Critical Stress Determination of Local and Distortional Buckling of Lipped Angle Columns under Axial Compression

Abstract

:1. Introduction

2. CUFSM for Solving Critical Stress of Elastic Buckling

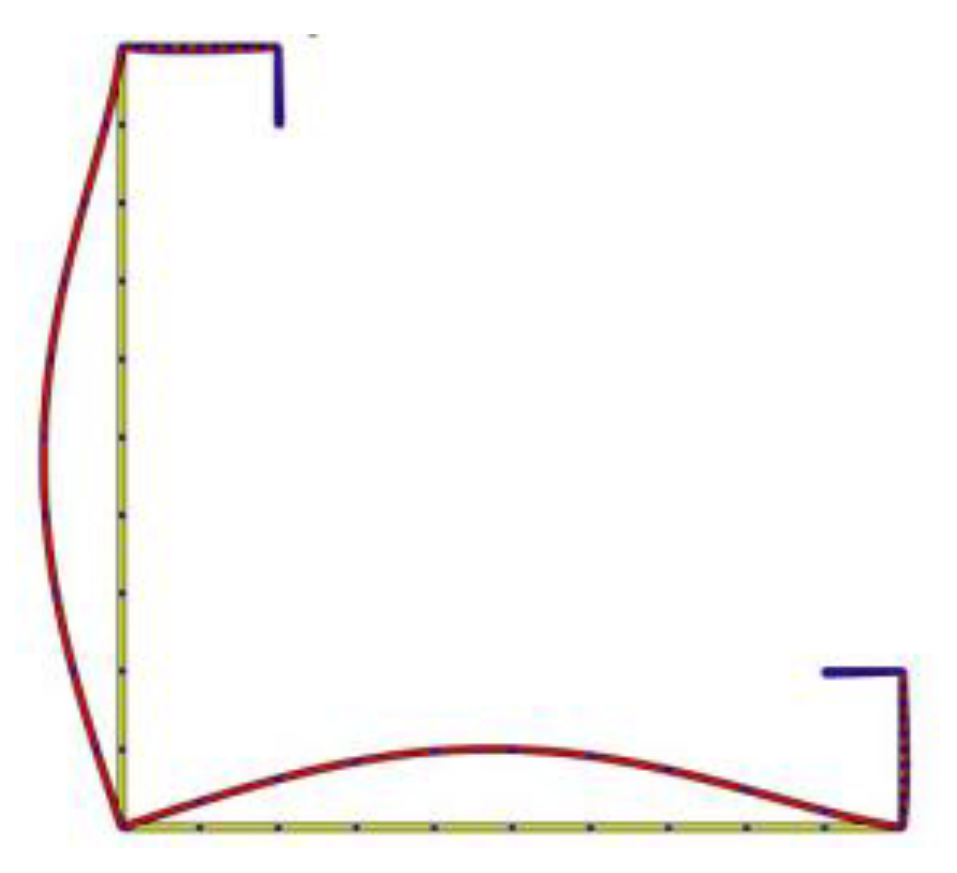

2.1. Introduction of CUFSM

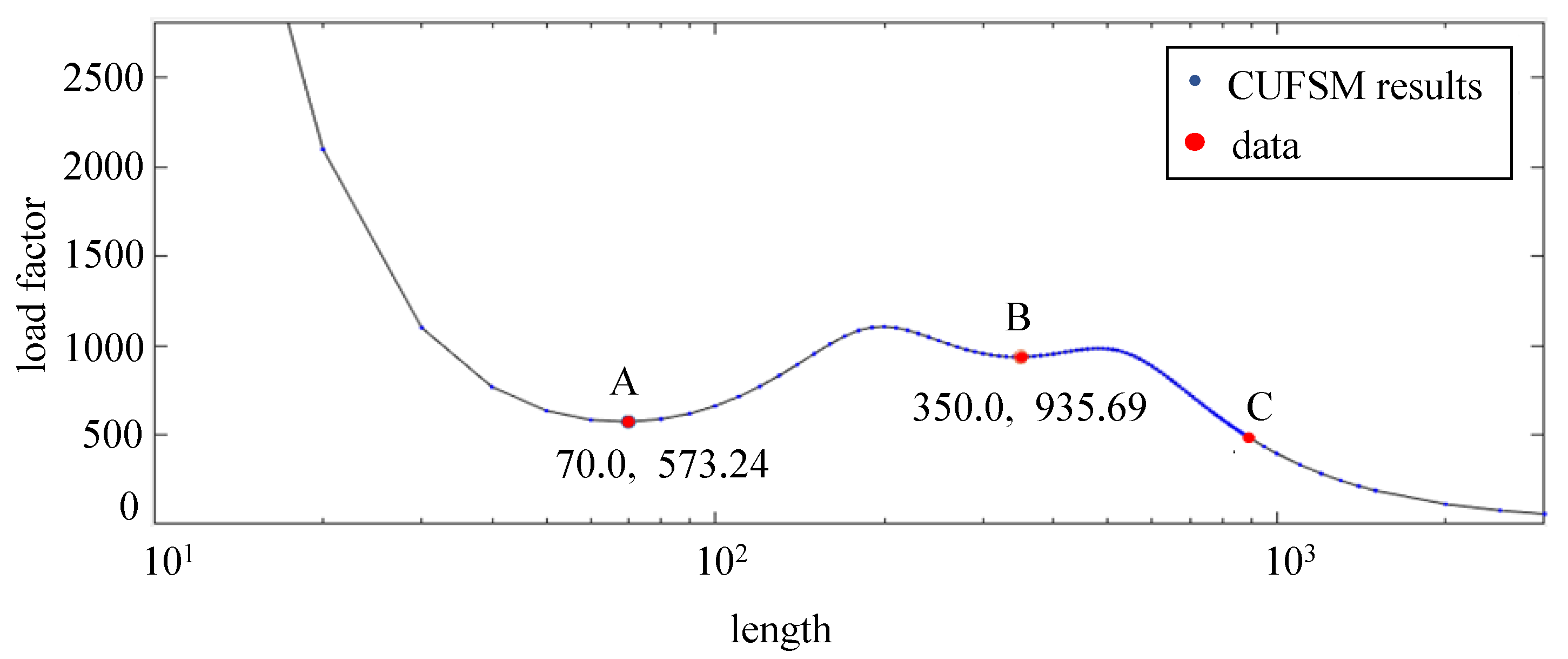

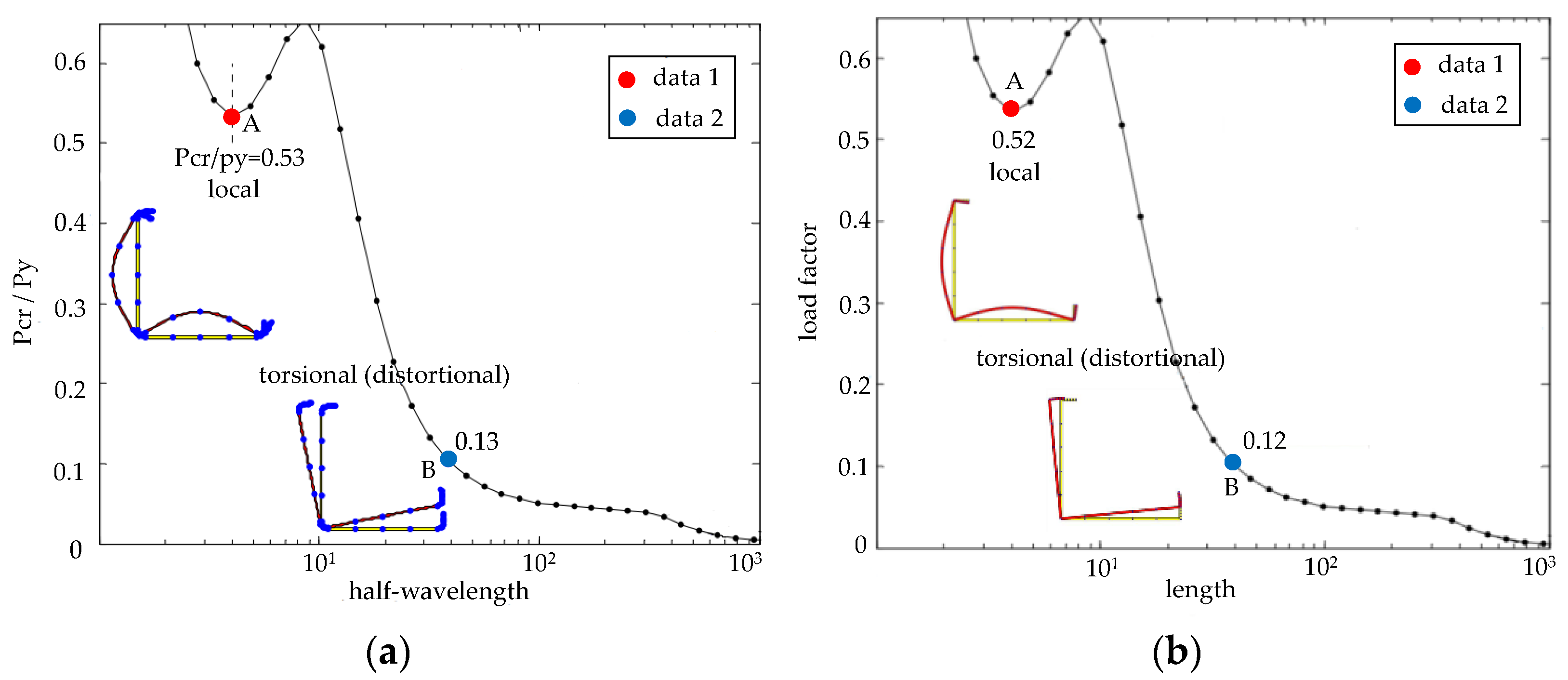

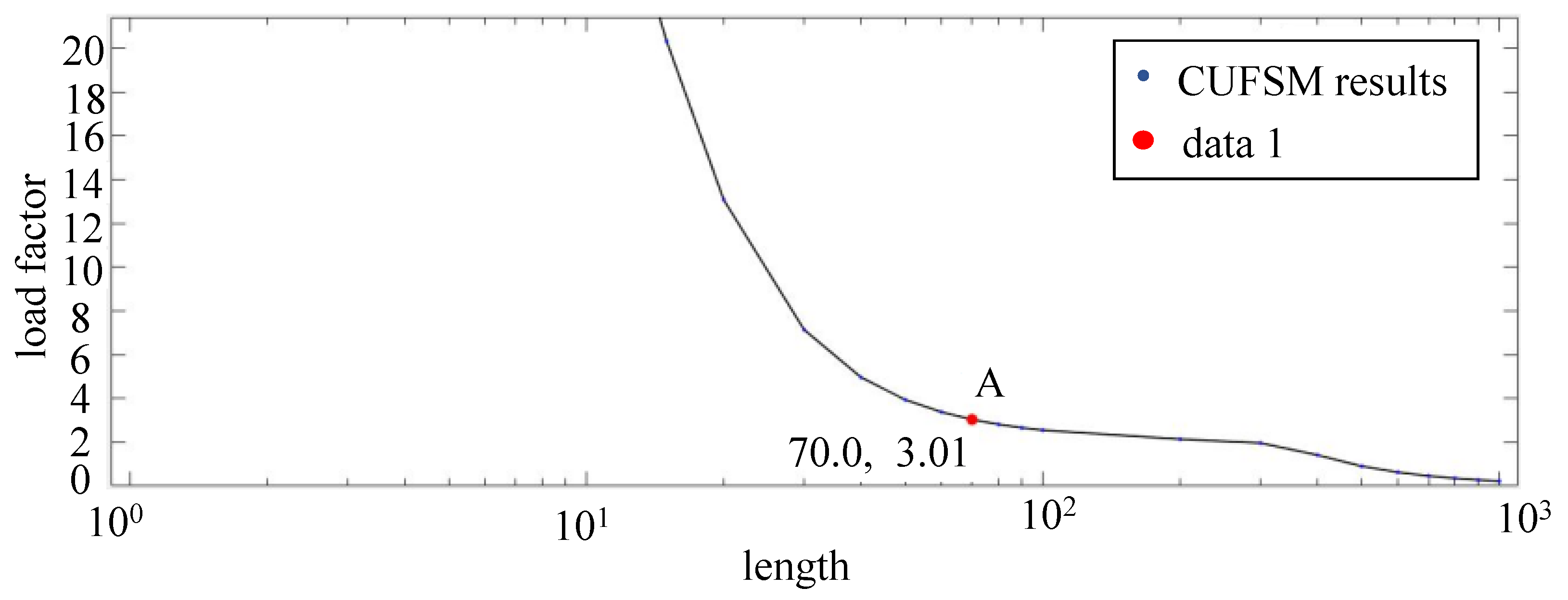

2.2. Verification of CUFSM

2.3. The Development of MATLAB Version of CUFSM

3. Critical Stress of Elastic Local Buckling of Angle Columns under Axial Compression

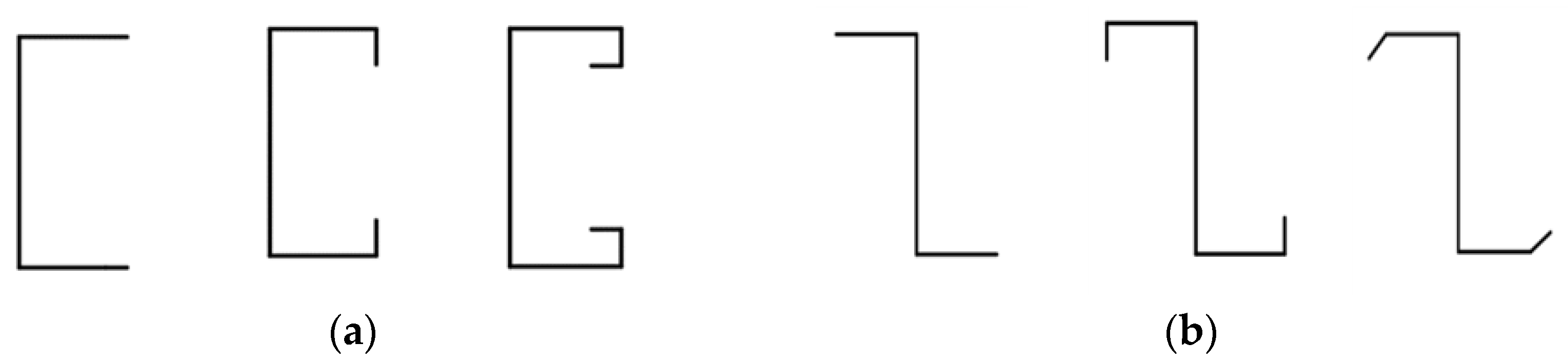

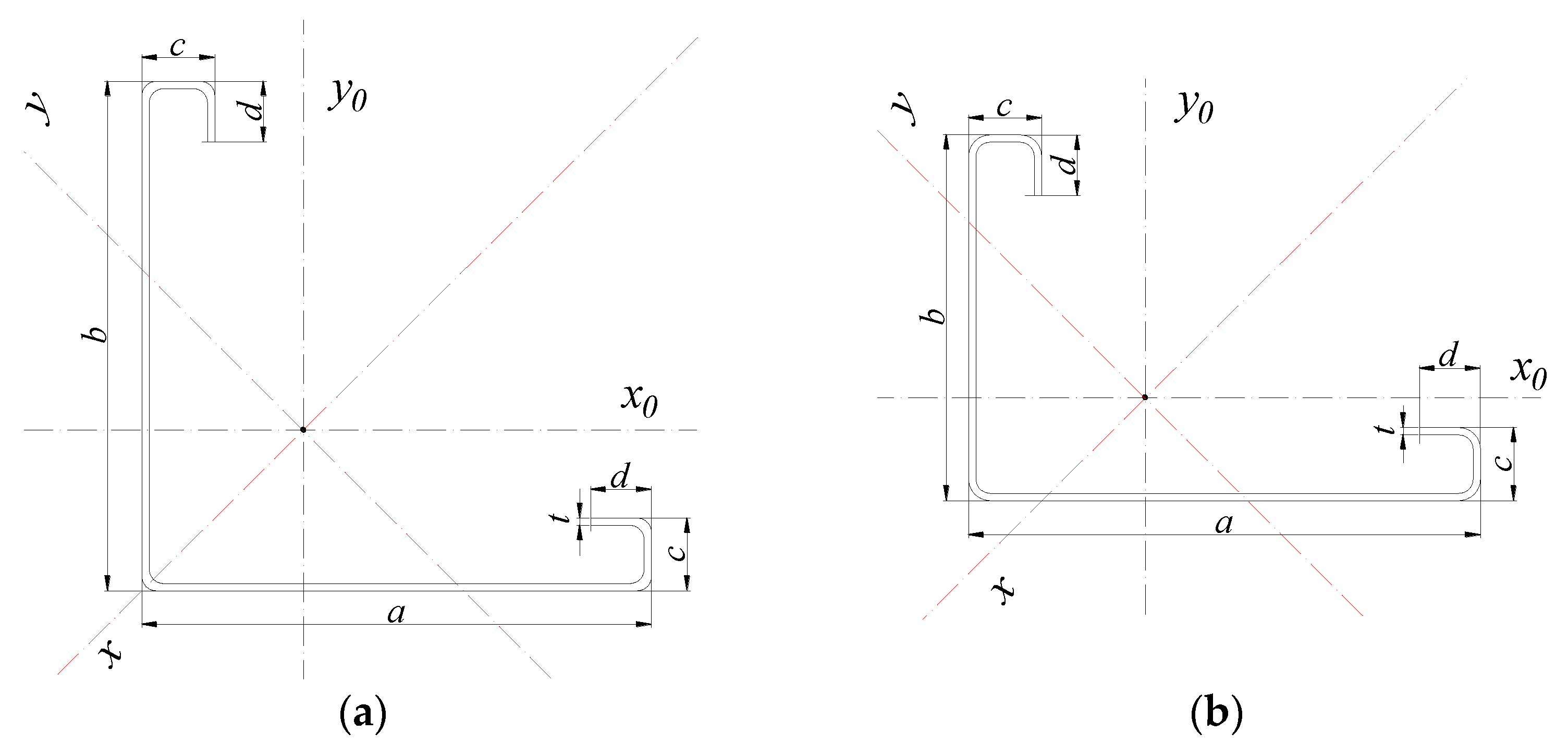

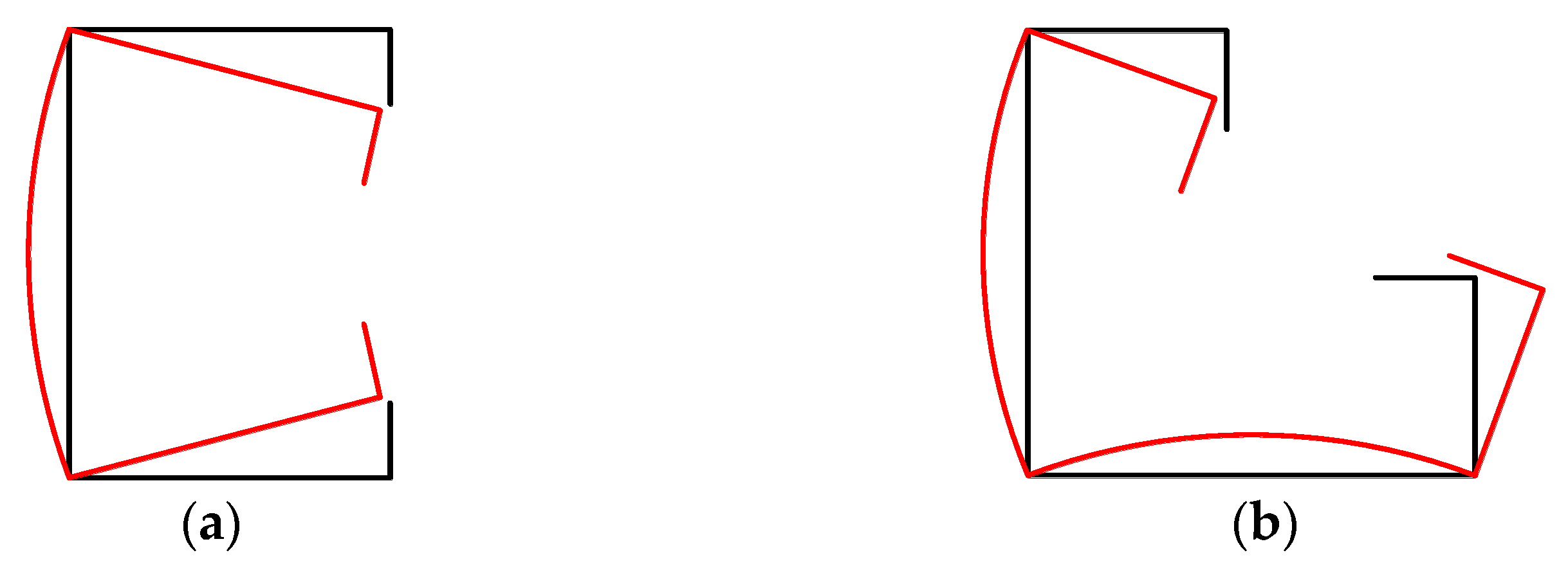

3.1. Sectional Dimension

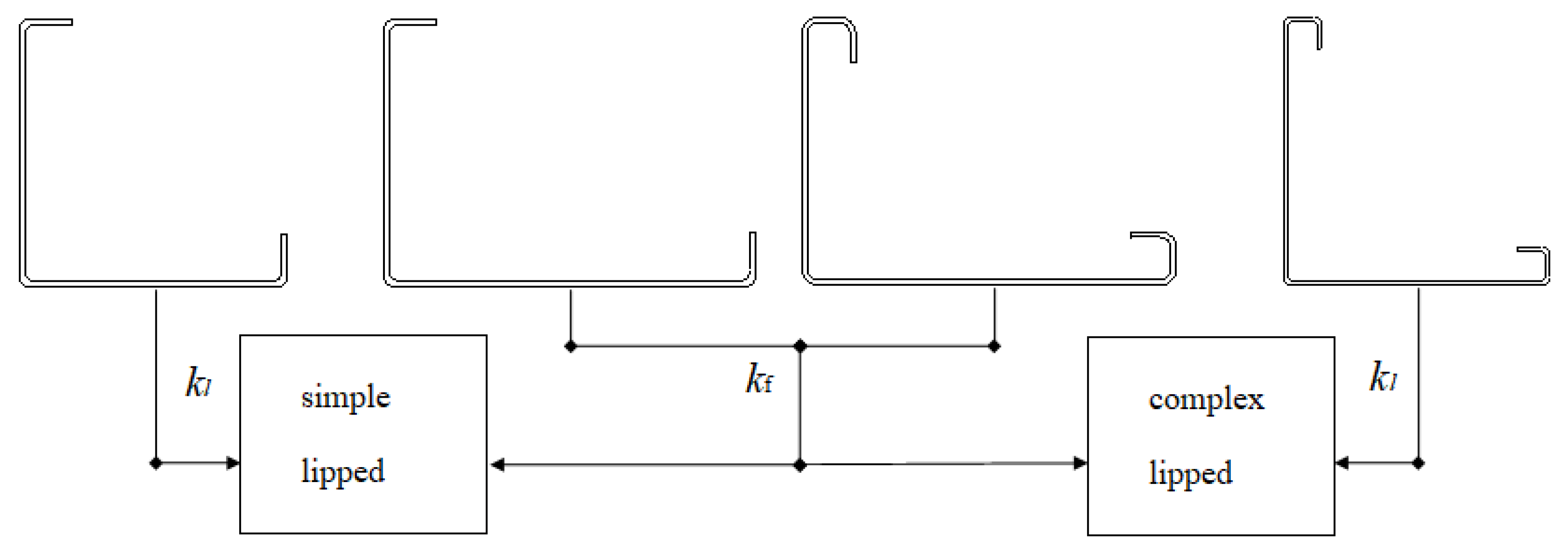

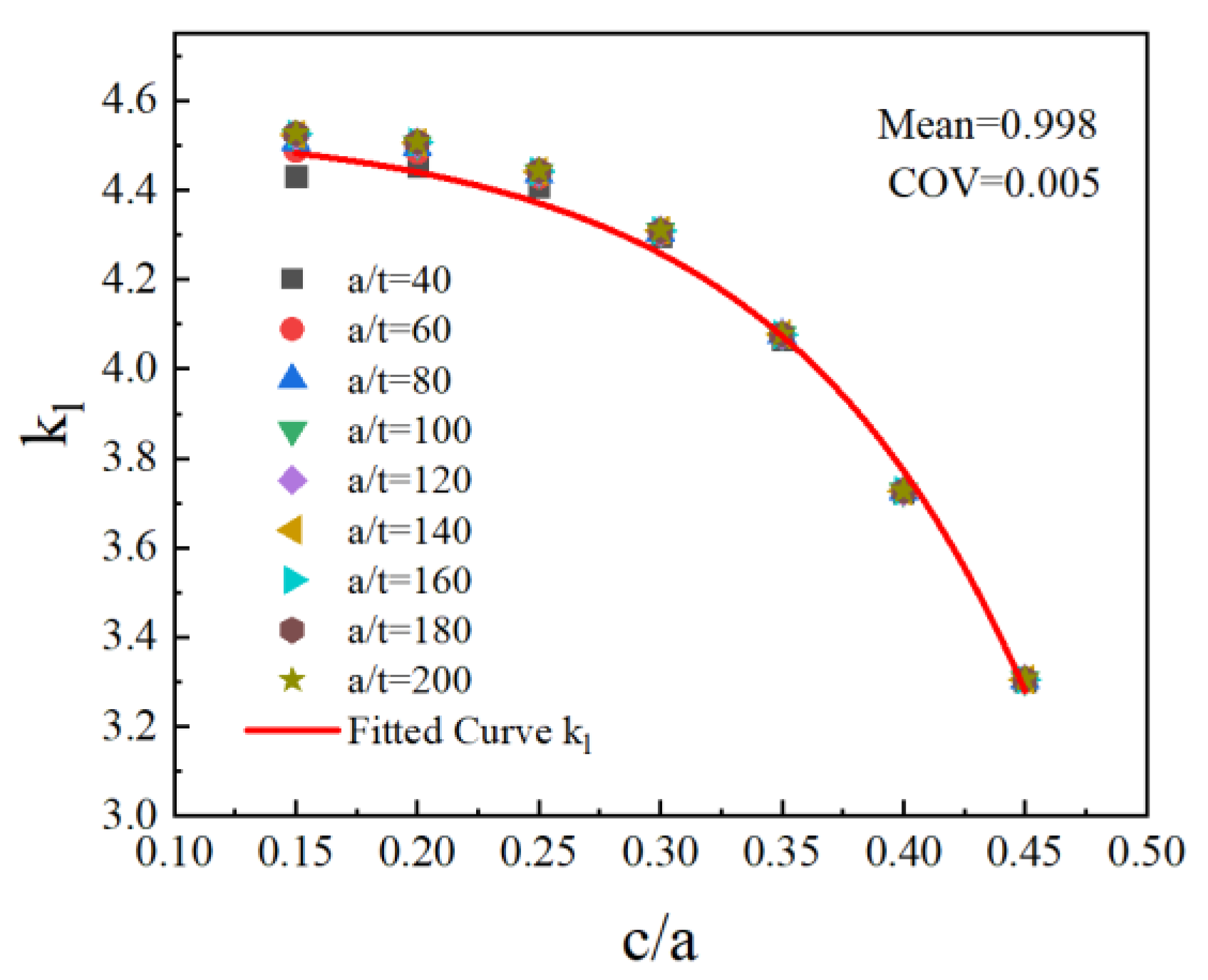

3.2. Critical Stress of Elastic Local Buckling of Simple Lipped Angle Members

3.3. Critical Stress of Elastic Local Buckling of Complex Lipped Angle Members

4. Critical Stress of the Elastic Distortional Buckling of Simple Lipped Angle Columns

5. Critical Stress of Elastic Distortional Buckling of Complex Lipped Angle Members

5.1. Section without Distortional Point

5.2. Section with Distortional Point

6. Conclusions

- (1)

- To calculate the critical stresses of elastic local buckling of the angle steel section, the interaction between the panels should be considered. The binding effect of different edge forms on the limb is not the same. The constraint effect of a complex edge on the limb is always greater than that of a simple edge.

- (2)

- The critical stress of elastic local buckling increases with the increase of the limb length ratio for both the simple lipped unequal limb angle steel and complex lipped unequal limb angle steel. Formulas for calculating the critical stress of elastic local buckling of lipped angle steel section considering the restraint between plates are proposed and verified.

- (3)

- According to the different methods of determining the critical stresses of elastic distortional buckling, the complex lipped angle steel sections are divided into two categories by judging the size of the first edge: (1) when c ≤ 0.3a, the curve doesn’t have the second minimum point, and the cross-section belongs to the section without distortional point; (2) when c > 0.3a, the second minimum point appears on the curve, and the cross-section belongs to the section with distortional point.

- (4)

- For the section without a distortional point, the critical stresses of elastic distortional buckling are taken as the lesser of the elastic critical stresses corresponding to the maximum deformation of distortion buckling (inflection point of curve) and the maximum probability of distortional buckling. For the section with a distortional point, the critical stress of the second minimum point (distortional point) in the curve can be taken as the critical stresses elastic of distortional buckling of the complex lipped angle section. The method proposed by Hancock can be used to calculate the elastic critical stresses of distortional buckling for this kind of section.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Deng, E.F.; Zong, L.; Ding, Y.; Zhang, Z.; Zhang, J.F.; Shi, F.W.; Cai, L.M.; Gao, S.C. Seismic performance of mid-to-high rise modular steel construction—A critical review. Thin-Walled Struct. 2020, 155, 106924. [Google Scholar] [CrossRef]

- Manikandan, P.; Aruna, G.; Balaji, S.; Sukumar, S.; Sivakumar, M. Evaluation on Effectiveness of Cold-Formed Steel Column with Various Types of Edge Stiffener. Arab. J. Sci. Eng. 2017, 42, 4157–4168. [Google Scholar] [CrossRef]

- Landolfo, R. Lightweight steel framed systems in seismic areas: Current achievements and future challenges. Thin-Walled Struct. 2019, 140, 114–131. [Google Scholar] [CrossRef]

- Chen, C.J.; Sun, L.; Meng, Y.J.; Liu, W. Study on the rise of container liner transportation industry against the trend under the epidemic situation: Research on liner monopoly mechanisaper. J. Phys. Conf. Ser. 2021, 1972, 012073. [Google Scholar] [CrossRef]

- Zhong, X.Y.; Zhang, H.Q.; Chen, H. Research on the Impact and Strategy of China’s Belt and Road Construction Enterprises from the Perspective of New Coronavirus Epidemic Situation. Front. Manag. Res. 2020, 4. [Google Scholar] [CrossRef]

- GB 50018-2020; Standard for Techniques of Cold-formed Steel Structures. Ministry of Construction of the People’s Republic of China, China Planning Press: Beijing, China, 2020. (In Chinese)

- Schafer, B.W.; Peköz, T. Direct strength prediction of cold-formed steel members using numerical elastic buckling solutions. In Proceedings of the Fourteenth International Specialty Conference on Cold-Formed Steel Structures, St. Louis, MO, USA, 15–16 October 1998; pp. 69–76. [Google Scholar]

- Rasmussen, K.J. Design of slender angle section beam-columns by the direct strength method. J. Struct. Eng. 2006, 132, 204–211. [Google Scholar] [CrossRef]

- Young, B.; Ellobody, E. Design of cold-formed steel unequal angle compression members. Thin-Walled Struct. 2007, 45, 330–338. [Google Scholar] [CrossRef]

- Young, B.; Chen, J. Column tests of cold-formed steel non-symmetric lipped angle sections. Constr. J. Constr. Steel Res. 2008, 64, 808–815. [Google Scholar] [CrossRef]

- AISI S100; North American Specification for the Design of Cold-Formed Steel Structural Members. American Iron and Steel Institute: Pittsburgh, PA, USA, 2016.

- Dos Santos, E.S.; Batista, E.M.; Camotim, D. Experimental investigation concerning lipped channel columns undergoing local-distortional-global buckling mode interaction. Thin-Walled Struct. 2012, 54, 19–34. [Google Scholar] [CrossRef]

- Torabian, S.; Zheng, B.F.; Schafer, B.W. Experimental response of cold-formed steel lipped channel beam–columns. Thin-Walled Struct. 2015, 89, 152–168. [Google Scholar] [CrossRef]

- Zhang, J.F.; Zhao, J.J.; Yang, D.Y.; Deng, E.F.; Wang, H.; Pang, S.Y.; Cai, L.M.; Gao, S.C. Mechanical-property tests on assembled-type light steel modular house. J. Constr. Steel Res. 2020, 168, 105981. [Google Scholar] [CrossRef]

- Zhang, J.F.; Pang, S.Y.; Zhou, Y.S.; Deng, E.F.; Wen, M.G.; Ye, L.; Guo, X.S. Axial compressive behavior of non-symmetric cold-formed angular column with complex edge. Thin-Walled Struct. 2021, 162, 107625. [Google Scholar] [CrossRef]

- Zhang, J.F.; Wang, B.; Wang, S.; Deng, E.F.; Zhang, P.; Pang, S.Y.; Wen, M.G.; Ye, L.; Guo, X.S.; Gao, J.L. Eccentric compressive distortional buckling and design of non-symmetric cold-formed angular column with complex edges. Thin-Walled Struct. 2021, 165, 107981. [Google Scholar] [CrossRef]

- Park, K.S.; Moon, J.; Lee, S.S.; Bae, K.W.; Roeder, C.W. Embedded steel column-to- foundation connection for a modular structural system. Eng. Struct. 2016, 110, 244–257. [Google Scholar] [CrossRef]

- CUFSM—CROSS-SECTION ELASTIC BUCKLING ANALYSIS. Available online: www.ce.jhu.edu/bschafer/cufsm (accessed on 1 September 2020).

- Sammy, C.W.; Hancock, G.J. Distortional Bcukling Formulas for Channel Columns. Struct. Eng. 1987, 113, 1063–1078. [Google Scholar]

- Jin, S.; Li, Z.J.; Tang, Q.; He, Z.Q.; Huang, H. A combined force/displacement-based constrained finite strip method for modal stability analysis of thin-walled members. Thin-Walled Struct. 2020, 159, 107322. [Google Scholar] [CrossRef]

- American Iron and Steel Institute; Committee on Specifications for the Design of Cold-Formed Steel Structural Members. Direct Strength Method (DSM) Design Guide; American Iron and Steel Institute: Washington, DC, USA, 2006. [Google Scholar]

- Young, B. Experimental investigation of cold-formed steel lipped angle concentrically loaded compression members. J. Struct. Eng. 2005, 131, 1390–1396. [Google Scholar] [CrossRef]

- Zhang, L.L.; Tan, K.H.; Zhao, O. Experimental and numerical studies of fixed-ended cold-formed stainless steel equal-leg angle section columns. Eng. Struct. 2019, 184, 134–144. (In Chinese) [Google Scholar] [CrossRef]

- Young, B. Tests and Design of Fixed-Ended Cold-Formed Steel Plain Angle Columns. J. Struct. Eng. 2004, 130, 1931–1940. [Google Scholar] [CrossRef]

- Zhou, Y.S. Study on the Stability Capacity of Cold-Formed Thin-Walled Steel Column with Complex Edging Unequal-Edge Angular Section. Master’s Dissertation, Zhengzhou University, Zhengzhou, China, 2020. (In Chinese). [Google Scholar]

| Series | a/t | a/b | c/a | d/a | d/c |

|---|---|---|---|---|---|

| Complex edge | 40~200 | 1.0~1.5 | 0.2~0.5 | 0.1~0.3 | 0.5~1.0 |

| a/t | Critical Stress of Elastic Local Buckling with Different c/a | ||||||

|---|---|---|---|---|---|---|---|

| 0.15 | 0.20 | 0.25 | 0.30 | 0.35 | 0.40 | 0.45 | |

| 40 | 515.63 | 518.02 | 512.94 | 499.99 | 472.89 | 433.36 | 384.09 |

| 60 | 232.11 | 231.96 | 229.06 | 222.53 | 210.65 | 192.60 | 170.86 |

| 80 | 131.13 | 130.81 | 129.05 | 125.25 | 118.57 | 108.40 | 96.14 |

| 100 | 84.09 | 83.82 | 82.66 | 80.20 | 75.89 | 69.40 | 61.54 |

| 120 | 58.46 | 58.25 | 57.42 | 55.71 | 52.72 | 48.19 | 42.74 |

| 140 | 42.97 | 42.80 | 42.19 | 40.94 | 38.73 | 35.40 | 31.40 |

| 160 | 32.91 | 32.78 | 32.30 | 31.34 | 29.65 | 27.11 | 24.04 |

| 180 | 26.01 | 25.90 | 25.53 | 24.76 | 23.43 | 21.42 | 19.00 |

| 200 | 21.07 | 20.98 | 20.68 | 20.06 | 18.98 | 17.35 | 15.39 |

| a/t | c/a | /MPa | /MPa | |

|---|---|---|---|---|

| 50 | 0.25 | 332.81 | 336.06 | 0.99 |

| 0.35 | 325.26 | 320.94 | 1.01 | |

| 0.45 | 287.79 | 278.80 | 1.03 | |

| 70 | 0.25 | 170.77 | 171.46 | 1.00 |

| 0.35 | 166.33 | 163.74 | 1.02 | |

| 0.45 | 146.83 | 142.24 | 1.03 | |

| 90 | 0.25 | 103.55 | 103.72 | 1.00 |

| 0.35 | 100.66 | 99.06 | 1.02 | |

| 0.45 | 88.90 | 86.05 | 1.03 | |

| 110 | 0.25 | 69.39 | 69.43 | 1.00 |

| 0.35 | 67.40 | 66.31 | 1.02 | |

| 0.45 | 59.50 | 57.60 | 1.03 | |

| Mean | 1.015 | |||

| COV | 0.013 |

| a/t | a/b | Critical Stresses of Local Buckling with Different c/a | ||||||

|---|---|---|---|---|---|---|---|---|

| 0.2 | 0.25 | 0.3 | 0.35 | 0.4 | 0.45 | 0.5 | ||

| 40 | 1.1 | 552.72 | 554.64 | 547.00 | 529.72 | 497.39 | 448.58 | 393.56 |

| 1.2 | 572.17 | 573.67 | 564.86 | 544.61 | 509.69 | 455.90 | 398.27 | |

| 1.3 | 583.39 | 584.61 | 574.92 | 553.01 | 515.77 | 459.98 | 400.96 | |

| 1.4 | 589.87 | 590.38 | 581.53 | 558.48 | 519.58 | 462.62 | 402.72 | |

| 1.5 | 594.07 | 594.48 | 586.23 | 562.44 | 522.30 | 464.51 | 403.92 | |

| 60 | 1.1 | 249.15 | 248.54 | 244.47 | 236.18 | 221.23 | 199.60 | 175.08 |

| 1.2 | 257.26 | 256.51 | 252.37 | 242.83 | 226.48 | 203.04 | 177.11 | |

| 1.3 | 261.69 | 260.80 | 256.45 | 246.60 | 229.44 | 204.92 | 178.18 | |

| 1.4 | 264.60 | 263.60 | 259.03 | 249.06 | 231.36 | 206.03 | 178.87 | |

| 1.5 | 266.72 | 265.65 | 260.90 | 250.85 | 232.62 | 206.83 | 179.37 | |

| 80 | 1.1 | 140.65 | 140.13 | 137.75 | 132.99 | 124.55 | 112.33 | 98.50 |

| 1.2 | 145.25 | 144.56 | 142.07 | 136.74 | 127.44 | 114.18 | 99.60 | |

| 1.3 | 147.87 | 147.08 | 144.38 | 138.87 | 129.06 | 115.21 | 100.22 | |

| 1.4 | 149.59 | 148.73 | 145.89 | 140.26 | 130.12 | 115.88 | 100.63 | |

| 1.5 | 150.71 | 149.94 | 146.99 | 141.27 | 130.88 | 116.37 | 100.92 | |

| 100 | 1.1 | 90.16 | 89.74 | 88.23 | 85.16 | 79.75 | 71.89 | 63.03 |

| 1.2 | 93.17 | 92.64 | 90.96 | 87.56 | 81.59 | 73.10 | 63.75 | |

| 1.3 | 94.79 | 94.27 | 92.47 | 88.92 | 82.62 | 73.77 | 64.15 | |

| 1.4 | 95.81 | 95.25 | 93.46 | 89.82 | 83.28 | 74.19 | 64.42 | |

| 1.5 | 96.56 | 95.97 | 94.19 | 90.42 | 83.76 | 74.49 | 64.61 | |

| 120 | 1.1 | 62.68 | 62.35 | 61.30 | 59.15 | 55.37 | 49.94 | 43.77 |

| 1.2 | 64.75 | 64.38 | 63.19 | 60.82 | 56.68 | 50.76 | 44.27 | |

| 1.3 | 65.88 | 65.47 | 64.25 | 61.77 | 57.39 | 51.22 | 44.56 | |

| 1.4 | 66.62 | 66.18 | 64.94 | 62.38 | 57.84 | 51.52 | 44.75 | |

| 1.5 | 67.16 | 66.70 | 65.41 | 62.80 | 58.17 | 51.74 | 44.88 | |

| 140 | 1.1 | 46.04 | 45.89 | 45.26 | 43.91 | 41.40 | 37.46 | 32.80 |

| 1.2 | 47.57 | 47.35 | 46.58 | 44.99 | 42.09 | 37.79 | 32.95 | |

| 1.3 | 48.43 | 48.15 | 47.31 | 45.60 | 42.49 | 37.99 | 33.04 | |

| 1.4 | 48.95 | 48.68 | 47.78 | 45.99 | 42.76 | 38.14 | 33.12 | |

| 1.5 | 49.33 | 49.04 | 48.13 | 46.28 | 42.97 | 38.25 | 33.18 | |

| 160 | 1.1 | 35.27 | 35.15 | 34.66 | 33.62 | 31.69 | 28.67 | 25.11 |

| 1.2 | 36.44 | 36.26 | 35.67 | 34.45 | 32.23 | 28.93 | 25.23 | |

| 1.3 | 37.08 | 36.88 | 36.23 | 34.91 | 32.54 | 29.09 | 25.30 | |

| 1.4 | 37.49 | 37.27 | 36.59 | 35.22 | 32.74 | 29.20 | 25.36 | |

| 1.5 | 37.79 | 37.55 | 36.86 | 35.44 | 32.90 | 29.29 | 25.40 | |

| 180 | 1.1 | 27.87 | 27.78 | 27.39 | 26.57 | 25.04 | 22.66 | 19.84 |

| 1.2 | 28.80 | 28.66 | 28.19 | 27.22 | 25.47 | 22.86 | 19.93 | |

| 1.3 | 29.31 | 29.14 | 28.63 | 27.59 | 25.71 | 22.99 | 19.99 | |

| 1.4 | 29.64 | 29.45 | 28.92 | 27.83 | 25.87 | 23.07 | 20.04 | |

| 1.5 | 29.87 | 29.68 | 29.13 | 28.01 | 26.00 | 23.14 | 20.07 | |

| 200 | 1.1 | 22.58 | 22.50 | 22.18 | 21.52 | 20.29 | 18.35 | 16.07 |

| 1.2 | 23.33 | 23.21 | 22.83 | 22.05 | 20.63 | 18.52 | 16.15 | |

| 1.3 | 23.75 | 23.61 | 23.19 | 22.35 | 20.83 | 18.62 | 16.19 | |

| 1.4 | 24.01 | 23.86 | 23.42 | 22.54 | 20.96 | 18.69 | 16.23 | |

| 1.5 | 24.20 | 24.04 | 23.59 | 22.69 | 21.06 | 18.74 | 16.26 | |

| a/t | a/b | /MPa | /MPa | |

|---|---|---|---|---|

| 70 | 1.1 | 175.34 | 171.57 | 1.02 |

| 1.2 | 179.67 | 176.16 | 1.02 | |

| 1.3 | 182.14 | 179.64 | 1.01 | |

| 1.4 | 183.80 | 182.01 | 1.01 | |

| 1.5 | 185.02 | 183.27 | 1.01 | |

| 110 | 1.1 | 71.10 | 69.48 | 1.02 |

| 1.2 | 72.85 | 71.34 | 1.02 | |

| 1.3 | 73.86 | 72.75 | 1.02 | |

| 1.4 | 74.49 | 73.71 | 1.01 | |

| 1.5 | 74.95 | 74.22 | 1.01 | |

| Mean | 1.016 | |||

| COV | 0.005 |

| a/t | d/c | Critical Stress of Elastic Local Buckling with Different c/a | |||||

|---|---|---|---|---|---|---|---|

| 0.20 | 0.25 | 0.30 | 0.35 | 0.40 | 0.45 | ||

| 40 | 0.50 | 553.17 | 578.69 | 583.60 | 583.57 | 581.68 | 579.08 |

| 0.75 | 576.74 | 587.51 | 588.06 | 585.83 | 582.64 | 579.00 | |

| 1.00 | 586.61 | 591.19 | 589.58 | 585.87 | 580.17 | - | |

| 60 | 0.50 | 259.53 | 263.49 | 263.18 | 261.95 | 260.57 | 258.98 |

| 0.75 | 265.15 | 265.33 | 263.92 | 262.27 | 260.59 | 256.00 | |

| 1.00 | 266.99 | 265.92 | 264.05 | 261.97 | 259.00 | - | |

| 80 | 0.50 | 148.84 | 149.18 | 148.43 | 147.47 | 146.51 | 145.59 |

| 0.75 | 150.55 | 149.86 | 148.73 | 147.57 | 146.46 | 144.00 | |

| 1.00 | 151.22 | 150.085 | 148.73 | 147.32 | 145.60 | - | |

| 100 | 0.50 | 96.12 | 95.82 | 95.18 | 94.52 | 93.90 | 93.32 |

| 0.75 | 96.79 | 96.08 | 95.29 | 94.54 | 93.85 | 92.30 | |

| 1.00 | 97.04 | 96.15 | 95.25 | 94.37 | 93.26 | - | |

| 120 | 0.50 | 67.07 | 66.71 | 66.18 | 65.67 | 65.21 | 64.77 |

| 0.75 | 67.41 | 66.83 | 66.24 | 65.68 | 65.16 | 64.10 | |

| 1 | 67.52 | 66.86 | 66.21 | 65.54 | 64.74 | - | |

| 140 | 0.5 | 49.39 | 49.04 | 48.63 | 48.26 | 47.93 | 47.62 |

| 0.75 | 49.59 | 49.12 | 48.66 | 48.26 | 47.93 | 47.10 | |

| 1.00 | 49.66 | 49.13 | 48.64 | 48.16 | 47.58 | - | |

| 160 | 0.50 | 37.88 | 37.58 | 37.26 | 36.97 | 36.70 | 36.45 |

| 0.75 | 38.00 | 37.62 | 37.28 | 36.96 | 36.66 | 36.10 | |

| 1.00 | 38.04 | 37.63 | 37.25 | 36.88 | 36.42 | - | |

| 180 | 0.50 | 29.98 | 29.71 | 29.44 | 29.21 | 29.00 | 28.81 |

| 0.75 | 30.05 | 29.74 | 29.45 | 29.20 | 28.97 | 28.50 | |

| 1.00 | 30.07 | 29.74 | 29.43 | 29.14 | 28.78 | - | |

| 200 | 0.50 | 24.30 | 24.07 | 23.85 | 23.67 | 23.49 | 23.33 |

| 0.75 | 24.35 | 24.09 | 23.86 | 23.66 | 23.47 | 23.10 | |

| 1.00 | 24.37 | 24.09 | 23.84 | 23.61 | 23.31 | - | |

| a/t | c/a | d/c | /MPa | /MPa | |

|---|---|---|---|---|---|

| 50 | 0.25 | 0.50 | 375.57 | 371.69 | 1.01 |

| 0.35 | 375.78 | 371.69 | 1.01 | ||

| 0.45 | 371.18 | 371.69 | 1.00 | ||

| 70 | 0.25 | 0.50 | 194.24 | 189.64 | 1.02 |

| 0.35 | 192.42 | 189.64 | 1.01 | ||

| 0.45 | 190.15 | 189.64 | 1.00 | ||

| 90 | 0.25 | 0.50 | 118.23 | 114.72 | 1.03 |

| 0.75 | 118.58 | 114.72 | 1.03 | ||

| 1.00 | 118.69 | 114.72 | 1.03 | ||

| 110 | 0.25 | 0.50 | 79.28 | 76.79 | 1.03 |

| 0.75 | 79.47 | 76.79 | 1.03 | ||

| 1.00 | 79.52 | 76.79 | 1.04 | ||

| Mean | 1.020 | ||||

| COV | 0.013 |

| a/t | a/b | Critical Stress of Elastic Local Buckling with Different c/a | ||||||

|---|---|---|---|---|---|---|---|---|

| 0.20 | 0.25 | 0.30 | 0.35 | 0.40 | 0.45 | 0.50 | ||

| 40 | 1.1 | 594.77 | 618.50 | 624.26 | 624.28 | 622.13 | 619.10 | 615.67 |

| 1.2 | 616.28 | 637.90 | 644.06 | 644.10 | 641.80 | 638.56 | 634.85 | |

| 1.3 | 627.99 | 648.71 | 655.10 | 655.16 | 652.77 | 649.41 | 645.54 | |

| 1.4 | 634.56 | 655.74 | 662.30 | 661.66 | 659.32 | 656.48 | 652.52 | |

| 1.5 | 639.31 | 660.85 | 666.77 | 665.42 | 663.06 | 660.29 | 657.32 | |

| 60 | 1.1 | 278.62 | 281.26 | 280.69 | 279.29 | 277.70 | 276.10 | 274.49 |

| 1.2 | 286.99 | 289.62 | 289.02 | 287.54 | 285.85 | 284.14 | 282.41 | |

| 1.3 | 291.52 | 294.24 | 293.62 | 292.09 | 290.35 | 288.58 | 286.78 | |

| 1.4 | 294.47 | 297.24 | 296.62 | 295.06 | 293.29 | 291.47 | 289.63 | |

| 1.5 | 296.61 | 299.44 | 298.81 | 297.23 | 295.43 | 293.58 | 291.70 | |

| 80 | 1.1 | 159.45 | 159.45 | 158.60 | 157.61 | 156.64 | 155.73 | 154.68 |

| 1.2 | 164.03 | 164.02 | 163.12 | 162.67 | 161.05 | 160.07 | 159.11 | |

| 1.3 | 166.54 | 166.17 | 165.61 | 164.53 | 163.47 | 162.46 | 161.46 | |

| 1.4 | 168.17 | 168.17 | 167.22 | 166.12 | 165.05 | 164.01 | 162.99 | |

| 1.5 | 169.36 | 169.36 | 168.40 | 167.29 | 166.19 | 165.14 | 164.10 | |

| 100 | 1.1 | 102.79 | 102.45 | 101.73 | 100.97 | 100.26 | 99.59 | 98.95 |

| 1.2 | 105.76 | 105.31 | 104.59 | 103.87 | 103.21 | 102.58 | 101.92 | |

| 1.3 | 107.34 | 106.88 | 106.14 | 105.40 | 104.71 | 104.07 | 103.44 | |

| 1.4 | 108.36 | 107.90 | 107.15 | 106.39 | 105.69 | 105.03 | 104.39 | |

| 1.5 | 109.11 | 108.65 | 107.90 | 107.12 | 106.40 | 105.73 | 105.08 | |

| 120 | 1.1 | 71.66 | 71.22 | 70.66 | 70.13 | 69.64 | 69.19 | 68.76 |

| 1.2 | 73.74 | 73.27 | 72.72 | 72.21 | 71.69 | 71.21 | 70.75 | |

| 1.3 | 74.82 | 74.34 | 73.78 | 73.25 | 72.77 | 72.33 | 71.85 | |

| 1.4 | 75.53 | 75.04 | 74.46 | 73.93 | 73.44 | 72.98 | 72.54 | |

| 1.5 | 76.04 | 75.55 | 74.96 | 74.42 | 73.92 | 73.46 | 73.01 | |

| 140 | 1.1 | 52.77 | 52.37 | 51.94 | 51.55 | 51.19 | 50.86 | 50.52 |

| 1.2 | 54.31 | 53.90 | 53.46 | 53.04 | 52.67 | 52.32 | 51.99 | |

| 1.3 | 55.10 | 54.67 | 54.24 | 53.85 | 53.48 | 53.12 | 52.78 | |

| 1.4 | 55.00 | 55.18 | 54.74 | 54.34 | 53.98 | 53.64 | 53.29 | |

| 1.5 | 55.97 | 55.55 | 55.10 | 54.69 | 54.33 | 53.99 | 53.66 | |

| 160 | 1.1 | 40.47 | 40.13 | 39.79 | 39.48 | 39.19 | 38.93 | 38.68 |

| 1.2 | 41.65 | 41.29 | 40.93 | 40.61 | 40.33 | 40.70 | 39.82 | |

| 1.3 | 42.25 | 41.89 | 41.55 | 41.23 | 40.94 | 40.67 | 40.41 | |

| 1.4 | 42.63 | 42.27 | 41.92 | 41.62 | 41.33 | 41.06 | 40.79 | |

| 1.5 | 42.92 | 42.55 | 42.20 | 41.89 | 41.61 | 41.34 | 41.07 | |

| 180 | 1.1 | 32.01 | 31.73 | 31.44 | 31.19 | 30.97 | 30.76 | 30.56 |

| 1.2 | 32.93 | 32.63 | 32.30 | 32.10 | 31.88 | 31.66 | 31.46 | |

| 1.3 | 33.41 | 33.12 | 32.83 | 32.58 | 32.35 | 32.14 | 31.94 | |

| 1.4 | 33.72 | 33.42 | 33.14 | 32.89 | 32.66 | 32.44 | 32.24 | |

| 1.5 | 33.94 | 33.63 | 33.35 | 33.11 | 32.88 | 32.66 | 32.45 | |

| 200 | 1.1 | 25.96 | 25.70 | 25.47 | 25.30 | 25.09 | 24.92 | 24.76 |

| 1.2 | 26.69 | 26.44 | 26.21 | 26.01 | 25.82 | 25.65 | 25.48 | |

| 1.3 | 26.87 | 26.83 | 26.60 | 26.39 | 26.21 | 26.04 | 25.87 | |

| 1.4 | 27.33 | 27.08 | 26.85 | 26.64 | 26.45 | 26.28 | 26.12 | |

| 1.5 | 27.51 | 27.25 | 27.02 | 26.82 | 26.63 | 26.46 | 26.29 | |

| a/t | a/b | /MPa | /MPa | |

|---|---|---|---|---|

| 70 | 1.1 | 205.67 | 198.70 | 1.04 |

| 1.2 | 211.80 | 204.02 | 1.04 | |

| 1.3 | 214.79 | 208.05 | 1.03 | |

| 1.4 | 216.72 | 210.79 | 1.03 | |

| 1.5 | 218.13 | 212.25 | 1.03 | |

| 110 | 1.1 | 83.46 | 80.47 | 1.04 |

| 1.2 | 85.86 | 82.62 | 1.04 | |

| 1.3 | 87.18 | 84.25 | 1.03 | |

| 1.4 | 88.03 | 85.36 | 1.03 | |

| 1.5 | 88.58 | 85.95 | 1.03 | |

| Mean | 1.033 | |||

| COV | 0.014 |

| a | b | c | d | a/b | d/c | c/a | Series | |

|---|---|---|---|---|---|---|---|---|

| 160 | 160 | 32 | 16 | 1.0 | 0.50 | 0.2 | 217 | without distortional point |

| 145 | 32 | 24 | 1.1 | 0.75 | 302 | |||

| 133 | 32 | 32 | 1.2 | 1.00 | 350 | |||

| 123 | 32 | 16 | 1.3 | 0.50 | 261 | |||

| 115 | 32 | 24 | 1.4 | 0.75 | 338 | |||

| 105 | 32 | 32 | 1.5 | 1.00 | 375 | |||

| 160 | 160 | 64 | 32 | 1.0 | 0.50 | 0.4 | 445 | with distortional point |

| 145 | 64 | 48 | 1.1 | 0.75 | 490 | |||

| 133 | 64 | 64 | 1.2 | 1.00 | 438 | |||

| 123 | 64 | 32 | 1.3 | 0.50 | 504 | |||

| 115 | 64 | 48 | 1.4 | 0.75 | 520 | |||

| 105 | 64 | 64 | 1.5 | 1.00 | 450 | |||

| 240 | 240 | 48 | 24 | 1.0 | 0.50 | 0.2 | 130 | without distortional point |

| 218 | 48 | 36 | 1.1 | 0.75 | 190 | |||

| 200 | 48 | 48 | 1.2 | 1.00 | 220 | |||

| 185 | 48 | 24 | 1.3 | 0.50 | 158 | |||

| 170 | 48 | 36 | 1.4 | 0.75 | 210 | |||

| 160 | 48 | 48 | 1.5 | 1.00 | 240 | |||

| 240 | 240 | 96 | 48 | 1.0 | 0.50 | 0.4 | 290 | with distortional point |

| 218 | 96 | 72 | 1.1 | 0.75 | 320 | |||

| 200 | 96 | 96 | 1.2 | 1.00 | 300 | |||

| 185 | 96 | 48 | 1.3 | 0.50 | 327 | |||

| 170 | 96 | 72 | 1.4 | 0.75 | 340 | |||

| 160 | 96 | 96 | 1.5 | 1.00 | 304 |

| Ca-b-c-d-t | a/b | Hancock | CUFSM | |

|---|---|---|---|---|

| C240-240-60-30-2 | 1.0 | 240.50 | 181.30 | 0.75 |

| C240-218-60-30-2 | 1.1 | 240.50 | 200.27 | 0.83 |

| C240-200-60-30-2 | 1.2 | 240.50 | 211.88 | 0.88 |

| C240-185-60-30-2 | 1.3 | 240.50 | 200.69 | 0.83 |

| C240-171-60-30-2 | 1.4 | 240.50 | 226.92 | 0.94 |

| C240-160-60-30-2 | 1.5 | 240.50 | 229.73 | 0.96 |

| C280-280-70-35-2 | 1.0 | 241.16 | 151.55 | 0.63 |

| C280-254-70-35-2 | 1.1 | 241.16 | 167.90 | 0.70 |

| C280-233-70-35-2 | 1.2 | 241.16 | 179.23 | 0.74 |

| C280-215-70-35-2 | 1.3 | 241.16 | 185.62 | 0.77 |

| C280-200-70-35-2 | 1.4 | 241.16 | 190.96 | 0.79 |

| C280-185-70-35-2 | 1.5 | 241.16 | 193.70 | 0.80 |

| C360-360-90-45-2 | 1.0 | 236.94 | 114.76 | 0.48 |

| C360-327-90-45-2 | 1.1 | 236.94 | 127.01 | 0.54 |

| C360-300-90-45-2 | 1.2 | 236.94 | 135.14 | 0.57 |

| C360-276-90-45-2 | 1.3 | 236.94 | 141.00 | 0.60 |

| C360-257-90-45-2 | 1.4 | 236.94 | 144.51 | 0.61 |

| C360-240-90-45-2 | 1.5 | 236.94 | 147.62 | 0.62 |

| Mean | 0.73 | |||

| COV | 0.14 |

| Ca-b-c-d-t | a/b | Hancock | CUFSM | |

|---|---|---|---|---|

| C240-240-108-54-2 | 1.0 | 321.54 | 302.39 | 0.94 |

| C240-218-108-54-2 | 1.1 | 321.54 | 307.88 | 0.96 |

| C240-200-108-54-2 | 1.2 | 321.54 | 317.82 | 0.99 |

| C240-185-108-54-2 | 1.3 | 321.54 | 327.78 | 1.02 |

| C240-171-108-54-2 | 1.4 | 321.54 | 334.34 | 1.04 |

| C240-160-108-54-2 | 1.5 | 321.54 | 338.77 | 1.05 |

| C280-280-126-63-2 | 1.0 | 268.80 | 257.41 | 0.96 |

| C280-254-126-63-2 | 1.1 | 268.80 | 270.61 | 1.01 |

| C280-233-126-63-2 | 1.2 | 268.80 | 279.14 | 1.04 |

| C280-215-126-63-2 | 1.3 | 268.80 | 284.77 | 1.05 |

| C280-200-126-63-2 | 1.4 | 268.80 | 288.58 | 1.07 |

| C280-185-126-63-2 | 1.5 | 268.80 | 291.10 | 1.08 |

| C360-360-162-81-2 | 1.0 | 200.66 | 198.4 | 0.99 |

| C360-327-162-81-2 | 1.1 | 200.66 | 208.64 | 1.04 |

| C360-300-162-81-2 | 1.2 | 200.66 | 215.26 | 1.07 |

| C360-276-162-81-2 | 1.3 | 200.66 | 219.65 | 1.09 |

| C360-257-162-81-2 | 1.4 | 200.66 | 221.00 | 1.10 |

| C360-240-162-81-2 | 1.5 | 200.66 | 224.00 | 1.11 |

| Mean | 1.033 | |||

| COV | 0.048 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Li, B.; Li, A.; Pang, S. Critical Stress Determination of Local and Distortional Buckling of Lipped Angle Columns under Axial Compression. Buildings 2022, 12, 712. https://doi.org/10.3390/buildings12060712

Zhang J, Li B, Li A, Pang S. Critical Stress Determination of Local and Distortional Buckling of Lipped Angle Columns under Axial Compression. Buildings. 2022; 12(6):712. https://doi.org/10.3390/buildings12060712

Chicago/Turabian StyleZhang, Junfeng, Bo Li, Anqi Li, and Shiyun Pang. 2022. "Critical Stress Determination of Local and Distortional Buckling of Lipped Angle Columns under Axial Compression" Buildings 12, no. 6: 712. https://doi.org/10.3390/buildings12060712

APA StyleZhang, J., Li, B., Li, A., & Pang, S. (2022). Critical Stress Determination of Local and Distortional Buckling of Lipped Angle Columns under Axial Compression. Buildings, 12(6), 712. https://doi.org/10.3390/buildings12060712