Designed Materials by Additive Manufacturing—Impact of Exposure Strategies and Parameters on Material Characteristics of AlSi10Mg Processed by Laser Beam Melting

Abstract

:1. Introduction

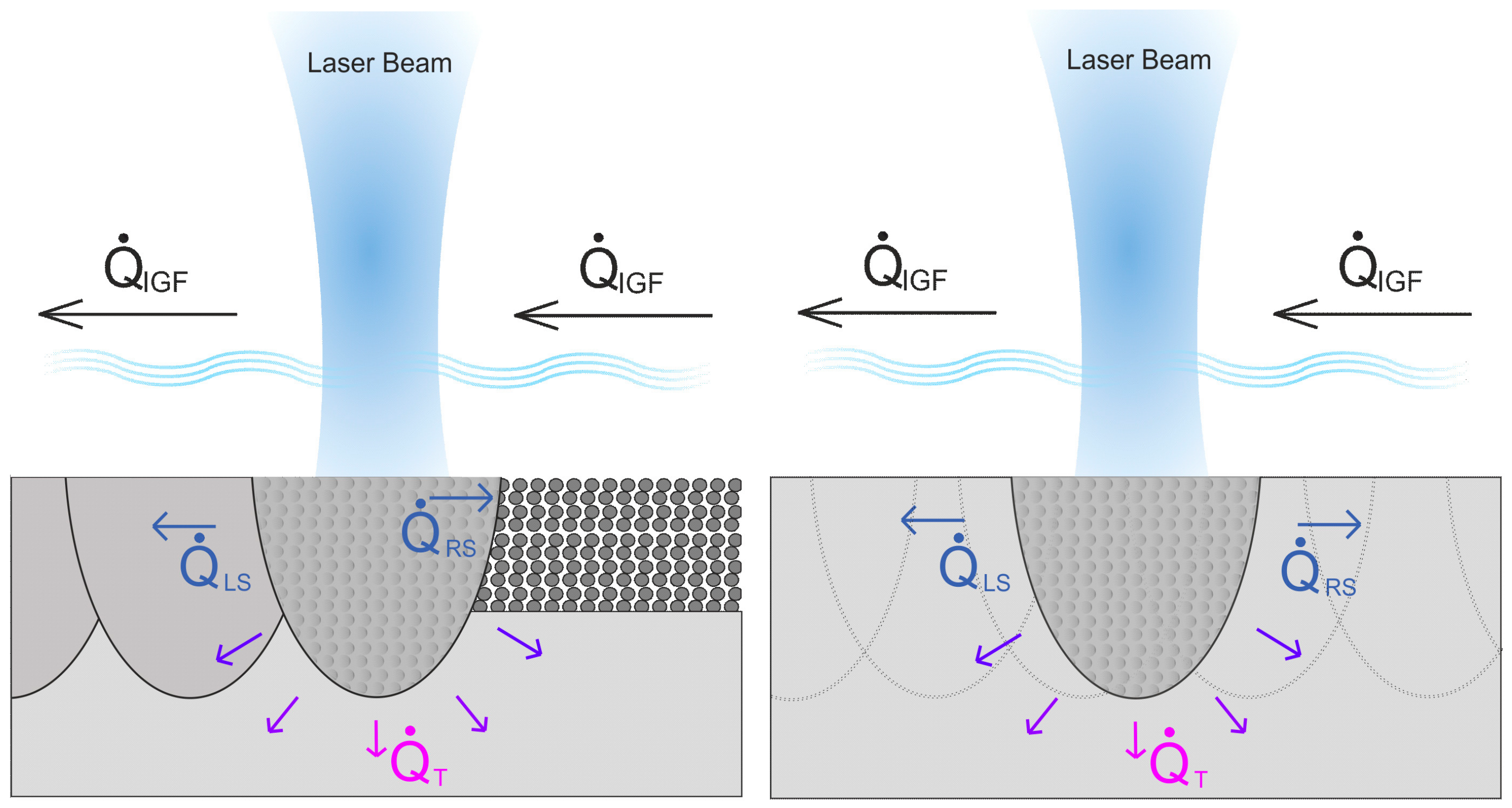

1.1. State of the Art Regarding Laser Beam Melting

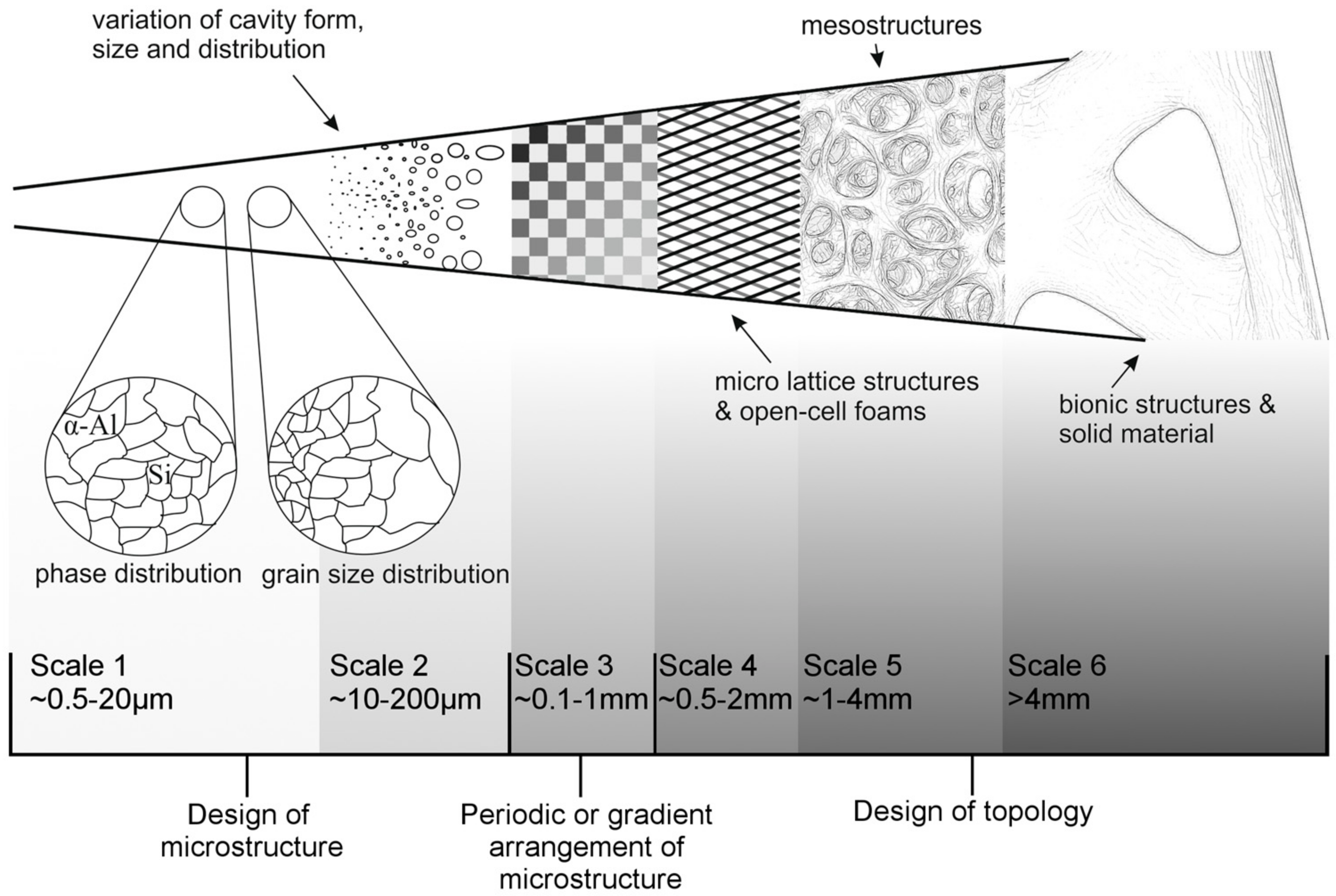

1.2. Methodology Proposistion Regarding Designed Materials

1.3. Relevant Preliminary Work Regarding Designed Materials

1.4. Research Objective

2. Materials and Methods

3. Results and Discussion

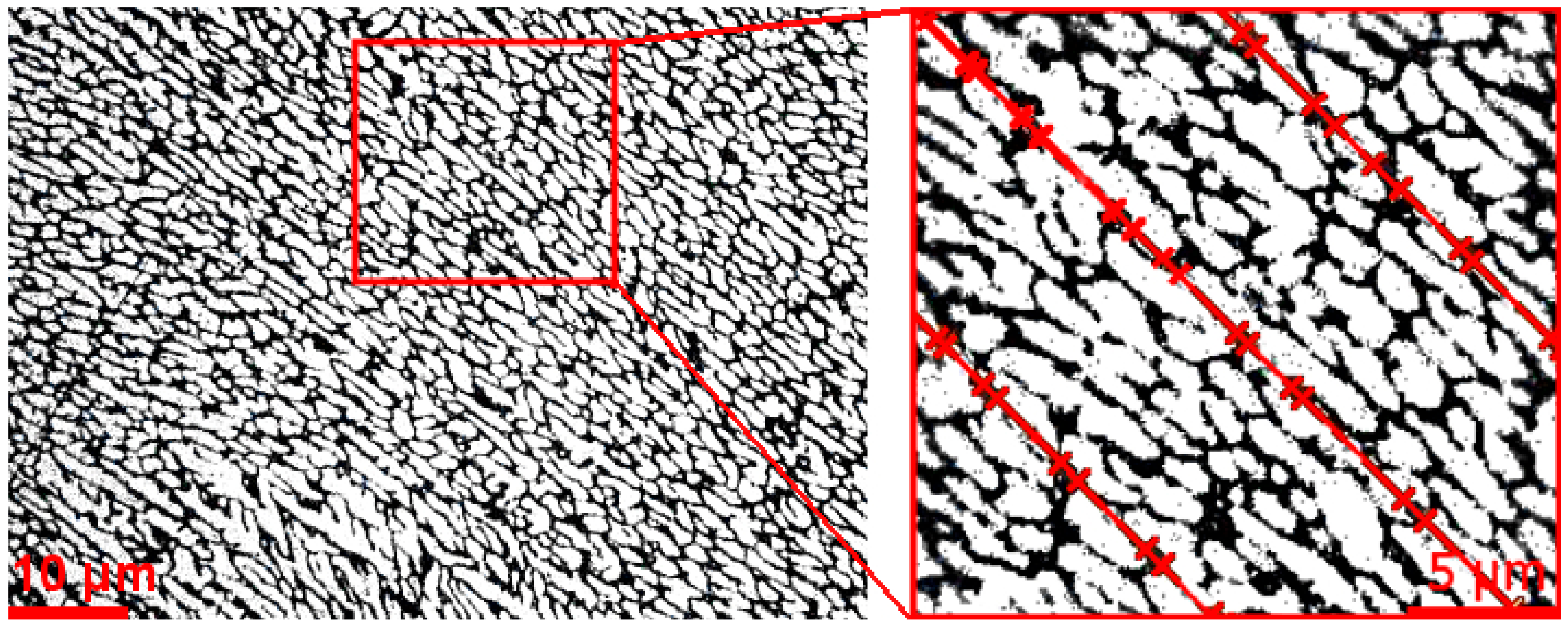

3.1. EDX Phase Analysis

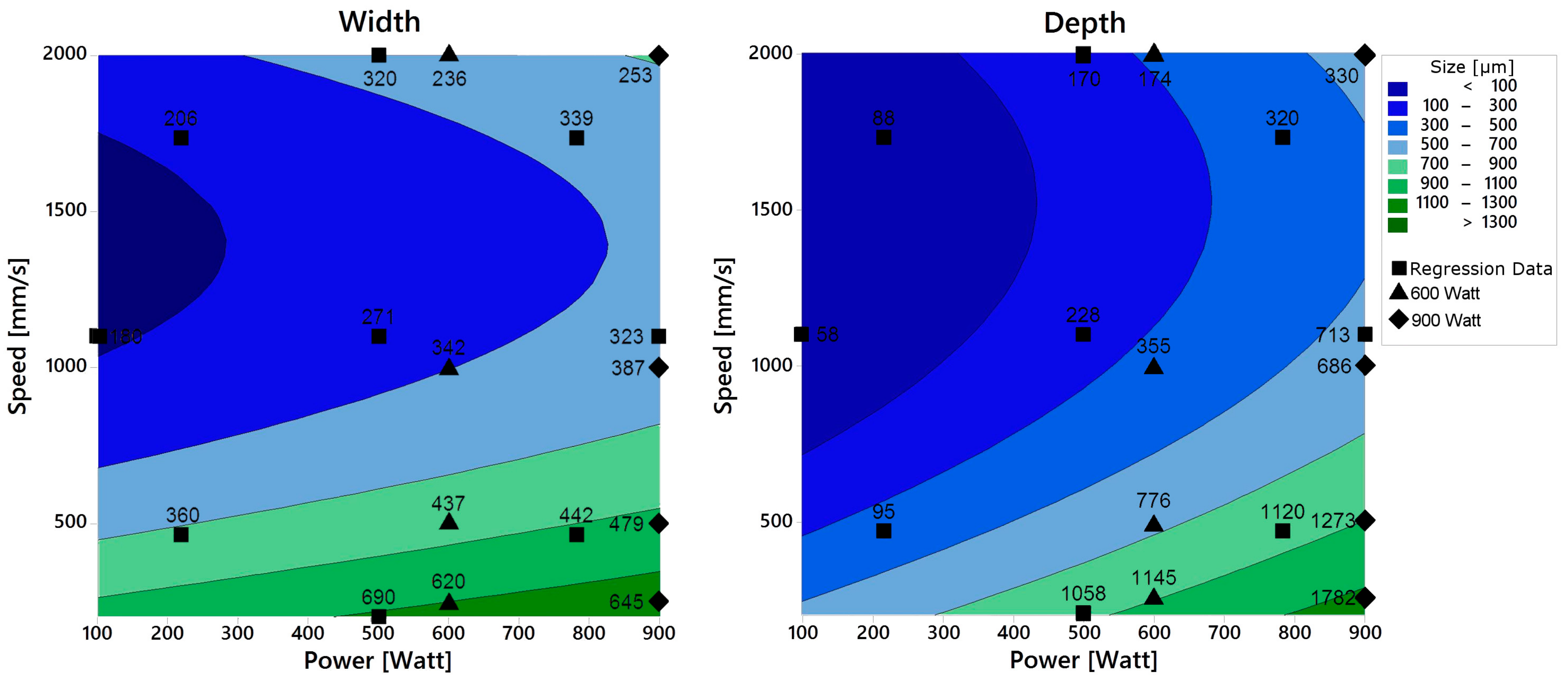

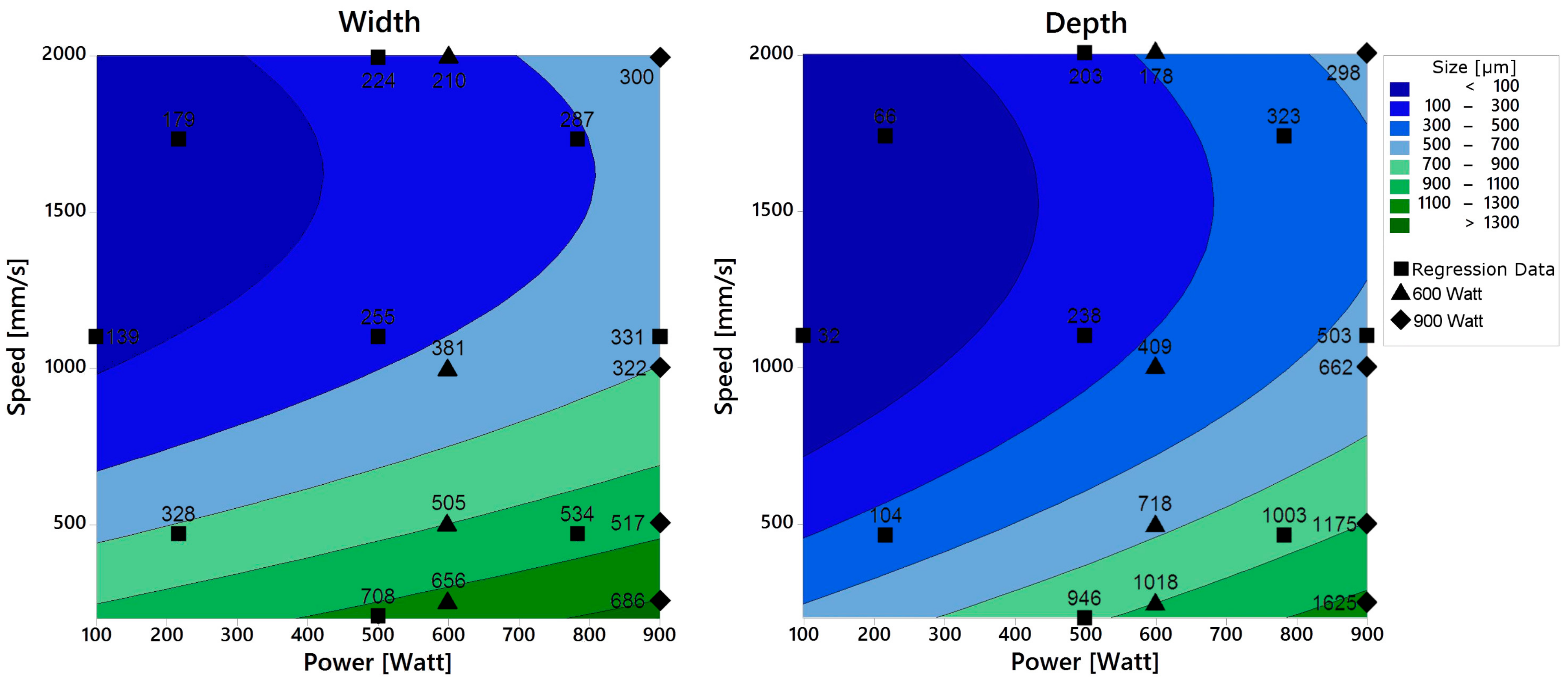

3.2. Melt Pool Dimension

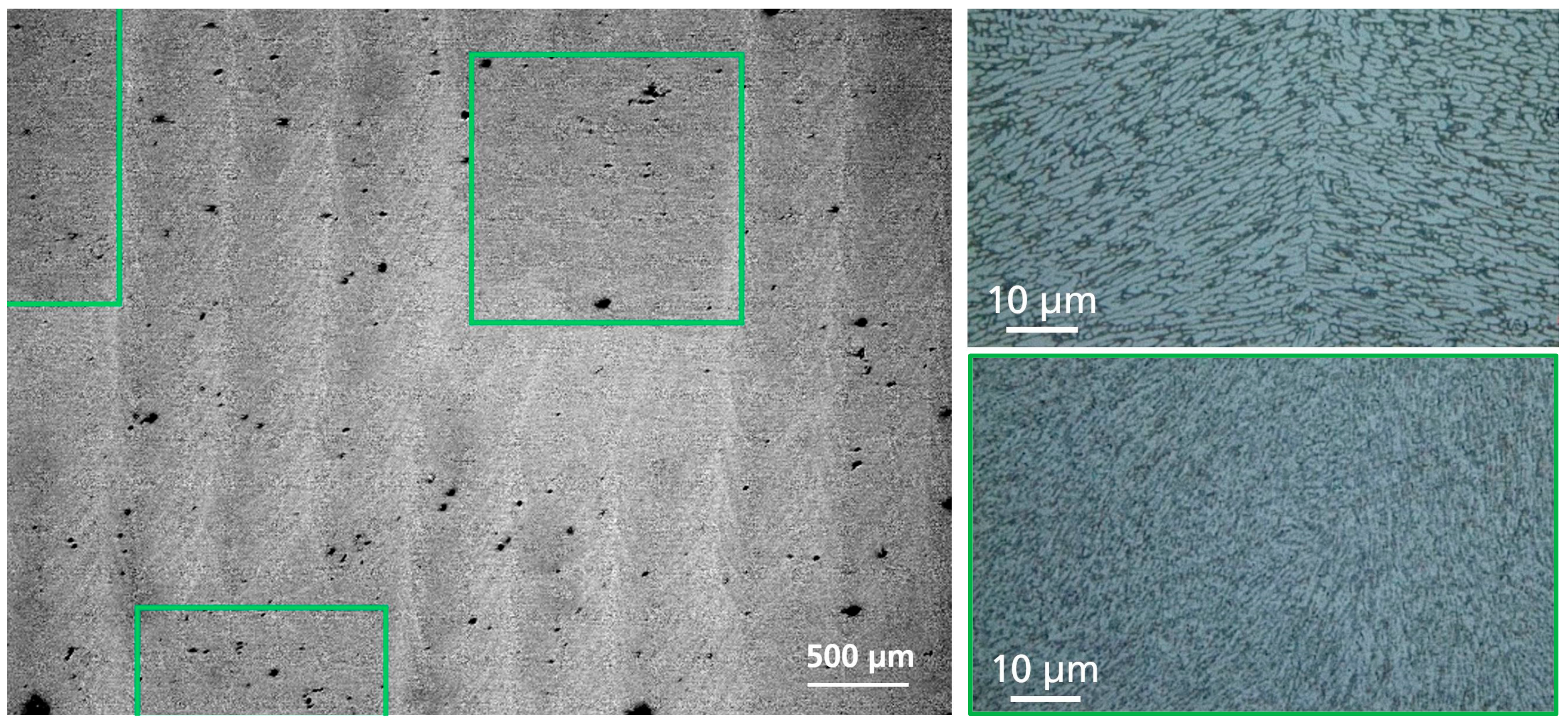

3.3. Grain Size

3.4. Application of Retrieved Data

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Exposure Parameters | Primary Laser Tracks | Secondary Laser Tracks | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Heat Affected Zone [µm] | Grain Length [µm] | Heat Affected Zone [µm] | Grain Length [µm] | |||||||

| Power [Watt] | Speed [mm/s] | Depth | Width | Al-Matrix | AlSi-Eutectic | Depth | Width | Al-Matrix | AlSi-Eutectic | |

| Full Factorial Design of Experiment | 217 | 464 | 95 | 361 | 1.48 | 0.49 | 105 | 328 | 1.30 | 0.81 |

| 217 | 1736 | 88 | 206 | 3.29 | 0.68 | 66 | 179 | 1.73 | 0.85 | |

| 783 | 464 | 1120 | 442 | 3.72 | 1.06 | 1003 | 534 | 4.64 | 0.69 | |

| 500 | 1100 | 196 | 232 | 2.23 | 0.68 | 192 | 262 | 1.48 | 0.57 | |

| 500 | 1100 | 235 | 260 | 2.88 | 0.75 | 216 | 316 | 1.57 | 0.88 | |

| 783 | 1736 | 320 | 339 | 2.15 | 0.62 | 323 | 287 | 0.60 | 0.78 | |

| 500 | 1100 | 249 | 302 | 2.52 | 1.00 | 194 | 377 | 1.46 | 0.48 | |

| 500 | 1100 | 218 | 281 | 1.90 | 0.49 | 228 | 322 | 1.60 | 1.99 | |

| 500 | 1100 | 213 | 314 | 1.95 | 0.49 | 248 | 253 | 1.57 | 1.30 | |

| 100 | 1100 | 58 | 180 | 1.83 | 0.49 | 32 | 139 | 4.43 | 1.09 | |

| 500 | 2000 | 170 | 320 | 3.00 | 0.75 | 203 | 224 | 1.03 | 0.81 | |

| 500 | 200 | 1058 | 690 | 3.83 | 0.89 | 946 | 708 | 4.01 | 1.27 | |

| 900 | 1100 | 713 | 323 | 3.06 | 0.60 | 503 | 331 | 3.52 | 0.83 | |

| 500 | 1100 | 228 | 271 | 2.29 | 0.68 | 238 | 255 | 1.57 | 0.75 | |

| Single Variation | 250 | 600 | 1782 | 686 | 4.44 | 0.66 | 178 | 210 | 4.41 | 0.80 |

| 500 | 600 | 1273 | 517 | 3.79 | 0.57 | 409 | 381 | 3.18 | 0.81 | |

| 1000 | 600 | 686 | 322 | 1.56 | 0.62 | 718 | 505 | 2.02 | 0.80 | |

| 2000 | 600 | 330 | 300 | 1.96 | 0.78 | 1018 | 656 | 1.42 | 0.76 | |

| 250 | 900 | 1145 | 656 | 4.58 | 0.62 | 298 | 300 | 4.78 | 0.75 | |

| 500 | 900 | 776 | 505 | 2.90 | 0.76 | 662 | 322 | 3.34 | 0.73 | |

| 1000 | 900 | 355 | 381 | 2.56 | 0.66 | 1175 | 517 | 2.16 | 0.75 | |

| 2000 | 900 | 174 | 210 | 2.48 | 0.72 | 1625 | 686 | 0.47 | 0.77 | |

References

- Wohler, T.; Campbell, R.I.; Caffrey, T.; Agarwala, M.; Alves, N.; Balc, N.; Beaman, J.; Benster, T.; Bernard, A.; Boivie, K.; et al. Wohlers Report 2016. 3D Printing and Additive Manufacturing State of the Industry. Annual Worldwide Progress Report; Wohlers Assoziation Inc.: Fort Collins, CO, USA, 2016; ISBN 978-0-9913332-2-6. [Google Scholar]

- Buchbinder, D. Selective Laser Melting von Aluminiumgusslegierungen. Ph.D. Thesis, Rheinisch-Westfälische Technische Hochschule Aachen, Aachen, German, 2013. [Google Scholar]

- Ensthaler, J.; Grimm, T.; Marquardt, B.; Munsch, M.; Müller, A.; Lohmeier, K. VDI Handlungsfelder Additive Fertigungsverfahren; VDI: Düsseldorf, Germany, 2016; ISBN 978-3-931384-82-1. [Google Scholar]

- Gartner, J. FI-JKU Bericht 2014: Generative Fertigungsverfahren Technologiefolgenabschätzung; Johannes Kepler Universität Linz: Linz, Austria, 2014. [Google Scholar]

- Popovich, V.A.; Borisov, E.V.; Popovich, A.A.; Sufiiarov, V.; Masaylo, D.V.; Alzina, L. Functionally graded Inconel 718 processed by additive manufacturing: Crystallographic texture, anisotropy of microstructure and mechanical properties. Mater. Des. 2017, 114, 441–449. [Google Scholar] [CrossRef]

- Zhang, Z.; Orlov, D.; Vajpai, S.K.; Tong, B.; Ameyama, K. Importance of Bimodal Structure Topology in the Control of Mechanical Properties of a Stainless Steel. Adv. Eng. Mater. 2016, 17, 791–795. [Google Scholar] [CrossRef]

- Zhang, D. Entwicklung des Selective Laser Melting (SLM) für Aluminiumwerkstoffe. Ph.D. Thesis, Rheinisch-Westfälische Technische Hochschule Aachen, Aachen, German, 2004. [Google Scholar]

- Aboulkhair, N.T.; Everitt, N.M.; Ashcroft, I.; Tuck, C. Reducing porosity in AlSi10Mg parts processed by selective laser melting. Addit. Manuf. 2014, 4, 77–86. [Google Scholar] [CrossRef]

- Read, N.; Wang, W.; Essa, K.; Attallah, M.M. Selective laser melting of AlSi10Mg alloy: Process optimisation and mechanical properties development. Mater. Des. 2014, 65, 417–424. [Google Scholar] [CrossRef]

- Brandl, E.; Heckenberger, U.; Holzinger, V.; Buchbinder, D. Additive manufactured AlSi10Mg samples using Selective Laser Melting (SLM). Mater. Des. 2012, 34, 159–169. [Google Scholar] [CrossRef]

- Thijs, L.; Verhaeghe, F.; Craeghs, T.; van Humbeeck, J.; Kruth, J. A study of the microstructural evolution during selective laser melting of Ti–6Al–4V. Acta Mater. 2010, 58, 3303–3312. [Google Scholar] [CrossRef]

- Poprawe, R. Lasertechnik für die Fertigung. Grundlagen, Perspektiven und Beispieles für den Innovativen Ingenieur; Springer: Berlin, Germany, 2005; ISBN 3-540-21406-2. [Google Scholar]

- Bliedtner, J.; Müller, H.; Barz, A. Lasermaterialbearbeitung. Grundlagen, Verfahren, Anwendungen, Beispiele; Carl-Hanser-Verlag: München, Germany, 2013; ISBN 9-783-44642929-1. [Google Scholar]

- Gong, H.; Gu, H.; Zeng, K.; Dilip, J.J.S.; Pal, D.; Stucker, B. Melt Pool Characterization for Selective Laser Melting of Ti-6Al-4V Pre-alloyed Powder. In Proceedings of the 25th Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 4–6 August 2014; pp. 256–267. [Google Scholar]

- Kruth, J.P.; Froyen, L.; van Vaerenbergh, J.; Mercelis, P.; Rombouts, M.; Lauwers, B. Selective laser melting of iron-based powder. J. Mater. Process. Technol. 2003, 149, 616–622. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Krakhmalev, P.; Yadroitsava, I. Selective laser melting of Ti6Al4V alloy for biomedical applications: Temperature monitoring and microstructural evolution. J. Alloy. Compd. 2014, 583, 404–409. [Google Scholar] [CrossRef]

- Vasinonta, A.; Beuth, J.; Griffith, M. Process Maps for Controlling Residual Stress and Melt Pool Size in Laser-Based SFF Processes. J. Manuf. Sci. Eng. 2007, 129, 101–109. [Google Scholar] [CrossRef]

- Tradowsky, U.; White, J.; Ward, R.M.; Read, N.; Reimers, W.; Attallah, M.M. Selective laser melting of AlSi10Mg. Mater. Des. 2016, 105, 212–222. [Google Scholar] [CrossRef]

- Hegde, S.; Prabhu, K.N. Modification of eutectic silicon in Al–Si alloys. J. Mater. Sci. 2008, 43, 3009–3027. [Google Scholar] [CrossRef]

| Spectrum | Al (wt %) | Si (wt %) |

|---|---|---|

| Al matrix | 97.05 | 2.95 |

| AlSi eutectic | 57.81 | 41.22 |

| Type of laser track | Melt pool characteristic | C1 | C2 | C3 | C4 | C5 | C6 | R2 [%] |

|---|---|---|---|---|---|---|---|---|

| Primary Laser Tracks | Width | 626 | 0.258 | −0.660 | 0 | 0.000203 | 0 | 87 |

| Depth | 117 | 2.176 | −0.764 | 0 | 0.000414 | 0.0011 | 95 | |

| Grain Size | 2.299 | 0.356 | 0 | 0 | 0.491000 | −0.845 | 82 | |

| Secondary Laser Tracks | Width | 655 | 0.184 | −0.727 | 0 | 0.000261 | 0 | 90 |

| Depth | 699 | 0.805 | −1.243 | 0 | 0.000407 | 0 | 87 | |

| Grain Size | 1.661 | 0 | −0.978 | 0.907 | 0 | 1.119 | 80 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pfaff, A.; Jäcklein, M.; Hoschke, K.; Wickert, M. Designed Materials by Additive Manufacturing—Impact of Exposure Strategies and Parameters on Material Characteristics of AlSi10Mg Processed by Laser Beam Melting. Metals 2018, 8, 491. https://doi.org/10.3390/met8070491

Pfaff A, Jäcklein M, Hoschke K, Wickert M. Designed Materials by Additive Manufacturing—Impact of Exposure Strategies and Parameters on Material Characteristics of AlSi10Mg Processed by Laser Beam Melting. Metals. 2018; 8(7):491. https://doi.org/10.3390/met8070491

Chicago/Turabian StylePfaff, Aron, Martin Jäcklein, Klaus Hoschke, and Matthias Wickert. 2018. "Designed Materials by Additive Manufacturing—Impact of Exposure Strategies and Parameters on Material Characteristics of AlSi10Mg Processed by Laser Beam Melting" Metals 8, no. 7: 491. https://doi.org/10.3390/met8070491

APA StylePfaff, A., Jäcklein, M., Hoschke, K., & Wickert, M. (2018). Designed Materials by Additive Manufacturing—Impact of Exposure Strategies and Parameters on Material Characteristics of AlSi10Mg Processed by Laser Beam Melting. Metals, 8(7), 491. https://doi.org/10.3390/met8070491