Research on Energy-Saving Optimization of Green Buildings Based on BIM and Ecotect

Abstract

1. Introduction

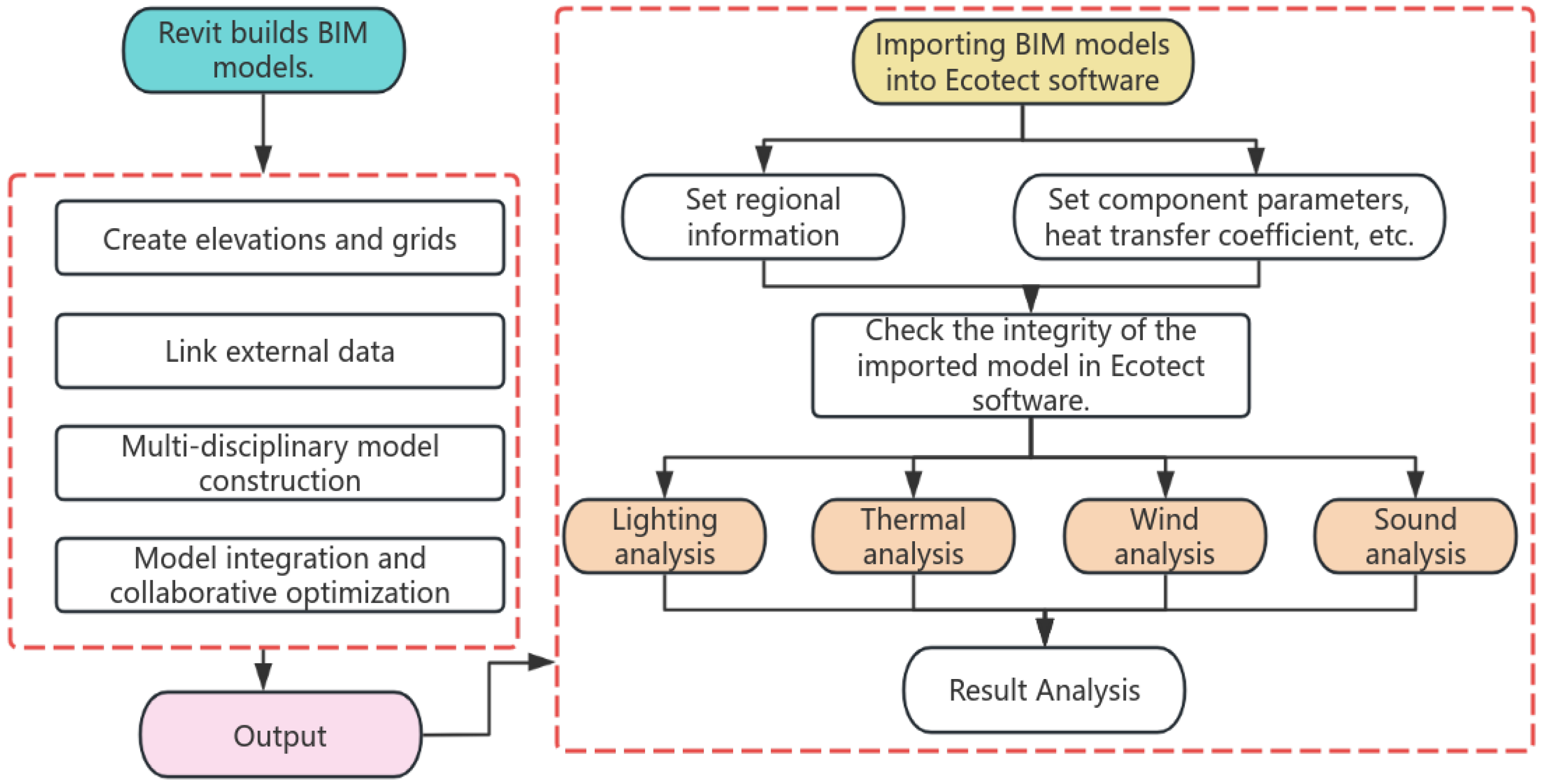

2. Research Process and Greening Evaluation Indicators

2.1. BIM Model and Ecotect Software

2.2. Green Degree Evaluation Index System and Calculation

2.3. Calculation of Green Degree and Grading Standards

3. Experimental Verification

3.1. Background

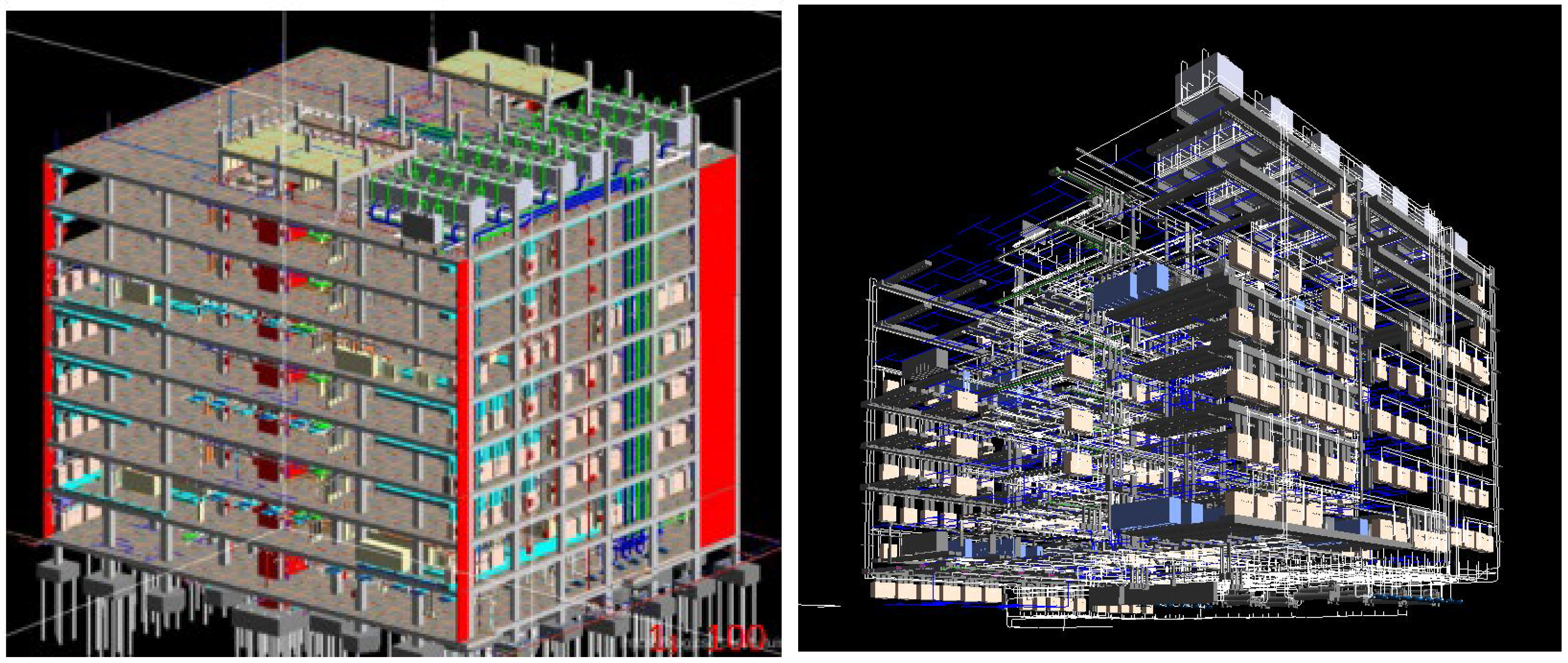

3.2. Model Establishment

4. Test Results

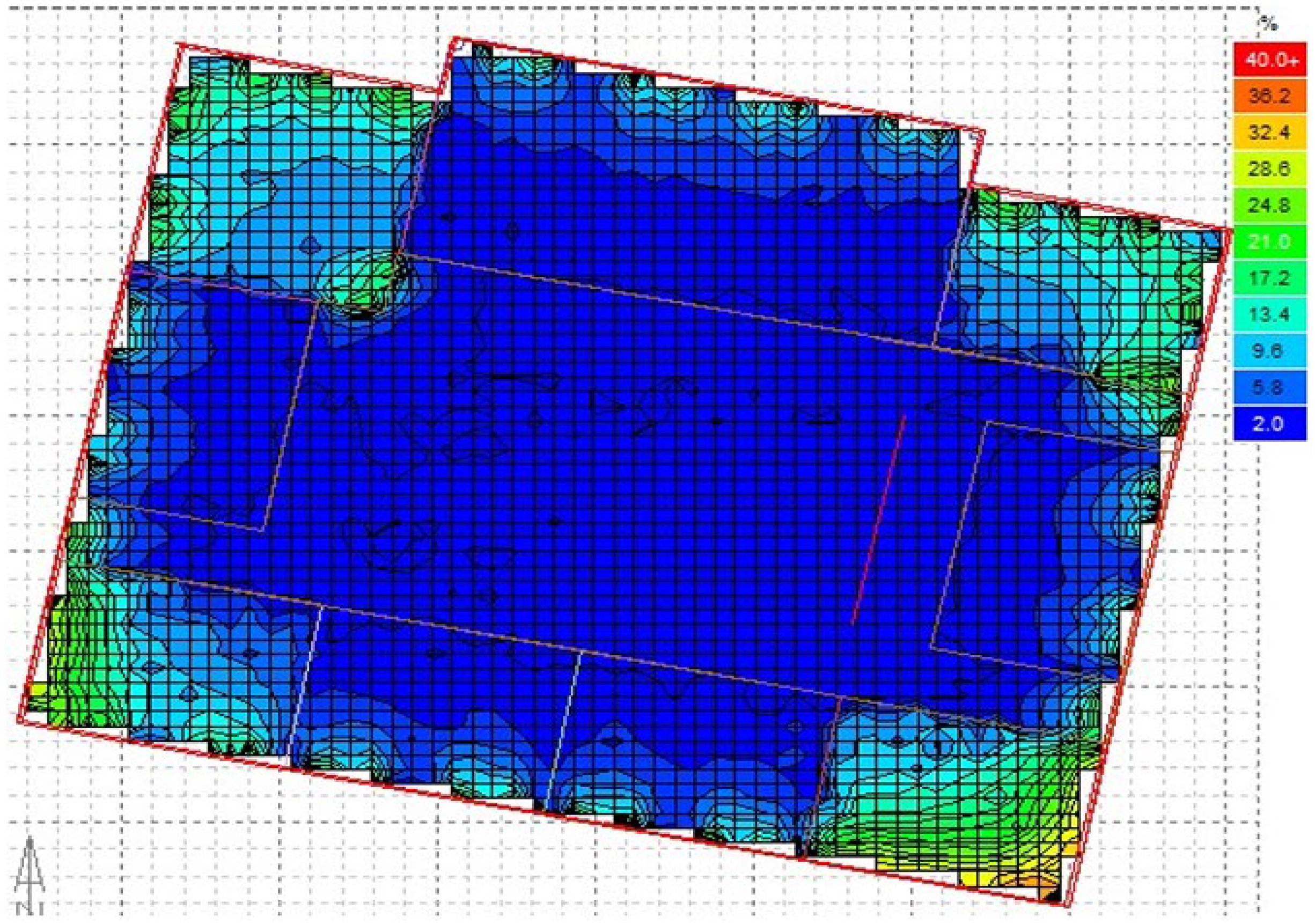

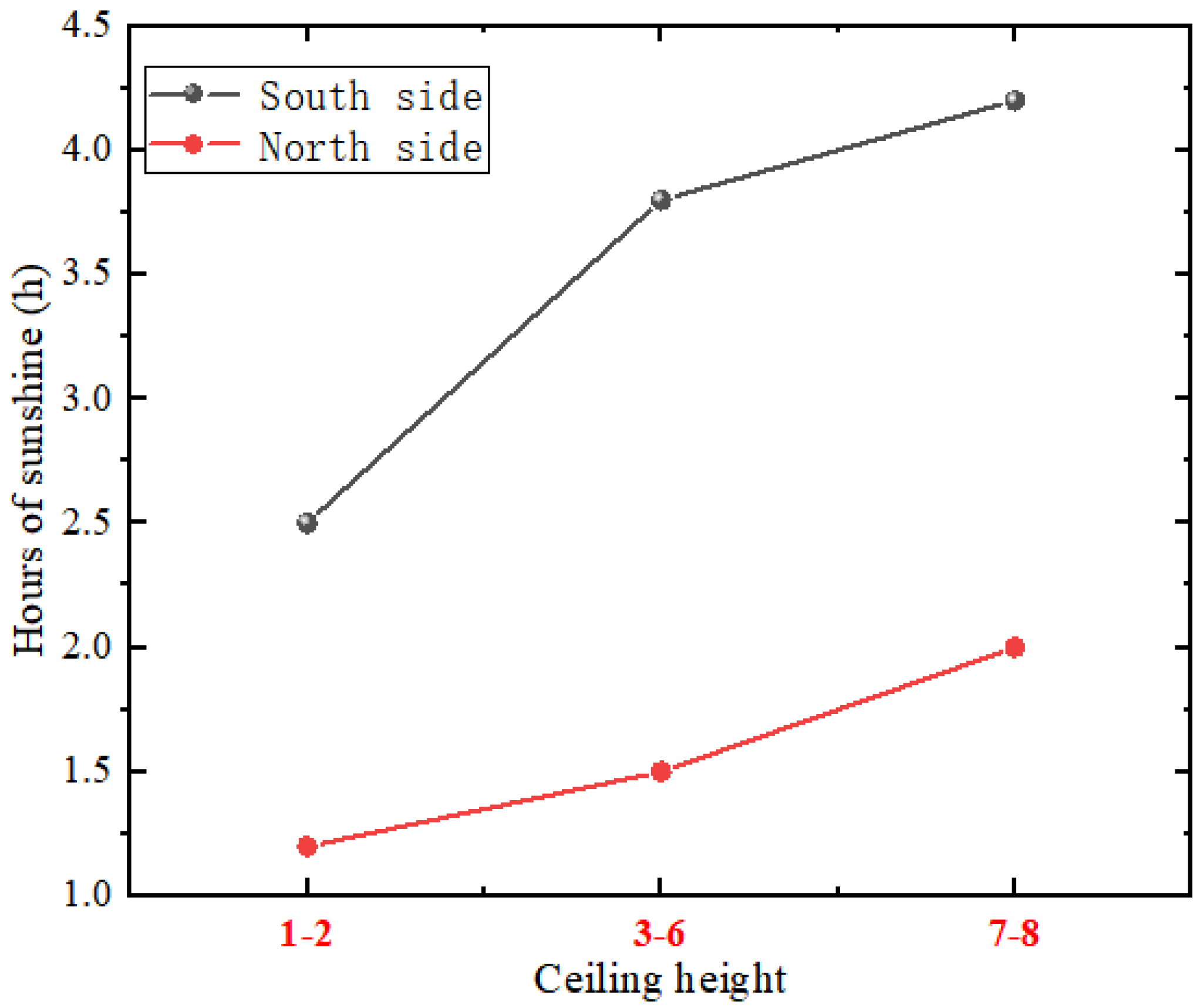

4.1. Daylighting and Solar Radiation Analysis Using Ecotect

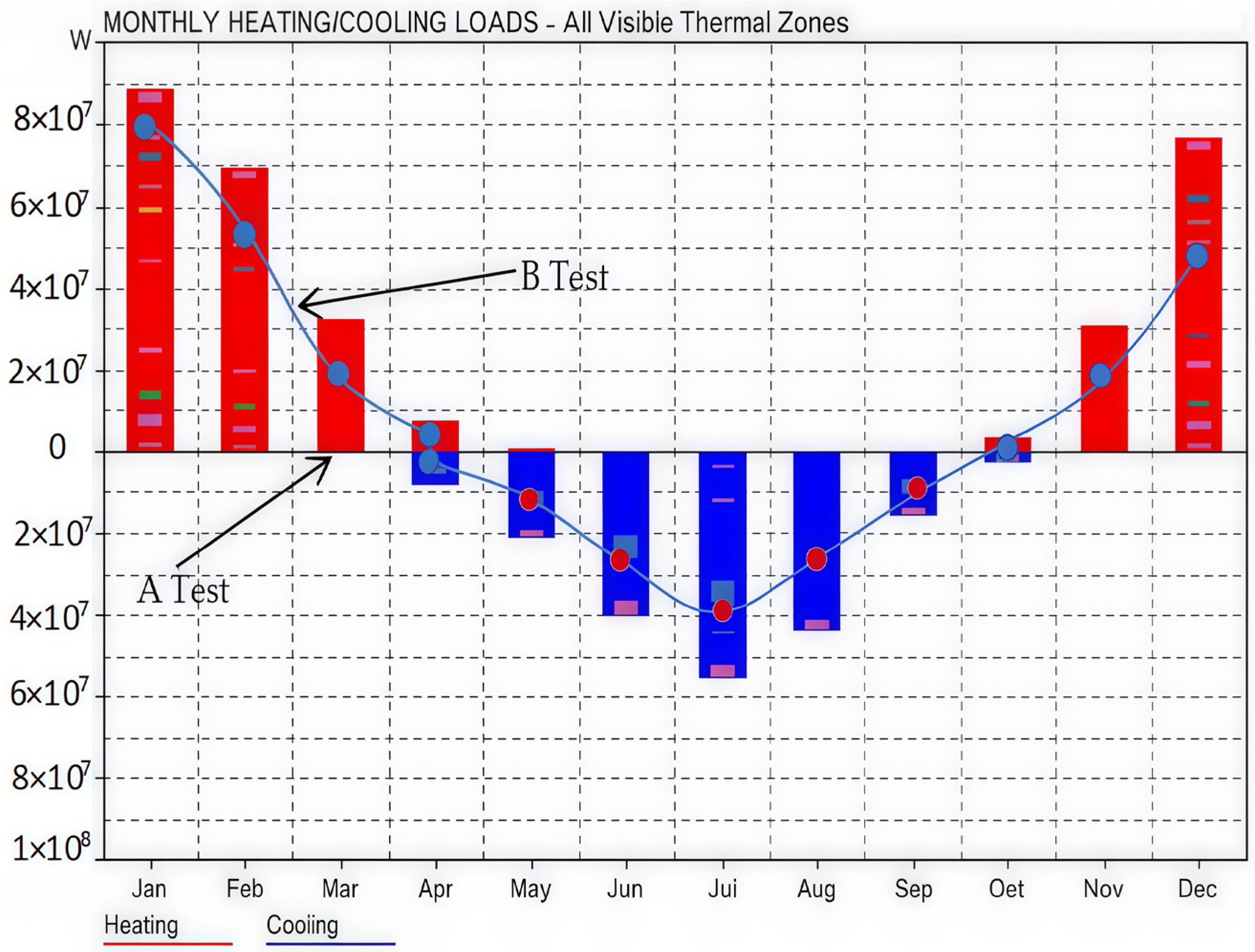

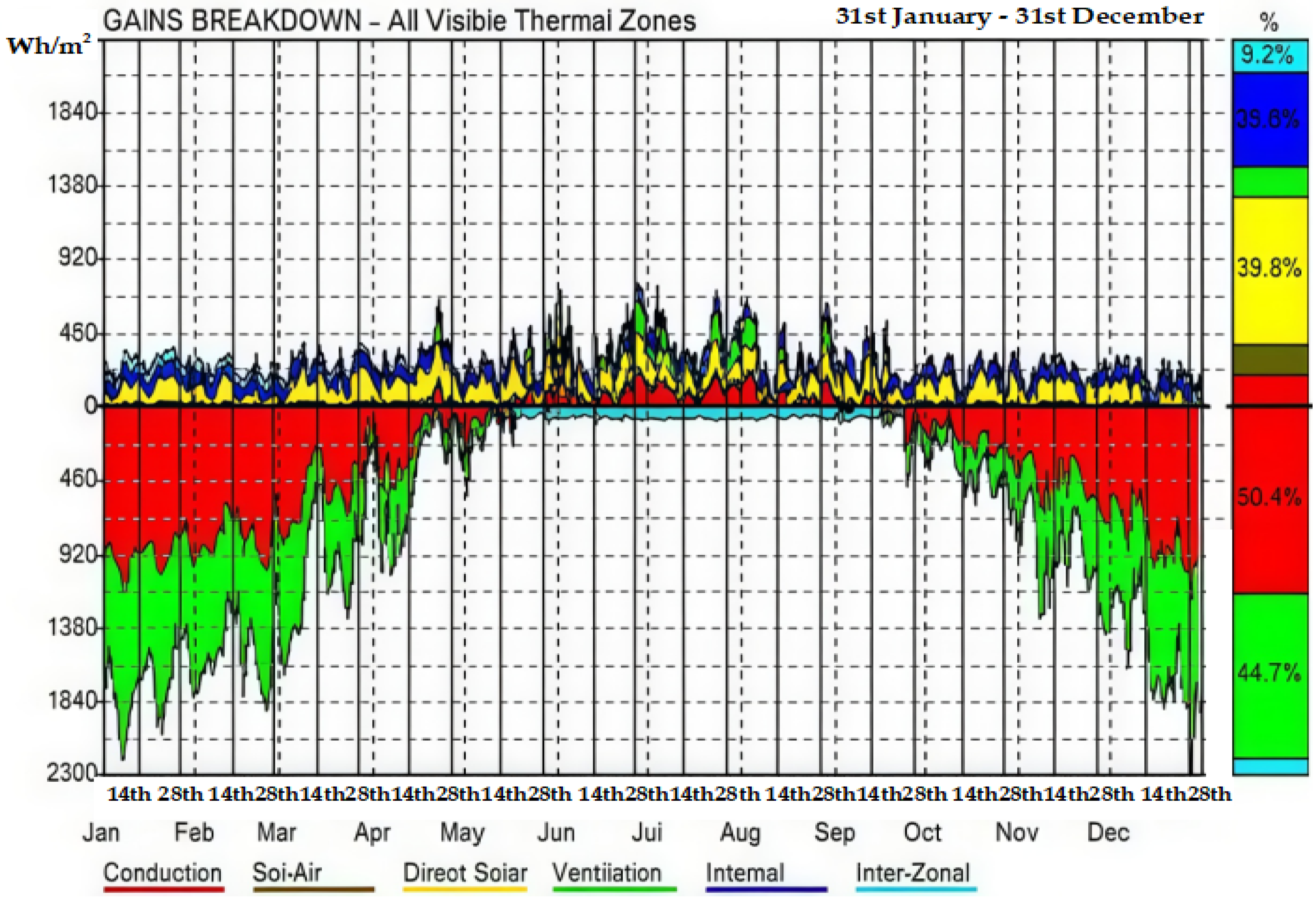

4.2. Heat and Energy Consumption Analysis

4.3. Noise Analysis

4.4. Ventilation Analysis

4.5. Green Degree Evaluation

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhao, W. Performance and Information Technology in Green Building Design. Urban Archit. 2015, 188–189, 257. [Google Scholar]

- Wang, C. Development Comparison and Optimization Suggestions of Green Building and Low-Carbon Building Evaluation Systems in China. Archit. Sci. 2023, 39, 235–244. [Google Scholar]

- Amirebrahimi, S.; Rajabifard, A.; Mendis, P.; Ngo, T. A framework for microscale flood damage assessment and visualization for a building using BIM-GIS integration. Int. J. Digit. Earth 2016, 9, 363–386. [Google Scholar] [CrossRef]

- Aizezi, G.; Yuan, X.; Lin, Y.; Zheng, A.; Pang, X.; Zhang, W. Research on the calculation method of the full life cycle carbon emissions of an office building based on BIM model. Intell. Build. Smart City 2025, 3, 103–106. [Google Scholar]

- Chen, Y.; Kang, H.; Fan, Y. Test and evaluation of interoperability between building information model and green building analysis software based on IFC and gbXML standards. J. Graph. 2018, 39, 530–537. [Google Scholar]

- Chen, Y.; Fan, Y. Research on data standards and applications of green building information model based on IFC and gbXML standards. Inf. Technol. Civ. Eng. Archit. 2018, 10, 9–15. [Google Scholar]

- Gourlis, G.; Kovacic, I. Building Information Modelling for analysis of energy efficient industrial buildings–A case study. Renew. Sustain. Energy Rev. 2017, 68, 953–963. [Google Scholar] [CrossRef]

- Ryan, M.E.; Sanquist, F.T. Validation of building energy modeling tools under idealized and realistic conditions. Energy Build. 2012, 47, 375–382. [Google Scholar] [CrossRef]

- Cho, C.S.; Chen, D.; Woo, S. Building information modeling (BIM)-Based design of energy efficient buildings. In Proceedings of the 28th International Symposium on Automation and Robotics in Construction, Seoul, Republic of Korea, 29 June–2 July 2011; pp. 1079–1084. [Google Scholar]

- Ye, J.L.; Chen, J.; Li, Y.Y. Research on BIM Design Method for Rural Houses Based on the Coupling of Life-cycle Carbon Emissions and Costs. J. Xi’an Univ. Archit. Technol. (Nat. Sci. Ed.) 2025, 57, 124–132. [Google Scholar]

- Numan, M.Y.; Almaziad, F.A.; AI-Khaja, W.A. Architectural and urban design potentials for residential building energy saving in the Gulf region. Appl. Energy 1999, 64, 401–410. [Google Scholar] [CrossRef]

- Wong, N.H.; Jusuf, S.K.; Syafii, N.I.; Chen, Y.; Hajadi, N.; Sathyanarayanan, H.; Manickavasagam, Y.V. Evaluation of the impact of the surrounding urban morphology on building energy consumption. Sol. Energy 2011, 85, 57–71. [Google Scholar] [CrossRef]

- Perez-Garcia, A.; Martin-Dorta, N.; Aranda, J.A. BIM requirements in the Spanish public tender—Analysis of adoption in construction contracts. Buildings 2021, 11, 594. [Google Scholar] [CrossRef]

- Cheng, Z.; Chen, J.; Sun, X.; Hammad, A. Lifecycle evaluation of building sustainability using BIM and RTLS. In Proceedings of the 2014 Winter Simulation Conference, Savannah, GA, USA, 7–10 December 2014; IEEE: New York, NY, USA; pp. 3236–3247. [Google Scholar]

- Shen, X.; Hu, W.; Xiao, Y.; Li, M.; Xue, M.; Wang, J. Energy consumption calculation and analysis of a green building simulation in Chongqing. Civ. Archit. Environ. Eng. 2013, 35, 177–180. [Google Scholar]

- Li, L.; Zhang, L.; Liu, G.; Liu, S.; Zheng, S. Numerical simulation analysis of wind environment of a green building. Civ. Archit. Environ. Eng. 2015, 37, 215–218. [Google Scholar]

- Yan, C. Secondary Development and Application of Building Model Information Based on Revit. Master’s Thesis, North University of China, Taiyuan, China, 2020. [Google Scholar]

- Amani, N. Building energy conservation in atrium spaces based on ECOTECT simulation software in hot summer and cold winter zone in Iran. Int. J. Energy Sect. Manag. 2018, 12, 298–313. [Google Scholar] [CrossRef]

- Fang, Z.; Wang, X.; Huang, Q.; Pang, Z. Simulation analysis of greenhouse environmental parameters based on Ecotect. J. Trop. Biol. 2016, 7, 99–103. [Google Scholar]

- Raja Muhammad Rooshdi, R.R.; Nazarrudin, N.A.; Ismail, N.A.A.; Sahamir, S.R.; Marhani, M.A. Challenges of implementing building information modeling (BIM) in green assessment tools. In Proceedings of the IConBEE 2022, Putrajaya, Malaysia, 18–19 October 2023. [Google Scholar]

- Qian, Q.Z.; Wang, Y.X. Application of Multi-level Extension Comprehensive Evaluation Method in Green Building Evaluation. J. Eng. Manag. 2014, 28, 11–16. [Google Scholar]

- He, Y.E.; Ding, Y. Comparison of Key Elements for Energy-saving Benefit Evaluation in International Typical Green Building Evaluation Systems. HVAC 2016, 46, 79–86. [Google Scholar]

- Yang, W.L. Energy Consumption Evaluation of Green Buildings Based on BIM Technology. Urban Dev. Res. 2016, 23, 14–17. [Google Scholar]

- Wang, Z.S.; Wang, L.G. Research on the Evaluation and Certification System of Green Degree of Building Materials under the Background of Green Buildings. Constr. Econ. 2015, 36, 108–112. [Google Scholar]

- Chen, H.Y.; Xu, G.; Wu, X.G.; Wang, X.Y.; Zhang, L.M. Research on Information-based Design and Green Degree Evaluation of Green Buildings Based on BIM. Build. Technol. 2019, 50, 996–1000. [Google Scholar]

- Zhang, C. Research on the Construction of Evaluation Standards for the Green Degree of Structural Systems and Qualitative Analysis. Master’s Thesis, Liaoning Technical University, Fuxin, China, 2012. [Google Scholar]

- Li, T.; Xu, G.; Chen, H.; Wu, X.; Wang, X. Evaluation and analysis of green degree of green buildings based on BIM technology. Constr. Technol. 2020, 49, 113–117. [Google Scholar]

- Zhan, C.; Xu, L.; Lin, L.; Song, W.; Qi, X.; Xu, W.; Yang, X. Pre-evaluation of performance of green hospital buildings based on BIM-lementary particle. J. Civ. Eng. Manag. 2022, 39, 80–87+107. [Google Scholar]

- Li, T.; Xu, G.; Chen, H.; Wu, X.; Wang, X. Green building green degree evaluation based on BIM technology analysis. J. Constr. Technol. 2020, 49, 113–117. [Google Scholar]

- Arranz, B.; Rodriguez-Ubinas, E.; Bedoya-Frutos, C.; Vega-Sánchez, S. Evaluation of three solar and daylighting control systems based on Calumen II, Ecotect and Radiance simulation programs. Energy Build. 2014, 83, 225–236. [Google Scholar] [CrossRef]

- Li, Z.; Wang, L.; Zhang, H. Research on the natural light environment of office spaces with photovoltaic glass: A case study of Tianjin. J. Light. Eng. 2015, 1, 23–28. [Google Scholar]

- ISO/CIE 19776:2014; Illuminance of Outdoor Work Places. International Organization for Standardization (ISO): Geneva, Switzerland, 2014.

- GB/T 50033-2021; Architectural Daylighting Design Standard. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2021.

- Chen, F.; Li, W.; Liao, S.; Gong, G. Simulation research on the thermal pipe air conditioning system of data centers: Based on thermodynamic simulation software CYCLPAD. Clean Air Cond. Technol. 2020, 4, 27–33. [Google Scholar]

- Wang, Z.; Xiong, W.; Liu, Y.; Jiang, C.; Zhu, C. Research on energy-saving application schemes of thermal pipe-cold storage air conditioning systems in data centers. Refrig. Air Cond. 2015, 35, 71–7480. [Google Scholar]

- Chen, F.; Gao, H. Thermodynamic study on waste heat recovery system of internal combustion engine based on Kalina cycle. J. Eng. Thermophys. 2020, 41, 271–276. [Google Scholar]

- GB/T 55038-2025; Introduction to the National Standard GB/T 55038-2025 (2025 Edition). Residential Project Specifications: Beijing, China, 2025.

- GB/T 18883-2022; Introduction to the National Standard GB/T 18883-2022 (2022 Edition). Indoor Air Quality Standards: Beijing, China, 2022.

- GB/T 50378-2019; Introduction to the National Standard GB/T 50378-2019 (2024 Edition). Green Building Evaluation Standard: Beijing, China, 2019.

- GB50189-2015; National Standard “Energy Efficiency Design Standard for Public Buildings”. China Architecture & Building Press: Beijing, China, 2018; pp. 39–45.

- Cheng, Y.; Shi, J.; Zhao, X.; Zhao, W.; Liu, Q.; Liu, H. Comprehensive assessment of green degree of building material using fuzzy AHP. In Frontiers of Green Building, Materials and Civil Engineering; Trans Tech Publications: Wollerau, Switzerland, 2011; pp. 765–773. [Google Scholar]

- Lv, Z.; Tang, J.; Zhang, J.; Lin, H. Space loop sunlight in a collection of residential in Dalian by the Autodesk Ecotect contrast group application. In Proceedings of the Dadt 2013, Beijing, China, 28 September 2013; pp. 158–168. [Google Scholar]

- Li, Y.; Lin, C. Green building design method based on BIM technology: A case study of Nanning Urban Planning Exhibition Hall. HVAC Refrig. 2012, 42, 50–53. [Google Scholar]

| Primary Indicators | Secondary Indicators | Classification Number |

|---|---|---|

| Light environment (L1, Q1) | The daylight factor complies with the national standard “Standard for Daylighting Design of Buildings”. | Q11 |

| The daylighting rate complies with the national standard “Standard for Daylighting Design of Buildings”. | Q12 | |

| Sunshine duration | Q13 | |

| The indoor illuminance complies with the national standard “Code for Lighting Design of Buildings”. | L11 | |

| Sun shading measures for exterior windows | Q14 | |

| The surface reflectance of the main functional rooms indoors complies with the national standard. | Q15 | |

| Thermal environment (L2, Q2) | Direct solar radiation time | Q21 |

| Diffuse solar radiation time | Q22 | |

| The heating facilities comply with the national standards. | L21 | |

| The annual heat gain of the indoor space | Q23 | |

| The thermal performance of the interior walls and floor slabs complies with the national energy-saving standards. | L22 | |

| The energy efficiency of the cooling and heating source units of the air conditioning system is superior to the national standards. | L23 | |

| Wind environment (Q3) | Dominant wind direction | Q31 |

| The operable parts of exterior windows and glass curtain walls can provide good ventilation for the building. | Q32 | |

| Building orientation | Q33 | |

| Acoustic environment (Q4) | The noise level of the main functional rooms complies with the national standards. | |

| “Code for Sound Insulation Design of Civil Buildings” | Q41 | |

| The noise level conforms to the national noise zoning standards. | Q42 | |

| The sound insulation performance of interior walls, floor slabs and doors and windows complies with the national standards. | ||

| “Code for Sound Insulation Design of Civil Buildings” | Q43 | |

| Sound insulation and noise reduction measures are adopted. | Q44 |

| Rating | |

|---|---|

| Excellent | (≥3.0) |

| Good | (1.5–3.0) |

| Average | (1.0–1.5) |

| Relatively poor | (0.5–1.0) |

| Poor | (≤0.5) |

| Parameter Name | Parameter Value | Note |

|---|---|---|

| Number of building floors | 8th floor | The floor height is 4 m. Total height 32 m. |

| Functional areas | Office (60%), Corridor (20%), Conference room (15%), Equipment room (5%) | The functional distribution of each floor is consistent. The area of each floor is 800 square meters. |

| Window-to-floor ratio | 1:6 (Southward), 1:8 (Northward) | The VLT of the glass is 0.6. |

| Reflectivity of the envelope structure | External walls 0.65, roof 0.50, floor 0.30 | Reflectivity of the envelope structure |

| Light climate parameters | K = 1.1, outdoor critical illuminance 4500 lx | Wuhan belongs to the IVth light climate zone. |

| Simulation grid accuracy | 0.5 m × 0.5 m | Ecotect grid division |

| Sky model | CIE overcast sky model | Dynamic correction based on TMY meteorological data |

| Functional Area | Lighting Coefficient (C) | Achievement Rate (C ≥ 2.0) | Illumination Uniformity (Emin/Emax) |

|---|---|---|---|

| Office (South) | 2.4 | 85% | 0.68 → 0.72 |

| Office (North) | 2.1 | 78% | 0.55 → 0.65 |

| Corridor | 1.2 | 40% | 0.30 → 0.35 |

| Conference Room (South) | 2.6 | 92% | 0.70 → 0.75 |

| Time | Dry Bulb Temperature (°C) | Relative Humidity (%) | The Amplitude of Direct Sunlight (W/m2) | Solar Scattering Amplitude (W/m2) | Wind Speed (m/s) |

|---|---|---|---|---|---|

| 8:00 | 5 | 70 | 200 | 100 | 4.0 |

| 10:00 | 8 | 60 | 450 | 180 | 5.5 |

| 12:00 | 10 | 50 | 550 | 220 | 6.5 |

| 14:00 | 9 | 48 | 400 | 175 | 5.3 |

| 16:00 | 6 | 65 | 150 | 80 | 4.0 |

| 18:00 | 2 | 80 | 0 | 0 | 2.6 |

| Parameter | Analog Value | Measured Value | Error Rate |

|---|---|---|---|

| The daylight factor of the south-facing office | 2.4 | 2.3 | 4.3% |

| Sunshine duration on the Winter Solstice (1st floor) | 2.5 h | 2.4 h | 4.0% |

| Uniformity of illuminance (conference room) | 0.75 | 0.72 | 4.0% |

| Parameter Name | Parameter Value (A Test) | Parameter Value (B Test) | Note |

|---|---|---|---|

| Building floor count | 8th floor | 8th floor | Floor height: 4 m Total construction area: 12,800 m2 |

| Thermal performance of building envelope | External wall U-value = 0.8 W/(m2·K) Exterior windows U-value = 3.0 W/(m2·K) Roof U-value = 1.2 W/(m2·K) | External wall U-value = 0.35 W/(m2·K) Exterior windows U-value = 1.8 W/(m2·K) Roof U-value = 0.4 W/(m2·K) | The exterior wall of Test A is made of concrete and cement mortar, while Test B features a 100 mm rock wool insulation layer. The SHGC for single-pane glass is 0.7 in Test A and 0.3 in Test B. Test A lacks roof insulation, while Test B features a 50 mm extruded polystyrene board. (In Test B, the glass adopted the low-emissivity (Low-E) coating technology). |

| Air conditioning system | Variable frequency multi-split air conditioning system (COP = 3.2/2.8) | Variable frequency multi-split air conditioning system (COP = 3.2/2.8) | Design temperature: 26 °C in summer and 20 °C in winter. |

| Simulation grid accuracy | Zone-by-zone hourly load analysis | Zone-by-zone hourly load analysis | Ecotect + EnergyPlus |

| Energy Consumption Type | Annual Energy Consumption (A Test) | Annual Energy Consumption (B Test) | Energy- Saving Rate | Standard Limit Value |

|---|---|---|---|---|

| Air conditioning cooling load (kWh/m2) | 39.2 | 29.3 | 25.3% | ≤75 (Three-star) |

| Air conditioning heat load (kWh/m2) | 64.58 | 49.32 | 23.6% | ≤40 (Three-star) |

| Energy consumption for lighting (kWh/m2) | 18.2 | 14.5 | 20.3% | ≤15 (Three-star) |

| Total energy consumption (kWh/m2) | 121.98 | 93.12 | 23.1% | ≤130 (Three-star) |

| Parameter Name | Parameter Value | Note |

|---|---|---|

| Building floors count | 8th floor | Floor height: 4 m |

| The main noise sources | Traffic noise (daytime equivalent sound level Leq = 70 dB(A)), equipment noise (air conditioning outdoor unit Leq = 55 dB(A)) | The main road is 15 m away from the building facade. |

| Sound insulation measures(C test) | Single-pane glass window (weighted sound insulation Rw = 30 dB) | The sound insulation of the wall Rw = 45 dB. |

| Sound insulation measures(D test) | Double-layer hollow soundproof window (Rw = 40 dB) | The south-facing windows will be replaced with double-pane soundproof windows (Rw = 40 dB, filled with argon gas); sound insulation barriers will be added to the outdoor air conditioner units (Noise reduction ≥ 10 dB). |

| Sound-absorbing materials | Ordinary gypsum board ceiling (NRC = 0.4) | ____ |

| Simulation grid accuracy | 1 m × 1 m | Cadna A acoustic model |

| Functional Area | Noise Level in the C Test Room Leq [dB(A)] | Noise Level in the D Test Room Leq [dB(A)] | Standard Limit Value |

|---|---|---|---|

| South-facing office (fronting the street) | 48 | 38 | ≤40 (GB 55038-2025) [37] |

| North-facing office (back street) | 42 | 35 | ≤40 (GB 55038-2025) |

| conference room | 40 | 32 | ≤35 (GB 55038-2025) |

| Corridor | 45 | 37 | ≤45 (GB 55038-2025) |

| Overall compliance rate | 65% | 92% |

| Parameter Name | Parameter Value | Note |

|---|---|---|

| Ventilation mode | Natural ventilation + mechanical assistance | Natural ventilation is mainly used during the transitional seasons. |

| Open mouth design (E test) | South-facing single-sided window opening (Area ratio: 12%) | The window is 1.5 m high and has no wind deflector. |

| Open mouth design (F test) | The opening rate has been increased to 20%. The skylight area accounts for 8%. | Add adjustable louvered vents to the south-facing side, and install operable skylights on the top of the atrium. |

| Air conditioning system | All-air system (air change rate: 2 times per hour) | Design wind speed ≤ 0.3 m/s |

| Simulation tool | Ecotect + ANSYS Fluent | CFD air flow organization analysis |

| Functional Area | Air Change Rate (Times per Hour) E Test | Air Change Rate (Times per Hour) F Test | The Concentration of CO2 (ppm) | Standard Limit Value |

|---|---|---|---|---|

| South-facing office | 1.2 | 1.2 | 720 → 550 | ≤800 (GB/T 18883-2022) [38] |

| Middle conference room | 0.8 | 0.8 | 850 → 620 | ≤800 (GB/T 18883-2022) |

| Corridor | 1.5 | 1.5 | 680 → 570 | ____ |

| Primary Indicators | Secondary Indicators | Indicator Type | Indicator Assignment Methods | Weighting Factor | Score |

|---|---|---|---|---|---|

| Light environment (L1, Q1) | Q11 | Scoring items | Daylighting and Sunlight Exposure | 0.1 | 100 |

| Q12 | Scoring items | Daylighting and Sunlight Exposure | 0.2 | 100 | |

| Q13 | Scoring items | Daylighting and Sunlight Exposure | 0.2 | 100 | |

| L11 | Control item | Illumination | 0.3 | 80 | |

| Q14 | Scoring items | Spatial visualization | 0.1 | 40 | |

| Q15 | Control item | Set the wall material in the BIM model. | 0.1 | 100 | |

| Thermal environment (L2, Q2) | Q21 | Scoring items | Solar radiation | 0.2 | 100 |

| Q22 | Scoring items | Solar radiation | 0.2 | 93 | |

| L21 | Scoring items | Indoor temperature | 0.2 | 100 | |

| Q23 | Scoring items | Heat environment loss | 0.1 | 83 | |

| L22 | Control item | Set the wall material in the BIM model. | 0.2 | 81 | |

| L23 | Control item | Indoor air conditioning distribution | 0.1 | 100 | |

| Wind environment (Q3) | Q31 | Scoring items | Airflow simulation | 0.3 | 57 |

| Q32 | Control item | window-to-wall ratio | 0.4 | 80 | |

| Q33 | Scoring items | Weather tool software simulation | 0.3 | 95 | |

| Acoustic environment (Q4) | Q41 | Scoring items | Time simulation | 0.3 | 100 |

| Q42 | Scoring items | Time simulation | 0.3 | 100 | |

| Q43 | Control item | Set the wall material in the BIM model. | 0.2 | 25 | |

| Q44 | Scoring items | Material usage, site greening | 0.2 | 80 |

| Primary Indicator | Secondary Indicator | Weight Coefficient | Score |

|---|---|---|---|

| Lighting analysis | 0.15 | 24 | |

| 0.20 | 64 | ||

| Energy consumption analysis | 0.15 | 46 | |

| 0.20 | 47 | ||

| Ventilation analysis | 0.20 | 78 | |

| Noise analysis | 0.10 | 81 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, M.; Yang, Y.; Dong, S. Research on Energy-Saving Optimization of Green Buildings Based on BIM and Ecotect. Buildings 2025, 15, 1819. https://doi.org/10.3390/buildings15111819

Zhao M, Yang Y, Dong S. Research on Energy-Saving Optimization of Green Buildings Based on BIM and Ecotect. Buildings. 2025; 15(11):1819. https://doi.org/10.3390/buildings15111819

Chicago/Turabian StyleZhao, Mengxue, Yuetao Yang, and Shan Dong. 2025. "Research on Energy-Saving Optimization of Green Buildings Based on BIM and Ecotect" Buildings 15, no. 11: 1819. https://doi.org/10.3390/buildings15111819

APA StyleZhao, M., Yang, Y., & Dong, S. (2025). Research on Energy-Saving Optimization of Green Buildings Based on BIM and Ecotect. Buildings, 15(11), 1819. https://doi.org/10.3390/buildings15111819