Abstract

Increasing environmental pollution has reinforced the necessity of implementing circular economy (CE) as a sustainable approach to reducing resource consumption, waste generation, and carbon emissions. Despite the construction industry’s significant environmental impact in terms of global carbon emissions, water consumption, and biodiversity loss, only 12% of its materials exhibit circular characteristics, necessitating improvements in terms of circularity in construction projects. This study develops a CE-based decision-making model for contractor selection, focusing on off-site construction (OSC), which offers greater circularity potential than conventional construction methods. The decision-making model, established through literature analysis and expert discussions, utilizes the fuzzy analytic hierarchy process (AHP) to evaluate CE criteria and employ the fuzzy Technique for Order Preference by Similarity to Ideal Solution (TOPSIS) to determine contractor suitability. The findings indicate that Material Circularity, Energy Circularity, and Product Circularity are the most influential criteria, with green procurement emerging as the highest-priority factor. The model was validated through a hypothetical case study involving four contractors experienced in sustainable construction. The results demonstrate the model’s capacity to produce sensitive outcomes in terms of decision-making.

1. Introduction

Increasing environmental pollution is making industries look for more sustainable solutions. As global resource consumption increases, the concept of circular economy (CE) has gained prominence, leading to its frequent mention in international standards [1]. The construction industry, due to its traditional structure, has faced challenges in adapting to changes. However, the adoption of technologies developed through the Construction 4.0 revolution, the increasing use of Building Information Modeling (BIM), and the incorporation of green building certifications (LEED, BREEAM, etc.) enhance sustainability in the construction industry. Nevertheless, buildings still consume 40% of the total energy consumed, with construction and demolition waste comprising the largest share of waste types, accounting for 36% [2]. Despite this, the global circularity rate decreased from 9.1% in 2018 to 8.6% in 2020, revealing a widening gap that should have been closed over time [3]. This situation underscores the increasing significance of circular economy (CE) initiatives within the construction industry.

While the applications of CE hold critical significance within the construction industry, the existing body of research addressing its implementation remains limited [4]. Furthermore, a consensus has yet to be established regarding the practical applications of CE in the building and construction industry [5]. Within this context, the present study recognizes off-site construction (OSC) as a promising avenue to enhance circularity in the construction sector. OSC entails the transition of construction processes from on-site locations to controlled manufacturing facilities, offering not only temporal, financial, and sustainability advantages, but also providing an opportunity for the integration of circular practices [6].

A review of studies on the circular economy (CE) emphasizes that selecting the right contractors remains a major challenge in achieving true circularity [7,8]. Research has shown that integrating CE principles with off-site construction (OSC) creates a mutually reinforcing effect, strengthening both approaches while making a significant contribution to sustainability [6]. Therefore, an OSC-focused study will be beneficial in increasing circularity in the construction industry. These construction projects, which involve the prefabrication of components off-site followed by their assembly on-site, differ from traditional construction similarly to sustainability evaluations. Hence, the development of a decision-making model capable of OSC would facilitate strategic decisions encompassing procurement, material choice, energy consumption, and circularity-efficient waste generation [9].

To overcome these challenges, this study proposes a contractor selection model rooted in CE principles for off-site construction projects. By promoting competent circular contractors, this study aims to improve the construction industry’s alignment with the SDGs. The primary impetus driving this study revolves around the potential to enhance efficiency by leveraging off-site construction techniques to amplify the adoption rate of CE within construction projects. This trajectory holds promise for the mitigation of waste generation, the curtailment of energy consumption and, notably, a reduction in raw material utilization in a manner conducive to circularity. Emerging from an exhaustive review of the existing literature, the prominent research gaps and pertinent contributions related to this current research endeavor can be succinctly summarized as follows:

- The adoption of OSC in the construction industry provides substantial benefits aligned with the three pillars of sustainability: economic, social, and environmental sustainability. Implicated in various SDGs, such as SDG 3, 6, 7, 8, 9, 11, 12, 13, 15, and 17, the concept of CE offers a notable opportunity for the advancement of OSC and the applicability of CE principles. However, the development of contractor selection models for OSC based on CE principles remains underexplored [6]. The existing literature primarily encompasses foundational definitions, factors, and strategies [1], the adaptation of technologies to CE principles [10], platform or framework proposals [11,12], and other dimensions of circular economy investigation. Therefore, the selection of contractors who are skilled in implementing CE principles through the proposed model can significantly enhance the adoption of these principles within construction projects [13].

- As robust multi-criteria decision-making (MCDM) methods, the fuzzy analytic hierarchy process (FAHP) and fuzzy TOPSIS techniques were integrated and employed for contractor selection in OSC. The hybrid fuzzy MCDM approach of criteria evaluation and alternative assessment stands as one of the most frequently employed methodologies in contractor selection [14]. While MCDM methods have been widely applied in various selection problems, including supplier selection, to the best of our knowledge, this study represents one of the first attempts to specifically employ a hybrid fuzzy MCDM approach for contractor selection in OSC. By utilizing this hybrid model, decision-makers aiming to achieve CE objectives can enhance the reliability of selection processes and improve circularity-driven decision-making.

- Among the barriers to OSC, “the lack of skilled contractors” ranks in the top three according to the literature [15]. There exists a gap in the literature regarding this issue in studies related to OSC. Contractor selections have been explored in the construction industry for different project types (i.e., infrastructure projects like road works, tunnel projects, superstructures, etc.) [16]. Therefore, this study represents a pioneering and original contribution to the field by addressing contractor selection in OSCs, such as prefabrication, modular construction, and industrialized building systems [17].

Despite the increasing recognition of the importance of CE principles in addressing environmental issues, their practical application in construction remains limited and lacks standardization. OSC offers a promising pathway to enhance circularity through controlled processes and improved sustainability, yet the integration of CE principles into OSC practices is underexplored. A key gap is the lack of decision-making models tailored to the selection of contractors for OSC projects based on CE criteria. Existing studies often focus on general CE frameworks or sustainability strategies, with limited attention paid to the role of contractor capabilities. Although hybrid fuzzy MCDM methods have shown success in various selection contexts, their use in CE-oriented OSC contractor selection is rare. Further complicating the issue is the shortage of skilled contractors in circular practices; this is one of the main barriers to OSC adoption yet it is rarely addressed in detail. Bridging these gaps is essential to supporting strategic and CE-aligned contractor selection in the construction industry.

Considering the gaps identified in the existing literature, this study aims to address these shortcomings by developing a practical and structured multi-criteria decision-making model for the selection of contractors capable of implementing circular economy (CE) principles in off-site construction (OSC) projects. The objectives of the study are as follows: (1) We aim to review previous academic research on contractor selection and identify the key evaluation criteria discussed in the literature. (2) We seek to examine the unique challenges associated with OSC projects and establish appropriate contractor evaluation criteria grounded in CE principles. (3) We aim to determine the relative importance of each criterion, thereby supporting the practical application of CE in the construction industry and contributing to the resolution of a commonly noted gap in the literature. (4) Further, we aim to develop a user-oriented and systematic decision-making model that facilitates the selection of the most suitable contractors for CE-focused OSC projects.

2. Literature Review

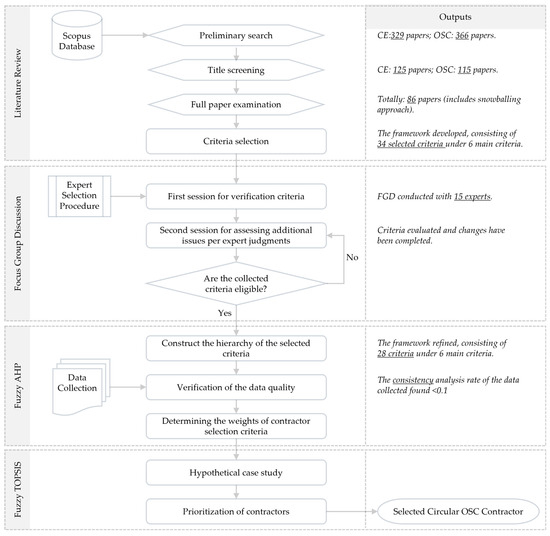

In this study, a systematic literature review was conducted on contractor selection and the circular economy within the construction industry. Scopus was selected as the primary database because of its extensive coverage, widespread use in academic research, and reliability in conducting systematic reviews [17]. To bridge the research gap in contractor selection within CE for OSC projects, the following search code was initially developed for CE: (TITLE-ABS-KEY (“circular economy” OR “circularity”) AND (“contractor”)). The following code was developed for OSC projects: ((TITLE-ABS-KEY (“off site construction” OR “Offsite” OR “modular construction” OR “prefabrication”) AND TITLE-ABS-KEY (“contractor”))). This search identified 695 documents published up to February 2024. The titles of the initially gathered articles were examined while considering exclusion criteria such as ‘non-English’ or ‘conference papers’, with a specific focus on ‘construction projects’. Subsequently, the abstracts and keywords of these articles were carefully reviewed. From the full-text assessment, 89 articles were selected for a more detailed analysis to address the topic more precisely. During this phase, any studies that did not specifically concentrate on OSC projects were excluded. Some relevant studies related to CE and OSC that were not retrieved in the initial Scopus search were identified through a snowballing strategy, including publications from Web of Science (WoS), Google Scholar, and other sources. This includes 3 reports from relevant organizations in CE, 2 books in these fields, and various articles. Combining the snowballing method with a systematic literature review, promising benefits are obtained [18]. Ultimately, 86 documents successfully passed the initial screening and underwent a comprehensive examination. These steps are summarized in Figure 1, while the subsequent stages of the study are detailed in Section 3.

In this section, we present a summary of the studies that focus on the relationship between CE and the construction industry, off-site construction practices, and contractor selection for off-site construction projects, respectively.

2.1. Circular Economy and the Construction Industry

The UN Environment Program (2015) highlights the shift towards the “circular economy”, altering waste management by emphasizing recycling. This shift from linear to circular economics signifies ongoing societal, governmental, and sectoral adaptation. Japan, the EU, and China have adopted models for transitioning [19]. The EU’s Green Deal (2020) requires sustainable business models for EU companies. The British Standards Institution’s Guide aids CE implementation [20]. Parallel initiatives within the construction industry aimed at identifying circular solutions to reduce raw material consumption, carbon emissions, and waste. Similarly to the Ellen MacArthur Foundation’s delineation of CE as a regenerative mechanism wherein materials are upheld at their utmost value within a “closed loop”, it is argued in [21] that within the realm of construction, it is imperative to repurpose end-of-life building materials. From their perspective, deconstructing these materials into their fundamental components is essential, allowing them to serve as resource repositories for new architectural projects and ensuring the continuation of a self-sustaining cycle. Various approaches exist for the implementation of CE. It is highlighted in [22] that, despite the increasing recognition of circular economy principles in the U.S. construction sector, challenges such as regulatory inconsistencies, budget constraints, and resistance to change hinder widespread adoption, necessitating multi-stakeholder collaboration and targeted policy interventions to drive systemic transformation. This diversity further highlights the necessity of a model for selecting contractors with a circular focus. In this study, the CS model proposed considers one or more of these approaches. Therefore, comprehensive research on CE practices applicable to the construction industry is presented in Table 1.

Table 1.

Circular conomy implementations.

Circular construction aims to create structures that can adapt to functional changes and serve as resources at the end of life; they are primarily constructed from recycled or reused materials [10]. This practice faces complexities due to traditional construction materials and industry-specific characteristics, making reuse or deconstruction challenging [34]. There is a strong awareness of CE principles, but the absence of standards stemming from construction methods and design strategies complicates the application of generic circularity indicators [35]. Consequently, academic studies have proposed various circularity indicators for circular construction. To enhance reliability and accuracy, Building Circularity Indicators (BCIs) have been developed [36]. These indicators not only find utility in CE models but also aid in identifying circular building components, enhancing end-of-life (EoL) performance through Life Cycle Assessment (LCA) and Material Flow Analysis (MFA), and facilitating the development of CE-LCA models [37]. In [38], it is outlined that in the construction industry, the supply chain is segmented into Forward Logistics (design, manufacturing, construction, operations) and Reverse Logistics (deconstruction, product reuse, waste distribution, material reprocessing) phases from a CE perspective, emphasizing the necessity of horizontal integration. The EMF’s Material Circularity Indicator (MCI) was adapted to construction in [39], which also introduced the Building Circularity Indicator (BCI) as a quantitative assessment method. These enhancements were integrated to create a BIM-based approach in [40]. A total of 30 indicators were identified in [5]; these were categorized into pillars such as Technical Cycle, Biological/Renewable, Recycling Efficiency, Functional Lifetime, Disassembly, Reusability Index, Adaptability, Energy, Emissions, Water, Heritage, and Economy. An analysis of 42 approaches presented in [10] highlighted CE constraints that do not align with reuse and refuse approaches (e.g., steel rusts, wood decomposes, bricks degrade). They stressed the need for an integrated CE perspective and underscored the potential of BIM in tracking materials and component data for efficient design.

However, the precise definition of circularity in construction, perhaps due to the industry’s relatively less mature CE understanding than manufacturing, has not yet been established [10]. The transition will be feasible with informed circular decision-making and increased awareness. Thus, this study will conduct a comprehensive circular assessment for Construction Sustainability (CS), building upon six core dimensions of circularity: functions, products, components, materials, embodied energy, and a reference scenario [33]. This research not only contributes to contractor selection but also supports the adaptation of CE in the construction industry.

2.2. Circular Economy and Its Relationship with Off-Site Construction Projects

The necessity of adhering to environmental standards and implementing measures to reduce environmental impact has prompted individuals involved in construction to embrace off-site construction (OSC) practices. Despite the benefits of OSC in meeting urbanization, housing, and sustainability goals, its adoption has been slow [41], particularly due to the lack of contractor selection tailored to OSC projects. OSC and circular construction (CC) are two interrelated concepts, with one being closely connected to the other. The increasing integration of Building Information Modeling (BIM), especially in conjunction with end-of-life circular economy strategies (e.g., 3R, 6R), is expected to enhance the utilization of OSC, particularly in modular structures [18]. The relationship between the CE and OSC projects is significant because OSC, often referred to as prefabrication or modular construction, inherently aligns with CE principles. OSC involves manufacturing, building components in a controlled factory environment that enables a reduction in waste and more efficient recycling within a CE framework [7]. Modular components, used in OSC, are designed for ease of assembly and disassembly. As a result of recycling and reducing OSC, extending lifespan and minimizing the need for new materials exist compared to traditional construction implications [34].

One of the other key points is longevity for CE. OSC produces durable, high-quality components that extend building lifespans, reducing the need for frequent replacements and resource-intensive renovation. In this respect, that procurement also influences circularity in OSC. Reference [42] addressed the lack of attention to procurement management in OSC. They formulated an MCDM model to choose suitable OSC procurement methods and identified project quality, cost control, and financial arrangements as the most crucial factors, whereas Integrated Project Delivery (IPD) and construction management (CM) methods received the highest benefit scores. The comparison between prefab and traditional buildings in the implementation of seven different CE strategies was addressed in [43]. The results indicate that, despite the common barriers associated with CE strategies, OSC methods should be treated differently from traditional construction due to differences such as lean applicability, lower complexity compared to traditional methods, carbon intensity, technological barriers in disassembling monolithic buildings, and degree of mobility. In the literature, there are supplier selection studies conducted specifically for OSC, recognizing its distinctiveness from traditional construction [44]. In the context of the circular economy, supplier selection aims to ensure that materials and resources are sustainable and suitable for recycling. The supplier selection studies conducted for the development of the CS model in this study will serve as a foundation. However, this study, which primarily addresses the contractor selection problem, will not only contribute to the performance of contractors but also provide a clear understanding, enhancing circularity within the project. Thus, the construction industry can overcome barriers related to its limited progress in circularity.

2.3. Contractor Selection Studies for Construction Projects

Contractor selection is a critical process that directly affects project success because the contractor’s competence is closely related to project performance. Since selecting an inappropriate contractor can increase the risk of project failure, a systematic and comprehensive evaluation approach is of great importance. To address this need, a multidimensional decision-making framework for the contractor prequalification process was developed in [45], emphasizing that contractor qualifications should be compatible with project objectives. This framework includes the evaluation of contractors according to criteria such as reputation, past performance, financial stability, technical expertise, and operational capacity. The Qualifier-1 Program, which supports this process, calculates a total weighted score by combining the scores received by each contractor according to the evaluation criteria [46]. In addition, an information-based model was developed to ensure more systematic and informed decisions, thus making the contractor selection process in construction projects more consistent and objective [47]. Over time, various decision-making methods have been developed for contractor selection, adapting to different project requirements and criteria. The literature highlights that selection processes differ based on project type and objectives. Unlike traditional approaches, off-site construction (OSC) involves designing, producing, and assembling structural elements at a location separate from their final installation site. Therefore, contractors in OSC projects must possess expertise, not only in on-site construction but also in planning, design, production, and modular assembly [42]. The distinct characteristics of OSC align with circular economy (CE) principles, promoting sustainability by optimizing resource use, minimizing waste, and enabling the reuse of structural elements. In this context, the current literature was examined to better understand how contractor selection differs in OSC. Important insights into existing methods are provided in [14] through a comprehensive analysis of contractor selection strategies. In addition, Table 2 summarizes recent studies addressing contractor selection criteria and methodologies used in different projects.

Table 2.

Prior research on selecting contractors.

3. Research Methodology

The methodology used to develop a CE-based decision-making model for contractor selection in off-site construction projects is summarized in Figure 1. Initially, a systematic literature review was conducted, as outlined in Section 2, to gather comprehensive information on the CE principles and OSCs for a comprehensive understanding of how off-site construction projects may use the circular economy. Based on the objectives of the study and the methodological flow, the following research questions were formulated:

RQ1: What are the key selection criteria for identifying circular contractors in construction projects?

RQ2: How can these criteria be validated and refined through focus group discussions (FGDs)?

RQ3: How can the prioritized selection criteria be integrated into a hybrid MCDM model for contractor evaluation in construction projects?

RQ4: How effective is the proposed fuzzy AHP–fuzzy TOPSIS-based model in evaluating and selecting the most appropriate circular contractor?

To address the proposed research questions, the study adopted a multi-stage approach. First, relevant criteria for CE-based contractor selection in OSC projects were identified. These criteria were refined and validated through focus group discussions (FGDs) with industry experts. A questionnaire survey was then conducted to assess the practical significance of the criteria. The data were analyzed using a fuzzy analytic hierarchy process (FAHP) to determine criteria weights. Finally, contractor alternatives were evaluated via fuzzy TOPSIS within a hypothetical case study to demonstrate model applicability.

Figure 1.

Comprehensive overview of methodological approach.

3.1. Validation of CE-Based Contractor Selection Criteria with Focus Group Discussion

This study utilized the focus group discussion (FGD) method for validating the identified criteria from the literature. The primary rationale for choosing FGD over other methods lies in its ability to facilitate discussions among participants with a background in CE and OSC, despite these being distinct subjects that complement each other. FGD, being an exploratory and collaborative technique, engages participants in dynamic discussions guided by a moderator to elicit valuable insights and opinions [64].

As suggested by [65], an effective focus group typically consists of 5 to 20 participants. Rather than following a strict numerical rule, the literature highlights three key principles for ensuring group quality [64]: avoiding groups larger than 20, as they can hinder effective moderation; maintaining at least 5 participants to ensure productive discussion [66]; and prioritizing expert competence over quantity. In accordance with these principles, our study assembled a group of 15 experts with diverse professional roles, including project owners, contractors, designers, and consultants, all of whom possess extensive experience in off-site construction and demonstrate strong familiarity with circular economy (CE) concepts (Table 3). The experts were selected based on the following criteria: (1) a minimum of 10 years of experience in the construction industry; (2) at least 5 years of direct involvement in off-site construction projects; (3) at least 5 years of knowledge or application of CE principles; (4) a minimum of 5 years in a managerial role; and (5) at least a bachelor’s degree in engineering or architecture. To ensure a global perspective, participants were drawn from multinational projects, with four experts based in the EU, five in the USA, and six in Turkey.

Table 3.

Participant demographics and expertise in the focus group discussion sessions.

FGDs were performed in two sessions. In the first FGD session, experts received clear theoretical insights on OSC and CE to familiarize them with the study’s background. Each expert was required to choose the methodology that most effectively addressed CE-based selection issues within the framework. These proposals underwent thorough deliberation among all experts, and the session concluded with the group reaching a consensus on the optimal approach advocated by [33]. The recommended approach delineates six dimensions (functions, products, components, materials, embodied energy, and a reference scenario) to systematically analyze the CE aspects within the context of OSC projects.

In the second session, using these categories, CE-based contractor selection criteria identified from the existing literature were presented to experts to assess the validity of the selection criteria based on the Likert scale. Subsequently, the assessments provided by the experts were scrutinized using descriptive techniques, as also recommended [67]. The results showed that criteria labeled as “Early-stage designer collaboration” were considered unsuitable as they received scores below 3, resulting in their removal from the list of criteria. The underlying reason for this outcome was that the item was perceived as a sub-criterion of other criteria (FC2, FC4, RC4). In this session, participants were also invited to propose additional selection factors. The moderator, also a co-author of this study, collected recommendations from each expert. These suggestions were then discussed, and their relevance was evaluated by the participants. A selection factor was considered valid if all experts agreed on its suitability. In cases where consensus was not achieved due to differing opinions, the moderator made the final decision based on the majority’s perspective.

As a result of the FGD session, an additional selection factor (EC5) was overlooked in the existing literature. Consequently, a total of 28 selection factors were identified and validated. Table 4 shows the finalized list of CS criteria along with their corresponding references.

Table 4.

Circular construction contractor selection criteria.

To improve conceptual clarity, the criteria listed in Table 4 were reviewed regarding the core CE principles: waste minimization, reuse/recycling, resource efficiency, and lifecycle thinking. Several criteria clearly support waste reduction (e.g., MC2, PC3), while others encourage reuse or recycled content (e.g., MC3, CC1, EC5). Resource efficiency is addressed through EC2 and PC1, and lifecycle thinking is reflected in criteria related to LCA, disassembly documentation, and service models (e.g., EC3, MC4, PC4). This demonstrates that the evaluation framework integrates CE foundations across its structure.

3.2. Application of Hybrid Fuzzy MCDM in Circular Contractor Selection

The application of fuzzy AHP has gained prominence in efforts to address the inherent uncertainties in expert evaluations, especially in CS studies. Recent research highlights the widespread use of fuzzy methodologies in this domain, emphasizing their effectiveness in accommodating imprecise assessments [78]. A comprehensive review of decision-making techniques tailored to contractor selection is provided by the authors in [14], underscoring the integration of fuzzy AHP and fuzzy TOPSIS as pivotal approaches. This is further supported by [79], who argue that traditional AHP and TOPSIS rely heavily on precise expert judgments, necessitating the use of fuzzy logic to account for evaluative ambiguities. Consequently, fuzzy-based methods have been widely adopted across various subfields of construction management. Building on this foundation, the present study employs a hybrid fuzzy multi-criteria analysis, combining fuzzy AHP and fuzzy TOPSIS to identify the most suitable contractor for circularity, as depicted in Figure 1. To enhance reliability in fuzzy AHP and fuzzy TOPSİS applications, fuzzy linguistic variables (Table 5) were employed instead of traditional numerical scales, offering a more intuitive approach.

Table 5.

Linguistic scales for fuzzy AHP and fuzzy TOPSIS.

3.2.1. Fuzzy AHP Application for MCDM

In the fuzzy AHP application, data collection utilized linguistic variables, which were later converted into triangular fuzzy numbers (TFNs). These TFNs encapsulate the smallest, largest, and most likely values of expert judgments, ensuring simplicity and clarity [80]. Data was gathered through a questionnaire survey administered to 15 experts, following a focus group discussion (FGD). The questionnaire survey was conducted both face-to-face and online, comprising two main sections. In the first section, experts conducted pairwise comparisons among the primary categories influencing selection factors. The second section involved pairwise comparisons of selection factors within specific dimensions, including requirement, ability, and outcome. Each expert completed a total of seven pairwise comparison matrices. To ensure the reliability of expert judgments, the consistency of their evaluations was assessed using the consistency ratio (CR), with a threshold of 0.1. Experts exceeding this limit received feedback to refine their assessments, ensuring high-quality data for analysis. The consistency index (CI) and CR were calculated using the following equations:

where represents the consistency index, is the maximum eigenvalue of the comparison matrix, is the number of criteria in the matrix, and denotes the random index.

Once consistent and reliable data sets were obtained, the pairwise evaluations were aggregated to derive group decisions. The linguistic expressions provided by the experts were transformed into triangular fuzzy equivalents based on Table 5. These transformed values were then aggregated using Equation (3) to form the group decision matrix, where K is the total number of respondents:

The extent analysis method described in [81], one of the most widely adopted fuzzy AHP approaches, was used to analyze the aggregated data, providing normalized weights for each selection factor. These weights were subsequently used as the weight vector in the fuzzy TOPSIS analysis, as shown in Figure 1. To address potential disagreements among experts, all pairwise comparisons were aggregated using the geometric means of TFNs. This method inherently captures judgment variability and integrates uncertainty into the final criteria weights.

3.2.2. Fuzzy TOPSIS Application for MCDM

The TOPSIS method is based on calculating the shortest distance from the Positive Ideal Solution (PIS) and the longest distance from the Negative Ideal Solution (NIS) to determine the most favorable alternative [65]. Due to its simplicity and robustness, this method is widely applied in various fields. To further adapt it to situations involving uncertain data, [82] extended the approach by introducing the fuzzy TOPSIS method. In this method, the weights and ratings are determined using linguistic variables, as outlined in Table 5. Although this analysis can be conducted using real contractor performance data, in this study, it was performed using a hypothetical case to validate the model’s structure and ensure its functionality under controlled conditions. The model can be directly implemented in practice by using actual contractor scores and executing the fuzzy TOPSIS steps accordingly.

During the survey, participants evaluated the decision alternatives based on the selection factors, and the resulting data were analyzed using the fuzzy TOPSIS approach, as detailed below.

In the first step, the importance of weights of the criteria is determined, representing the calculated weights of each selection factor, as described in Section 3.2.1.

In Step 2, the individual decision matrices from all experts are combined using the following equation:

where represents the decision matrix of the decision-maker. This aggregation process generates the overall decision matrix, structured as follows:

In Step 4, a linear scale transformation is applied to convert the various criteria scales into a comparable format, resulting in the normalized decision matrix , as computed using Equation (7) below:

Ultimately, the normalized fuzzy decision matrix is multiplied by the criteria weights obtained through the fuzzy AHP method to generate the weighted normalized fuzzy performance matrix.

Step 6 involves determining the fuzzy Positive Ideal Solution (PIS) and Negative Ideal Solution (NIS) using the normalized fuzzy numbers, where the minimum and maximum values of these numbers are identified.

The distance of each alternative from the fuzzy PIS and fuzzy NIS is calculated using the formulas provided, which measure how far each alternative is from both the fuzzy PIS and the fuzzy NIS:

The proximity coefficient (PCi) indicates how close each alternative is to both the fuzzy PIS and fuzzy NIS. It is calculated by comparing the distances from both ideal solutions:

Overall, this study assessed four alternative contractors based on their adherence to 28 circularity criteria (Table 4).

4. Results

This section presents the results of fuzzy AHP and fuzzy TOPSIS analyses, respectively.

4.1. Fuzzy AHP Analysis Results

The model was developed using a combination of methods, including focus group discussions (FGDs), fuzzy AHP, and fuzzy TOPSIS analysis, to provide a comprehensive framework that aids decision-makers in making informed choices. Before applying the fuzzy AHP method, the consistency of participants responses was assessed, and all responses found to be consistent (Table 6). The consistency ratio (CR) for each matrix remained within the acceptable 10% threshold, with no violations observed. These results confirm that the data collected from experts is both reliable and robust, being usable in further analysis.

Table 6.

Consistency ratios of experts with respect to CE criteria.

The key findings of the study are summarized in Table 7, which outlines the selection factors, their corresponding weights, circularity criteria, and their priorities. This framework enhances the reliability, accuracy, and effectiveness of decision-making, particularly in construction projects. By integrating a diverse set of selection factors and assessing their relative importance, the model supports decision-makers in systematically evaluating and selecting the most suitable contractor.

Table 7.

Ranking of CE-base contractor selection criteria.

Moreover, the model emphasizes the prioritization of circular economy (CE) criteria, guiding decision-makers in selecting the most suitable methods based on their specific requirements. The findings also highlight the complexity of choosing the most appropriate circular contractor, necessitating the use of a systematic approach to consider all relevant factors. Neglecting such an approach may raise concerns about the accuracy and validity of the decision, particularly among stakeholders like project owners. Therefore, decision-makers are encouraged to apply the proposed model to ensure a more reliable and effective selection process for circular contractors in construction projects.

According to Table 7, the findings indicate that Material Circularity, Energy Circularity, and Product Circularity were the most critical criteria in the model, with corresponding weights of 0.1928, 0.1790, and 0.1702, respectively. Indicator-based assessments of the criteria revealed that green procurement (PC1) was not only the most significant factor in product circularity but also the most influential factor across the entire model. In the overall evaluation, while Material Circularity (MC) was chosen as the most important main group, it was determined that PC1, PC2, and FC3 emerged as the most critical criteria overall.

4.2. Fuzzy TOPSIS Analysis Results

In this study, four hypothetical contractors were designed by a group of experts, aligning with methodologies previously established in related research [65]. The purpose of this step was to validate the applicability of the model. Although this study did not involve an actual contractor selection process, the evaluations were based on real firms known to the experts. Each expert provided ratings for the criteria based on their knowledge and experience, and these responses were processed by the moderator in a structured Excel sheet, which was then analyzed using the fuzzy TOPSIS method. To achieve this, two experts (E3, E9) provided ratings based on companies they currently work for, while the other two (E12, E15) assessed companies they had previously worked for. All four companies, represented by four experts separately, have prior experience with prefabrication or modular construction in their past projects, demonstrating their capability in off-site construction methodologies. While contractors B and C, both engaged in green building projects, had the opportunity to score higher overall due to their sustainability-oriented practices, it is essential to emphasize that this modeling exercise was designed to test the robustness and applicability of the proposed decision-making framework. Moreover, contractors A, B, and C represent firms operating on an international scale, particularly in the U.S. and Europe, whereas contractor D primarily focuses on transportation projects and is in the early stages of integrating sustainability-driven construction practices. A total of 112 data points were collected for the four companies and evaluated using the fuzzy TOPSIS method. Experts received detailed information about the contractors and evaluated them based on 28 CE criteria using a 7-point Likert scale (Table 5), appropriate for the fuzzy TOPSIS application. Contractors B and C, being involved in green building projects, were given the opportunity to score higher overall. During the evaluation, judgments about the companies were made based on the available information, and a single decision-maker performed the scoring.

Table 8 presents the overall performance of the contractors based on their CCi values, calculated using the fuzzy TOPSIS analysis. It also includes the individual CCi values for each indicator.

Table 8.

Assessment of the contractors.

The results show that contractor C (CCi: 0.2991) was the most circular, followed closely by contractor B (CCi: 0.2991). The other two contractors performed well in terms of RC and FC but were not selected in the overall ranking. In cases where multiple contractors need to be involved in a project, the decision-maker is provided with the flexibility to select more than one alternative based on the key CE criteria, allowing for the consideration of multiple viable options.

5. Discussion

The main criteria identified as critical in the study include Material Circularity (MC), Energy Circularity (EC), and Product Circularity (PC). These results are in line with existing circularity assessment methods in the literature, such as Material Flow Analysis and Life Cycle Assessment [36]. Modular components used in OSC projects extend material lifetime and reduce the need for new resources with their easy assembly and disassembly features [72]. Furthermore, green procurement (PC1) emerged as the most influential factor in the model, supporting the recommendations of [29] to increase circularity through business models and design strategies. Based on these findings, procurement strategies (PC1 and PC2) emerge as key factors in the transition to a circular economy. However, many contractors lack the infrastructure needed to effectively integrate sustainable supply chains. This gap between theoretical relevance and real-world implementation poses a major challenge for the sector. It suggests that systemic reforms may be necessary to support meaningful circular adoption. In addition, the factors weighted highly, such as PC1, EC1, EC3, and MC3, share a common feature: they are all directly linked to emission mitigation during the operational phase of construction projects. This highlights the model’s alignment with current sustainability priorities, particularly the need for cost-effective carbon reduction strategies in building operations, as emphasized in the recent literature [37].

The study also highlights that circularity is a structural challenge beyond just material choices. For example, project delivery methods (FC3) play an important role in determining whether circular outcomes can be achieved. This finding underlines the need for alternative project management approaches, such as Integrated Project Delivery (IPD) and Construction Management (CM), to provide a more appropriate framework for circular construction practices. Successful adoption of Product-as-a-Service models (PC4) and utilization of recycled raw materials (MC3) were also identified as key enablers of circular construction. However, the results indicate a change in contractor selection criteria. While traditional evaluation criteria remain relevant, factors such as occupational safety and workforce wellbeing (RC5) and previous construction experience (RC4) appear to be less important in the context of circularity. This suggests that traditional experience alone is no longer a dominant evaluation factor, but rather the contractor’s ability to integrate circular economy principles into its operations has become a more decisive factor.

The study demonstrates that the inherent nature of OSC projects aligns well with CE principles. Increased integration of BIM and recent CE strategies (e.g., 3R, 6R) are expected to boost OSC adoption [18]. Particularly, the ease of assembly and disassembly of modular components enhances reuse potential, contributing to circularity. The comparative analysis of traditional and modular construction presented in [43] confirms the potential of OSC to promote circularity. The findings suggest that selecting the right contractor directly impacts project circularity and sustainability objectives. OSC’s alignment with Material Circularity facilitates effective waste recovery and reduces the carbon footprint of projects [13]. Furthermore, supply chain management is a critical factor influencing circularity in OSC projects. It is emphasized in [42] that strategies like Integrated Project Delivery (IPD) and Construction Management (CM) improve decision-making processes in OSC projects. Moreover, the comparisons in [43] comparisons reveal that OSC has lower carbon intensity and reduced complexity compared to traditional construction methods. The need to reassess supplier selection for OSC from a circular perspective is highlighted in [44], emphasizing its critical role in achieving project sustainability objectives. In support of these findings, the case study results showed that contractors with higher CE alignment—particularly contractors A and B—also performed better on OSC-relevant criteria such as project delivery methods (FC3), modular design (PC3), and component circularity (CC). In contrast, contractor D, with limited OSC and international experience, received the lowest scores. These observations show a parallel with previous empirical studies suggesting that modular and prefabricated construction methods—key components of OSC—can lead to up to 87% waste reduction, more than 15% lower embodied carbon, and 60–68% less energy consumption compared to traditional construction [7]. This consistency reinforces the view that firms that are strong in CE are also more capable of delivering circular outcomes in OSC contexts. Although they are derived based on a hypothetical scenario, these results support the leverage effect discussed in the literature [7,43], indicating that contractors with experience in OSC are likely to hold a competitive advantage in CE-based evaluations. However, further empirical studies involving real-world contractor assessments are needed to validate and generalize these findings.

The model demonstrates how decisions guided by CE principles redefine waste as a resource and promote the more efficient use of materials and resources in off-site construction (OSC) projects. However, its applicability extends beyond OSC projects and provides a versatile framework for broader applications. Given the significant impact of CE, this study focuses specifically on OSC projects and provides a practical perspective from which CE can be effectively addressed. A significant gap in the literature lies in the practical application of CE, particularly in contractor selection. This study fills this gap by incorporating CE-based criteria into the selection process. It also adds value by providing a structured implementation roadmap, not only at the project initiation stage but also throughout the project lifecycle. The findings from the hypothetical case study suggest that aligning contractor selection with CE criteria can significantly improve circularity performance. This suggests that a shift from traditional selection methods to CE-compliant criteria can promote more sustainable contractor practices, thus reinforcing the idea that the sector can accelerate its transition to a circular and resource-efficient model.

The construction industry traditionally follows a linear economic cycle where materials are used and discarded [83]. Achieving circularity requires a fundamental shift towards CE principles. While economic concerns are often cited as an obstacle to this transition, this study focuses on demonstrating how CE can be implemented in practice. As a result, economic factors are not treated as the primary selection criterion but are included under financial resilience (RC1). The lower weight assigned to this factor suggests that circular decisions may lead to cost increases, but other considerations take precedence. In addition, strategies such as ‘product-as-a-service’ models (PC4) not only contribute to cost savings, but also enhance resource efficiency, reinforcing circularity in construction projects. By integrating environmental, economic and social dimensions, this approach is aligned with the three pillars of sustainability. Thus, this study differentiates itself from broader sustainable construction research by maintaining a specific CE-focused perspective. Furthermore, country-level policies provide crucial insights into the practical challenges and opportunities of implementing CE in construction. The EU, through the Green Deal and the British Standards Institution’s guidance, actively promotes circularity in the sector [20]. Countries like The Netherlands have set ambitious goals, such as achieving a fully circular construction economy by 2050 [19]. In contrast, Japan focuses on industrial efficiency and material reuse [19], while the U.S. still faces fragmented CE adoption due to regulatory inconsistencies and financial constraints [22]. These differences underline the need for flexible and context-aware contractor selection models that align with national regulatory maturity and strategic goals.

The study can be improved by making the contractor selection process iterative and integrating agile methods with continuous improvement mechanisms. Reference [84] showed that the Scrum methodology can be applied in construction projects in the design phase and also in the construction phase. Similarly, Scrum’s sprint logic can ensure that contractor compliance with CE criteria is monitored throughout the project through periodic performance evaluation. Sprint-based progress, especially in the production and delivery processes of prefabricated modules, can prevent material waste by providing a more flexible and optimized supply chain management. In addition, sustainability performance can be continuously measured during the project process and improvement sprints can be created, so that contractors can be effectively guided in achieving CE goals by receiving faster feedback. Given the challenge of performance-based assessment of criteria, a web-based model with improved accessibility could be developed. To address the common issue of data loss, data gathered by selected contractors can be integrated with BIM. This integration would contribute to enhancing time, cost, and quality management and enhance other project success factors such as integration, scope, human resources, communication, and risk management. It is anticipated that the smart systems and AI integration offered by Industry 5.0 will further enhance the effectiveness of circularity strategies in OSC projects.

6. Conclusions

This study underscores the necessity of integrating CE principles into contractor selection for off-site construction (OSC) projects to enhance circularity in the construction industry. By leveraging a fuzzy AHP and fuzzy TOPSIS-based decision-making model, this research provides a structured approach for evaluating contractor suitability based on key circularity criteria. The findings demonstrate that contractor selection significantly impacts the adoption of CE principles, emphasizing the need for systematic decision-making to improve sustainability outcomes. Also, CE is not merely a waste management process but a comprehensive approach encompassing all phases of a project, from design to closure. Therefore, if a truly circular construction industry is to be established, selecting contractors that comply with CE requirements will not only enhance motivation within the sector but also improve the circularity of projects and, consequently, the entire construction industry. Over time, this increased circularity can enable the construction industry to integrate with other industries, fostering a broader CE ecosystem.

The proposed model includes selection factors, their respective weights, circularity criteria, and their priorities. This framework is designed to facilitate more reliable, accurate, and effective decision-making across various contexts, particularly in construction projects. By incorporating a broad range of selection factors and assessing their relative importance, the model enables decision-makers to comprehensively evaluate and choose the most suitable contractor. Moreover, the model highlights the prioritization of CE criteria, assisting decision-makers in selecting the most appropriate methods tailored to their specific requirements. The results further demonstrate that choosing the most suitable circular contractor is inherently complex and requires a systematic approach to account for all relevant factors. Failing to adopt such an approach could lead to questions regarding the accuracy and validity of the decision, particularly from stakeholders such as project owners. Therefore, decision-makers are advised to utilize the proposed decision model to ensure a more reliable and effective selection process for circular contractors in construction projects.

While this study applied the proposed model to four hypothetical contractors, it is important to acknowledge that the outcomes were shaped by the characteristics of these selected firms. Contractor D, being a firm primarily focused on transportation projects and not an internationally operating construction company, exhibited relatively lower circularity performance compared to the others. However, this does not imply that local contractors inherently fail to meet CE requirements. On the contrary, the model’s evaluation criteria are designed to provide unbiased results, independently of a contractor’s scale or market reach. Moreover, the nature of a company’s past project types was not considered a direct criterion for circularity assessment, as the evaluation focused on broader sustainability indicators rather than specific sectoral experience. As the number of evaluated contractors increases, the model’s accuracy in distinguishing circularity performance among different firms will improve. Future implementations of this model could benefit from expanding the number of evaluated contractors to refine the decision-making process further. Additionally, if the model is integrated into a digital tool, it could serve as a decision-support system that not only ranks contractors based on CE compliance but also provides a roadmap to enhance their alignment with circularity principles. Such a tool would enable alternative contractors to understand their performance across the six main CE categories and identify key areas for improvement, ultimately fostering a more circular construction industry.

In summary, this study highlights the importance of CE criteria in contractor selection while underlining the necessity of integrated approaches in project management. The adoption of innovative methods, facilitated by Industry 5.0’s AI and smart systems, is expected to enhance circularity in construction projects and minimize their environmental impact. As [40] emphasized, implementing reduction-, reuse-, and recycling-focused strategies in contractor selection will increase CE’s effectiveness in the construction sector. By integrating BIM, the model can help prevent data loss in projects, improving not only time, cost, and quality management but also other key success factors such as integration, scope, human resources, communication, and risk management. This, in turn, will enhance the accessibility and usability of CE through technology, paving the way for a more sustainable future in the construction industry. For this reason, future research could focus on developing a digital tool to enhance both the accessibility and usability of the model. This could be achieved by designing a prequalification checklist that clearly outlines contractor capabilities with respect to specific CE principles such as a reduction in material waste and the lean production chain (MC2) or the prioritization of modular elements (CC3). In addition, establishing measurable performance indicators under each criterion would provide an objective evaluation framework and strengthen conceptual coherence. In this way, not only would the specific requirements of CE in the construction industry be clearly defined, but the model, having been transformed into a functional tool, could be effectively adopted within the sector.

Author Contributions

Conceptualization, A.T.D., H.A. and Z.I.; methodology, A.T.D. and H.A.; validation, A.T.D.; formal analysis, A.T.D.; investigation, A.T.D.; resources, A.T.D., Z.I. and M.J.S.; writing—original draft preparation, A.T.D.; writing—review and editing, A.T.D., H.A., Z.I. and M.J.S.; visualization, A.T.D.; supervision, H.A., Z.I. and M.J.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by The Scientific and Technological Research Council of Turkiye (TUBITAK), Science fellowships and grant program directorate, 2214-A—International Research Fellowship Programme for PhD Students.

Data Availability Statement

The data generated or analyzed during the study are available from the corresponding author on request.

Acknowledgments

The authors would like to acknowledge that this paper is submitted in partial fulfillment of the requirements for a PhD degree at Yıldız Technical University.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Wilson, D.C.; Rodic, L.; Modak, P.; Soos, R.; Carpintero, A.; Velis, K.; Iyer, M.; Simonett, O. (Eds.) Global Waste Management Outlook; UNEP: Nairobi, Kenya, 2016. [Google Scholar] [CrossRef]

- Circle Economy. The Circularity Gap Report 2022. Available online: https://www.circularity-gap.world/2022 (accessed on 10 May 2025).

- Nußholz, J.; Çetin, S.; Eberhardt, L.; De Wolf, C.; Bocken, N. From circular strategies to actions: 65 European circular building cases and their decarbonisation potential. Resour. Conserv. Recycl. Adv. 2023, 17, 200130. [Google Scholar] [CrossRef] [PubMed]

- Khadim, N.; Agliata, R.; Marino, A.; Thaheem, M.J.; Mollo, L. Critical review of nano and micro-level building circularity indicators and frameworks. J. Clean. Prod. 2022, 357, 131859. [Google Scholar] [CrossRef]

- Obi, L.; Arif, M.; Daniel, E.I.; Oladinrin, O.T.; Goulding, J.S. Establishing underpinning concepts for integrating circular economy and offsite construction: A bibliometric review. Built Environ. Proj. Asset Manag. 2023, 13, 123–139. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q. Developing critical success factors for integrating circular economy into modular construction projects in Hong Kong. Sustain. Prod. Consum. 2022, 29, 574–587. [Google Scholar] [CrossRef]

- Koc, K.; Ekmekcioglu, Ö.; Işık, Z. Developing a Hybrid Fuzzy Decision-Making Model for Sustainable Circular Contractor Selection. J. Constr. Eng. Manag. 2023, 149, 04023095. [Google Scholar] [CrossRef]

- Okudan, O.; Cevikbas, M.; Işık, Z. Selection framework of disruption analysis methods for megaprojects: An integrated fuzzy multi-criteria decision-making approach. Eng. Constr. Archit. Manag. 2023, 32, 59–86. [Google Scholar] [CrossRef]

- Charef, R.; Lu, W.; Hall, D. The transition to the circular economy of the construction industry: Insights into sustainable approaches to improve the understanding. J. Clean. Prod. 2022, 364, 132421. [Google Scholar] [CrossRef]

- Kovacic, I.; Honic, M.; Sreckovic, M. Digital Platform for Circular Economy in AEC Industry. Eng. Proj. Organ. J. 2020, 9, 16. [Google Scholar] [CrossRef]

- Wu, W.; Xie, L.; Hao, J.L. An integrated trading platform for construction and demolition waste recovery in a circular economy. Sustain. Chem. Pharm. 2022, 25, 100597. [Google Scholar] [CrossRef]

- Kazancoglu, Y.; Ozkan-Ozen, Y.D.; Sagnak, M.; Kazancoglu, I.; Dora, M. Framework for a sustainable supply chain to overcome risks in transition to a circular economy through Industry 4.0. Prod. Plan. Control 2023, 34, 902–917. [Google Scholar] [CrossRef]

- Khoso, A.R.; Yusof, A.M.; Chen, Z.S.; Skibniewski, M.J.; Chin, K.S.; Khahro, S.H.; Sohu, S. Comprehensive analysis of state-of-the-art contractor selection models in construction environment-A critical review and future call. Socioecon. Plann. Sci. 2022, 79, 101137. [Google Scholar] [CrossRef]

- Gan, X.; Chang, R.; Zuo, J.; Wen, T.; Zillante, G. Barriers to the transition towards off-site construction in China: An Interpretive structural modeling approach. J. Clean. Prod. 2018, 197, 8–18. [Google Scholar] [CrossRef]

- Liang, R.; Zhang, J.; Wu, C.; Sheng, Z.; Wang, X. Joint-Venture Contractor Selection Using Competitive and Collaborative Criteria with Uncertainty. J. Constr. Eng. Manag. 2019, 145, 04018123. [Google Scholar] [CrossRef]

- Hosseini, M.R.; Martek, I.; Zavadskas, E.K.; Aibinu, A.A.; Arashpour, M.; Chileshe, N. Critical evaluation of off-site construction research: A Scientometric analysis. Autom. Constr. 2018, 87, 235–247. [Google Scholar] [CrossRef]

- Jayawardana, J.; Kulatunga, A.K.; Jayasinghe, J.A.S.C.; Sandanayake, M.; Zhang, G. Environmental Sustainability of Off-Site Construction in Developed and Developing Regions: A Systematic Review. J. Archit. Eng. 2023, 29, 04023008. [Google Scholar] [CrossRef]

- Pauliuk, S. Critical appraisal of the circular economy standard BS 8001:2017 and a dashboard of quantitative system indicators for its implementation in organizations. Resour. Conserv. Recycl. 2018, 129, 81–92. [Google Scholar] [CrossRef]

- Institution, B.S. Framework for Implementing the Principles of the Circular Economy in Organizations-Guide; BSI Standards Limited: London, UK, 2017. [Google Scholar]

- Hopkinson, P.; Chen, H.-M.; Zhou, K.; Wang, Y.; Lam, D. Recovery and reuse of structural products from end-of-life buildings. Proc. Inst. Civ. Eng.-Eng. Sustain. 2019, 172, 119–128. [Google Scholar] [CrossRef]

- Guerra, B.C.; Leite, F. Circular economy in the construction industry: An overview of United States stakeholders’ awareness, major challenges, and enablers. Resour. Conserv. Recycl. 2021, 170, 105617. [Google Scholar] [CrossRef]

- Geiser, K. Kenneth Geiser Foreword by Barry Commoner. 2001. Available online: https://direct.mit.edu/books/monograph/2534/bookpreview-pdf/2411982 (accessed on 10 May 2025).

- Allwood, J.M.; Ashby, M.F.; Gutowski, T.G.; Worrell, E. Material efficiency: A white paper. Resour. Conserv. Recycl. 2011, 55, 362–381. [Google Scholar] [CrossRef]

- Sihvonen, S.; Ritola, T. Conceptualizing ReX for Aggregating End-of-life Strategies in Product Development. Procedia CIRP 2015, 29, 639–644. [Google Scholar] [CrossRef]

- Khaw-Ngern, K.; Peuchthonglang, P.; Klomkul, L.; Khaw-Ngern, C. The 9Rs Strategies for the Circular Economy 3.0. Psychol. Educ. 2021, 58, 1440–1446. [Google Scholar] [CrossRef]

- Bag, S.; Gupta, S.; Kumar, S. Industry 4.0 adoption and 10R advance manufacturing capabilities for sustainable development. Int. J. Prod. Econ. 2021, 231, 107844. [Google Scholar] [CrossRef]

- Potting, J.; Hekkert, M.; Worrell, E.; Hanemaaijer, A. Circular Economy: Measuring Innovation in the Product Chain Policy Report. 2017. Available online: https://www.pbl.nl/downloads/pbl-2016-circular-economy-measuring-innovation-in-product-chains-2544pdf (accessed on 10 May 2025).

- Bocken, N.M.P.; de Pauw, I.; Bakker, C.; van der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef]

- Shi, H.; Chertow, M.; Song, Y. Developing country experience with eco-industrial parks: A case study of the Tianjin Economic-Technological Development Area in China. J. Clean. Prod. 2010, 18, 191–199. [Google Scholar] [CrossRef]

- Jackson, M.; Lederwasch, A.; Giurco, D. Transitions in Theory and Practice: Managing Metals in the Circular Economy. Resources 2014, 3, 516–543. [Google Scholar] [CrossRef]

- Foundation, E.M. Towards a Circular Economy: Business Rationale for an Accelerated Transition. 2015. Available online: https://www.ellenmacarthurfoundation.org/towards-a-circular-economy-business-rationale-for-an-accelerated-transition (accessed on 10 May 2025).

- Moraga, G.; Huysveld, S.; Mathieux, F.; Blengini, G.A.; Alaerts, L.; Van Acker, K.; Dewulf, J. Circular economy indicators: What do they measure? Resour. Conserv. Recycl. 2019, 146, 452–461. [Google Scholar] [CrossRef]

- Antwi-Afari, P.; Ng, S.T.; Chen, J. Developing an integrative method and design guidelines for achieving systemic circularity in the construction industry. J. Clean. Prod. 2022, 354, 131752. [Google Scholar] [CrossRef]

- Benachio, G.L.F.; Freitas, M.D.C.D.; Tavares, S.F. Circular economy in the construction industry: A systematic literature review. J. Clean. Prod. 2020, 260, 121046. [Google Scholar] [CrossRef]

- Heisel, F.; Hebel, D.E. Building Better-Less-Different: Circular Construction and Circular Economy; De Gruyter: Berlin, Germany, 2022. [Google Scholar] [CrossRef]

- van Stijn, A.; Eberhardt, L.C.M.; Jansen, B.W.; Meijer, A. A Circular Economy Life Cycle Assessment (CE-LCA) model for building components. Resour. Conserv. Recycl. 2021, 174, 105683. [Google Scholar] [CrossRef]

- Ding, L.; Wang, T.; Chan, P.W. Forward and reverse logistics for circular economy in construction: A systematic literature review. J. Clean. Prod. 2023, 388, 135981. [Google Scholar] [CrossRef]

- Verberne, J.; Building Circularity Indicators an Approach for Measuring Circularity of A Building. Eindhoven University of Technology. 2016. Available online: https://research.tue.nl/en/studentTheses/building-circularity-indicators (accessed on 10 May 2025).

- Charef, R. The use of Building Information Modelling in the circular economy context: Several models and a new dimension of BIM (8D). Clean. Eng. Technol. 2022, 7, 100414. [Google Scholar] [CrossRef]

- Kamali, M.; Hewage, K. Life cycle performance of modular buildings: A critical review. Renew. Sustain. Energy Rev. 2016, 62, 1171–1183. [Google Scholar] [CrossRef]

- Assaf, M.; Hussein, M.; Abdelkhalek, S.; Zayed, T. A Multi-Criteria Decision-Making Model for Selecting the Best Project Delivery Systems for Offsite Construction Projects. Buildings 2023, 13, 571. [Google Scholar] [CrossRef]

- Minunno, R.; O’Grady, T.; Morrison, G.; Gruner, R.; Colling, M. Strategies for Applying the Circular Economy to Prefabricated Buildings. Buildings 2018, 8, 125. [Google Scholar] [CrossRef]

- Alkhuzaim, L.; Zhu, Q.; Sarkis, J. Evaluating Emergy Analysis at the Nexus of Circular Economy and Sustainable Supply Chain Management. Sustain. Prod. Consum. 2021, 25, 413–424. [Google Scholar] [CrossRef]

- Russell, J.S.; Skibniewski, M.J. Decision Criteria in Contractor Prequalification. J. Manag. Eng. 1988, 4, 148–164. [Google Scholar] [CrossRef]

- Russell, J.S.; Skibniewski, M.J. QUALIFIER-1: Contractor Prequalification Model. J. Comput. Civ. Eng. 1990, 4, 77–90. [Google Scholar] [CrossRef]

- Russell, J.S.; Skibniewski, M.J.; Cozier, D.R. Qualifier-2: Knowledge-Based System for Contractor Prequalification. J. Constr. Eng. Manag. 1990, 116, 157–171. [Google Scholar] [CrossRef]

- Mergawy, R.T.; Hosny, H.E.; Abdelazeem, A.S. Decision Support Model for Contractor Selection. Open Civ. Eng. J 2023, 17, e230215-2022-51. [Google Scholar] [CrossRef]

- Alkaabi, S.A.M.; Mahjoob, A.M.R. Using the ordinal priority approach for selecting the contractor in construction projects. Organ. Technol. Manag. Constr. Int. J. 2023, 15, 136–156. [Google Scholar] [CrossRef]

- Stojanović, I. Selection of a Green Contractor for the Implementation of a Solar Power Plant Project. Symmetry 2024, 16, 441. [Google Scholar] [CrossRef]

- Jain, S.; Jauhar, S.K.; Piyush. A machine-learning-based framework for contractor selection and order allocation in public construction projects considering sustainability, risk, and safety. Ann. Oper. Res. 2024, 338, 225–267. [Google Scholar] [CrossRef]

- Afolayan, A.H.; Ojokoh, B.A.; Adetunmbi, A.O. Performance analysis of fuzzy analytic hierarchy process multi-criteria decision support models for contractor selection. Sci. African 2020, 9, e00471. [Google Scholar] [CrossRef]

- Nguyen, T.; Nguyen, L.H.; Chileshe, N.; Hallo, L. Investigating critical risk factors of selecting joint venture contractors for infrastructure projects implementation in Vietnam. Int. J. Constr. Manag. 2023, 23, 2438–2451. [Google Scholar] [CrossRef]

- Tafazzoli, M.; Hazrati, A.; Shrestha, K.; Kisi, K. Enhancing Contractor Selection through Fuzzy TOPSIS and Fuzzy SAW Techniques. Buildings 2024, 14, 1861. [Google Scholar] [CrossRef]

- Demirci, F.S.; Isik, Z. Developing a community responsive resilient contractor selection model for post-disaster reconstruction projects: A build back better approach. Eng. Constr. Archit. Manag. 2024; ahead of print. [Google Scholar] [CrossRef]

- Gurgun, A.P.; Koc, K. Contractor prequalification for green buildings—Evidence from Turkey. Eng. Constr. Archit. Manag. 2020, 27, 1377–1400. [Google Scholar] [CrossRef]

- Yu, W.-D.; Chang, H.-K.; Hsu, Y.-Y.; Cheng, S.-T.; Wang, K.-W. Pretendering Decision Model for Contractor Selection of Public Procurement Projects. J. Constr. Eng. Manag. 2020, 146, 04020126. [Google Scholar] [CrossRef]

- Zhao, L.; Liu, W.; Wu, Y. Bid evaluation decision for major project based on analytic hierarchy process and data envelopment analysis cross-efficiency model. J. Ambient. Intell. Humaniz. Comput. 2020, 11, 3639–3647. [Google Scholar] [CrossRef]

- Le, C.; Jeong, H.D.; Le, T.; Kang, Y. Evaluating Contractors’ Production Performance in Highway Projects Using Historical Daily Work Report Data. J. Manag. Eng. 2020, 36, 04020015. [Google Scholar] [CrossRef]

- Alshamrani, O.S.D.; Saleem, M.; AlYousif, I.K.; Alluqmani, A. Development of a pre-qualification and selection framework for construction projects’ contractors in Saudi Arabia. J. Asian Archit. Build. Eng. 2023, 22, 1545–1563. [Google Scholar] [CrossRef]

- Liang, R.; Li, R.; Chong, H.-Y. Sustainable supplier selection for prefabricated megaprojects during COVID-19: A novel large group decision-making model. Build. Res. Inf. 2023, 51, 533–554. [Google Scholar] [CrossRef]

- Chen, Z.-S.; Zhang, X.; Rodríguez, R.M.; Pedrycz, W.; Martínez, L. Expertise-based bid evaluation for construction-contractor selection with generalized comparative linguistic ELECTRE III. Autom. Constr. 2021, 125, 103578. [Google Scholar] [CrossRef]

- Marović, I.; Perić, M.; Hanak, T. A Multi-Criteria Decision Support Concept for Selecting the Optimal Contractor. Appl. Sci. 2021, 11, 1660. [Google Scholar] [CrossRef]

- Nyumba, T.O.; Wilson, K.; Derrick, C.J.; Mukherjee, N. The use of focus group discussion methodology: Insights from two decades of application in conservation. Methods Ecol. Evol. 2018, 9, 20–32. [Google Scholar] [CrossRef]

- Okudan, O.; Demirdöğen, G.; Işık, Z. A decision-support framework for suspension of public infrastructure projects: A combined use of neutrosophic AHP and TOPSIS. Eng. Constr. Archit. Manag. 2024, 32, 3187–3216. [Google Scholar] [CrossRef]

- Budayan, C.; Okudan, O.; Dikmen, I. Identification and prioritization of stage-level KPIs for BOT projects–evidence from Turkey. Int. J. Manag. Proj. Bus. 2020, 13, 1311–1337. [Google Scholar] [CrossRef]

- Budayan, C. Evaluation of Delay Causes for BOT Projects Based on Perceptions of Different Stakeholders in Turkey. J. Manag. Eng. 2019, 35, 04018057. [Google Scholar] [CrossRef]

- Hao, J.L.; Yu, S.; Tang, X.; Wu, W. Determinants of workers’ pro-environmental behaviour towards enhancing construction waste management: Contributing to China’s circular economy. J. Clean. Prod. 2022, 369, 133265. [Google Scholar] [CrossRef]

- Zhu, J.; Zhang, Y.; Zhang, J.; Chen, Y.; Liu, Y.; Liu, H. Multi-Criteria Seismic Risk Assessment Based on Combined Weight-TOPSIS Model and CF-Logistic Regression Model—A Case Study of Songyuan City. China Sustain. 2023, 15, 11216. [Google Scholar] [CrossRef]

- Liu, Z.; Hwang, B.-G.; Lim, J.M. Prefabricated and Prefinished Volumetric Construction: Assessing Implementation Status, Perceived Benefits, and Critical Risk Factors in the Singapore Built Environment Sector. J. Manag. Eng. 2023, 39, 04023045. [Google Scholar] [CrossRef]

- Lim, P.Y.; Yahya, K.; Aminudin, E.; Zakaria, R.; Haron, Z.; Mohamad Zin, R.; Redzuan, A.A.H. Carbon footprint of construction using industrialised building system. IOP Conf. Ser. Mater. Sci. Eng. 2017, 271, 012107. [Google Scholar] [CrossRef]

- Antwi-Afari, P.; Ng, S.T.; Chen, J. Determining the optimal partition system of a modular building from a circular economy perspective: A multicriteria decision-making process. Renew. Sustain. Energy Rev. 2023, 185, 113601. [Google Scholar] [CrossRef]

- Zhuang, G.L.; Shih, S.G.; Wagiri, F. Circular economy and sustainable development goals: Exploring the potentials of reusable modular components in circular economy business model. J. Clean. Prod. 2023, 414, 137503. [Google Scholar] [CrossRef]

- Geng, Y.; Fu, J.; Sarkis, J.; Xue, B. Towards a national circular economy indicator system in China: An evaluation and critical analysis. J. Clean. Prod. 2012, 23, 216–224. [Google Scholar] [CrossRef]

- Ruiz, L.A.L.; Ramón, X.R.; Domingo, S.G. The circular economy in the construction and demolition waste sector–A review and an integrative model approach. J. Clean. Prod. 2020, 248, 119238. [Google Scholar] [CrossRef]

- Magnier, C.; Auzanneau, M.; Calatayud, P.; Gauche, M.; Ghewy, X.; Granger, M.; Margontier, S.; Pautard, E.; Moreau, S.; Bottin, A.; et al. 10 Key Indicators for Monitoring the Circular Economy. 2017 Edition. 1 March 2017. Available online: https://inis.iaea.org/search/search.aspx?orig_q=RN:50078470 (accessed on 1 November 2023).

- Heisel, F.; Nelson, C. RhinoCircular: Development and Testing of a Circularity Indicator Tool for Application in Early Design Phases and Architectural Education. Proc. ACSA Fall Conf. 2020, 154–159. [Google Scholar] [CrossRef]

- Tomczak, M.; Jaśkowski, P. Application of Type-2 Interval Fuzzy Sets to Contractor Qualification Process. KSCE J. Civ. Eng. 2018, 22, 2702–2713. [Google Scholar] [CrossRef]

- Ekmekcioğlu, Ö.; Koc, K.; Dabanli, I.; Deniz, A. Prioritizing urban water scarcity mitigation strategies based on hybrid multi-criteria decision approach under fuzzy environment. Sustain. Cities Soc. 2022, 87, 104195. [Google Scholar] [CrossRef]

- Li, F.; Phoon, K.K.; Du, X.; Zhang, M. Improved AHP Method and Its Application in Risk Identification. J. Constr. Eng. Manag. 2013, 139, 312–320. [Google Scholar] [CrossRef]

- Chang, D.Y. Applications of the extent analysis method on fuzzy AHP. Eur. J. Oper. Res. 1996, 95, 649–655. [Google Scholar] [CrossRef]

- Chen, C.-T. Extensions of the TOPSIS for group decision-making under fuzzy environment. Fuzzy Sets Syst. 2000, 114, 1–9. [Google Scholar] [CrossRef]

- Khadim, N.; Agliata, R.; Thaheem, M.J.; Mollo, L. Whole building circularity indicator: A circular economy assessment framework for promoting circularity and sustainability in buildings and construction. Build. Environ. 2023, 241, 110498. [Google Scholar] [CrossRef]

- Jethva, S.S.; Skibniewski, M.J. Agile project management for design-build construction projects: A case study. Int. J. Appl. Sci. Eng. 2022, 19, 1–11. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).