Prediction on Slip Modulus of Screwed Connection for Timber–Concrete Composite Structures Based on Machine Learning

Abstract

1. Introduction

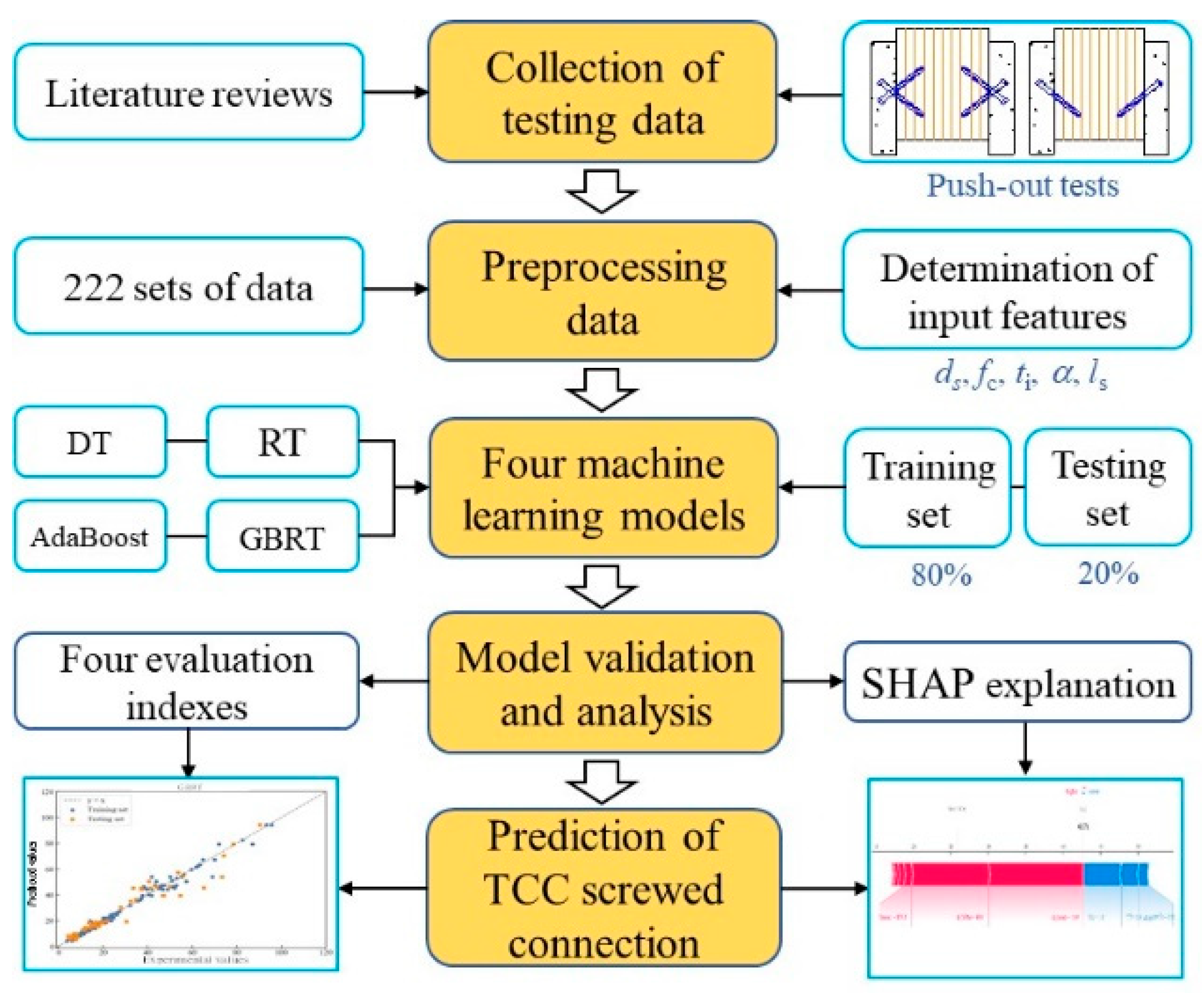

2. Establishment of Experimental Data Set

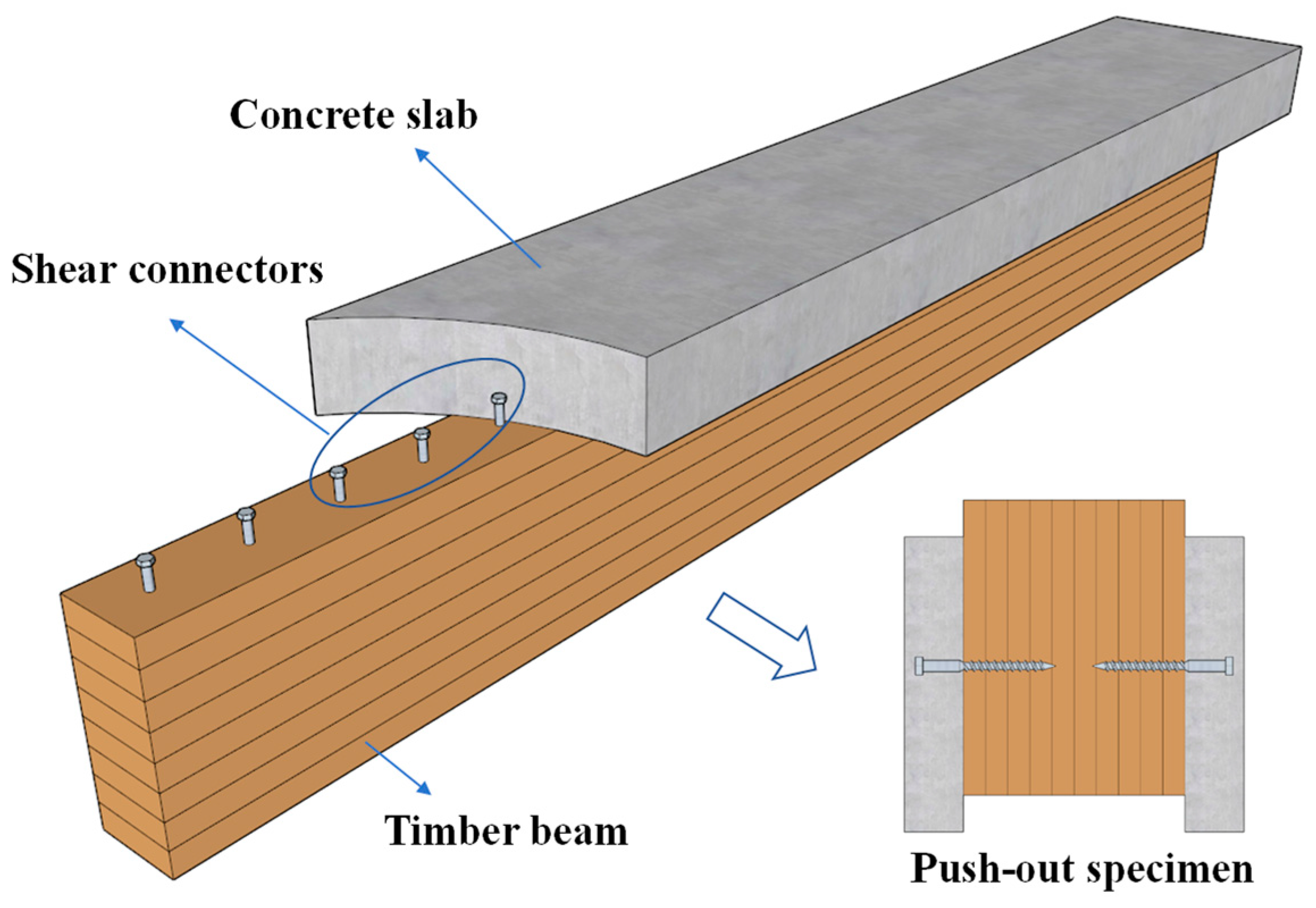

2.1. Introduction of Interfacial Shear Tests for TCC Structures

2.2. Data Set Processing and Determination of Input Parameters

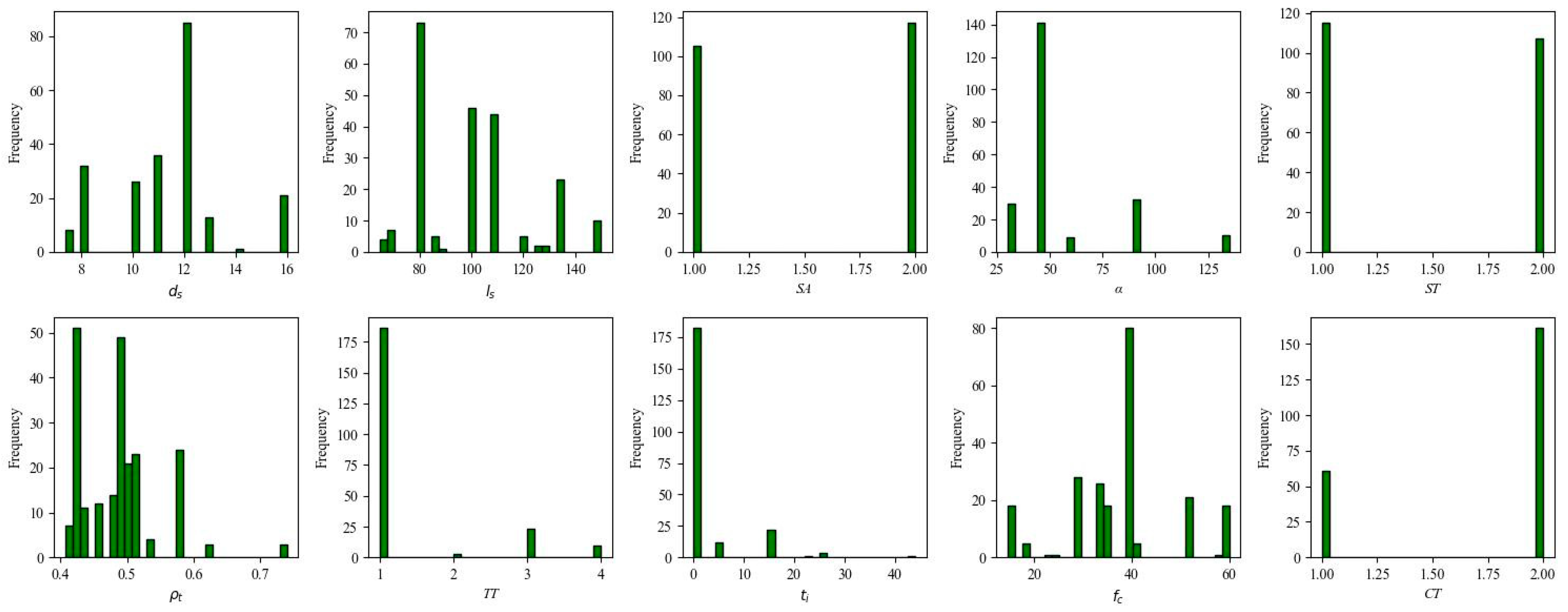

2.2.1. Data Set Collection

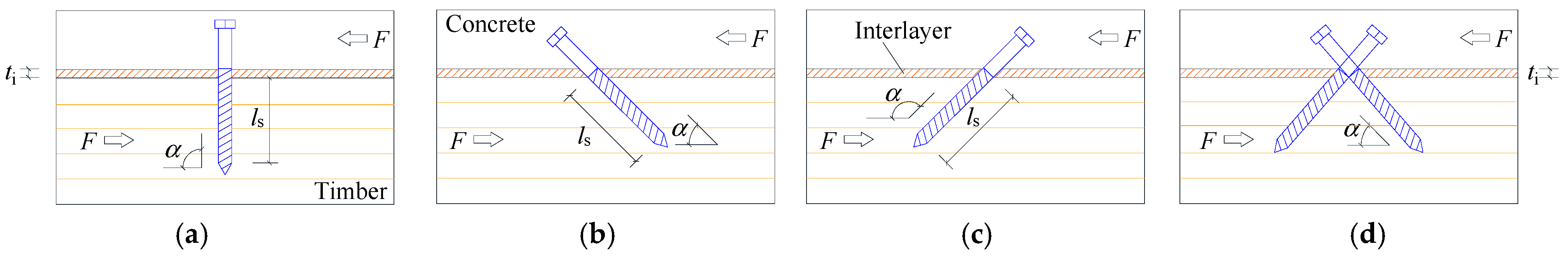

2.2.2. Determination of Input Features

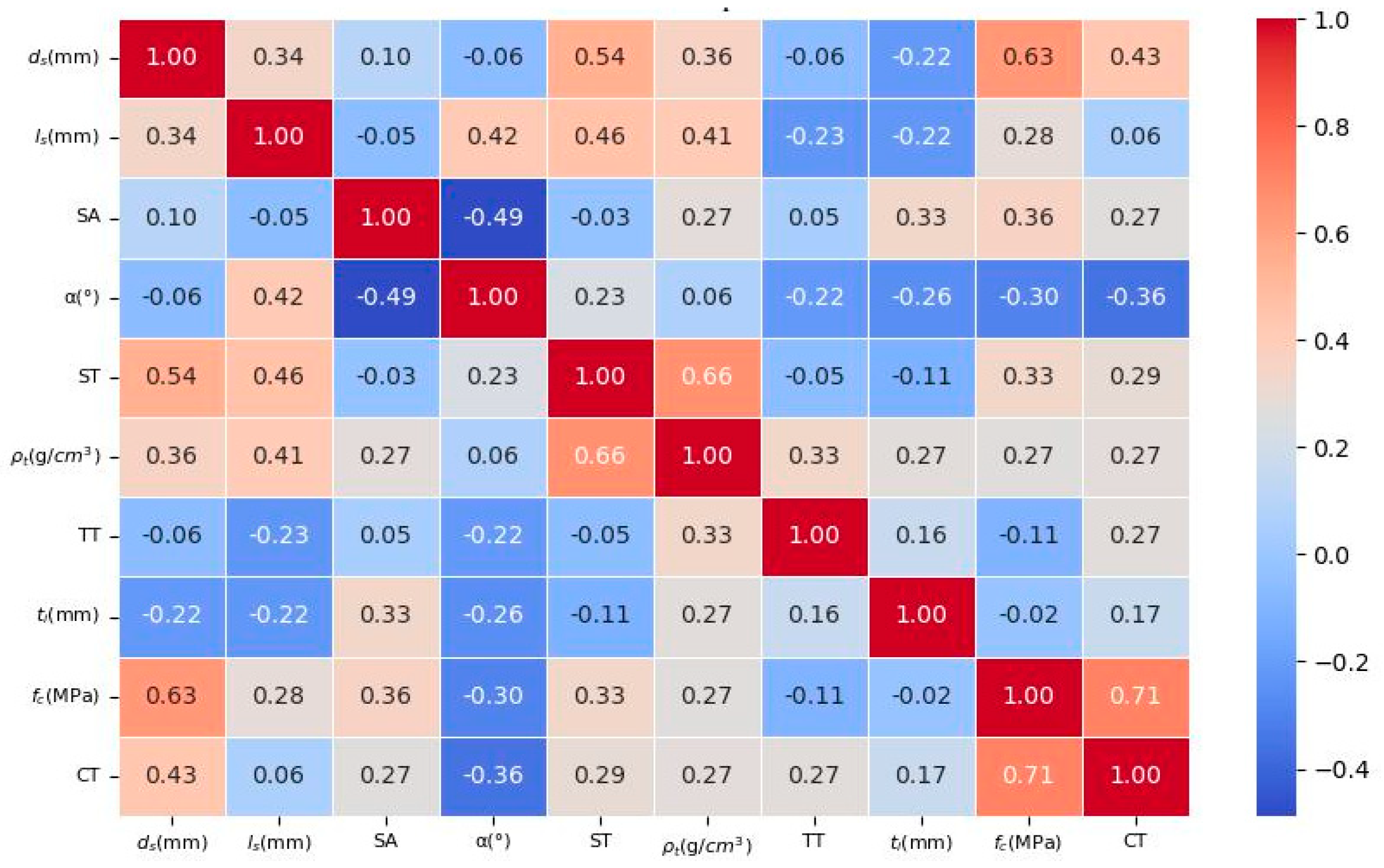

2.3. Processing and Correlation Analysis

3. ML Algorithms

3.1. ML Methods

3.1.1. Decision Tree

3.1.2. Random Forest

3.1.3. Adaptive Boosting Machine

3.1.4. Gradient Boosting Regression Tree

3.2. Quantitative Indices

4. Development and Results of ML Models

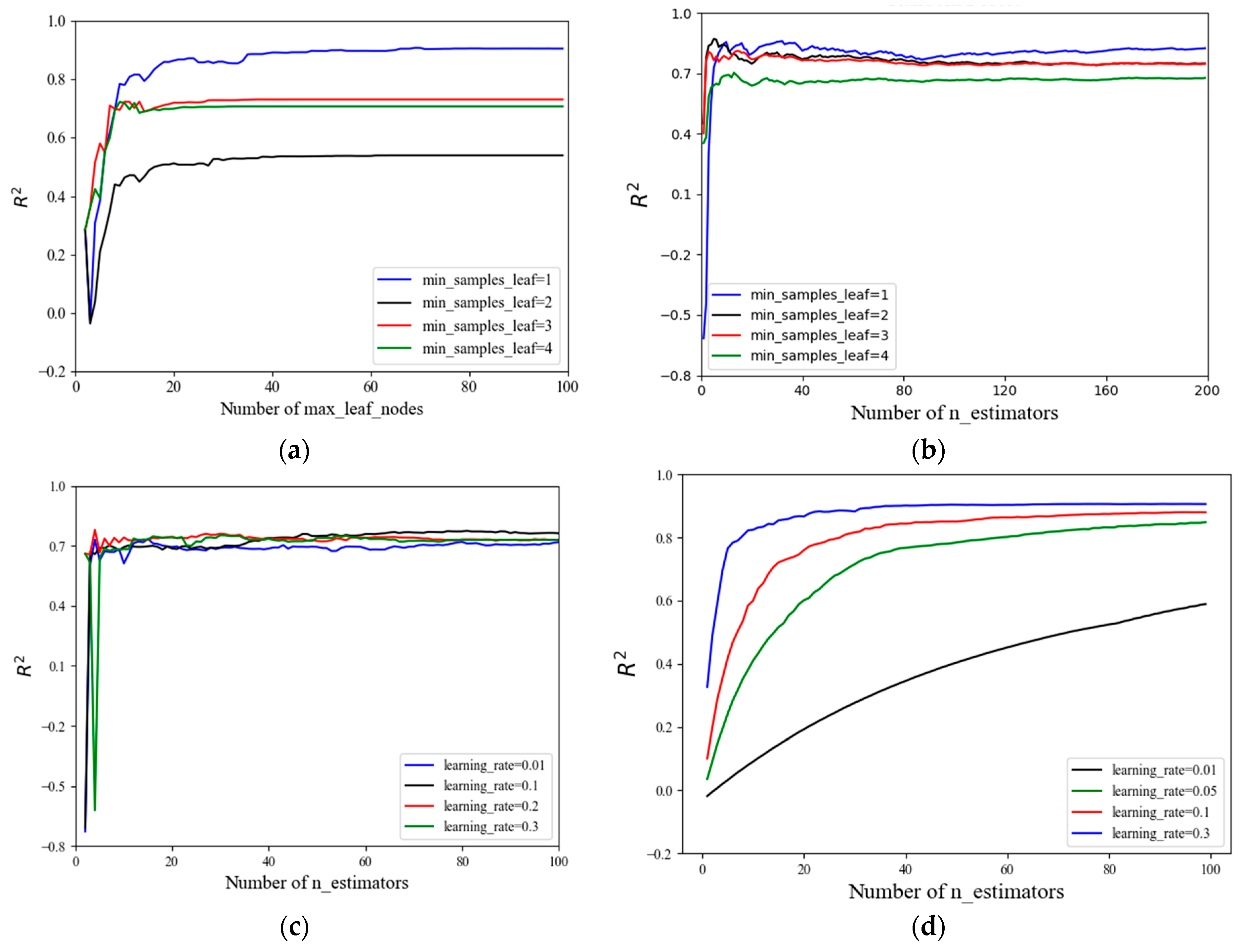

4.1. Hyperparameter Tuning

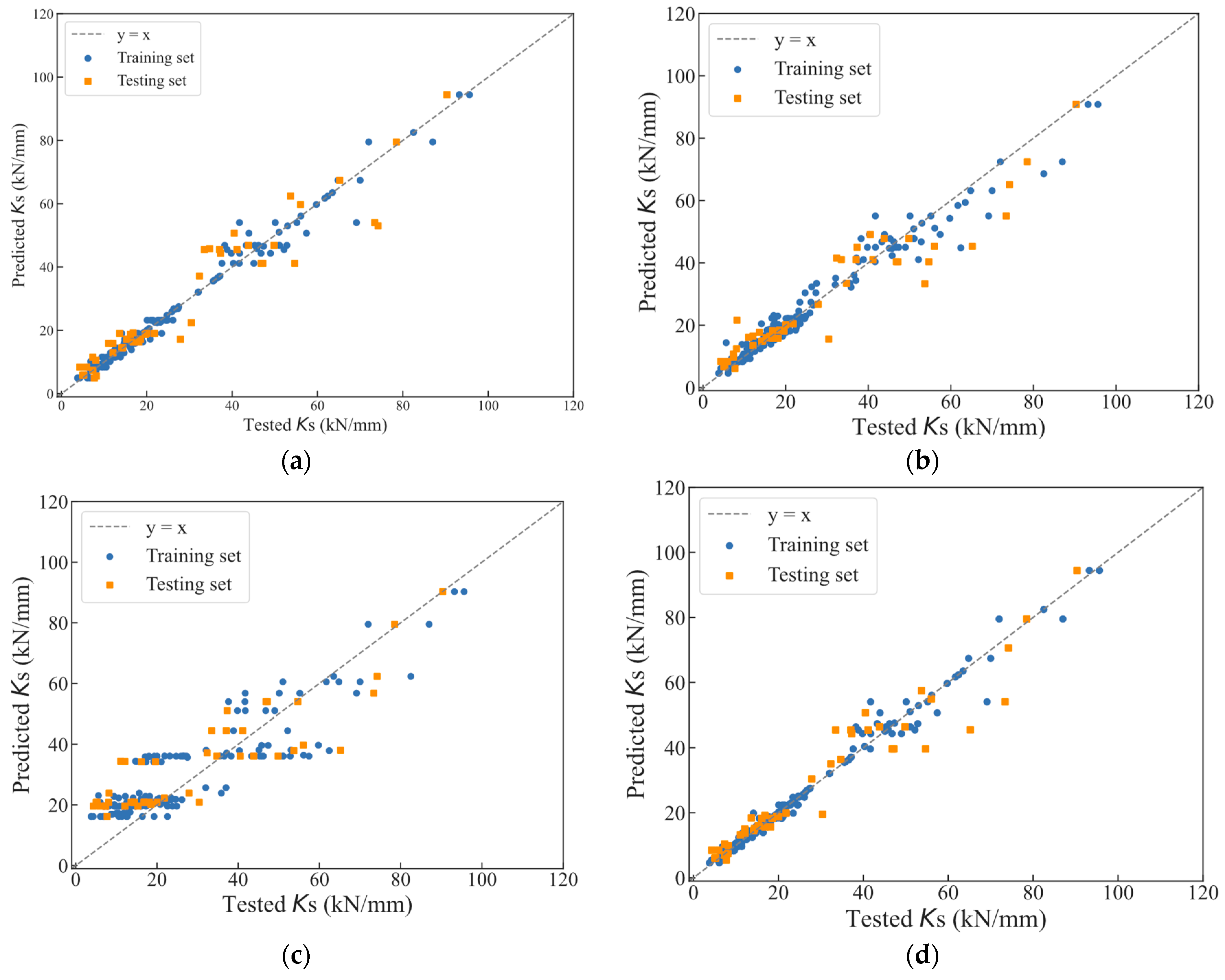

4.2. Prediction Accuracy

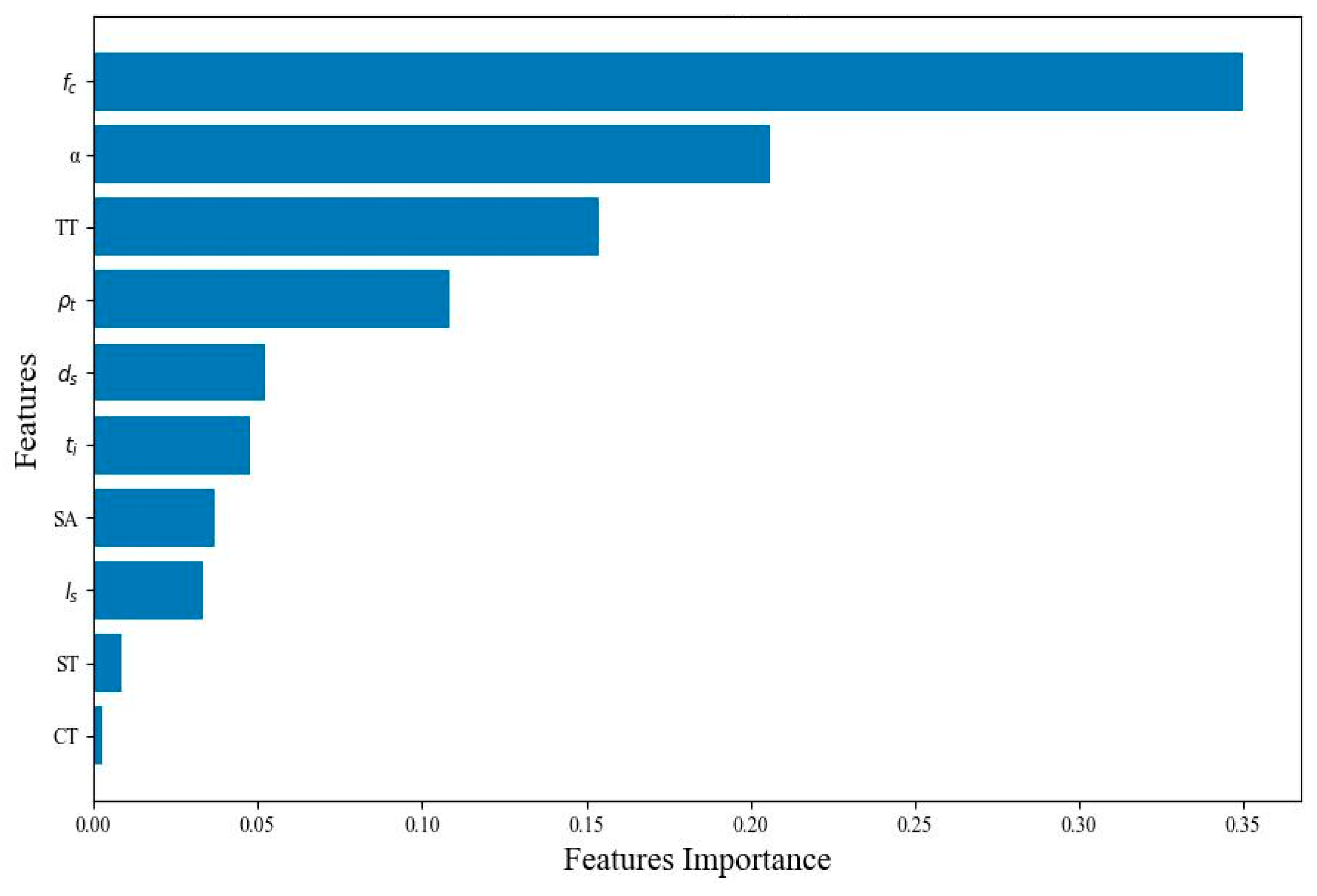

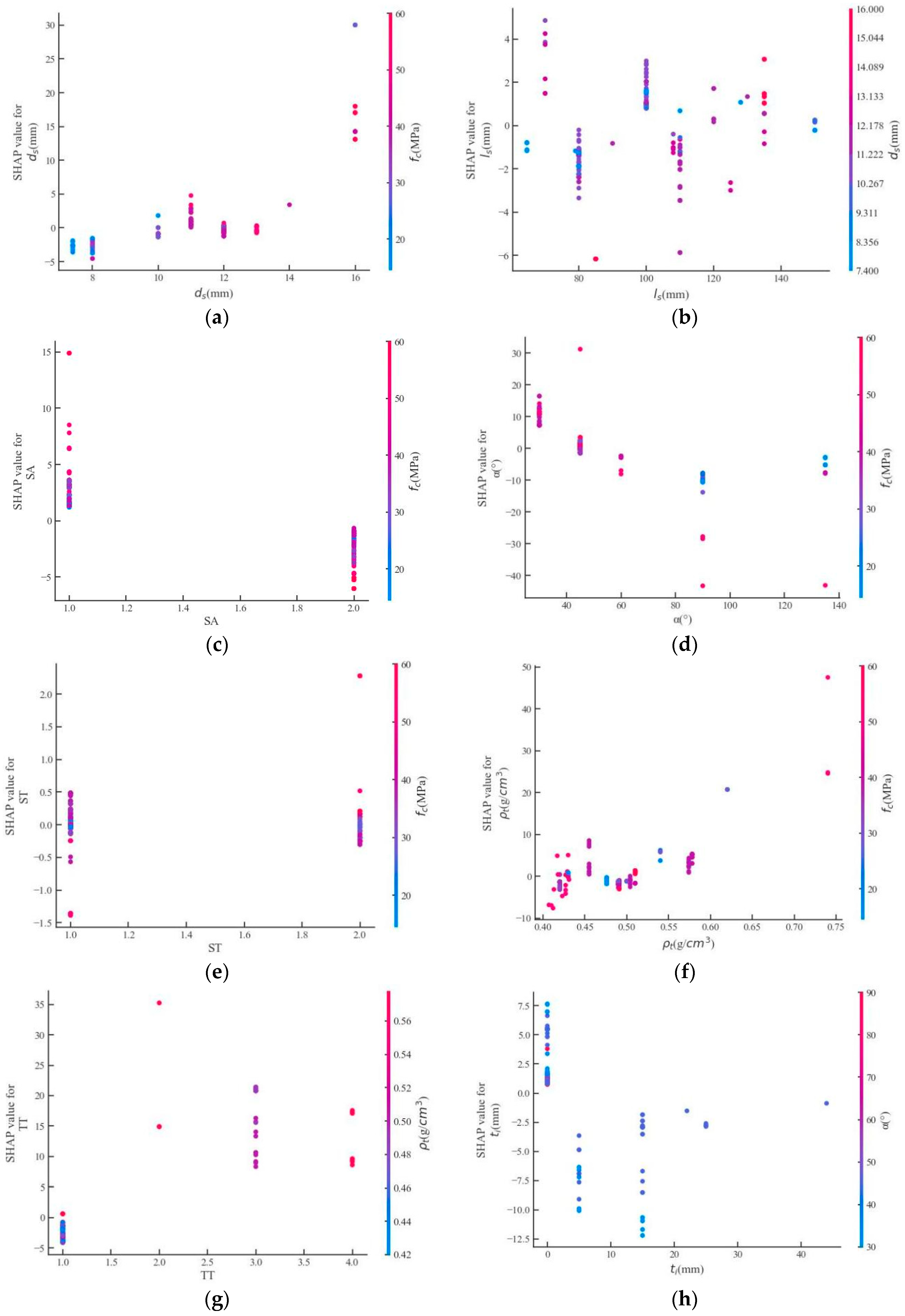

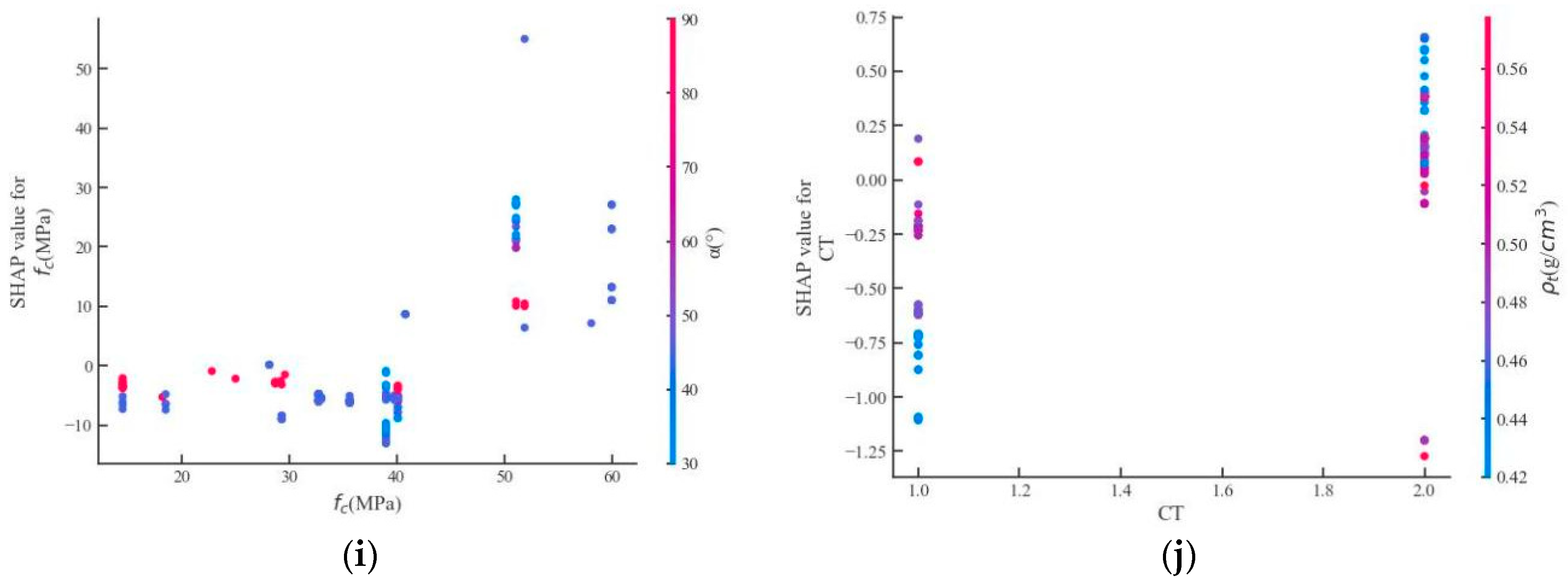

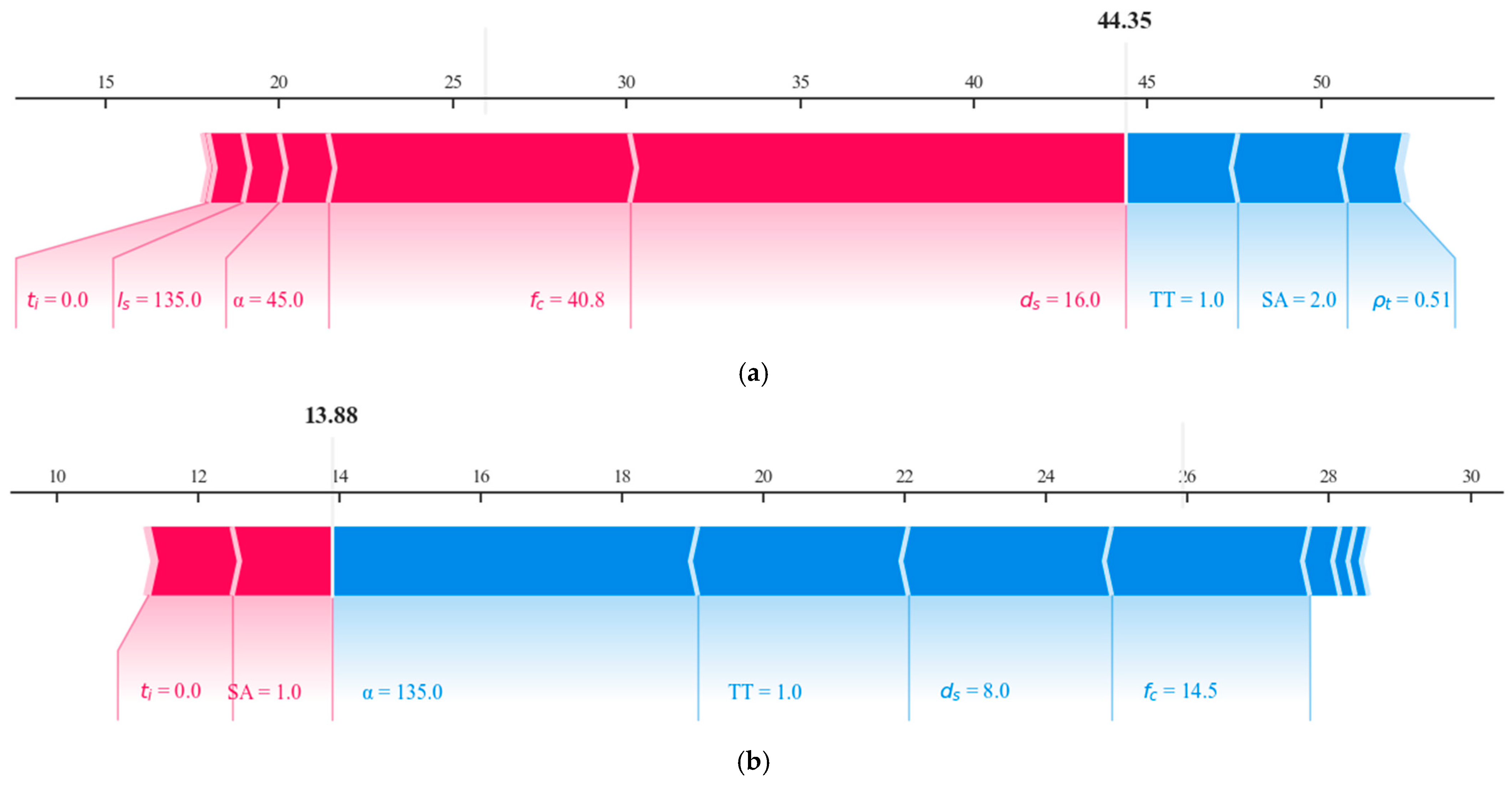

4.3. Interpretation of the GBRT Model Using Shapley Additive Explanations

4.4. Interpretation of GBRT

5. Compared with Existing Models

5.1. Existing Analytical Methods

- (a)

- Empirical formula suggested in Eurocode 5 [29].

- (b)

- Dias’s model [79].

- (c)

- Wilkinson’s model [81].

- (d)

- Theoretical formula proposed by Du et al. [51].

- (e)

- Theoretical formula proposed by Tao et al. [26]

5.2. Accuracy of Existing Design Methods

- (i)

- High accuracy and extensive applicability. The ML-based methods show better prediction accuracy in terms of the four quantitative indices. In addition, the existing theoretical and empirical models mostly apply to a specific connection arrangement depicted in Figure 2. ML-based methods can be used for the slip modulus prediction of any potential connection arrangement, as well as connection-dimensional parameters and material characteristics, which are covered in the data set.

- (ii)

- Discovery in the interface slip mechanism of a TCC screwed connection. With the use of the SHAP framework, the importance of each feature and its influence on the slip modulus of screwed connections are shown in Figure 9 and Figure 10, respectively. This provides guidance for the optimal design of TCC screwed connections. Particularly, the compressive strength, which is largely overlooked in existing design models, has been verified to exert significantly positive effects on the slip modulus, whereas the influence of the interlayer thickness may have been overestimated in the past [52].

- (iii)

- High feasibility and convenience. The physical characteristics (input features) of the screwed connection covered in the data set are easy to obtain and determine, which means that the prediction using ML-based methods is remarkably convenient in the process of service engineering design. For comparison, the theoretical and empirical models rely on the determination of the timber foundation coefficient, axial screw pull-out modulus, and concrete foundation coefficient that need to be determined through material tests.

6. Conclusions

- (i)

- GBRT shows the highest accuracy in terms of R2, RMSE, MAE, and MAPE compared with the other three ML algorithms. The GBRT algorithm for the training and testing sets showed R2 values of 0.9879 and 0.9197, respectively, followed by the DT algorithm corresponding to R2 values of 0.9872 and 0.9076, respectively.

- (ii)

- The ML algorithms demonstrate higher prediction accuracy and applicability than existing design methods. The empirical formula listed in Eurocode 5 exhibits acceptable accuracy only when it is applied to predict the slip modulus of vertical screw connections without interlayers. The theoretical models face limitations in the arrangement of screws, the presence of an interlayer, and the determination of some physical parameters.

- (iii)

- Through the SHAP framework, it was verified that the concrete compressive strength exerts the highest influence on the slip modulus of the TCC screwed connection, which is overlooked in existing theoretical models. The SHAP values of the screw inclination, the timber type, and the density, which also greatly affect the slip modulus, follow closely behind the concrete compressive strength.

- (iv)

- Through an input feature impact analysis and two typical experimental cases, it was demonstrated that increasing the timber density, concrete compressive strength, and screw diameter, as well as decreasing the screw inclination angle and interlayer thickness, can effectively improve the slip modulus of TCC screwed connections, which can provide diverse choices for the performance-based design of TCC structures. The machine-learning method tested in this study can be effectively applied to predict the slip modulus of the screwed connections, providing precise predictions for the parametric and performance-based design of interface connections in timber–concrete composite structures.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Dias, A.; Skinner, J.; Crews, K.; Tannert, T. Timber-concrete-composites increasing the use of timber in construction. Eur. J. Wood Prod. 2016, 74, 443–451. [Google Scholar] [CrossRef]

- Frangi, A.; Knobloch, M.; Fontana, M. Fire design of timber-concrete composite slabs with screwed connections. J. Struct. Eng. 2010, 136, 219–228. [Google Scholar] [CrossRef]

- Wen, B.; Tao, H.; Shi, B.; Yang, H. Dynamic properties of timber–concrete composite beams with crossed inclined coach screw connections: Experimental and theoretical investigations. Buildings 2023, 13, 2268. [Google Scholar] [CrossRef]

- Zhang, C.; Lu, X.; Shi, B.; Yang, H.; Tao, H.; Liu, J. Experimental and numerical investigations on flexural behavior of stress-laminated timber-concrete composite decks with butt joints. Eng. Struct. 2024, 316, 118534. [Google Scholar] [CrossRef]

- Höltke, T.; Bleicher, A. Experimental and numerical investigations of a timber-concrete composite frame joint for high-rise buildings. Eng. Struct. 2025, 333, 120034. [Google Scholar] [CrossRef]

- Otero-Chans, D.; Suárez-Riestra, F.; Martín-Gutiérrez, E.; Estévez-Cimadevila, J. Experimental and numerical analysis of a full-scale timber-concrete-composite beam from simply supported to frame-connected. Eng. Struct. 2025, 327, 119624. [Google Scholar] [CrossRef]

- Chen, H.; Ma, W.; Kasal, B.; Wei, Y.; Yan, L. Flexural behavior of adhesively bonded cross-laminated timber-concrete composite (TCC) panel with glass-fiber textile mesh as reinforcement in concrete: Experimental studying and numerical simulation. Eng. Struct. 2025, 330, 119916. [Google Scholar] [CrossRef]

- Tao, H.; Yang, H.; Zhou, Z.; Wu, Y.; Ju, G.; Shi, B. Influence of slab composite effect on the seismic performance of a six-story timber-concrete composite moment-resisting frame. J. Build. Eng. 2025, 101, 111815. [Google Scholar] [CrossRef]

- Shi, B.; Zhou, X.; Tao, H.; Yang, H.; Wen, B. Long-term behavior of timber–concrete composite structures: A literature review on experimental and numerical investigations. Buildings 2024, 14, 1770. [Google Scholar] [CrossRef]

- Yang, H.; Lu, Y.; Ling, X.; Tao, H.; Shi, B. Experimental and theoretical investigation on shear performances of glued-in perforated steel plate connections for prefabricated timber–concrete composite beams. Case Stud. Constr. Mater. 2023, 18, e01885. [Google Scholar] [CrossRef]

- Rasmussen, P.K.; Sørensen, J.H.; Hoang, L.C.; Feddersen, B.; Larsen, F. Notched connection in timber-concrete composite deck structures: A literature review on push-off experiments & design approaches. Constr. Build. Mater. 2023, 397, 131761. [Google Scholar] [CrossRef]

- Shi, B.; Dai, Y.; Tao, H.; Yang, H. Shear performances of hybrid notch-screw connections for timber-concrete composite structures. BioResources 2022, 17, 2259–2274. [Google Scholar] [CrossRef]

- Zhang, L.; Zhou, J.; Chui, Y.H. Development of high-performance timber-concrete composite floors with reinforced notched connections. Structures 2022, 39, 945–957. [Google Scholar] [CrossRef]

- Suárez-Riestra, F.; Estévez-Cimadevila, J.; Martín-Gutierrez, E.; Otero-Chans, D. Perforated shear + reinforcement bar connectors in a timber-concrete composite solution. Analytical and numerical approach. Compos. Part B Eng. 2019, 156, 138–147. [Google Scholar] [CrossRef]

- Dias, A.; Schaenzlin, J.; Dietsch, P. Design of Timber-Concrete Composite Structures, COST Action FP1402/WG4; Shaker Verlag: Düren, Germany, 2018. [Google Scholar]

- Steinberg, E.; Selle, R.; Faust, T. Connectors for timber–lightweight concrete composite structures. J. Struct. Eng. 2013, 129, 1538–1545. [Google Scholar] [CrossRef]

- Dias, A.M.P.G.; Cruz, H.M.P.; Lopes, S.M.R.; van de Kuilen, J.W. Stiffness of dowel-type fasteners in timber–concrete joints. Proc. Inst. Civ. Eng. -Struct. Build. 2010, 163, 257–266. [Google Scholar] [CrossRef]

- Marchi, L.; Scotta, R.; Pozza, L. Experimental and theoretical evaluation of TCC connections with inclined self-tapping screws. Mater. Struct. 2017, 50, 180. [Google Scholar] [CrossRef]

- Symons, D.; Persaud, R.; Stanislaus, H. Slip modulus of inclined screws in timber–concrete floors. Proc. Inst. Civ. Eng. -Struct. Build. 2010, 163, 245–255. [Google Scholar] [CrossRef]

- Gan, Z.; Sun, Y.; Sun, X. Push-out performance of inclined screw shear connectors used in nail-laminated timber-concrete composite. Constr. Build. Mater. 2023, 366, 130175. [Google Scholar] [CrossRef]

- Sebastian, W.; Piazza, M.; Harvey, T.; Webster, T. Forward and Reverse shear transfer in beech LVL-concrete composites with singly inclined coach screw connectors. Eng. Struct. 2018, 175, 231–244. [Google Scholar] [CrossRef]

- Appavuravther, E.; Vandoren, B.; Henriques, J. Behaviour of screw connections in timber-concrete composites using low strength lightweight concrete. Constr. Build. Mater. 2021, 28, 122973. [Google Scholar] [CrossRef]

- Martins, C.; Dias, A.M.; Costa, R.; Santos, P. Environmentally friendly high performance timber–concrete panel. Constr. Build. Mater. 2016, 102, 1060–1069. [Google Scholar] [CrossRef]

- Tao, H.; Yang, H.; Ju, G.; Xu, J.; Shi, B. Effective width of timber-concrete composite beams with crossed inclined coach screw connections at the serviceability state. Eng. Struct. 2022, 267, 114716. [Google Scholar] [CrossRef]

- Zhu, W.; Yang, H.; Liu, W.; Shi, B.; Ling, Z.; Tao, H. Experimental investigation on innovative connections for timber–concrete composite systems. Constr. Build. Mater. 2019, 207, 345–356. [Google Scholar] [CrossRef]

- Tao, H.T.; Yang, H.F.; Liu, W.Q.; Wang, C.; Shi, B.; Ling, X. Mechanical behavior of crossed inclined coach screw shear connections for prefabricated timber-concrete composite structures. J. Build. Struct. 2022, 43, 164–174. (In Chinese) [Google Scholar] [CrossRef]

- Deam, B.L.; Fragiacomo, M.; Buchanan, A.H. Connections for composite concrete slab and LVL flooring systems. Mater. Struct. 2008, 41, 495–507. [Google Scholar] [CrossRef]

- China Association for Engineering Construction Standardization. Technical Standard for Timber-Concrete Composite Structures; China Architecture & Building Press: Beijing, China, impending publication.

- EN 1995-1-1:2004; Eurocode 5: Design of Timber Structures—Part 1–1: General—Common Rules and Rules for Buildings. European Committee for Standardization: Brussels, Belgium, 2004.

- Auclair, S.C. Design Guide for Timber-Concrete Composite Floors in Canada; FPInnovations: Pointe-Claire, QC, Canada, 2020. [Google Scholar]

- Di Nino, S.; Gregori, A.; Fragiacomo, M. Experimental and numerical investigations on timber-concrete connections with inclined screws. Eng. Struct. 2020, 209, 109993. [Google Scholar] [CrossRef]

- Mirdad, A.H.; Chui, Y.H. Stiffness prediction of Mass Timber Panel-Concrete (MTPC) composite connection with inclined screws and a gap. Eng. Struct. 2020, 207, 110215. [Google Scholar] [CrossRef]

- Chou, J.-S.; Tsai, C.-F.; Pham, A.-D.; Lu, Y.-H. Machine learning in concrete strength simulations: Multi-nation data analytics. Constr. Build. Mater. 2014, 73, 771–780. [Google Scholar] [CrossRef]

- Sun, H.; Burton, H.V.; Huang, H. Machine learning applications for building structural design and performance assessment: State-of-the-art review. J. Build. Eng. 2021, 33, 101816. [Google Scholar] [CrossRef]

- Xu, J.-G.; Hong, W.; Zhang, J.; Hou, S.-T.; Wu, G. Seismic performance assessment of corroded RC columns based on data-driven machine-learning approach. Eng. Struct. 2022, 255, 113936. [Google Scholar] [CrossRef]

- Zhang, S.; Xu, J.; Lai, T.; Yu, Y.; Xiong, W. Bond stress estimation of profiled steel-concrete in steel reinforced concrete composite structures using ensemble machine learning approaches. Eng. Struct. 2023, 294, 116725. [Google Scholar] [CrossRef]

- Kazemi, F.; Asgarkhani, N.; Jankowski, R. Optimization-based stacked machine-learning method for seismic probability and risk assessment of reinforced concrete shear walls. Expert Syst. Appl. 2024, 255, 124897. [Google Scholar] [CrossRef]

- van Blokland, J.; Nasir, V.; Cool, J.; Avramidis, S.; Adamopoulos, S. Machine learning-based prediction of surface checks and bending properties in weathered thermally modified timber. Constr. Build. Mater. 2021, 307, 124996. [Google Scholar] [CrossRef]

- Li, Z.; Tao, D.; Li, M. Prediction of damage accumulation effect of wood structural members under long-term service: A machine learning approach. Materials 2019, 12, 1243. [Google Scholar] [CrossRef]

- Shams, S.A.; Ge, H.; Wang, L. Hygrothermal modeling in mass timber constructions: Recent advances and machine learning prospects. J. Build. Eng. 2024, 96, 110500. [Google Scholar] [CrossRef]

- Rahimi, S.; Avramidis, S.; Sassani, F.; Nasir, V. Machine learning-based prediction of internal moisture variation in kiln-dried timber, Wood Mater. Sci. Eng. 2024, 19, 499–510. [Google Scholar] [CrossRef]

- EN 26891:1991; Timber Structures—Joints Made with Mechanical Fasteners—General Principles for the Determination of Strength and Deformation Characteristics. European Committee for Standardization: Brussels, Belgium, 1991.

- Ling, Z.B.; Li, Z.-J.; Rong, X.Q. Effect of test configurations and loading protocols on performance of timber-concrete connectors. Constr. Build. Mater. 2023, 367, 130244. [Google Scholar] [CrossRef]

- Mirdad, M.A.H.; Chui, Y.H. Load-slip performance of Mass Timber Panel-Concrete (MTPC) composite connection with Self-tapping screws and insulation layer. Constr. Build. Mater. 2019, 213, 696–708. [Google Scholar] [CrossRef]

- Berardinucci, B.; Di Nino, S.; Gregori, A.; Fragiacomo, M. Mechanical behavior of timber–concrete connections with inclined screws. Int. J. Comp. Meth. Exp. Meas. 2017, 5, 807–820. [Google Scholar] [CrossRef][Green Version]

- Jiang, Y.-C. Mechanical Behaviour and Design Methods of Glulam-Lightweight Concrete Composite Beams. Ph.D. Thesis, Nanjing Tech University, Nanjing, China, 2018. (In Chinese). [Google Scholar]

- Huang, B.-W. Investigations on Flexural Behavior of Timber-Lightweight Concrete Composite Beams. Master’s Thesis, Nanjing Tech University, Nanjing, China, 2022. (In Chinese). [Google Scholar]

- Bao, Y.-W. Study on Flexural Behavior of Cross Laminated Timber (CLT)–Concrete Composite Floor. Master’s Thesis, Nanjing Tech University, Nanjing, China, 2021. (In Chinese). [Google Scholar]

- Du, H.; Hu, X.; Sun, Z.; Meng, Y.; Han, G. Load carrying capacity of inclined crossing screws in glulam-concrete composite beam with an interlayer. Compos. Struct. 2020, 245, 112333. [Google Scholar] [CrossRef]

- Du, H.; Hu, X.-M.; Wang, H.-C.; Zhang, J.; Sun, Z.-X. Shear performance of inclined screws in glulam-concrete composite beams. J. Build. Struct. 2020, 41, 191–200. (In Chinese) [Google Scholar]

- Du, H.; Hu, X.; Xie, Z.; Wang, H. Study on shear behavior of inclined cross lag screws for glulam-concrete composite beams. Constr. Build. Mater. 2019, 224, 132–143. [Google Scholar] [CrossRef]

- Jorge, L.F.C.; Lopes, S.M.R.; Cruz, H.M.P. Interlayer Influence on Timber-LWAC Composite Structures with Screw Connections. J. Struct. Eng. 2011, 137, 618–624. [Google Scholar] [CrossRef]

- Bao, Y.; Lu, W.; Yue, K.; Zhou, H.; Lu, B.; Chen, Z. Structural performance of cross-laminated timber-concrete composite floors with inclined self-tapping screws bearing unidirectional tension-shear loads. J. Build. Eng. 2022, 55, 104653. [Google Scholar] [CrossRef]

- Jiang, Y.; Hong, W.; Hu, X.; Crocetti, R.; Wang, L.; Sun, W. Early-age performance of lag screw shear connections for glulam-lightweight concrete composite beams. Constr. Build. Mater. 2017, 151, 36–42. [Google Scholar] [CrossRef]

- Derikvand, M.; Fink, G. Deconstructable connector for TCC floors using self-tapping screws. J. Build. Eng. 2021, 42, 102495. [Google Scholar] [CrossRef]

- Du, H.; Xu, R.; Liu, P.; Yuan, S.; Wei, Y. Experimental and theoretical evaluation of inclined screws in glued laminated bamboo and timber-concrete composite beams. J. Build. Eng. 2024, 91, 109579. [Google Scholar] [CrossRef]

- Tao, H.; Yang, H.; Liu, W.; Wang, C.; Shi, B.; Ling, X. Experimental and nonlinear analytical studies on prefabricated timber–concrete composite structures with crossed inclined coach screw connections. J. Struct. Eng. 2021, 147, 04021043. [Google Scholar] [CrossRef]

- Niederwestberg, J.; Zhou, J.; Chui, Y.-H. Mechanical properties of innovative, multi-layer composite laminated panels. Buildings 2018, 8, 142. [Google Scholar] [CrossRef]

- Chen, D.; Montano, V.; Huo, L.; Song, G. Depth detection of subsurface voids in concrete-filled steel tubular (CFST) structure using percussion and decision tree. Measurement 2020, 163, 107869. [Google Scholar] [CrossRef]

- Zhang, S.; Chen, X.; Ran, X.; Li, Z.; Cao, W. Prioritizing causation in decision trees: A gramework for interpretable modeling. Eng. Appl. Artif. Intel. 2024, 133 Pt C, 108224. [Google Scholar] [CrossRef]

- He, Z.; Wang, J.; Jiang, M.; Hu, L.; Zou, Q. Random subsequence forests. Inform. Sci. 2024, 667, 120478. [Google Scholar] [CrossRef]

- Bhatt, P.P.; Sharma, N.; Kodur, V.K.R.; Naser, M.Z. Machine learning approach for predicting fire resistance of FRP-strengthened concrete beams. Struct. Concr. 2024, 1–23. [Google Scholar] [CrossRef]

- Arasteh-Khoshbin, O.; Seyedpour, S.M.; Mandl, L.; Lambers, L.; Ricken, T. Comparing durability and compressive strength predictions of hyperoptimized random forests and artificial neural networks on a small dataset of concrete containing nano SiO2 and RHA. Eur. J. Environ. Civ. Eng. 2024, 1–20. [Google Scholar] [CrossRef]

- Kim, T.-K.; Hwang, S.-H.; Kim, J.; Jung, W.-T.; Yoon, J. Analysis of bond strength of CFRP cables with concrete using random forest model. J. Build. Eng. 2024, 96, 110658. [Google Scholar] [CrossRef]

- Li, R.-H.; Li, M.-Y.; Zhu, X.-Y.; Zeng, X.-W. Application of random forest algorithm in estimating dynamic mechanical behaviors of reinforced concrete column members. Appl. Sci. 2024, 14, 2546. [Google Scholar] [CrossRef]

- Lei, Q.; Yu, H.; Lin, Z. Understanding China’s CO2 emission drivers: Insights from random forest analysis and remote sensing data. Heliyon 2024, 10, e29086. [Google Scholar] [CrossRef]

- Cai, R.; Han, T.; Liao, W.; Huang, J.; Li, D.; Kumar, A.; Ma, H. Prediction of surface chloride concentration of marine concrete using ensemble machine learning. Cem. Concr. Res. 2020, 136, 106164. [Google Scholar] [CrossRef]

- Feng, J.; Zhang, H.; Gao, K.; Liao, Y.; Yang, J.; Wu, G. A machine learning and game theory-based approach for predicting creep behavior of recycled aggregate concrete. Case Stud. Constr. Mater. 2022, 17, e01653. [Google Scholar] [CrossRef]

- Chao, Z.; Li, Z.; Dong, Y.; Shi, D.; Zheng, J. Estimating compressive strength of coral sand aggregate concrete in marine environment by combining physical experiments and machine learning-based techniques. Ocean Eng. 2024, 308, 118320. [Google Scholar] [CrossRef]

- Jiang, J.; Xin, C.; Wu, S.; Chen, W.; Li, H.; Ran, Z.; Rao, K.R. Enhancing concrete workability prediction through ensemble learning models: Emphasis on slump and material factors. Adv. Civ. Eng. 2024, 2024, 4616609. [Google Scholar] [CrossRef]

- Wudil, Y.S.; Al-Fakih, A.; Al-Osta, M.A.; Gondal, M. Effective carbon footprint assessment strategy in fly ash geopolymer concrete based on adaptive boosting learning techniques. Environ. Res. 2025, 266, 120570. [Google Scholar] [CrossRef]

- Friedman, J.H. Greedy function approximation: A gradient boosting machine. Ann. Stat. 2001, 29, 1189–1232. [Google Scholar] [CrossRef]

- Xu, N.; Wang, Z.; Dai, Y.; Li, Q.; Zhu, W.; Wang, R.; Finkelman, R.B. Prediction of higher heating value of coal based on gradient boosting regression tree model. Int. J. Coal Geol. 2023, 274, 104293. [Google Scholar] [CrossRef]

- Pan, Y.; Chen, S.; Qiao, F.; Ukkusuri, S.V.; Tang, K. Estimation of real-driving emissions for buses fueled with liquefied natural gas based on gradient boosted regression trees. Sci. Total Environ. 2019, 660, 741–750. [Google Scholar] [CrossRef] [PubMed]

- Nie, P.; Roccotelli, M.; Fanti, M.P.; Ming, Z.; Li, Z. Prediction of home energy consumption based on gradient boosting regression tree. Energy Rep. 2021, 7, 1246–1255. [Google Scholar] [CrossRef]

- Xu, J.G.; Chen, S.Z.; Xu, W.J.; Shen, Z.S. Concrete-to-concrete interface shear strength prediction based on explainable extreme gradient boosting approach. Constr. Build. Mater. 2021, 308, 125088. [Google Scholar] [CrossRef]

- Nguyen, H.; Vu, T.; Vo, T.P.; Thai, H.-T. Efficient machine learning models for prediction of concrete strengths. Constr. Build. Mater. 2021, 266 Pt B, 120950. [Google Scholar] [CrossRef]

- Lungberg, S.M.; Lee, S.-I. An unified approach to interpreting model predictions. In Proceedings of the 31st International Conference on Neural Information Processing Systems, Long Beach, CA, USA, 4–9 December 2017; pp. 4768–4777. [Google Scholar]

- Dias, A.M.P.G. Mechanical Behaviour of Timber-Concrete Joints. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2005. [Google Scholar]

- EN 1993-1-1: 2005; Eurocode 3: Design of Steel Structures—Part 1-1: General Rules and Rules for Buildings. European Committee for Standardization: Brussels, Belgium, 2005.

- Wilkinson, T.L. Analysis of nailed joints with dissimilar member. J. Struct. Div. 1972, 98, 2005–2013. [Google Scholar] [CrossRef]

- Stamatopoulos, H.; Malo, K.A. Withdrawal stiffness of threaded rods embedded in timber elements. Constr. Build. Mater. 2016, 116, 263–272. [Google Scholar] [CrossRef]

- Mirdad, M.A.H.; Jucutan, A.; Khan, R.; Niederwestberg, J.; Chui, Y.H. Embedment and withdrawal stiffness predictions of self-tapping screws in timber. Constr. Build. Mater. 2022, 345, 128394. [Google Scholar] [CrossRef]

| Methods | Hyper-Param1 | Hyper-Param2 | Hyper-Param3 |

|---|---|---|---|

| DT | max_depth(1, 20)/13 | max_leaf_nodes(1, 100)/69 | min_samples_leaf(1, 10)/1 |

| RF | n_estimators(1, 500)/18 | max_depth(1, 20)/11 | min_samples_leaf(1, 10)/1 |

| AdaBoost | n_estimators(1, 500)/21 | Learning_rate(0, 1)/0.3230 | / |

| GBRT | n_estimators(1, 500)/431 | max_depth(1, 10)/3 | learning_rate(0, 0.5)/0.3096 |

| Indexes | R2 | MAE | RMSE | MAPE (%) | ||||

|---|---|---|---|---|---|---|---|---|

| Training | Testing | Training | Testing | Training | Testing | Training | Testing | |

| DT | 0.9872 | 0.9076 | 1.5156 | 4.8574 | 2.6026 | 6.7942 | 7.35 | 20.09 |

| RF | 0.9421 | 0.8873 | 2.6902 | 5.1744 | 5.5326 | 7.5037 | 11.02 | 23.48 |

| AdaBoost | 0.8751 | 0.8176 | 6.1825 | 7.4909 | 8.1253 | 9.5454 | 41.11 | 54.36 |

| GBRT | 0.9879 | 0.9197 | 1.3870 | 4.2255 | 2.5338 | 6.3064 | 6.38 | 18.71 |

| References | Feature | Para. 1 | Pos. 1 | Result 1 | Para. 2 | Pos. 2 | Result 2 |

|---|---|---|---|---|---|---|---|

| Tao et al. [26] | fc | 40.8 | Lines 41–45 | 42.92 | 60.0 | Lines 26–30 | 57.91 |

| Jiang et al. [54] | fc | 18.2 | Line 145 | 16.11 | 22.8 | Line 146 | 24.87 |

| Du et al. [50] | α | 45 | Lines 5–6 | 14.39 | 90 | Lines 11–13 | 9.49 |

| Derikvand [55] | α | 30 | Line 208 | 64.80 | 60 | Line 210 | 32.00 |

| Appavuravther [22] | ds | 8 | Lines 52–54 | 6.25 | 10 | Lines 55–57 | 9.62 |

| Marchi et al. [18] | ds | 8 | Lines 122–125 | 6.91 | 12 | Lines 130–133 | 8.20 |

| Mirdad et al. [44] | ρt | 0.574 | Line 175 | 59.74 | 0.455 | Line 190 | 53.69 |

| Mirdad et al. [44] | ti | 0 | Line 187 | 27.88 | 5 | Line 188 | 17.18 |

| Jorge et al. [52] | ti | 0 | Line 201 | 10.1 | 25 | Line 202 | 14.60 |

| Methods | Data Set | R2 | RMSE | MAE | MAPE (%) |

|---|---|---|---|---|---|

| GBRT | Testing set | 0.9197 | 4.2255 | 6.3064 | 18.71 |

| AdaBoost | Testing set | 0.8176 | 7.4909 | 9.5454 | 54.36 |

| Eurocode 5 [29] | Vertical and shear– compression screws | 0.2490 | 2.8602 | 2.0440 | 18.04 |

| Dias [79] | Vertical screw | 0.1584 | 6.7453 | 6.2532 | 74.63 |

| Wilkinson [81] | Vertical screw | −1.4492 | 11.5094 | 10.5199 | 110.65 |

| Du et al. [51] | Vertical and shear– tension screws | −0.3864 | 32.1054 | 18.9610 | 56.72 |

| Tao et al. [26] | Bidirectional screws | 0.1028 | 15.7801 | 11.2528 | 19.45 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, W.-W.; Chen, Y.-W.; Xu, J.-G.; Yang, H.-F.; Tao, H.-T.; Zheng, W.; Shi, B.-K. Prediction on Slip Modulus of Screwed Connection for Timber–Concrete Composite Structures Based on Machine Learning. Buildings 2025, 15, 2458. https://doi.org/10.3390/buildings15142458

Lu W-W, Chen Y-W, Xu J-G, Yang H-F, Tao H-T, Zheng W, Shi B-K. Prediction on Slip Modulus of Screwed Connection for Timber–Concrete Composite Structures Based on Machine Learning. Buildings. 2025; 15(14):2458. https://doi.org/10.3390/buildings15142458

Chicago/Turabian StyleLu, Wen-Wu, Yu-Wei Chen, Ji-Gang Xu, Hui-Feng Yang, Hao-Tian Tao, Wei Zheng, and Ben-Kai Shi. 2025. "Prediction on Slip Modulus of Screwed Connection for Timber–Concrete Composite Structures Based on Machine Learning" Buildings 15, no. 14: 2458. https://doi.org/10.3390/buildings15142458

APA StyleLu, W.-W., Chen, Y.-W., Xu, J.-G., Yang, H.-F., Tao, H.-T., Zheng, W., & Shi, B.-K. (2025). Prediction on Slip Modulus of Screwed Connection for Timber–Concrete Composite Structures Based on Machine Learning. Buildings, 15(14), 2458. https://doi.org/10.3390/buildings15142458