Experimental and Numerical Assessment of the Thermal Bridging Effect in a Reinforced Concrete Corner Pillar

Abstract

1. Introduction

2. Materials and Methods

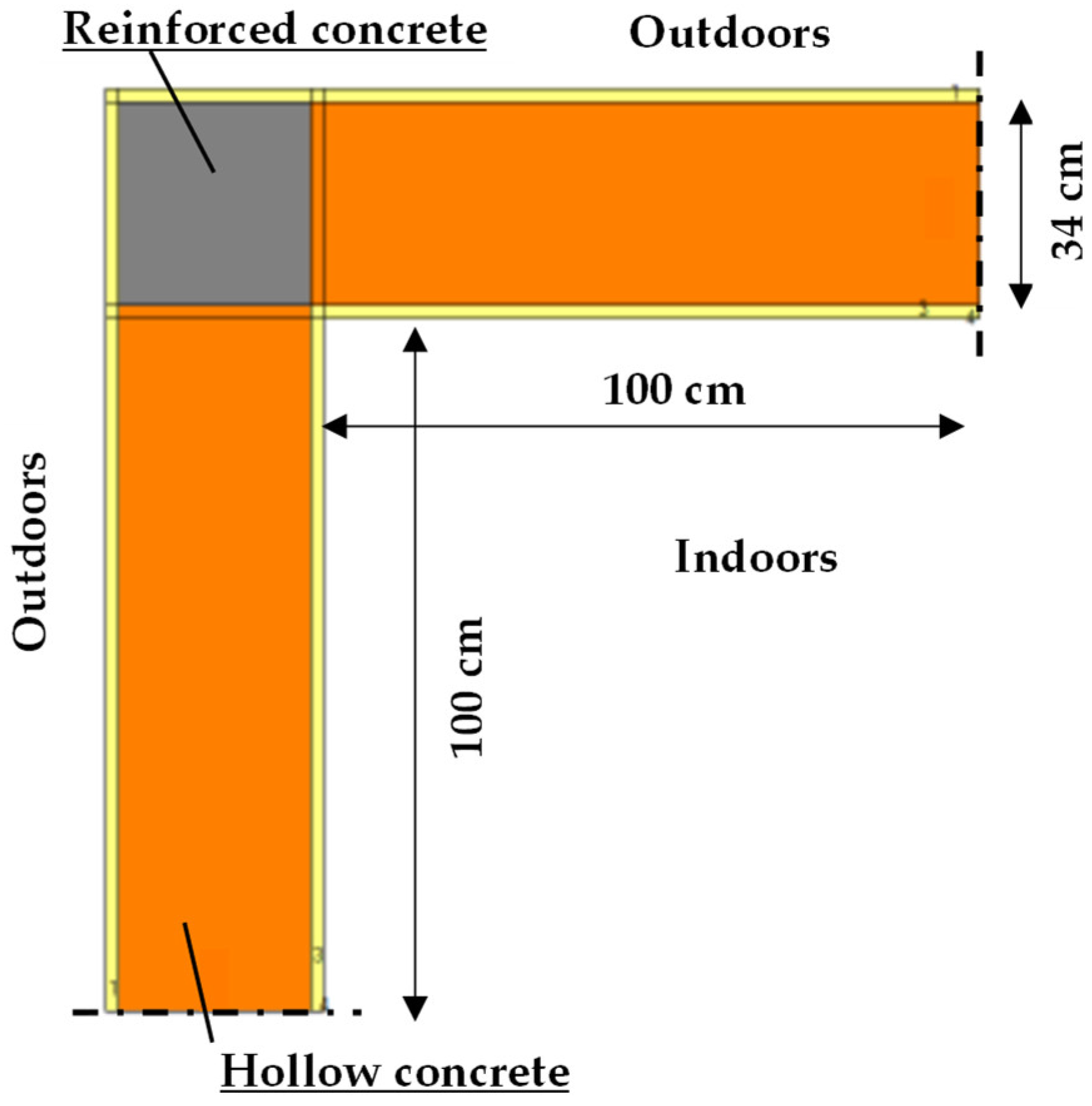

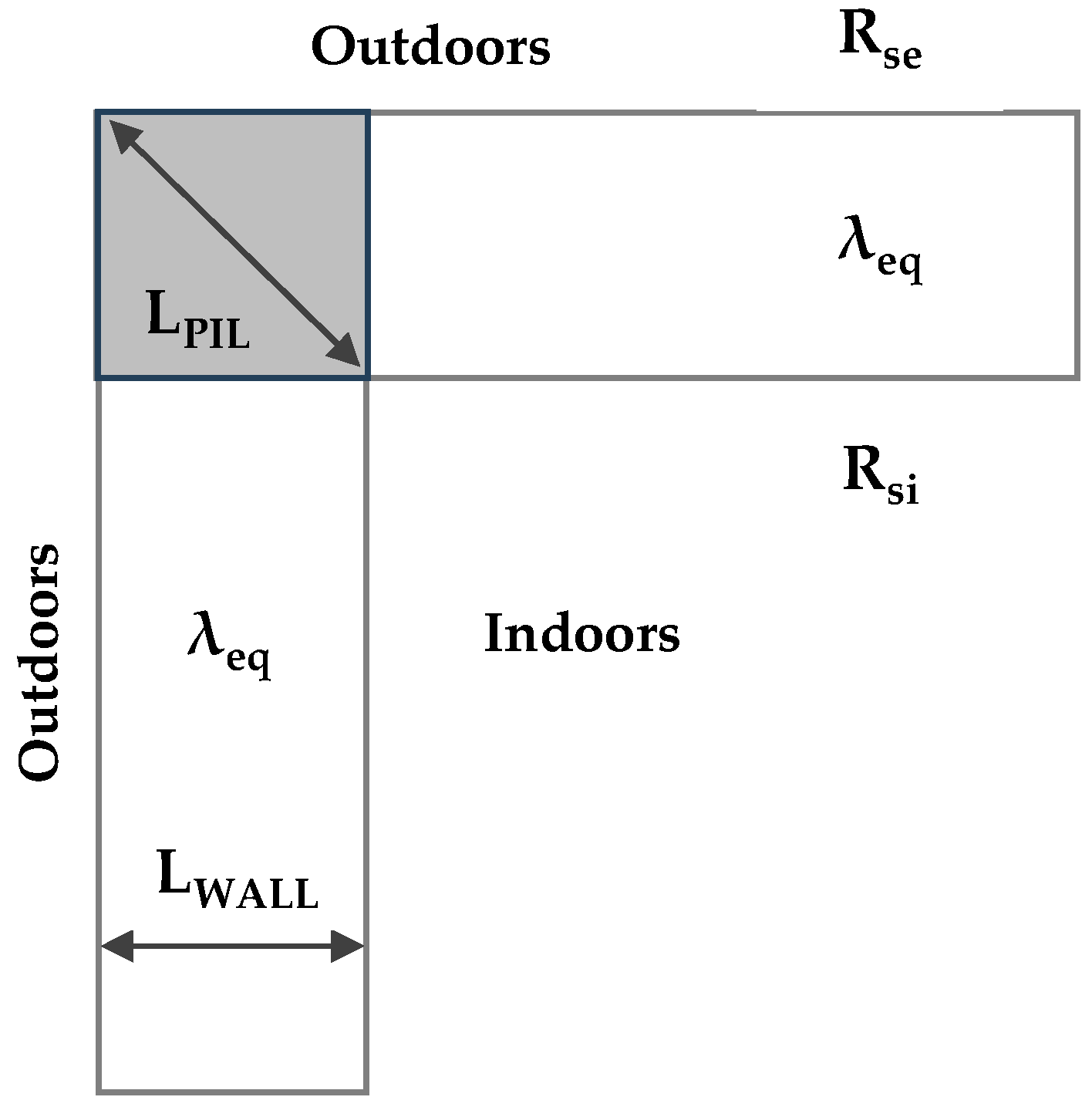

2.1. A 2D Numerical Modelling

| Material | Thickness | Conductivity | Density |

|---|---|---|---|

| [cm] | [W∙m−1∙K−1] | [kg∙m−3] | |

| Inner cement plaster | 2 | 0.70 | 1300 |

| Hollow concrete blocks [32] | 30 | 0.55 | 770 |

| Reinforced concrete | 30 | 2.50 | 2300 |

| Outer gypsum plaster | 2 | 0.40 | 1800 |

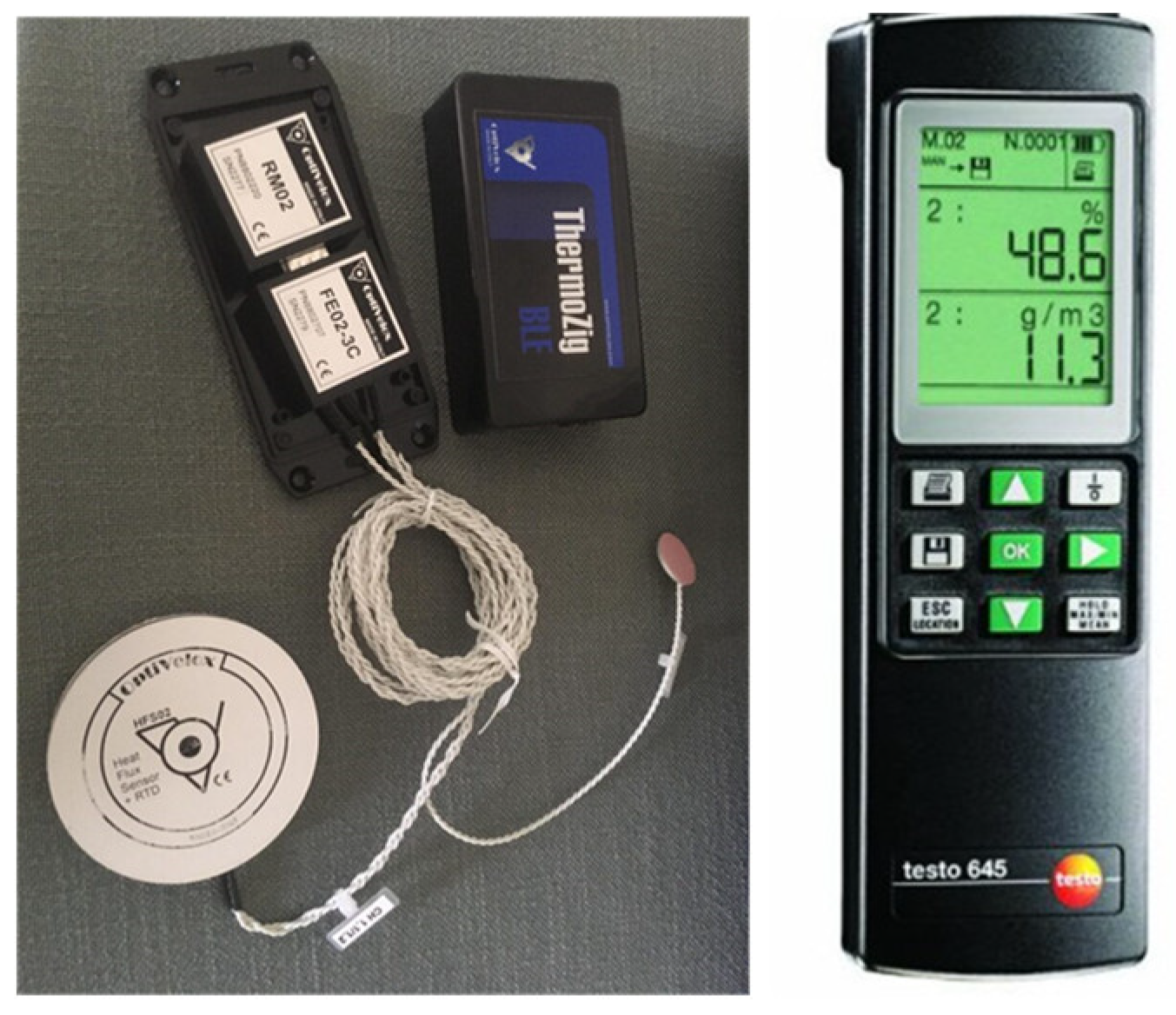

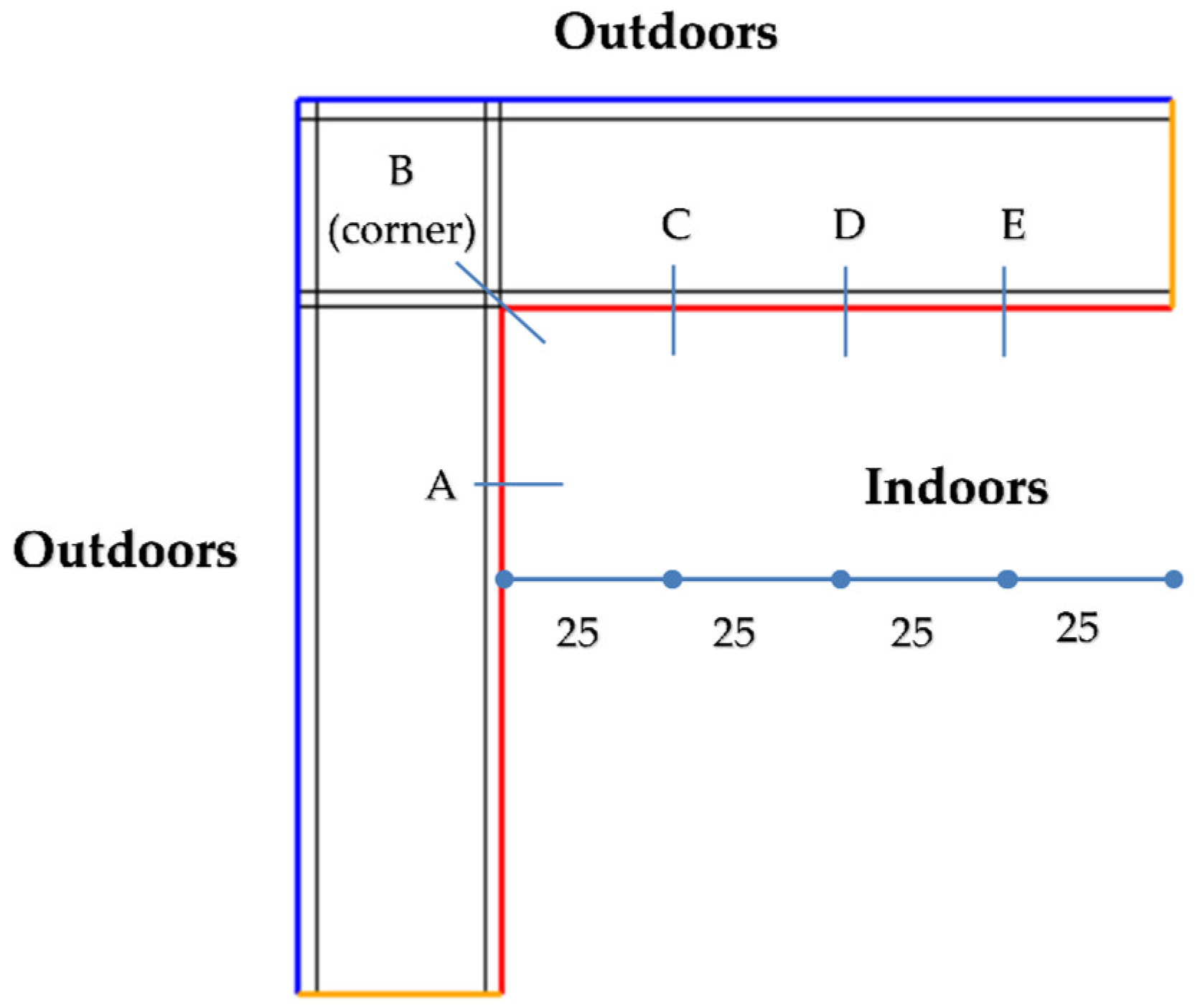

2.2. Experimental Measurements

- Temperature range: from −200 °C to +200 °C;

- Temperature resolution: ±0.1 °C;

- Temperature accuracy: ±0.2 °C;

- Relative Humidity range: from 0% to +100%;

- Relative Humidity resolution: ±0.1%.

- Indoors: TI = 17.0 °C and RHI = 52.1%;

- Outdoors: TE = 10.7 °C and RHE = 58.4%.

- Temperature range: from −50 °C to +150 °C;

- Temperature resolution: ±0.01 °C;

- Temperature accuracy: ±0.15 °C.

- Resolution: 320 × 240 pixels;

- Thermal sensitivity: 0.08 °C at 30 °C;

- Spectral range: 7.5 to 13 μm;

- Temperature range: from −20 °C to +55 °C;

- Temperature accuracy: ±2 °C.

2.3. Determination of the Linear Thermal Transmittance

3. Results and Discussion

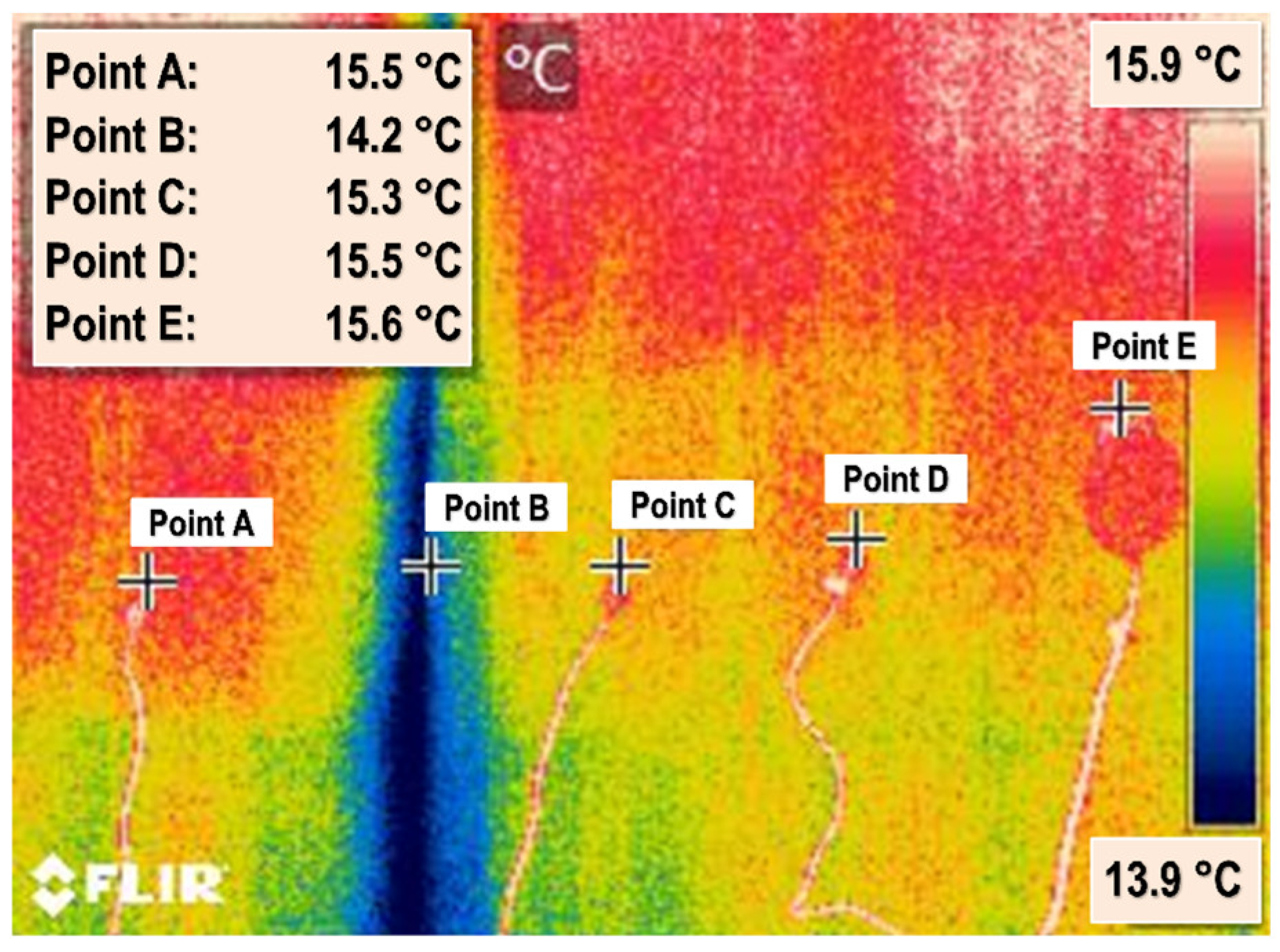

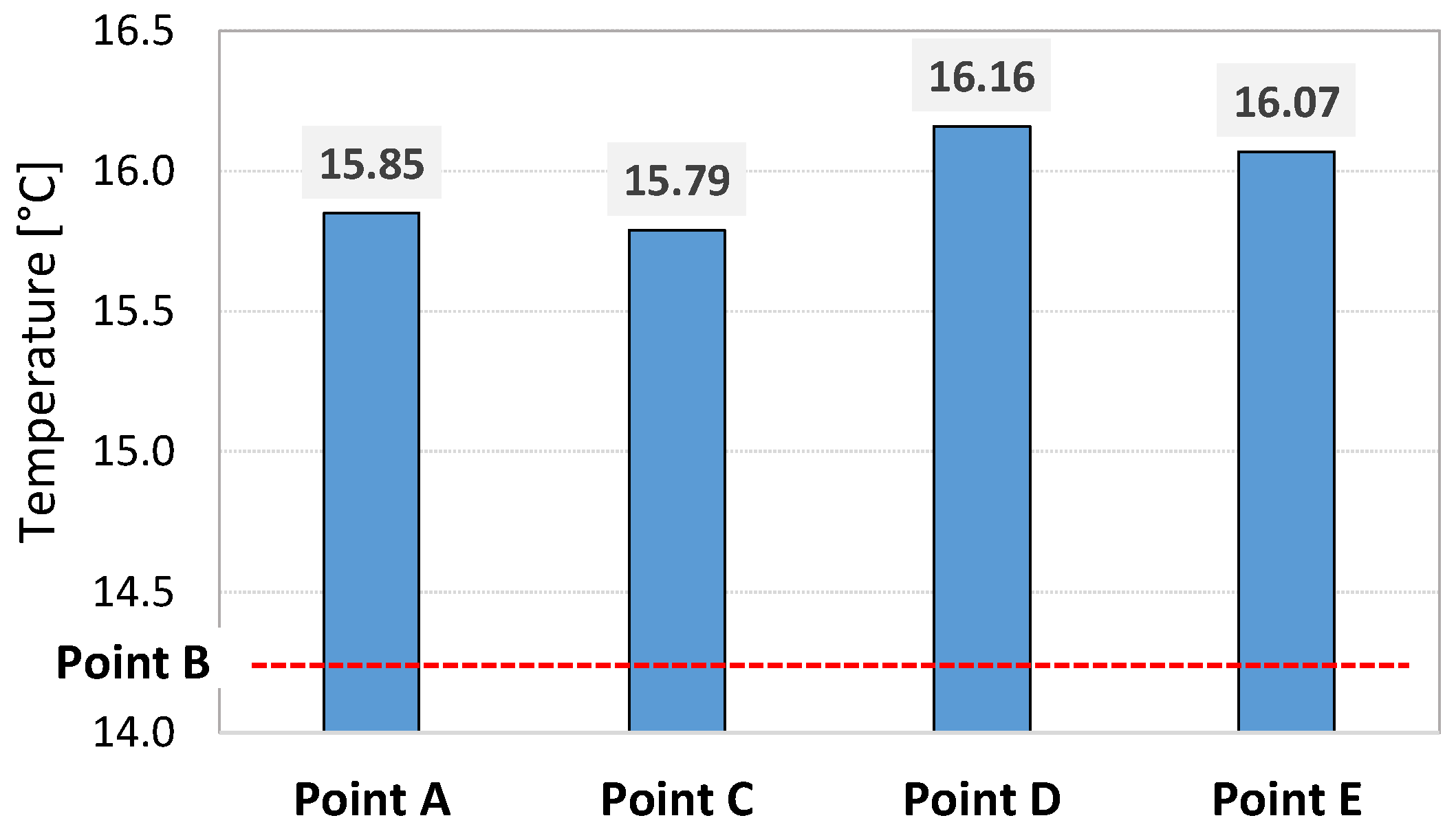

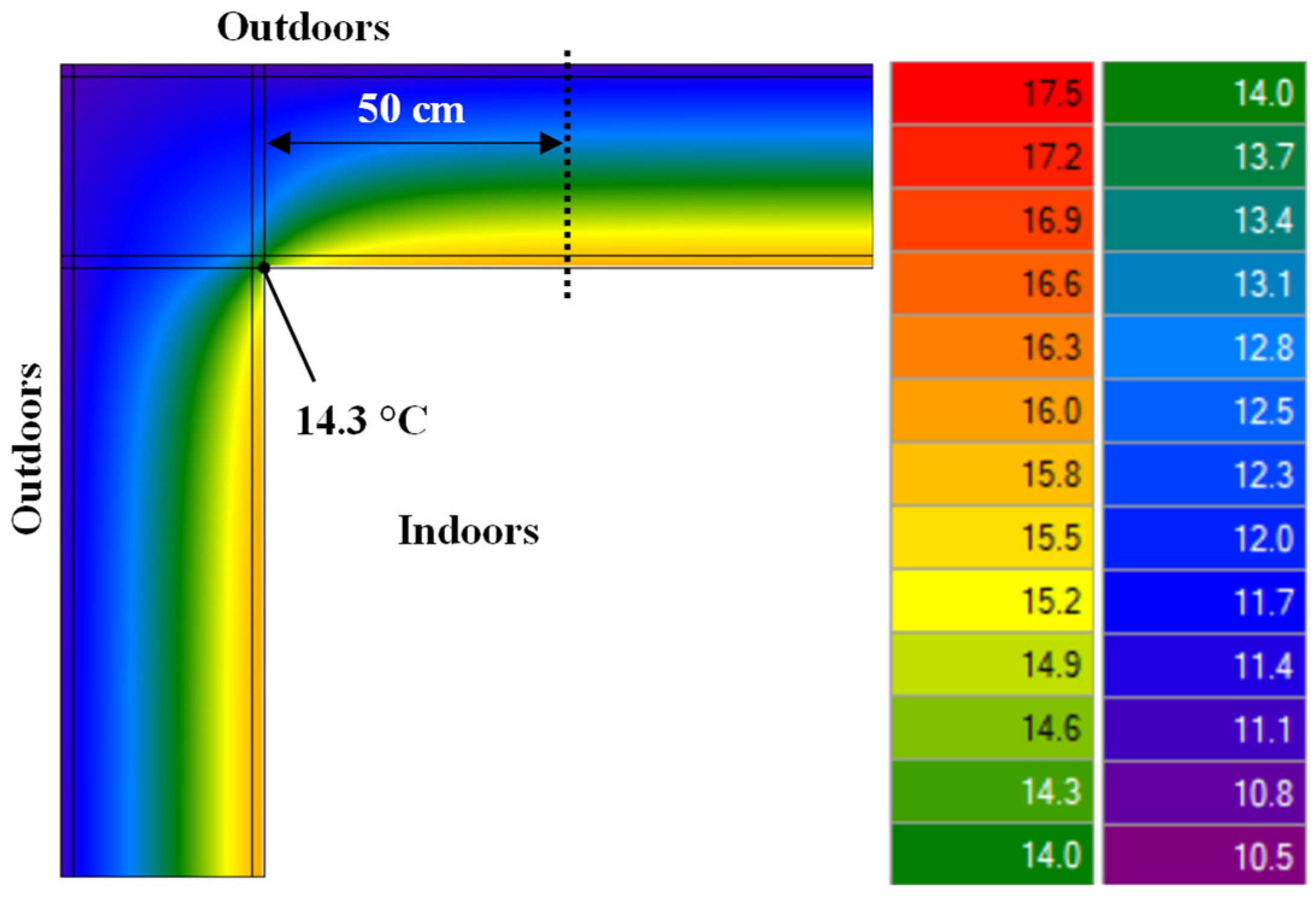

3.1. Surface Temperature

3.2. Transmitted Heat Flux

3.3. Linear Thermal Transmittance

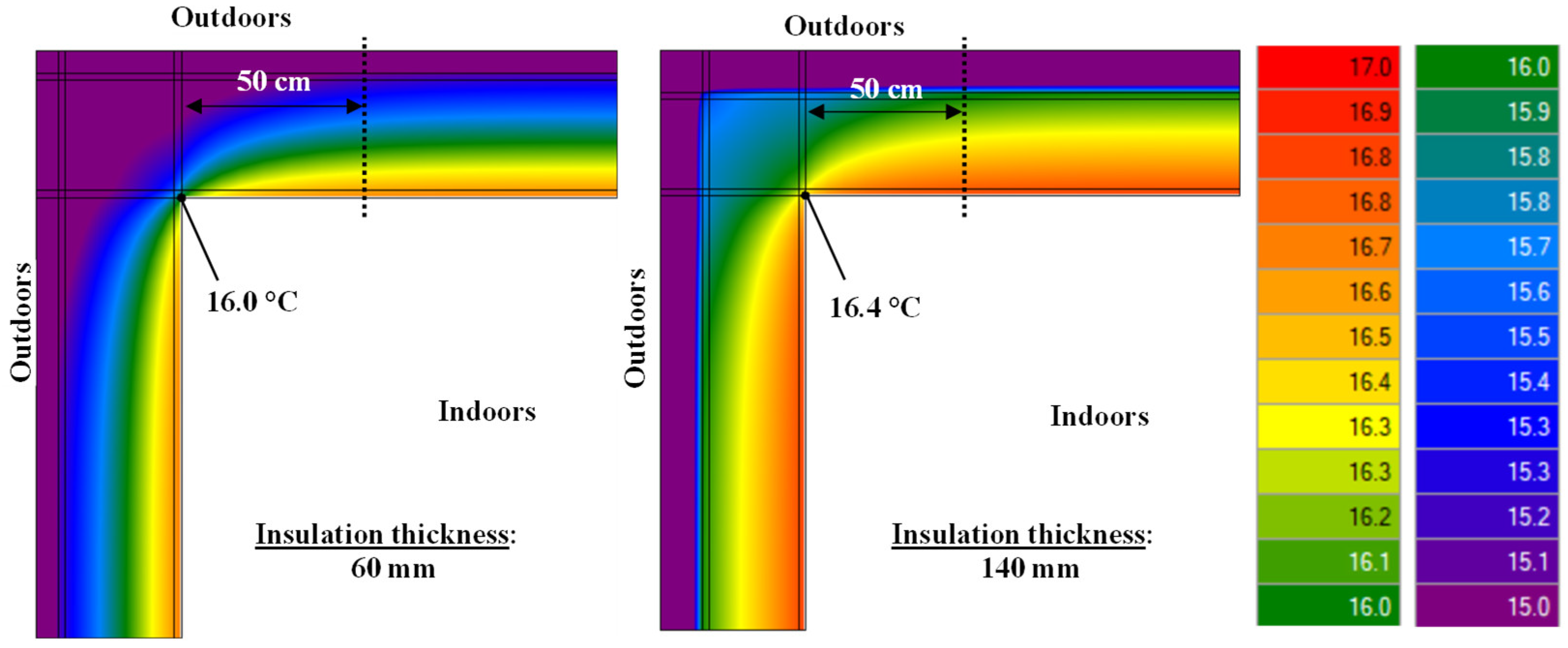

4. Effect of ETICS Renovation on Thermal Bridges

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Symbol | Quantity | Unit |

| A | Area per unit length | m2∙m−1 |

| H | Height | m |

| HDD | Heating Degree Days | °C∙day |

| L | Thickness | m |

| q | Heat flux per unit length | W∙m−1 |

| R | Thermal resistance | m2∙K∙W−1 |

| RH | Relative Humidity | % |

| T | Temperature | °C |

| U | Thermal transmittance | W∙m−2∙K−1 |

| W | Width | m |

| ε | Thermal emissivity | - |

| λ | Thermal conductivity | W∙m−1∙K−1 |

| ρ | Density | kg∙m−3 |

| ψ | Linear thermal transmittance | W∙m−1∙K−1 |

| Subscript | Meaning | |

| eq | Equivalent | |

| PIL | Pillar | |

| RC | Reinforced Concrete | |

| se | External surface | |

| si | Internal surface | |

| Acronyms | Meaning | |

| ETICS | External Thermal Insulation Composite System | |

| NA | Not Available | |

| XPS | Extruded Polystyrene | |

References

- Odyssee-Mure Project Website, Sectoral Profile—Overview, Final Energy Consumption by Sector in EU. Available online: https://www.odyssee-mure.eu/publications/efficiency-by-sector/overview/final-energy-consumption-by-sector.html (accessed on 4 January 2024).

- European Commission, Department of Energy. In Focus: Energy Efficiency in Buildings. Brussels. 17 February 2020. Available online: https://ec.europa.eu/info/news/focus-energy-efficiency-buildings-2020-lut-17_en (accessed on 23 December 2023).

- EN ISO 10211; CEN, European Committee for Standardisation. Thermal Bridges in Building Construction—Heat Flows and Surface Temperatures—Detailed Calculations. CEN: Brussels, Belgium, 2017.

- Ilomets, S.; Kalamees, T. Evaluation of the criticality of thermal bridges. J. Build. Pathol. Rehabil. 2016, 1, 11. [Google Scholar] [CrossRef]

- Alhawari, A.; Mukhopadhyaya, P. Thermal bridges in building envelopes—An overview of impacts and solutions. Int. Rev. Appl. Sci. Eng. 2018, 9, 31–40. [Google Scholar] [CrossRef]

- Janssen, A.; Van Londersele, E.; Vandermarcke, B.; Roels, S.; Standaert, P.; Wouters, P. Development of limits for the linear thermal transmittance of thermal bridges in buildings. In Proceedings of the X International Conference on Thermal Performance of the Exterior Envelopes of Whole Buildings—ASHRAE, Clearwater Beach, FL, USA, 1–5 December 2013. [Google Scholar]

- Ilomets, S.; Kuusk, K.; Paap, L.; Arumägi, E.; Kalamees, T. Impact of linear thermal bridges on thermal transmittance of renovated apartment buildings. J. Civ. Eng. Manag. 2017, 23, 96–104. [Google Scholar] [CrossRef]

- Zhang, X.; Jung, G.-J.; Rhee, K.-N. Performance evaluation of thermal bridge reduction method for balcony in apartment buildings. Buildings 2022, 12, 63. [Google Scholar] [CrossRef]

- Evola, G.; Costanzo, V.; Urso, A.; Tardo, C.; Margani, G. Energy performance of a prefabricated timber-based retrofit solution applied to a pilot building in Southern Europe. Build. Environ. 2022, 222, 109442. [Google Scholar] [CrossRef]

- Curto, D.; Franzitta, V.; Guercio, A.; Martorana, P. FEM analysis: A review of the most common thermal bridges and their mitigation. Energies 2022, 15, 2318. [Google Scholar] [CrossRef]

- Kim, M.-Y.; Kim, H.-G.; Kim, J.-S.; Hong, G. Investigation of thermal and energy performance of the thermal bridge breaker for reinforced concrete residential buildings. Energies 2022, 15, 2854. [Google Scholar] [CrossRef]

- Ge, H.; McClung, V.R.; Zhang, S. Impact of balcony thermal bridges on the overall thermal performance of multi-unit residential buildings: A case study. Energy Build. 2013, 60, 163–173. [Google Scholar] [CrossRef]

- Baba, F.; Ge, H. Dynamic effect of balcony thermal bridges on the energy performance of a high-rise residential building in Canada. Energy Build. 2016, 116, 78–88. [Google Scholar] [CrossRef]

- Aghasizadeh, S.; Kari, B.M.; Fayaz, R. Thermal performance of balcony thermal bridge solutions in reinforced concrete and steel frame structures. J. Build. Eng. 2022, 48, 103984. [Google Scholar] [CrossRef]

- Theodosiou, T.G.; Papadopoulos, A.M. The impact of thermal bridges on the energy demand of buildings with double brick wall constructions. Energy Build. 2008, 40, 2083–2089. [Google Scholar] [CrossRef]

- Evola, G.; Margani, G.; Marletta, L. Energy and cost evaluation of thermal bridge correction in Mediterranean climate. Energy Build. 2011, 43, 2385–2393. [Google Scholar] [CrossRef]

- Kotti, S.; Teli, D.; James, P.A.B. Quantifying thermal bridge effects and assessing retrofit solutions in a Greek residential building. Procedia Environ. Sci. 2017, 38, 306–313. [Google Scholar] [CrossRef]

- Alayed, E.; O’Hegarty, R.; Kinnane, O. Solutions for exposed structural concrete bridged elements for a more sustainable concrete construction in hot climates. Buildings 2022, 12, 176. [Google Scholar] [CrossRef]

- Cirami, S.; Evola, G.; Gagliano, A.; Margani, G. Thermal and economic analysis of renovation strategies of a historic building in Mediterranean area. Buildings 2017, 7, 60. [Google Scholar] [CrossRef]

- EN ISO 14683; CEN, European Committee for Standardisation. Thermal Bridges in Building Construction—Linear Thermal Transmittance—Simplified Methods and Default Values. CEN: Brussels, Belgium, 2017.

- Berggren, B.; Wall, M. Calculation of thermal bridges in (Nordic) building envelopes—Risk of performance failure due to inconsistent use of methodology. Energy Build. 2013, 65, 331–339. [Google Scholar] [CrossRef]

- CENED, Atlante dei Ponti Termici. 2011. Available online: https://www.cened.it/download (accessed on 25 March 2023). (In Italian).

- Capozzoli, A.; Corrado, V.; Gorrino, A.; Soma, P. Atlante Nazionale dei Ponti Termici: Conforme alle UNI EN ISO 14683 e UNI EN ISO 10211; Edizioni Edilclima: Novara, Italy, 2011. (In Italian) [Google Scholar]

- Office Fédéral de L’ÉNergie (OFEN). Catalogue des Ponts Thermiques; Office Fédéral de L’ÉNergie (OFEN): Bern, Switzerland, 2003. [Google Scholar]

- Passive House Institute (PHI). Thermal Bridge Catalogue; Passive House Institute: Darmstadt, Germany, 2019. [Google Scholar]

- Basiricò, T.; Cottone, A.; Enea, D. Analytical mathematical modeling of the thermal bridge between reinforced concrete wall and inter-floor slab. Sustainability 2020, 12, 9964. [Google Scholar] [CrossRef]

- Theodosiou, T.; Tsikaloudaki, K.; Kontoleon, K.; Giarma, C. Assessing the accuracy of predictive thermal bridge heat flow methodologies. Renew. Sustain. Energy Rev. 2021, 136, 110437. [Google Scholar] [CrossRef]

- O’Grady, M.; Lechowska, A.A.; Harte, A.M. Infrared thermography technique as an in-situ method of assessing heat loss through thermal bridging. Energy Build. 2017, 135, 20–32. [Google Scholar] [CrossRef]

- Baldinelli, G.; Bianchi, F.; Rotili, A.; Costarelli, D.; Seracini, M.; Vinti, G.; Asdrubali, F.; Evangelisti, L. A model for the improvement of thermal bridges quantitative assessment by infrared thermography. Appl. Energy 2018, 211, 854–864. [Google Scholar] [CrossRef]

- Presidential Decree 412/93. Regulation Containing the Laws for Design, Installation, Operation and Maintenance of Buildings Heating Systems in order to Reduce Energy Consumptions, for the implementation of the item 4, paragraph 4, of the Law 9th January 1991, n. 10. Available online: http://www.normattiva.it/atto/caricaDettaglioAtto?atto.dataPubblicazioneGazzetta=1993-10-14&atto.codiceRedazionale=093G0451 (accessed on 29 January 2024). (In Italian).

- IRIS v.5.1, Software ANIT. Available online: https://www.anit.it/iris (accessed on 12 April 2023).

- UNI 10355; UNI, Ente Nazionale di Normazione. Murature e Solai. Valori Della Resistenza Termica e Metodo di Calcolo. UNI: Rome, Italy, 1994.

- EN ISO 6946; CEN, European Committee for Standardisation. Building Components and Building Elements—Thermal Resistance and Thermal Transmittance—Calculation Methods. CEN: Brussels, Belgium, 2017.

- Règles Th-K 77: Règles de Calcul des Caractéristiques Thermiques Utiles des Parois de Construction, Mises à Jour au 1er Janvier 1990; Centre Scientifique et Technique du Bâtiment, CSTB: Marne-la-Vallée, France, 1990.

- Bergero, S.; Chiari, A. The influence of thermal bridge calculation method on the building energy need: A case study. Energy Procedia 2018, 148, 1042–1049. [Google Scholar] [CrossRef]

- Hallik, J.; Kalamees, T. The effect of flanking element length in thermal bridge calculation and possible simplifications to account for combined thermal bridges in well insulated building envelopes. Energy Build. 2021, 252, 111397. [Google Scholar] [CrossRef]

| Source | ψI (W∙m−1∙K−1) | ψE (W∙m−1∙K−1) |

|---|---|---|

| Numerical simulation (IRIS) | 0.385 | −0.471 |

| CENED abacus | 0.401 | −0.456 |

| Edilclima atlas | - | −0.380 |

| French regulation (Th-K 77) | 0.15 | - |

| Linear Thermal Transmittance ψE | ||

|---|---|---|

| U-Value | Thickness = 30 cm | Thickness = 40 cm |

| 0.70 W∙m−2∙K−1 | −0.16 W∙m−1∙K−1 | −0.21 W∙m−1∙K−1 |

| 0.60 W∙m−2∙K−1 | −0.13 W∙m−1∙K−1 | −0.17 W∙m−1∙K−1 |

| 0.50 W∙m−2∙K−1 | −0.11 W∙m−1∙K−1 | −0.14 W∙m−1∙K−1 |

| 0.40 W∙m−2∙K−1 | −0.09 W∙m−1∙K−1 | −0.11 W∙m−1∙K−1 |

| 0.30 W∙m−2∙K−1 | −0.07 W∙m−1∙K−1 | −0.09 W∙m−1∙K−1 |

| 0.20 W∙m−2∙K−1 | −0.06 W∙m−1∙K−1 | −0.07 W∙m−1∙K−1 |

| 0.10 W∙m−2∙K−1 | −0.06 W∙m−1∙K−1 | −0.06 W∙m−1∙K−1 |

| Insulation Thickness | 6 cm | 8 cm | 10 cm | 12 cm | 14 cm |

|---|---|---|---|---|---|

| UWALL [W∙m−2∙K−1] | 0.399 | 0.325 | 0.274 | 0.237 | 0.209 |

| Minimum TSI (°C) | 16.0 | 16.1 | 16.2 | 16.3 | 16.4 |

| Linear thermal transmittance—external ψE (W∙m−1∙K−1) | |||||

| Numerical simulation (IRIS) | −0.099 | −0.083 | −0.073 | −0.067 | −0.063 |

| CENED abacus (case ASP.005) | −0.096 | −0.098 | −0.099 | −0.098 | −0.097 |

| EDILCLIMA atlas (case C14) | −0.100 | −0.085 | −0.075 | −0.070 | −0.065 |

| Linear thermal transmittance—internal ψI (W∙m−1∙K−1) | |||||

| Numerical simulation (IRIS) | 0.220 | 0.190 | 0.168 | 0.151 | 0.137 |

| CENED abacus (case ASP.005) | 0.205 | 0.205 | 0.204 | 0.201 | 0.199 |

| EDILCLIMA atlas (case C14) | NA | NA | NA | NA | NA |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Evola, G.; Gagliano, A. Experimental and Numerical Assessment of the Thermal Bridging Effect in a Reinforced Concrete Corner Pillar. Buildings 2024, 14, 378. https://doi.org/10.3390/buildings14020378

Evola G, Gagliano A. Experimental and Numerical Assessment of the Thermal Bridging Effect in a Reinforced Concrete Corner Pillar. Buildings. 2024; 14(2):378. https://doi.org/10.3390/buildings14020378

Chicago/Turabian StyleEvola, Gianpiero, and Antonio Gagliano. 2024. "Experimental and Numerical Assessment of the Thermal Bridging Effect in a Reinforced Concrete Corner Pillar" Buildings 14, no. 2: 378. https://doi.org/10.3390/buildings14020378

APA StyleEvola, G., & Gagliano, A. (2024). Experimental and Numerical Assessment of the Thermal Bridging Effect in a Reinforced Concrete Corner Pillar. Buildings, 14(2), 378. https://doi.org/10.3390/buildings14020378