Effect of Pozzolanic Additive on Properties and Surface Finish Assessment of Concrete

Abstract

1. Introduction

2. Materials and Methods

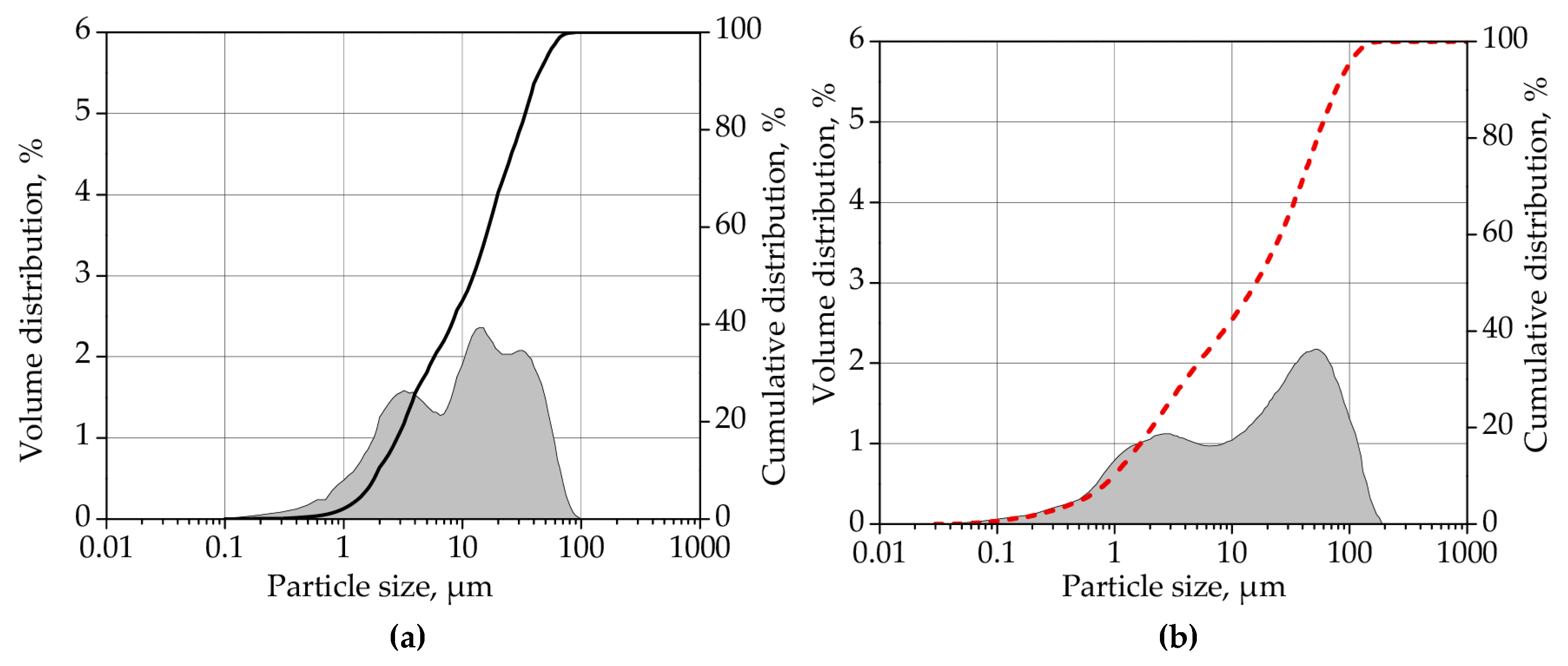

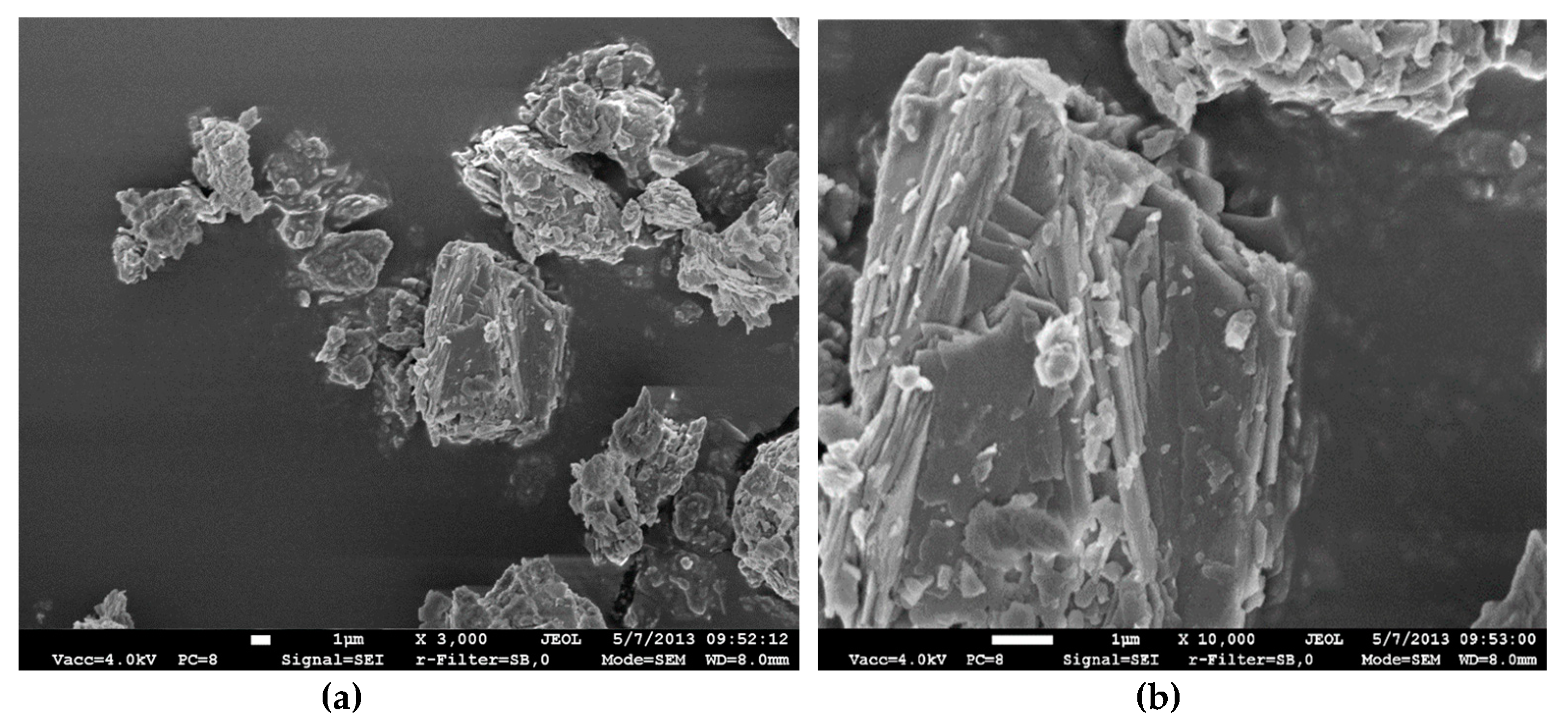

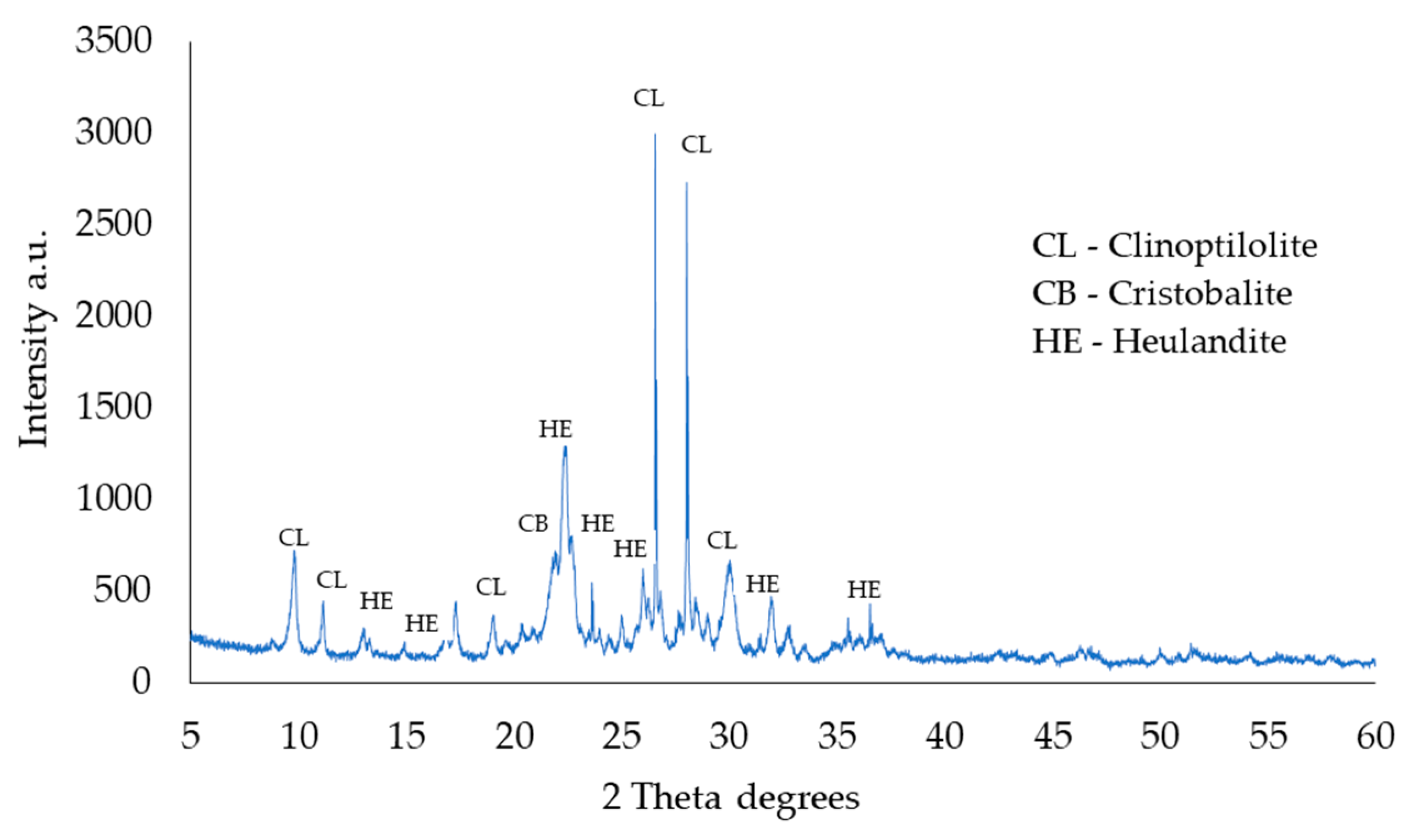

2.1. Materials

2.2. Preparation and Moulding of Concrete Specimens and Compositions

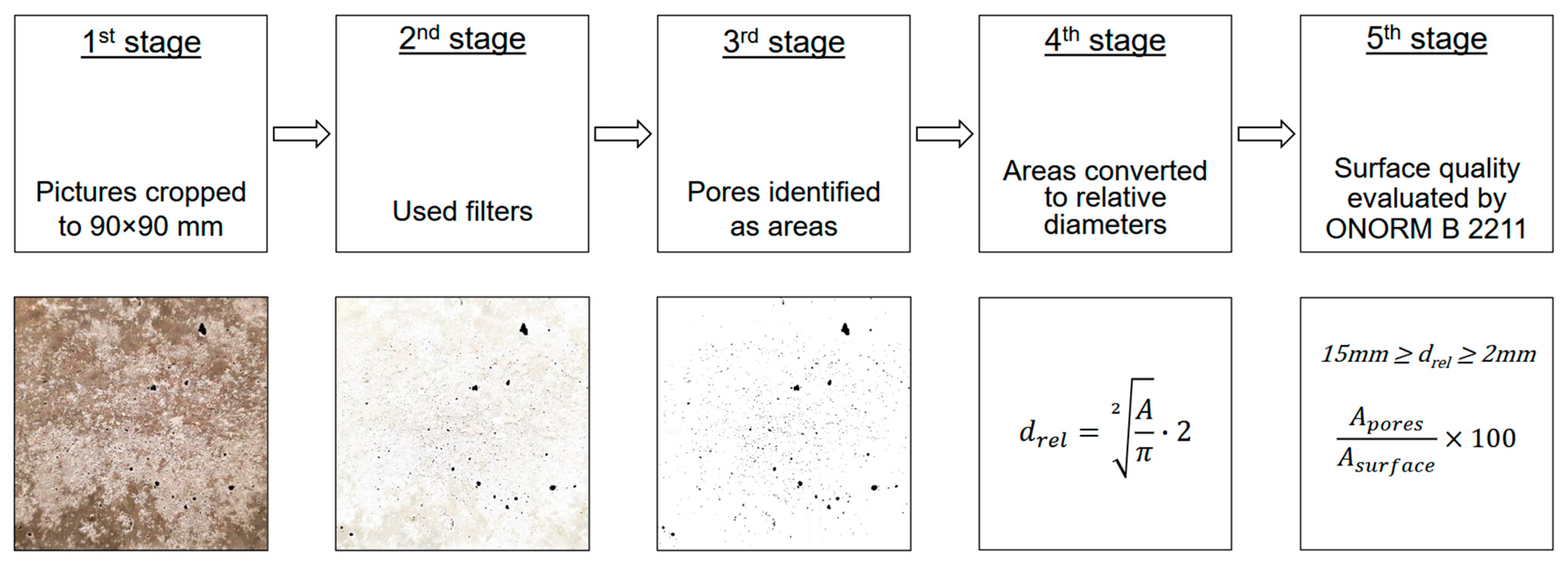

2.3. Test Methods

3. Results and Discussion

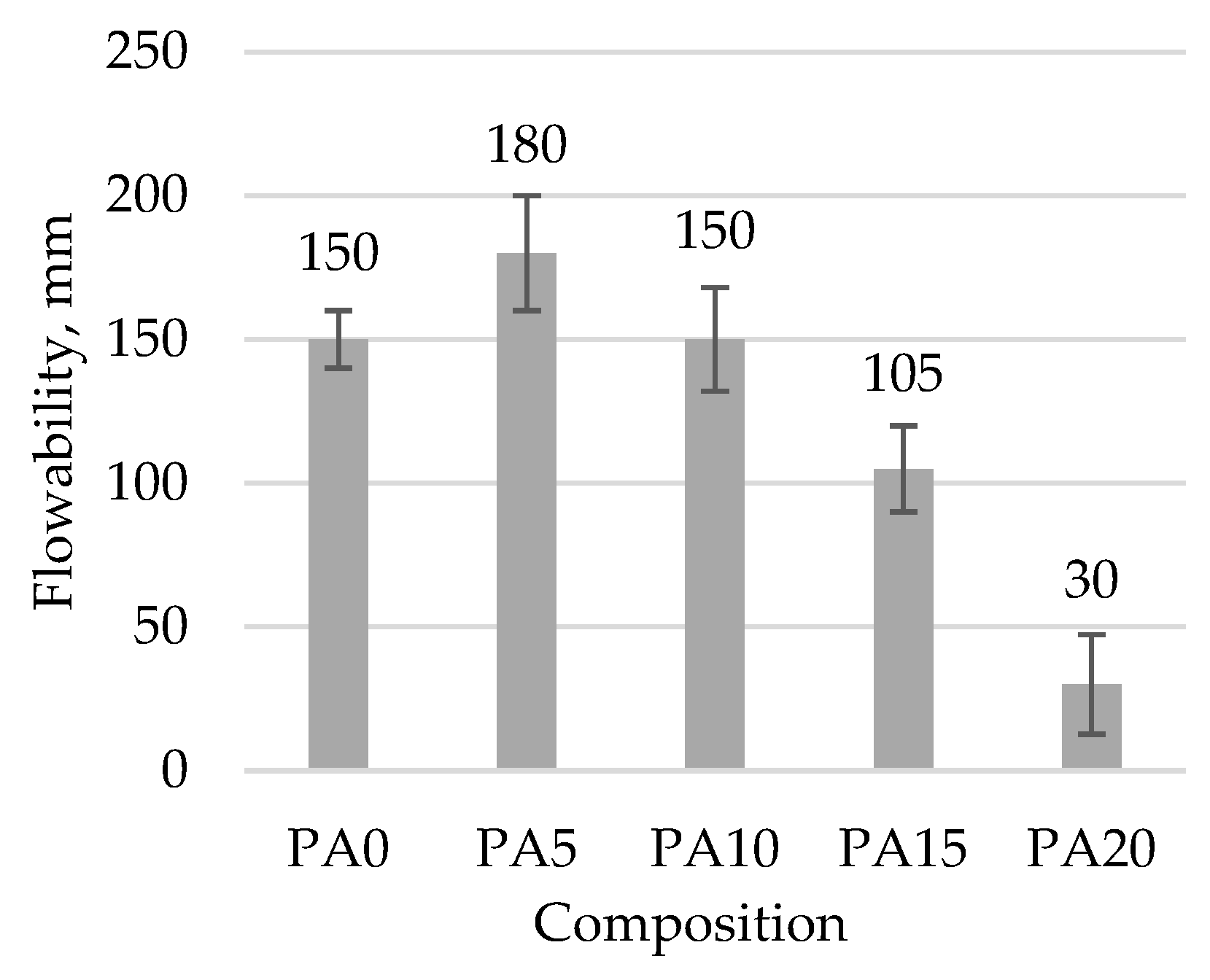

3.1. Fresh Concrete Properties

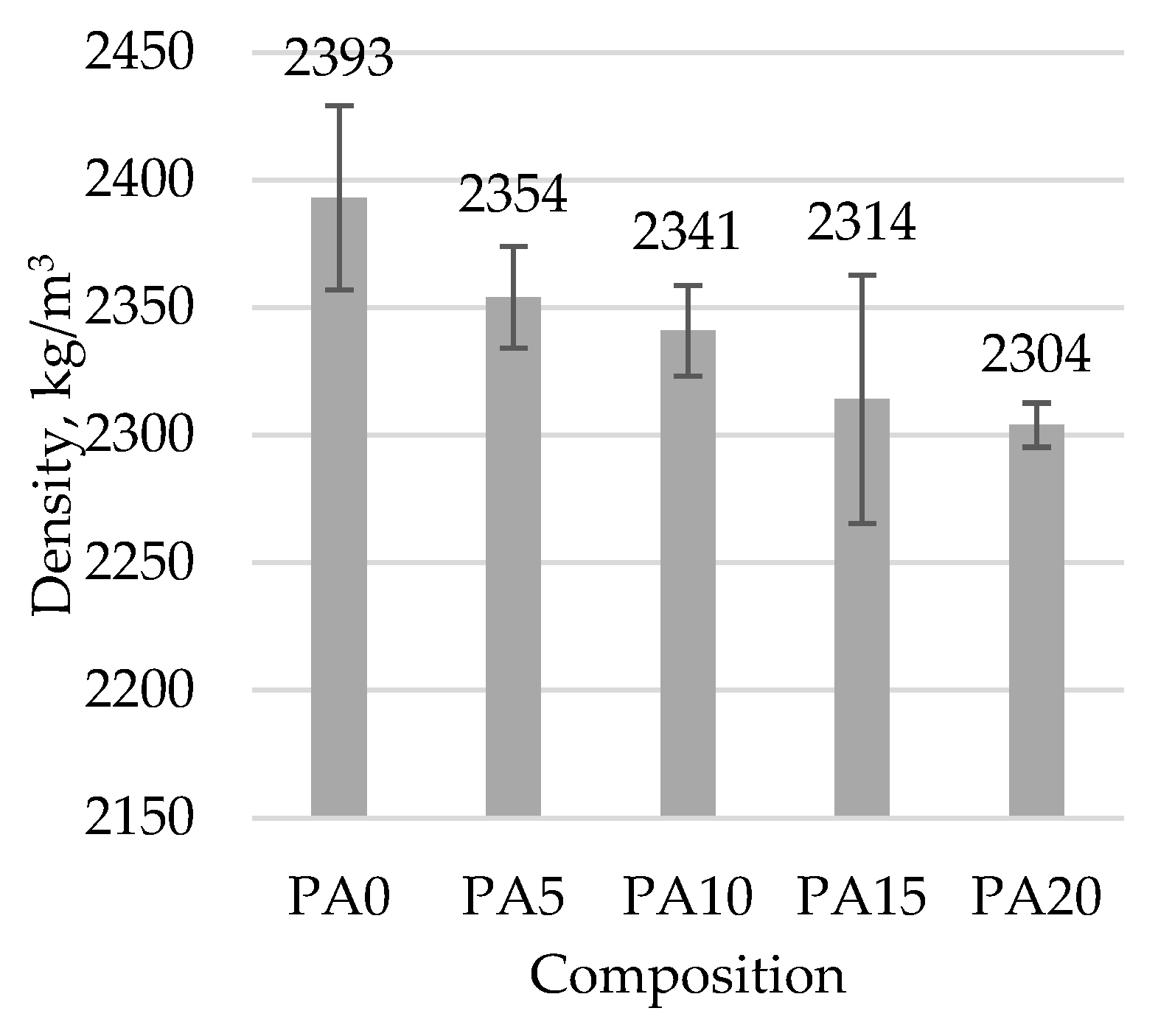

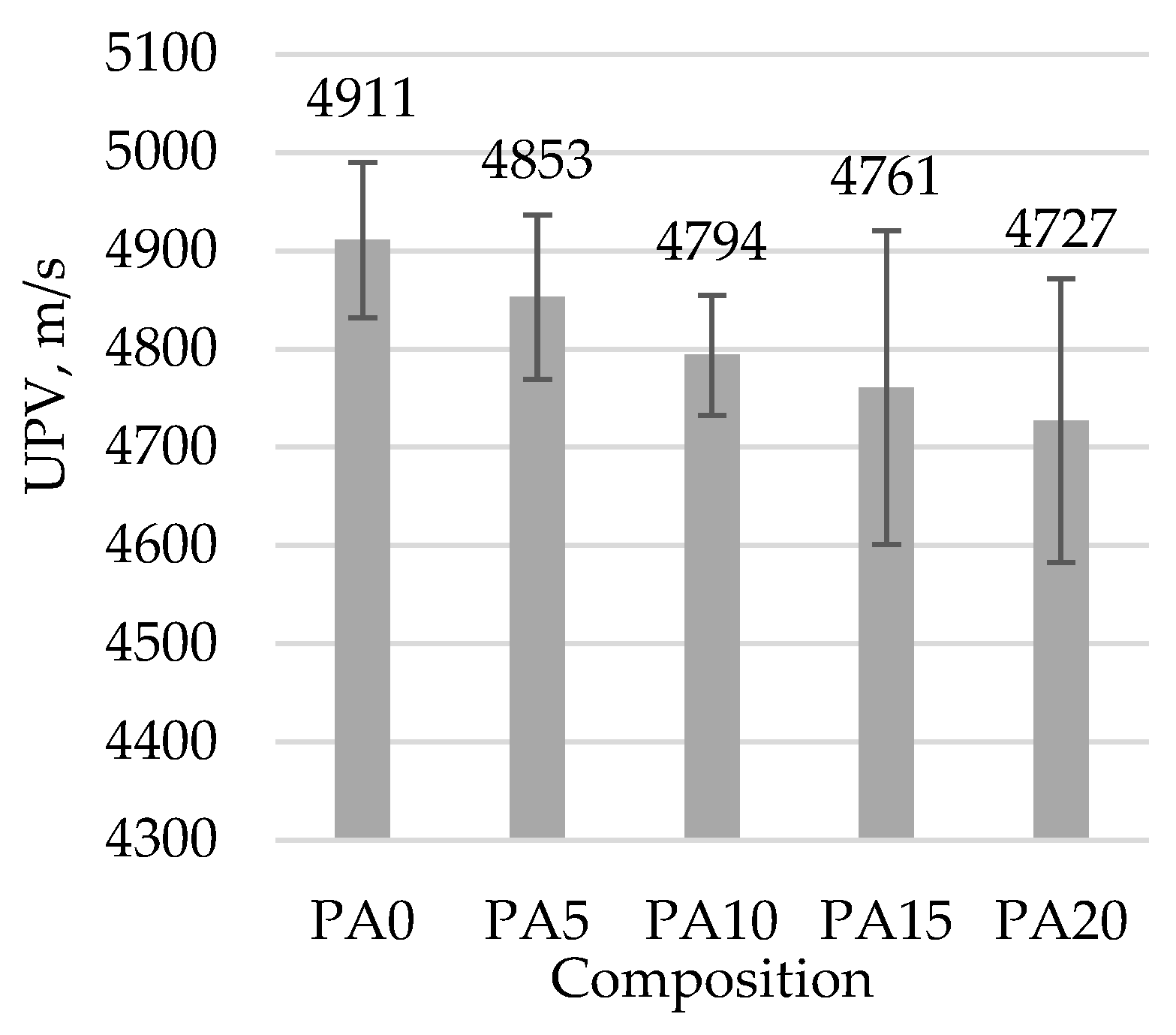

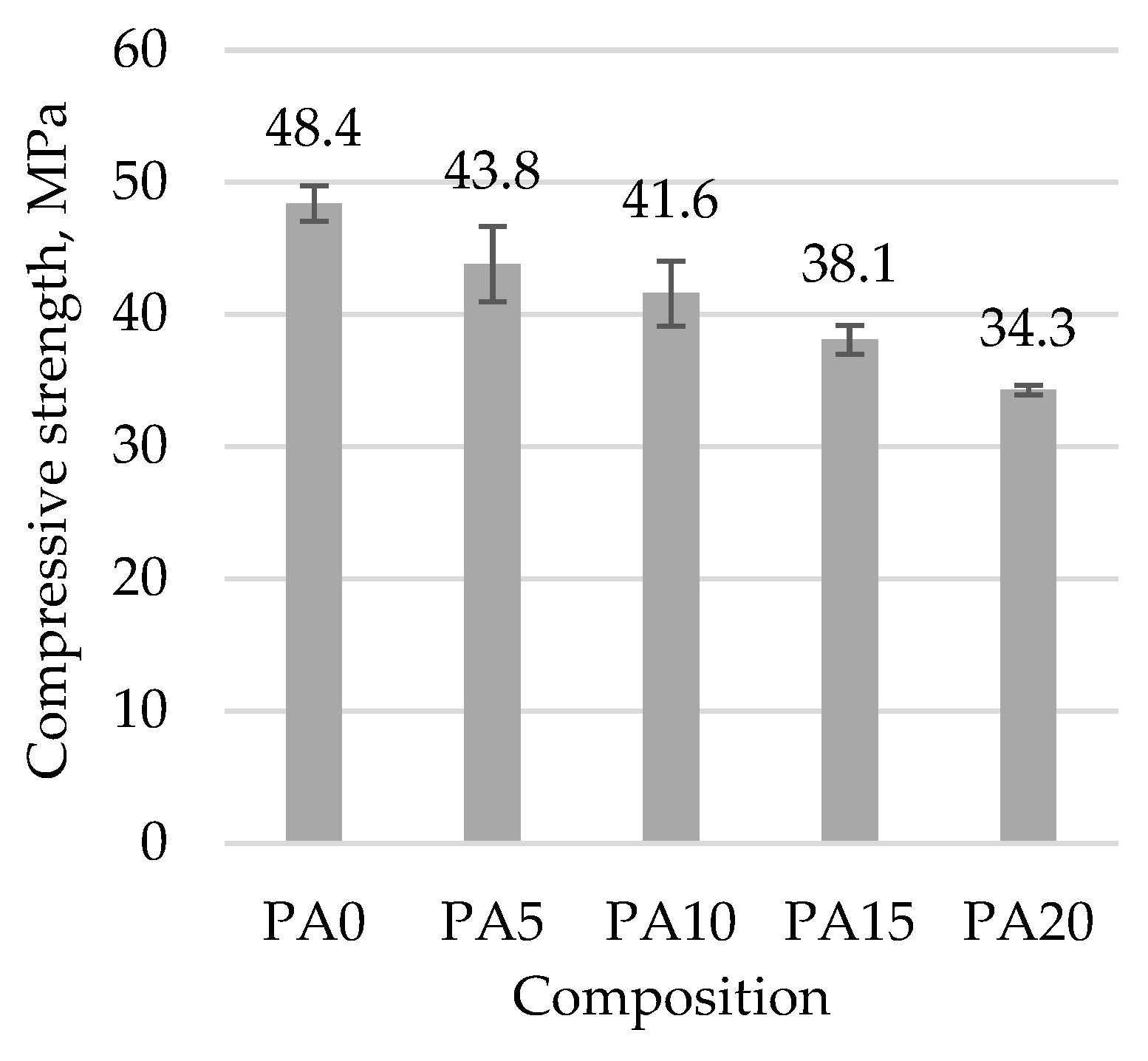

3.2. Physical and Mechanical Properties of Concrete

3.3. Concrete Water Absorption

3.4. Porosity

3.5. Frost Resistance

3.6. Assessment of Concrete Surface

4. Conclusions

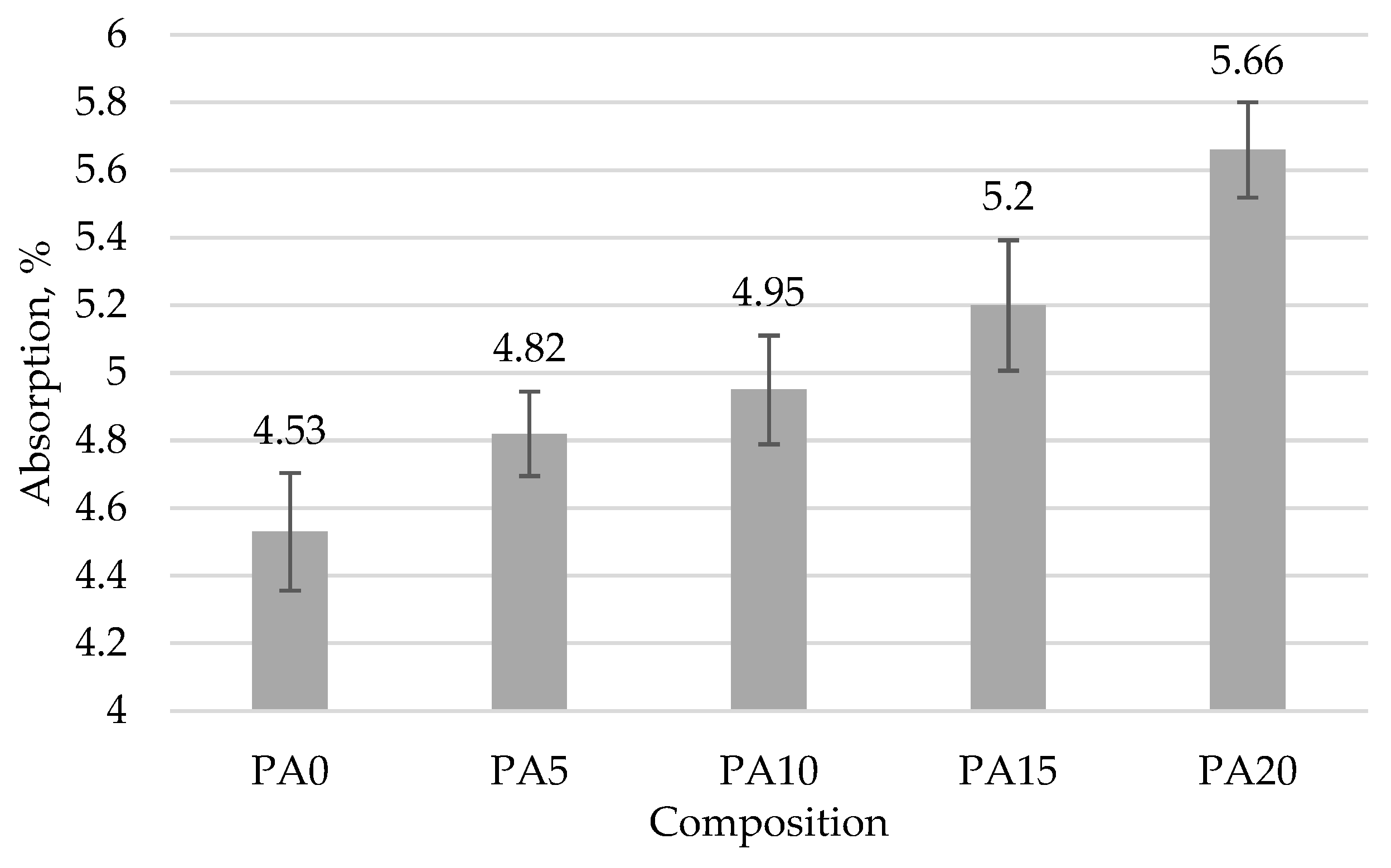

- The incorporation of NPA causes air entrainment in the PC mixture (3.8% in the reference composition, 4.6% in the composition with 15% NPA). A low amount of NPA added increases the slump of the mixture. The addition of NPA reduces the density of hardened concrete and increases water absorption due to the lower specific density of NPA compared to the PC density.

- The early compressive strength test results (at 7 days) showed that NPA deteriorates mechanical properties. The compressive strength gradually decreased, reaching a 29% drop in the specimens with the highest NPA content of 20%. Similar trends were observed in adjusted early compressive strength test results. Consistent with the findings of other authors, the test results suggest that pozzolanic reactions of NPA often occur in late stages of hydration, i.e., after 14 or more days.

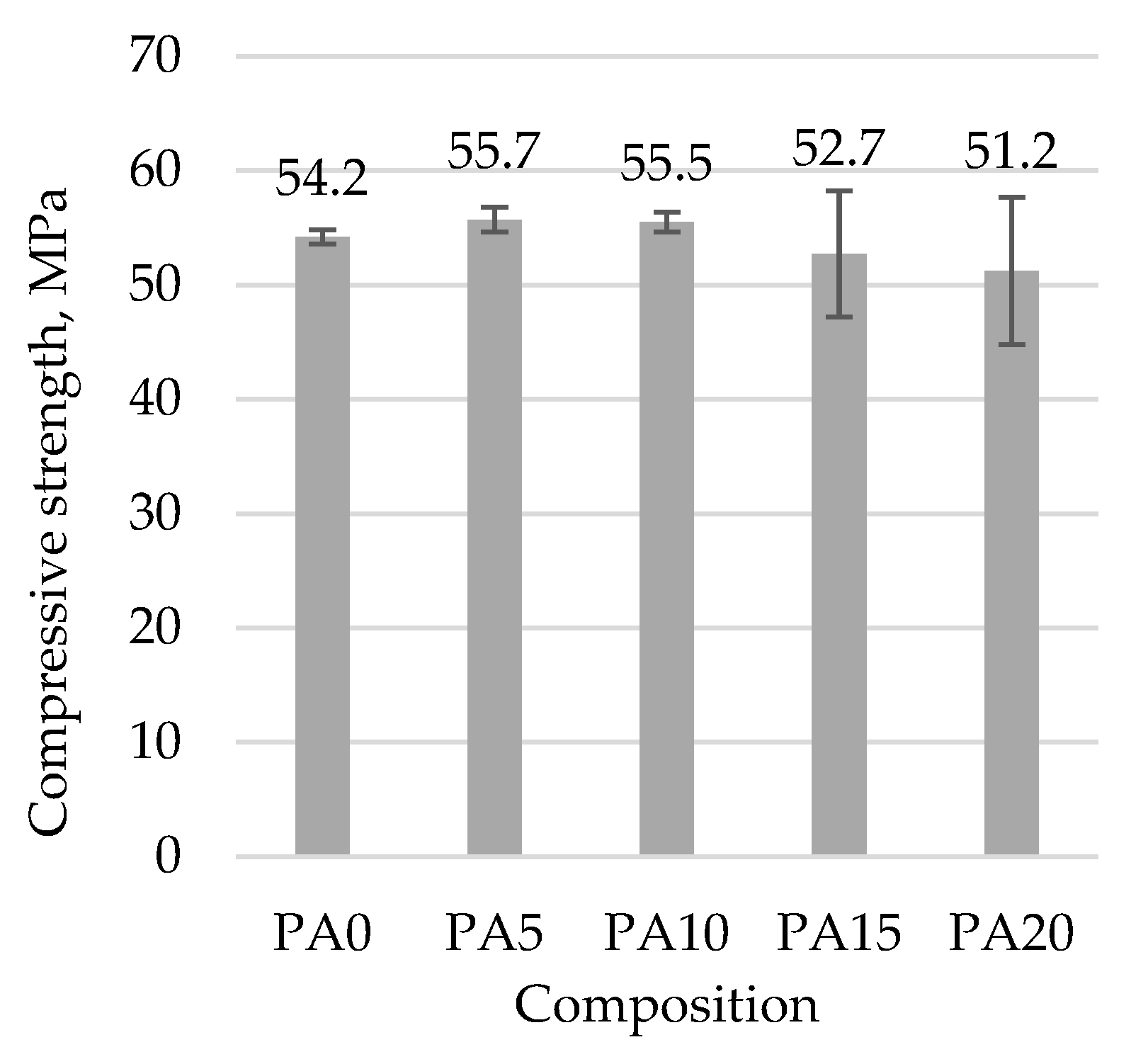

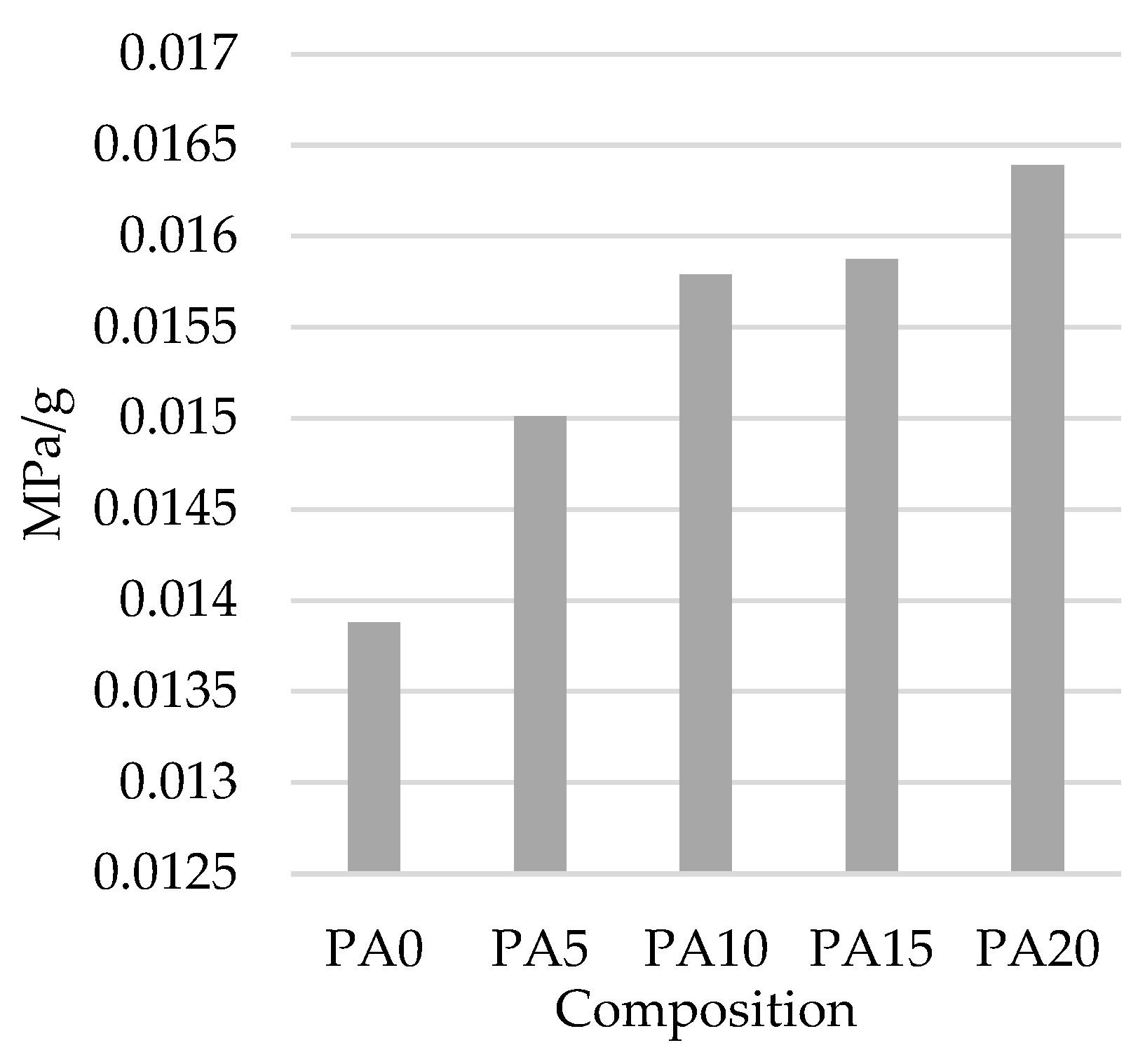

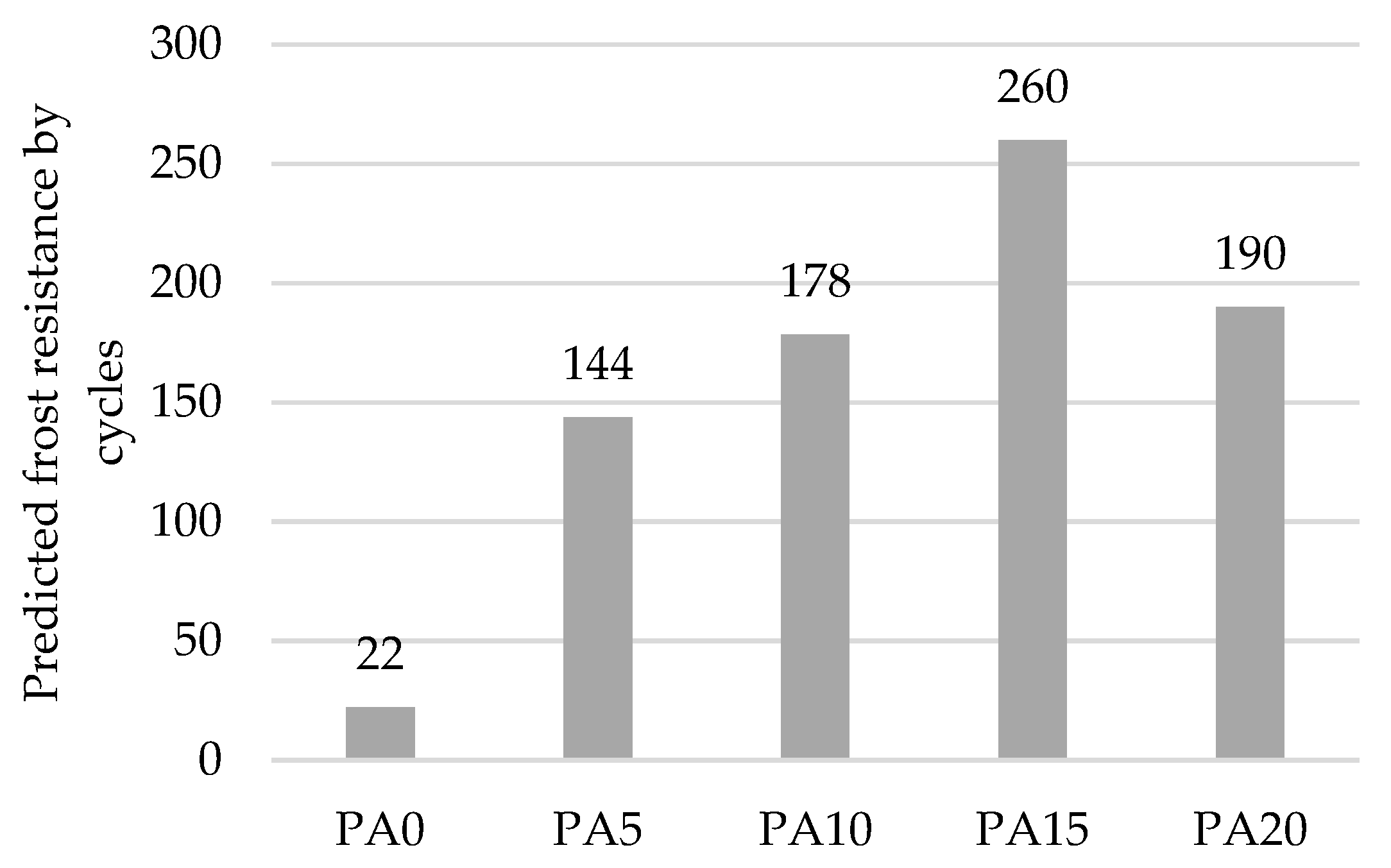

- In the specimens modified with 5% NPA (after 28 days), the compressive strength increased by 2.7%. When PC was replaced with 10% NPA, the compressive strength decreased slightly to 55.5 MPa. After the adjustment (recalculation) of strength results per unit weight of PC, the compressive strength of all specimens modified with up to 20% NPA was higher than the strength of the reference specimen.

- The replacement of 5% PC with NPA caused a 13.13% increase in the total porosity. The open porosity also increased to 11.35%, and the closed porosity increased significantly to 1.14%. Similar trends were observed in the specimens modified with 10–15% NPA, where open and closed porosity values increased along with the total porosity. The closed porosity decreased in the specimens with a higher NPA content of 20%, although the total porosity increased. Freeze–thaw test results correlated with porosity test results—concrete with more closed pores was more durable and, thus, could sustain more freeze–thaw cycles. The porosity tests suggest that 15% is the optimum/maximum amount of NPA that can be added by weight to PC to produce durable concrete.

- The surface finish of NPA-modified concrete was evaluated by quantifying air voids, determining the largest effective air void diameter, and calculating the air void square area and the ratio between the air void square area and the surface area assessed. A proportion of 15% NPA can be added to obtain an excellent surface finish in the exposed concrete. Concrete specimens containing 15% NPA had a warmer beige hue, different from the dark grey colour of reference specimens.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Al-Kheetan, M.J.; Al-Tarawneh, M.; Ghaffar, H.S.; Chougan, M.; Jweihan, Y.S.; Rahman, M.M. Resistance of hydrophobic concrete with different moisturecontents to advanced freeze–thaw cycles. Struct. Concr. 2020, 22, E1050–E1061. [Google Scholar]

- Pereira, C.L.; Savastano, H.J.; Paya Bernabeu, J.J.; Santos, S.F.; Borrachero Rosado, M.V.; Monzó Balbuena, J.M.; Soriano Martinez, L. Use of highly reactive rice husk ash in the production of cement matrixreinforced with green coconut fiber. Ind. Crops Prod. 2013, 49, 88–96. [Google Scholar] [CrossRef]

- İpek, S. Macro and micro characteristics of eco-friendly fly ash-based geopolymer composites made ofdifferent types of recycled sand. J. Build. Eng. 2022, 52, 104431. [Google Scholar] [CrossRef]

- Öz, H.Ö.; Yücel, H.E.; Güneş, M.; Köker, T.Ş. Fly-ash-based geopolymer composites incorporating cold-bonded lightweight fly ash aggregates. Constr. Build. Mater. 2021, 272, 121963. [Google Scholar] [CrossRef]

- Niş, A.; Eren, N.A.; Çevik, A. Effects of recycled tyre rubber and steel fibre on the impact resistance of slag-based self-compacting alkali-activated concrete. Eur. J. Environ. Civ. Eng. 2023, 27, 519–537. [Google Scholar] [CrossRef]

- de Brito, J.; Kurda, R. The past and future of sustainable concrete: A critical review and new strategies on cement-based materials. J. Clean. Prod. 2021, 281, 123558. [Google Scholar]

- Singh, N.; Mithulraj, M.; Arya, S. Utilization of coal bottom ash in recycled concrete aggregates based self-compacting concrete blended with metakaolin. Resour. Conserv. Recycl. 2019, 144, 240–251. [Google Scholar] [CrossRef]

- Mangi, S.A.; Wan Ibrahim, M.H.; Jamaluddin, N.; Arshad, M.F.; Putra Jaya, R. Short-term effects of sulphate and chloride on the concrete containing coal bottom ash as supplementary cementitious material. Eng. Sci. Technol. Int. J. 2019, 22, 515–522. [Google Scholar] [CrossRef]

- Al-Yousuf, A.; Pokharel, T.; Lee, J.; Gad, E.; Abdouka, K.; Sanjayan, J. Effect of fly ash and slag on properties of normal and high strength concrete including fracture energy by wedge splitting test: Experimental and numerical investigations. Constr. Build. Mater. 2021, 271, 121553. [Google Scholar] [CrossRef]

- Zhang, J.; Ding, X.; Wang, Q.; Zheng, X. Effective solution for low shrinkage and low permeability of normal strength concrete using calcined zeolite particles. Constr. Build. Mater. 2018, 160, 57–65. [Google Scholar] [CrossRef]

- Khan, M.N.N.; Saha, A.K.; Sarker, P.K. Reuse of waste glass as a supplementary binder and aggregate for sustainable cement-based construction materials: A review. J. Build. Eng. 2020, 28, 101052. [Google Scholar] [CrossRef]

- El-Gamal, S.M.A.; Amin, M.S.; Ramadan, M. Hydration characteristics and compressive strength of hardened cement pastes containing nano-metakaolin. HBRC J. 2017, 13, 114–121. [Google Scholar] [CrossRef]

- Cook, D.J. Natural pozzolanas. In Cement Replacement Materials; Swamy, R.N., Ed.; Surrey University Press: Surrey, UK, 1986; p. 259. [Google Scholar]

- Martinez-Ramirez, S.; Blanco-Varela, M.T.; Erena, I.; Gener, M. Pozzolanic reactivity of zeolitic rocks from different Cuban deposits: Characterisation of reaction products. Appl. Clay Sci. 2006, 32, 40–52. [Google Scholar] [CrossRef]

- Martens, G.; Snellings, R.; van Balen, K.; Bicer-Simsir, B.; Verlooy, P.; Elsen, J. Pozzolanic reactions of common natural zeolites with lime and parameters affecting their reactivity. Cem. Concr. Res. 2009, 39, 233–240. [Google Scholar] [CrossRef]

- Chandra Paul, S.; Šavija, B.; Babafemi, A.J. A comprehensive review on mechanical and durability properties of cement-based materials containing waste recycled glass. J. Clean. Prod. 2018, 198, 891–906. [Google Scholar] [CrossRef]

- Rojas, M.F.; Cabrera, J. The effect of temperature on the hydration rate and stability of the hydration phases of metakaolin-lime-water systems. Cem. Concr. Res. 2002, 32, 133–138. [Google Scholar] [CrossRef]

- Shi, C. Pozzolanic reaction and microstructure of chemical activated lime-fly ash pastes. ACI Mater. J. 1998, 95, 537–545. [Google Scholar]

- Janotka, I.; Krajci, L. Utilization of natural zeolite in Portland cement of increased sulphate resistance. ACI Spec. Publ. 2003, 22, 223–229. [Google Scholar]

- Ahmadi, B.; Shekarchi, M. Use of natural zeolite as a supplementary cementitious material. Cem. Concr. Compos. 2010, 32, 134–141. [Google Scholar] [CrossRef]

- Payra, P.; Dutta, P.K. Zeolites: A primer. In Handbook of Zeolite Science and Technology; CRC Press: Boca Raton, FL, USA, 2003; pp. 1–24. [Google Scholar]

- Muraoka, K.; Chaikittisilp, W.; Okubo, T. Energy analysis of aluminosilicate zeolites with comprehensive ranges of framework topologies. Chemical Compositions, and Aluminum Distributions. J. Am. Chem. Soc. 2016, 138, 6184–6193. [Google Scholar] [CrossRef]

- Rahhal, V.F.; Pavlík, Z.; Tironi, A.; Castellano, C.C.; Trezza, M.A.; Černý, R.; Irassar, E.F. Effect of cement composition on the early hydration of blended cements with natural zeolite. J. Therm. Anal. Calorim. 2017, 128, 721–733. [Google Scholar] [CrossRef]

- Stanislao, C.; Rispoli, C.; Vola, G.; Cappelletti, P.; Morra, V.; Gennaro, M. Contribution to the knowledge of ancient Roman seawater concretes: Phlegrean pozzolan adopted in the construction of the harbour at Soli-Pompeiopolis (Mersin. Turkey). Period Miner. 2011, 80, 471–488. [Google Scholar]

- Mumpton, F.A. Natural zeolites. In Mineralogy and Geology of Natural Zeolites; Mumpton, F.A., Ed.; Mineralogical Society of America: Chantilly, VA, USA, 1981; pp. 1–18. [Google Scholar]

- Ulmanu, M. Mineralogy of natural zeolites. In Handbook of Natural Zeolites; Inglezakis, V.J., Zorpas, A.A., Eds.; Bentham Science Publishers: Sharjah, The United Arab Emirates, 2012; pp. 52–69. [Google Scholar]

- Feng, N.Q.; Li, G.Z.; Zang, X.W. High-strength and flowing concrete with a zeolitic mineral admixture. Cem. Concr. Aggreg. 1990, 12, 61–69. [Google Scholar] [CrossRef]

- Fragoulis, D.; Chaniotakis, E.; Stamatakis, M.G. Zeolitic tuffs of Kimolos Island, Aegean Sea, Greece and their industrial potential. Cem. Concr. Res. 1997, 27, 889–905. [Google Scholar] [CrossRef]

- Uzal, B.; Turanli, L. Blended cements containing high volume of natural zeolites: Properties, hydration and paste microstructure. Cem. Concr. Compos. 2012, 34, 101–109. [Google Scholar] [CrossRef]

- Valipour, M.; Pargar, F.; Shekarchi, M.; Khani, S. Comparing a natural pozzolan, zeolite, to metakaolin and silica fume in terms of their effect on the durability characteristics of concrete: A laboratory study. Constr. Build. Mater. 2013, 41, 879–888. [Google Scholar] [CrossRef]

- Vejmelková, E.; Koňáková, D.; Kulovaná, T.; Keppert, M.; Žumár, J.; Rovnaníková, P.; Keršner, Z.; Sedlmajer, M.; Černý, R. Engineering properties of concrete containing natural zeolite as supplementary cementitious material: Strength, toughness, durability, and hygrothermal performance. Cem. Concr. Compos. 2015, 55, 259–267. [Google Scholar] [CrossRef]

- Tran, Y.T.; Lee, J.; Kumar, P.; Kim, K.H.; Lee, S.S. Natural zeolite and its application in concrete composite production. Compos. Part B Eng. 2019, 165, 354–364. [Google Scholar] [CrossRef]

- Takemoto, K.; Uchikawa, H. Hydration of pozzolanic cement. In 7th International Congress on the Chemistry of Cement; Éditions Septima: Paris, France, 1980; Volume 1, pp. IV-2/1–IV-2/29. [Google Scholar]

- Nguyen, Q.H.; Lorente, S.; Duhard-Barone, A. Effect of the pore size of cement based materials on ionic transport. Constr. Build. Mater. 2017, 147, 160–167. [Google Scholar] [CrossRef]

- Neithalath, N.; Jain, J. Relating rapid chloride transport parameters of concretes to microstructural features extracted from electrical impedance. Cem. Concr. Res. 2010, 40, 1041–1051. [Google Scholar] [CrossRef]

- Sant, G.; Bentz, D.; Weiss, J. Capillary porosity depercolation in cement-based materials: Measurement techniques and factors which influence their interpretation. Cem. Concr. Res. 2011, 41, 854–864. [Google Scholar] [CrossRef]

- Yu, Z.; Ni, C.; Tang, M.; Shen, X. Relationship between water permeability and pore structure of Portland cement paste blended with fly ash. Constr. Build. Mater. 2018, 175, 458–466. [Google Scholar] [CrossRef]

- Zhang, J.; Bian, F.; Zhang, Y.; Fang, Z.; Fu, C.; Guo, J. Effect of pore structures on gas permeability and chloride diffusivity of concrete. Constr. Build. Mater. 2018, 163, 402–413. [Google Scholar] [CrossRef]

- Bernal Camacho, J.; Mahmoud Abdelkader, S.; Reyes Pozo, E.; Moragues Terrades, A. The influence of ion chloride on concretes made with sulfate-resistant cements and mineral admixtures. Constr. Build. Mater. 2014, 70, 483–493. [Google Scholar] [CrossRef]

- Pavlík, Z.; Fořt, J.; Pavlíková, M.; Kulovaná, T.; Černý, R. Characterization of Cement Pastes Containing Natural Zeolite as a Pozzolanic Admixture. Appl. Mech. Mater. 2015, 719, 206–209. [Google Scholar] [CrossRef]

- de La Cruz, J.C.; del Campo, J.M.; Colorado, D. Comparative study on porosity and permeability of conventional concrete and concrete with variable proportions of natural zeolite additions. Rev. Constr. 2015, 14, 72–78. [Google Scholar] [CrossRef]

- Bilim, C. Properties of cement mortars containing clinoptilolite as a supplementary cementitious material. Constr. Build. Mater. 2011, 25, 3175–3180. [Google Scholar] [CrossRef]

- Miller, S.A.; Horvath, A.; Ostertag, C.P. Greenhouse gas emissionsfrom concrete can be reducedbyusing mix proportions, geometricaspects, and age as designfactors. Environ. Res. Lett. 2015, 10, 114017–114028. [Google Scholar] [CrossRef]

- Minano, I.; Benito, F.; Parra, C.; Hidalgo, P. Concrete Sustainable Light and of High Performance Sustainable. Dev. Renov. Archit. 2017, 263–273. [Google Scholar] [CrossRef]

- Liu, B.; Yang, T. Image analysis for detection of bugholeson concrete surface. Constr. Build. Mater. 2017, 137, 432–440. [Google Scholar] [CrossRef]

- LST EN 197-1:2011; Cement—Part 1: Composition, Specifications and Conformity Criteria for Common Cements. Lithuanian Standards Board: Vilnius, Lithuania, 2011.

- LST EN 12620:2003+A1:2008; Aggregates for Concrete. Lithuanian Standards Board: Vilnius, Lithuania, 2003.

- LST EN 1008:2003; Mixing Water for Concrete—Specification for Sampling, Testing and Assessing the Suitability of Water, Including Water Recovered from Processes in the Concrete Industry, as Mixing Water for Concrete. Lithuanian Standards Board: Vilnius, Lithuania, 2003.

- LST EN 196-1:2016; Methods of Testing Cement—Part 1: Determination of Strength. Lithuanian Standards Board: Vilnius, Lithuania, 2016.

- LST EN 196-6:2010; Methods of Testing Cement—Part 6: Determination of Fineness. Lithuanian Standards Board: Vilnius, Lithuania, 2010.

- LST EN 12350-7:2009; Testing Fresh Concrete—Part 7: Air Content—Pressure Methods. Lithuanian Standards Board: Vilnius, Lithuania, 2009.

- LST EN 12350-2:2009; Testing Fresh Concrete—Part 2: Slump-Test. Lithuanian Standards Board: Vilnius, Lithuania, 2009.

- LST EN 12390-3:2019; Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens. Lithuanian Standards Board: Vilnius, Lithuania, 2019.

- LST EN 12390-3:2019; Testing Hardened Concrete—Part 4: Compressive Strength—Specification for Testing Machines. Lithuanian Standards Board: Vilnius, Lithuania, 2019.

- LST EN 1015-10:2002; Methods of Test for Mortar for Masonry. Part 10: Determination of Dry Bulk Density of Hardened Mortar. Lithuanian Standards Board: Vilnius, Lithuania, 2002.

- LST EN 13369:2018; Common Rules for Precast Concrete Products. Lithuanian Standards Board: Vilnius, Lithuania, 2018.

- Nagrockiene, D.; Daugela, A. Investigation into the properties of concrete modified with biomass combustion fly ash. Constr. Build. Mater. 2018, 174, 369–375. [Google Scholar] [CrossRef]

- Xu, W.; Chen, J.J.; Wei, J.; Zhang, B.; Yuan, X.; Xu, P.; Yu, Q.; Ren, J. Evaluation of inherent factors on flowability, cohesiveness and strength of cementitious mortar in presence of zeolite powder. Constr. Build. Mater. 2019, 214, 61–73. [Google Scholar] [CrossRef]

- Mehta, P.K. Natural Pozzolans: Supplementary Cementing Materials in Concrete; CANMET Special Publication: Athens, Greece, 1987; pp. 1–33. [Google Scholar]

- Tokushige, H.; Kamehima, H.; Kawakami, M.; Bier, T.A. Effect of use of natural zeolite as a mineral admixture and an aggregate on physical properties of cement mortar and porous concrete. In Proceedings of the 4th International Conference on Construction Materials: Performance, Innovations and Structural Implications, Nagoya, Japan, 24–26 August 2009; pp. 1231–1236. [Google Scholar]

- Ramezanianpour, A.A.; Mousavi, R.; Kalhori, M.; Sobhani, J.; Najimi, M. Micro and macro level properties of natural zeolite contained concretes. Constr. Build. Mater. 2015, 101, 347–358. [Google Scholar] [CrossRef]

- Poon, C.S.; Lam, L.; Kou, S.C.; Lin, Z.S. A study on the hydration rate of natural zeolite blended cement pastes. Constr. Build. Mater. 1999, 13, 427–432. [Google Scholar] [CrossRef]

- Koťátková, J.; Reiterman, P. Long-term properties of special concrete with natural additive. Sustain. Constr. Mater. Technol. 2016, 1, 317–324. [Google Scholar]

- Perraki, T.; Kontori, E.; Tsivilis, S.; Kakali, G. The effect of zeolite on the properties and hydration of blended cements. Cem. Concr. Compos. 2010, 32, 128–133. [Google Scholar] [CrossRef]

- Feng, N.; Yang, H.; Zu, L.-H. The strength effect of mineral admixture on cement concrete. Cem. Concr. Res. 1988, 18, 464–472. [Google Scholar]

- Shekarchi, M.; Libre, N.A.; Ahmadi, B.; Sabet, F.S. An Investigation on the effect of natural zeolite on rheology and stability of self-consolidating mortar. In Proceedings of the 6th International RILEM Symposium Self-Compacting Concrete, Montreal, QC, Canada, 26–29 September 2010; pp. 503–513. [Google Scholar]

- Samimi, K.; Kamali-Bernard, S.; Maghsoudi, A.A.; Lgcgm, S.K.B.; Civil, E. Resistance to chloride penetration of high strength self-compacting concretes: Pumice and zeolite effect. Int. J. Civ. Environ. Eng. 2018, 3, 250–259. [Google Scholar]

- Chan, S.Y.; Ji, X. Comparative study of the initial surface absorption and chloride diffusion of high performance zeolite, silica fume and PFA concretes. Cem. Concr. Compos. 1999, 21, 293–300. [Google Scholar] [CrossRef]

- Jana, D. A new look to an old pozzolan, clinoptilolite–a promising pozzolan in concrete. In Proceedings of the Twenty-ninth Conference on Cement Microscopy, Quebec City, PQ, Canada, 20–24 May 2007; pp. 168–206. [Google Scholar]

- Feng, N.; Feng, X.; Hao, T.; Xing, F. Effect of ultrafine mineral powder on the charge passed of the concrete. Cem. Concr. Res. 2002, 32, 623–627. [Google Scholar] [CrossRef]

- Bentz, D.P.; Jensen, O.M. Mitigation strategies for autogenous shrinkage cracking. Cem. Concr. Compos. 2004, 26, 677–685. [Google Scholar] [CrossRef]

- Lura, P.; Jensen, O.M.; Igarashi, S.I. Experimental observation of internal water curing of concrete. Mater. Struct. 2007, 40, 211–220. [Google Scholar] [CrossRef]

- Lee, H.; Hanif, A.; Usman, M.; Sim, J.; Oh, H. Performance evaluation of concrete incorporating glass powder and glass sludge wastes as supplementary cementing material. J. Clean. Prod. 2018, 170, 683–693. [Google Scholar] [CrossRef]

- Najimi, M.; Sobhani, J.; Ahmadi, B.; Shekarchi, M. An experimental study on durability properties of concrete containing zeolite as a highly reactive natural pozzolan. Constr. Build. Mater. 2012, 35, 1023–1033. [Google Scholar] [CrossRef]

- Ackley, M. Application of natural zeolites in the purification and separation of gases. Microporous Mesoporous Mater. 2003, 61, 25–42. [Google Scholar] [CrossRef]

- Markiv, T.; Sobol, K.; Franus, M.; Franus, W. Mechanical and durability properties of concretes incorporating natural zeolite. Arch. Civ. Mech. Eng. 2016, 16, 554–562. [Google Scholar] [CrossRef]

- Milovic, T.; Šupic, S.; Malešev, M.; Radonjanin, V. The Effects of Natural Zeolite as Fly Ash Alternative on Frost Resistance and Shrinkage of Blended Cement Mortars. Sustainability 2022, 14, 2736. [Google Scholar] [CrossRef]

- Kwasny, J.; Sonebi, M.; Amziane, S.; Plasse, J. Effect of mix composition on rheology and surface finish of cementbased mortars. Constr. Build. Mater. 2015, 89, 102–109. [Google Scholar] [CrossRef]

- Hilal, A.A.; Thom, N.H.; Dawson, A.R. On entrained pore size distribution of foamed concrete. Constr. Build. Mater. 2015, 75, 227–233. [Google Scholar] [CrossRef]

- Harding, M.A. Vibrating Concrete in Wall Forms. Concr. Constr. 1995, 40, 180–184. [Google Scholar]

- Samuelsson, P. Voids in Concrete Surfaces. ACI J. 1970, 67, 868–874. [Google Scholar]

- Han, L.H.; Yao, G.H. Influence of concrete compaction on the strength of concrete-filled steel RHS columns. J. Constr. Steel Res. 2003, 59, 751–767. [Google Scholar] [CrossRef]

- Tastani, S.P.; Balafas, I.; Dervisis, A.; Pantazopoulou, S.J. Effect of core compaction on deformation capacity of FRP-jacketed concrete columns. Constr. Build. Mater. 2013, 47, 1078–1092. [Google Scholar] [CrossRef]

| Binders | Oxide Content, % | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| CaO | SiO2 | Al2O3 | Fe2O3 | MgO | SO3 | K2O | Na2O | LOI | |

| PC | 61.4 | 19.5 | 5.0 | 3.1 | 3.9 | 2.5 | 1.1 | 0.1 | 3.4 |

| NPA | 3.3 | 72.5 | 12.5 | 1.7 | 0.6 | - | 3.6 | 0.2 | 5.6 |

| Properties | PC | NPA |

|---|---|---|

| Specific density, kg/m3 | 3150 | 2350 |

| Average particle size, μm | 17.6 | 29.0 |

| Specific surface area, m2/kg | 440 | 760 |

| Essential Characteristics | Declared/Limit Value |

|---|---|

| Grain size (fraction) | 0/4 |

| Particle density | 2650 kg/m3 |

| Fineness modulus | 4.0 |

| Fines content | f3 |

| Organic impurities (humus) | none |

| Essential Characteristics | Declared/Limit Value |

|---|---|

| Grain size (fraction) | 4/16 |

| Particle density | 2600 kg/m3 |

| Fines content | f1.5 |

| Freeze–thaw resistance | F1 |

| Organic impurities (humus) | none |

| Compositions | PA0 | PA5 | PA10 | PA15 | PA20 |

|---|---|---|---|---|---|

| PC | 355.00 | 337.27 | 319.55 | 301.82 | 284.00 |

| NPA | - | 17.75 | 35.50 | 53.25 | 71.00 |

| NPA, % | 0 | 5 | 10 | 15 | 20 |

| Sand | 890 | 890 | 890 | 890 | 890 |

| Gravel | 1025 | 1025 | 1025 | 1025 | 1025 |

| Plasticiser | 2.84 | 2.84 | 2.84 | 2.84 | 2.84 |

| Water | 174.64 | 174.64 | 174.64 | 174.64 | 174.64 |

| W/C | 0.49 | 0.52 | 0.55 | 0.58 | 0.61 |

| Composition | Air Void Quantity | Largest Effective Air Void Diameter, mm | Air Void Sq. Area (mm2): | Ratio of Air Void Sq. Area to Assessed Surface Area |

|---|---|---|---|---|

| PA0 | 9 | 4.77 | 69 | 0.19 |

| PA5 | 7 | 4.71 | 58 | 0.16 |

| PA10 | 12 | 4.34 | 74 | 0.21 |

| PA15 | 11 | 4.45 | 74 | 0.21 |

| PA20 | 27 | 6.17 | 212 | 0.60 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Girskas, G.; Kriptavičius, D.; Kizinievič, O.; Malaiškienė, J. Effect of Pozzolanic Additive on Properties and Surface Finish Assessment of Concrete. Buildings 2025, 15, 1617. https://doi.org/10.3390/buildings15101617

Girskas G, Kriptavičius D, Kizinievič O, Malaiškienė J. Effect of Pozzolanic Additive on Properties and Surface Finish Assessment of Concrete. Buildings. 2025; 15(10):1617. https://doi.org/10.3390/buildings15101617

Chicago/Turabian StyleGirskas, Giedrius, Dalius Kriptavičius, Olga Kizinievič, and Jurgita Malaiškienė. 2025. "Effect of Pozzolanic Additive on Properties and Surface Finish Assessment of Concrete" Buildings 15, no. 10: 1617. https://doi.org/10.3390/buildings15101617

APA StyleGirskas, G., Kriptavičius, D., Kizinievič, O., & Malaiškienė, J. (2025). Effect of Pozzolanic Additive on Properties and Surface Finish Assessment of Concrete. Buildings, 15(10), 1617. https://doi.org/10.3390/buildings15101617