Durability Test and Service Life Prediction Methods for Silicone Structural Glazing Sealant

Abstract

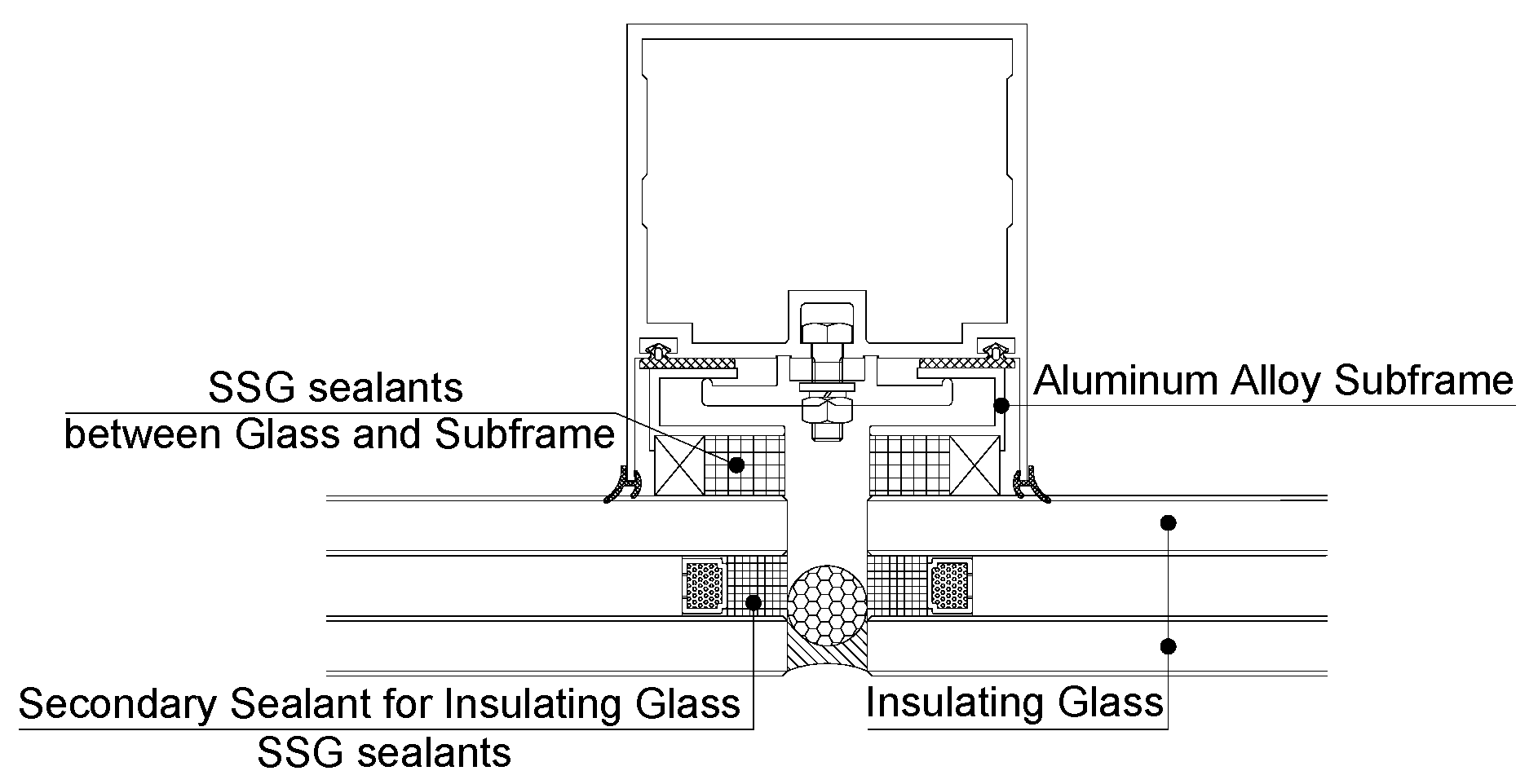

1. Introduction

2. Experimental

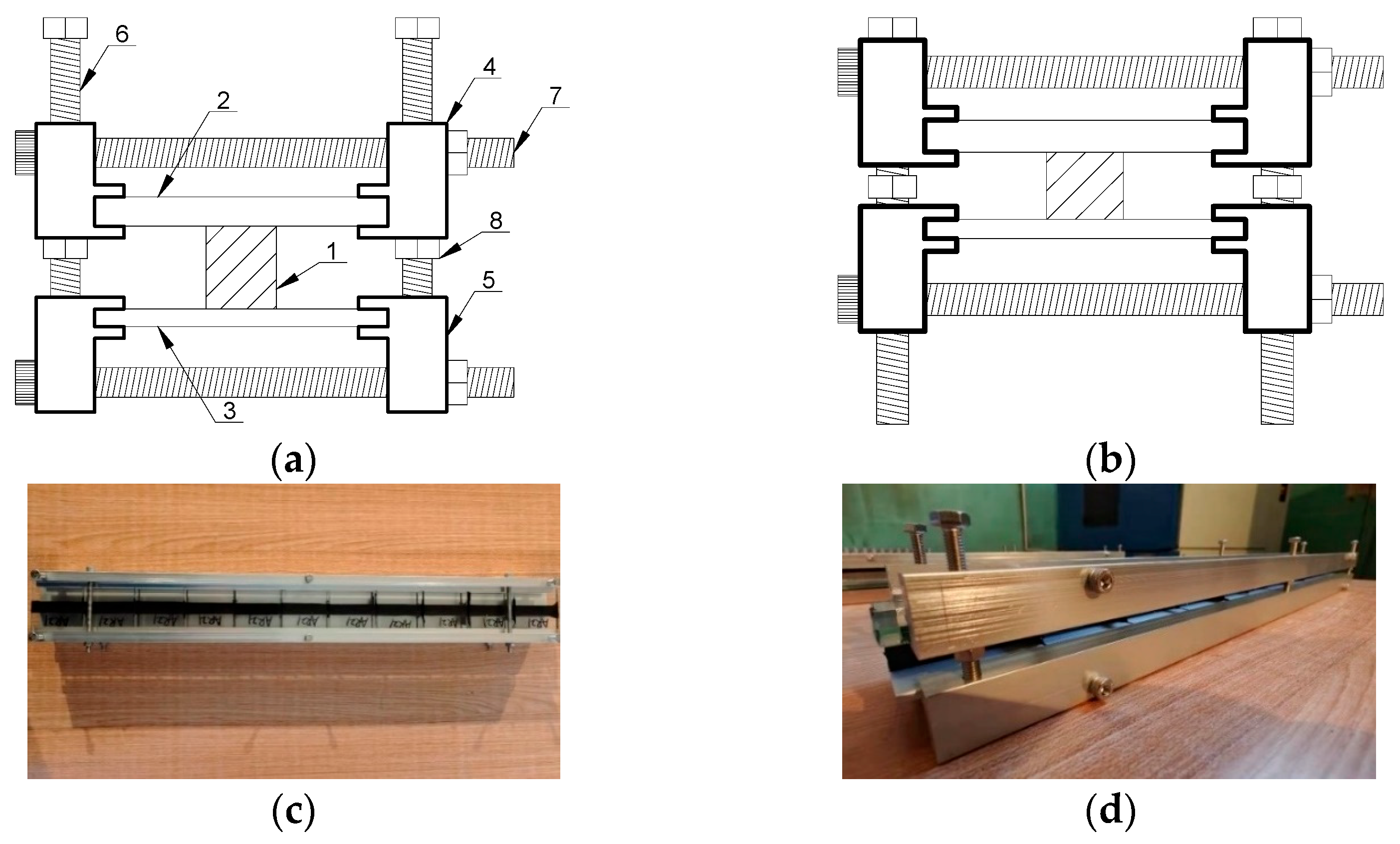

2.1. Materials and Specimen Preparation

2.2. Aging Test Conditions

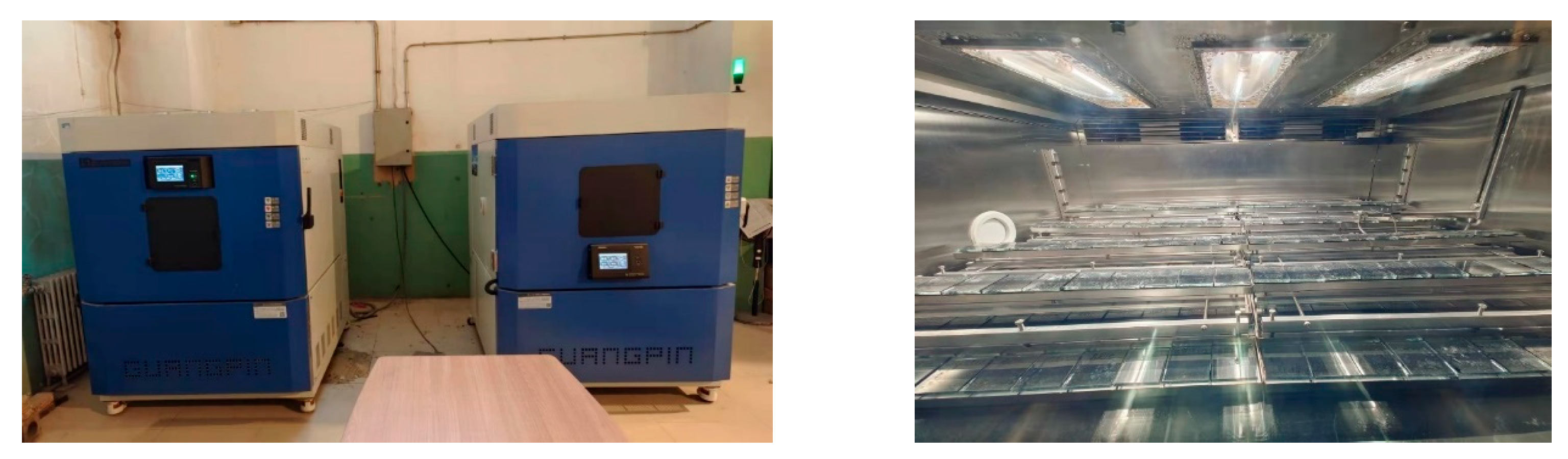

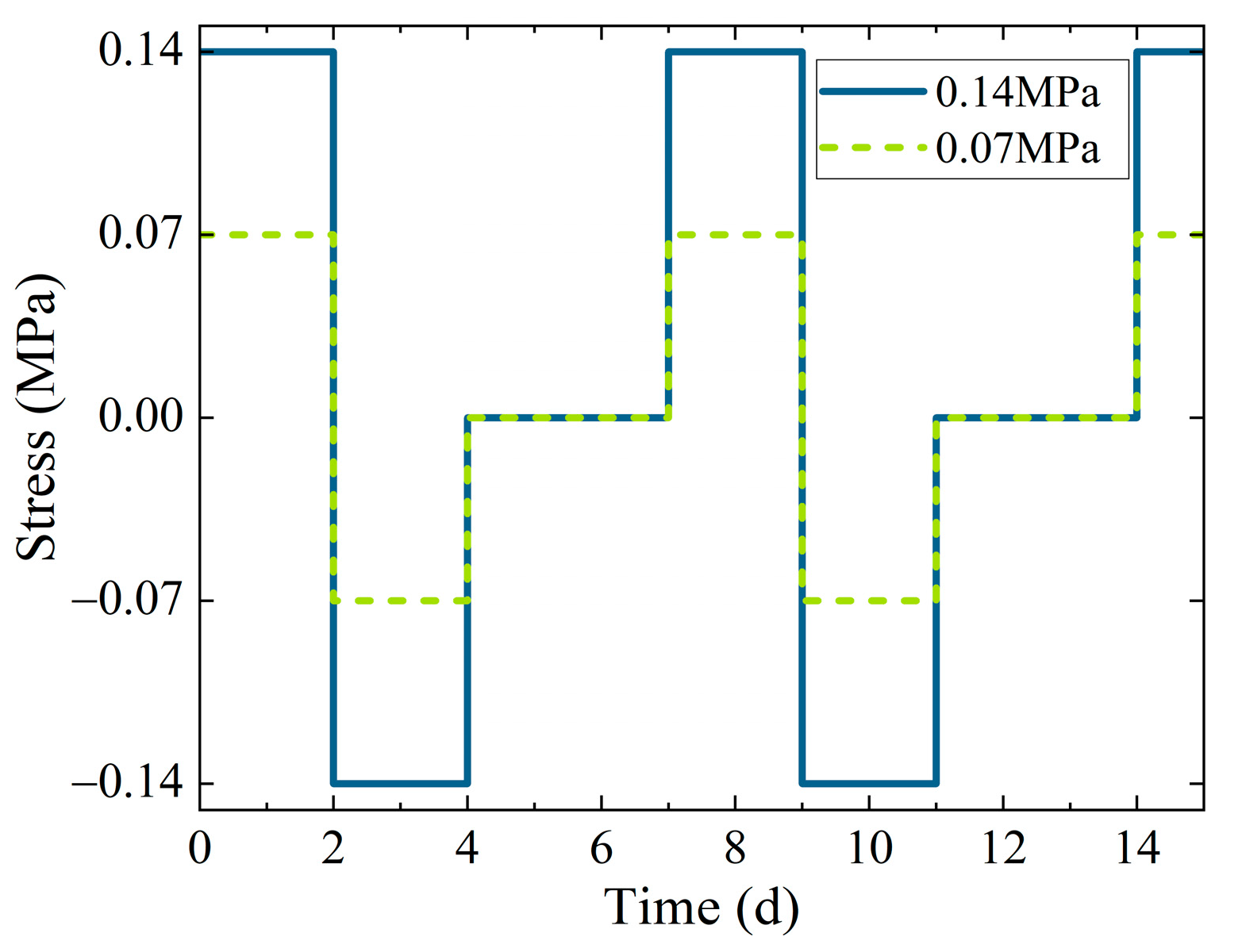

2.2.1. Laboratory Aging Test

2.2.2. Outdoor Aging Test

2.3. Test Measurements

3. Results and Discussion

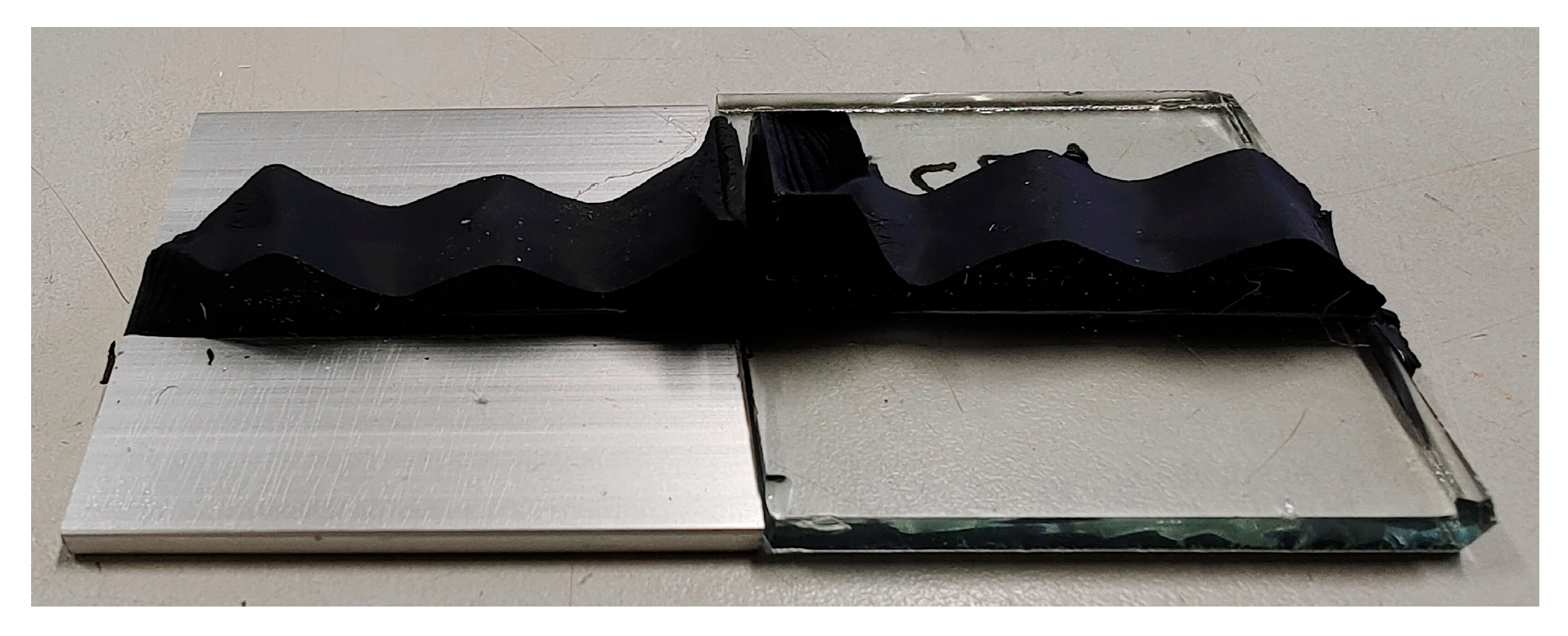

3.1. Failure Mode

3.2. Laboratory Aging Test Results

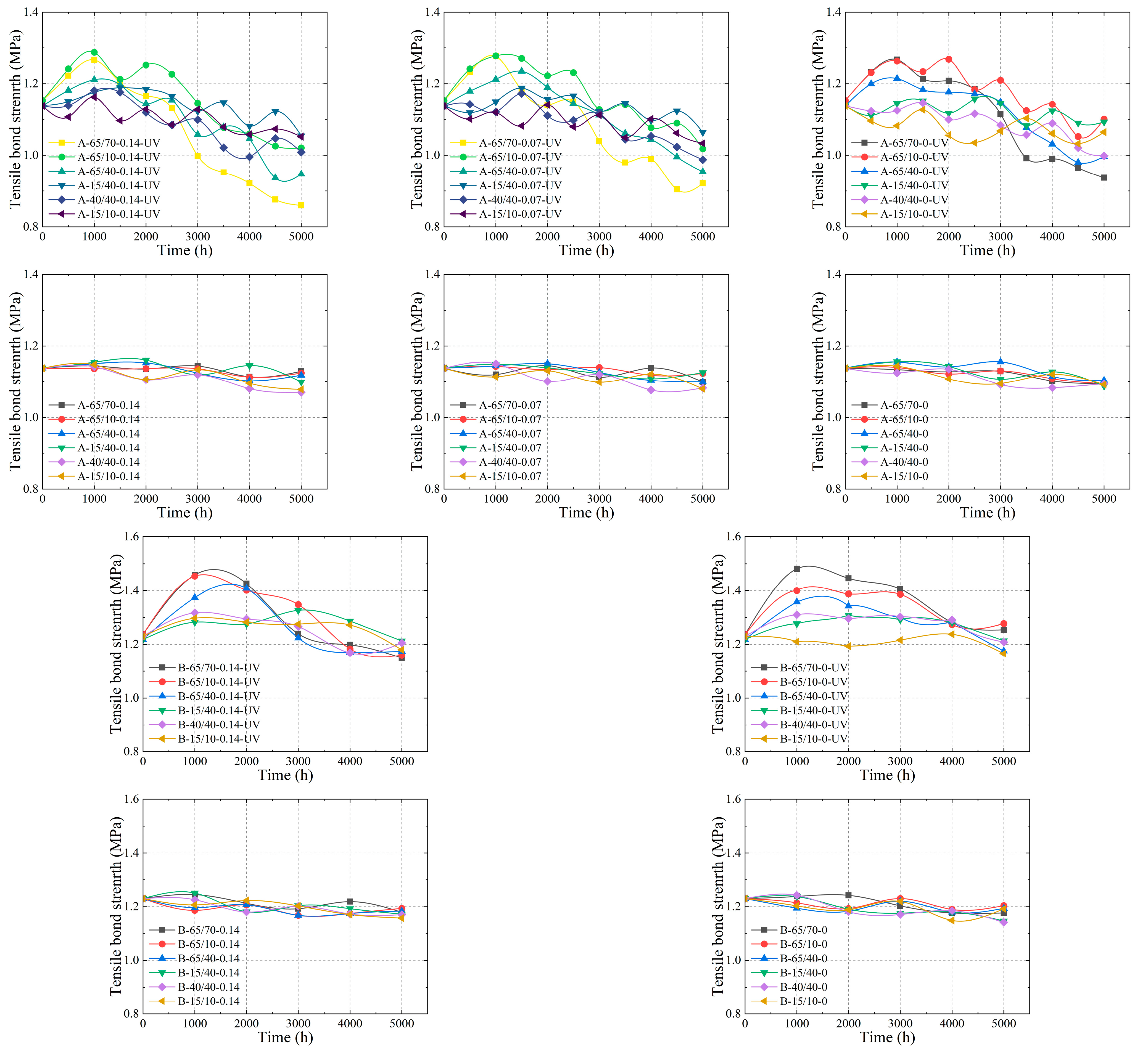

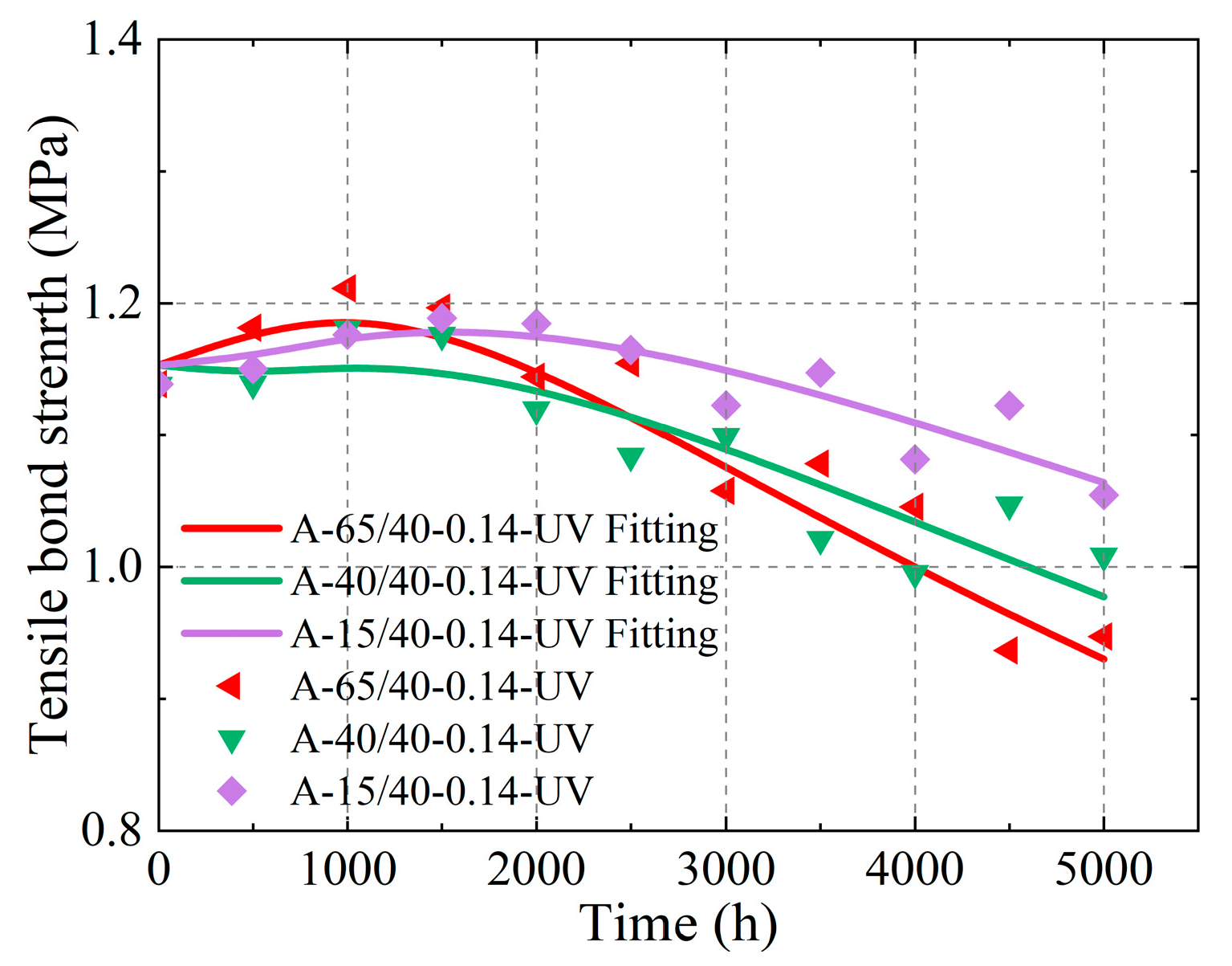

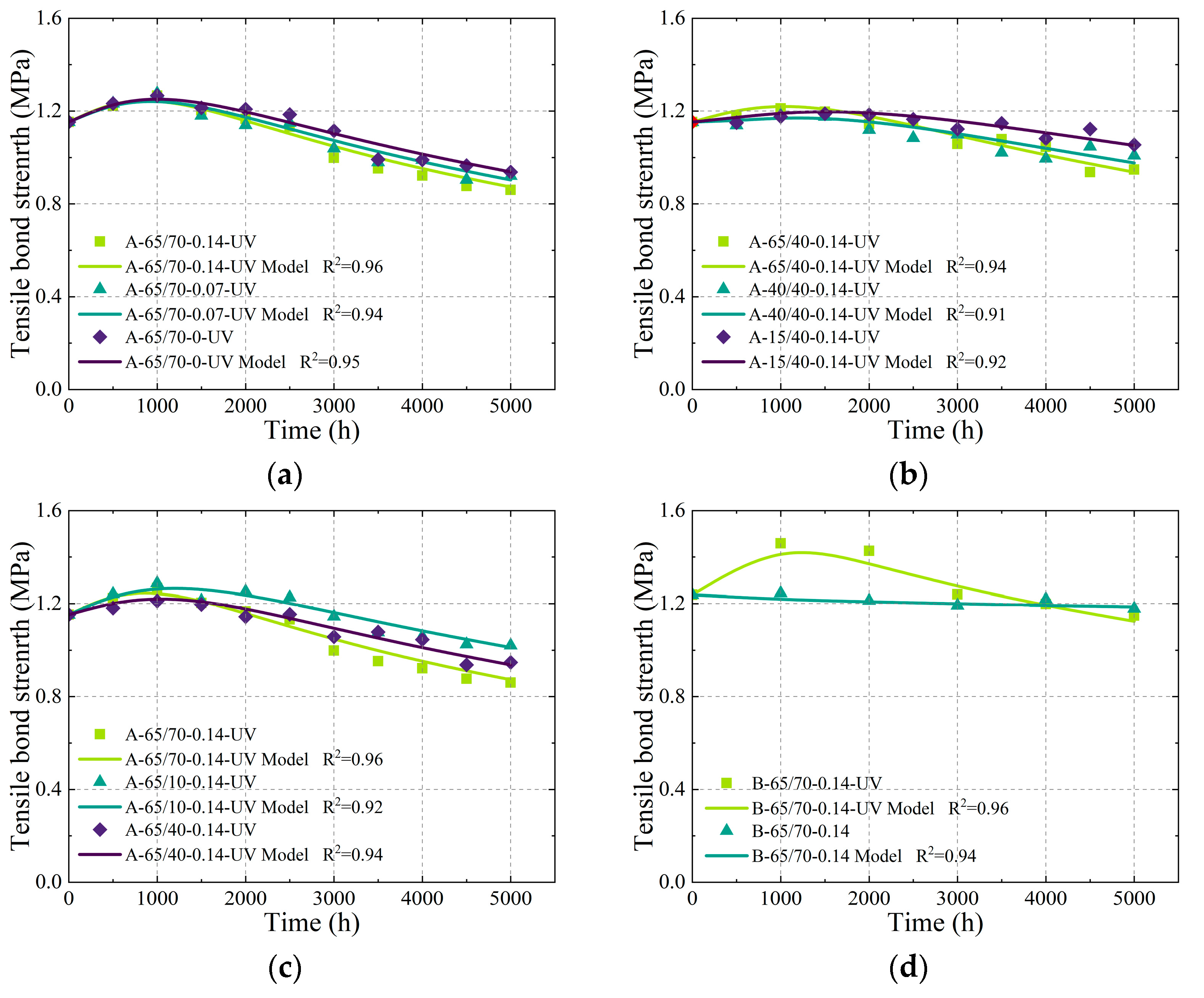

3.2.1. Effect of Temperature

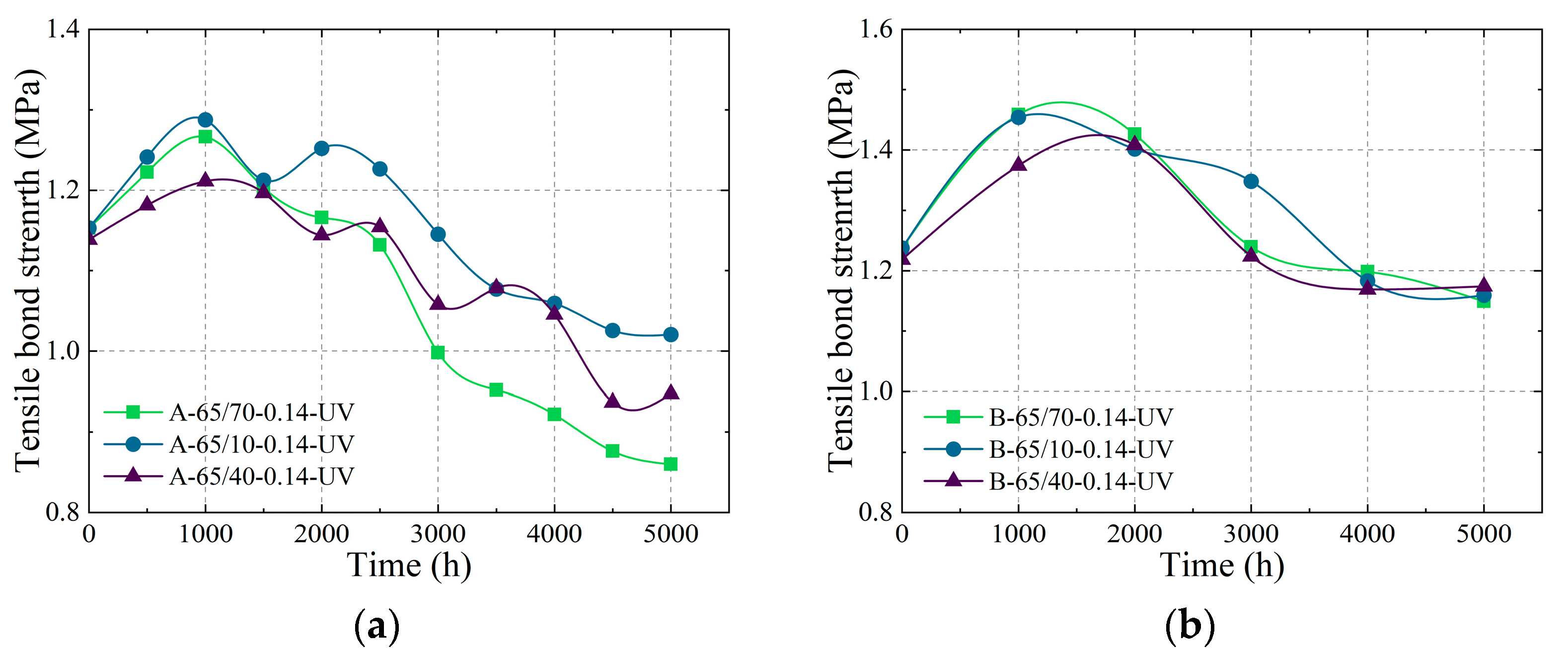

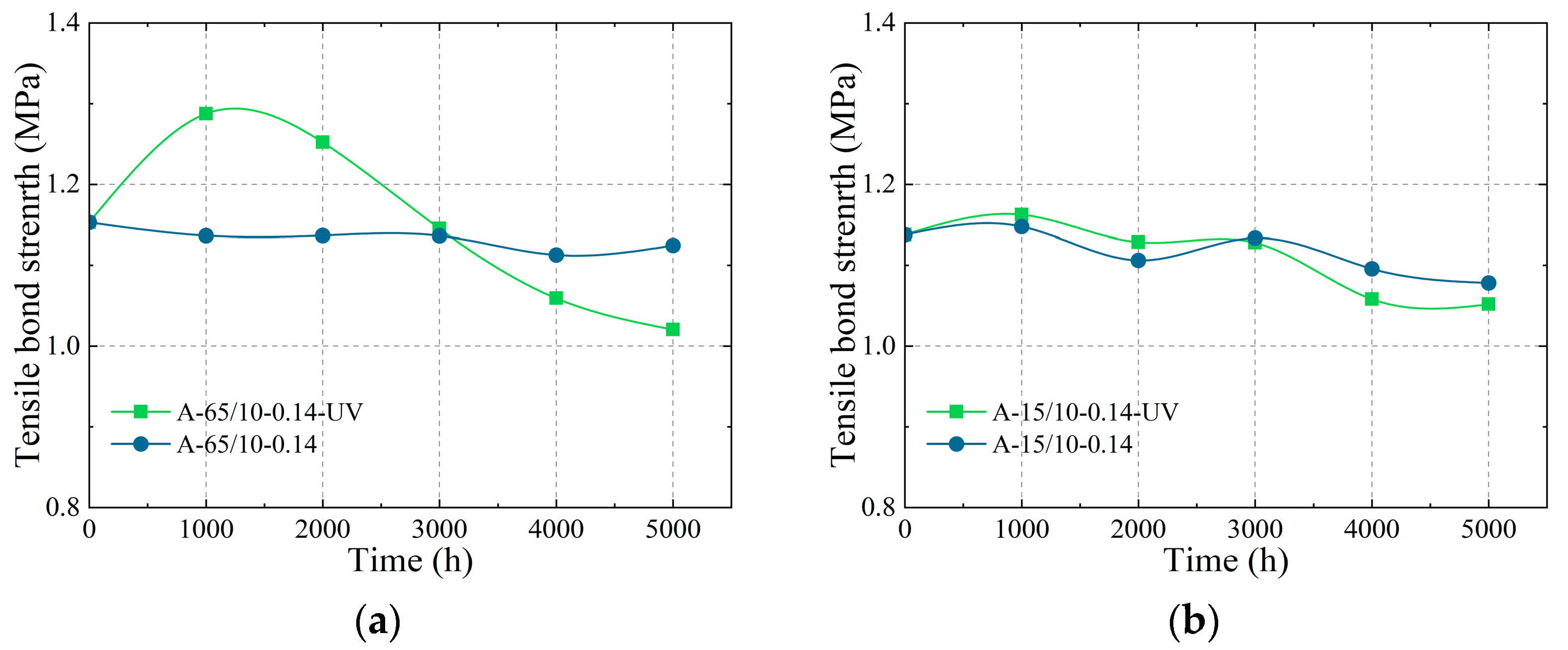

3.2.2. Effect of Humidity

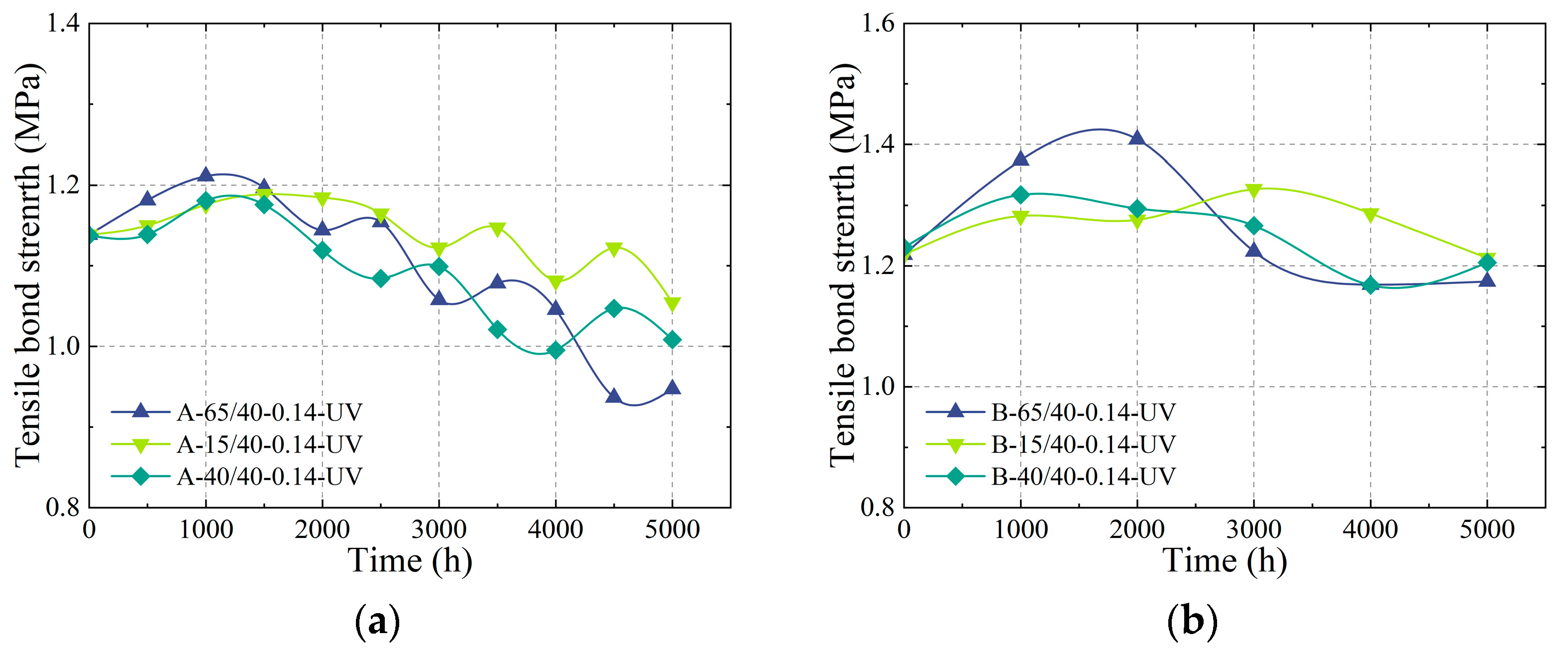

3.2.3. Effect of Stress

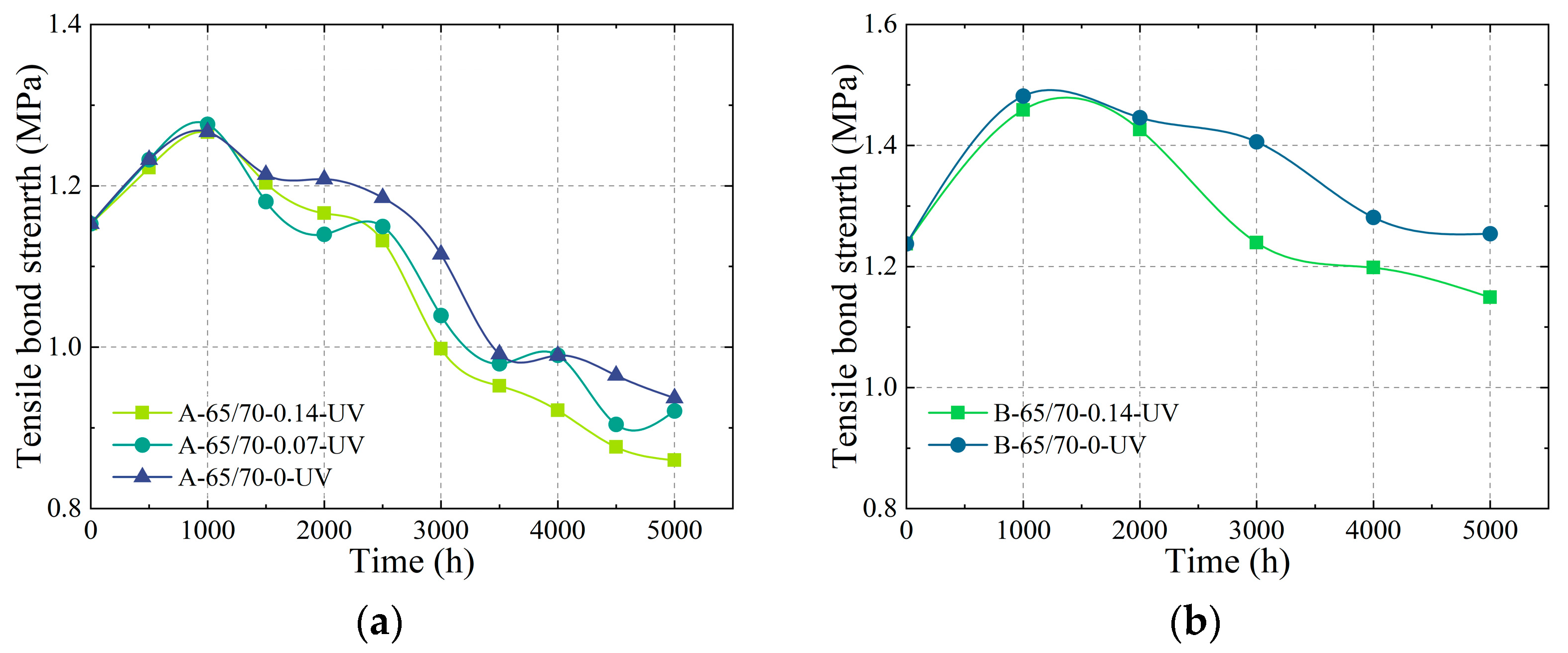

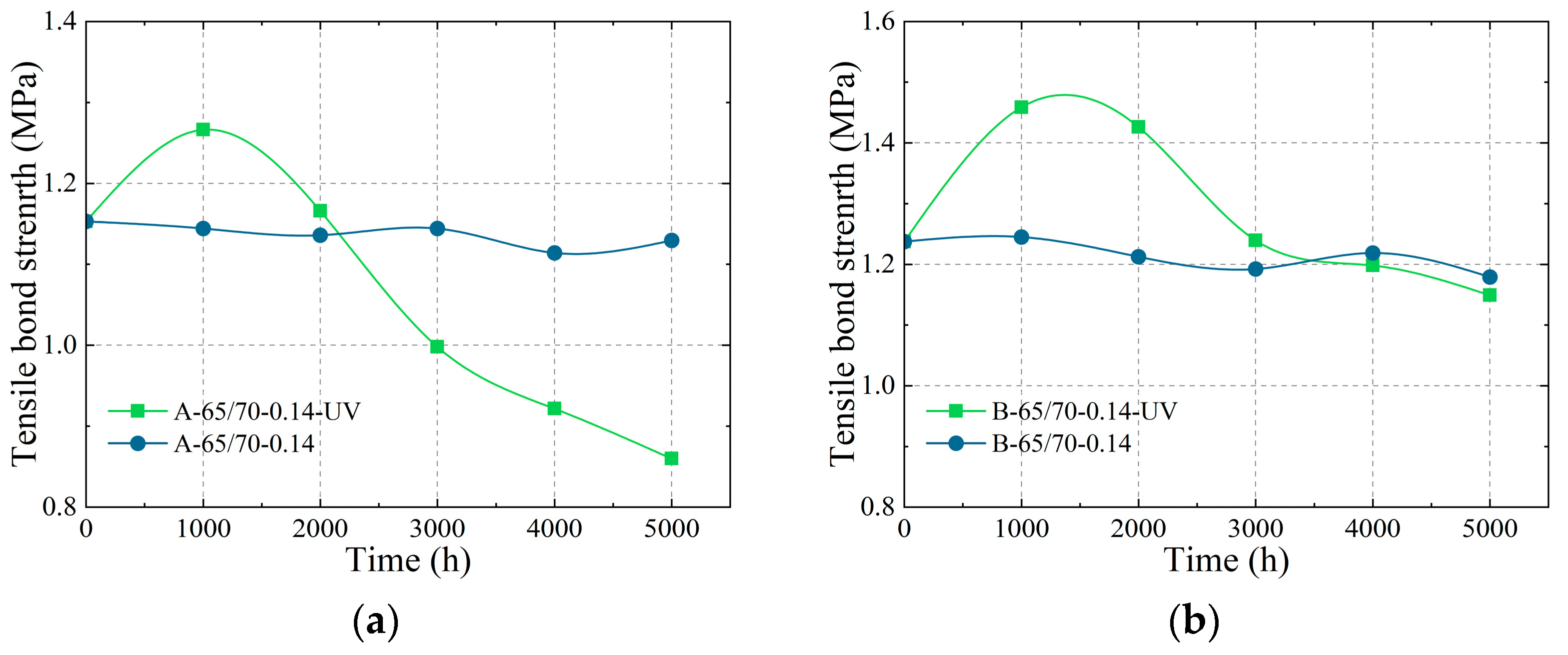

3.2.4. Effect of UV Irradiance

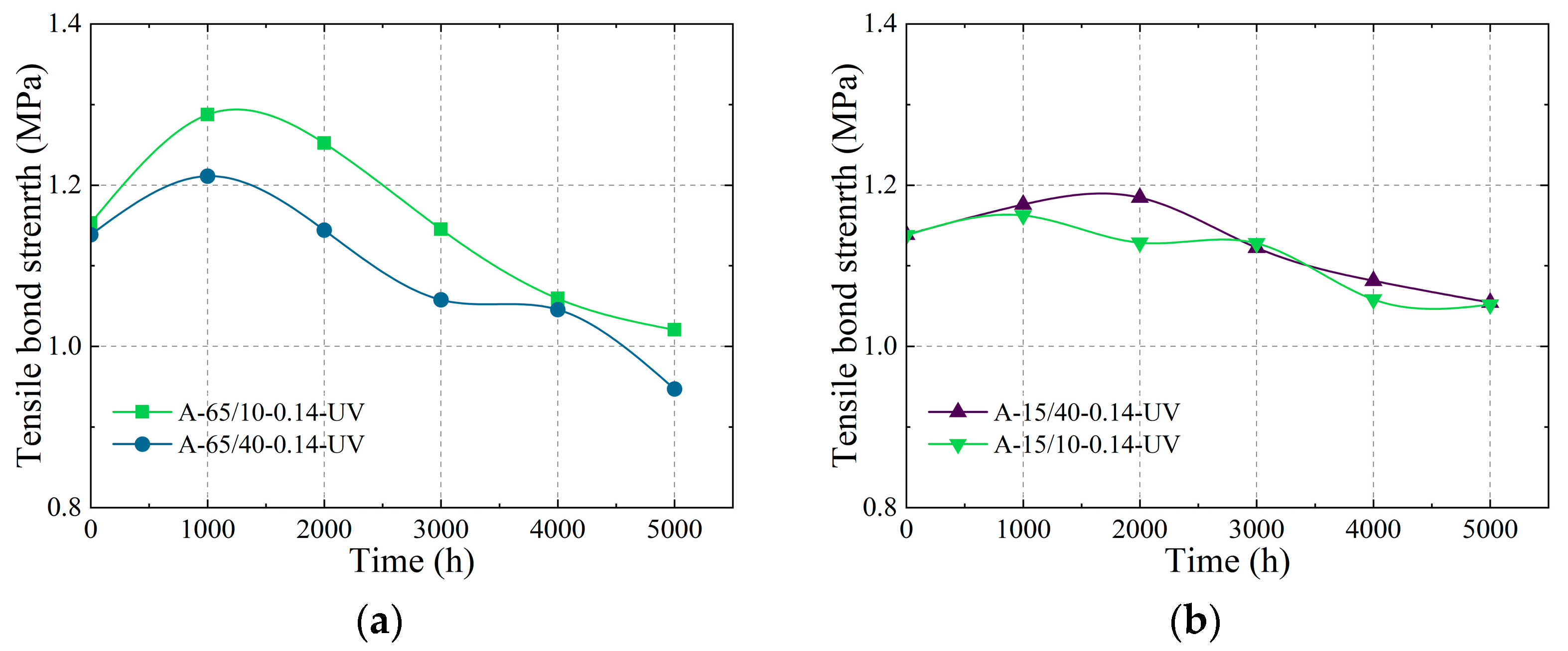

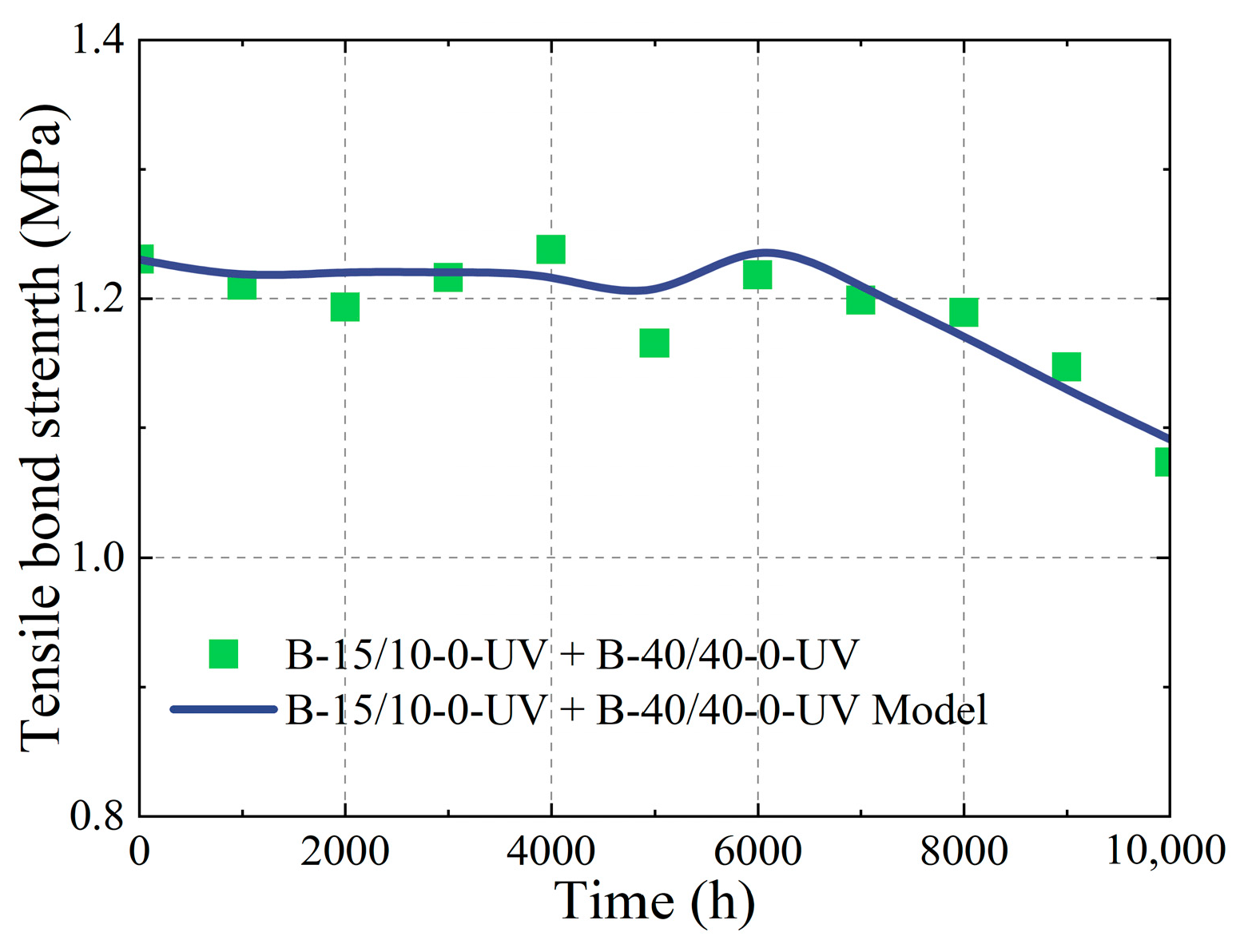

3.2.5. Synergistic Effects of Environmental Factors

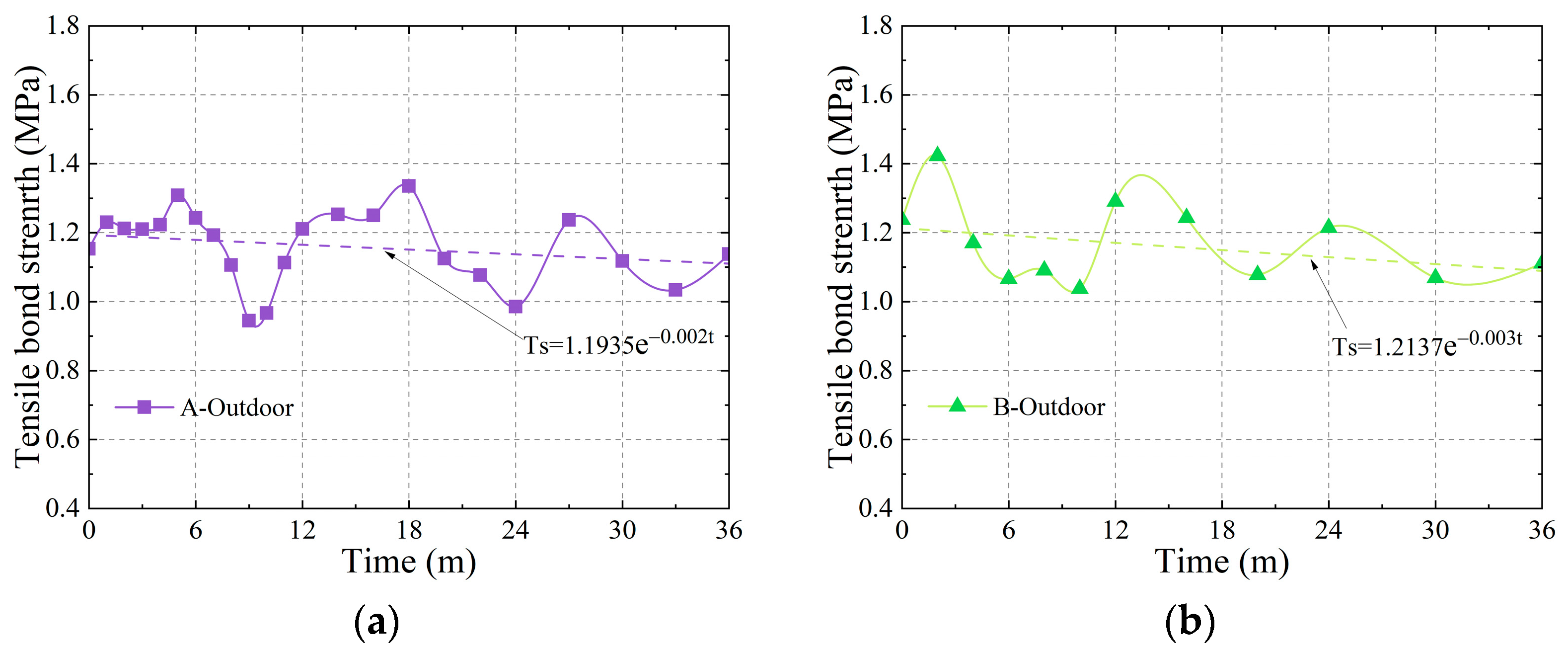

3.3. Outdoor Aging Test Results

4. Degradation Model

4.1. Establishment of TBS Degradation Model

4.2. Parameters Calculation

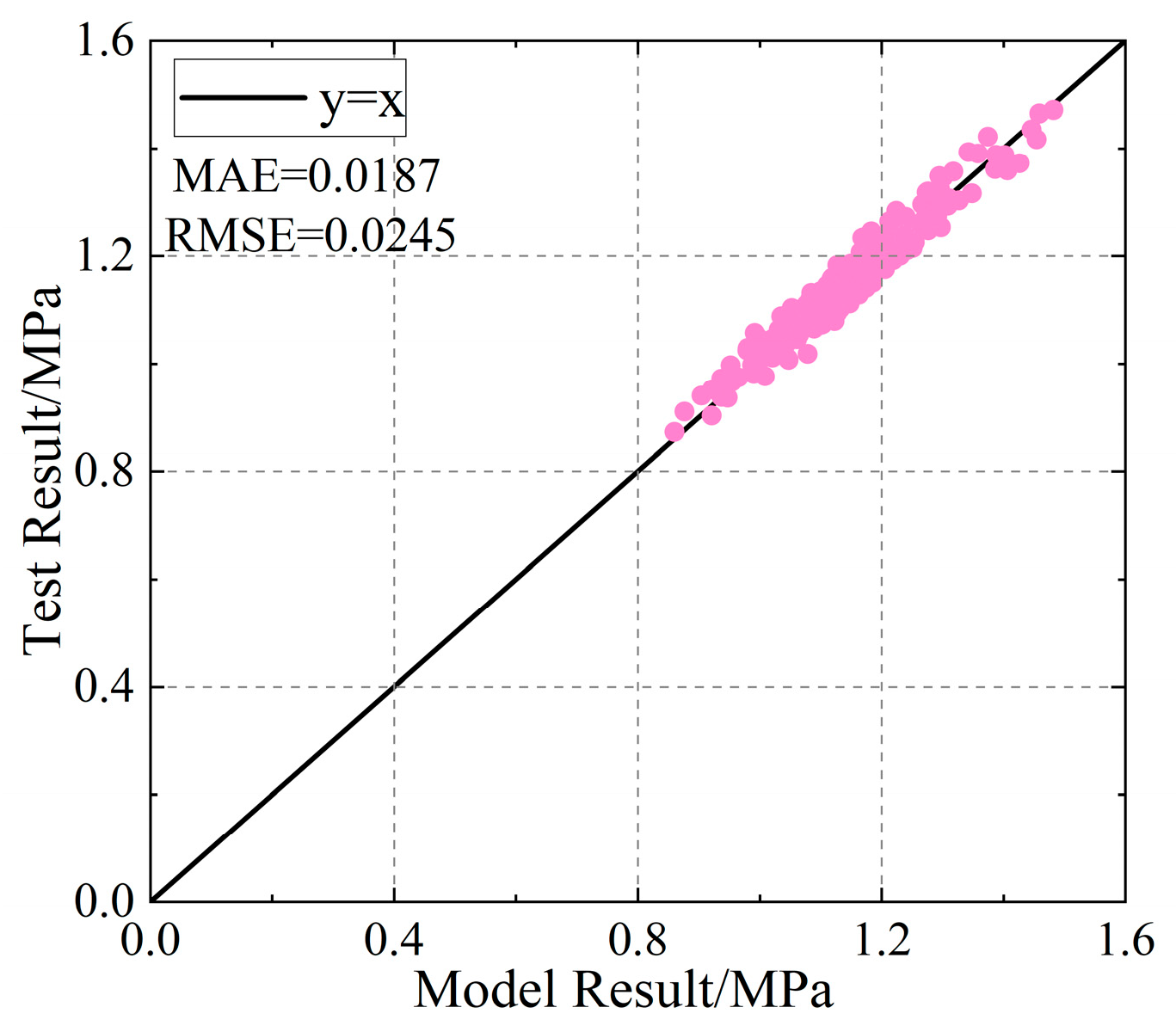

4.3. Error Analysis

5. Service Life Prediction Method

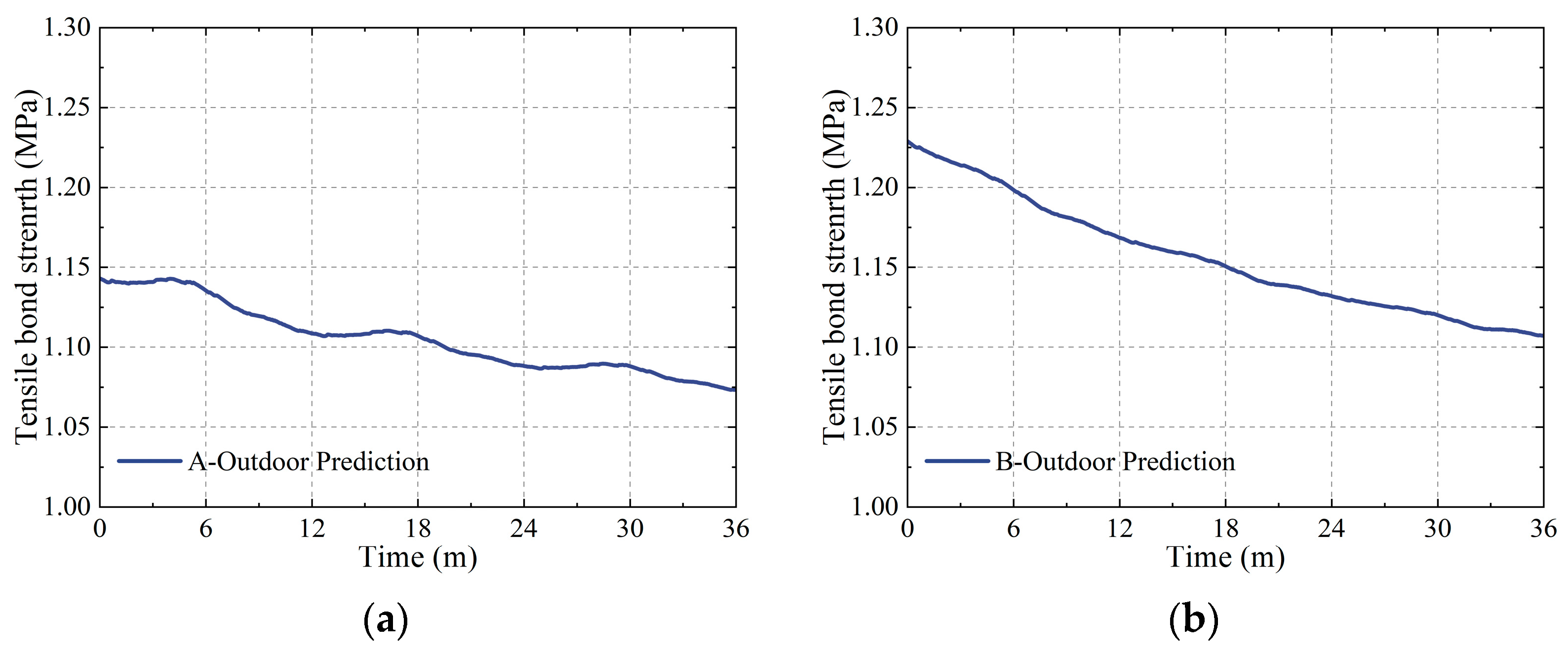

5.1. Recursive Method

5.2. Two-Stage Test for Sealant B

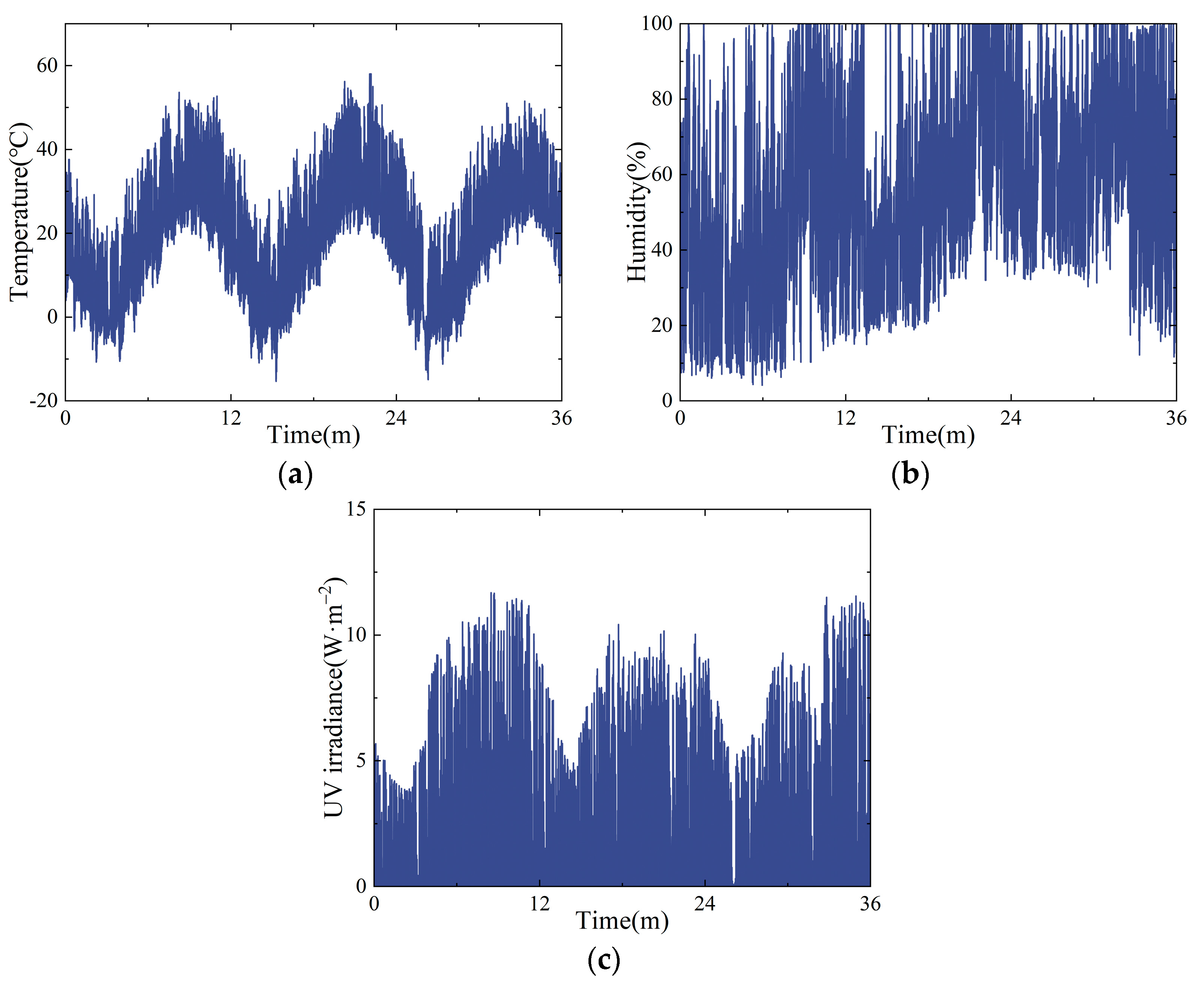

5.3. Environmental Conditions Record of Outdoor Aging Test

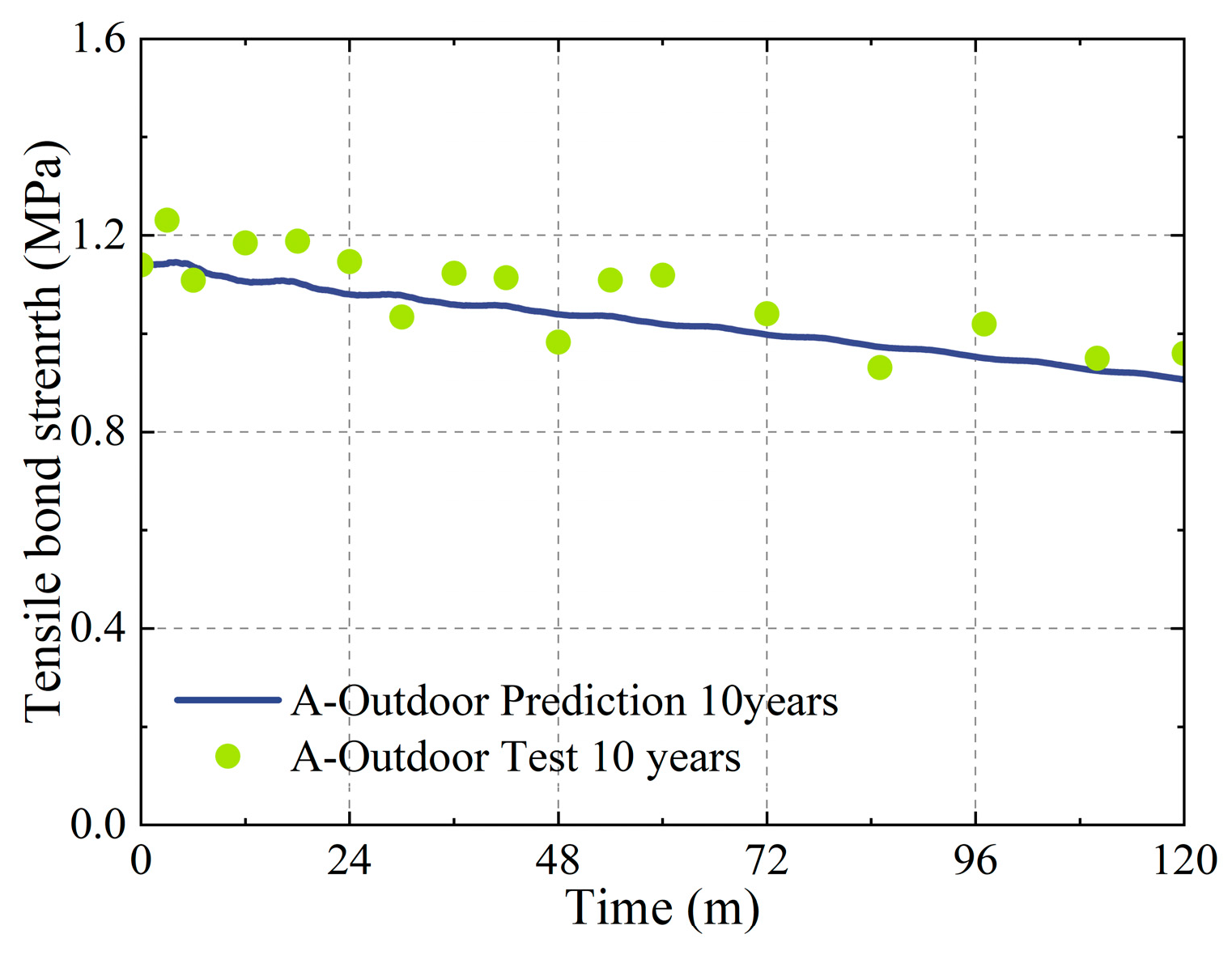

5.4. Outdoor Aging Test Verification

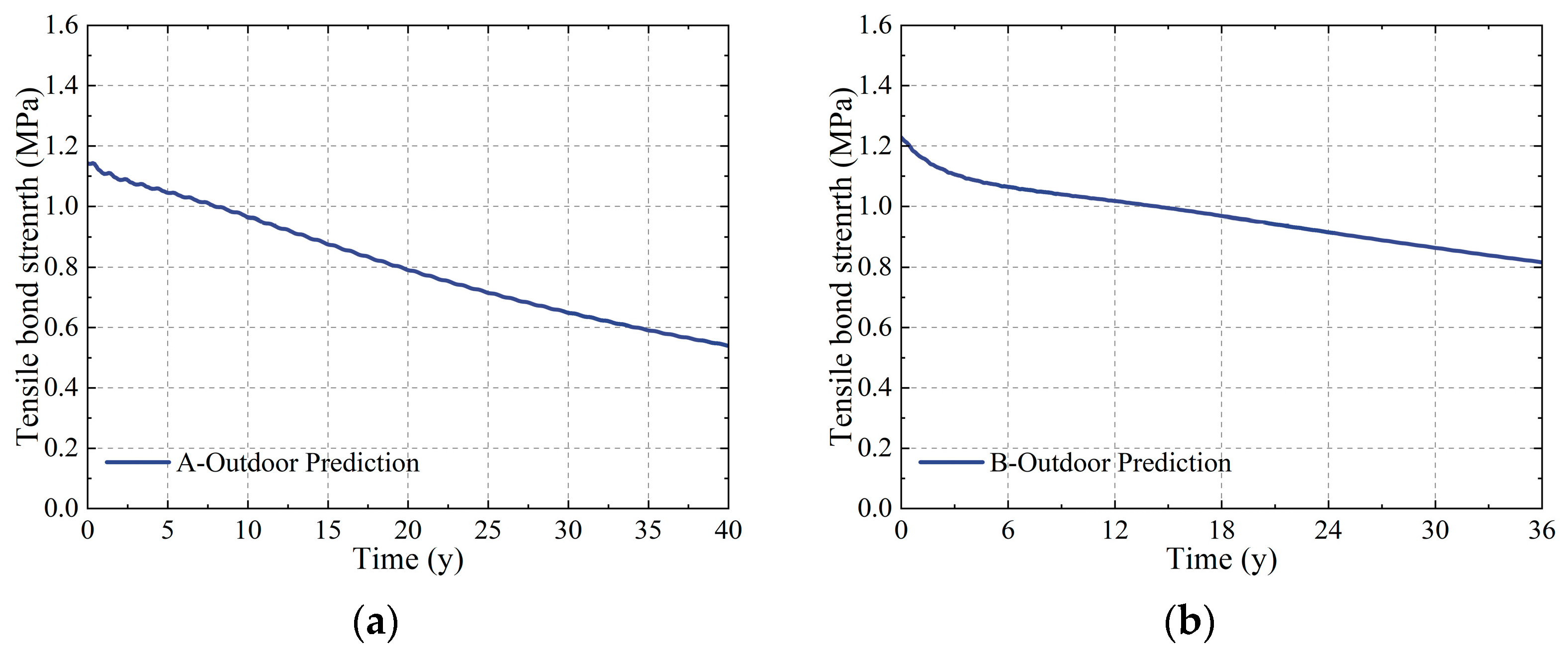

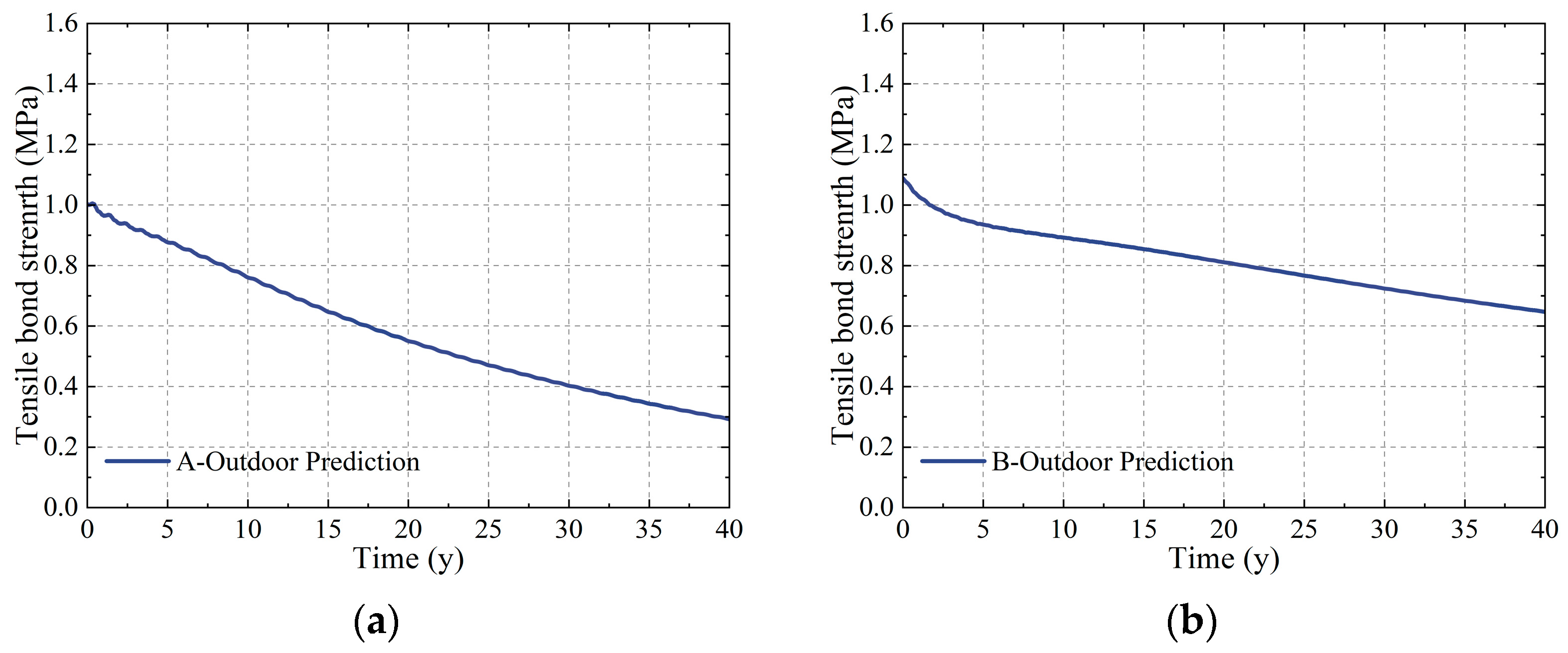

5.5. Service Life Prediction

6. Conclusions

- By setting multiple levels for temperature, humidity, stress, and UV irradiance, a multi-level matrix test condition was formed. Comparing the test results under different conditions, the influence patterns of temperature, humidity, stress, and UV irradiance on the TBS of SSG sealants were obtained: The TBS is affected by the combined effects of crosslinking and degradation reactions, where crosslinking increases the TBS while degradation decreases it. An increase in temperature, humidity, stress, and UV irradiance accelerates the chemical reaction rates of both crosslinking and degradation, with their influence ranked from strongest to weakest as UV irradiance, temperature, humidity, and stress. The rates of crosslinking and degradation reactions determine the changes in TBS—in the early aging stage, the crosslinking rate exceeds degradation, leading to an increase in TBS, while, in the later aging stage, degradation surpasses crosslinking, resulting in a decrease in TBS. Different types of sealants exhibit variations in TBS changes because their crosslinking and degradation reaction rates are influenced differently by temperature, humidity, stress, and UV irradiance;

- There exist synergistic effects among temperature, humidity, stress, and UV irradiance, with the coupling effect of UV irradiance being the most significant, amplifying the combined effects of other aging factors. However, UV irradiation alone cannot significantly accelerate the decline in TBS of SSG sealants; its effect is primarily manifested through synergistic interactions with other aging factors. In the combined effects of temperature, humidity, and stress, the temperature term accounts for approximately 50%, the temperature–humidity coupling term accounts for about 35%, and the total proportion of temperature-related terms reaches approximately 90%;

- Based on the aging patterns and experimental data obtained from laboratory aging tests, a new degradation model for the aging of TBS in SSG sealants was established. This model incorporates temperature, humidity, stress, and UV irradiance as variables to reflect their influence on the aging of TBS. Using the aging test data, the unknown parameters in the degradation model were calculated using the MCMC algorithm based on Bayesian theory. The calculated results showed excellent agreement with the experimental data (R2 > 0.9, MAE = 0.019 MPa, RMSE = 0.0245 MPa), demonstrating high accuracy for both the degradation model and the computational method;

- Natural aging tests were conducted simultaneously with laboratory aging tests, during which temperature, humidity, and UV irradiance were recorded. A recursive algorithm was proposed to calculate the TBS degradation under actual service conditions based on the degradation model and environmental condition records. Using the recorded environmental conditions from natural aging tests, the degradation model and recursive algorithm were applied to obtain predicted TBS results for natural aging. These predictions showed good agreement with the natural aging test data, demonstrating the validity and accuracy of this method;

- The long-term aged TBS prediction results of SSG sealants were calculated using the degradation model combined with environmental condition records through a recursive algorithm. By incorporating the TBS limit requirements specified in different national standards, the predicted service life of SSG sealants was determined. The minimum limit value of characteristic TBS, which considers material discreteness and strength assurance rate, serves as a reliable evaluation criterion for assessing the service life of SSG sealants. The service life prediction method proposed in this study provides an important theoretical and methodological foundation for ensuring the long-term safety and maintenance strategies of glass curtain walls.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| SSG | Silicone structural glazing |

| UV | Ultraviolet |

| SPHERE | Simulated photodegradation via high energy radiant exposure |

| SBS | Styrene–butadiene–styrene |

| TG | Thermogravimetric |

| PDMS | Polydimethylsiloxane |

| MTMS | Methyltrimethoxysilane |

| APS | Aminopropyltriethoxysilane |

| DBTL | Dibutyltin dilaurate |

| TBS | Tensile bond strength |

| MCMC | Markov chain Monte Carlo |

| MAE | Mean absolute error |

| RMSE | Root mean square error |

| T | Temperature |

| RH | Relative humidity |

References

- Wolf, A.T. Studies of the aging behavior of gun-grade building joint sealants—The state of the art. Mater. Struct. 1990, 23, 142–157. [Google Scholar] [CrossRef]

- Wang, Z.Y.; Liu, J.J.; Li, D.; Yang, K.X.; Chen, M.H.; Wang, C. Experimental and numerical study on load-bearing performance in triple-glazed insulating glass units. Constr. Build. Mater. 2024, 418, 135385. [Google Scholar] [CrossRef]

- Jones, T.G.B.; Hutchinson, A.R.; Wolf, A.T. Experimental Results Obtained with Proposed RILEM Durability Test Method for Curtain Wall Sealants. Mater. Struct. 2001, 34, 332–341. [Google Scholar] [CrossRef]

- Wolf, A.T. RILEM TC190-SBJ: Development of recommendations on novel durability test methods for wet applied curtain-wall sealants. Mater. Struct. 2008, 41, 1473–1486. [Google Scholar] [CrossRef][Green Version]

- Wang, Q.; Li, S.; Wu, X.; Wang, S.; Ouyang, C. Weather aging resistance of different rubber modified asphalts. Constr. Build. Mater. 2016, 106, 443–448. [Google Scholar] [CrossRef]

- Celina, M.; Clough, R.L.; Jones, G.D. Initiation of polymer degradation via transfer of infectious species. Polym. Degrad. Stab. 2006, 91, 1036–1044. [Google Scholar] [CrossRef]

- Jin, J.; Chen, S.; Zhang, J. UV aging behavior of ethylene-vinyl acetate copolymers (EVA) with different vinyl acetate contents. Polym. Degrad. Stab. 2010, 95, 725–732. [Google Scholar] [CrossRef]

- Wilma, W.; Christoph, R.; Glen, J.S. Structural silicone sealants after exposure to laboratory test for durability assessment. J. Appl. Polym. Sci. 2021, 138, 50881. [Google Scholar] [CrossRef]

- Kaneko, T.; Ito, S.; Minakawa, T.; Hirai, N.; Ohki, Y. Degradation mechanisms of silicone rubber under different aging conditions. Polym. Degrad. Stab. 2019, 168, 108936. [Google Scholar] [CrossRef]

- Yazdan, M.; Hajipour, P.; Karampoor, M.R. Effects of humidity, ionic contaminations and temperature on the degradation of silicone-based sealing materials used in microelectronics. Microelectron. Reliab. 2024, 164, 115554. [Google Scholar] [CrossRef]

- Miyauchi, H.; Tanaka, K. Estimation of the fatigue resistance of sealants to movement at intersections of sealed joints and improvements in the joint design method. J. ASTM Int. 2004, 1, 13. [Google Scholar] [CrossRef]

- Takeshi, I.; Arild, G.; Bjørn, P.J. Fatigue resistance of double sealant composed of polyisobutylene sealant adjacent to silicone sealant. Constr. Build. Mater. 2014, 66, 467–475. [Google Scholar] [CrossRef]

- Ding, S.H.; Liu, D.Z. Durability evaluation of building sealants by accelerated weathering and thermal analysis. Constr. Build. Mater. 2006, 20, 878–881. [Google Scholar] [CrossRef]

- Wu, F.; Chen, B.; Yan, Y.; Chen, Y. Degradation of Silicone Rubbers as Sealing Materials for Proton Exchange Membrane Fuel Cells under Temperature Cycling. Polymers 2018, 10, 522. [Google Scholar] [CrossRef]

- Tan, K.T.; White, C.C.; Benatti, D.J.; Hunston, D.L. Effects of ultraviolet radiation, temperature and moisture on aging of coatings and sealants—A chemical and rheological study. Polym. Degrad. Stab. 2010, 95, 1551–1556. [Google Scholar] [CrossRef]

- Mojdeh, M.K.; Allan, M.; Thiru, A. Synergistic effects of hygrothermal conditions and solar ultraviolet radiation on the properties of structural particulate-filled epoxy polymer coatings. Constr. Build. Mater. 2021, 277, 122336. [Google Scholar] [CrossRef]

- Kychkin, A.K.; Startsev, O.V.; Lebedev, M.P.; Polyakov, V.V. Effect of solar radiation and synergism of the effect of UV radiation, temperature and moisture on the distraction of polymer composite materials in a cold climate. Procedia Struct. Integr. 2020, 30, 71–75. [Google Scholar] [CrossRef]

- Wang, Z.Y.; Liu, J.J.; Li, D.; Li, J.H.; Wang, C.; Yang, B.; Liu, Y. Experimental and numerical study on temperature-deformation behavior of insulating glass units. J. Build. Eng. 2025, 99, 111629. [Google Scholar] [CrossRef]

- Miyauchi, H.; Enomoto, N. Artificial weathering and cyclic movement test results based on the RILEM TC139DBS durability test method for construction sealants. J. ASTM Int. 2004, 1, 1–7. [Google Scholar] [CrossRef]

- RILEM Technical Committees. RILEM Technical Recommendation TC 139-DBS: Durability of building sealants, Durability test method-determination of changes in adhesion, Cohesion and appearance of elastic weatherproofing sealants for high movement facade joints after exposure to artificial weathering. Mater. Struct. 2001, 34, 579–588. [Google Scholar] [CrossRef]

- Yan, F. Long-Term Performance Evolution of the Material and Component of Hidden Frame Supported Glass Curtain Wall. Ph.D. Thesis, Zhejiang University, Hangzhou, China, 2019. [Google Scholar]

- White, C.; Hunston, D.; Tan, K.T. An accelerated exposure and testing apparatus for building joint sealants. Rev. Sci. Instrum. 2013, 84, 095113. [Google Scholar] [CrossRef] [PubMed]

- Adam, L.P.; White, C.C. Predicting Field Degradation of Sealants Using Accelerated Tests from the NIST Solar SRHERE. In Service Life Prediction of Polymers and Plastics Exposed to Outdoor Weathering, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2018; pp. 135–159. [Google Scholar] [CrossRef]

- Wang, Z.Y.; Liu, J.J.; Li, D.; Li, J.H.; Wang, C.; Liu, Y. Thermal-deformation behaviors of the primary sealants in double, triple, and multi-glazed insulating glass units. Constr. Build. Mater. 2024, 450, 138631. [Google Scholar] [CrossRef]

- Lee, S.K.; Hirouki, M.; Jeong, J.Y. Reliability assessment of structural sealant durability. In Durability of Building and Construction Sealants and Adhesives: 5th Volume; ASTM International: West Conshohocken, PA, USA, 2015; pp. 65–84. [Google Scholar] [CrossRef]

- White, C.C.; Donald, L.H.; Adam, P. Designing of an accelerated test method to determine the design life of building joint sealant using the ASTM C1850 procedure. In Durability of Building and Construction Sealants and Adhesives: 6th Volume; ASTM International: West Conshohocken, PA, USA, 2018; pp. 74–93. [Google Scholar] [CrossRef]

- Adam, L.P.; White, C.C.; Sung, L.P. Bayesian hierarchical models for service-life prediction of polymers. In Service Life Prediction of Polymers and Coatings; Elsevier: Amsterdam, The Netherlands, 2020; pp. 209–231. [Google Scholar] [CrossRef]

- ASTM C1135-19; Standard Test Method for Determining Tensile Adhesion Properties of Structural Sealants. ASTM Committee E06: West Conshohocken, PA, USA, 2019.

- JG/T 475-2015; SSG Sealant for Building Curtain Wall. Department of Construction of the PRC, China Standards Press: Beijing, China, 2015.

- ASTM C1401-14; Standard Guide for Structural Sealant Glazing. ASTM Committee E06: West Conshohocken, PA, USA, 2014.

- JGJ 102-2013; Technical Code for Glass Curtain Wall Engineering. Department of Construction of the PRC, China Standards Press: Beijing, China, 2013.

- Ding, S.H. Studies on Weathering and Durability of Building Sealants. Ph.D. Thesis, Zhengzhou University, Zhengzhou, China, 2006. [Google Scholar]

- Li, J.J.; Zhang, H.H.; Li, G.F. Infrared spectral analysis and aging mechanism of UV-irradiated high-temperature vulcanized silicone rubber. Spectrosc. Spectr. Anal. 2020, 40, 1063–1070. [Google Scholar]

- Wolf, A.T. RILEM Technical Recommendation TC 190-SBJ: Service-life prediction of sealed building and construction joints, Durability test method: Determination of changes in adhesion, cohesion and appearance of elastic weatherproofing sealants after exposure of statically cured specimens to artificial weathering and mechanical cycling. Mater. Struct. 2008, 41, 1497–1508. [Google Scholar] [CrossRef]

- Wolf, A.T. Recommendation of RILEM TC 190-SBJ: Service-life prediction of sealed building and construction joints. Mater. Struct. 2008, 41, 1487–1495. [Google Scholar] [CrossRef]

- Liu, J.J.; Liu, R.C.; Yan, F. Study on loading sensitivity of structural adhesive of glass curtain walls. China Build. Waterpr. 2019, 7, 33–36. [Google Scholar]

- ASTM C1184-14; Standard Specification for Structural Silicone Sealants. ASTM Committee E06: West Conshohocken, PA, USA, 2014.

- Guniyev, T. Life prediction of polymer-based composite materials. J. Mater. Eng. 1994, 2, 53–56. [Google Scholar]

- Gelman, A. Prior distributions for variance parameters in hierarchical models. Bayesian Anal. 2006, 1, 515–533. [Google Scholar] [CrossRef]

- Wang, Z.Y.; Liu, J.J.; Li, J.H.; Chen, S.W. Whole-life wind-induced deflection of insulating glass units. Wind Struct. 2023, 37, 289–302. [Google Scholar] [CrossRef]

- ETAG 002-2012; Guideline for European Technical Approval for Structural Sealant Glazing Kits: Part 1 Supported and Unsupported Systems. European Organisation for Technical Approvals: Brussels, Belgium, 2012.

| Sealant Type | Tensile Bond Strength (MPa) | Maximum Elongation Rate (%) | Modulus at 20% Elongation (MPa) | Shore Hardness (HA) |

|---|---|---|---|---|

| A | 1.14 | 205 | 1.69 | 37 |

| B | 1.23 | 154 | 1.91 | 43 |

| Condition ID | Specimen Group ID | Sealant Type | Temperature (°C) | Humidity (%) | Stress (MPa) | UV Irradiance (W/m2) | Test Interval (h) |

|---|---|---|---|---|---|---|---|

| I | A-65/70-0.14-UV | A | 65 | 70 | 0.14 | 40 | 500 |

| A-65/70-0.07-UV | A | 65 | 70 | 0.07 | 40 | 500 | |

| A-65/70-0-UV | A | 65 | 70 | 0 | 40 | 500 | |

| A-65/70-0.14 | A | 65 | 70 | 0.14 | 0 | 1000 | |

| A-65/70-0.07 | A | 65 | 70 | 0.07 | 0 | 1000 | |

| A-65/70-0 | A | 65 | 70 | 0 | 0 | 1000 | |

| B-65/70-0.14-UV | B | 65 | 70 | 0.14 | 40 | 1000 | |

| B-65/70-0-UV | B | 65 | 70 | 0 | 40 | 1000 | |

| B-65/70-0.14 | B | 65 | 70 | 0.14 | 0 | 1000 | |

| B-65/70-0 | B | 65 | 70 | 0 | 0 | 1000 | |

| II | *-65/10-*-* | In the same condition I | 65 | 10 | In the same condition I | In the same condition I | In the same condition I |

| III | *-65/40-*-* | In the same condition I | 65 | 40 | In the same condition I | In the same condition I | In the same condition I |

| IV | *-15/40-*-* | In the same condition I | 15 | 40 | In the same condition I | In the same condition I | In the same condition I |

| V | *-40/40-*-* | In the same condition I | 40 | 40 | In the same condition I | In the same condition I | In the same condition I |

| VI | *-15/10-*-* | In the same condition I | 15 | 10 | In the same condition I | In the same condition I | In the same condition I |

| Temp-Hum | Temp-Str | Hum-Str | Temp-UV | Hum-UV | UV-Str | |

|---|---|---|---|---|---|---|

| ΔTSAB (MPa) | 0.076 | 0.011 | 0.031 | 0.138 | 0.067 | 0.064 |

| Specimen Group ID | Fitting Parameter Results | R2 | |||

|---|---|---|---|---|---|

| η | β | λ/×10−4 | θ/×10−4 | ||

| A-65/40-0.14-UV | 0.6 | 0.4 | 10.17 | 12.95 | 0.94 |

| A-40/40-0.14-UV | 0.6 | 0.4 | 7.20 | 10.87 | 0.85 |

| A-15/40-0.14-UV | 0.6 | 0.4 | 6.02 | 8.03 | 0.85 |

| A-65/70-0.14-UV | 0.6 | 0.4 | 14.59 | 16.15 | 0.90 |

| A-65/10-0.14-UV | 0.6 | 0.4 | 7.64 | 9.11 | 0.89 |

| A-65/40-0.07-UV | 0.6 | 0.4 | 8.79 | 11.57 | 0.91 |

| A-65/40-0-UV | 0.6 | 0.4 | 7.42 | 10.18 | 0.92 |

| A-65/40-0.14 | 0.6 | 0.4 | 0.34 | 0.76 | 0.90 |

| Sealant ID | η | β | α1/10−4 | α2/10−4 | α3/10−4 | α4/10−4 | α5/10−4 | α6/10−4 | α7/10−4 | α8/10−4 |

|---|---|---|---|---|---|---|---|---|---|---|

| A | 0.7052 | 0.3954 | 0.0754 | 9571.88 | 0.6358 | 2047.02 | 0.0055 | 4965.90 | 0.0913 | 6980.18 |

| B | 0.7572 | 0.3280 | 0.0453 | 9585.89 | 0.4294 | 3024.16 | 0.0043 | 5779.88 | 0.1247 | 4185.66 |

| Sealant ID | α9/10−4 | α10/10−4 | α11 | α12 | α13/10−4 | α14/10−4 | α15/10−4 | α16/10−4 | α17/10−4 | α18/10−4 |

|---|---|---|---|---|---|---|---|---|---|---|

| A | 0.0074 | 0.0362 | 3.5884 | 3.1055 | 0.2350 | 0.4915 | 0.0623 | 0.0736 | 0.0243 | 0.0670 |

| B | 0.0076 | 0.0516 | 4.2834 | 3.2124 | 0.1006 | 0.2945 | 0.0379 | 0.0921 | 0.0111 | 0.0839 |

| Specimen Group ID | λ | θ | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| λT | λH | λσ | λTH | λTσ | λHσ | λU/10−4 | θT | θH | θσ | θTH | θTσ | θHσ | θU/10−4 | ||

| A-65/70-0.14-UV | 2.2486 | 0.1069 | 0.1014 | 1.8333 | 0.6948 | 0.2313 | 36.18 | 0.9272 | 0.0631 | 0.0678 | 0.5272 | 0.1128 | 0.0878 | 22.32 | |

| PCT | 43.11% | 2.05% | 1.94% | 35.15% | 13.32% | 4.43% | 51.92% | 3.53% | 3.80% | 29.52% | 6.32% | 4.92% | |||

| A-65/70-0.14 | 2.2486 | 0.1069 | 0.1014 | 1.8333 | 0.6948 | 0.2313 | 1 | 0.9272 | 0.0631 | 0.0678 | 0.5272 | 0.1128 | 0.0878 | 1 | |

| PCT | 43.11% | 2.05% | 1.94% | 35.15% | 13.32% | 4.43% | 51.92% | 3.53% | 3.80% | 29.52% | 6.32% | 4.92% | |||

| A-65/70-0.07-UV | 2.2486 | 0.1069 | 0.0507 | 1.8333 | 0.3474 | 0.1156 | 36.18 | 0.9272 | 0.0631 | 0.0339 | 0.5272 | 0.0564 | 0.0439 | 22.32 | |

| PCT | 47.82% | 2.27% | 1.08% | 38.98% | 7.39% | 2.46% | 56.14% | 3.82% | 2.05% | 31.92% | 3.41% | 2.66% | |||

| A-15/10-0.14-UV | 1.4553 | 0.0794 | 0.1014 | 0.1164 | 0.3088 | 0.0330 | 36.18 | 0.6782 | 0.0002 | 0.0678 | 0.0335 | 0.0501 | 0.0125 | 22.32 | |

| PCT | 69.49% | 3.79% | 4.84% | 5.56% | 14.74% | 1.58% | 80.52% | 0.02% | 8.05% | 3.97% | 5.95% | 1.49% | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, B.; Liu, J.; Li, J.; Wang, C.; Wang, Z. Durability Test and Service Life Prediction Methods for Silicone Structural Glazing Sealant. Buildings 2025, 15, 1664. https://doi.org/10.3390/buildings15101664

Yang B, Liu J, Li J, Wang C, Wang Z. Durability Test and Service Life Prediction Methods for Silicone Structural Glazing Sealant. Buildings. 2025; 15(10):1664. https://doi.org/10.3390/buildings15101664

Chicago/Turabian StyleYang, Bo, Junjin Liu, Jianhui Li, Chao Wang, and Zhiyuan Wang. 2025. "Durability Test and Service Life Prediction Methods for Silicone Structural Glazing Sealant" Buildings 15, no. 10: 1664. https://doi.org/10.3390/buildings15101664

APA StyleYang, B., Liu, J., Li, J., Wang, C., & Wang, Z. (2025). Durability Test and Service Life Prediction Methods for Silicone Structural Glazing Sealant. Buildings, 15(10), 1664. https://doi.org/10.3390/buildings15101664