The Mechanical Properties and Durability of the PE-BFRP Hybrid-Fiber-Engineered Cementitious Composite (ECC)

Abstract

1. Introduction

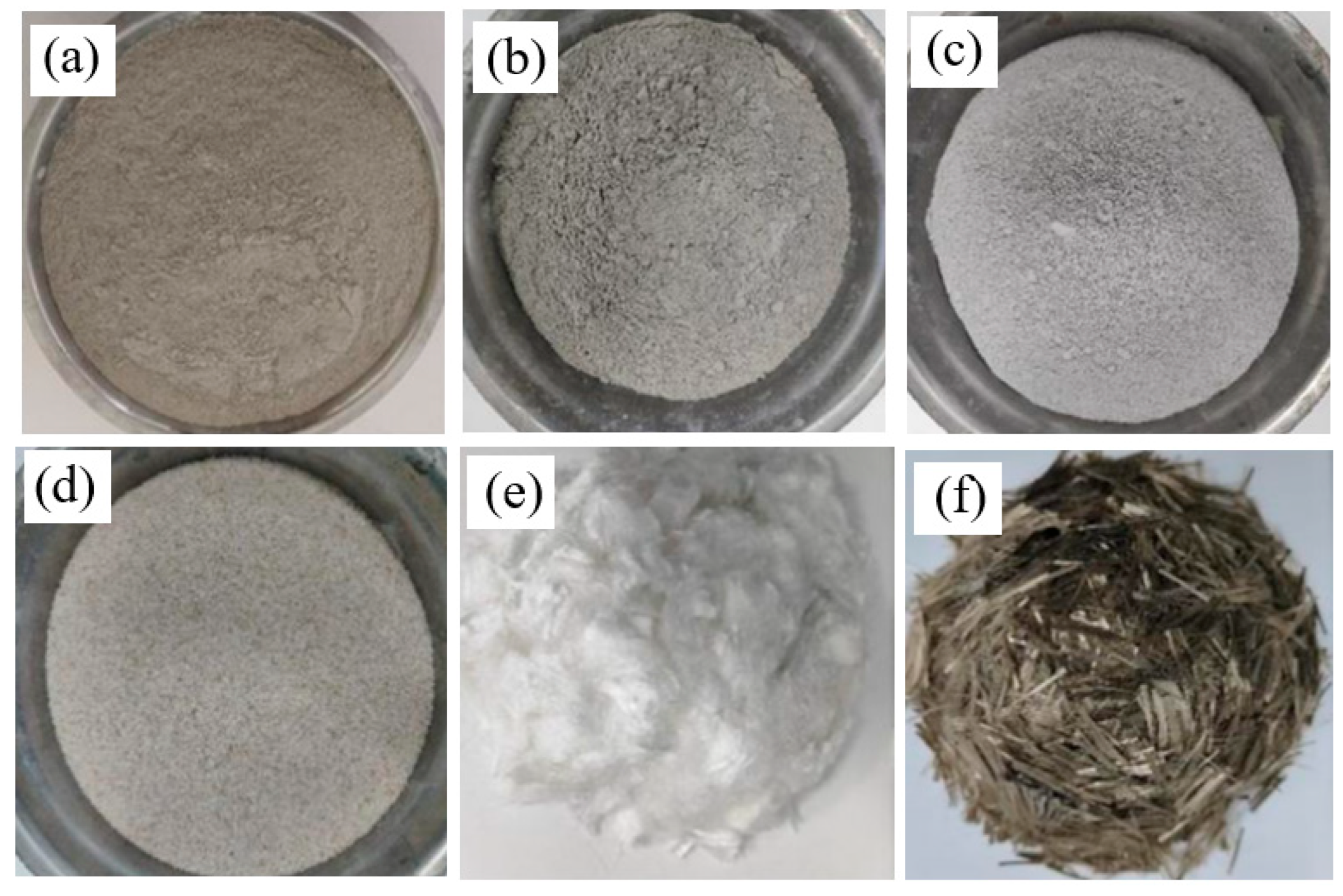

2. Materials and Experimental Setup

3. Results and Discussion

3.1. Flowability Test Analysis

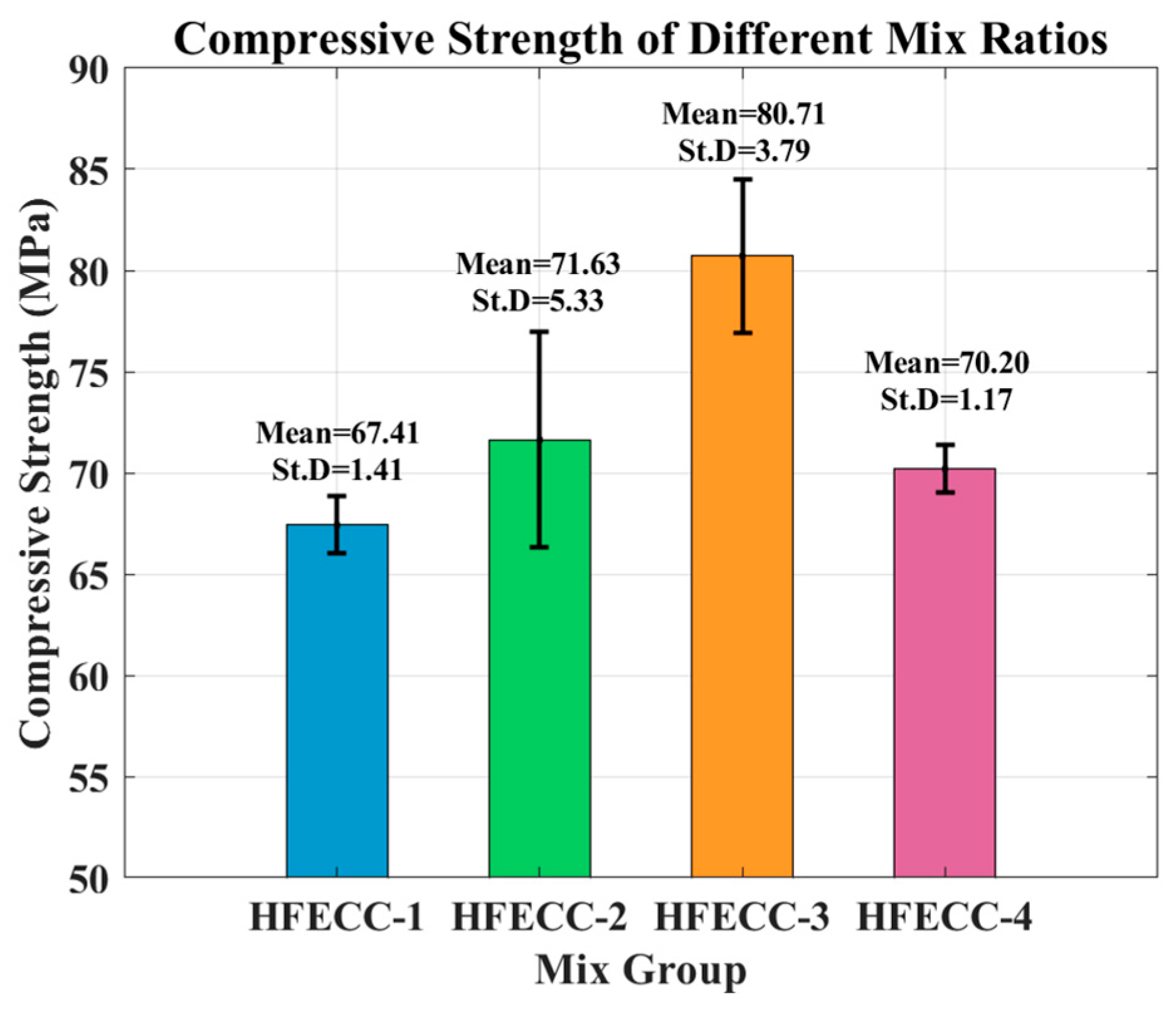

3.2. Compressive Strength Test Analysis

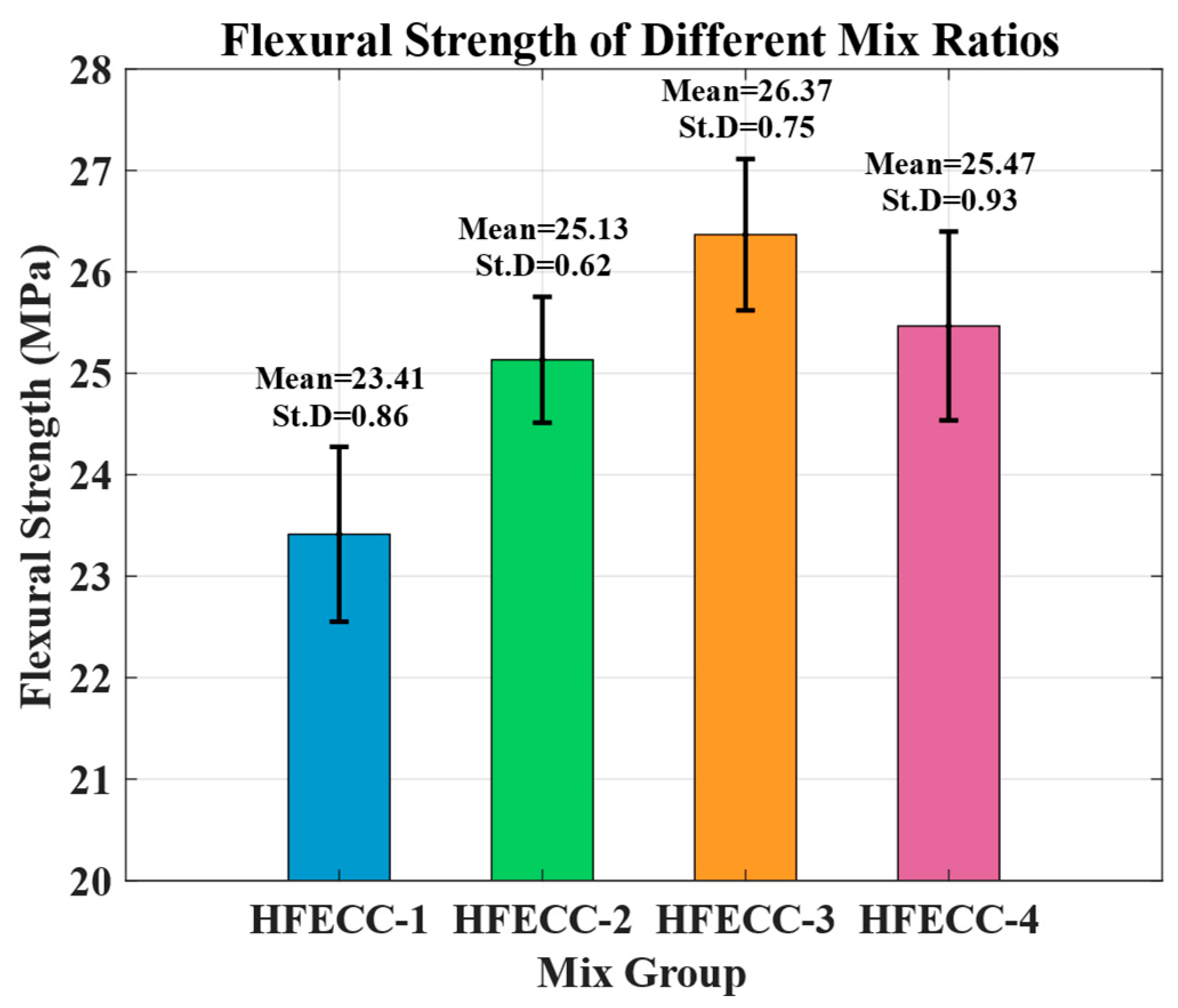

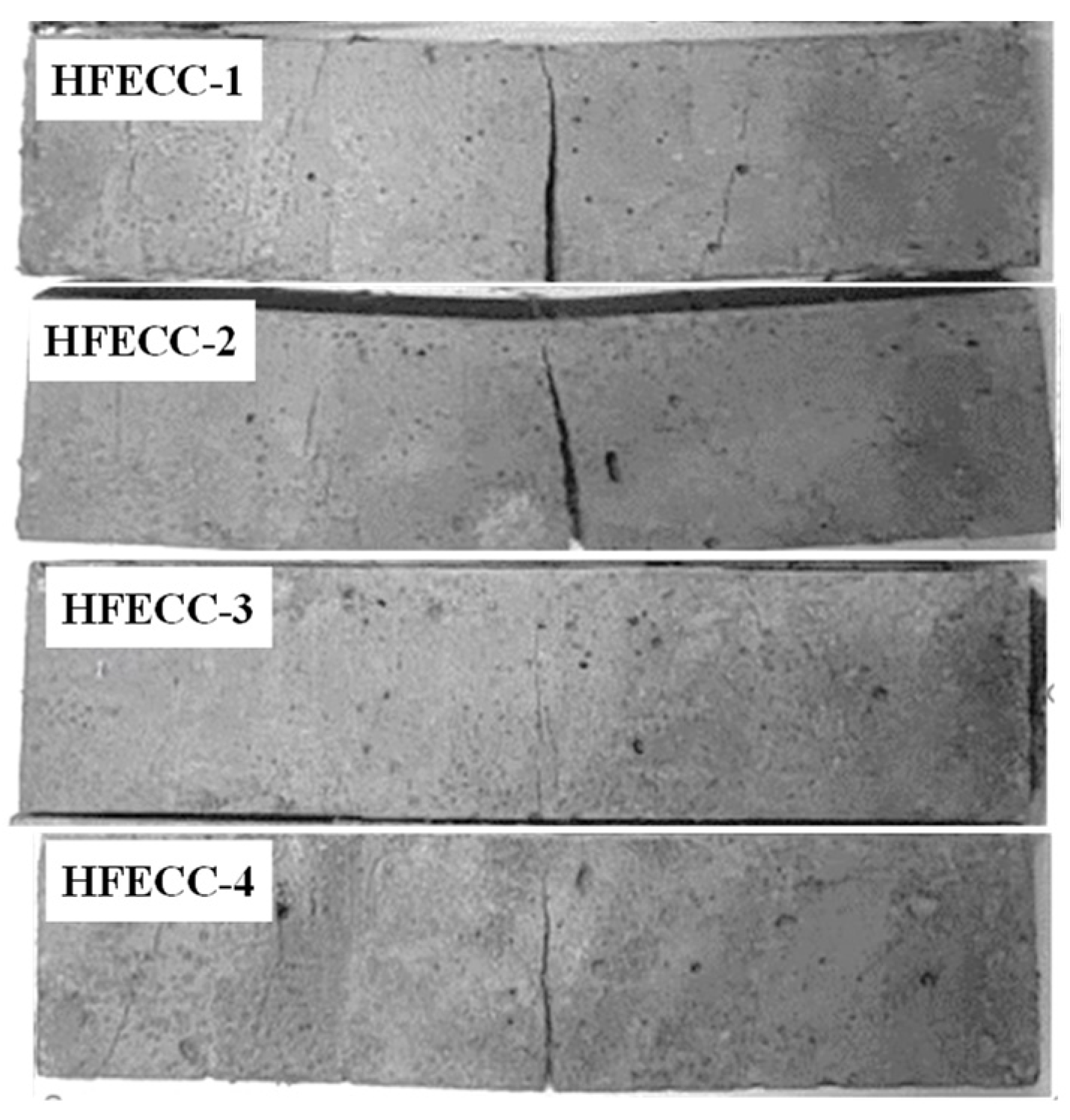

3.3. Three-Point Flexural Strength Test Analysis

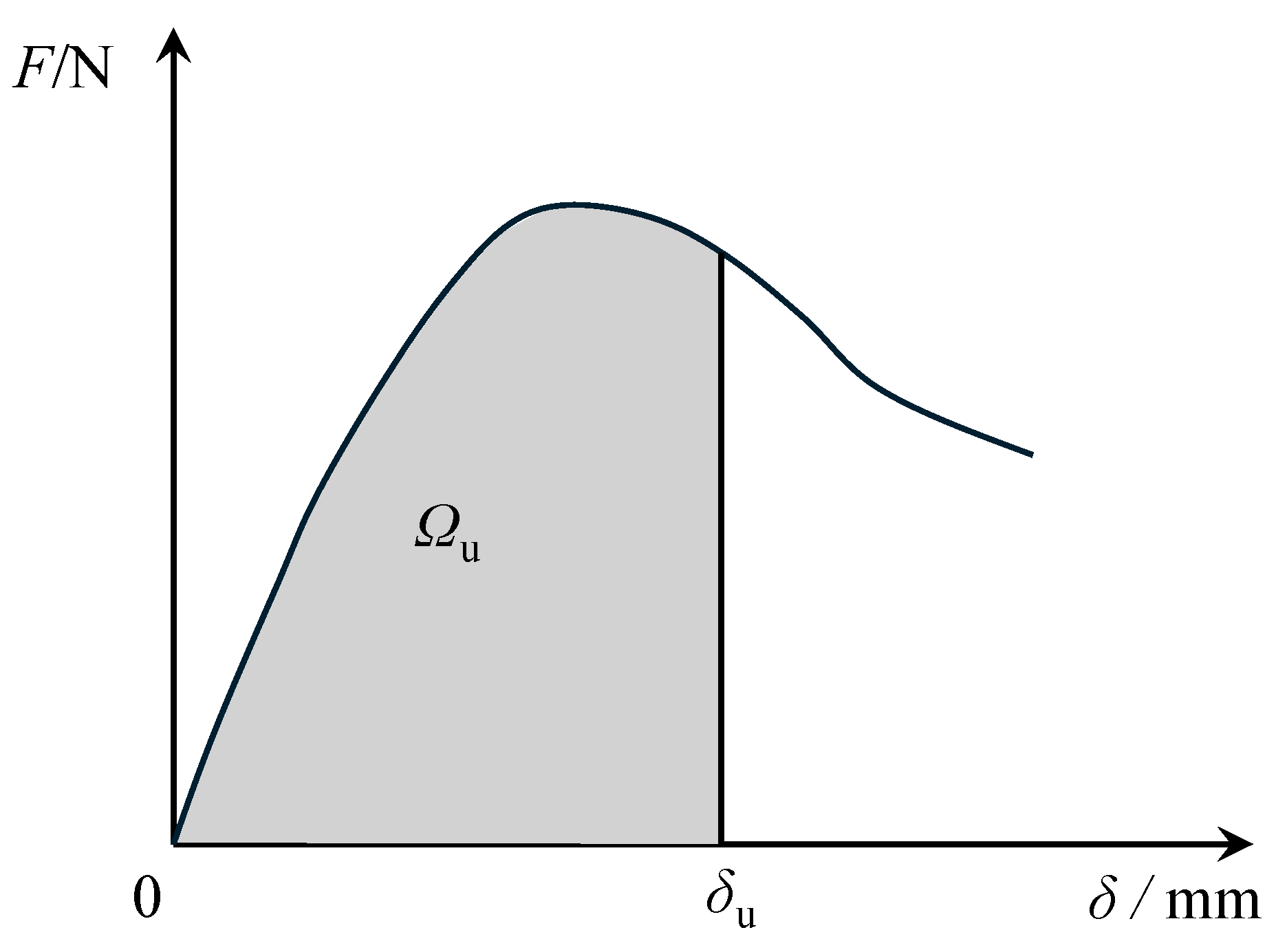

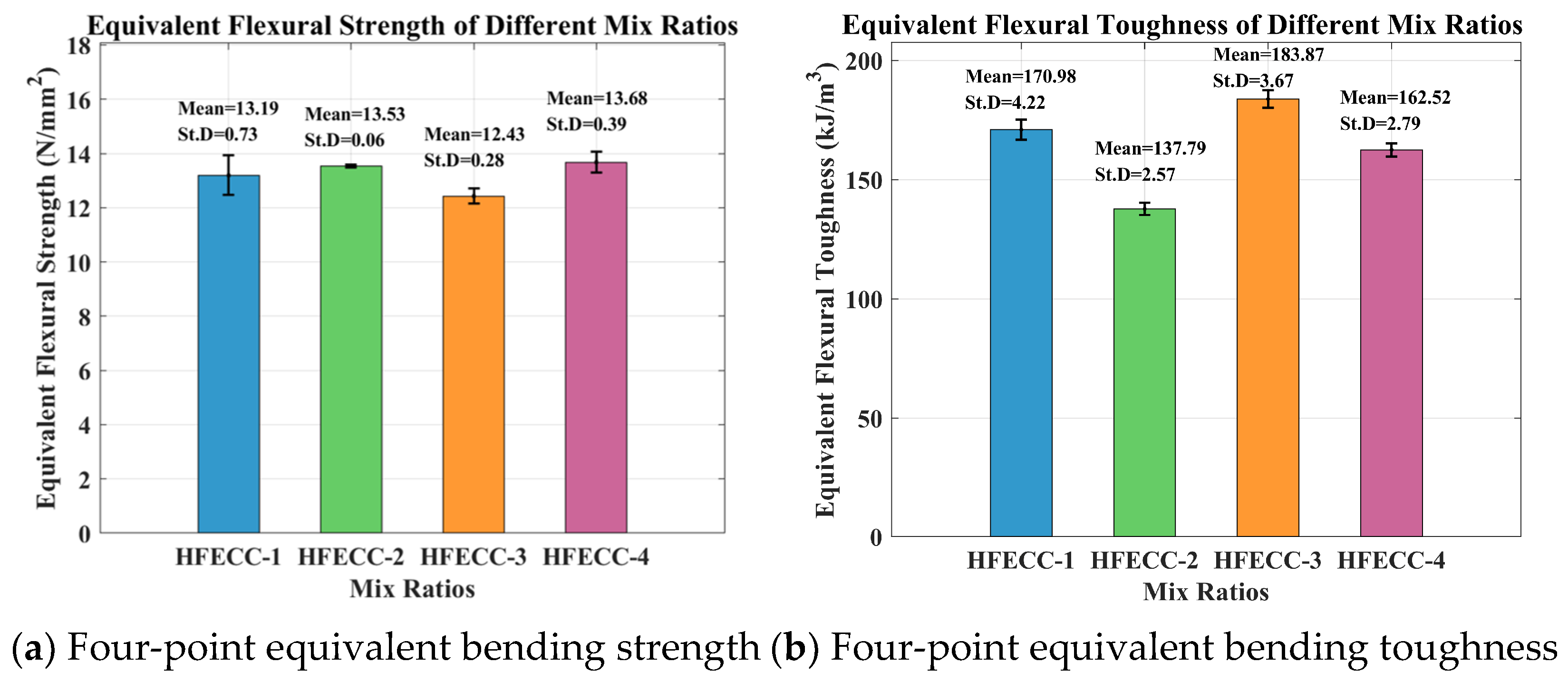

3.4. Four-Point Equivalent Bending Strength and Toughness Test Analysis

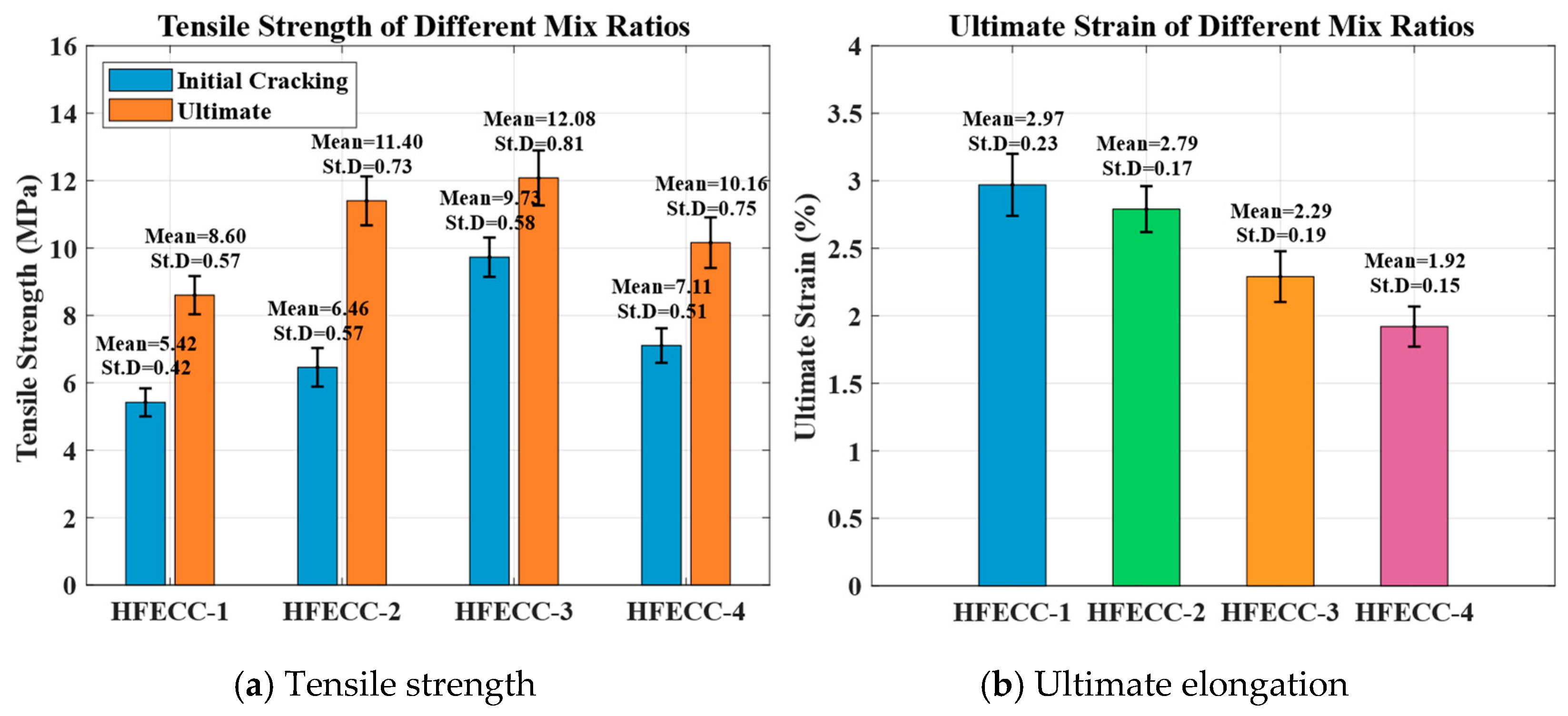

3.5. Tensile Strength Test Analysis

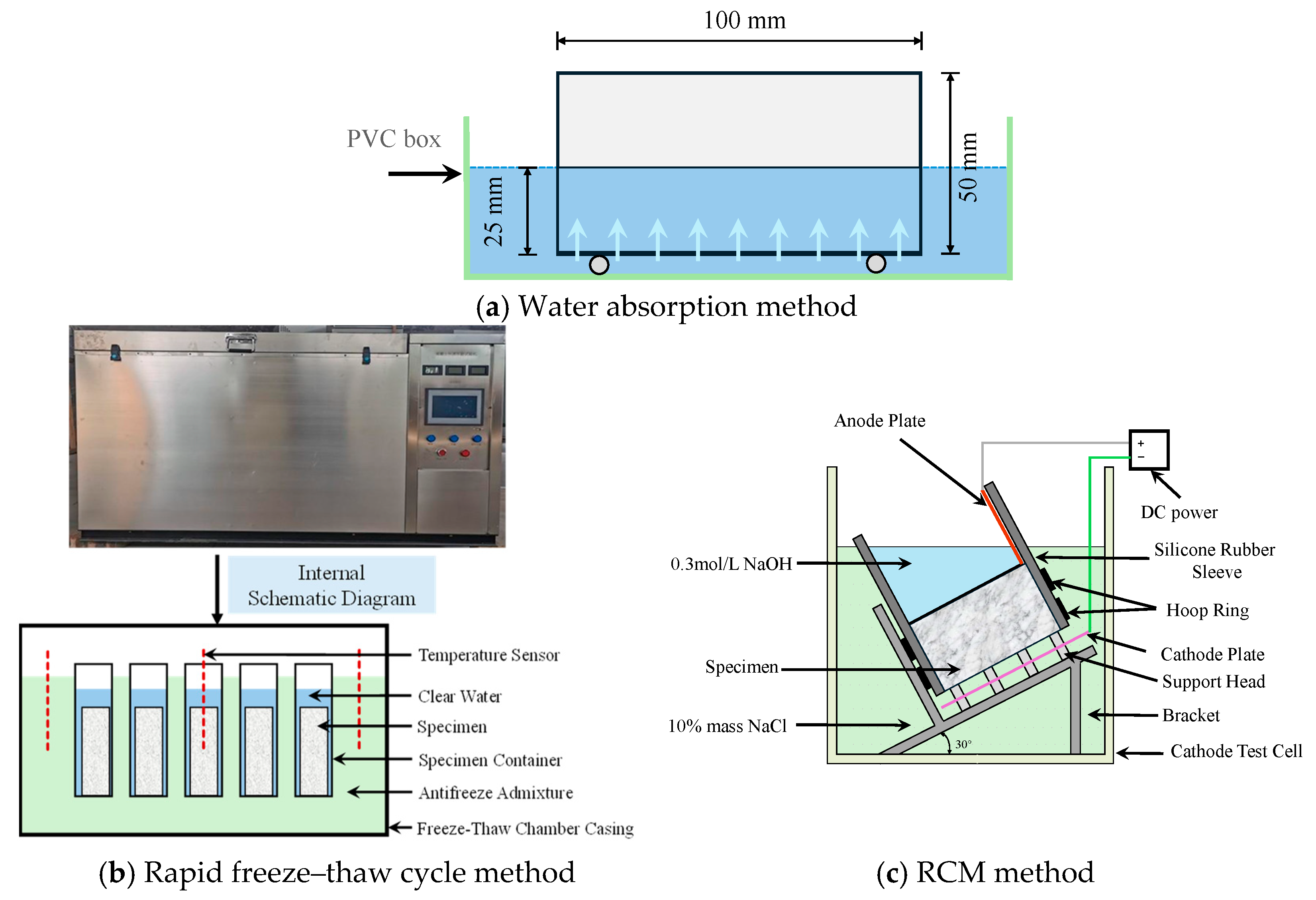

3.6. Water Absorption Test Analysis

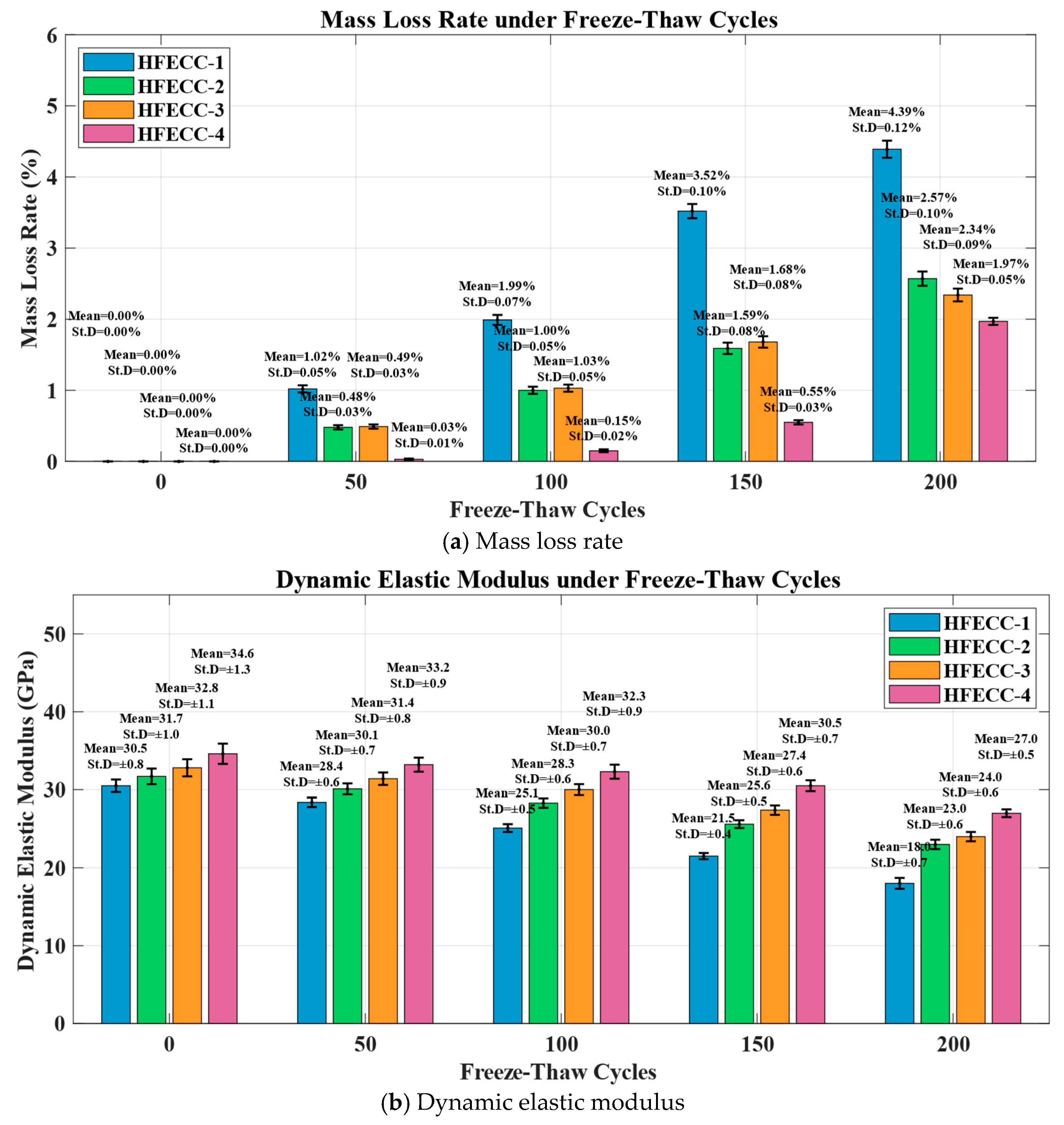

3.7. Freeze–Thaw Cycle Test Analysis

3.8. Chloride Ion Penetration Resistance Test Analysis

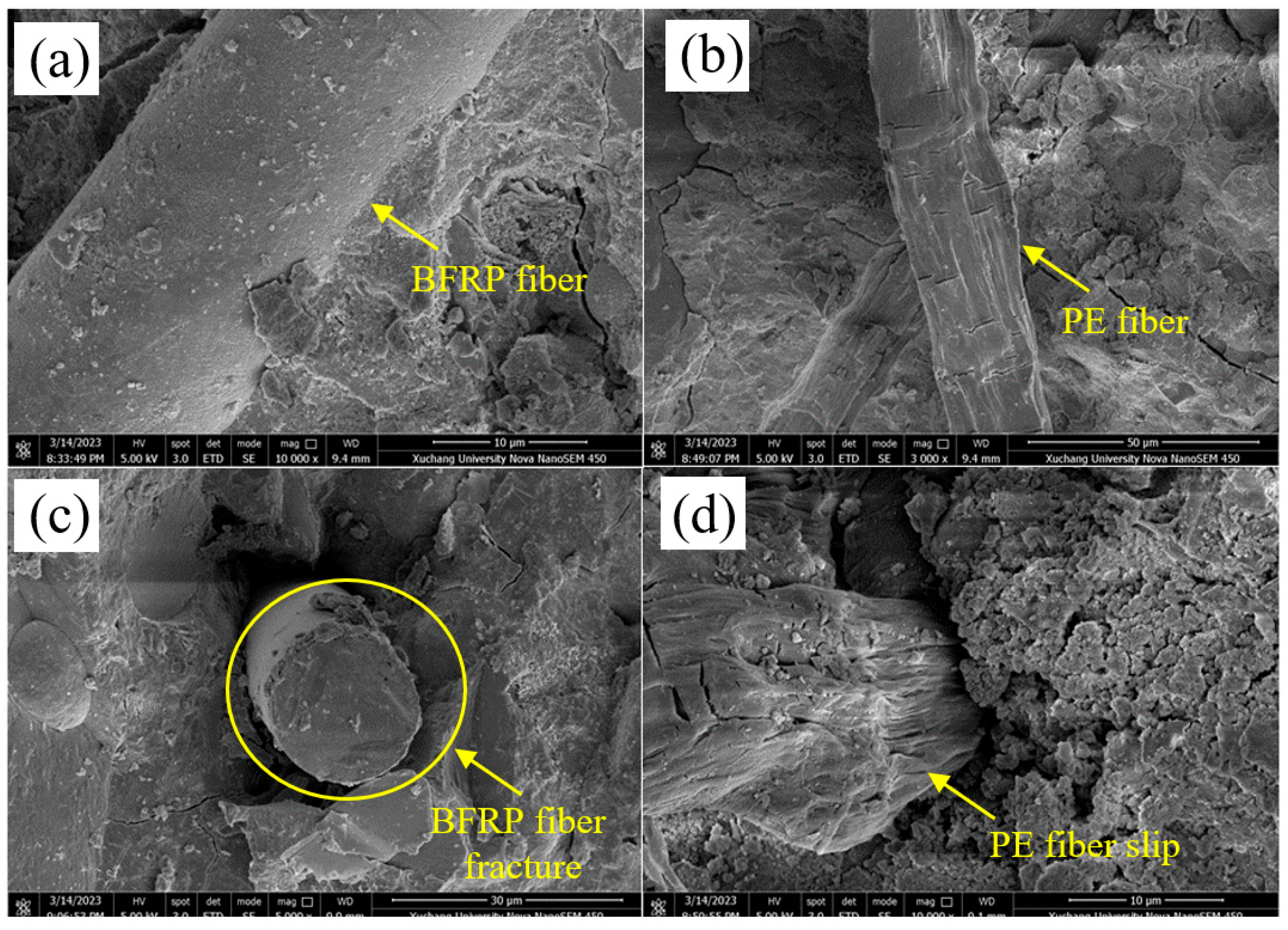

3.9. SEM Result and Analysis

4. Conclusions

- (1)

- HFECC with a total fiber volume of 1.6% (PE + BFRP) shows good workability, with flowability of around 180 mm for all mix ratios.

- (2)

- As the BFRP content increases, compressive, flexural, and tensile strengths first rise and then decline. HFECC-3 (0.30% BFRP + 1.30% PE) achieves the best overall mechanical performance. While fiber ratio changes have little impact on equivalent bending strength, HFECC-3 exhibits the highest bending toughness. However, elongation decreases with more BFRP fibers due to their higher stiffness and brittleness.

- (3)

- Freeze–thaw resistance improves with increased BFRP content. When BFRP increases from 0.20% to 0.35%, the mass loss rate after 200 cycles drops from 4.39% to 1.97%. Simultaneously, the initial dynamic elastic modulus increases from 30.5 GPa to 34.6 GPa. After freeze–thaw cycles, the modulus of the 0.35% BFRP mix remains higher (27.0 GPa) than that of the 0.20% mix (18.0 GPa), indicating improved durability. With increasing BFRP content, chloride ion penetration resistance is enhanced due to the formation of a three-dimensional fiber network that physically obstructs ion transport and mitigates microcrack propagation. The migration coefficient decreases from 10.2 × 10−13 m2/s to 6.3 × 10−13 m2/s when the BFRP volume increases from 0.20% to 0.35%.

- (4)

- SEM analysis shows a synergistic effect between PE and BFRP fibers. The combined bridging and pull-out mechanisms enhance both strength and toughness. These findings suggest that hybrid fiber reinforcement effectively balances strength, ductility, and durability in HFECC.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, V.C.; Leung, C.K.Y. Steady-State and Multiple Cracking of Short Random Fiber Composites. J. Eng. Mech. 1992, 118, 2246–2264. [Google Scholar] [CrossRef]

- Li, V. From Micromechanics to Structural Engineering—The Design of Cementitous Composites for Civil Engineering Applications. Struct. Eng. Earthq. Eng. 1994, 10, 1–34. [Google Scholar]

- Ma, H.; Zhang, Z. Paving an engineered cementitious composite (ECC) overlay on concrete airfield pavement for reflective cracking resistance. Constr. Build. Mater. 2020, 252, 119048. [Google Scholar] [CrossRef]

- Shoji, D.; He, Z.; Zhang, D.; Li, V.C. The greening of engineered cementitious composites (ECC): A review. Constr. Build. Mater. 2022, 327, 126701. [Google Scholar] [CrossRef]

- Liu, Y.; Wu, W.-Z.; Zhang, Y.-X.; Hou, W.; Zhang, H.; Peng, L.-G. Engineered/strain-hardening cementitious composites (ECC/SHCC) for resilient cold-region infrastructure: A critical review of freeze-thaw durability. Case Stud. Constr. Mater. 2025, 22, e04362. [Google Scholar] [CrossRef]

- Wu, W.-Z.; Zhang, Y.-X.; Liu, Y.; Hou, W.; Zhu, J.-X.; Jiang, F.; Xu, L.-Y. Impacts of chloride salt, freeze-thaw cycling, and pre-cracking on mechanical properties of Engineered Cementitious Composites (ECC). Constr. Build. Mater. 2025, 475, 141221. [Google Scholar] [CrossRef]

- Khan, M.; Ali, M. Use of glass and nylon fibers in concrete for controlling early age micro cracking in bridge decks. Constr. Build. Mater. 2016, 125, 800–808. [Google Scholar] [CrossRef]

- Zhao, C.; Wang, Z.; Zhu, Z.; Guo, Q.; Wu, X.; Zhao, R. Research on different types of fiber reinforced concrete in recent years: An overview. Constr. Build. Mater. 2023, 365, 130075. [Google Scholar] [CrossRef]

- Loukil, M.; Hassine, W.B.; Limam, O.; Kotronis, P. Experimental determination of GFRC tensile parameters from three-point bending tests using an analytical damage model. Constr. Build. Mater. 2019, 223, 477–490. [Google Scholar] [CrossRef]

- Wang, W.; Li, L.; Chen, J.; Dai, K. Experimental and analytical study on flexural behavior of corroded RC beams strengthened with CFRP rods and UHPC. Eng. Struct. 2025, 323, 119299. [Google Scholar] [CrossRef]

- Pan, Z.; Wu, C.; Liu, J.; Wang, W.; Liu, J. Study on mechanical properties of cost-effective polyvinyl alcohol engineered cementitious composites (PVA-ECC). Constr. Build. Mater. 2015, 78, 397–404. [Google Scholar] [CrossRef]

- Li, V.; Wu, C.; Wang, S.X.; Ogawa, A.; Saito, T. Interface tailoring for strain-hardening polyvinyl alcohol-engineered cementitious composite (PVA-ECC). ACI Mater. J. 2002, 99, 463–472. [Google Scholar]

- Liu, D.; Yu, J.; Qin, F.; Zhang, K.; Zhang, Z. Mechanical performance of high-strength engineering cementitious composites (ECC) with hybriding PE and steel fibers. Case Stud. Constr. Mater. 2023, 18, e01961. [Google Scholar] [CrossRef]

- Huo, Y.; Liu, T.; Lu, D.; Han, X.; Sun, H.; Huang, J.; Ye, X.; Zhang, C.; Chen, Z.; Yang, Y. Dynamic tensile properties of steel fiber reinforced polyethylene fiber-engineered/strain-hardening cementitious composites (PE-ECC/SHCC) at high strain rate. Cem. Concr. Compos. 2023, 143, 105234. [Google Scholar] [CrossRef]

- Yu, K.; Ding, Y.; Liu, J.; Bai, Y. Energy dissipation characteristics of all-grade polyethylene fiber-reinforced engineered cementitious composites (PE-ECC). Cem. Concr. Compos. 2020, 106, 103459. [Google Scholar] [CrossRef]

- Liu, L.; Xiao, J.; Wu, Z. The effect of fiber content on the static and dynamic performance of PE-ECC. Case Stud. Constr. Mater. 2024, 20, e03041. [Google Scholar] [CrossRef]

- Wang, Z.; Liang, X.; Zhai, T. Predicting the flexural behavior of steel-PVA hybrid fiber reinforced cementitious composite. Structures 2023, 51, 1189–1204. [Google Scholar] [CrossRef]

- Hou, M.; Li, V.C. Tailoring crack width control of LC3-based engineered cementitious composites (ECC) via fiber hybridization: From micromechanics design to macro investigation. Mater. Des. 2023, 235, 112433. [Google Scholar] [CrossRef]

- Ahmed, S.F.U.; Maalej, M.; Paramasivam, P. Flexural responses of hybrid steel–polyethylene fiber reinforced cement composites containing high volume fly ash. Constr. Build. Mater. 2007, 21, 1088–1097. [Google Scholar] [CrossRef]

- Zhou, Y.; Xi, B.; Yu, K.; Sui, L.; Xing, F. Mechanical Properties of Hybrid Ultra-High Performance Engineered Cementitous Composites Incorporating Steel and Polyethylene Fibers. Materials 2018, 11, 1448. [Google Scholar] [CrossRef]

- Tinoco, M.P.; de Andrade Silva, F. On the mechanical behavior of hybrid fiber reinforced strain hardening cementitious composites subjected to monotonic and cyclic loading. J. Mater. Res. Technol. 2021, 11, 754–768. [Google Scholar] [CrossRef]

- Özkan, Ş.; Demir, F. The hybrid effects of PVA fiber and basalt fiber on mechanical performance of cost effective hybrid cementitious composites. Constr. Build. Mater. 2020, 263, 120564. [Google Scholar] [CrossRef]

- Dias, D.P.; Thaumaturgo, C. Fracture Toughness of Geopolymeric Concretes Reinforced with Basalt Fibers. Cem. Concr. Compos. 2005, 27, 74–75. [Google Scholar] [CrossRef]

- Branston, J.; Das, S.; Kenno, S.Y.; Taylor, C. Mechanical Behavior of Basalt Fiber Reinforced Concrete. Constr. Build. Mater. 2016, 124, 878–886. [Google Scholar] [CrossRef]

- Ayub, T.; Shafiq, N.; Nuruddin, M.F. Mechanical Properties of High-Performance Concrete Reinforced with Basalt Fibers. Procedia Eng. 2014, 77, 131–139. [Google Scholar] [CrossRef]

- Zhou, H.; Jia, B.; Huang, H.; Mou, Y. Experimental Study on Basic Mechanical Properties of Basalt Fiber Reinforced Concrete. Materials 2020, 13, 1362. [Google Scholar] [CrossRef]

- Wang, Z.T. Experimental Study on the Frost Resistance of Basalt Fiber Reinforced Concrete. Master’s Thesis, Harbin Engineering University, Harbin, China, 2017. (In Chinese). [Google Scholar]

- Wang, Z.S.; Xing, L.X.; Wu, B.; Zhang, Y. Study on the Effect of Basalt Fiber Content on the Durability of Concrete Under Sulfate Corrosion. Build. Struct. 2020, 50, 91–95+46. (In Chinese) [Google Scholar]

- Liu, Y. Experimental Study and Mechanism Analysis of Basalt Fiber Reinforced Concrete in Acidic Environment. Master’s Thesis, Xi’an University of Technology, Xi’an, China, 2017. (In Chinese). [Google Scholar]

- GB 175-2007; Common Portland Cement. Standardization Administration of China: Beijing, China, 2007.

- ASTM C150/C150M-22; Standard Specification for Portland Cement. ASTM International: West Conshohocken, PA, USA, 2022.

- EN 197-1:2011; Cement—Part 1: Composition, Specifications and Conformity Criteria for Common Cements. European Committee for Standardization (CEN): Brussels, Belgium, 2011.

- GB/T 2419-2005; Test Method for Fluidity of Cement Mortar. Standardization Administration of China: Beijing, China, 2005. (In Chinese)

- GB/T 50081-2019; Standard for Test Method of Mechanical Properties on Ordinary Concrete. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2019. (In Chinese)

- GB/T 17671-2021; Test Method of Mechanical Properties of Cement Mortar. Standardization Administration of China: Beijing, China, 2021. (In Chinese)

- DBJ41/T 236-2020; Technical Specification for Application of Recycled Concrete in Buildings. Department of Housing and Urban-Rural Development of Henan Province: Zhengzhou, China, 2020. (In Chinese)

- Zhang, Y.; Zhang, S.; Deng, M. Four-point bending tests of ECC: Mechanical response and toughness evaluation. Case Stud. Constr. Mater. 2022, 17, e01573. [Google Scholar] [CrossRef]

- JC/T 2461-2018; Technical Specification for Recycled Fine Aggregate for Concrete and Mortar. Ministry of Industry and Information Technology of the People’s Republic of China: Beijing, China, 2018. (In Chinese)

- GB/T 50082-2024; Standard for Durability Test Method of Ordinary Concrete. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2024. (In Chinese)

- Sabir, B.B.; Wild, S.; O’Farrell, M. A water sorptivity test for mortar and concrete. Mater. Struct. 1998, 31, 568–574. [Google Scholar] [CrossRef]

- ASTM C1585-20; Standard Test Method for Measurement of Rate of Absorption of Water by Hydraulic-Cement Concretes. ASTM International: West Conshohocken, PA, USA, 2020.

- Kabir, H.; Wu, J.; Dahal, S.; Joo, T.; Garg, N. Automated Estimation of Cementitious Sorptivity via Computer Vision. Nat. Commun. 2024, 15, 53993. [Google Scholar] [CrossRef]

- Niu, R.; Yang, Y.; Liu, Z.; Ding, Z.; Peng, H.; Fan, Y. Durability of Two Epoxy Adhesive BFRP Joints Dipped in Seawater under High Temperature Environment. Polymers 2023, 15, 3232. [Google Scholar] [CrossRef] [PubMed]

- Wawkuschewski, A.; Cantow, H.J.; Magonov, S.N. Surface morphology and nanostructure of high modulus polyethylene fiber. Polym. Bull. 1994, 32, 235–240. [Google Scholar] [CrossRef]

- Zhang, Z.; Ji, Y.; Ji, W. Durability Performance Investigation for Engineering Fiber Cementitious Composites (ECC): Review. Polymers 2023, 15, 931. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Wang, L.; Li, H.; Liu, Y.; Zhao, X.; Zhang, T. Compressive Properties of Basalt Fibers and Polypropylene Fiber-Reinforced Lightweight Concrete. ACS Omega 2023, 9, 26973–26982. [Google Scholar] [CrossRef]

- Jia, T.F.; Liu, H.W.; Chu, F.J.; Sun, H.; Yang, S.W.; Yang, T.Y. Water Absorption of Basalt Fiber Reinforced Cement. Adv. Mater. Res. 2012, 627, 823–826. [Google Scholar] [CrossRef]

- Wang, S.; Liu, J.; Tian, Y.; Zhao, P. Influence of Composite C-S-H Seed Prepared by Wet Grinding on High-Volume Fly Ash Concrete. Buildings 2025, 15, 270. [Google Scholar] [CrossRef]

- Dai, K.; Li, S.; Hu, P.; Jiang, N.; Wang, D. Effect of outer rust layer on cathodic protection and corrosion behavior of high-strength wire hangers with sheath crack in marine rainfall environment. Case Stud. Constr. Mater. 2023, 18, e02043. [Google Scholar] [CrossRef]

- Hu, P.; Li, S.; Dai, K.; Jiang, N.; Wang, D. Analysis of hydrogen embrittlement and applied potential of 1670, 1770, and 1860 MPa ultrahigh-strength steel wire for impressed current cathodic protection on cables and hangers. Int. J. Hydrogen Energy 2024, 50, 1–20. [Google Scholar] [CrossRef]

| Material | Density (g/cm3) | Diameter (μm) | Tensile Strength (GPa) | Elastic Modulus (GPa) | Elongation at Break (%) |

|---|---|---|---|---|---|

| PE Fiber | 0.97 | 16 | 4.4 | 65 | 3.5 |

| BFRP fiber | 2.63 | 17 | 3.66 | 110 | 3.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, S.; Li, W.; Wang, X.; Zhang, H.; Liu, J.; Jiang, H.; Wang, X.; Ma, H.; Shi, J.; Yu, Z.; et al. The Mechanical Properties and Durability of the PE-BFRP Hybrid-Fiber-Engineered Cementitious Composite (ECC). Buildings 2025, 15, 1860. https://doi.org/10.3390/buildings15111860

Xu S, Li W, Wang X, Zhang H, Liu J, Jiang H, Wang X, Ma H, Shi J, Yu Z, et al. The Mechanical Properties and Durability of the PE-BFRP Hybrid-Fiber-Engineered Cementitious Composite (ECC). Buildings. 2025; 15(11):1860. https://doi.org/10.3390/buildings15111860

Chicago/Turabian StyleXu, Shasha, Wei Li, Xuezhen Wang, Hongze Zhang, Ju Liu, Hui Jiang, Xuebin Wang, Hongke Ma, Jun Shi, Zhenyun Yu, and et al. 2025. "The Mechanical Properties and Durability of the PE-BFRP Hybrid-Fiber-Engineered Cementitious Composite (ECC)" Buildings 15, no. 11: 1860. https://doi.org/10.3390/buildings15111860

APA StyleXu, S., Li, W., Wang, X., Zhang, H., Liu, J., Jiang, H., Wang, X., Ma, H., Shi, J., Yu, Z., & Dai, K. (2025). The Mechanical Properties and Durability of the PE-BFRP Hybrid-Fiber-Engineered Cementitious Composite (ECC). Buildings, 15(11), 1860. https://doi.org/10.3390/buildings15111860