Abstract

This study explores the application of wood ash (WA) as a partial replacement for PC in mortar. Three pre-treatment methods were applied to WA to enhance its reactivity, and it was then incorporated into mortar at two different substitution levels of 10 and 30%. Tests on compressive and flexural strength were conducted on the hardened mortar samples. All hardened mortar samples containing WA showed a decrease in mechanical properties compared to the reference sample without WA. The highest compressive and flexural strength of the samples with WA were observed for those containing 10% of sieved and slaked WA. The compressive and flexural strength of these samples after 28 days were 56 and 9 MPa, respectively, whereas those of the reference samples were 62 and 10 MPa, respectively. Based on the results, the best-performing samples on the compressive test underwent additional testing for freeze–thaw resistance to assess their durability. The mass loss of the reference sample and that with 10% of sieved and slaked WA after 56 freeze–thaw cycles was 11,800 and 13,800 g/m2, respectively. The findings revealed that increasing the proportion of WA typically led to a decline in the mechanical properties of mortar compared to conventional mixtures. However, with appropriate pre-treatment techniques, the quality and performance of mortar containing WA were significantly improved, demonstrating its potential as a sustainable alternative in reducing the carbon footprint of PC production.

1. Introduction

Portland cement (PC) is one of the most used materials in the concrete industry [1]. The production of PC is considered highly polluting and emits high amounts of greenhouse gasses. The production of PC alone emits up to 9% of the total anthropogenic CO2 amount and depletes a huge amount of natural resources [2]. To reduce the global CO2 emissions, blended cements have been developed, where some clinker is replaced with other materials [3]. Traditionally, coal fly ash, a by-product of coal combustion in thermal power plants, has been widely used as a supplementary cementitious material due to its pozzolanic properties and ability to enhance concrete durability, reduce permeability, and improve workability. However, with the global shift away from coal-fired power generation driven by decarbonization efforts and stricter environmental policies, the availability of coal fly ash has become increasingly constrained. For example, many developed nations, including those in the EU and North America, have significantly reduced their reliance on coal for energy, leading to a scarcity of this once-abundant by-product.

In the last few years, the demand for wood as a renewable energy source has risen to achieve the goals of the European Green Deal and the 2030 Climate Target Plan. Biomass as a fuel source is considered carbon-neutral as the amount of carbon dioxide which is produced by biomass burning equals the total amount of CO2 fixed during the biomass growth process that occurs through photosynthesis [4]. In total, about 95–97% of the world’s bioenergy is produced by the direct combustion of biomass, which leads to approximately 476 million tons of biomass ash (BA) generated worldwide annually [5]. Using BA as a partial PC replacement minimizes the use of non-renewable resources, mitigates greenhouse gas emissions, and is a good solution for ash management [6]. In parallel, the use of biomass as a renewable energy source has grown significantly, with biomass combustion now replacing coal in many heating and power generation facilities. This transition has resulted in a corresponding increase in the production of BA, including wood ash (WA), rice husk ash, and sugarcane bagasse ash. These by-products are gaining attention as alternative supplementary materials (SCMs) due to their environmental benefits and pozzolanic potential [7].

To address the environmental effects that are related to cement manufacturing, the possibility of using SCMs to develop sustainable mortars and concrete needs to be emphasized. The use of WA as an SCM for the partial replacement of cement has economic, technical, and environmental benefits, such as the conservation of natural resources and a reduction in greenhouse gas emissions in the cement industry [8]. Partially replacing cement with WA will contribute to the global demand for carbon-efficient solutions that reduce CO2 emissions and utilize waste, which is consistent with the goals of the Paris Agreement [9]. Research has demonstrated that certain types of BA, when processed and characterized appropriately, can react with calcium hydroxide, forming calcium silicate hydrates (C-S-H) like those in PC [10]. This reaction not only helps improve the mechanical properties of mortars but also addresses the issue of disposing of biomass combustion residues, promoting a circular economy [1,11]. Recent studies reveal that in general, mechanical properties, such as the compressive and bending strengths of concrete, in which part of cement is replaced with WA, decrease with an increase in the content of WA. However, it is possible to maintain or even improve the mechanical properties of concrete containing WA, compared to conventional concrete, when pre-treatment is applied to WA. Pre-treatment techniques such as sieving, grinding, washing, calcination, and chemical activation improve the reactivity and compatibility of WA with PC [12,13,14]. Several studies have shown that incorporating pre-treated BA at a replacement level of up to 20% by mass can achieve comparable or even superior concrete properties while significantly reducing the carbon footprint associated with PC production [14]. These innovations are paving the way for more sustainable and resource-efficient practices in the construction industry. In the work of N. Ristić [15], the compressive strength of concrete samples containing 10% WA was higher than that of the reference mixture by 1.4% and 3.2% at 28 and 90 days, respectively. This effect at longer curing ages was attributed to internal curing, which was provided by WA, and to the higher compactness of concrete due to the reduced amount of free water in the mixture. Meanwhile, in the work of Z. Yang [16], the compressive strength of all the concrete samples with WA was reduced compared to the reference sample. Overall, the use of WA as an SCM to partially replace PC offers the possibility of inserting this waste into the production chain and an alternative method for the disposal of WA. However, due to the chemical and physical characteristics of WA that depend on several factors such as combustion temperature, wood type, furnace type, and burning conditions, before incorporating WA in mortars, these characteristics should be investigated. According to available research, the most optimal replacement percentage for WA is between 5 and 20%, where the best results are obtained with 10% replacement [14].

To better understand the chemical interaction between WA particles and those of cement, it is valuable to incorporate techniques such as FTIR and XRD. The FTIR spectrum results of hardened mortars can be used to characterize compressive strength fluctuations by determining the peak intensity of the bonds that are responsible for strength [17]. In other studies, the peak intensity changes in the bonds, such as Si-O and O-H, of a reference mortar and a mortar containing WA were analyzed [18,19]. To assess the degree of hydration in mortars at different curing times, XRD results can be used [19,20].

In this research, the influence of WA as a partial PC replacement on mortar properties, such as compressive strength, bending strength, and freeze–thaw resistance, were assessed. Three pre-treatment methods, including sieving, sieving/slaking, and sieving/grinding, were applied to WA and used at the same replacement levels of 10 and 30% in mortars in order to compare the influence of them on mechanical properties. The main aim of this study is to understand the changes in mortar properties when the same WA is pre-treated with different methods and used as a partial cement replacement.

2. Materials and Methods

2.1. Wood Ash Characterization

The WA used in the study was collected from the thermal plant Gren Latvia Ltd. (Jelgava, Latvia). The chemical composition was studied by X-ray fluorescence (XRF). The crystalline phases of WA were identified by X-ray diffraction (XRD) analysis. The size and shape of WA were analyzed by using variable pressure scanning electron microscopy (VP-SEM). In addition, energy-dispersive X-ray (EDX) analysis was performed in order to characterize the elemental composition of WA. The particle size distribution was determined by using the sieving method according to the LVS EN 933-1 standard [21].

2.2. Raw Materials and Mixture Designs

In this research, locally manufactured pure PC (>95% of cement) with the brand name Schwenk (Broceni, Latvia) CEM I 42.5 N, meeting the European Union and Latvian State standards governing the composition, specifications, and compliance criteria of the cement (LVS EN 197-1:2012 [22]), was used. The chemical composition of this PC is given in Table 1. Sand was obtained from the local manufacturer Sakret Ltd. (Riga, Latvia) with a grain size of 0–2 mm. This sand fraction is specifically manufactured for mortar applications and has an optimized particle size distribution. To improve workability and reduce cracking, liquid superplasticizer Vincents Polyline Floormix was used in the same amount in all mortar samples.

Table 1.

Chemical composition of PC.

Three mortar series with different WA treatment methods were created, and the following WA treatment procedures were applied:

- (1)

- In the first mortar series (WA1), the WA sample portion was subjected to sieving through a 2 mm sieve in order to separate unburnt carbon particles.

- (2)

- In the second mortar series (WA2), the WA sample portion was sieved through a 2 mm sieve and slaked in order to prevent the ash from swelling [23]. To avoid this phenomenon, WA was immersed in water for 24 h with a water–ash weight ratio of 1. A WA2 slurry was included in the mixture composition and water adjusted to the needed amount.

- (3)

- In the third mortar series (WA3), the WA sample was sieved and ground by using a planetary ball mill Retsch PM400 (Dusseldorf, Germany) for 10 min at 300 rpm. Before the milling process, WA3 was dried to avoid the clumping of WA particles.

The mixture compositions of mortar samples and their designations are given in Table 2. In total, 7 mortar mixtures were prepared. WA was incorporated to replace 10 or 30% by mass of PC. The amount of water and plasticizer was constant in all mixtures with WA and was not affected by the applied WA treatment method. The sand–PC ratio increased for the mixtures with a higher WA replacement level from 2.0 to 2.9, while the total sand–(PC + WA) ratio remained the same (2.0).

Table 2.

Mixture compositions of mortar with WA as supplementary cementitious material.

2.3. Hardened Mortar Properties

Compressive and bending strengths for all mortar samples were determined according to the LVS EN 196-1 standard [24]. Hardened mortar specimens were produced in 40 × 40 × 160 mm steel molds. The mortar specimens were removed from the molds 24 h after production and placed in water. Strength tests were carried out after 2, 7, and 28 days. A three-point bending test was performed with a span of 100 mm and a test speed of 0.5 mm/min by using a WDW-20 20 kN testing machine (Jinan Hensgrand Instrument Co., Ltd., Jinan, China). A compressive test on 62.5 × 40 × 40 mm mortar specimens was performed with a test speed of 0.8 MPa/s by using a Controls 3000 kN compression machine. Freeze–thaw resistance was determined for the mixture WA2-10%. A freeze–thaw test was carried out according to the Latvian standard LVS CEN/TS 12390-9 requirements [25]. During the freeze–thaw test, five surfaces of a mortar cube of 10 × 10 × 10 cm were covered with a waterproofing material. The exposed face of the mortar cube was immersed in a 3% sodium chloride solution. The freeze–thaw mass loss was determined after 14, 28, and 56 cycles, with each cycle including 12 h of freezing to −20 °C and 12 h of thawing to 20 °C.

3. Results

3.1. XRF and XRD Results of WA

In this research, the standards applied to coal ash utilization in mortars were used as a basis for the characterization of WA [1]. The chemical compositions of the studied WA are presented in Table 3. The obtained results show a dominant content of SiO2 (49.6%), followed by CaO (20.9%). Many types of biomasses, such as wood, agricultural residues, and grasses, naturally contain significant amounts of calcium in their structure. This calcium is absorbed from soil during the plant’s growth and is present in the form of calcium salts, such as calcium carbonate (CaCO3) and calcium oxalate. During combustion, these compounds decompose, forming calcium oxide (CaO) in the ash [26].

Table 3.

Chemical composition and LOI of WA.

The sum of the total amount of SiO2, Al2O3, and Fe2O3 was 55% by mass, which was lower than the minimal amount of 70% by mass specified by ASTM C 618 [27] and EN 450-1 [28] to be classified as a class F pozzolanic material. According to ASTM C 618, the WA used in this study falls under class C as the sum of the total amount of SiO2, Al2O3, and Fe2O3 is between 50 and 70% by mass. Regarding the content of CaO, WA meets the criteria for class C as the amount of CaO is more than 20% by mass [1]. The WA used was very rich in alkalis with 1.12% of Na2O and 4.51% of K2O, both by mass, and contained significant amounts of magnesium oxides, sulfates, and chlorides [1,29]. According to the European standard EN 450-1, the WA meets the criteria for category B (<7%) in terms of the loss of ignition (LOI) value [1]. Most of the wood fly ash and coal fly ash blends are considered by ASTM C618-15, 2015 [30], as class C ashes [1]. The particle size of WA does not meet any standards (i.e., EN 450 [28], C618−22 [31]) as approximately less than 5% by mass of particles are retained when sieved on the 45 µm sieve [23].

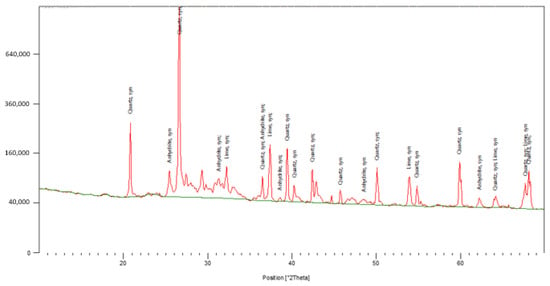

The mineralogical composition of WA varies depending on factors such as the type of wood, the combustion process, and the combustion temperature. The main crystalline phases identified were quartz (ref. no. 00-046-1045), anhydrite (00-037-1496), and lime (00-037-1497) (Figure 1).

Figure 1.

XRD patterns of raw WA.

3.2. SEM-EDX Results of WA

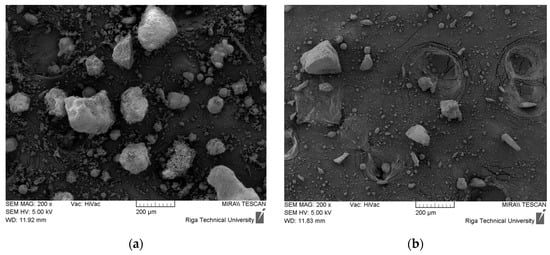

The SEM images of the sieved WA before and after ball-milling for 10 min at 300 rpm are shown in Figure 2. The particles of the sieved WA consisted of irregularly sized and shaped grains [32], and smaller particles were densely packed due to agglomeration [33]. The shapes of the sieved WA particles were irregular, rounded, and angular. The ball-milling process reduced the particle size and separated the agglomerated particles [34] and led to homogenous shapes. Ball-milling for too long can have an adverse effect on particle size reduction. According to the work of S. Kumar [35], the biggest impact on particle size reduction occurs in the first 10 min of grinding, and then the impact decreases. However, some larger particles were present even after the ball-milling process.

Figure 2.

(a) SEM image of sieved WA (WA1); (b) SEM image of sieved and ball-milled WA (WA3).

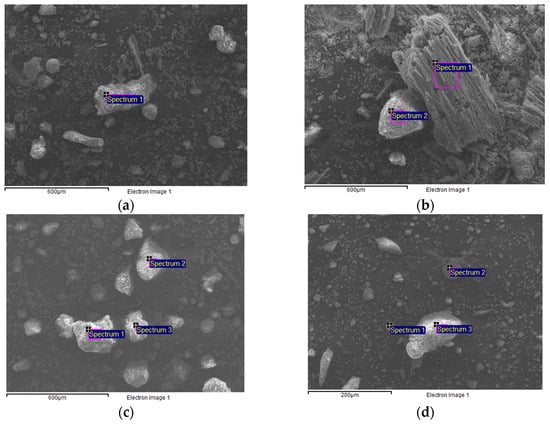

A SEM-EDX analysis of elements was performed in spot mode. In total, nine different spots of the sieved WA sample (WA1) were chosen and analyzed (Figure 3). It was concluded that when calculated according to the chemical composition of oxides, the elemental compositions were consistent with the chemical compositions found via XRF and the mineral compositions. The elemental compositions of the WA sample are shown in Table 4.

Figure 3.

(a) spot of a particle chosen for elemental composition represented in Table 4; (b) spots of particles chosen for elemental composition represented in Table 4; (c) spots of particles chosen for elemental composition represented in Table 4; (d) spots of particles chosen for elemental composition represented in Table 4.

Table 4.

Elemental compositions of WA.

The most dominant elements of the WA particles were oxygen, silica, and calcium, according to the XRD analysis, and they were the main constituents of quartz, anhydrite, and lime. The obtained quantitative results regarding the elemental compositions had good consistency with the chemical compositions obtained via XRF. The LOI parameter indicates the percentage of unburned carbonaceous material [14]. The amount of unburned carbonaceous material in WA was rather low as the LOI value of the used WA shown in Table 3 met the European standard EN 450-1 class B (<7%) requirements. Spectrum 1 in Figure 3b represents a typical unburned carbon particle which is characterized by a rough surface, high porosity, and high specific area with carbon as its dominant element [31,36].

3.3. Particle Size Distribution of WA

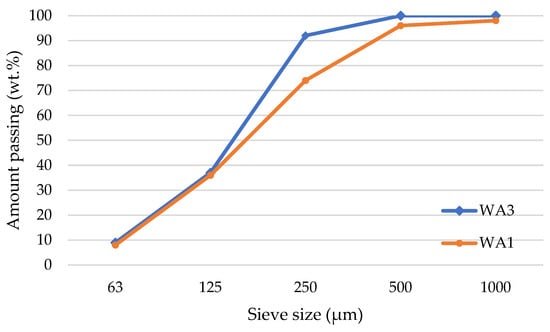

The particle size distribution for sieved WA (WA1) and sieved/milled WA (WA3) was determined by the sieve analysis procedure conducted using differential sieve weighing. Before this procedure, both WA samples were dried at 110 °C to constant weight. Then, an equal amount of 200 g of both ash samples was weighed and passed through a series of sieves of different sizes organized from larger on top to smaller sizes at the bottom. After sieving the amount of retained particles, each sample was weighed, and the particle size distribution of the WA samples was determined. The obtained results are shown in Figure 4. According to Figure 4, the biggest impact of ball-milling occurred in the particle size range of 125 to 500 µm.

Figure 4.

Particle size distribution of WA1 and WA3.

3.4. Mechanical Strength of Mortar Samples

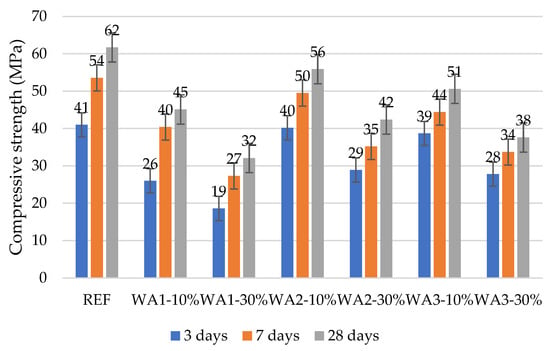

The compressive and bending strengths of the mortar samples were determined at 3, 7, and 28 days. Figure 5 presents the compressive strength results of the mortar mixtures at various curing ages (i.e., 3, 7, 28 days). From the results of compressive strength testing, it was observed that the highest compressive strength among all mortar samples was recorded in the samples with no cement replacement by WA. With an increase in WA content, compressive strength tended to be reduced for all mixtures. Out of the three treatment methods, it was concluded that the best results were obtained for samples with WA2, although the results of the samples with WA3 were close to those with WA2.

Figure 5.

Comparison of compressive strength of different treatment methods with various amounts of WA.

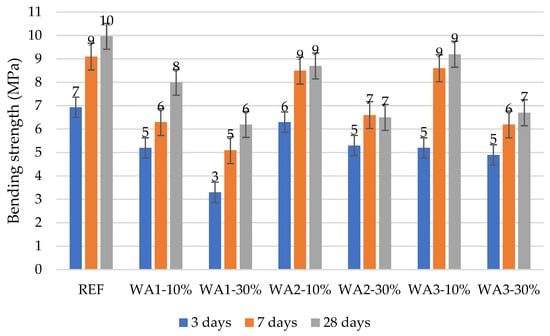

The results of bending strength testing exhibited a similar pattern to those of compressive strength testing (Figure 6). Similar to the compressive strength results, the best tensile strength was for the samples with WA2 and WA3, and the final results between the two samples were very close.

Figure 6.

Comparison of bending strength of different WA treatment methods with various amounts of WA.

The reduction in both the compressive and bending strengths of the mortar samples with WA is attributed to the less dense packaging of WA, which decreases the density of the cement matrix [1] as the particles of WA are coarser than those of Portland cement, as well as the lower pozzolanic activity levels of WA [14]. This results in a higher amount of bigger closed pores that reduce the mechanical properties of the material.

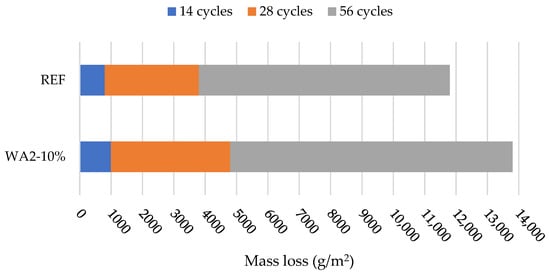

The freeze–thaw test mass loss of the most promising sample WA2 and REF is shown in Figure 7. The mass loss of WA2-10% was higher than that of the reference sample (WA-0%) at all cycles. The final mass loss at 56 cycles of WA2-0% and WA2-10% was 11,800 and 13,800 g/m2, respectively. This was attributed to higher water absorption due to larger open pores that formed due to the poor packing of WA2 particles. The freeze–thaw resistance of mortar depends on both open porosity and closed porosity [6,37].

Figure 7.

Mass loss of REF and WA2-10% after freeze–thaw cycles.

4. Discussion

In this study, the effects of WA on the properties of mortar were investigated. The main crystalline phases of the studied WA were quartz, anhydrite, and lime. According to ASTM C 618 and EN 450-1, which are used for coal ash classification, the WA used in this study met the criteria for the class C classification, which was consistent with other studies where WA was used as a cement replacement [1,30,33]. From the XRF and SEM-EDX results, it was concluded that the main chemical constituents of the WA particles were oxygen, silica, and calcium. Three different WA pre-treatment methods including sieving, grinding, and slaking were applied before WA incorporation into mortar. The primary purpose of pre-treating WA was to enhance the feasibility of WA for developing cementitious materials [13]. Better results were obtained for the samples WA2 and WA3 which were pre-treated with sieving/grinding and sieving/slaking, respectively, compared to WA1 which was only sieved. Both the compressive and bending strengths of all mortar samples with WA were reduced with an increase in the WA mass content. Similar tendencies with the increase in WA content were observed in other studies as well [16]. The 28-day compressive and bending strengths for the reference sample were 62 and 10 MPa, respectively. Better mechanical results were observed for the samples where WA underwent extra treatment processes apart from sieving. The best sample containing WA was WA2-10% with 28-day compressive and bending strengths of 56 and 9 MPa, respectively. The 28-day compressive test result of WA3-10% was 51 MPa, which was close to that of WA2-10%, whereas the 28-day bending test results of WA3-10% and WA2-10% were almost the same. WA1-10%, which contained only sieved WA, performed worse in terms of mechanical properties. The compressive and bending strengths of WA1-10% were 45 and 8 MPa, respectively. Compared to WA2-10%, the compressive strength of WA1-10% was reduced by 20%. At the 30% WA replacement level, the absolute compressive and bending strength values declined compared to the 10% WA replacement level. The mechanical strength distributions at the 30% WA replacement level between the samples was similar to those at the 10% WA replacement level. The reduction in the compressive and bending strengths of the mortar samples containing WA was attributed to the less dense packaging of WA particles, which decreases the density of the cement matrix [1]. Less dense packaging results in a higher number of bigger closed pores that reduce the mechanical properties of the material. Another factor contributing to strength reduction is the presence of unburned carbon particles in WA [30]. Mortar samples with pre-treated WA showed better compressive and flexural strengths than those with untreated WA. The highest compressive strength of the mortar samples with WA was seen in the WA2-10% samples, whereas the highest flexural strength of the mortar samples with WA was seen in the WA3-10% samples.

Based on previously published data, the freeze–thaw mass loss was shown to not be significantly affected by the WA content, even up to 40% by mass [6]. This is contrary to the results obtained in this study. The freeze–thaw mass loss of WA2-10% was higher than that of the reference sample, possibly due to higher porosity. The freeze–thaw mass loss at 56 cycles for the reference sample and WA2-10% was 11,800 and 13,800 g/m2, respectively, which accounts for an extra 14% of mass loss compared to the reference. This was attributed to higher water absorption due to larger open pores that formed due to the poor packing of WA2 particles. The freeze–thaw resistance of mortar depends on both open porosity and closed porosity [37]. Another aspect that could reduce the freeze–thaw resistance of mortar is associated with the constituents present in WA. Anhydrite and lime can cause the swelling of the cement matrix and be easily damaged by freezing and thawing. The high alkali content in WA can also contribute to a reduction in freeze–thaw resistance [6].

According to studies that focus on the life cycle analysis (LCA) of sustainable building materials and the circular economy of biomass ash, it can be concluded that incorporating biomass ash into mortars and concrete can significantly reduce the emissions of overall carbon dioxide and greenhouse gasses [38,39,40]. These findings suggest that although WA has promising mechanical potential when properly processed, its durability under environmental stress requires further optimization. Importantly, incorporating WA into cementitious systems can significantly reduce reliance on Portland cement, lowering carbon emissions and promoting the circular use of biomass waste. Future work should focus on enhancing durability, scaling up mixing designs for 3D printing applications, and exploring combined SCM systems to balance mechanical performance and long-term durability in sustainable construction materials.

5. Conclusions

The importance of finding new cementitious supplementary materials in the cement industry has brought attention to wood biomass ash. The increasing availability of WA has started to pique the interest of large industries. This study highlights the feasibility of using wood ash as a supplementary cementitious material in mortar production. The application of wood ash in cement compositions remains a challenge to be investigated as the following conclusions can be drawn from this research:

- According to the pozzolan standards used for the classification of coal ash, the WA used in this study met the criteria of the class C classification in terms of the total amount of 55% of SiO2, Al2O3, and Fe2O3; a CaO amount of 21%; and a loss on ignition value of 6% and 5% by mass of particles retained on the 45 µm sieve.

- The most notable impact of ball-milling wood ash occurred in the particle sizes of 125 to 500 µm. Outside this particle size range, the ball-milling impact was unnoticeable.

- Both the compressive and bending strengths of all mortar samples containing wood ash were reduced with an increase in the wood ash mass content compared to the reference sample. The compressive and bending strengths of the reference sample after 28 days were 62 and 10 MPa, respectively. The best-performing sample with wood ash was WA2-10%, with 28-day compressive and bending strengths of 56 and 9 MPa, respectively, while the worst-performing sample was WA1-30%, with 28-day compressive and bending strengths of 32 and 6 MPa, respectively.

- Among the three treatment methods, WA2 (sieved/slaked) and WA3 (sieved/ground) showed significant improvements in mechanical performance compared to WA1 (only sieved), with WA2-10% demonstrating the highest compressive strength and WA3-10% exhibiting the best flexural strength. The better mechanical properties of the mortar samples with WA2 were attributed to the complete water absorption of WA. The mechanical improvement in WA3 was attributed to its denser mortar matrix due to a finer particle size.

- At 56 freeze–thaw cycles, the mass loss of the WA2-10% sample was 13,800 g/m2, whereas that of the reference was 11,800 g/m2, which is 14% lower compared to WA2-10%. The higher freeze–thaw mass loss of WA2-10% was attributed to bigger pores on the exposed surface of the sample.

Author Contributions

Conceptualization, O.L., G.B. and D.B.; methodology, A.S. and M.S.; validation, O.L., G.B. and D.B.; formal analysis, O.L., A.S. and G.B.; investigation, A.S. and M.S.; resources, M.S., X.Z. and D.B.; data curation, O.L., A.S. and M.S.; writing—original draft preparation, O.L. and G.B.; writing—review and editing, O.L., G.B., M.S., D.B. and X.Z.; visualization, O.L. and A.S.; supervision, G.B., M.S., X.Z. and D.B.; project administration, M.S. and D.B.; funding acquisition, G.B., M.S. and D.B. All authors have read and agreed to the published version of the manuscript.

Funding

This activity/work was supported by the EU Recovery and Resilience Facility within Project No 5.2.1.1.i.0/2/24/I/CFLA/003 “Implementation of consolidation and management changes at Riga Technical University, Liepaja University, Rezekne Academy of Technology, Latvian Maritime Academy and Liepaja Maritime College for the progress towards excellence in higher education, science and innovation” academic career doctoral grant (ID 1069).

Data Availability Statement

All results are presented in this article.

Acknowledgments

This article is based on work by COST Action (CircularB— Implementation of Circular Economy in the Built Environment, CA21103), supported by COST (European Cooperation in Science and Technology).

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Teixeira, E.R.; Camões, A.; Branco, F.G. Valorisation of Wood Fly Ash on Concrete. Resour. Conserv. Recycl. 2019, 145, 292–310. [Google Scholar] [CrossRef]

- Eštoková, A.; Wolfová Fabiánová, M.; Ondová, M. Concrete Structures and Their Impacts on Climate Change and Water and Raw Material Resource Depletion. Int. J. Civ. Eng. 2022, 20, 735–747. [Google Scholar] [CrossRef]

- Lothenbach, B.; Scrivener, K.; Hooton, R.D. Supplementary Cementitious Materials. Cem. Concr. Res. 2011, 41, 1244–1256. [Google Scholar] [CrossRef]

- Lei, Z.; Pavia, S. Biomass Ash (BA) Waste as an Activator to Produce Carbon-Negative Cement. CEMENT 2024, 18, 100112. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G. An Overview of the Chemical Composition of Biomass. Fuel 2010, 89, 913–933. [Google Scholar] [CrossRef]

- Fořt, J.; Šál, J.; Keppert, M.; Mildner, M.; Hotěk, P.; Ślosarczyk, A.; Klapiszewski, Ł.; Černý, R. Durability Analysis of Sustainable Mortars with Biomass Fly Ash as High-Volume Replacement of Portland Cement. J. Build. Eng. 2024, 91, 109565. [Google Scholar] [CrossRef]

- Sigvardsen, N.M.; Geiker, M.R.; Ottosen, L.M. Reaction Mechanisms of Wood Ash for Use as a Partial Cement Replacement. Constr. Build. Mater. 2021, 286, 122889. [Google Scholar] [CrossRef]

- Malaiškienė, J.; Vaičienė, M. The Influence of Silica Fly Ash and Wood Bottom Ash on Cement Hydration and Durability of Concrete. Materials 2024, 17, 4031. [Google Scholar] [CrossRef]

- Hills, C.D.; Tripathi, N.; Singh, R.S.; Carey, P.J.; Lowry, F. Valorisation of Agricultural Biomass-Ash with CO2. Sci. Rep. 2020, 10, 13801. [Google Scholar] [CrossRef]

- Hamid, Z.; Rafiq, S. An Experimental Study on Behavior of Wood Ash in Concrete as Partial Replacement of Cement. Mater. Today Proc. 2020, 46, 3426–3429. [Google Scholar] [CrossRef]

- Sata, V.; Tangpagasit, J.; Jaturapitakkul, C.; Chindaprasirt, P. Effect of W/B Ratios on Pozzolanic Reaction of Biomass Ashes in Portland Cement Matrix. Cem. Concr. Compos. 2012, 34, 94–100. [Google Scholar] [CrossRef]

- Rosales, J.; Cabrera, M.; Beltrán, M.G.; López, M.; Agrela, F. Effects of Treatments on Biomass Bottom Ash Applied to the Manufacture of Cement Mortars. J. Clean Prod. 2017, 154, 424–435. [Google Scholar] [CrossRef]

- Liang, X.; Li, Z.; Dong, H.; Ye, G. A Review on the Characteristics of Wood Biomass Fly Ash and Their Influences on the Valorization in Cementitious Materials. J. Build. Eng. 2024, 97, 110927. [Google Scholar] [CrossRef]

- Nascimento, L.C.; Baptista Junior, G.; Xavier, G.d.C.; Monteiro, S.N.; Vieira, C.M.F.; de Azevedo, A.R.G.; Alexandre, J. Use of Wood Bottom Ash in Cementitious Materials: A Review. J. Mater. Res. Technol. 2023, 23, 4226–4243. [Google Scholar] [CrossRef]

- Ristić, N.; Grdić, Z.; Topličić-ćurčić, G.; Grdić, D.; Dodevski, V. Properties of Self-Compacting Concrete Produced with Biomass Wood Ash. Teh. Vjesn. 2021, 28, 495–502. [Google Scholar]

- Yang, Z.; Huddleston, J.; Brown, H. Effects of Wood Ash on Properties of Concrete and Flowable Fill. J. Mater. Sci. Chem. Eng. 2016, 4, 101–114. [Google Scholar] [CrossRef]

- Tararushkin, E.V.; Shchelokova, T.N.; Kudryavtseva, V.D. A Study of Strength Fluctuations of Portland Cement by FTIR Spectroscopy. IOP Conf. Ser. Mater. Sci. Eng. 2020, 919, 022017. [Google Scholar] [CrossRef]

- Wembe, J.T.; Ngueyep, L.L.M.; Elat, E.; Pliya, P.; Telefouet, A.J.P.; Ndjaka, J.M.B.; Noumowe, A. Valorization of Ashes from Different Wood Species in Cementitious Materials. Discov. Sustain. 2024, 5, 257. [Google Scholar] [CrossRef]

- Dehkordi, B.A.; Nilforoushan, M.R.; Talebian, N.; Tayebi, M. A Comparative Study on the Self-Cleaning Behavior and Antibacterial Activity of Portland Cement by Addition of TiO2and ZnO Nanoparticles. Mater. Res. Express. 2021, 8, 035403. [Google Scholar] [CrossRef]

- Chu, D.C.; Kleib, J.; Amar, M.; Benzerzour, M. Determination of the Degree of Hydration of Portland Cement Using Three Different Approaches: Scanning Electron Microscopy (SEM-BSE) and Thermogravimetric Analysis (TGA). Case Stud. Constr. Mater. 2021, 15, p.e00754. [Google Scholar] [CrossRef]

- LVS EN 933-1:2012 A; Tests for Geometrical Properties of Aggregates—Part 1: Determination of Particle Size Distribution—Sieving Method. CEN: Brussels, Belgium, 2012.

- LVS EN 197-1:2012; Cement—Part 1: Composition, Specifications and Conformity Criteria for Common Cements. CEN: Brussels, Belgium, 2012.

- Ayobami, A.B. Performance of Wood Bottom Ash in Cement-Based Applications and Comparison with Other Selected Ashes: Overview. Resour. Conserv. Recycl. 2021, 166, 105351. [Google Scholar] [CrossRef]

- LVS EN 196-1:2016; Methods of Testing Cement—Part 1: Determination of Strength. CEN: Brussels, Belgium, 2016.

- LVS CEN/TS 12390-9:2017; Testing Hardened Concrete—Part 9: Freeze-Thaw Resistance with de-icing Salts—Scaling. CEN: Brussels, Belgium, 2017.

- Nath, B.D.; Sarkar, G.; Siddiqua, S.; Rokunuzzaman, M.; Islam, M.R. Geotechnical Properties of Wood Ash-Based Composite Fine-Grained Soil. Adv. Civ. Eng. 2018, 2018, 9456019. [Google Scholar] [CrossRef]

- Olatoyan, O.J.; Kareem, M.A.; Adebanjo, A.U.; Olawale, S.O.A.; Alao, K.T. Potential Use of Biomass Ash as a Sustainable Alternative for Fly Ash in Concrete Production: A Review. Hybrid Adv. 2023, 4, 100076. [Google Scholar] [CrossRef]

- EN 450-1:2012; Fly Ash for Concrete—Part 1: Definition, Specifications and Conformity Criteria. CEN: Brussels, Belgium, 2012.

- Berra, M.; Mangialardi, T.; Paolini, A.E. Reuse of Woody Biomass Fly Ash in Cement-Based Materials. Constr. Build. Mater. 2015, 76, 286–296. [Google Scholar] [CrossRef]

- ASTM C618-15; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. ASTM: West Conshohocken, PA, USA, 2015.

- C618−22; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. ASTM: West Conshohocken, PA, USA, 2015.

- Tran Thi, K.D.; Liao, M.C.; Vo, D.H. The Characteristics of Alkali-Activated Slag-Fly Ash Incorporating the High Volume Wood Bottom Ash: Mechanical Properties and Microstructures. Constr. Build. Mater. 2023, 394, 132240. [Google Scholar] [CrossRef]

- Rumman, R.; Kamal, M.R.; Bediwy, A.; Alam, M.S. Partially Burnt Wood Fly Ash Characterization and Its Application in Low-Carbon Mortar and Concrete. Constr. Build. Mater. 2023, 402, 132946. [Google Scholar] [CrossRef]

- Yao, X.; Mao, J.; Li, L.; Sun, L.; Xu, K.; Ma, X.; Hu, Y.; Zhao, Z.; Chen, S.; Xu, K. Characterization Comparison of Bottom Ash and Fly Ash during Gasification of Agricultural Residues at an Industrial-Scale Gasification Plant—Experiments and Analysis. Fuel 2021, 285, 119122. [Google Scholar] [CrossRef]

- Kumar, S.; Kumar, R. Mechanical Activation of Fly Ash: Effect on Reaction, Structure and Properties of Resulting Geopolymer. Ceram Int. 2011, 37, 533–541. [Google Scholar] [CrossRef]

- Narani, S.S.; Siddiqua, S.; Perumal, P. Wood Fly Ash and Blast Furnace Slag Management by Alkali-Activation: Trace Elements Solidification and Composite Application. J. Env. Manag. 2024, 354, 120341. [Google Scholar] [CrossRef]

- Nagrockienė, D.; Daugėla, A. Investigation into the Properties of Concrete Modified with Biomass Combustion Fly Ash. Constr. Build. Mater. 2018, 174, 369–375. [Google Scholar] [CrossRef]

- Kumari, S.; Walia, R. Life Cycle Assessment of Sustainable Concrete by Utilizing Groundnut Husk Ash in Concrete. Mater. Today Proc. 2021, 49, 1910–1915. [Google Scholar] [CrossRef]

- Caldas, L.R.; Da Gloria, M.Y.R.; Pittau, F.; Andreola, V.M.; Habert, G.; Toledo Filho, R.D. Environmental Impact Assessment of Wood Bio-Concretes: Evaluation of the Influence of Different Supplementary Cementitious Materials. Constr. Build. Mater. 2021, 268, 121146. [Google Scholar] [CrossRef]

- Dufossé, K.; Marie-charlotte, M.; Augiseau, V.; Henrion, T.; Djelal, H. Quantification and Environmental Assessment of Wood Ash from Biomass Power Plants: Case Study of Brittany Region in France. Sustainability 2022, 14, 99. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).