the inclusion of silica fume and fly ash enables the production of structurally lightweight concrete with compressive strengths exceeding 17.2 MPa. Yazıcıoğlu and Bozkurt [

12] confirmed that silica fume-reinforced pumice concretes maintain consistent performance across different curing periods. Nayir et al. [

13] emphasized the benefits of lightweight aggregates in reducing structural weight, improving thermal performance, and enhancing freeze–thaw durability. Sahan and Yilmaz [

14] also explored the potential of pumice for the adsorption of Co(II) ions.

Additional studies have highlighted the effects of fiber reinforcement and lightweight aggregates on concrete’s toughness and ductility [

15], bond strength [

16], and the comparative behavior of lightweight versus normal-weight concretes [

17,

18]. According to RILEM classification, as cited by Gonen [

19], lightweight concrete is categorized as structural, structural insulation, or non-structural insulation concrete, based on density and compressive strength. Production typically utilizes aggregates with low unit weight. Lightweight concrete is widely used in block production to reduce dead loads, offering benefits in thermal insulation, seismic resistance, fire protection, and aesthetics. However, pumice aggregates may also exhibit brittleness and reduced mechanical strength, as noted by Kockal and Camurlu [

20].

Karahan et al. [

21] reported that ground granulated pumice decreases the workability of fresh mortar mixes. By TS EN 206-1 [

22], lightweight concrete is classified based on unit weight and compressive strength. TS 2511 [

23] defines load-bearing lightweight concrete as having a density below 1800 kg/m

3 and compressive strength above 17 MPa. Classification criteria and comparative values for specific gravity and compressive strength are summarized in

Table 1,

Table 2,

Table 3 and

Table 4.

This study experimentally investigates the mechanical and physical properties of lightweight concrete incorporating acidic pumice aggregate sourced from the Bitlis-Tatvan region, without using binders. Using a quantitative design, the study evaluates compressive strength, flexural strength, capillary water absorption, and thermal performance. The central hypothesis is that incorporating acidic pumice from Bitlis-Tatvan significantly affects strength, absorption, and thermal resistance at high temperatures, potentially enhancing thermal performance while reducing mechanical strength. While earlier research has shown pumice improves insulation and reduces density [

7,

8,

13], its mechanical behavior under elevated temperatures remains inconclusive and warrants further study. This research aims to contribute a valuable reference for future work on pumice in concrete technology.

Beyond its technical merits, pumice as a lightweight aggregate offers clear environmental advantages. Its natural abundance and low density reduce transportation costs and associated carbon emissions. Although a full Life Cycle Assessment (LCA) was not conducted, the material’s low embodied energy and reduced transportation burden suggest a favorable sustainability profile.

3. Results

3.1. Evaluation of Flexural Strength of Lightweight Concretes

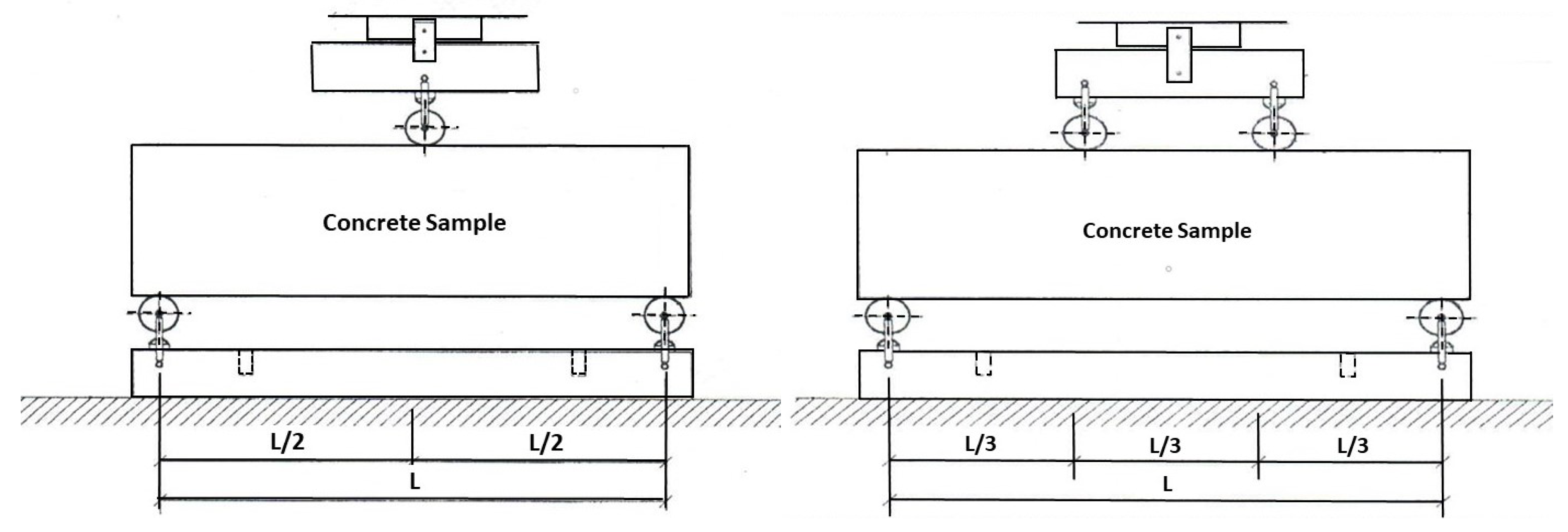

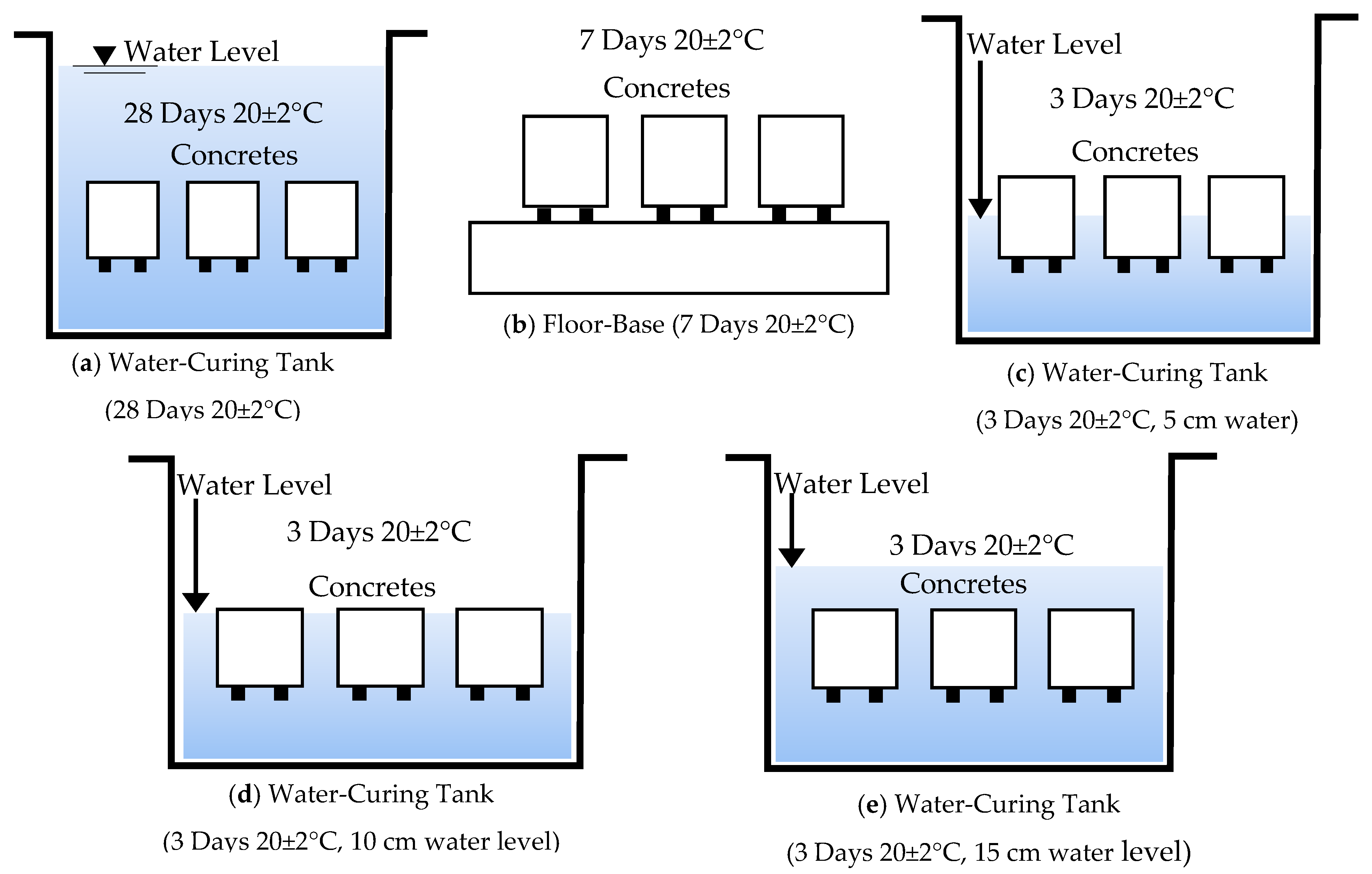

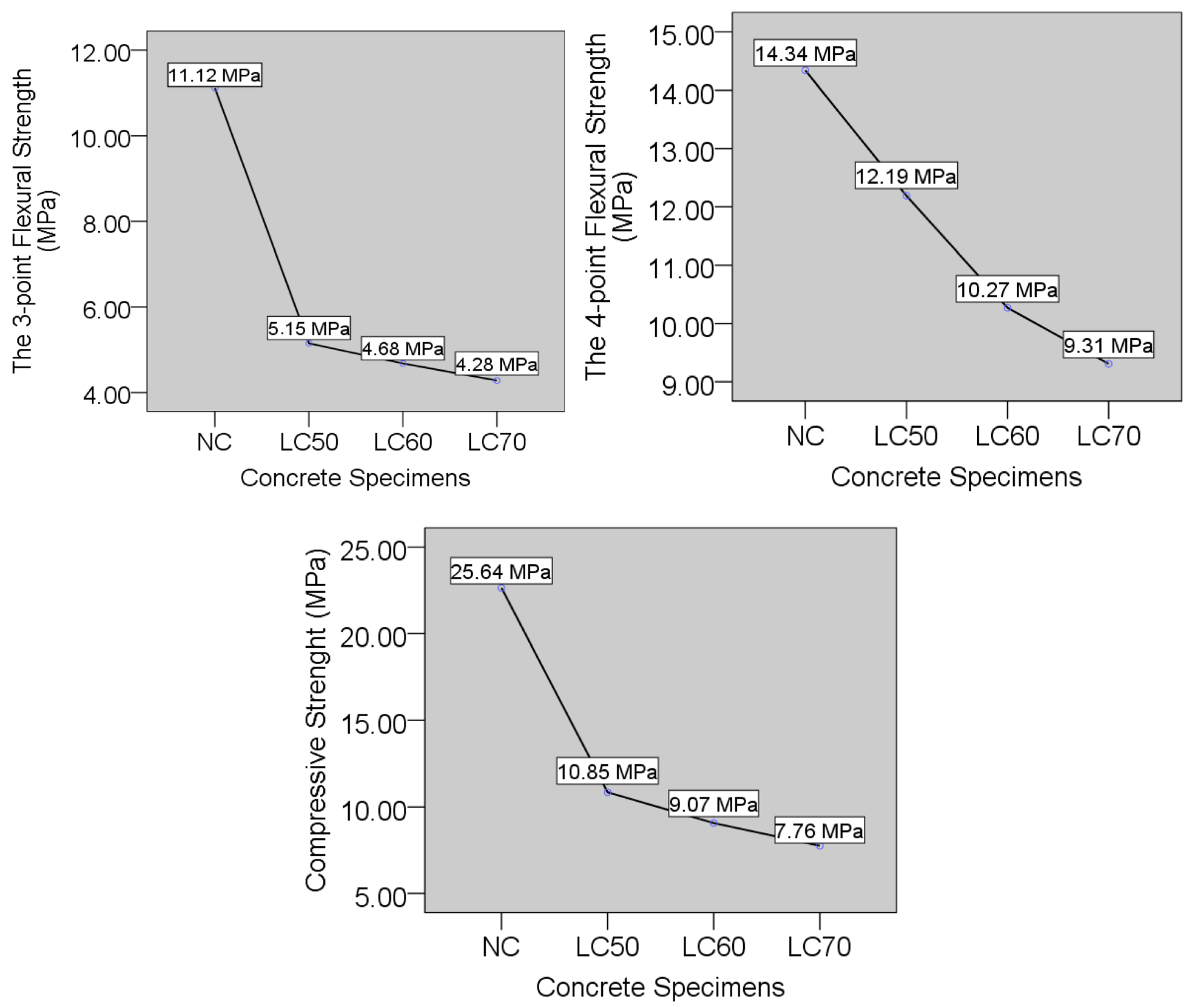

As shown in

Figure 7, replacing limestone aggregate with acidic pumice aggregate resulted in a systematic reduction in both three-point and four-point flexural strengths of the concrete specimens. Specifically, the three-point flexural strength decreased from 11.12 MPa in the normal concrete (NC) mix to 4.28 MPa in the LC70 mix, representing an approximate 61.5% reduction. This significant decline highlights the critical impact of aggregate porosity and the weakened interfacial bond between the pumice particles and the cementitious matrix on the concrete’s flexural resistance.

The reduction in flexural performance is attributed not only to the lower density of the pumice aggregate but also to its high surface porosity, which negatively affects the integrity of the aggregate–matrix interface.

While such strength reductions are generally accepted as inherent trade-offs in lightweight concrete applications, the present results emphasize the importance of optimizing the interfacial transition zone (ITZ) between the aggregate and cement paste. Potential approaches to improve the tensile and flexural properties include the incorporation of fibers or other reinforcement methods.

3.2. Evaluation of Compressive Strength of Lightweight Concretes

As shown in

Figure 8, increasing the proportion of acidic pumice aggregate in the concrete mix results in a significant decrease in compressive strength. The control concrete (NC) exhibited a compressive strength of 25.64 MPa, which decreased to 7.76 MPa in the LC70 mix containing 70% pumice aggregate. This corresponds to an approximate 69.7% reduction in compressive strength from the control to the highest pumice substitution level.

This substantial strength loss is consistent with previous studies that report a strong inverse correlation between aggregate porosity and compressive strength in lightweight concretes [

35]. The high porosity and low density of pumice aggregates reduce mechanical interlocking and load-bearing capacity, thereby compromising the overall compressive performance.

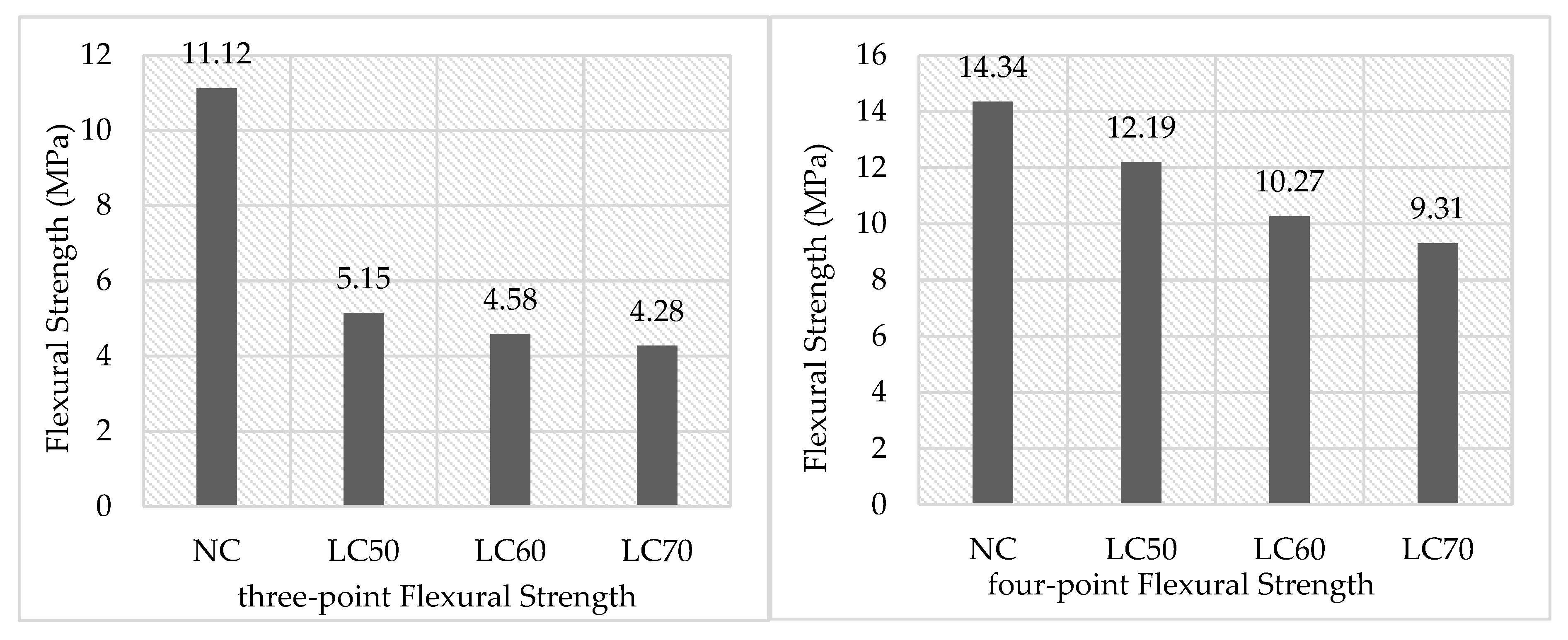

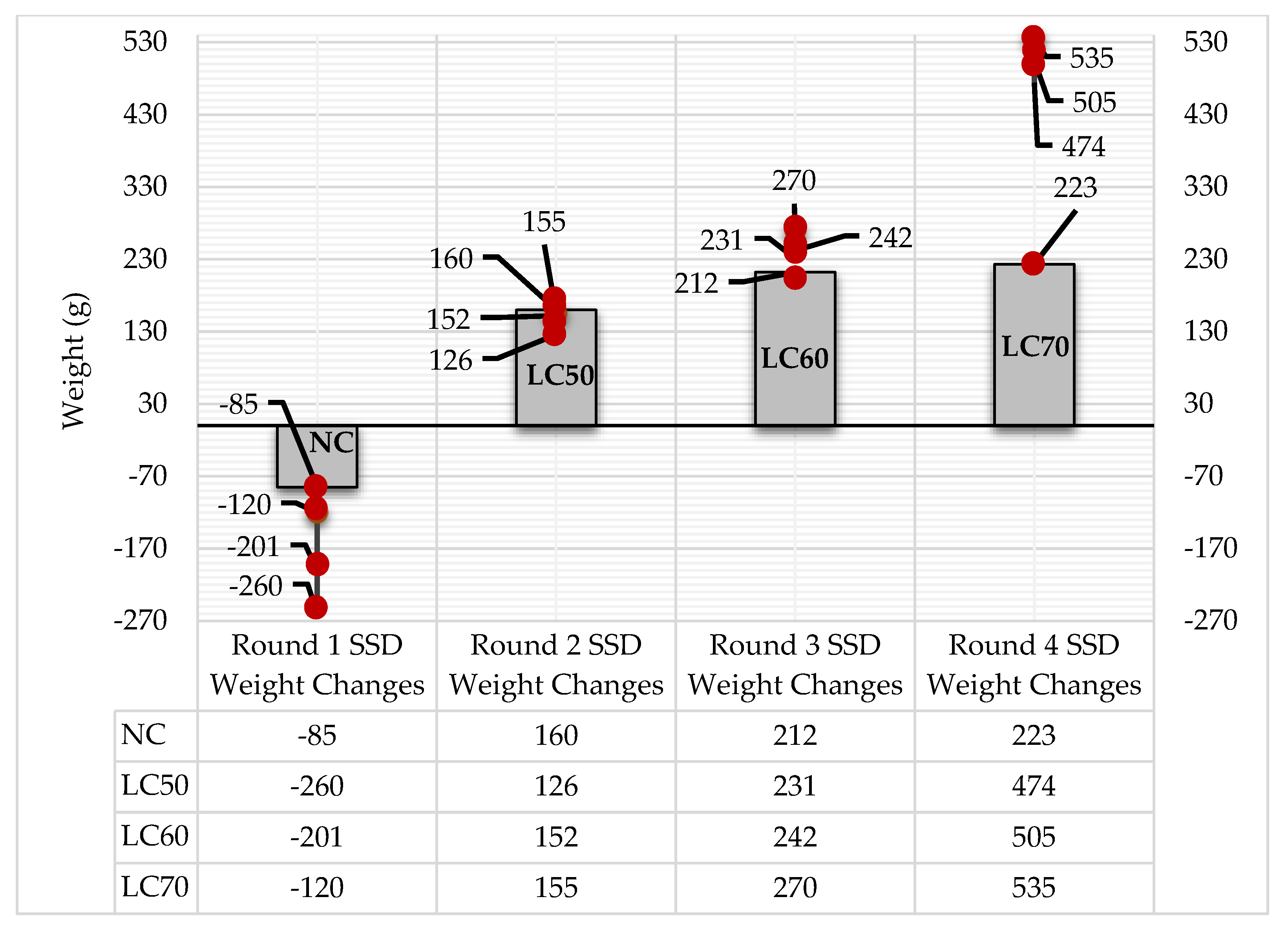

3.3. Evaluation of Water Absorption Behavior of Lightweight Concretes

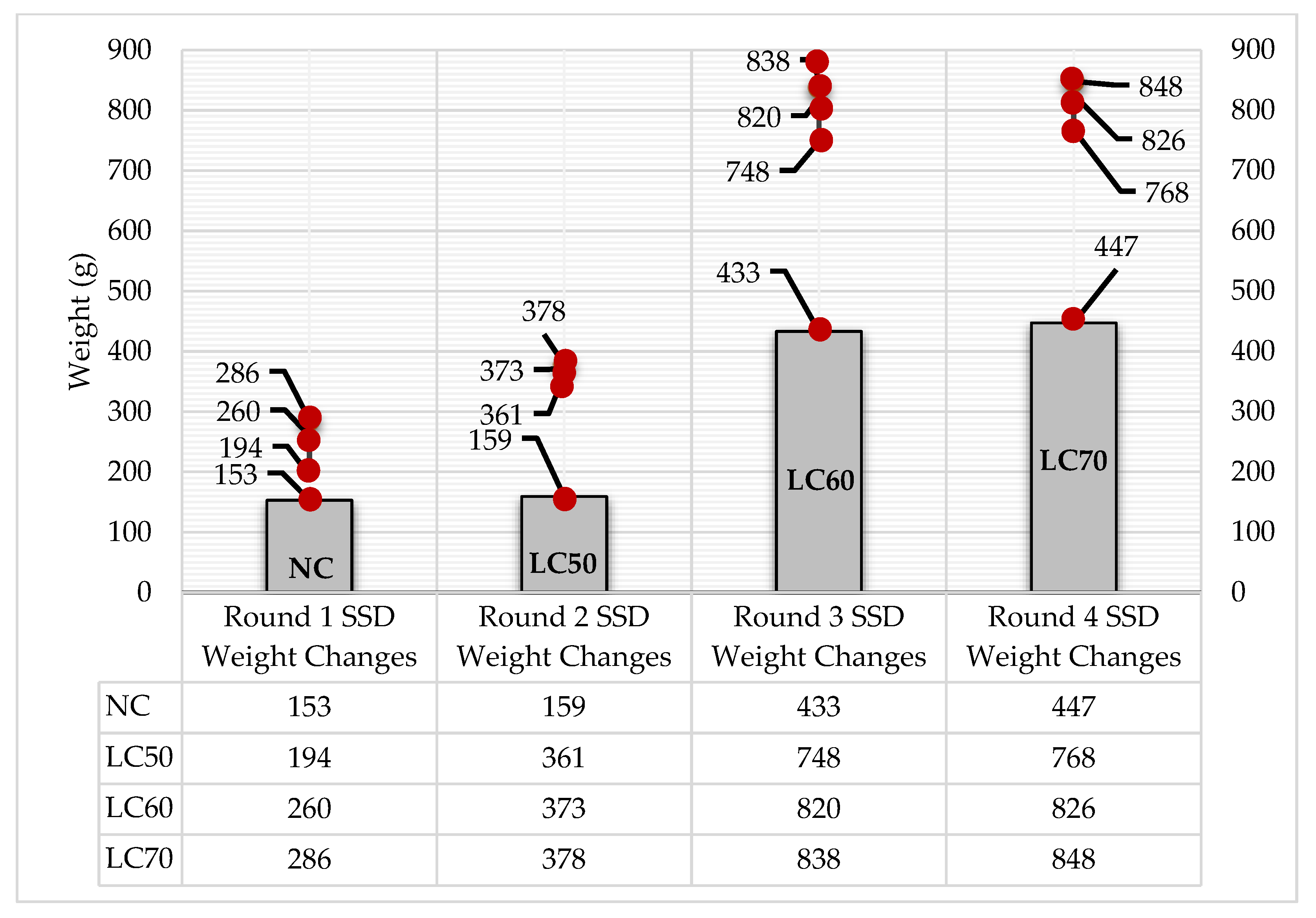

The results shown in

Figure 9 illustrate the water absorption behavior. The initial reduction in water content caused by natural air drying, followed by subsequent increases in water absorption, is detailed in

Figure 10.

As shown in

Figure 10, the 28-day-old concrete specimens were first air-dried under laboratory conditions for 168 h. Following this period, a stepwise immersion procedure was applied to assess capillary water absorption behavior. The specimens were immersed in water at incremental depths of 5 cm, 10 cm, and 15 cm, each for a duration of 72 h. After each interval, the amount of water absorbed was measured using a precision scale with an accuracy of 0.01 g. This incremental immersion method was designed to simulate gradual and controlled water exposure conditions.

Throughout the testing, water temperature was maintained at 20 ± 2 °C to ensure consistency. At the end of the test, all concrete specimens exhibited increased water absorption, with the LC70 mix showing the highest value at 415 g. This elevated absorption is attributed to the higher porosity and greater volume fraction of pumice aggregate in the LC70 mix.

Following 168 h of exposure to ambient outdoor conditions, the 28-day-old normal concrete (NC) specimen exhibited a mass loss of 85 g, primarily due to the evaporation of pore water. Among all samples, the LC50 mix showed the highest moisture loss, with a mass reduction of 260 g. This finding suggests that lightweight concrete mixes with higher pumice content are more susceptible to moisture evaporation.

The significantly higher water absorption observed in the LC70 mix further supports the conclusion that the open pore structure of acidic pumice aggregates remains largely accessible even after curing. This behavior may be attributed to the limited penetration of cement paste into the interconnected pore network of the pumice during mixing. As a result, continuous capillary channels are likely to form, facilitating both water ingress and egress.

3.4. Mass Loss and Structural Changes in Lightweight Concrete Under High Temperatures

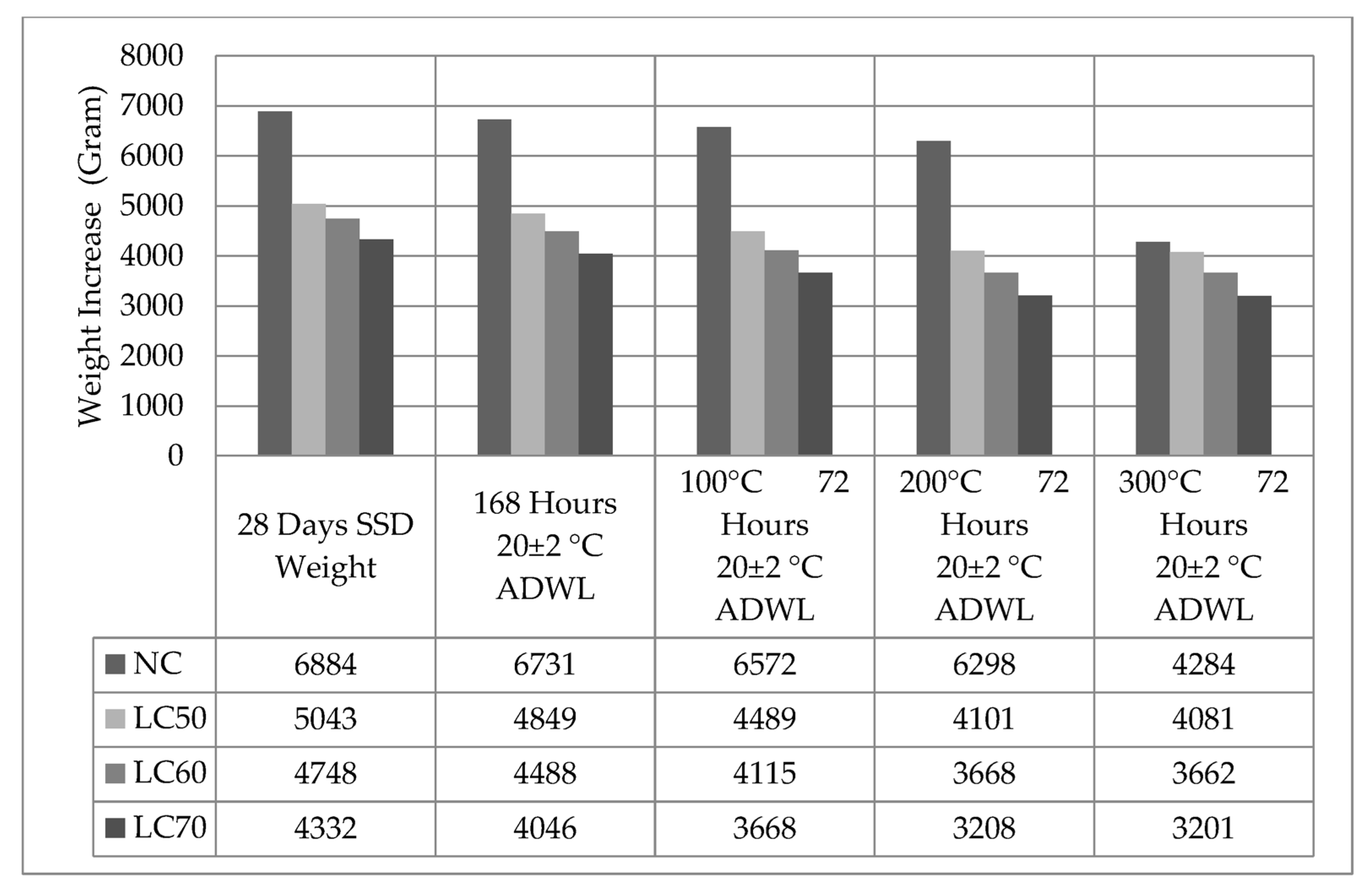

The thermal behavior of the concrete specimens was assessed 68 days after exposure to elevated temperatures of 100 °C, 200 °C, and 300 °C. As illustrated in

Figure 11 and

Figure 12, increasing the volumetric replacement of limestone with acidic pumice aggregate resulted in a consistent increase in mass loss across all temperature levels. This reduction in weight is primarily attributed to the evaporation of free and chemically bound water retained within the concrete’s porous matrix.

Specimens with higher pumice content exhibited more pronounced mass loss under thermal exposure, likely due to the amorphous and highly porous nature of pumice, which facilitates deeper heat penetration and accelerates internal moisture evaporation.

In addition to mass loss, visible structural changes were observed. After exposure to 200 °C and 300 °C, concretes containing 60% and 70% pumice developed distinct surface voids, typically ranging from 1 to 3 mm in depth. These voids were most prominent in the LC70 specimens, indicating that high pumice content increases susceptibility to thermally induced microstructural degradation and surface damage.

3.5. Correlation and Discrepancy Analysis of Mechanical Strengths

To comprehensively assess the relationship between the measured mechanical properties, a correlation analysis was conducted between compressive and flexural strength. Compressive strength values decreased from 25.64 MPa in the normal concrete (NC) mix to 7.76 MPa in the LC70 mix. Similarly, three-point flexural strength declined from 11.12 MPa to 4.28 MPa, while the four-point flexural test followed the same downward trend, consistently yielding slightly higher values.

As shown in

Figure 7 and

Figure 8, a clear linear relationship exists between compressive and flexural strengths. Increasing the proportion of pumice aggregate results in simultaneous reductions in both, indicating that flexural strength diminishes in parallel with compressive strength.

For a quantitative evaluation, the Pearson correlation coefficient was calculated as r = 0.88, indicating a strong positive linear correlation. In other words, as compressive strength decreases, flexural strength also declines in a directly proportional manner. A linear regression analysis further confirmed this relationship, and the following equation was derived to model it:

In this equation, Y

flexural represents flexural strength (MPa), and X

compressive represents compressive strength (MPa). The regression line exhibits a high degree of fit to the data points, which is visually supported in

Figure 7 and

Figure 8 and statistically substantiated by an R

2 = 0.77 value.

3.6. Relationship Between Compressive and Flexural Strength

In conventional concrete, flexural strength typically represents 10–15% of compressive strength. However, the flexural-to-compressive strength ratios observed in this study ranged from 25% to 35%, indicating relatively enhanced flexural performance. This improvement may be attributed to the unique morphology of the acidic pumice aggregate and the resulting microstructural characteristics of the concrete, which may contribute to better crack-bridging and energy dissipation under bending-induced tensile stresses.

Nevertheless, as detailed in

Section 3.1 and

Section 3.2, the general reduction in both compressive and flexural strengths with increasing pumice content reflects an inherent trade-off in the use of lightweight aggregates. These reductions are primarily linked to the high porosity of pumice and the associated weakening of the aggregate–matrix interface.

From an engineering standpoint, the existence of a predictable and robust correlation between these two fundamental mechanical properties simplifies structural design and improves reliability in performance predictions under various loading conditions. However, the reduction in absolute strength values must be carefully considered when selecting lightweight concrete for structural applications. In cases where tensile bending resistance is critical—such as pavements, slabs, or precast components—the relatively strong flexural performance of the pumice-based mixtures, even at lower compressive strengths, presents a promising advantage.

These findings highlight the need for continued optimization and deeper investigation into the effects of lightweight aggregate characteristics on the structural performance of concrete.

4. Analysis of Findings

As quantitatively demonstrated in

Section 3.6—through a Pearson correlation coefficient of r = 0.88 and a high coefficient of determination (R

2) from regression analysis—a strong and positive correlation was established between compressive and flexural strengths. This relationship underscores a critical aspect of the mechanical behavior of the lightweight concrete mixtures investigated. While it aligns with the general understanding that higher compressive strength often correlates with greater bending resistance, the proportional behavior observed in this study remains notable despite the substantial strength reductions associated with acidic pumice-based mixtures.

This analysis systematically evaluates the impact of pumice content on the mechanical and durability properties of concrete, based on the quantitative data presented in the preceding sections.

All correlations were found to be statistically significant, with

p-values of

p = 0.000, well below the standard α-level of 0.05 (see

Table 7). These findings are further illustrated in

Figure 13, which highlights substantial reductions in compressive and flexural strengths in the LC50, LC60, and LC70 mixtures relative to the normal concrete (NC).

The correlation coefficient between three-point flexural strength and pumice content was calculated as r = −0.988, indicating a very strong negative correlation—well beyond the conventional threshold of |r| > 0.70. This clearly demonstrates that increasing the volume fraction of pumice aggregate significantly reduces three-point flexural strength. Similarly strong inverse relationships were identified for four-point flexural strength (r = −0.952) and compressive strength (r = −0.994), confirming that the mechanical performance of concrete is highly sensitive to pumice incorporation. These results are summarized in

Table 8.

The near-perfect negative correlation coefficients suggest a quasi-deterministic relationship, establishing pumice content as a key predictive variable in determining mechanical performance in lightweight concrete systems.

Beyond strength-related parameters, strong correlations were also observed in durability metrics. Specifically, water absorption and capillary-driven weight changes showed correlation coefficients of r = 0.983 and r = −0.987, respectively. These values underscore the dual functionality of pumice—as both a lightweight aggregate and a moisture-responsive material—highlighting its complex role in long-term durability under environmental stressors such as heat and water exposure.

In summary, the statistical analyses reveal the inherent trade-offs in the use of acidic pumice aggregates: while they lower density and enhance thermal insulation, they simultaneously reduce mechanical strength and increase sensitivity to moisture and thermal degradation.

For the concrete specimens, the correlation coefficients for weight change over 28 days and 168 h were calculated as r = −0.997 and r = −0.953, respectively. Both values represent strong negative correlations, well exceeding the commonly accepted threshold of |r| > 0.70. These results indicate that weight loss over time is closely and inversely related to the pumice content in the concrete mixtures.

Similarly, the correlation coefficients between water absorption and weight gain during incremental immersion at water depths of 5 cm, 10 cm, and 15 cm (each for 72 h) were found to be r = 0.951, r = 0.963, and r = 0.983, respectively. These values confirm a strong positive relationship between water absorption and weight gain during immersion: as concrete absorbs more water, its weight correspondingly increases.

In terms of high-temperature exposure, LC70 concrete exhibited more pronounced mass loss than NC concrete, primarily due to its higher pumice content. This aligns with the trend observed across all mixtures: as the proportion of pumice increases, both water absorption and susceptibility to moisture-related mass loss also rise.

Table 9 shows a statistically significant correlation (

p = 0.003) between water absorption and specimen weight, confirming the reliability of this relationship at a significance level of

p < 0.05. These results are detailed in

Table 10.

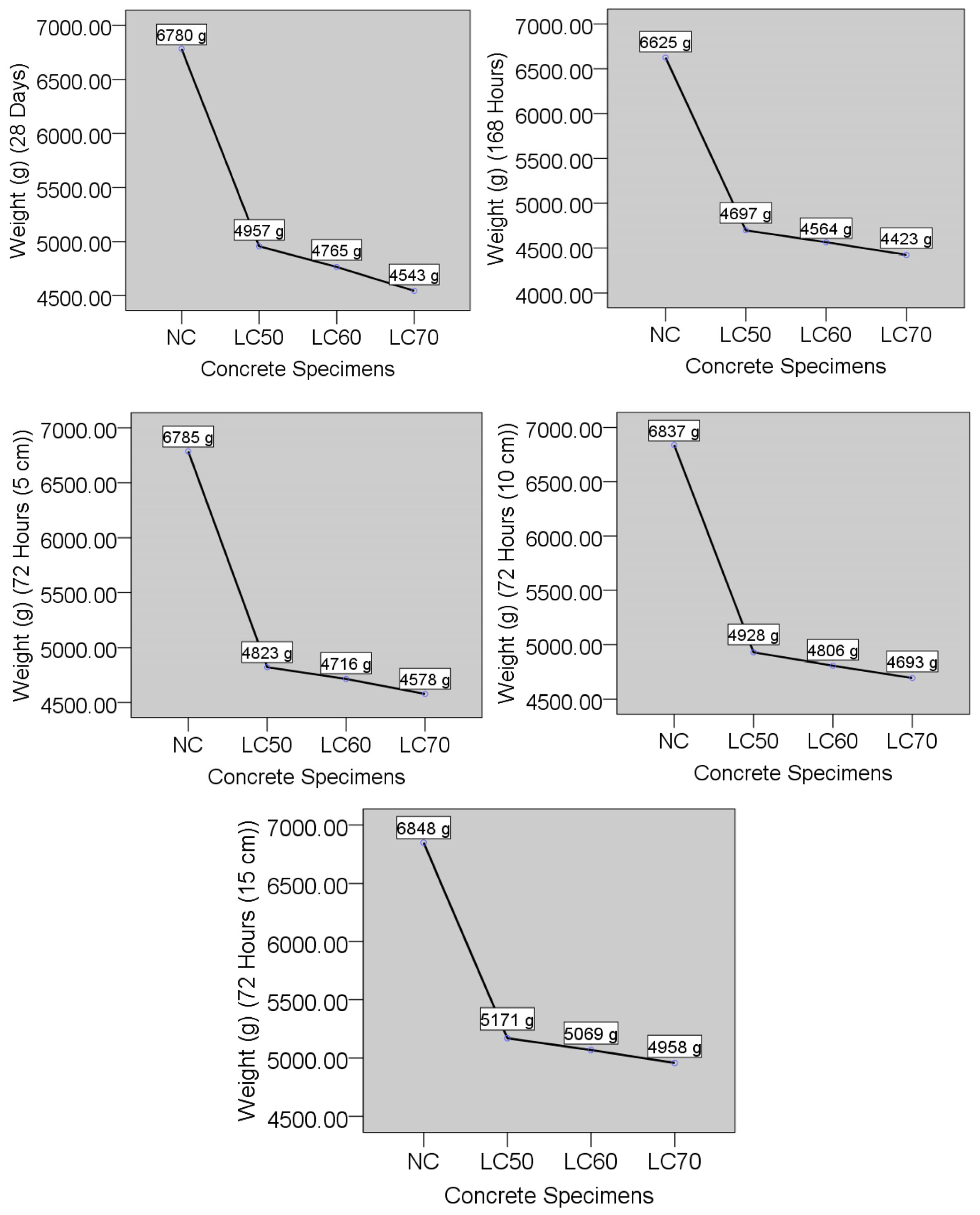

As depicted in

Figure 14, after 168 h of natural air drying, the mass of the NC specimen decreased from 6710 g to 6625 g, LC50 from 4957 g to 4697 g, and LC70 from 3150 g to 2890 g. These observations clearly demonstrate the enhanced moisture loss in pumice-based concretes, attributable to their higher porosity and more open internal structure.

The correlation coefficients between concrete weight changes measured at 28 days and after 168 h—both under ambient conditions of 20 ± 2 °C—were found to be r = −0.911 and r = −0.920, respectively. These strong negative correlations (|r| > 0.70) indicate that increasing thermal exposure leads to a significant reduction in specimen mass.

For example, the mass of the normal concrete (NC) decreased from 6884 g to 4284 g after exposure to 300 °C, while the LC70 mix showed a reduction from 4332 g to 3201 g under the same conditions. This confirms that elevated temperatures accelerate moisture loss and drive off bound water, particularly in mixtures with higher pumice content.

Increased pumice content was also found to negatively impact the thermal resistance of the concrete. The correlation coefficients between temperature and mass loss for NC, LC50, LC60, and LC70 exposed to 100 °C, 200 °C, and 300 °C were −0.913, −0.915, and −0.987, respectively. The LC70 mix exhibited the highest weight loss, attributable to its greater porosity and lower thermal stability.

As detailed in

Table 11, higher pumice proportions were also associated with increased water absorption capacity. Correlations between elevated temperature and weight loss were all statistically significant (

p = 0.000, see

Table 12), confirming the reliability of these observations.

Furthermore, mass loss in NC concrete increased from 153 g at ambient conditions to 447 g after 72 h at 300 °C. For LC70, mass loss rose from 286 g to 846 g under the same thermal regime (

Figure 15). These results clearly indicate that higher pumice content substantially reduces thermal durability.

In addition, the results underscore a cumulative pattern of water ingress and retention in porous matrices. The stepwise immersion method effectively simulates capillary-driven saturation, revealing that water uptake increases more aggressively with higher pumice content.

Discussion of Results with Literature

The results obtained from this experimental study show both convergence and divergence with existing literature on lightweight concretes incorporating pumice or other porous aggregates.

Mechanical Strength: The observed reduction in compressive strength from 25.64 MPa (NC) to 7.76 MPa (LC70) aligns with earlier findings by Topcu and Uygunoglu (2007), who reported significant strength loss in lightweight concretes due to the porous nature and weak mechanical interlocking of pumice aggregates [

35]. Similarly, Kilic et al. (2003) demonstrated that increasing pumice content reduces the internal cohesion and interfacial bond strength, resulting in decreased compressive and flexural capacities [

36]. The high correlation coefficients (r > 0.98) obtained in this study reinforce these trends, further quantifying the sensitivity of strength parameters to pumice substitution levels.

Flexural Behavior: The distinction between three-point and four-point flexural strength in this study also supports findings from Neville (2012), who emphasized that four-point bending tends to produce higher strength values due to distributed load application [

37]. The flexural strength reduction of up to 61.5% in LC70 also reflects the conclusions of Demirboga and Gul (2003), who highlighted that porous lightweight aggregates compromise tensile resistance, particularly at the aggregate–paste interface [

38].

Water Absorption and Moisture Transport: Water absorption values increasing up to 10.90% in LC70 are consistent with ASTM C642 [

34] based studies such as those by Chandra and Berntsson (2003), which confirmed that volcanic aggregates such as pumice exhibit high open porosity, resulting in substantial moisture uptake [

39]. The strong correlation (r = 0.983) between immersion depth and water absorption observed here complements the capillary rise patterns documented in TS EN 13057 [

32] and ASTM C1585 [

33], further validating the experimental method used.

High-Temperature Behavior: While most studies examine thermal resistance above 600 °C [

40], the present study focuses on early-stage thermal degradation (100–300 °C), providing a novel approach to understanding the role of bound water loss and pore evaporation. Surface void formation observed in LC60 and LC70 after exposure to 300 °C is in agreement with the microcrack patterns reported by Hager (2013), who noted that lightweight concretes with high porosity are more prone to thermal spalling and dehydration-related deterioration [

41].

Density and Structural Implications: The reduction in density from 2170 kg/m

3 (NC) to 1832 kg/m

3 (LC70) confirms the classification of these mixes as lightweight concrete per ACI 213R-14 [

42] and EN 206-1 [

43], and supports the suitability of pumice concrete for non-load-bearing applications as emphasized by Short and Kinniburgh (1963) and later reinforced in Mehta and Monteiro (2014) [

44,

45].

Novelty and Differentiation: Although previous works [

35,

39] have investigated pumice-based concretes, this study distinguishes itself by: quantifying the correlation coefficients between thermal exposure, weight loss, and pumice content, comparing flexural test types (three-point vs. four-point) systematically and statistically, and employing a multi-step capillary absorption protocol, which better simulates field-like moisture behavior.

5. Conclusions

This experimental study examined the mechanical and physical performance of lightweight concrete incorporating acidic pumice aggregate under elevated temperature conditions. The key findings are summarized below:

Mechanical Properties:

Increasing the proportion of acidic pumice aggregate significantly reduced both compressive and flexural strengths. Correlation coefficients of −0.994 (compressive strength) and −0.988 (three-point flexural strength) confirm a strong inverse relationship between pumice content and mechanical performance. The compressive strength of the LC70 mix was approximately 69.7% lower than that of the control mix (NC).

Water Absorption:

Specimens with higher pumice content exhibited substantially greater water absorption, attributed to the aggregate’s high intrinsic porosity. A correlation coefficient of 0.983 (at 15 cm immersion) highlights the direct relationship between pumice substitution and moisture uptake. The LC70 mix recorded a water absorption of 10.90%, compared to 1.21% for NC.

High-Temperature Behavior:

Exposure to temperatures of 100 °C, 200 °C, and 300 °C resulted in increased mass loss in concretes with higher pumice content due to the evaporation of free and chemically bound water. The porous structure of pumice facilitated deeper heat penetration, intensifying moisture loss. Surface voids ranging from 1 to 3 mm were observed in LC60 and LC70 mixes after thermal exposure, indicating early-stage microstructural degradation.

Practical Implications:

While acidic pumice aggregates reduce the unit weight of concrete and enhance its thermal characteristics, they lead to reductions in mechanical strength. These concretes are best suited for non-load-bearing applications—such as insulation layers, partition walls, screeds, and filler elements—where lightweight and thermal performance are prioritized over structural capacity.

Recommendations for Future Research:

To offset mechanical strength reductions, future studies should explore the use of high-temperature-resistant fibers and supplementary cementitious materials (SCMs), such as fly ash and slag. Microstructural analyses (e.g., SEM, XRD) are recommended to investigate pore structure evolution and mineralogical changes under thermal exposure. Evaluations at higher temperatures (600–800 °C), representative of fire conditions, would provide further insight into fire resistance. Comparative studies using inert lightweight aggregates would help isolate pumice-specific effects.

This study goes beyond previous research by integrating quantitative mass loss measurements with surface damage observations, offering a more complete understanding of early thermal degradation mechanisms in lightweight concrete. The results provide a solid experimental basis for optimizing the balance between weight, mechanical performance, and thermal behavior in pumice-based lightweight concrete systems.

Table 13 shows a comparison of acidic pumice concrete results with the literature.