Technical Performance Overview of Bio-Based Insulation Materials Compared to Expanded Polystyrene

Abstract

1. Introduction

2. Results

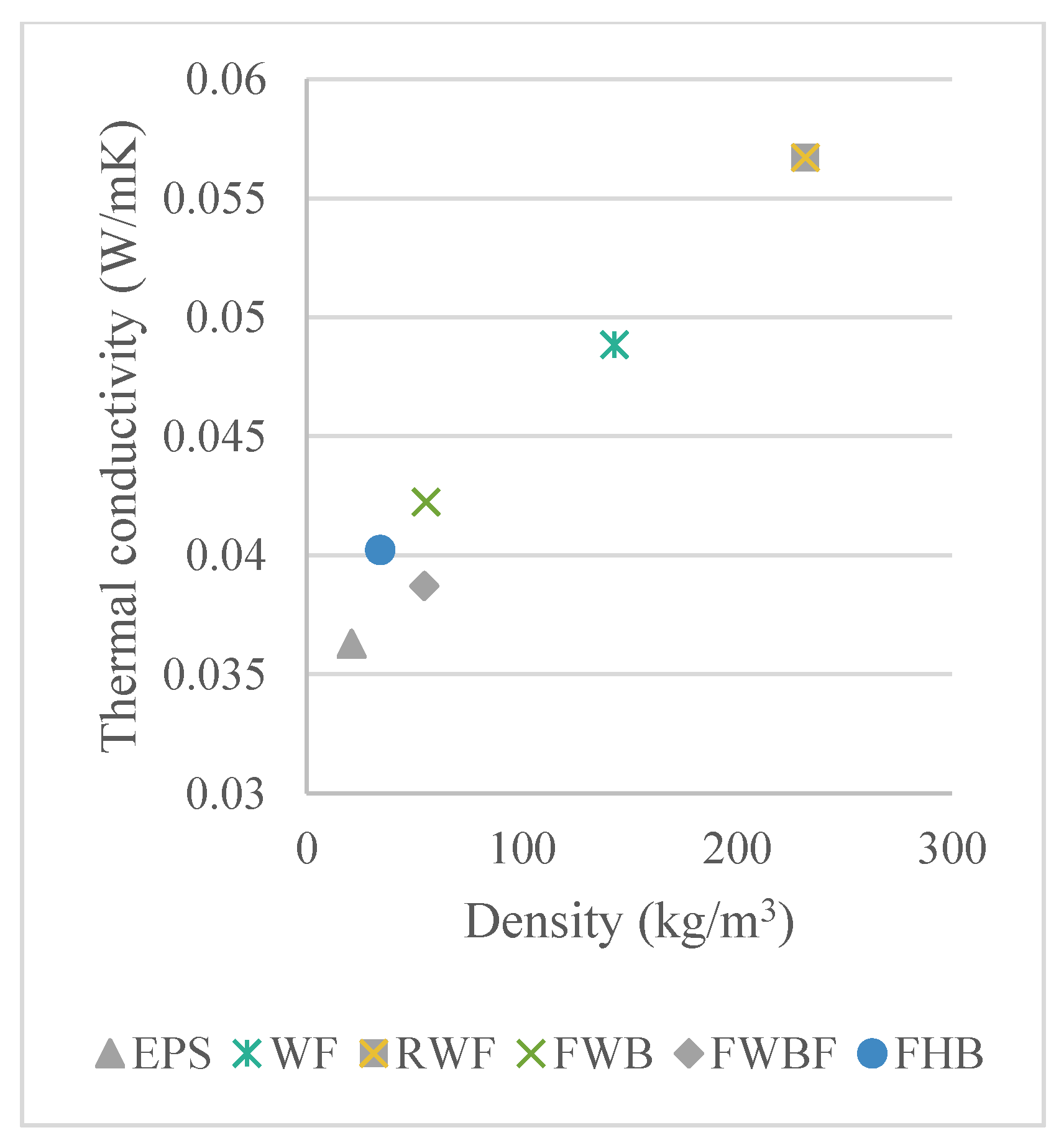

2.1. Density vs. Thermal Conductivity

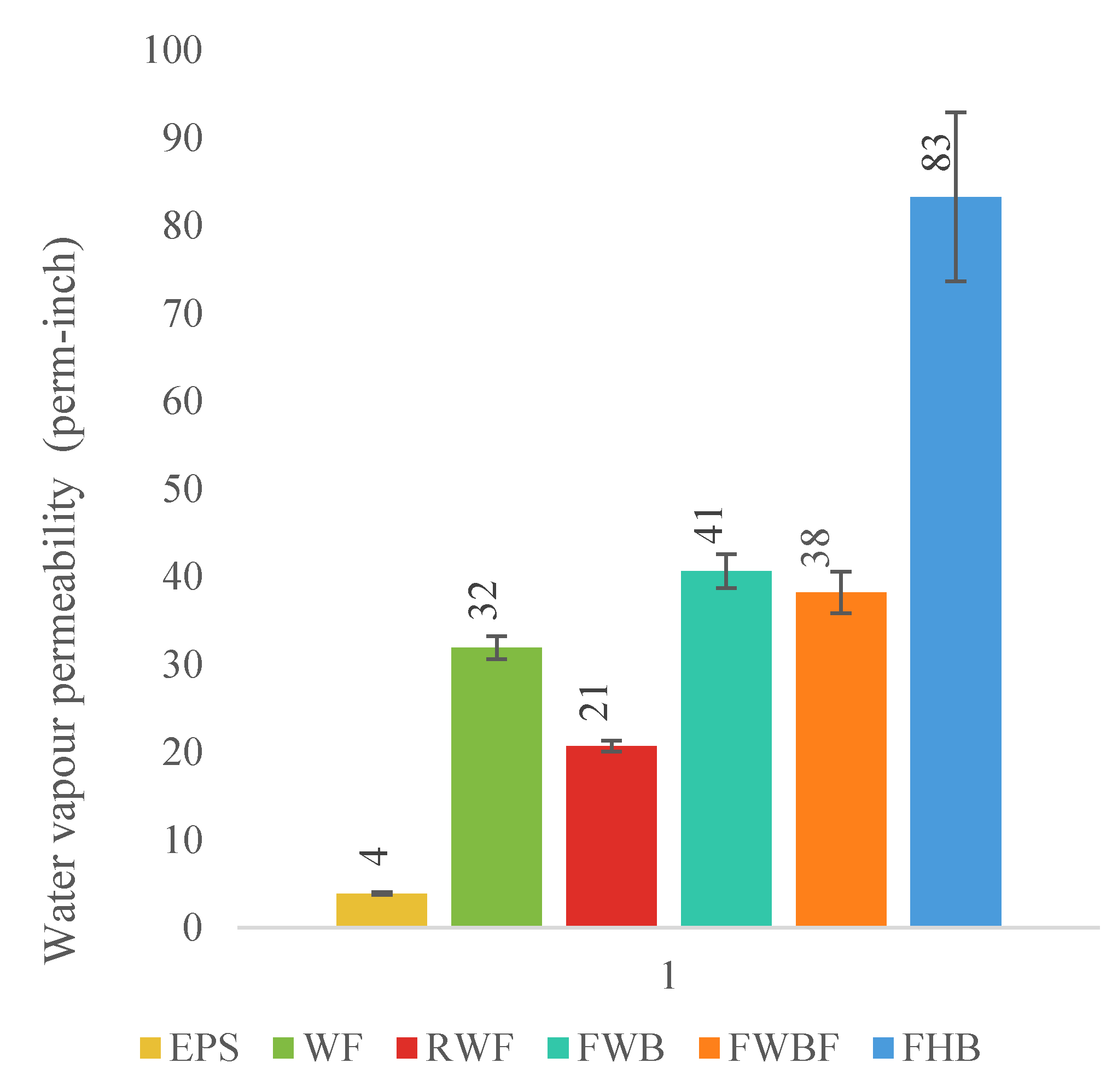

2.2. Water Vapor Permeability

2.3. Fire Behavior

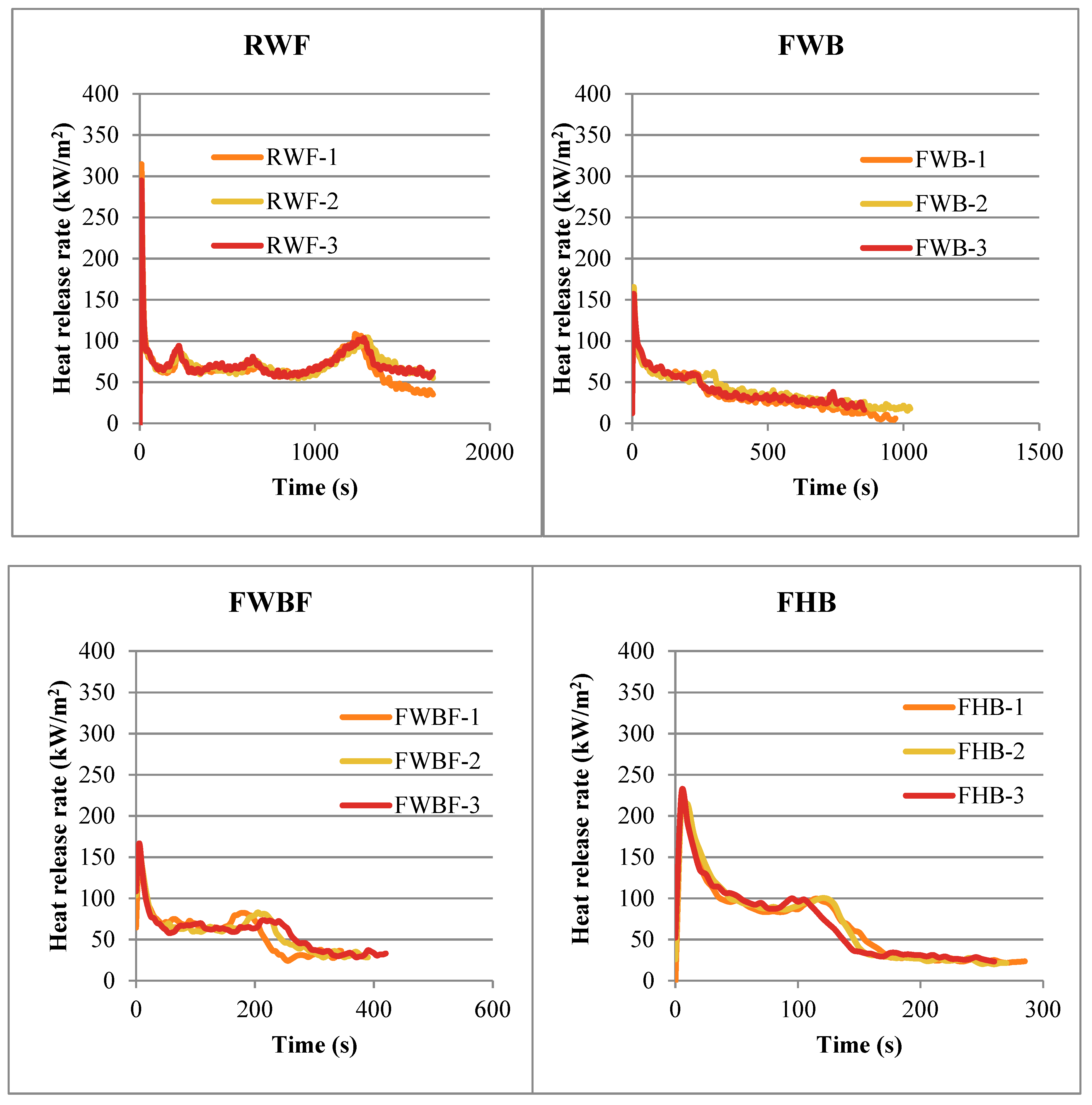

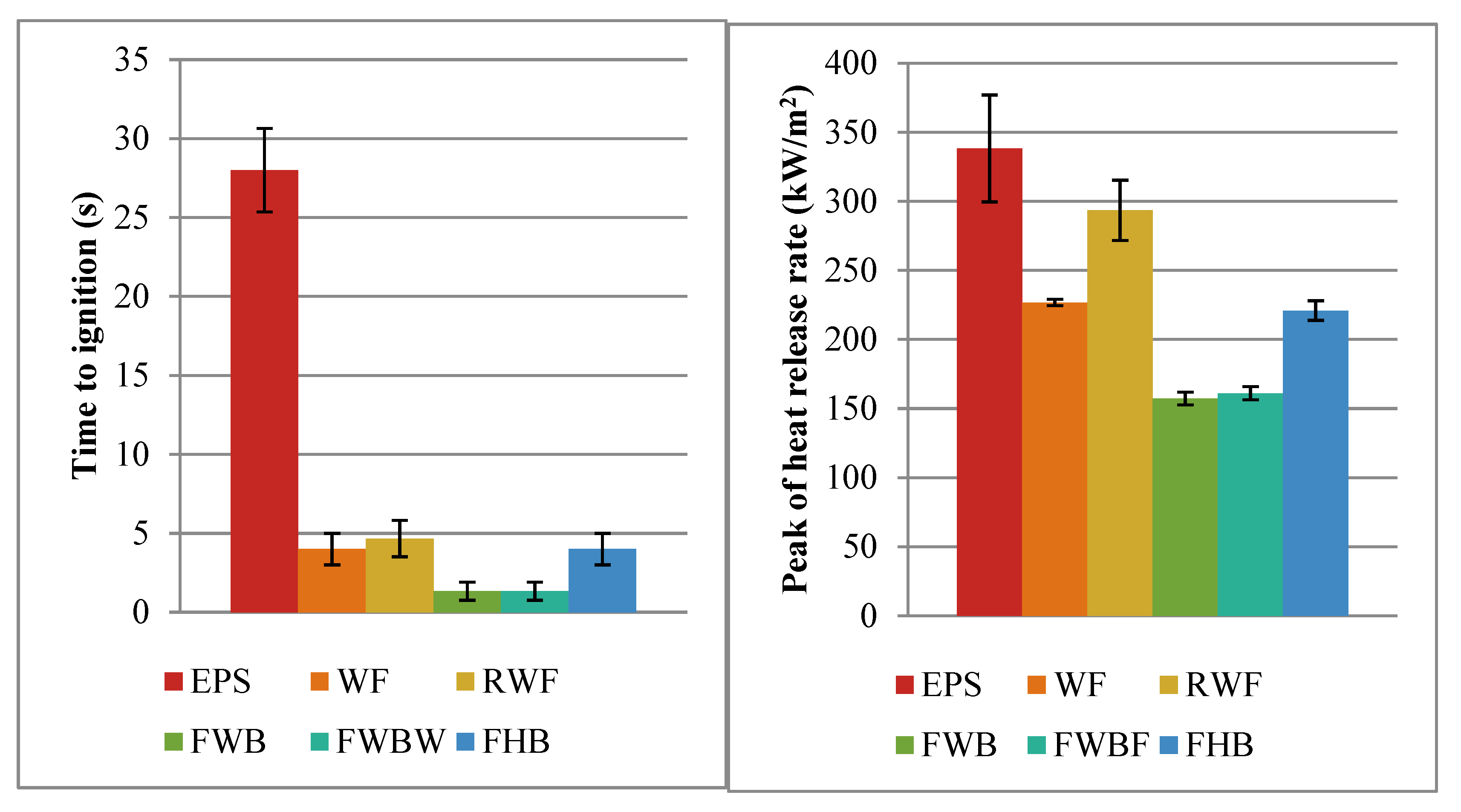

2.3.1. Heat Release and Ignition

2.3.2. Smoke Obscuration

2.3.3. Toxic Gases

2.4. Relative Assessment

3. Materials and Methods

3.1. Materials

3.2. Thermal Conductivity

3.3. Water Vapor Transmission

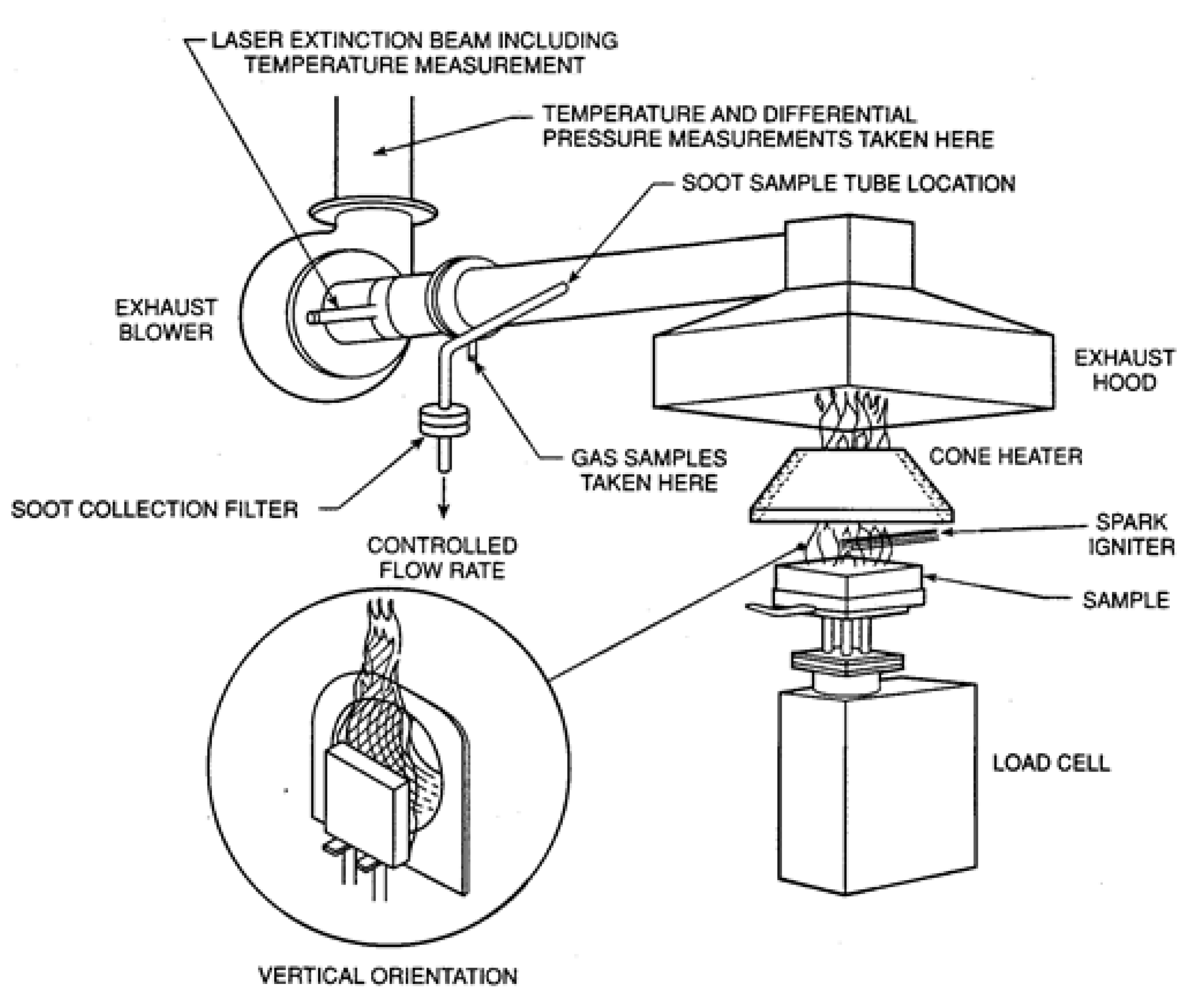

3.4. Fire Behaviour

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Papadopoulos, A.M. State of the art in thermal insulation materials and aims for future developments. Energy Build. 2005, 37, 77–86. [Google Scholar] [CrossRef]

- Grand View Research, Inc. North America Building Thermal Insulation Market Analysis by Product (Glass Wool, Mineral Wool, EPS, XPS), by Application (Roof, Wall, Floor), by End-use (Residential, Non-residential). Compet. Landsc. Segm. Forecast. 2016, 2014–2025. [Google Scholar]

- IEA. Global Status Report for Buildings and Construction 2019; IEA: Paris, France, 2019. [Google Scholar]

- Thormark, C. The effect of material choice on the total energy need and recycling potential of a building. Build. Environ. 2006, 41, 1019–1026. [Google Scholar] [CrossRef]

- Cetiner, I.; Shea, A.D. Wood waste as an alternative thermal insulation for buildings. Energy Build. 2018, 168, 374–384. [Google Scholar] [CrossRef]

- Balo, F. Feasibility study of “green” insulation materials including tall oil: Environmental, economical and thermal properties. Energy Build. 2015, 86, 161–175. [Google Scholar] [CrossRef]

- Volf, M.; Diviš, J.; Havlík, F. Thermal, moisture and biological behaviour of natural insulating materials. Energy Procedia 2015, 78, 1599–1604. [Google Scholar] [CrossRef]

- Ziegler, A.R.; Bajwa, S.G.; Holt, G.A.; McIntyre, G.; Bajwa, D.S. Evaluation of physico-mechanical properties of mycelium reinforced green biocomposites made from cellulosic fibers. Appl. Eng. Agric. 2016, 32, 931–938. [Google Scholar]

- Halpern, J.M.; Urbanski, R.; Weinstock, A.K.; Iwig, D.F.; Mathers, R.T.; von Recum, H.A. A biodegradable thermoset polymer made by esterification of citric acid and glycerol. J. Biomed. Mater. Res. Part A 2014, 102, 1467–1477. [Google Scholar] [CrossRef] [PubMed]

- Asdrubali, F.; D’Alessandro, F.; Schiavoni, S. A review of unconventional sustainable building insulation materials. Sustain. Mater. Technol. 2015, 4, 1–17. [Google Scholar] [CrossRef]

- Reif, M.; Zach, J.; Hroudová, J. Studying the properties of particulate insulating materials on natural basis. Procedia Eng. 2016, 151, 368–374. [Google Scholar] [CrossRef]

- Vink, E.T.; Rabago, K.R.; Glassner, D.A.; Gruber, P.R. Applications of life cycle assessment to NatureWorks™ polylactide (PLA) production. Polym. Degrad. Stab. 2003, 80, 403–419. [Google Scholar] [CrossRef]

- Steen-Hansen, A.; Jensen, U.E.; Mikalsen, R.F. Smouldering combustion in loose-fill wood fibre thermal insulation: An experimental study. Fire Technol. 2018, 54, 1585–1608. [Google Scholar] [CrossRef]

- Cai, X.; Deng, X.J.; Dery, N.; Lebel, S.; Brunette, S.G. Method of Producing Ultra-Low Density Fiber Composite Materials. Patent WO2015066806A1, 12 June 2014. [Google Scholar]

- Wood Panel Industries Federation; TRADA Technology Ltd.; National Panel Products Division, Panel Guide (V4). 2014. Available online: http://wpif.org.uk/PanelGuide (accessed on 6 December 2018).

- ASHRAE. American Society of Heating, Handbook-Fundamentals; ASHRAE: Atlanta, GA, USA, 2017. [Google Scholar]

- Al-Homoud, M. Performance characteristics and practical applications of common building thermal insulation materials. Build. Environ. 2005, 40, 353–366. [Google Scholar] [CrossRef]

- Hidalgo-Medina, J.P. Performance-Based Methodology of Fire Safe Design of Insulation Materials in Energy Efficient Buildings; The University of Edinburgh: Edinburgh, UK, 2015. [Google Scholar]

- Lowden, L.; Hull, T. Flammability behaviour of wood and a review of the methods for its reduction. Fire Sci. Rev. 2013, 2, 4. [Google Scholar] [CrossRef]

- Palumbo, M.; Lacasta, A.; Navarro, A.; Giraldo, M.; Lesar, B. Improvement of fire reaction and mould growth resistance of a novel bio-based thermal insulation material. Constr. Build. Mater. 2016, 139, 531–539. [Google Scholar] [CrossRef]

- Ostman, B.; Tsantaridis, L. Innovative Eco-Efficient High Fire Performance Wood Products for Demanding Applications SP Report 30; Wood Technology: Stockholm, Sweden, 2006. [Google Scholar]

- Isolofoam. Isolofoam ISO R Plus Premium: Interior Isulation for Walls and Ceilings. 2019. Available online: https://www.isolofoam.com/english/iso-r-plus-premium (accessed on 6 December 2018).

- MSL. MSL SONOclimat eco4: The Most Environmentally Friendly Insulation Panel in Canada. 2019. Available online: http://www.mslre.com/Produits/Fiche/13/SONOclimatECO4 (accessed on 6 December 2018).

- American Society for Testing and Materials. Standard Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- American Society for Testing and Materials. Standard Test Methods for Water Vapor Transmission of Materials; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- Dagenais, C. Assessment of Combustibility Parameters of Structural Composite Lumber; FPInnovations: Vancouver, BC, Canada, 2014. [Google Scholar]

- Huggett, C. Estimation of Rate of Heat Release by eans of Oxygen Consumption Measurements. Fire Mater. 1980, 4, 61–65. [Google Scholar] [CrossRef]

- Dagenais, C.; Côté, F.; Grandmont, J.-F.; Knudons, R.M. Part XII: Combustion Properties of Multi-Functional Panels and Panel Components; FPInnovations: Québec, QC, Canada, 2016. [Google Scholar]

| Vapor Impermeable | 0.1 Perm or Less |

|---|---|

| Vapor semi-impermeable | 1.0 perm or less and greater than 0.1 perm |

| Vapor semi-permeable | 10 perms or less and greater than 1.0 perm |

| Vapor permeable | greater than 10 perms |

| Sample Abbreviation | Product | Commercial Name | Manufacturer |

|---|---|---|---|

| EPS | Expanded graphite polystyrene | Iso R plus Premium | Isolofoam (Canada) |

| WF | Wood fiberboard | STEICO internal | STEICO (Poland) |

| RWF | Recycled wood fiberboard | SONO climat ECO4 | MSL (Canada) |

| FWB | Flexible wood batt | Steico flex036 | STEICO (Poland) |

| FWBF | Flexible wood batt with foaming process | Ultra-low density composite (R&D state) | FPInnovations (Canada) |

| FHB | Flexible hemp batt | Naturechanvre | Naturefibres (Canada) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lafond, C.; Blanchet, P. Technical Performance Overview of Bio-Based Insulation Materials Compared to Expanded Polystyrene. Buildings 2020, 10, 81. https://doi.org/10.3390/buildings10050081

Lafond C, Blanchet P. Technical Performance Overview of Bio-Based Insulation Materials Compared to Expanded Polystyrene. Buildings. 2020; 10(5):81. https://doi.org/10.3390/buildings10050081

Chicago/Turabian StyleLafond, Cassandra, and Pierre Blanchet. 2020. "Technical Performance Overview of Bio-Based Insulation Materials Compared to Expanded Polystyrene" Buildings 10, no. 5: 81. https://doi.org/10.3390/buildings10050081

APA StyleLafond, C., & Blanchet, P. (2020). Technical Performance Overview of Bio-Based Insulation Materials Compared to Expanded Polystyrene. Buildings, 10(5), 81. https://doi.org/10.3390/buildings10050081