Modeling Intra-Organization Fragmentation and Integration to Enhance Performance in Industrialized Timber Construction

Abstract

1. Introduction

2. Background

2.1. Fragmentation and Integration in the Architectural, Engineering, and Construction Industry

2.2. Organization: Differentiation, Integration, and Fragmentation

2.3. Virtual Design Team

3. Methodology

3.1. Case Study Selection

3.2. Data Collection

3.3. Development and Validation of the VDT Conceptual Model

- Step 1: Explanation of the VDT conceptual model: The authors first introduce the meaning of each shape and link of the VDT model that represents the organization and processes. Then, the authors explained the composition of the company organization, links among project participants or groups, the type of meetings, links between participants and processes, the sequence of the processes, and links among processes.

- Step 2: Comparison between the VDT conceptual model and the actual project events: After familiarizing themselves with the VDT conceptual model in Step 1, the key participants compared real-world organizations and processes to the model’s graphical representation. They confirmed or corrected aspects such as the organizational structure, participant relationships, activity links, and process sequencing in an open discussion.

3.4. Simulations

4. Results

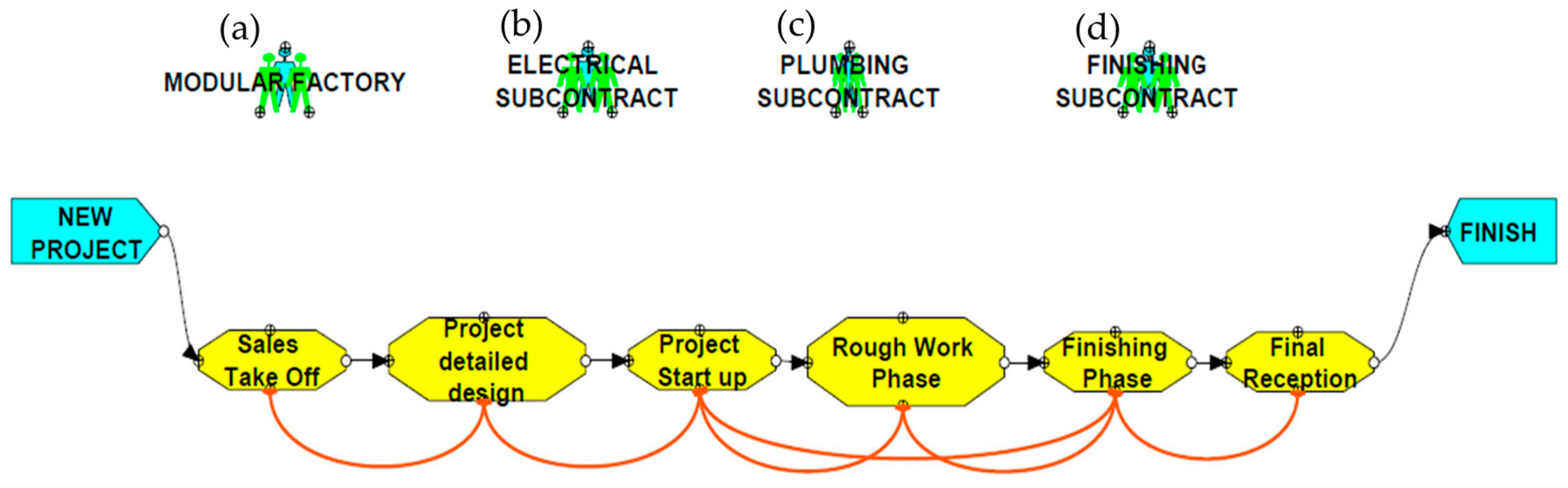

4.1. Description of VDT Conceptual Model

- (a)

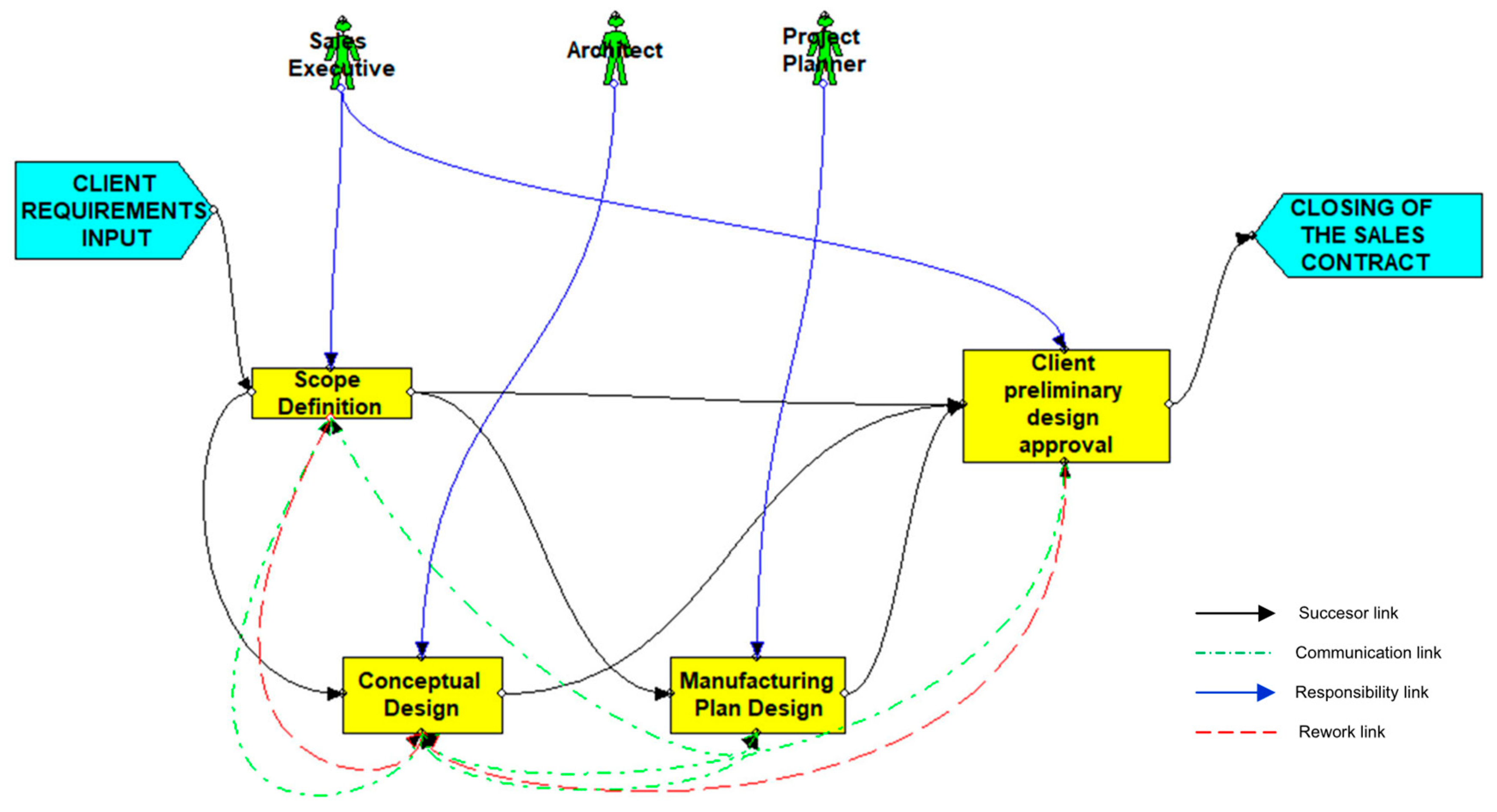

- Phase 1: Sales Takeoff (Figure 3): The project process starts with the commercial process in the Sales Takeoff phase (a). The client defines its project requirements with the sales executive during this process. Then, the architect and project planner work separately on conceptual design and preliminary technical specifications. This phase ends when the client approves the preliminary design. In this phase, it is highlighted that the client’s approval of the preliminary design negatively impacts scope definition and conceptual design tasks due to the corrective iterations generated during this phase.

- (b)

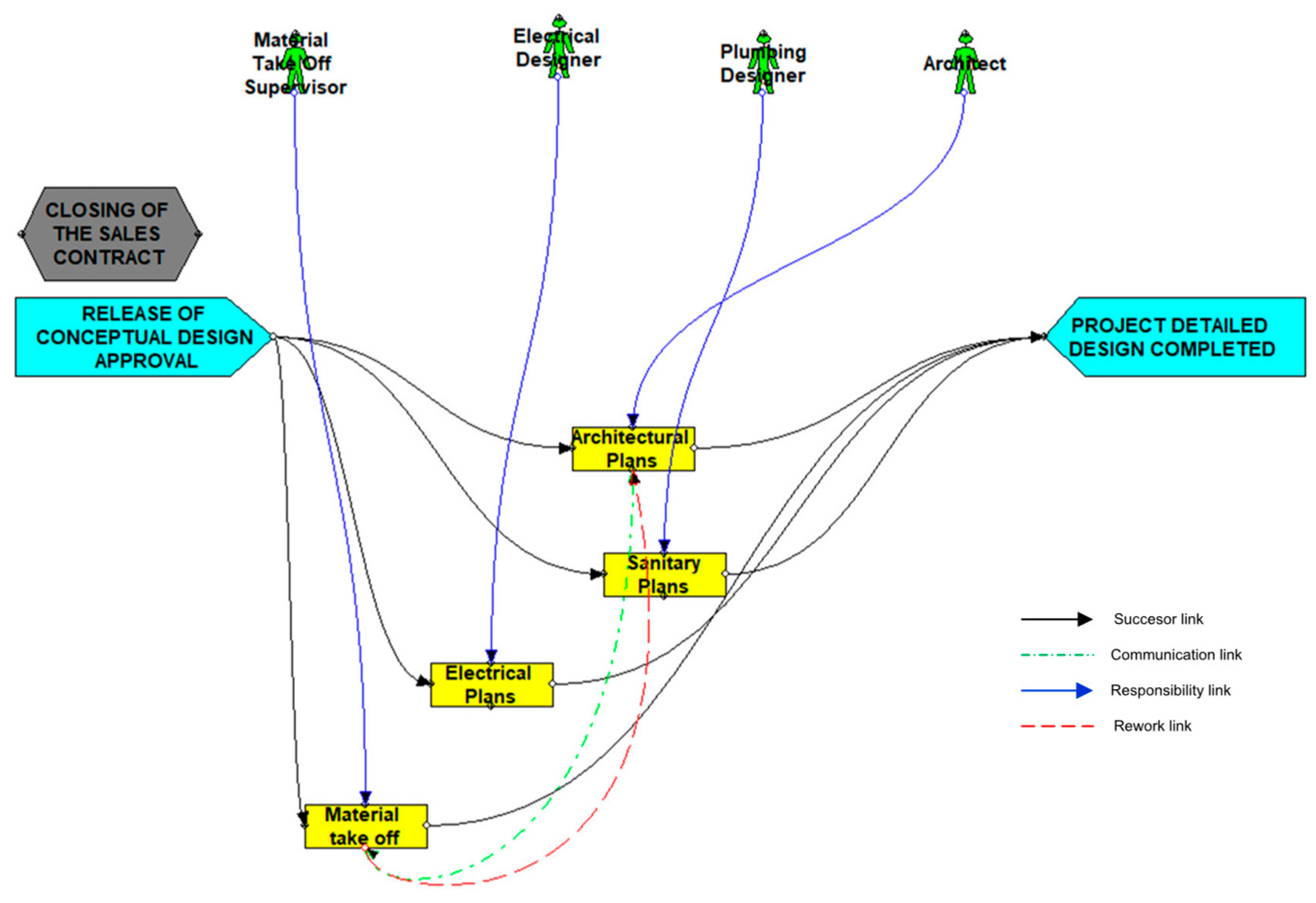

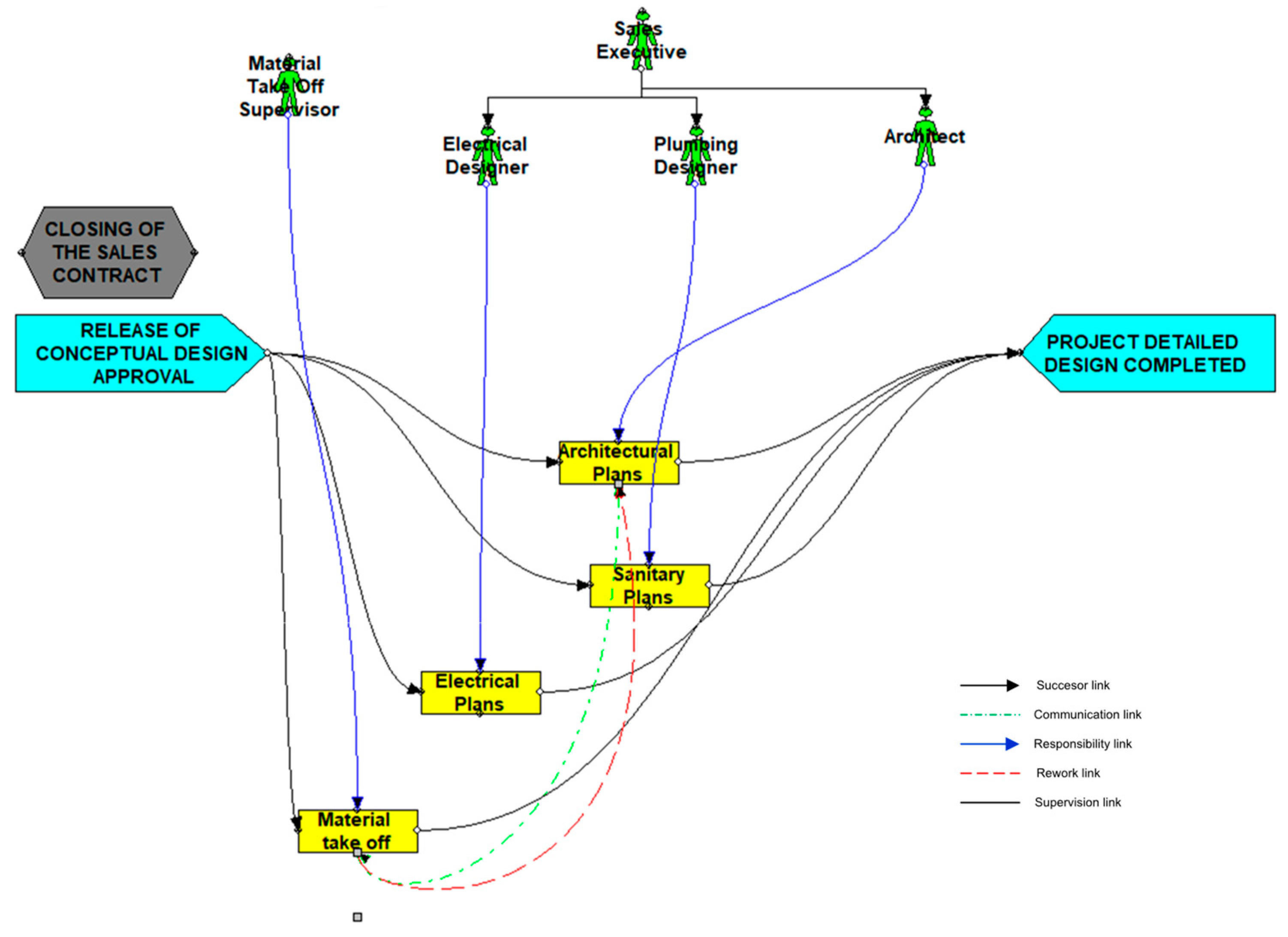

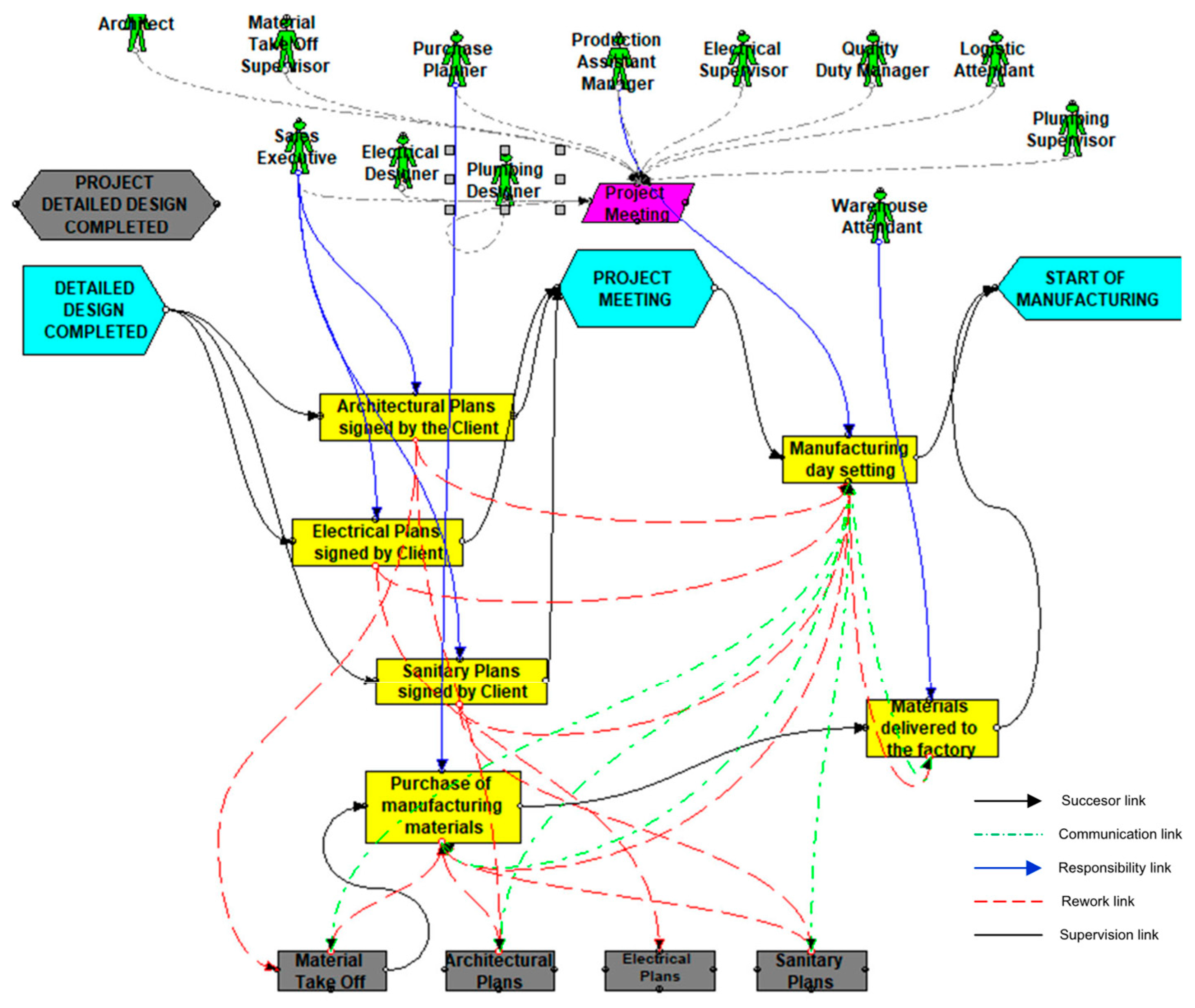

- Phase 2: Project Detailed Design (Figure 4): Once the client approves the conceptual design, the material takeoff supervisor, architect, electrical designer, and plumbing designer start with the detailed design, where each specialty works separately. This phase comprises the following tasks: material takeoff, electrical plans, sanitary plans, and architectural plans. The architectural plans task is connected with the material takeoff task with a rework and communication link. The final product of this phase is the detailed design.

- (c)

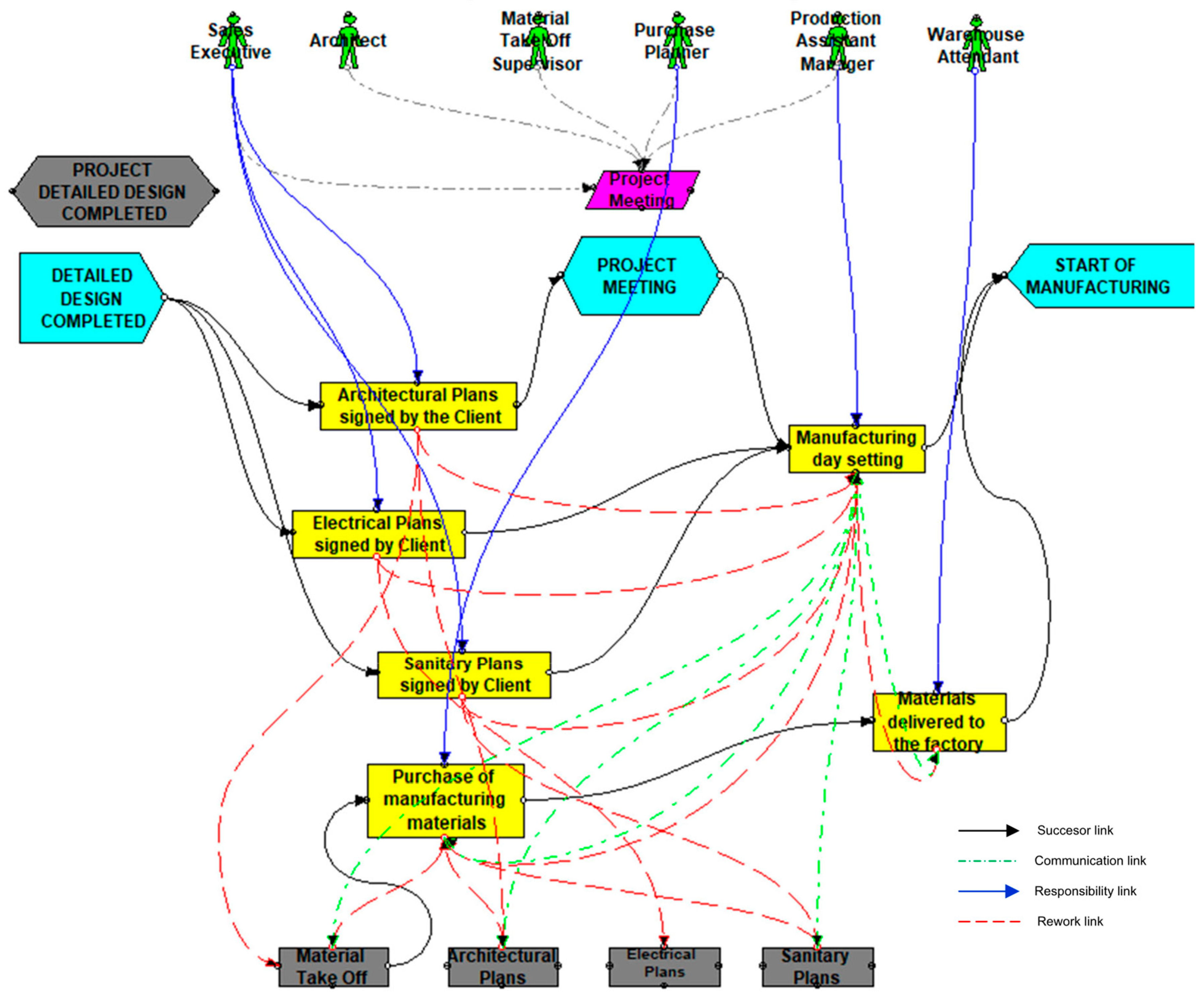

- Phase 3: Project Startup (Figure 5): Then, in the project startup, the participants prepare the final plans (architectural, electrical, and sanitary), which are submitted for the client’s approval and subsequently released as “approved plans for construction.” To accomplish this project goal, the sales executive, architect, material takeoff supervisor, purchase planner, warehouse attendant, and production assistant manager participate in the “project meeting.” In this meeting, they make decisions and define the approved plans for construction. The manufacturing day setting task is connected with rework links to all other tasks in this phase. This task is also connected with communication links with tasks from Phase 2 (gray rectangles). All tasks are connected with rework links to tasks from Phase 2. In this phase, the purchase planner works on the tasks of purchasing manufacturing materials and their delivery to the factory.

- (d)

- Phase 4: Rough Work (Figure 6): Based on these approved plans, the production assistant manager coordinates with wood, framework, electrical, and plumbing supervisors on the rough work phase. The process focuses on the fabrication of modules. This phase comprises four main milestones: framework, electrical pipes, plumbing, and rough work. All framework, electrical, and plumbing-related tasks are connected with rework links, including architectural and electrical plans signed by the client from Phase 3 (gray rectangles). The communication links are only present at the level of supervision tasks.

- (e)

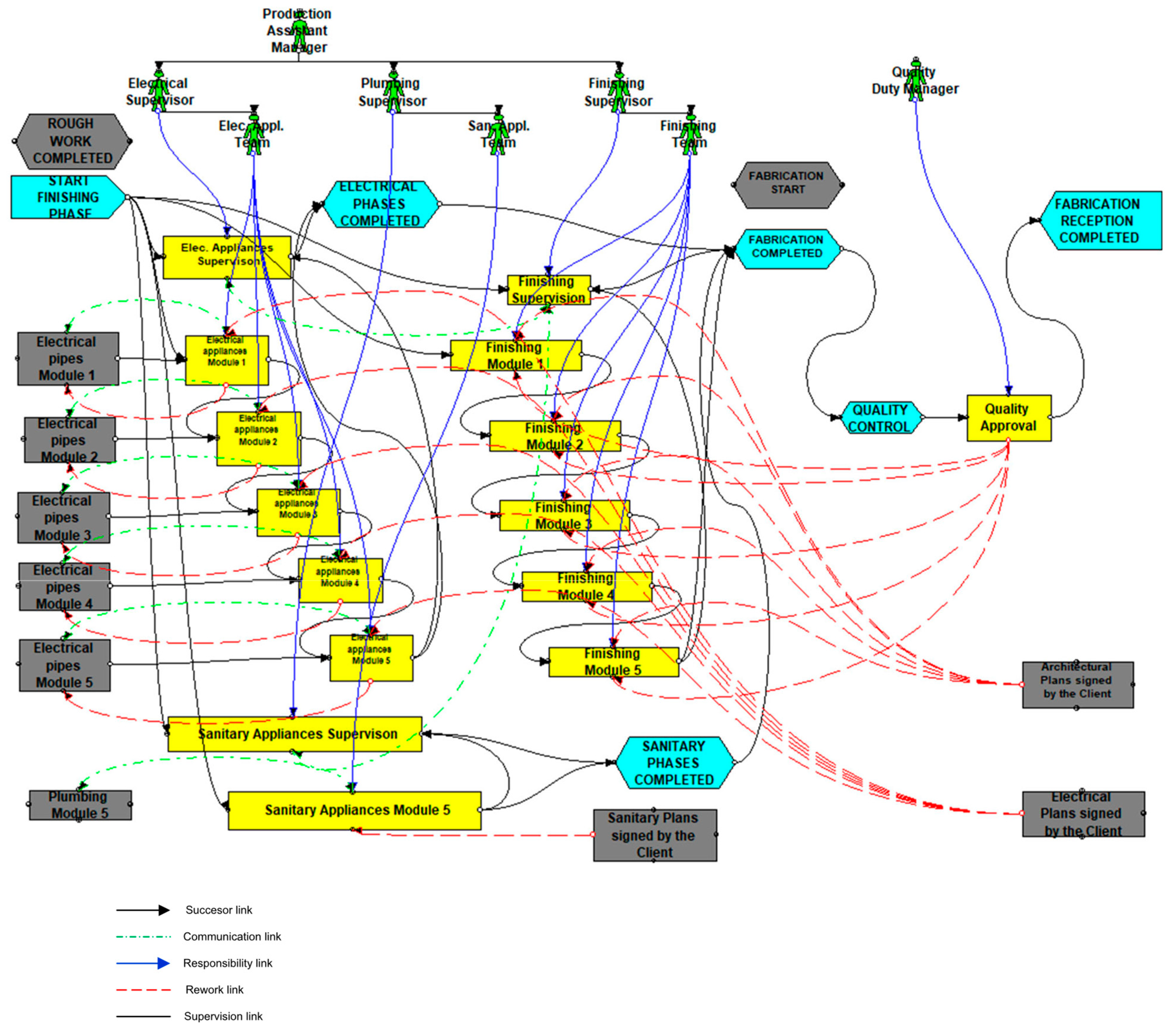

- Phase 5: Finishing (Figure 7): The process focuses on installing electrical and sanitary appliances and finishing, and ends with the quality approval task. The production assistant manager coordinates with electrical, plumbing, and finishing supervisors on the finishing phase. This phase has four main milestones: electrical, sanitary, fabrication, and quality control. All electrical tasks are connected to electrical tasks from Phase 4 (gray rectangles), and electrical plans signed by the client from Phase 3 (gray rectangles) with rework links. Finishing tasks are also connected to architectural plans signed by the client from Phase 3, with rework links. The quality approval task is connected to electrical and finishing tasks using rework links. The communication links are only present at the level of supervision tasks. The final product of this phase is the fabrication.

- (f)

- Phase 6: Final Reception (Figure 8): The logistic attendant is responsible for delivering the modules to the client when the manufacturing processes are completed. This phase is closed with the client’s final reception.

4.2. Description of VDT Simulation Model

- Project priority indicates how important this phase is to the overall project (high—medium—low).

- Team continuity measures how successfully the team has performed related projects (high—medium—low).

- Decision level indicates the qualitative degree to which decision-making and exception-handling responsibilities are decentralized to individual responsible positions (low) or centralized to senior project managers (high). If the decision level is low, rework decisions can be evaluated by the responsible positions. If the decision level is higher, the decision is more likely to be escalated to a supervisor somewhere in the hierarchy—a subteam leader if the decision level is medium.

- Meeting preference measures how formal the communication is in an organization. High meeting preference means communication tends to occur in formal meetings.

- Cross-function team measures the extent to which positions are located in skill-based functional departments and supervised directly by functional managers (low) or co-located with other skill specialists in dedicated project teams and have project supervision from a project manager (high).

- Task communication measures the level of communication in the project between positions responsible for tasks linked by communications (green) links (0.0 to 1.0).

- Distraction level measures the “effect of interruptions in the ordinary working day that take time away from performing the project tasks.” (0.0 to 1.0).

- Work complexity is the probability that a task will fail and require rework (0.0 to 1.0).

- Project uniqueness is the probability that a task will fail and generate rework for itself and all dependent tasks connected to it by rework links (0.0 to 1.0).

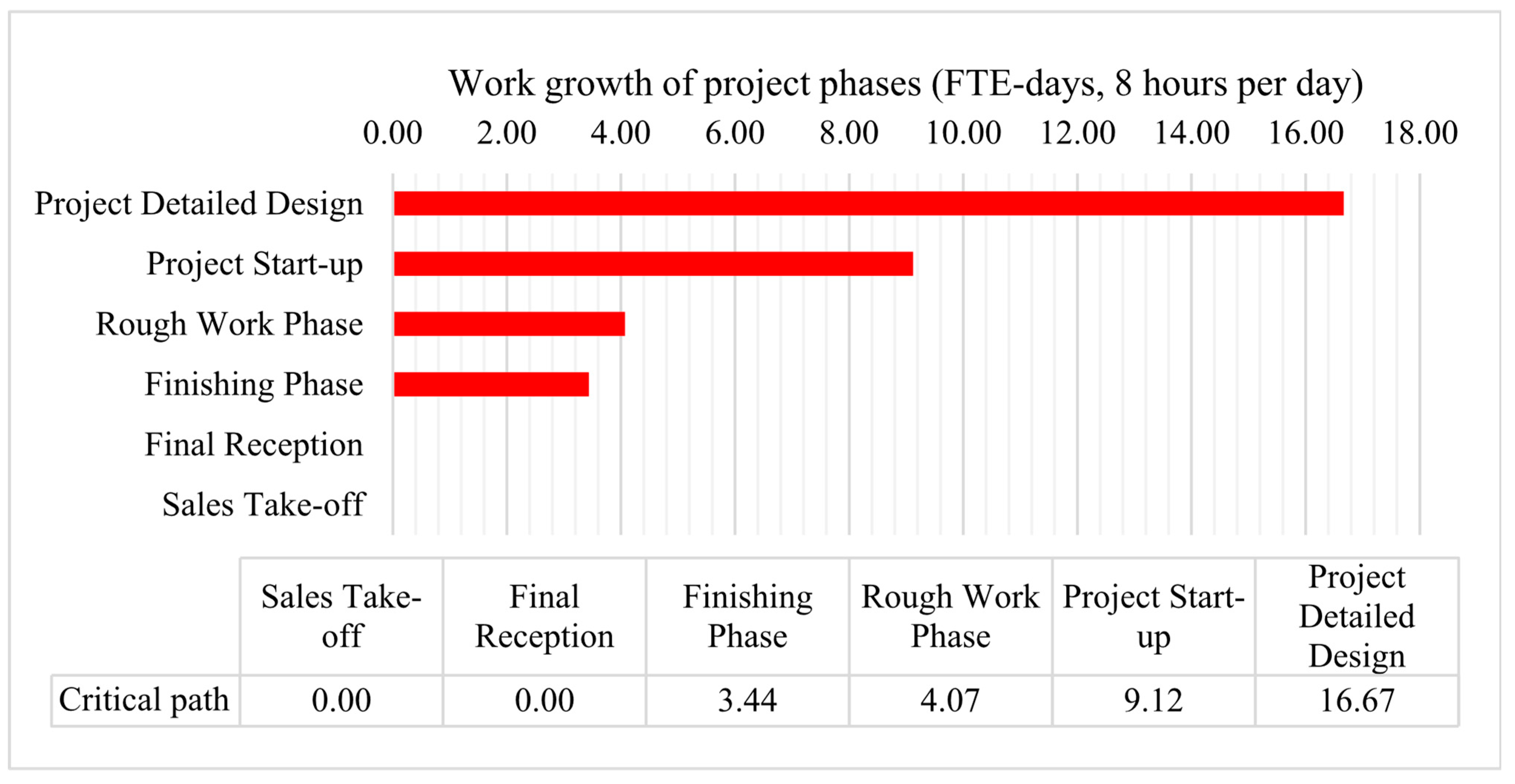

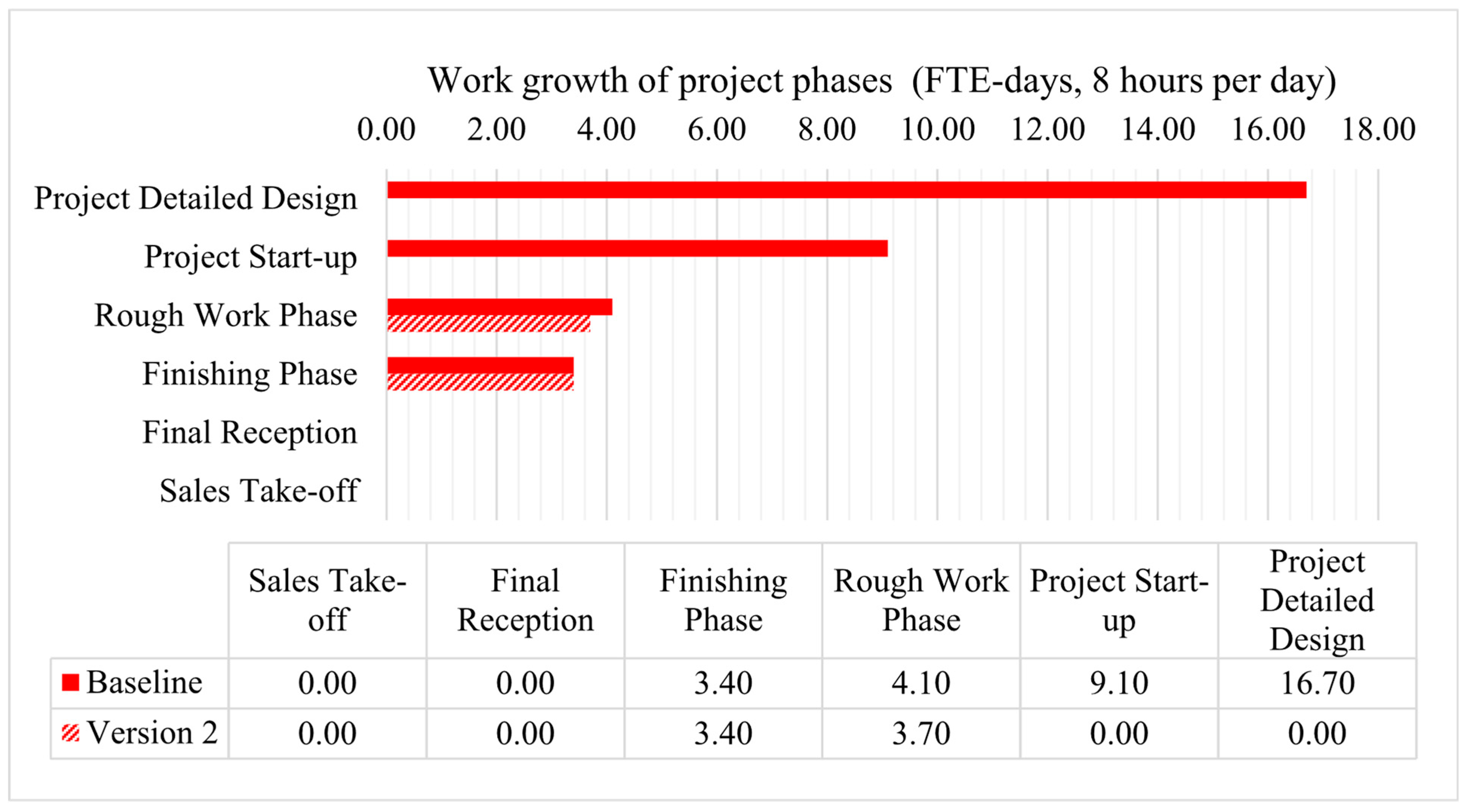

4.3. VDT Simulation Results

4.3.1. Project Duration and Schedule Growth

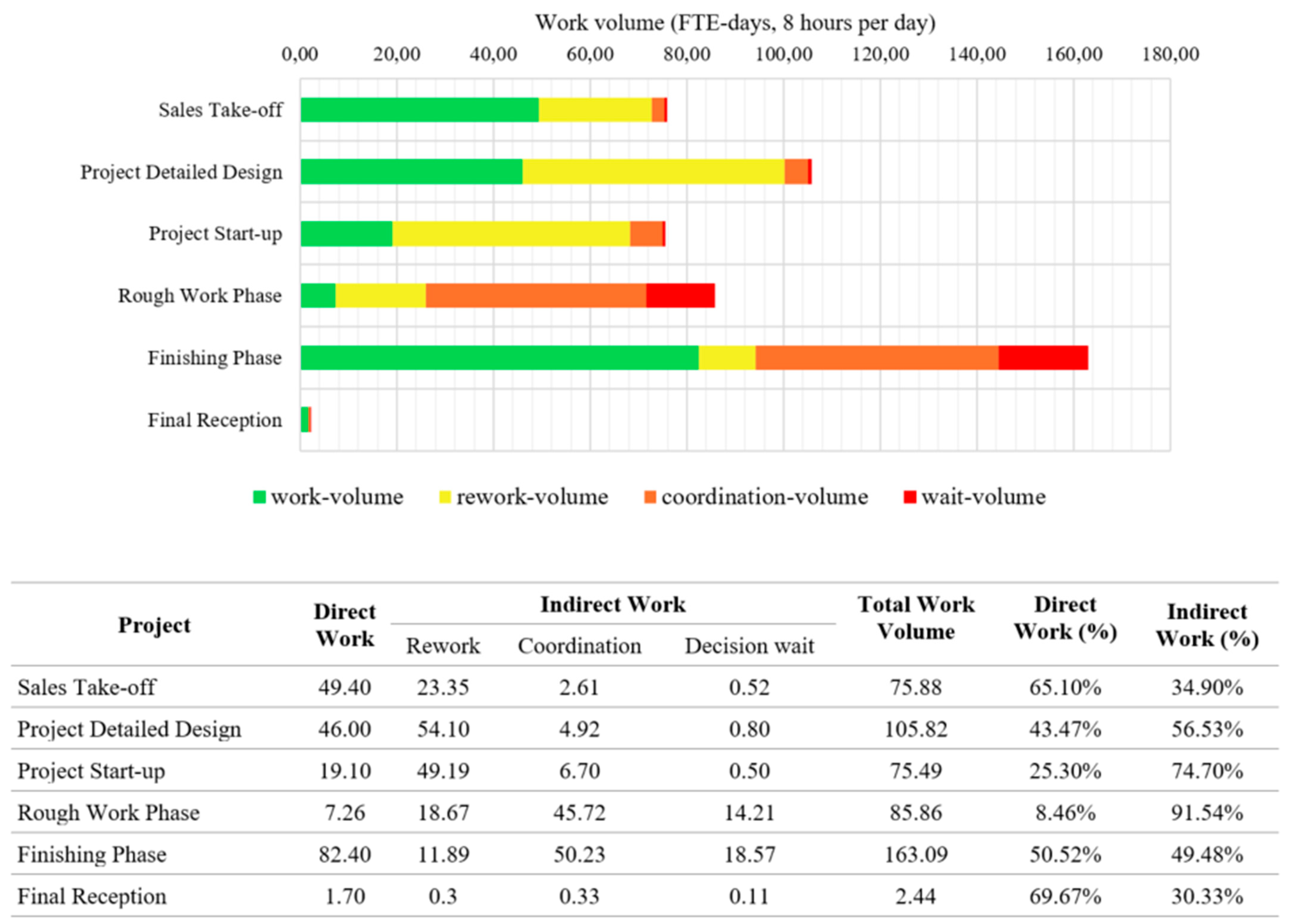

4.3.2. Project Work Volume

- Direct work volume is the predicted time that all positions on a project spend performing the original work that a task requires before any exceptions are handled.

- Rework volume refers to the predicted time needed for all positions on a project to do work that has to be redone on a task due to exceptions.

- Coordination volume is the predicted time during a project or program that all positions spend at meetings and processing information requests from other positions.

- Wait volume is the cumulative time spent by positions waiting for decisions to be made in a project.

5. Discussion of VDT Simulation Results

Sensitivity Analysis

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| VDT | Virtual Design Team |

| AEC | Architectural, Engineering, and Construction |

References

- Seaton, H. The Construction Technology Handbook; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2021. [Google Scholar] [CrossRef]

- Costa, S.; Carvalho, M.S.; Pimentel, C.; Duarte, C. A Systematic Literature Review and Conceptual Framework of Construction Industrialization. J. Constr. Eng. Manag. 2023, 149, 03122013. [Google Scholar] [CrossRef]

- Attouri, E.; Lafhaj, Z.; Ducoulombier, L.; Linéatte, B. The Current Use of Industrialized Construction Techniques in France: Benefits, Limits and Future Expectations. Clean. Eng. Technol. 2022, 7, 100436. [Google Scholar] [CrossRef]

- Koppelhuber, J.; Bauer, B.; Wall, J.; Heck, D. Industrialized Timber Building Systems for an Increased Market Share—A Holistic Approach Targeting Construction Management and Building Economics. Procedia Eng. 2017, 171, 333–340. [Google Scholar] [CrossRef]

- Zhou, J.X.; Huang, L.; Shen, G.Q.; Wu, H.; Luo, L. Modeling Stakeholder-Associated Productivity Performance Risks in Modular Integrated Construction Projects of Hong Kong: A Social Network Analysis. J. Clean. Prod. 2023, 423, 138699. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q.; Osei-Kyei, R. Quantitative Evaluation and Ranking of the Critical Success Factors for Modular Integrated Construction Projects. Int. J. Constr. Manag. 2022, 22, 2108–2120. [Google Scholar] [CrossRef]

- Larsson, J.; Eriksson, P.E.; Olofsson, T.; Simonsson, P. Industrialized Construction in the Swedish Infrastructure Sector: Core Elements and Barriers. Constr. Manag. Econ. 2014, 32, 83–96. [Google Scholar] [CrossRef]

- Zhang, W.; Lee, M.W.; Jaillon, L.; Poon, C.S. The Hindrance to Using Prefabrication in Hong Kong’s Building Industry. J. Clean. Prod. 2018, 204, 70–81. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q. Towards a Decision Support for Modular Integrated Construction: An Integrative Review of the Primary Decision-Making Actors. Int. J. Constr. Manag. 2022, 22, 929–948. [Google Scholar] [CrossRef]

- Tsz Wai, C.; Wai Yi, P.; Ibrahim Olanrewaju, O.; Abdelmageed, S.; Hussein, M.; Tariq, S.; Zayed, T. A Critical Analysis of Benefits and Challenges of Implementing Modular Integrated Construction. Int. J. Constr. Manag. 2023, 23, 656–668. [Google Scholar] [CrossRef]

- Pan, W.; Yang, Y.; Pan, M. Implementing Modular Integrated Construction in High-Rise High-Density Cities: Perspectives in Hong Kong. Build. Res. Inf. 2023, 51, 354–368. [Google Scholar] [CrossRef]

- Al-Aidrous, A.H.M.; Shafiq, N.; Rahmawati, Y.; Mohammed, B.S.; Al-Ashmori, Y.Y.; Baarimah, A.O.; Alawag, A.M. Major Blocking Factors Affecting the Application of Industrialized Building System. Ain Shams Eng. J. 2023, 14, 102151. [Google Scholar] [CrossRef]

- Ortega, J.; Mesa, H.A.; Alarcón, L.F. The Interrelationship between Barriers Impeding the Adoption of Off-Site Construction in Developing Countries: The Case of Chile. J. Build. Eng. 2023, 73, 106824. [Google Scholar] [CrossRef]

- Demirkesen, S.; Ozorhon, B. Impact of Integration Management on Construction Project Management Performance. Int. J. Proj. Manag. 2017, 35, 1639–1654. [Google Scholar] [CrossRef]

- Baiden, B.K.; Price, A.D.F.; Dainty, A.R.J. The Extent of Team Integration within Construction Projects. Int. J. Proj. Manag. 2006, 24, 13–23. [Google Scholar] [CrossRef]

- Baiden, B.K.; Price, A.D.F. The Effect of Integration on Project Delivery Team Effectiveness. Int. J. Proj. Manag. 2011, 29, 129–136. [Google Scholar] [CrossRef]

- Mesa, H.A.; Molenaar, K.R.; Alarcón, L.F. Modeling Supply Chain Integration in an Integrated Project Delivery System. Sustainability 2020, 12, 5092. [Google Scholar] [CrossRef]

- Franz, B.; Esmaeili, B.; Leicht, R.; Molenaar, K.; Messner, J. Exploring the Role of the Team Environment in Building Project Performance. In Proceedings of the Construction Research Congress 2014: Construction in a Global Network, Atlanta, Georgia, 19–21 May 2014; pp. 1997–2010. [Google Scholar] [CrossRef]

- Pellicer, E.; Sanz, M.A.; Esmaeili, B.; Molenaar, K.R. Exploration of Team Integration in Spanish Multifamily Residential Building Construction. J. Manag. Eng. 2016, 32, 05016012. [Google Scholar] [CrossRef]

- Hall, D.M. The Joint Impact of Supply Chain Integration Practices on Construction Schedule Performance for California Healthcare Projects. In Proceedings of the Construction Research Congress 2018: Infrastructure and Facility Management—Selected Papers from the Construction Research Congress 2018, New Orleans, LA, USA, 2–4 April 2018; pp. 180–190. [Google Scholar] [CrossRef]

- Faris, H.; Gaterell, M.; Hutchinson, D. Investigating Underlying Factors of Collaboration for Construction Projects in Emerging Economies Using Exploratory Factor Analysis. Int. J. Constr. Manag. 2022, 22, 514–526. [Google Scholar] [CrossRef]

- Hietajärvi, A.M.; Aaltonen, K.; Haapasalo, H. Managing Integration in Infrastructure Alliance Projects: Dynamics of Integration Mechanisms. Int. J. Manag. Proj. Bus. 2017, 10, 5–31. [Google Scholar] [CrossRef]

- Mitropoulos, P.; Tatum, C. Management-Driven Integration. J. Manag. Eng. 2000, 16, 48–58. [Google Scholar] [CrossRef]

- Alashwal, A.M.; Fong, P.S.-W. Empirical Study to Determine Fragmentation of Construction Projects. J. Constr. Eng. Manag. 2015, 141, 04015016. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q.P.; Mahmud, A.T. Critical Risk Factors in the Application of Modular Integrated Construction: A Systematic Review. Int. J. Constr. Manag. 2022, 22, 133–147. [Google Scholar] [CrossRef]

- Dhawan, K.; Tookey, J.E.; Ghaffarianhoseini, A.; Poshdar, M.; Rudberg, M.; Thunberg, M.; Sezer, A.; Janné, M.; Dhawan, K.; Tookey, J.E.; et al. Using Transport to Quantify the Impact of Vertical Integration on the Construction Supply Chain: A New Zealand Assessment. Sustainability 2023, 15, 1298. [Google Scholar] [CrossRef]

- Ekanayake, E.M.A.C.; Shen, G.Q.P.; Kumaraswamy, M.M.; Owusu, E.K.; Saka, A.B. Modeling Supply Chain Resilience in Industrialized Construction: A Hong Kong Case. J. Constr. Eng. Manag. 2021, 147, 05021009. [Google Scholar] [CrossRef]

- Wang, B.; Geng, L.; Dang, P.; Zhang, L. Developing a Framework for Dynamic Organizational Resilience Analysis in Prefabricated Construction Projects: A Project Life Cycle Perspective. J. Constr. Eng. Manag. 2022, 148, 04022110. [Google Scholar] [CrossRef]

- Hyun, H.; Kim, H.; Lee, H.S.; Park, M.; Lee, J. Integrated Design Process for Modular Construction Projects to Reduce Rework. Sustainability 2020, 12, 530. [Google Scholar] [CrossRef]

- Kunz, J.C.; Christiansen, T.R.; Cohen, G.P.; Jin, Y.; Levitt, R.E. A Computational Simulation Model of Project Organizations That Is Usable and Predictive for Routine, Project-Oriented Design Tasks. Commun. ACM 1998, 41, 84–91. [Google Scholar] [CrossRef]

- Levitt, R. Overview of The Virtual Design Team (VDT) Research Program: 1988–2010; CIFE Working Paper; Center for Integrated Facility Engineering: Stanford, CA, USA, 2009. [Google Scholar]

- Anumba, C.J.; Baugh, C.; Khalfan, M.M.A. Organisational Structures to Support Concurrent Engineering in Construction. Ind. Manag. Data Syst. 2002, 102, 260–270. [Google Scholar] [CrossRef]

- Othman, M.Z.; Nasrun, M.; Nawi, M.; Akmar, F.; Nifa, A.; Yaakob, M.; Rofie, K.; Zan, Z.M.; Affendi, M.; Pozin, A. A Strategy towards Team Integration Practice for Improving the Design and Construction Process in the Malaysian Industrialized Building System Projects. Int. Rev. Manag. Mark. 2016, 6, 226–229. [Google Scholar]

- Mohd Nawi, M.N.; Baluch, N.; Bahauddin, A.Y. Impact of Fragmentation Issue in Construction Industry: An Overview. MATEC Web Conf. 2014, 15, 01009. [Google Scholar] [CrossRef]

- Mitropoulos, P. Management-Driven Integration; Center for Integrated Facility Engineering: Stanford, CA, USA, 1994. [Google Scholar]

- Akintoye, A.; McIntosh, G.; Fitzgerald, E. A Survey of Supply Chain Collaboration and Management in the UK Construction Industry. Eur. J. Purch. Supply Manag. 2000, 6, 159–168. [Google Scholar] [CrossRef]

- Bresnen, M.; Marshall, N. Partnering in Construction: A Critical Review of Issues, Problems and Dilemmas. Constr. Manag. Econ. 2000, 18, 229–237. [Google Scholar] [CrossRef]

- Dulaimi, M.; Khalfan, M.M.A.; Mcdermott, P. Innovating for Supply Chain Integration within Construction. Constr. Innov. 2006, 6, 143–157. [Google Scholar] [CrossRef]

- Bygballe, L.E.; Jahre, M.; Swärd, A. Partnering Relationships in Construction: A Literature Review. J. Purch. Supply Manag. 2010, 16, 239–253. [Google Scholar] [CrossRef]

- Koolwijk, J.S.J.; van Oel, C.J.; Wamelink, J.W.F.; Vrijhoef, R. Collaboration and Integration in Project-Based Supply Chains in the Construction Industry. J. Manag. Eng. 2018, 34, 04018001. [Google Scholar] [CrossRef]

- Lawrence, P.R.; Lorsch, J.W. Differentiation and Integration in Complex Organizations. Adm. Sci. Q. 1967, 12, 1–47. [Google Scholar] [CrossRef]

- Jin, Y.; Levitt, R.E. The Virtual Design Team: A Computational Model of Project Organizations. Comput. Math. Organ. Theory 1996, 2, 171–195. [Google Scholar] [CrossRef]

- Xue, X.; Li, X.; Shen, Q.; Wang, Y. An Agent-Based Framework for Supply Chain Coordination in Construction. Autom. Constr. 2005, 14, 413–430. [Google Scholar] [CrossRef]

- Ospina-Alvarado, A.; Castro-Lacouture, D.; Roberts, J.S. Unified Framework for Construction Project Integration. J. Constr. Eng. Manag. 2016, 142, 04016019. [Google Scholar] [CrossRef]

- Cheng, J.C.P.; Law, K.H.; Bjornsson, H.; Jones, A.; Sriram, R. A Service Oriented Framework for Construction Supply Chain Integration. Autom. Constr. 2010, 19, 245–260. [Google Scholar] [CrossRef]

- Albanese, R. Team-Building Process: Key to Better Project Results. J. Manag. Eng. 1994, 10, 36–44. [Google Scholar] [CrossRef]

- Fong, P.; Lung, B. Interorganizational Teamwork in the Construction Industry. J. Constr. Eng. Manag. 2007, 133, 157–168. [Google Scholar] [CrossRef]

- Chan, A.; Ho, D.; Tam, C. Effect of Interorganizational Teamwork on Project Outcome. J. Manag. Eng. 2001, 17, 34–40. [Google Scholar] [CrossRef]

- Love, P.E.D.; Irani, Z.; Cheng, E.; Li, H. A Model for Supporting Inter-Organizational Relations in the Supply Chain. Eng. Constr. Archit. Manag. 2002, 9, 2–15. [Google Scholar] [CrossRef]

- Concha, M.; Mourgues, C.; Alarcón, L.F. Reference Virtual Design Team (Vdt) Probabilities to Design Construction Project Organizations. Rev. Constr. 2015, 14, 29–34. [Google Scholar] [CrossRef]

- Kunz, J.C.; Christiansen, T.R.; Cohen, G.P.; Jin, Y.; Levitt, R.E. The Virtual Design Team. Commun. ACM 1998, 41, 84–91. [Google Scholar] [CrossRef]

- Levitt, R.E. The Virtual Design Team: Designing Project Organizations as Engineers Design Bridges. J. Organ. Des. 2012, 1, 14–41. [Google Scholar] [CrossRef]

- Levitt, R.E.; Nissen, M.E. The Virtual Design Team (VDT): A Multi-Agent Analysis Framework for Designing Project Organizations. In Proceedings of the IEMC ’03 Proceedings. Managing Technologically Driven Organizations: The Human Side of Innovation and Change (IEEE Cat. No.03CH37502), Cambridge, MA, USA, 30 September–4 October 2003; Institute of Electrical and Electronics Engineers (IEEE): Piscataway, NJ, USA, 2003; pp. 115–120. [Google Scholar]

- Vité SimVision User Guide 2024, 1–742.

- Christiansen, T.R. The Virtual Design Team: Using Simulation of Information Processing to Predict the Performance of Project Teams; Stanford University Press: Redwood City, CA, USA, 1992. [Google Scholar]

- Levitt, R.E.; Kunz, J. WP073: Design Your Project Organization as Engineers Design Bridges; Center for Integrated Facility Engineering: Stanford, CA, USA, 2002. [Google Scholar]

- Ibrahim, R.; Nissen, M. Simulating Environmental Contingencies Using SimVision®. In Proceedings of the North American Association for Computational Social and Organizational Science, Pittsburgh, PA, USA, 27–29 June 2004. [Google Scholar]

- Kunz, J.; Fischer, M. Virtual Design and Construction: Themes, Case Studies and Implementation Suggestions; Center for Integrated Facility Engineering: Stanford, CA, USA, 2012. [Google Scholar]

- Kunz, J.C.; Levitt, R.E.; Thomsen, J. Intervention Studies Using the Virtual Design Team. In Proceedings of the IEEE International Conference on Systems, Man and Cybernetics, Orlando, FL, USA, 12–15 October 1997; IEEE: Piscataway, NJ, USA, 1997; Volume 5, pp. 4483–4487. [Google Scholar]

- Phillips, L.D. A Theory of Requisite Decision Models. Acta Psychol. 1984, 56, 29–48. [Google Scholar] [CrossRef]

- Thompson, J.D. Organizations in Action: Social Science Bases of Administrative Theory; Routledge: New York, NY, USA, 2017; pp. 1–192. [Google Scholar] [CrossRef]

- Lundberg, C.C.; Thompson, J.D. Organizations in Action. Adm. Sci. Q. 1967, 12, 339. [Google Scholar] [CrossRef]

- Wynn, D.C.; Eckert, C.M. Perspectives on Iteration in Design and Development. Res. Eng. Des. 2017, 28, 153–184. [Google Scholar] [CrossRef]

- Egan, J. Rethinking Construction: The Report of the Construction Task Force (The Egan Report); John Wiley & Sons: Hoboken, NJ, USA, 1998. [Google Scholar]

| Property | Phase 1 | Phase 2 | Phase 3 | Phase 4 | Phase 5 | Phase 6 |

|---|---|---|---|---|---|---|

| Priority | Medium | Medium | High | High | High | Medium |

| Team continuity | High | High | High | High | High | High |

| Decision level | Medium | Medium | Medium | Medium | Medium | Medium |

| Meeting preferences | Medium | Medium | Medium | Medium | Medium | Medium |

| Cross-functional team | Low | Low | Low | Low | Low | Low |

| Task communication | 0.2 | 0.4 | 0.4 | 0.6 | 0.6 | 0.5 |

| Distraction level | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 |

| Work complexity | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.05 |

| Project uniqueness | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.5 |

| Property | Phase 1 | Phase 2 | Phase 3 | Phase 4 | Phase 5 | Phase 6 |

|---|---|---|---|---|---|---|

| Priority | Medium | Medium | High | High | High | Medium |

| Team continuity | High | High | High | High | High | High |

| Decision level | Low | Low | Low | Medium | Medium | Medium |

| Meeting preferences | Medium | Medium | Medium | Medium | Medium | Medium |

| Cross function team | Medium | Medium | Medium | Medium | Medium | Medium |

| Task communication | 0.2 | 0.4 | 0.4 | 0.6 | 0.6 | 0.5 |

| Distraction level | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 |

| Work complexity | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.05 |

| Project uniqueness | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mesa, H.; Ramírez, M.; Guindos, P.; Carpio, M. Modeling Intra-Organization Fragmentation and Integration to Enhance Performance in Industrialized Timber Construction. Buildings 2025, 15, 2206. https://doi.org/10.3390/buildings15132206

Mesa H, Ramírez M, Guindos P, Carpio M. Modeling Intra-Organization Fragmentation and Integration to Enhance Performance in Industrialized Timber Construction. Buildings. 2025; 15(13):2206. https://doi.org/10.3390/buildings15132206

Chicago/Turabian StyleMesa, Harrison, Macarena Ramírez, Pablo Guindos, and Manuel Carpio. 2025. "Modeling Intra-Organization Fragmentation and Integration to Enhance Performance in Industrialized Timber Construction" Buildings 15, no. 13: 2206. https://doi.org/10.3390/buildings15132206

APA StyleMesa, H., Ramírez, M., Guindos, P., & Carpio, M. (2025). Modeling Intra-Organization Fragmentation and Integration to Enhance Performance in Industrialized Timber Construction. Buildings, 15(13), 2206. https://doi.org/10.3390/buildings15132206