Room Temperature Mechanical Properties of A356 Alloy with Ni Additions from 0.5 Wt to 2 Wt %

Abstract

:1. Introduction

2. Materials and Methods

2.1. Melt Preparation and Specimen Casting

2.2. Tensile and Microhardness Tests

2.3. Microstructural Investigations

3. Results

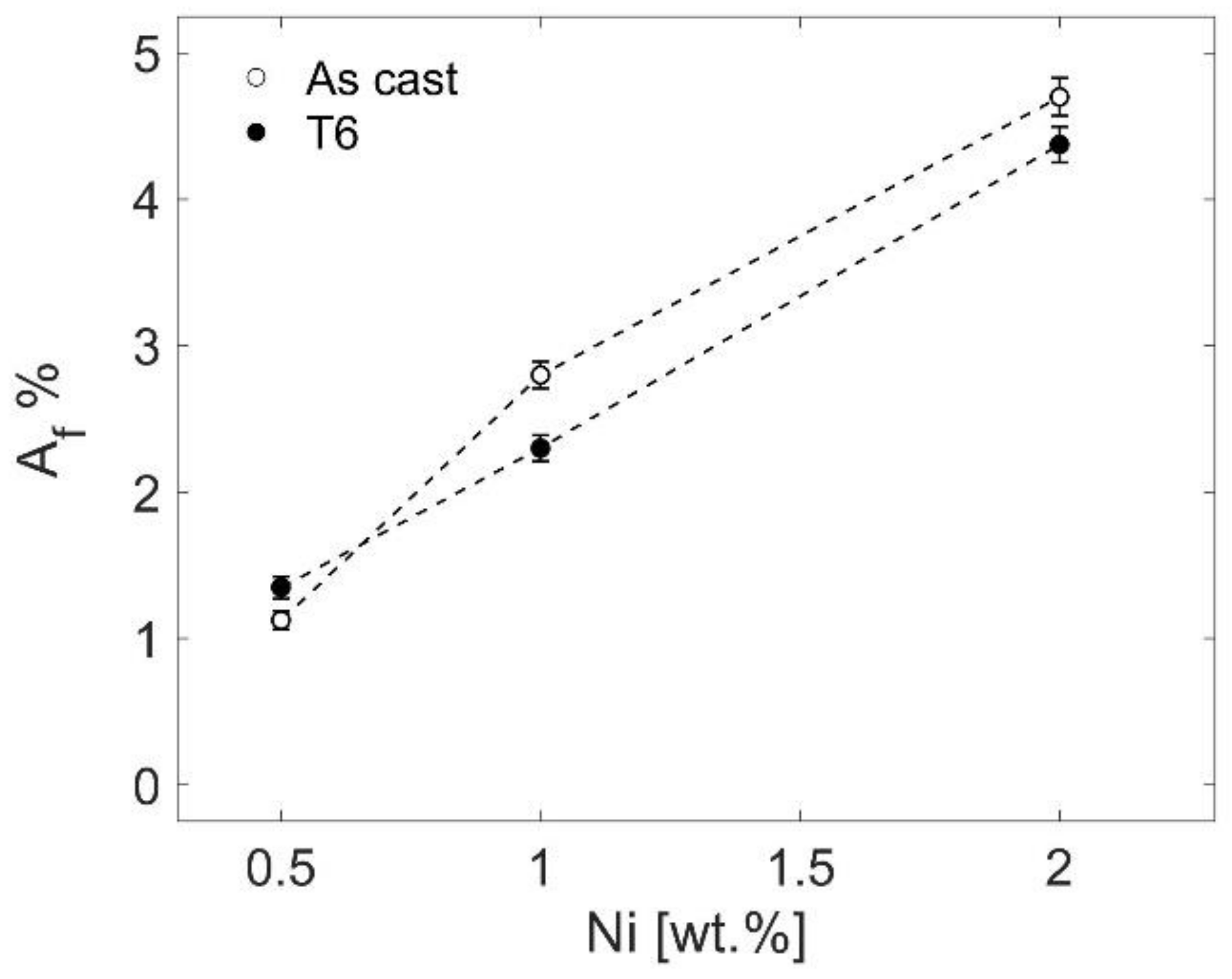

3.1. Mechanical Properties

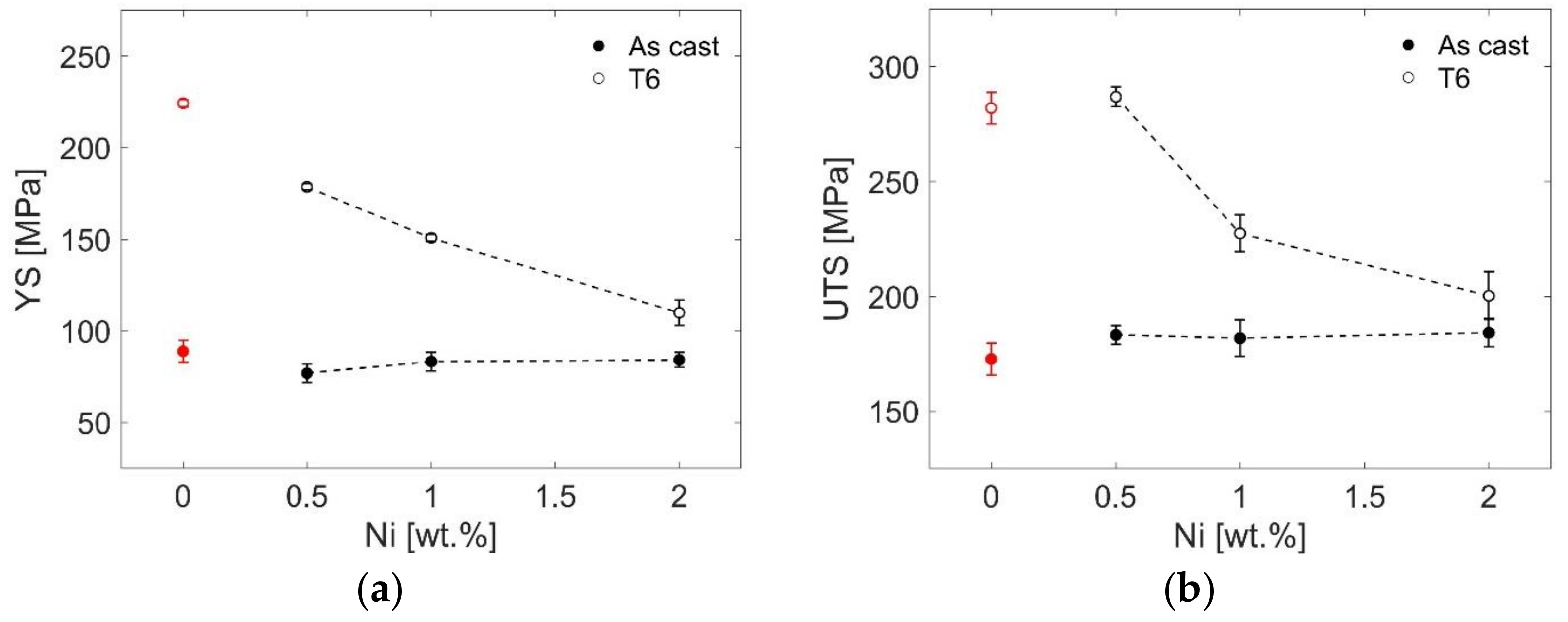

3.1.1. Tensile Properties

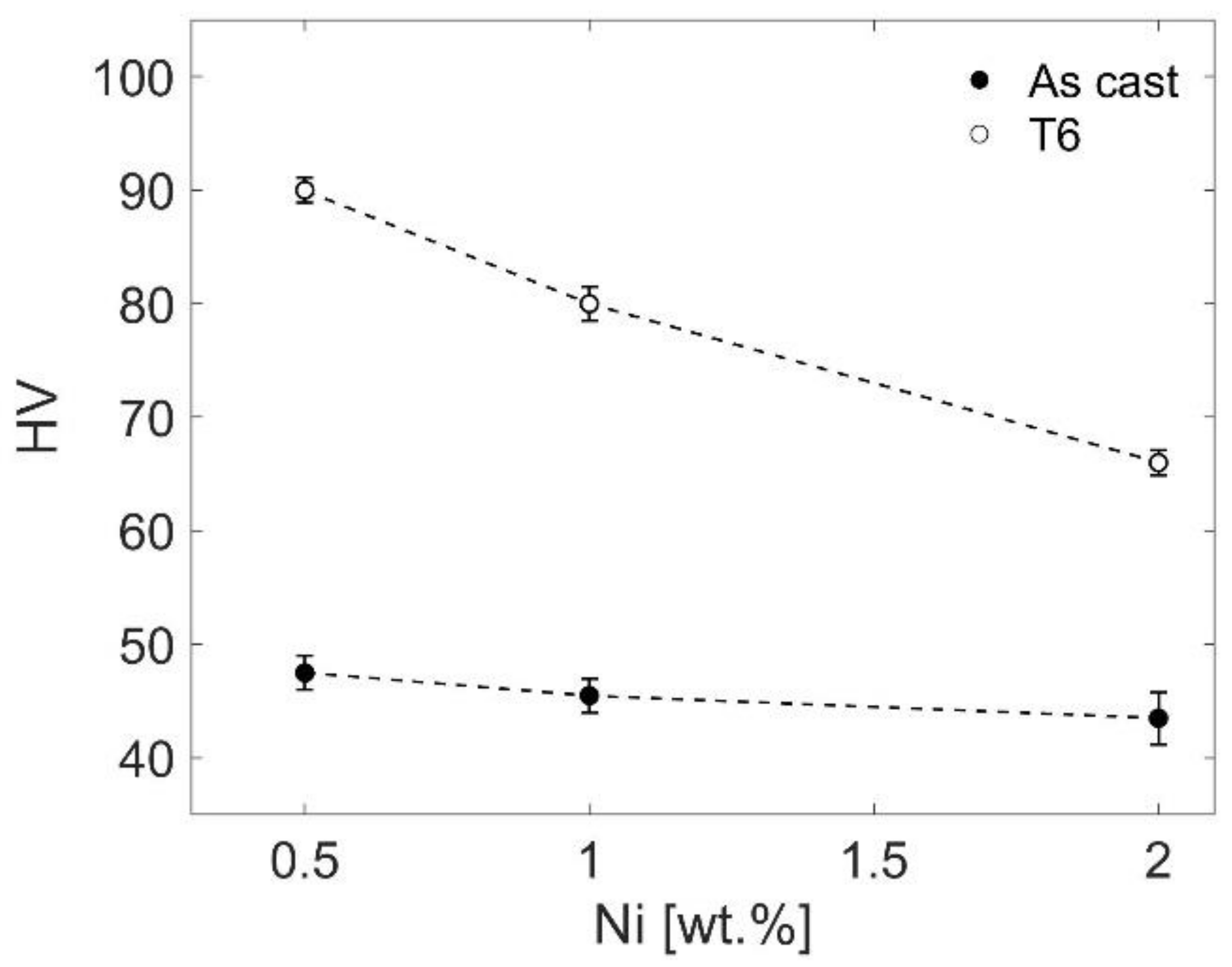

3.1.2. Microhardness

3.2. Microstructural and Fractographic Observations

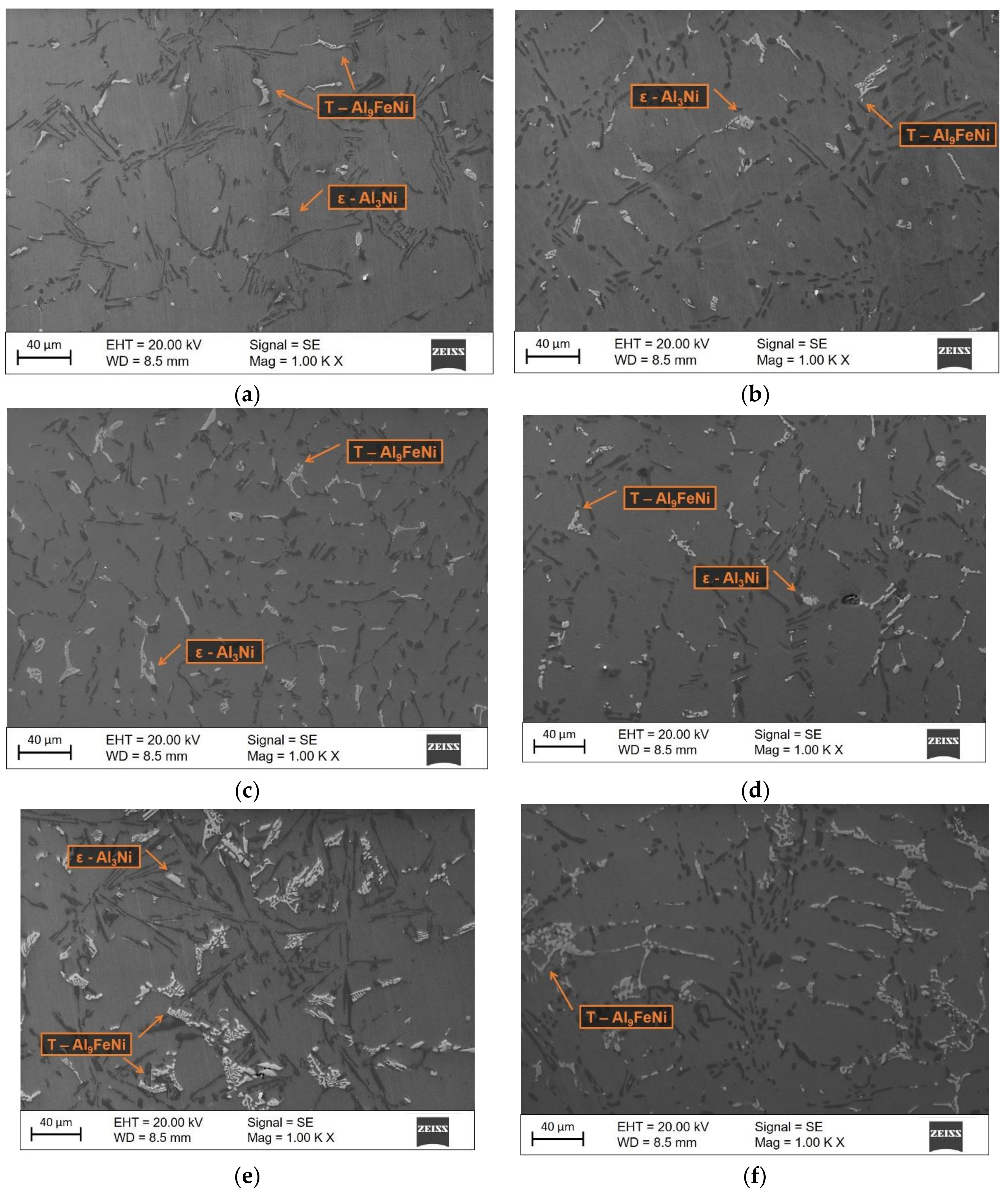

3.2.1. Microstructural Investigations

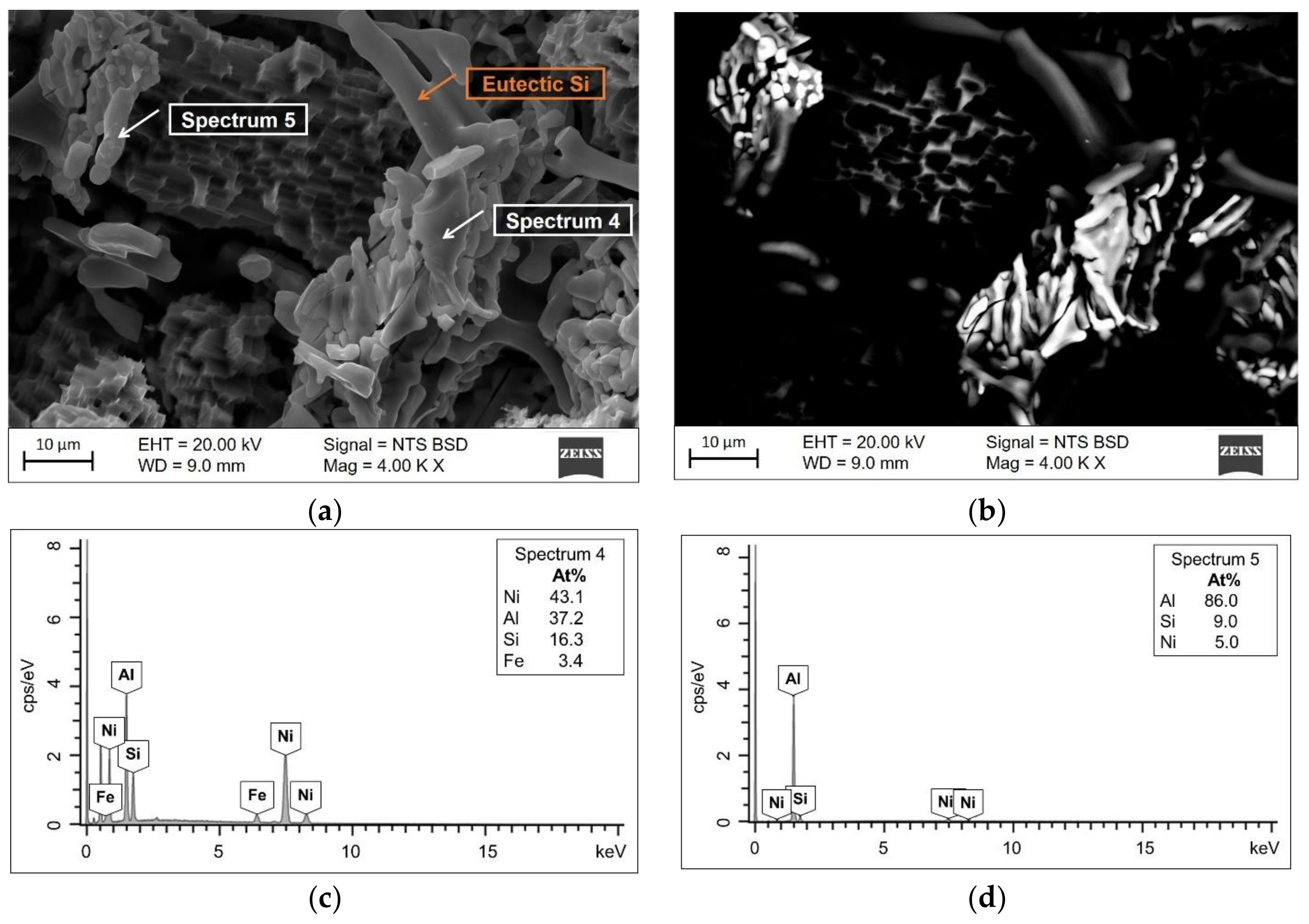

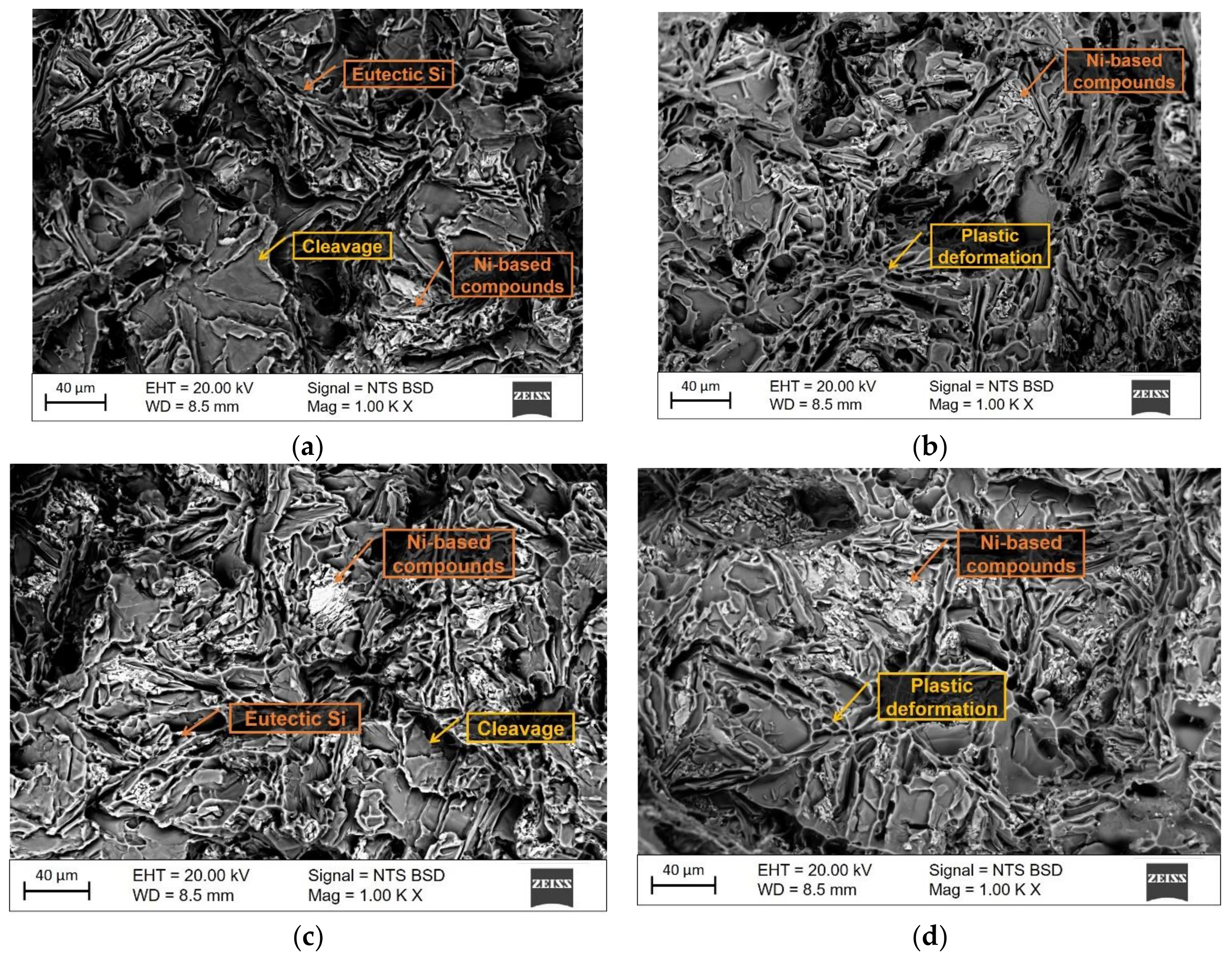

3.2.2. Fractography

3.3. Image Analysis and Statistical Evaluations

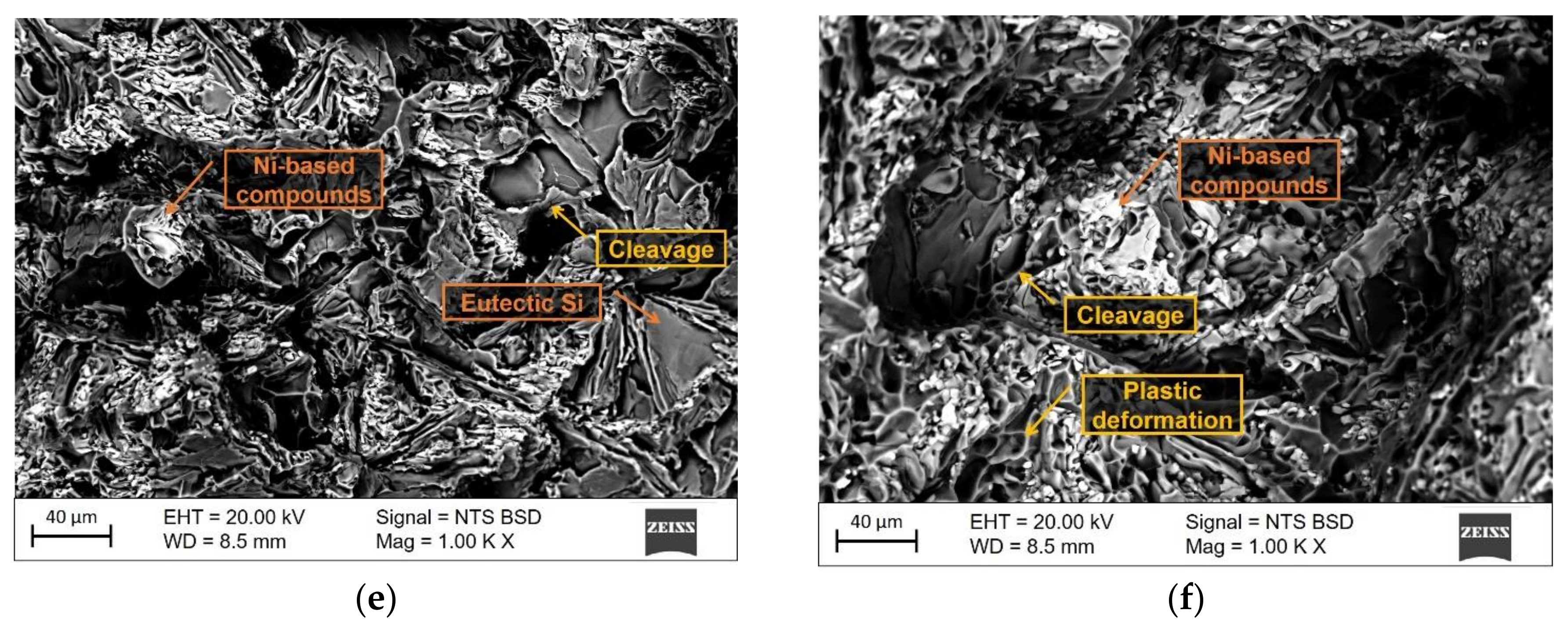

3.3.1. Eutectic Si

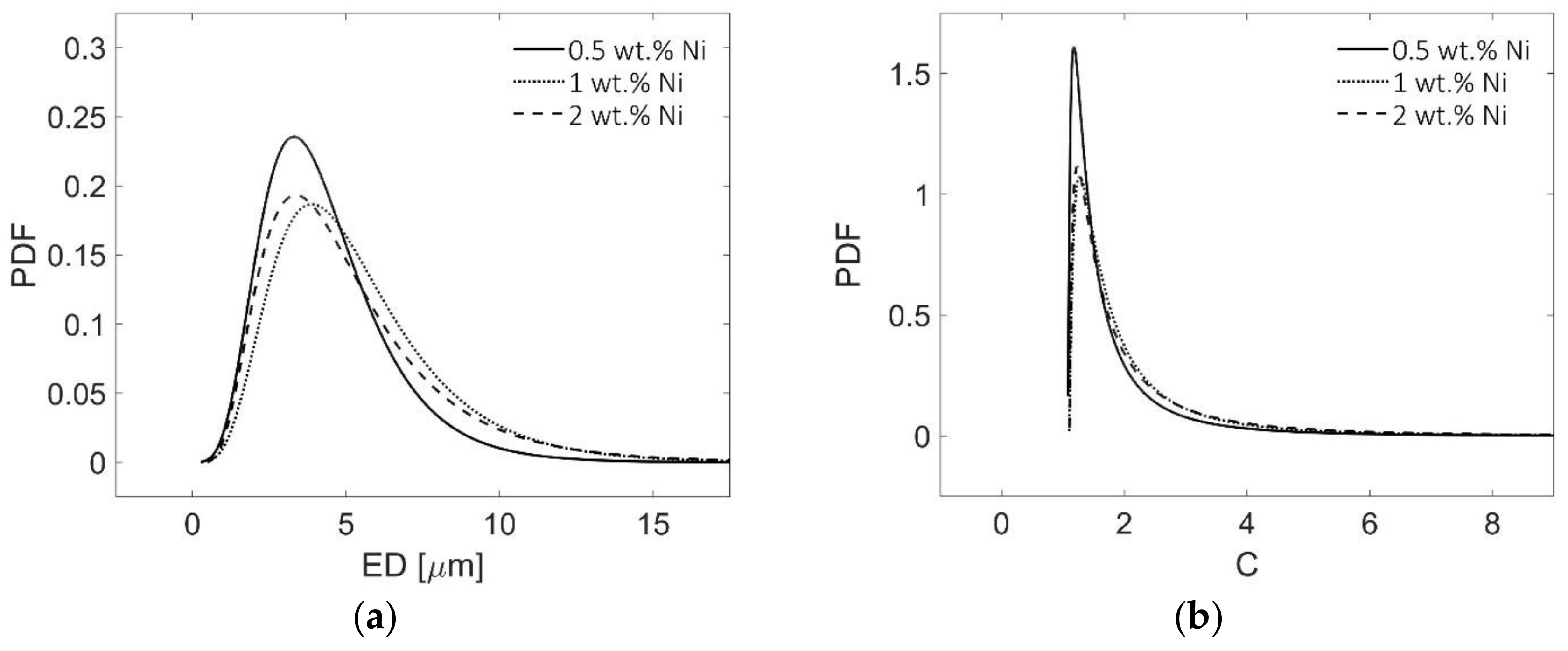

3.3.2. Ni-Based Phases

4. Discussion

4.1. As-Cast Condition

4.2. T6 Heat-Treated Condition

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Quested, T.E. Understanding mechanisms of grain refinement of aluminium alloys by inoculation. Mater. Sci. Technol. 2004, 20, 1357–1369. [Google Scholar] [CrossRef]

- Darlapudi, A.; McDonald, S.D.; StJohn, D.H. The influence of Cu, Mg and Ni on the solidification and microstructure of Al-Si alloys. IOP Conf. Ser. Mater. Sci. Eng. 2016, 117, 1–7. [Google Scholar] [CrossRef]

- Tocci, M.; Pola, A.; Raza, L.; Armellin, L.; Afeltra, U. Optimization of heat treatment parameters for a non-conventional Al-Si-Mg alloy with Cr addition by DoE method. La Metall. Ital. 2016, 6, 141–144. [Google Scholar]

- Pola, A.; Montesano, L.; Tocci, M.; La Vecchia, G.M. Influence of ultrasound treatment on cavitation erosion resistance of AlSi7 alloy. Materials 2017, 10, 256. [Google Scholar] [CrossRef] [PubMed]

- Asghar, Z.; Requena, G.; Zahid, G.H.; Rafi-ud-Din. Effect of thermally stable Cu- and Mg-rich aluminides on the high-temperature strength of an AlSi12CuMgNi alloy. Mater. Charact. 2014, 88, 80–85. [Google Scholar] [CrossRef]

- Stadler, F.; Antrekowitsch, H.; Fragner, W.; Kaufmann, H.; Uggowitzer, P.J. Effect of main alloying elements on strength of Al-Si foundry alloys at elevated temperatures. Int. J. Cast Met. Res. 2012, 25, 215–224. [Google Scholar] [CrossRef]

- Casari, D.; Poli, F.; Merlin, M.; Di Giovanni, M.T.; Li, Y.; Di Sabatino, M. Effect of Ni additions on A356 alloy’s microstructure and high-temperature mechanical properties. La Metall. Ital. 2016, 6, 37–40. [Google Scholar]

- Moffat, A.J.; Mellor, B.G.; Sinclair, I.; Reed, P.A.S. The mechanisms of long fatigue crack growth behavior in Al-Si casting alloys at room and elevated temperature. Mater. Sci. Technol. 2007, 23, 1396–1401. [Google Scholar] [CrossRef]

- Asghar, Z.; Requena, G.; Boller, E. Three-dimensional rigid multiphase networks providing high-temperature strength to cast AlSi10Cu5Ni1-2 piston alloys. Acta Mater. 2011, 59, 6420–6432. [Google Scholar] [CrossRef] [PubMed]

- Asghar, Z.; Requena, G.; Degischer, H.P.; Cloetens, P. Three-dimensional study of Ni aluminides in an AlSi12 alloy by means of light optical and synchrotron microtomography. Acta Mater. 2009, 57, 4125–4132. [Google Scholar] [CrossRef]

- Rohatgi, P.K.; Sharma, R.C.; Prabhakar, K.V. Microstructure and mechanical properties of unidirectionally solidified Al-Si-Ni ternary eutectic. Metall. Trans. A 1975, 6, 569–575. [Google Scholar] [CrossRef]

- Sreeja Kumari, S.S.; Pillai, R.M.; Pai, B.C. A study on the structural, age hardening and mechanical characteristics of Mn and Ca added Al-7Si-0.3Mg-0.6Fe alloy. J. Alloys Compd. 2008, 453, 167–173. [Google Scholar] [CrossRef]

- Farkoosh, A.R.; Javidani, M.; Hoseini, M.; Larouche, D.; Pekguleryuz, M. Phase formation in as-solidified and heat-treated Al-Si-Cu-Mg-Ni alloys: Thermodynamic assessment and experimental investigation for alloy design. J. Alloys Compd. 2013, 551, 596–606. [Google Scholar] [CrossRef]

- Belov, N.A.; Eskin, D.G.; Aksenov, A.A. Multicomponent Phase Diagrams: Applications for Commercial Aluminum Alloys; Elsevier Science: Oxford, UK, 2005; p. 233. ISBN 9780080456966. [Google Scholar]

- Chen, C.-L.; Richter, A.; Thomson, R.C. Investigation of mechanical properties of intermetallic phases in multi-component Al-Si alloys using hot-stage nanoindentation. Intermetallics 2010, 18, 499–508. [Google Scholar] [CrossRef]

- Asghar, Z.; Requena, G.; Kubel, F. The role of Ni and Fe aluminides on the elevated temperature strength of an AlSi12 alloy. Mater. Sci. Eng. A 2010, 527, 5691–5698. [Google Scholar] [CrossRef]

- Mohamed, M.J.S. Influence of nickel addition effect of heat treatment on aluminum-silicon piston alloys. Int. J. Sci. Res. 2015, 4, 781–784. [Google Scholar]

- Nwankwo, N.E.; Nwoke, V.U.; Nnuka, E.E. Effect of Ni-additions on the microstructure and mechanical properties of Fe-based chill-cast Al-Si alloys for production of pistons for automobile engine applications. Int. J. Sci. Res. Eng. Technol. 2015, 1, 21–24. [Google Scholar]

- Yang, Y.; Yu, K.; Li, Y.; Zhao, D.; Liu, X. Evolution of nickel-rich phases in Al-Si-Cu-Ni-Mg piston alloys with different Cu additions. Mater. Des. 2012, 33, 220–225. [Google Scholar] [CrossRef]

- Yang, H.; Watson, D.; Wang, Y.; Ji, S. Effect of Nickel on the Microstructure and Mechanical Property of Die-cast Al-Mg-Si-Mn Alloy. J. Mater. Sci. 2014, 49, 8412–8422. [Google Scholar] [CrossRef]

- Stadler, F.; Antrekowitsch, H.; Fragner, W.; Kavfmann, H.; Uggowitzer, P.J. The effect of Ni on the high-temperature strength of Al-Si cast alloys. Mater. Sci. Forum 2011, 690, 274–277. [Google Scholar] [CrossRef]

- Fang, L.; Zhang, X.; Hu, H.; Nie, X.; Tjong, J. Microstructure and tensile properties of squeeze cast aluminum alloy A380 containing Ni and Sr addition. Adv. Mater. Proc. Technol. 2017, 3, 362–373. [Google Scholar] [CrossRef]

- García-Hinojosa, J.A.; González, C.R.; González, G.M.; Houbaert, Y. Structure and properties of Al-7Si-Ni and Al-7Si-Cu cast alloys nonmodified and modified with Sr. J. Mater. Process. Technol. 2003, 143, 306–310. [Google Scholar] [CrossRef]

- Friel, J. Practical Guide to Image Analysis; ASM International: Materials Park, OH, USA, 2000; p. 158. ISBN 0871706881. [Google Scholar]

- Casari, D.; Ludwig, T.H.; Merlin, M.; Arnberg, L.; Garagnani, G.L. The effect of Ni and V trace elements on the mechanical properties of A356 aluminium foundry alloy in as-cast and T6 heat-treated conditions. Mater. Sci. Eng. A 2014, 610, 414–426. [Google Scholar] [CrossRef]

- Alexopoulos, N.D.; Tiryakioglu, M.; Vasilakos, A.N.; Kourkoulis, S.K. The effect of Cu, Ag, Sm and Sr additions on the statistical distributions of Si particles and tensile properties in A357-T6 alloy castings. Mater. Sci. Eng. A 2014, 604, 40–45. [Google Scholar] [CrossRef]

- Tiryakioglu, M. Si particle size and aspect ratio distributions in an Al-7%Si-0.6%Mg alloy during solution treatment. Mater. Sci. Eng. A 2008, 473, 1–6. [Google Scholar] [CrossRef]

- Uggowitzer, P.J.; Stüwe, H.P. Plasticity of ferritic-martensitic two-phase steels. Z. Metallk. 1982, 73, 277–285. [Google Scholar]

- Lasagni, F.; Lasagni, A.; Marks, E.; Holapfel, C.; Muckich, F.; Degischer, H.P. Three-dimensional characterization of ‘as-cast’ and solution-treated AlSi12(Sr) alloys by high-resolution FIB tomography. Acta Mater. 2007, 55, 3875–3882. [Google Scholar] [CrossRef]

- Moffat, A.J. Micromechanistic Analysis of Fatigue in Aluminium Silicon Casting Alloys. Ph.D. Thesis, University of Southampton, Southampton, UK, 2007. [Google Scholar]

- Song, J.-M.; Lin, T.-Y.; Chuang, H.-Y. Microstructural characteristics and vibration fracture properties of Al-g-Si alloys with excess Cu and Ni. Mater. Trans. 2007, 48, 854–859. [Google Scholar] [CrossRef]

| Alloy | Si | Fe | Mg | Ni | Al | Condition |

|---|---|---|---|---|---|---|

| A356 + 0.5 wt % Ni | 6.64 | 0.08 | 0.24 | 0.44 | balance | As-cast |

| T6 | ||||||

| A356 + 1 wt % Ni | 6.87 | 0.08 | 0.25 | 0.95 | balance | As-cast |

| T6 | ||||||

| A356 + 2 wt % Ni | 7.13 | 0.08 | 0.23 | 1.88 | balance | As-cast |

| T6 |

| Geometrical Parameter | Ni (wt %) | μ | σ | τ | AD | Mode |

|---|---|---|---|---|---|---|

| ED (μm) | 0.5 | 1.537 | 0.39339 | −0.679 | 0.50 | 3.31 |

| 1 | 1.682 | 0.43720 | −0.560 | 0.41 | 3.88 | |

| 2 | 1.506 | 0.52589 | −0.057 | 0.27 | 3.36 | |

| C | 0.5 | −0.860 | 1.194 | 1.178 | 1.56 | 1.18 |

| 1 | −0.479 | 1.107 | 1.025 | 0.82 | 1.27 | |

| 2 | −0.472 | 1.247 | 1.103 | 0.47 | 1.23 |

| Geometrical Parameter | Condition | Ni (Wt %) | μ | σ | τ | AD | Mode |

|---|---|---|---|---|---|---|---|

| ED (μm) | As-cast | 0.5 | −0.114 | 1.098 | 0.115 | 1.93 | 0.38 |

| 1 | 0.518 | 1.045 | 0.065 | 0.80 | 0.63 | ||

| 2 | 0.579 | 1.027 | −0.003 | 5.47 | 0.62 | ||

| T6 | 0.5 | 0.222 | 0.959 | 0.015 | 3.19 | 0.51 | |

| 1 | 0.199 | 1.133 | 0.065 | 3.16 | 0.40 | ||

| 2 | 1.152 | 0.541 | −0.849 | 2.59 | 1.51 | ||

| C | As-cast | 0.5 | −0.167 | 1.002 | 1.152 | 0.23 | 1.46 |

| 1 | 0.149 | 0.999 | 1.093 | 0.23 | 1.52 | ||

| 2 | −0.048 | 1.262 | 1.101 | 0.22 | 1.30 | ||

| T6 | 0.5 | −0.643 | 1.204 | 1.104 | 1.14 | 1.23 | |

| 1 | −0.354 | 1.081 | 1.038 | 1.99 | 1.26 | ||

| 2 | −0.724 | 1.147 | 1.077 | 0.65 | 1.21 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lattanzi, L.; Di Giovanni, M.T.; Giovagnoli, M.; Fortini, A.; Merlin, M.; Casari, D.; Di Sabatino, M.; Cerri, E.; Garagnani, G.L. Room Temperature Mechanical Properties of A356 Alloy with Ni Additions from 0.5 Wt to 2 Wt %. Metals 2018, 8, 224. https://doi.org/10.3390/met8040224

Lattanzi L, Di Giovanni MT, Giovagnoli M, Fortini A, Merlin M, Casari D, Di Sabatino M, Cerri E, Garagnani GL. Room Temperature Mechanical Properties of A356 Alloy with Ni Additions from 0.5 Wt to 2 Wt %. Metals. 2018; 8(4):224. https://doi.org/10.3390/met8040224

Chicago/Turabian StyleLattanzi, Lucia, Maria Teresa Di Giovanni, Maverick Giovagnoli, Annalisa Fortini, Mattia Merlin, Daniele Casari, Marisa Di Sabatino, Emanuela Cerri, and Gian Luca Garagnani. 2018. "Room Temperature Mechanical Properties of A356 Alloy with Ni Additions from 0.5 Wt to 2 Wt %" Metals 8, no. 4: 224. https://doi.org/10.3390/met8040224

APA StyleLattanzi, L., Di Giovanni, M. T., Giovagnoli, M., Fortini, A., Merlin, M., Casari, D., Di Sabatino, M., Cerri, E., & Garagnani, G. L. (2018). Room Temperature Mechanical Properties of A356 Alloy with Ni Additions from 0.5 Wt to 2 Wt %. Metals, 8(4), 224. https://doi.org/10.3390/met8040224