Abstract

In this work, we sought to study the properties of OSB panels manufactured with new green adhesives for wood that can replace formaldehyde-based wood adhesives currently on the market. After the manufacturing of the OSB panels, physical, mechanical, thermal, and formaldehyde emissions tests were performed according to international standards. From the results, it was found that OSB panels produced with green adhesives are less susceptible to color change after UV exposure than an OSB panel manufactured with phenol-formaldehyde adhesive. Furthermore, the OSB panels produced with green adhesives presented statistically the same dimensional stability as an OSB panel manufactured with phenol-formaldehyde adhesive. In terms of mechanical properties, sample OSB-1 outperformed the control sample by 7% (MOE flatwise) and 13% (MOR edgewise) and reached 68% of the tensile strength, 85% of the internal bond strength, and 87% of the Janka hardness of the control sample. Regarding the mechanical properties and formaldehyde emissions evaluation results, all three OSB samples tested could be classified into OSB/2 of the E1 classification, which means that the OSB panels produced with green adhesives presented a performance comparable to that of the OSB panels manufactured with a formaldehyde-based wood adhesive. Hence, the green adhesives could be a potential replacement for the phenol-formaldehyde adhesive in the manufacturing of OSB panels because they yielded, in most cases, results equal to those for a control OSB panel.

1. Introduction

Flakeboard or oriented strand board (OSB) is a panel designed primarily for structural use. It is made from wood fibers bonded with a resin that is impermeable under pressure and heat and used for roof, wall, and floor sheathing in residential and commercial construction. In general, in the OSB manufacturing process, debarked logs are heated and then cut into thin pieces of wood, forming the wood flakes, and subsequently mixed with resin and wax and shaped into thick, loosely consolidated mats that are pressed with pressure and a temperature between 177 and 204 °C for 3–5 min for general resin curing [1]. Oriented strand boards are composed of layers of wood flakes, usually three, where each layer is pressed with the chips oriented in the same direction, and then the layers are joined together, leaving the center layer perpendicular to allow greater stability and strength, making them an alternative to solid wood in many applications [2].

The main adhesive widely used in OSB panel manufacture is phenol formaldehyde (PF), the second most important wood composite adhesive, which is of an exterior grade. Nevertheless, PF has the defect of having a slow curing time, and it requires higher temperatures than urea formaldehyde adhesives [3]. Another important disadvantage is that these formaldehyde-based adhesives emit gases that are potentially harmful to human health, causing, for example, throat and nose cancer [4]. The emissions of formaldehyde-type gases, which are toxic to humans, are present in most of the commercial adhesives used in OSB manufacture or other wood-based panels. This is why different alternatives used for the production of different types of boards in the construction and furniture industry by American and European markets have undergone great development, which is reflected in the demanding regulations regarding the maximum emission of volatile organic compounds (VOCs) allowed for market products, while in South America, there is a low level of innovation both in terms of production techniques and in the development of different bio-based adhesives for the manufacture of boards.

This creates an opportunity to develop boards in compliance with the most demanding regulations worldwide, with the possibility of placing a product in this market by taking advantage of the abundant natural resources available in Chile.

Green or bio-based adhesives were used in the 1970s before being replaced by PF adhesives due to the greater bond durability provided by such adhesives. The most common bio-based adhesives are protein-based adhesives, such as bone, animal skin, blood, and soy. Protein-based adhesives are not useful when one is working with high moisture levels. However, the most important factor is their environmental benefit, although improvements in the performance and production cost of synthetic resins had not been achieved until 2004, when Li et al. developed adhesives based on soybean flour and combined them with other adhesives [5,6]. When soybean flour becomes part of the adhesive network instead of being used only as a filler, it can replace approximately half of the phenol in formulations, meeting the performance requirements of commercial OSB adhesives [7]. Green adhesives can also be derived from wood components like tannin and lignin. Tannins, though highly reactive and usable as partial phenol substitutes, are costly and limited in availability, with issues such as high viscosity and inconsistent reactivity. Lignin, a low-cost byproduct of papermaking, is less reactive but more abundant. Modified forms like lignosulfonates show promise, and advances in biorefinery technology may enhance lignin’s reactivity, increasing its potential as a sustainable adhesive component [6,8,9].

Several researchers have been studying green adhesives to partially or completely replace formaldehyde-based adhesives; the latest investigations about this are the following ones. Sugahara et al. [10], in 2025, investigated the feasibility of using fast-growing eucalyptus wood and castor oil polyurethane adhesive to produce OSB panels and evaluated their physical and mechanical properties. Strikun et al. [11], in 2024, manufactured environmentally friendly thermal insulation panels made of pine wood fibers with a bio-based adhesive and determined their relevant technical properties. During the same year, 2024, Siahkamari [12] developed a lignin-based phenolic adhesive for engineered wood products, studying the potential of lignin and glyoxal as sustainable replacements for phenol and formaldehyde. In 2024, Widyorini et al. [13] analyzed the properties of eco-friendly oriented strand board produced from oil palm trunks in which natural adhesives made from sucrose and ammonium dihydrogen were incorporated. In 2023, Núñez-Decap et al. [14] manufactured a bio-based wood adhesive from yeast protein, probed its efficiency regarding physical–mechanical properties, and conducted an evaluation of the formaldehyde emissions of particleboard. In 2022, Asafu-Adjaye et al. [15] investigated the use of fast pyrolysis bio-oil-based epoxy as an adhesive in oriented strand board (OSB) production. In 2021, Hornus et al. [16] explored the partial substitution of polymeric methylene diphenyl diisocyanate (pMDI) with lignin-containing cellulose nanofibrils in low-density OSB. That same year, Paul et al. [17] studied particleboard’s mechanical properties and formaldehyde release manufactured with lignin-based adhesives. In 2020, Ayrilmis, Özbay and Kökten [18] examined the properties of OSB produced using phenol-formaldehyde resin synthesized from bio-oil derived from lignocellulosic waste. In 2018, Bandara and Wu [19] developed randomly oriented strand board composites using nanoengineered protein-based wood adhesive. In 2017, Hand et al. [20] substituted liquid phenol binders with soy-based adhesives for flakeboard production. In 2016, Núñez-Decap et al. [21] demonstrated the feasibility of using yeast protein extracts to formulate wood adhesives, highlighting several advantages over other plant-derived proteins.

This work aims to promote the use of wood while exploring new environmentally friendly adhesives that can serve as alternatives to conventional adhesives, which are typically derived from fossil fuels such as natural gas and petroleum. The limited availability of these resources, along with increasing regulations on the emission of volatile organic compounds (VOCs), has driven interest in the development of bio-based adhesives [22]. Specifically, this study focuses on evaluating the properties of oriented strand boards (OSBs) manufactured with protein-based adhesives, with the goal of matching or surpassing the performance of commercially available adhesives. The comparison primarily centers on phenol-formaldehyde adhesives and includes a review of results from other studies, with particular attention to the physical–mechanical properties and formaldehyde emissions of the OSB panels.

2. Materials and Methods

2.1. Materials

The oriented strand board (OSB) panels were fabricated using three layers of Pinus radiata D. DON flakes (with a moisture content of 4%), arranged perpendicularly to each other. The flakes were bonded using a phenol-formaldehyde (PF) adhesive and two green adhesives (GAs), formulated according to the method described by Núñez-Decap et al. [14], 2023. The properties of the adhesives are summarized in Table 1. Each panel measured 400 mm in length, 400 mm in width, and 12 mm in thickness. Both the wood flakes and adhesives were provided by PRODIMA-LAB (Concepción, Chile).

Table 1.

Characterization of the phenol formaldehyde and green adhesives.

2.2. Manufacture of OSB Samples Using Different Wood Adhesives

The flakes were sorted by a sieve in a drawer with the dimensions of the target board (40 cm × 40 cm) and separated into three layers. The flakes in the first layer were oriented in one direction, the second layer was oriented perpendicular to the first, and the third layer was oriented in the same direction as the first. The adhesives were applied at a sizing ratio of 7%.

Subsequently, a 5-min cold pre-press was carried out inside the mold box. The flakes were arranged inside the press between two aluminum layers, separated by two 12 mm thick steel bars to ensure the target board thickness.

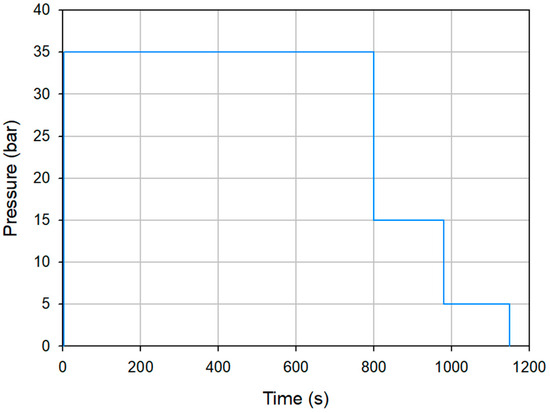

The flakes were pressed using a hydraulic press. For the boards, a pressing factor of 1.6 min/mm was applied, and a temperature of 180 °C was used for all three types of adhesives. A maximum pressure of 35 bar was applied at the beginning. After 70% of the cycle time, the pressure was reduced to 15 bar, and after 85% of the time, it was further reduced to 5 bar, as shown in Figure 1. This gradual reduction was intended to prevent sudden steam release and thus avoid board delamination. The OSB panels were stored at room temperature for 7 days immediately after pressing.

Figure 1.

Pressing cycle for the manufacture of OSB panels.

Three different OSB panels were manufactured: a control sample (OSB-C) using phenol-formaldehyde adhesive, and two samples (OSB-1 and OSB-2) employing green adhesives. Five replicates of each OSB sample, with dimensions of 40 cm in length × 40 cm in width × 1.2 cm in thickness, were produced using 90 g of adhesive and an open time of 2 min. Additionally, it is important to note that there was no difference in the manufacturing process among the samples.

Finally, a squaring saw was used to cut the OSB panels for the determination of their physical, mechanical, and thermal properties, as well as formaldehyde emissions, following the respective specifications of the European and American standards.

2.3. Assessment of Accelerated UV Weathering

Accelerated UV weathering was assessed following the ASTM G154 [23] standard specifications, using three specimens per OSB sample with dimensions of 290 mm in length × 50 mm in width, which were exposed to a continuous UV weathering cycle. A general factorial experimental design was conducted using Design Expert® V10.01 software to examine the impact of color change and surface appearance of the tested OSB panels based on the adhesives used. These adhesives were the factors considered, and the response variable was the CIELAB color change.

2.4. Physical Properties

Density was measured following the UNE-EN 323 [24] standard specifications on six specimens per OSB sample with dimensions of 50 mm in length × 50 mm in width. Moisture content was measured following the UNE-EN 322 [25] standard specifications on four specimens per OSB sample with dimensions of 50 mm in length × 50 mm in width. Additionally, thickness swelling was measured, following the UNE-EN 317 [26] standard specifications on eight specimens per sample, also with dimensions of 50 mm in length × 50 mm in width, which were immersed in water for 24 and 48 h.

2.5. Mechanical Properties

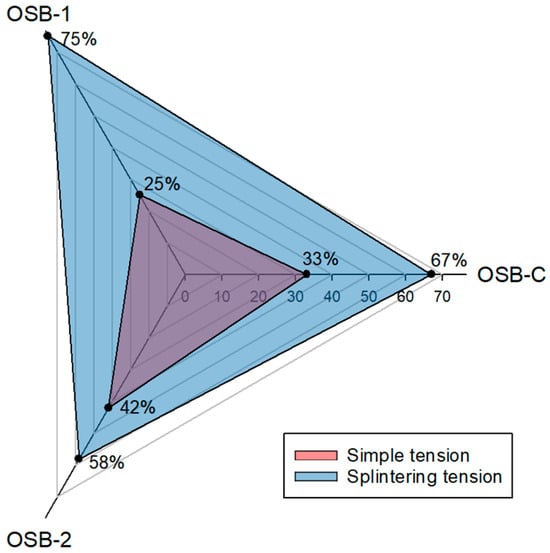

Flexural stiffness and strength were evaluated following the UNE-EN 310 [27] standard specifications, using 12 specimens per OSB sample with dimensions of 290 mm in length × 50 mm in width. The mode of failure was observed and classified according to the ASTM D143 [28] standard, which includes simple tension, cross-grain tension, splintering tension, brash tension, compression, and horizontal shear.

Tensile strength was measured following the ASTM D3500 method A [29] standard specifications, using six specimens per OSB sample with dimensions as specified in ASTM D3500, considering 12 mm.

The internal bond strength (IB) was measured following the UNE-EN 319 [30] standard specifications, using eight specimens per OSB sample with dimensions of 50 mm in length × 50 mm in width × 12 mm in thickness.

Janka hardness was measured following the ASTM D1037 [31] standard specifications using six specimens with dimensions of 100 mm in length × 50 mm in width. The hardness of each specimen corresponds to the average of two measurements taken on each face.

A universal testing machine, Instron EMIC 23-100, equipped with the software BlueHill v4.47, was used to perform the mechanical tests.

2.6. Thermal Properties

Thermal conductivity was measured following the ASTM D5334 [32] standard specifications using a Decagon KD2 PRO device, on six specimens per OSB sample in both flat- and edgewise positions, with dimensions of 100 mm in length × 50 mm in width. The results could be compared to the requirements established in the UNE-EN 13986:2006 + A1:2015 [33] standard, which specifies a thermal conductivity value (λ: 0.13 W/m·K) for an average density (ρ: 650 kg/m3) for OSB panels. It also states that for different density values, thermal conductivity can be calculated by interpolation.

2.7. Evaluation of Formaldehyde Emissions

Formaldehyde emissions were evaluated following the ASTM D6007 [34] standard specifications, using a dynamic microchamber (DMC), on three specimens per OSB sample with dimensions of 200 mm in length × 381 mm in width × 150 mm in thickness. The results obtained were compared to the requirements of the UNE-EN 13986:2006 + A1:2015 [33] standard, and the OSB samples were then classified according to their formaldehyde emissions levels.

2.8. Data Analysis

Data analysis consisted of a one-way analysis of variance for each measured property, in which multiple range tests were performed to determine which means were significantly different from others. The method currently used to discriminate among the means is Fisher’s least significant difference (LSD) at the 95% confidence level. The software used was Statgraphics Centurion 19, and the results of the data analysis are presented in each relevant table.

3. Results and Discussion

3.1. Assessment of Accelerated UV Weathering

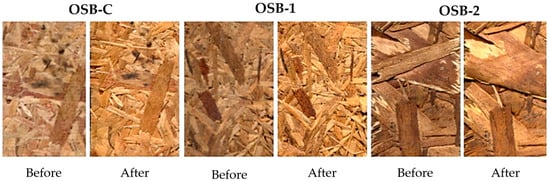

Digital images of the exposed surfaces revealed significant color changes in all tested OSB samples (Figure 2). These changes, caused by accelerated climatic exposure, are primarily attributed to the photodegradation of lignin in the wood [35], as lignin is among the first cell wall polymers to degrade under UV radiation [36]. The results presented in Table 2 indicate that the samples produced with green adhesives, OSB-1 and OSB-2, exhibited 27% and 46% lower susceptibility to color change compared to the OSB-C sample, respectively. These results are consistent with the study by Núñez-Decap et al. [14], who used the same green adhesives and obtained similar findings.

Figure 2.

Color change results in the OSB-C, OSB-1, and OSB-2 samples.

Table 2.

Color change in OSB samples due to artificial weathering.

The results provide a good indication of the durability of OSB boards, as durability against external agents, such as UV radiation exposure, is a key characteristic sought in board manufacturing. According to the results, it could be inferred that the green adhesives in this case also functioned as a barrier against UV radiation, which could help improve the long-term performance of OSB boards under various environmental conditions [37].

3.2. Physical Properties

Table 3 presents the results for the physical properties: density, moisture content, and thickness swelling.

Table 3.

Results of physical properties of the OSB samples.

The densities obtained for each OSB sample ranged between 705 and 822 kg/m3, with the OSB-1 sample reaching 86% of the density of the control sample, while the OSB-2 sample showed statistically the same density as the OSB-C sample.

The moisture content results for the OSB samples ranged between 2% and 5%. The OSB-C and OSB-1 samples presented the same value, while the OSB-2 sample showed an increase of approximately 150% compared to the other samples. However, all values remained within the expected range (2–6%).

The thickness swelling results after 24 h ranged between 31.22% and 32.07%, while the results after 48 h ranged between 33.31% and 33.97%. This physical property showed no significant differences between the samples tested (OSB produced with green adhesives and those with phenol-formaldehyde adhesive), nor between the two immersion durations. This indicates that the OSB samples produced with green adhesives exhibited the same dimensional stability under water immersion as the control sample manufactured with a formaldehyde-based adhesive.

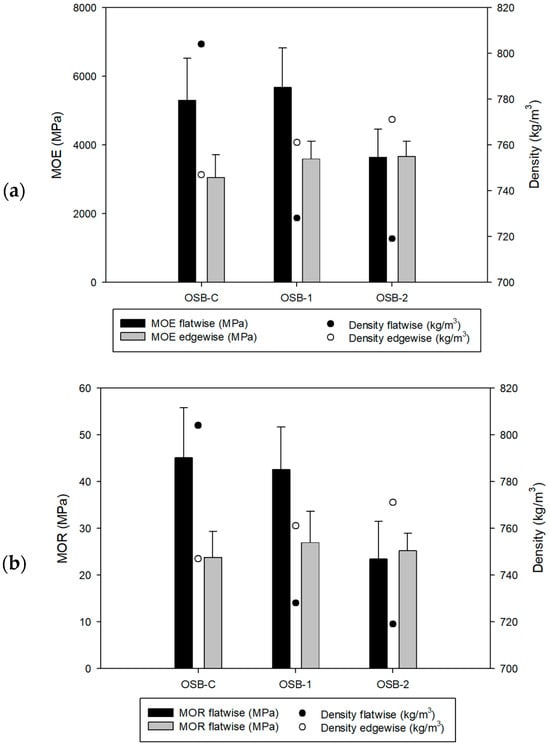

3.3. Mechanical Properties

The results for the stiffness property (MOE) of the different samples subjected to the bending test in the flatwise position are presented in Figure 3 and ranged from 3646 MPa (OSB-2) to 5675 MPa (OSB-1). The OSB-1 sample showed the highest stiffness but did not present statistically significant differences compared to the control sample (OSB-C). On the other hand, the OSB-2 sample reached 68.71% of the stiffness measured in the control sample and showed significant statistical differences compared to both OSB-C and OSB-1.

Figure 3.

Results of bending test: (a) MOE and (b) MOR in flatwise and edgewise positions.

In the edgewise position, the results ranged from 3051 MPa (OSB-C) to 3666 MPa (OSB-2), with the OSB-1 and OSB-2 samples outperforming the control sample by 17.86% and 20.15%, respectively. Nevertheless, no statistically significant differences were observed among the three tested samples.

The results for the strength property (MOR) of the different samples subjected to the bending test in the flatwise position are also presented in Figure 3 and ranged from 23.44 MPa (OSB-2) to 45.11 MPa (OSB-C). The OSB-1 and OSB-2 samples reached 94.35% and 51.96%, respectively, of the strength measured in the control sample OSB-C. Although no statistically significant differences were found between the OSB-1 and OSB-C samples, significant differences were observed between OSB-2 and both OSB-1 and OSB-C.

In the edgewise position, the results ranged from 23.79 MPa (OSB-C) to 26.97 MPa (OSB-1), with the OSB-1 and OSB-2 samples outperforming the control sample by 13.37% and 5.97%, respectively. Nevertheless, no statistically significant differences were observed among the tested samples.

In general, the results revealed that the samples of OSB-1 in a flatwise position and both OSB-1 and OSB-2 samples in an edgewise position exhibited the same behavior as the control sample manufactured with phenol-formaldehyde adhesive. These results are consistent with those of Bandara and Wu, 2018 [19], who also obtained similar MOE and MOR values when comparing OSB panels manufactured with a PF adhesive against LPF modified with different percentages of canola protein with ammonium.

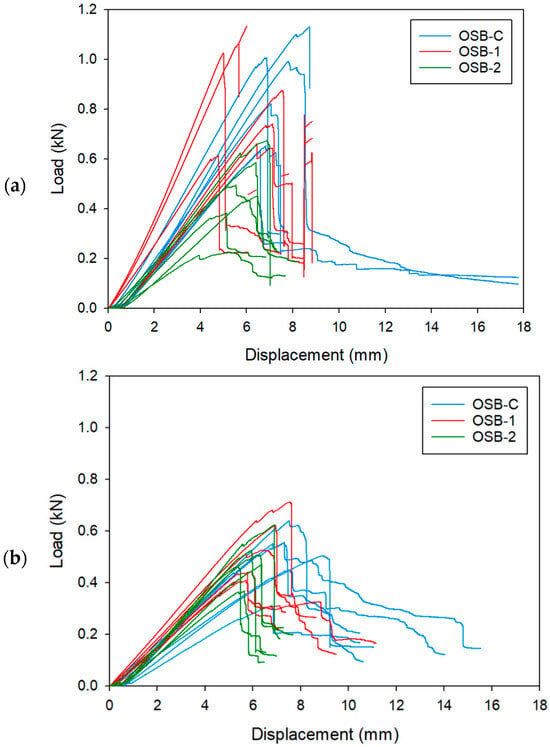

From the bending test, it was also possible to obtain load–displacement curves for the flatwise and edgewise positions of each sample (Figure 4), as well as the resulting modes of failure (Figure 5). Figure 4 shows that the OSB samples in the flatwise position exhibited stiffer performance and reached higher loads than the those in the edgewise position, especially OSB-C and OSB-1. This explains why OSB panels are primarily used in flatwise applications, where their vertical density profile, high face densities and low core density are advantageous; higher face stiffness enhances flexural behavior [38].

Figure 4.

Load–displacement curves of each sample subjected to bending test in (a) flatwise and (b) edgewise positions.

Figure 5.

Modes of failure of each sample result after the bending test.

On the other hand, after analyzing the modes of failure (Figure 5), only two types were observed: simple tension and splintering tension, with the predominant mode being splintering tension. This result was expected due to the composition of the OSB panels (flake distribution).

Table 4 presents the results of the mechanical properties derived from the tensile strength, internal bond, and Janka hardness tests.

Table 4.

Results of tensile strength, internal bond strength, and Janka hardness of each OSB sample.

The tensile strength results for the different OSB samples ranged from 6.85 MPa (OSB-2) to 14.08 MPa (OSB-C), with OSB-1 and OSB-2 achieving 68.47% and 48.65%, respectively, of the tensile strength measured in the control sample OSB-C. Additionally, there were significant statistical differences between the OSB-C and OSB-2 samples, while the OSB-1 sample showed no significant statistical differences compared to either the OSB-C or OSB-2 samples. These results were similar to those obtained by Núñez-Decap et al. [14], who compared formaldehyde-based and protein-based wood adhesives, in tensile strength tests, which were also statistically comparable.

The internal bond strength (IB) results of the different samples were in the range of 0.62 MPa (OSB-2) to 0.95 MPa (OSB-C), where the OSB-1 and OSB-2 samples reached 85.23% and 65.26%, respectively, of the IB strength measured in the control sample OSB-C. Additionally, the OSB-1 sample showed no significant statistical differences compared to the control sample OSB-C, while the OSB-2 sample did present significant statistical differences compared to the OSB-C sample. These results are consistent with and higher than those obtained by various authors who manufactured OSB panels using PF modified with canola protein and ammonium adhesives [19], or partial substitution of pMDI with lignin-containing cellulose nanofibrils [16], among others.

In both cases, tensile strength and internal bond strength, there were no statistically significant differences between the OSB-C and OSB-1 samples, indicating that the OSB panels manufactured with GA1 exhibited the same performance as panels manufactured with phenol-formaldehyde adhesive. This also indicates good adhesion, efficient resin spreading, and fine atomization [39]. These properties reflect the weakest layer within the panel [40]. These findings underscore the significance of optimizing panel structure, resin type, and fabrication parameters to enhance internal bond and overall panel quality [41].

The Janka hardness results of the different samples ranged from 7669 N (OSB-2) to 8896 N (OSB-C), with OSB-1 and OSB-2 reaching 87.47% and 86.21%, respectively, of the hardness obtained by the control sample OSB-C.

In severe end-use surfaces, hardness plays an important role [42]; for example, it is a property that can significantly affect repeated use [43]. In this case, where there were no significant statistical differences between all three samples, the OSB panels produced with green adhesives had statistically the same performance as the OSB panel manufactured with a formaldehyde-based adhesive. Furthermore, the increase in hardness is related to OSB density [42], which could explain the similar results, given that the OSB panel densities were similar.

In general, based on the results obtained for bending properties and internal bond strength, all three types of OSB panels tested could be classified as structural panels for use in dry environments, corresponding to technical class OSB/2, according to the UNE-EN 300 [44] standard. Nevertheless, the thickness swelling results do not meet the requirement. However, it is important to note that the OSB-GA panels do not include the incorporation of kerosene or any hydrophobic product, which was included in the control OSB sample. This means that the OSB panels manufactured with GA exhibited similar behavior and quality to OSB panels manufactured with phenol-formaldehyde adhesive, considering the aforementioned properties.

After analyzing the performance of the OSB-C, OSB-1, and OSB-2 samples under mechanical testing, it is important to mention the difference in the results observed in the OSB-2 sample compared to the OSB-C and OSB-1 samples. This difference could be associated with the characterization and composition of the wood adhesives used, or with differences in the OSB density results, which ideally should have been similar, considering that the manufacturing process and conditions were the same. This difference in densities could explain why the mechanical properties of the OSB-2 sample did not fall within the range of the other samples. This may be due to the elastic recovery of wood, known as “spring-back” [45], where the OSB panels manufactured with green adhesives exhibited increased thickness after pressing, resulting in a larger volume and therefore lower density, and ultimately, a higher degree of spring-back.

3.4. Thermal Properties

The OSB-GA samples showed the same behavior as the OSB control sample in terms of thermal conductivity properties in both flatwise and edgewise positions. The results are presented in Table 5.

Table 5.

Thermal conductivity results in the flatwise and edgewise positions of the OSB samples.

The thermal property results of the different samples in the flatwise position were in the range of 0.159 W/m·K (OSB-2) to 0.165 W/m·K (OSB-1), where the OSB-2 sample reached 98.76% of the thermal conductivity obtained by the control sample OSB-C, while the OSB-1 sample outperformed the control sample by 2.48%. On the other hand, in the edgewise position, the results were in the range of 0.140 W/m·K (OSB-C) to 0.149 W/m·K (OSB-2), where the OSB-1 and OSB-2 samples outperformed the control sample by 3.57% and 6.43%, respectively.

The results showed that the OSB-GA samples exhibited the same thermal insulation performance as the OSB control sample in terms of thermal conductivity in both flatwise and edgewise positions. This could indicate that the different adhesives used do not influence the thermal conductivity results of the OSB panels, but rather the wood species used. The thesis of Acuña-Alegría [46] explains that thermal conductivity depends on the density and moisture content of the wood. This author tested radiata pine wood species and obtained a thermal conductivity of approximately 0.18 W/m·K for a moisture content in the range of 2–5%, which is consistent with the results obtained. These results are also consistent with the thermal insulation requirements of the standard UNE-EN 13986 [33] (Table 5).

3.5. Evaluation of Formaldehyde Emissions

The formaldehyde emissions of the OSB samples were evaluated at 2 h and 7 days. These results are presented in Table 6.

Table 6.

Results of the formaldehyde emission evaluation of the OSB samples.

The evaluation of the formaldehyde emissions of the OSB samples revealed that the samples presented similar results. In the case of 2 h of exposure, the OSB-2 sample emitted the lowest amount of formaldehyde (0.009 ppm), while the OSB-1 sample emitted the highest amount (0.013 ppm); however, the difference between the samples is not significant. On the other hand, in the case of formaldehyde emissions at 7 days, the OSB-C sample emitted the lowest amount (0.005 ppm), while the OSB-1 sample emitted the highest (0.007 ppm), with differences that are also not significant.

It can be said that the OSB panels manufactured with GA presented formaldehyde emissions as low as those manufactured with PF adhesive, which was expected because, in general, phenol-formaldehyde adhesive corresponds to the formaldehyde-based adhesive that discharges the lowest amount of formaldehyde compared to other formaldehyde-based adhesives like urea-formaldehyde (UF), due to PF resins tending to be more chemically stable and less susceptible to hydrolysis than UF resins [47]. On the other hand, the results obtained are so low that they almost correspond to the formaldehyde naturally emitted by the wood itself. For example, radiata pine wood discharges approximately 0.05 ppm of formaldehyde [48].

In any case, the formaldehyde emissions of the three evaluated samples meet the requirement of the UNE-EN 18,986 [33] standard (formaldehyde emission requirement ≤ 0.101 ppm) and could be classified as class E1. Furthermore, Commission Regulation (EU) 2023/1464 [49] has proposed a requirement of 0.05 ppm for formaldehyde emissions in furniture and wood-based articles, which will be effective in 2026.

4. Conclusions

OSB panels manufactured with green adhesives were up to 46% less susceptible to color change after UV exposure and presented statistically the same dimensional stability under water immersion as an OSB panel manufactured with phenol-formaldehyde adhesive.

In terms of mechanical properties, the OSB-1 sample outperformed the control sample by 7% (MOE in flatwise), 13% (MOR in edgewise), and reached 68% (tensile strength), 85% (internal bond strength), and 87% (Janka hardness) of the control sample. In most cases, the OSB samples manufactured with green adhesives presented statistically the same performance as the OSB samples manufactured with PF adhesive. Furthermore, all the OSB samples tested could be classified as OSB/2, E1.

The phenol-formaldehyde adhesives could be easily substituted by green adhesives in the manufacturing of OSB panels, considering the fabrication parameters, and physical, mechanical, and thermal properties, since they evidenced, in most cases, statistically equal results to the control OSB panel.

Author Contributions

Conceptualization, M.N.-D., F.D.-S. and C.O.-C.; methodology, M.N.-D., F.D.-S., B.M.-R. and V.H.-C.; software, M.N.-D. and C.O.-C.; validation, M.N.-D., F.D.-S., C.O.-C. and M.V.-V.; formal analysis, M.N.-D., F.D.-S., C.O.-C., B.M.-R. and M.V.-V.; investigation, M.N.-D., F.D.-S., C.O.-C., B.M.-R. and M.V.-V.; resources, M.N.-D. and F.D.-S.; data curation, M.N.-D., F.D.-S. and C.O.-C.; writing—original draft preparation, M.N.-D. and C.O.-C.; writing—review and editing, M.N.-D. and C.O.-C.; visualization, M.N.-D.; supervision, M.N.-D.; project administration, M.N.-D.; funding acquisition, M.N.-D. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding; nevertheless, the APC was funded by Centro Nacional de Excelencia para la Industria de la Madera (CENAMAD)—ANID BASAL FB210015.

Data Availability Statement

The data are unavailable due to privacy restrictions associated with an ongoing investigation project.

Acknowledgments

We extend our gratitude to the Wood and Adhesive Engineering Products Laboratory (PRODIMA-LAB) of the Department of Civil and Environmental Engineering at the Universidad del Bío-Bío for their collaboration, as well as the equipment and infrastructure they provided.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Youngquist, J.A. Wood-based composites and panel products. In Wood Handbook: Wood as an Engineering Material; General technical report FPL; FTR-113; USDA Forest Service, Forest Products Laboratory: Madison, WI, USA, 1999; pp. 10.11–10.31. [Google Scholar]

- Gysling, J.; Soto, D.; Kahler, C.; Álvarez, V.; Poblete, P.; Pardo, E. Madera y Construcción Hacia Una Simbiosis Estratégica; Instituto Forestal (INFOR): Nuñoa, Chile, 2021. [Google Scholar] [CrossRef]

- Pizzi, A.; Mittal, K.L. Handbook of Adhesive Technology, 3rd ed.; Taylor & Francis Group: Boca Raton, FL, USA, 2017; p. 658. [Google Scholar]

- IARC Classifies Formaldehyde as Carcinogenic. Oncol. Times 2004, 26, 72. [CrossRef]

- Li, K.; Peshkova, S.; Geng, X. Investigation of soy protein-kymene® adhesive systems for wood composites. J. Am. Oil Chem. Soc. 2004, 81, 487–491. [Google Scholar] [CrossRef]

- Sandberg, D. Additives in Wood Products—Today and Future Development. In Environmental Impacts of Traditional and Innovative Forest-based Bioproducts; Kutnar, A., Muthu, S.S., Eds.; Springer: Singapore, 2016; pp. 105–172. [Google Scholar]

- Frihart, C.R. Wood Adhesives: Vital for Producing Most Wood Products. For. Prod. J. 2011, 61, 4–12. [Google Scholar] [CrossRef]

- Pizzi, A. Recent developments in eco-efficient bio-based adhesives for wood bonding: Opportunities and issues. J. Adhes. Sci. Technol. 2006, 20, 829–846. [Google Scholar] [CrossRef]

- Rowell, R.M. Handbook of Wood Chemistry and Wood Composites, 1st ed.; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Sugahara, E.S.; Dias, A.M.A.; Botelho, E.C.; Campos, C.I.; Dias, A.M.P.G. Feasibility of using eucalyptus wood and castor oil adhesive to produce OSB panels. Eur. J. Wood Wood Prod. 2025, 83, 70. [Google Scholar] [CrossRef]

- Strikun, V.V.; Bajandin, M.A.; Ermolin, V.N.; Pásztory, Z. Thermal Insulation Panels with Bio-Based Adhesives. E3S Web Conf. 2024, 514, 04001. [Google Scholar] [CrossRef]

- Siahkamari, M. Developing Lignin-Bases Phenolic Adhesives for Engineered Wood Products; Michigan State University: East Lansing, MI, USA, 2024. [Google Scholar]

- Widyorini, R.; Dewi, G.K.; Nuryawan, A.; Heraldy, E.; Masruchin, N. Properties of Eco-Friendly Oriented Strand Board Produced from Oil Palm Trunk. J. Renew. Mater. 2024, 12, 1757–1770. [Google Scholar] [CrossRef]

- Núñez-Decap, M.; Canales-Constanzo, E.; Opazo-Carlsson, C.; Moya-Rojas, B.; Vidal-Vega, M.; Opazo-Vega, A. A Study of the Properties of UV-Aged and Low Formaldehyde Emissions Particleboards Manufactured with Bio-Based Wood Protein Adhesives. Forests 2023, 14, 1488. [Google Scholar] [CrossRef]

- Asafu-Adjaye, O.A.; Street, J.; Bansode, A.; Auad, M.L.; Peresin, M.S.; Adhikari, S.; Liles, T.; Via, B.K. Fast Pyrolysis Bio-Oil-Based Epoxy as an Adhesive in Oriented Strand Board Production. Polymers 2022, 14, 1244. [Google Scholar] [CrossRef]

- Hornus, M.; Via, B.K.; Gallagher, T.; Peresin, M.S. Partial substitution of pMDI with lignin containing cellulose nanofibrils: Low density oriented strand board. Wood Mater. Sci. Eng. 2021, 16, 391–396. [Google Scholar] [CrossRef]

- Balea Paul, G.; Timar, M.C.; Zeleniuc, O.; Lunguleasa, A.; Coșereanu, C. Mechanical Properties and Formaldehyde Release of Particleboard Made with Lignin-Based Adhesives. Appl. Sci. 2021, 11, 8720. [Google Scholar] [CrossRef]

- Ayrilmis, N.; Özbay, G.; Kökten, E.S. Properties of Oriented Stransboard Produced Using Phenol-Formaldehyde Resin Synthesized with Bio-Oil of Lignocellulosic Wastes. Mater. Int. 2020, 2, 131–138. [Google Scholar] [CrossRef]

- Bandara, N.; Wu, J. Randomly Oriented Strand Board Composites from Nanoengineered Protein-Based Wood Adhesive. ACS Sustain. Chem. Eng. 2018, 6, 457–466. [Google Scholar] [CrossRef]

- Hand, W.; Cheng, G.; Via, B.; Banerjee, S. Soy-substituted liquid phenol formaldehyde binders for flakeboard. Eur. J. Wood Wood Prod. 2017, 75, 135–138. [Google Scholar] [CrossRef]

- Núñez Decap, M.; Ballerini Arroyo, A.; Alarcón Énos, J. Evaluation of single cell protein from yeast for the development of wood adhesives. Eur. J. Wood Wood Prod. 2016, 74, 821–828. [Google Scholar] [CrossRef]

- Athanassiadou, E.; Tsiantzi, S. Producing Panels with Formaldehyde Emission at Wood Levels. In Proceedings of the 7th European Wood-Based Panel Symposium, Hannover, Germany, 13–15 October 2010. [Google Scholar]

- ASTM G154-23; Standard Practice for Operating Fluorescent Ultraviolet (UV) Lamp Apparatus for Exposure of Nonmetallic Materials. ASTM International: West Conshohocken, PA, USA, 2023.

- UNE-EN 323; Wood-Based Panels—Determination of Density. U.N.: Española, NM, USA, 1994.

- UNE-EN 322; Wood-Based Panels. Determination of Moisture Content. U.N.: Española, NM, USA, 1994.

- UNE-EN 317; Particleboards and Fibreboards. Determination of Swelling in Thickness after Immersion in Water. U.N.: Española, NM, USA, 1994.

- UNE-EN 310; Wood-Based Panels. Determination of Modulus of Elasticity in Bending and of Bending Strength. U.N.: Española, NM, USA, 1994.

- ASTM D143-23; Standard Test Methods for Small Clear Specimens of Timber. ASTM International: West Conshohocken, PA, USA, 2023.

- ASTM D3500-20; Standard Test Methods for Wood Structural Panels in Tension. ASTM International: West Conshohocken, PA, USA, 2020.

- UNE-EN 319; Particleboards and Fibreboards. Determination of Tensile Strength Perpendicular to the Plane of the Board. U.N.: Española, NM, USA, 1993.

- ASTM D1037-12; Standard Test Methods for Evaluating Properties of Wood-Base Fiber and Particle Panel Materials. ASTM International: West Conshohocken, PA, USA, 2012.

- ASTM D5334-22; Standard Test Method for Determination of Thermal Conductivity of Soil and Rock by Thermal Needle Probe Procedure. ASTM International: West Conshohocken, PA, USA, 2000.

- UNE-EN 13986:2006+A1:2015; Tableros Derivados de la Madera Para Utilización en la Construcción—Características, Evaluación de la Conformidad y Marcado. U.N.: Española, NM, USA, 2015.

- ASTM D6007-22; Standard Test Method for Determining Formaldehyde Concentrations in Air from Wood Products Using a Samll-Scale Chamber. ASTM International: West Conshohocken, PA, USA, 2022.

- Evans, P.D. Development of Commercial Wood Preservatives; American Chemical Society: Washington, DC, USA, 2008; Volume 982. [Google Scholar]

- Herrera, R.; Sandak, J.; Robles, E.; Krystofiak, T.; Labidi, J. Weathering resistance of thermally modified wood finished with coatings of diverse formulations. Prog. Org. Coat. 2018, 119, 145–154. [Google Scholar] [CrossRef]

- Vladimirova, E.; Gong, M. Advancements and Applications of Wood-Based Sandwich Panels in Modern Construction. Buildings 2024, 14, 2359. [Google Scholar] [CrossRef]

- Beck, K.; Cloutier, A.; Salenikovich, A.; Beauregard, R. Comparison of mechanical properties of oriented strand board made from trembling aspen and paper birch. Eur. J. Wood Wood Prod. 2010, 68, 27–33. [Google Scholar] [CrossRef]

- Okino, E.Y.A.; Teixeira, D.E.; de Souza, M.R.; Santana, M.A.E.; de Sousa, M.E. Properties of oriented strandboard made of wood species from Brazilian planted forests: Part 1: 80 mm-long strands of Pinus taeda L. Holz Als Roh-Und Werkstoff 2004, 62, 221–224. [Google Scholar] [CrossRef]

- Suzuki, S.; Miyagawa, H. Effect of element type on the internal bond quality of wood-based panels determined by three methods. J. Wood Sci. 2003, 49, 513–518. [Google Scholar] [CrossRef]

- Fauziyyah, S.; Tomas, P.; Slobodan, S.; Wimmer, R. Wood-based panels derived from fast growing tropical lightwood species: Panel properties and environmental impact assessment. Wood Mater. Sci. Eng. 2025, 1–15. [Google Scholar] [CrossRef]

- Copak, A.; Jirouš-Rajković, V.; Španić, N.; Miklečić, J. The Impact of Post-Manufacture Treatments on the Surface Characteristics Important for Finishing of OSB and Particleboard. Forests 2021, 12, 975. [Google Scholar] [CrossRef]

- Hrazsky, J.; Kral, P. Analysis of properties of boards for concrete formwork. J. For. Sci. 2004, 50, 382–398. [Google Scholar] [CrossRef]

- UNE-EN 300; Tableros De Virutas Orientadas (OSB)—Definiciones, Clasificación Y Especificaciones. U.N.: Española, NM, USA, 2007.

- Vidal-Vega, M.; Núñez-Decap, M.; Hernández-Durán, J.; Catricura-Muñoz, P.; Jara-Briones, C.; Moya-Rojas, B.; Opazo-Carlsson, C. Comparative Study of Carbon Nanotubes and Lignosulfonate as Polyvinyl Acetate (PVAc) Wood Adhesive-Reinforcing Agents. Appl. Sci. 2024, 14, 365. [Google Scholar] [CrossRef]

- Acuña-Alegría, L. Determinación Inversa de la Conductividad Térmica en Madera de Pinus Radiata; Universidad del Bío-Bío: Concepción, Chile, 2017. [Google Scholar]

- Chrobak, J.A.-O.; Iłowska, J.; Chrobok, A.A.-O. Formaldehyde-Free Resins for the Wood-Based Panel Industry: Alternatives to Formaldehyde and Novel Hardeners. Molecules 2022, 27, 4862. [Google Scholar] [CrossRef]

- Salem, M.Z.M.; Böhm, M. Understanding of Formaldehyde Emissions from Solid Wood: An Overview. BioResources 2013, 8, 4775–4790. [Google Scholar] [CrossRef]

- Von Der Leyen, U. Commission Regulation (EU) 2023/1464—Amending Annex XVII to Regulation (EC) No 1907/2006 of the European Parliament and of the Council as regards formaldehyde and formaldehyde releasers. Off. J. Eur. Union 2023, L180/12. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=OJ:L:2023:180:TOC (accessed on 11 May 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).