Effect of Annealing Temperature on Microstructure, Texture, and Magnetic Properties of Non-Oriented Silicon Steel for Electric Vehicle Traction Motors

Abstract

1. Introduction

2. Experimental Materials and Methods

3. Results and Discussion

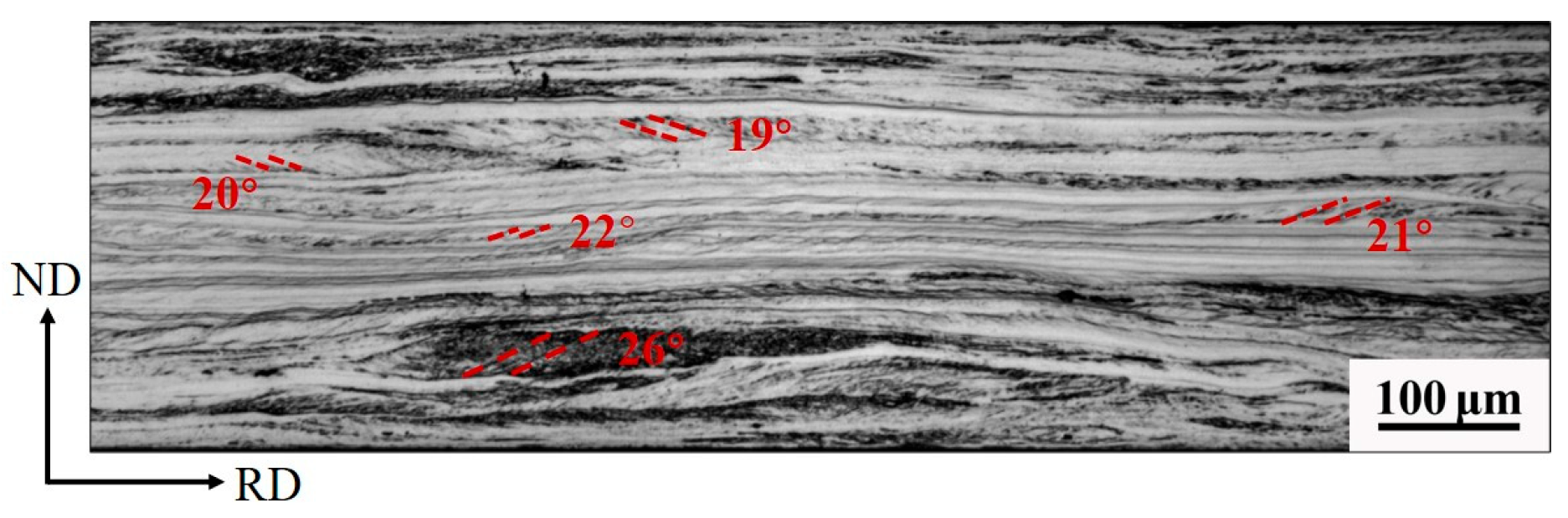

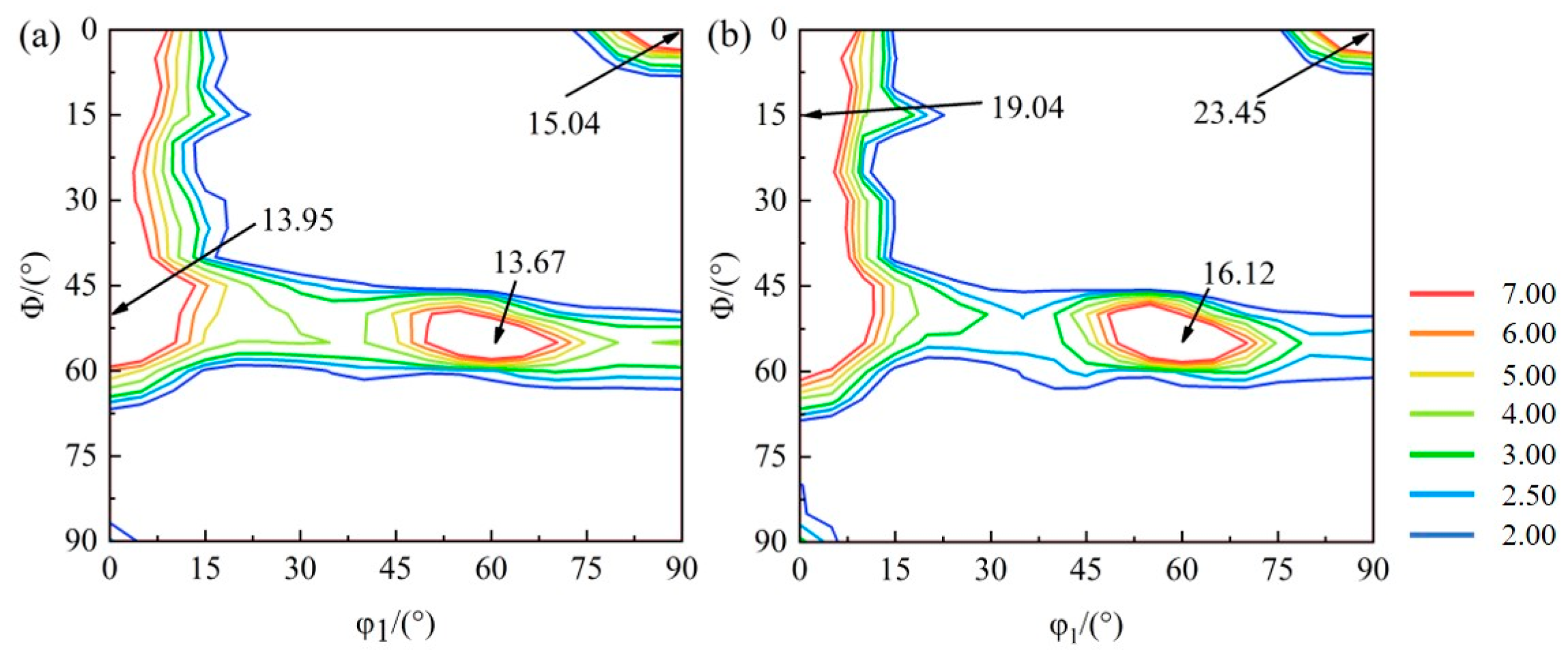

3.1. Microstructure and Texture of Cold-Rolled Sheet

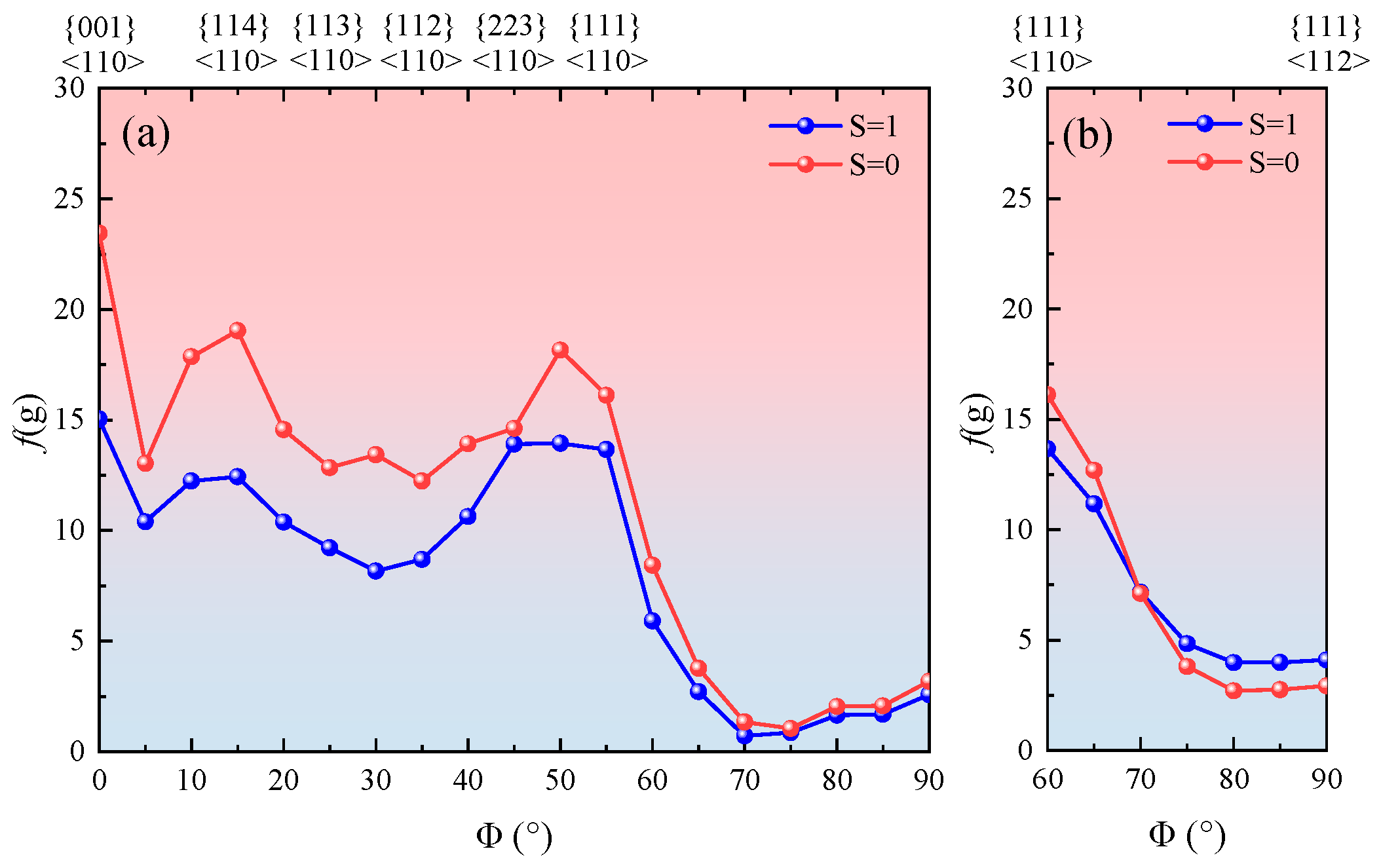

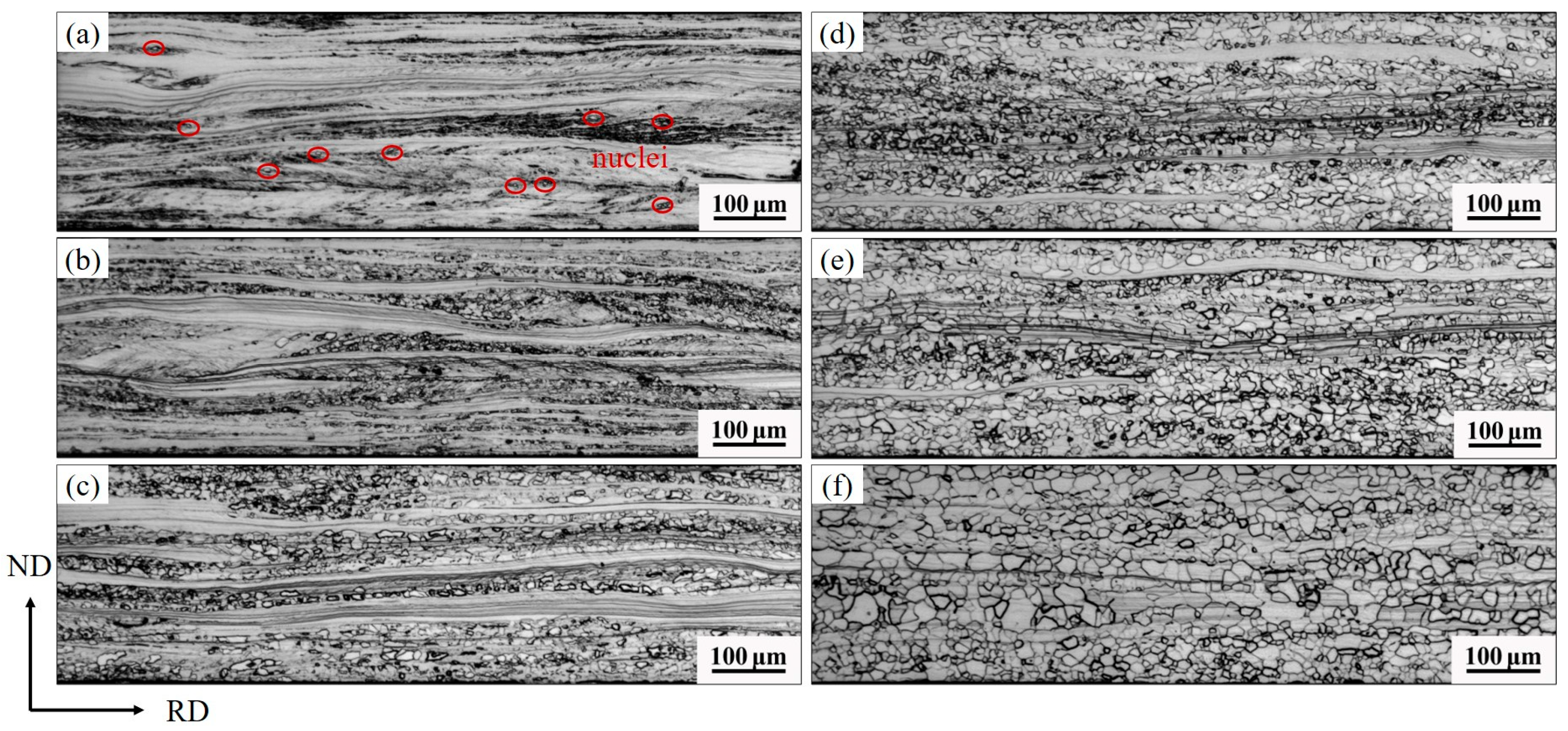

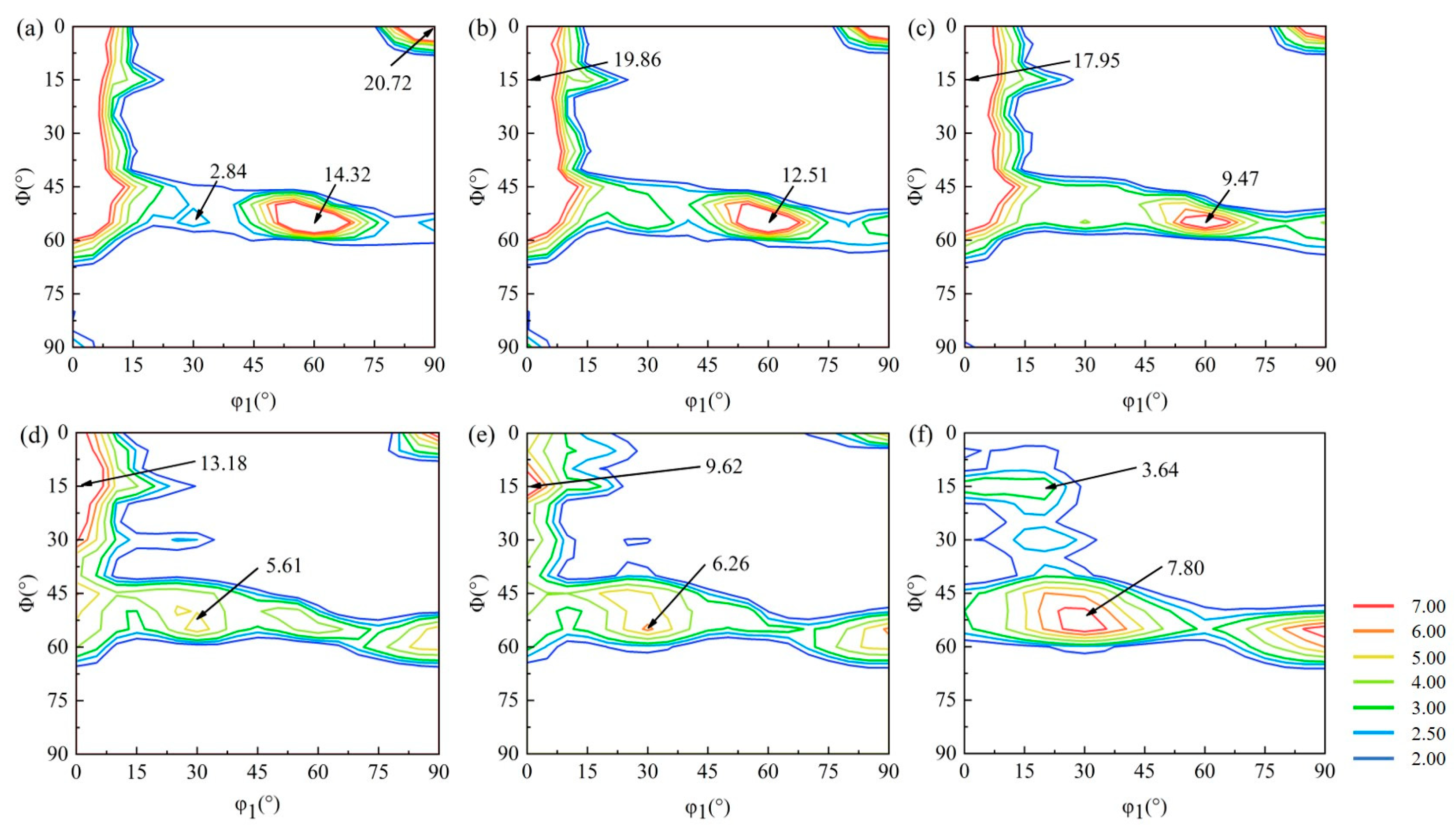

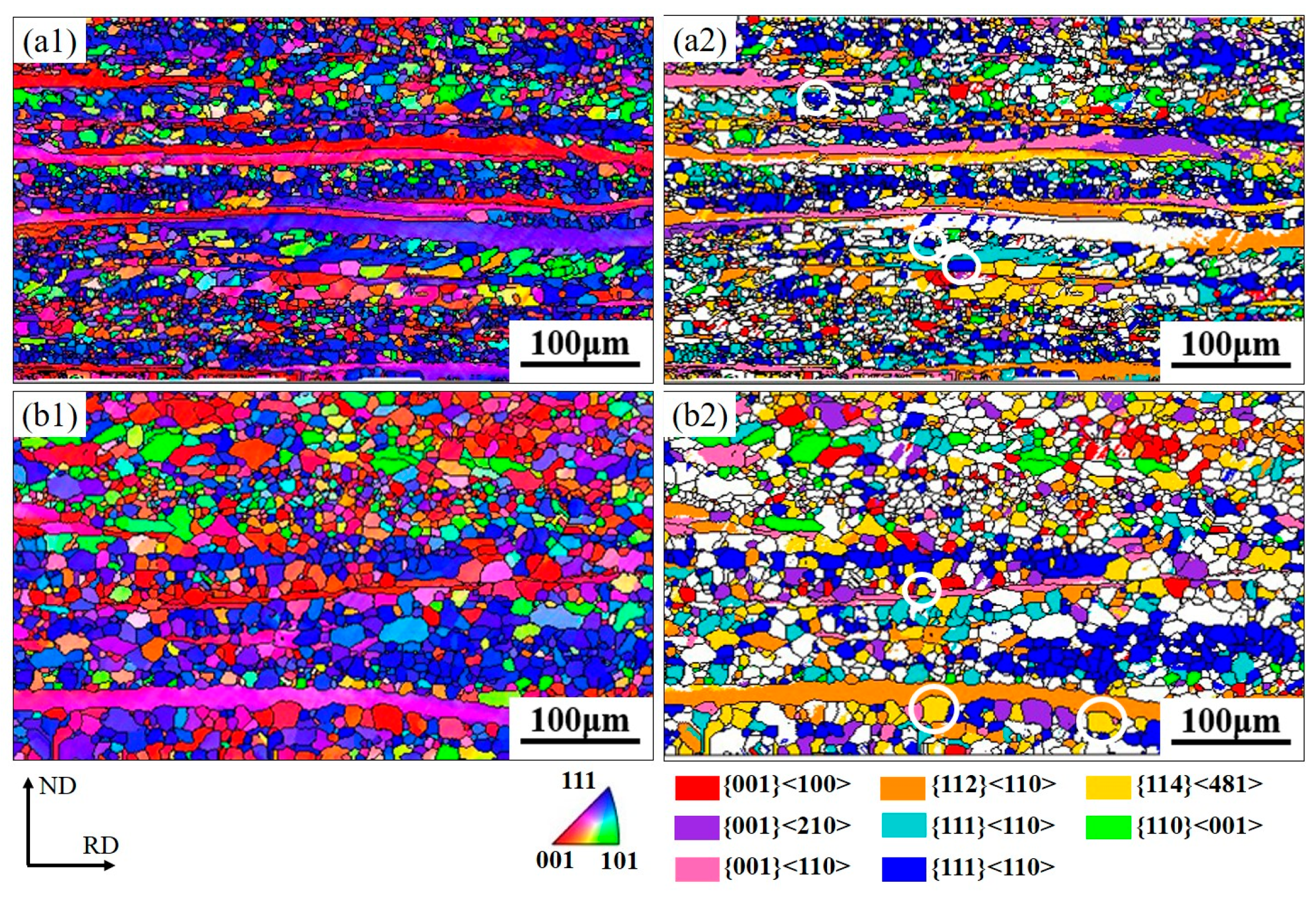

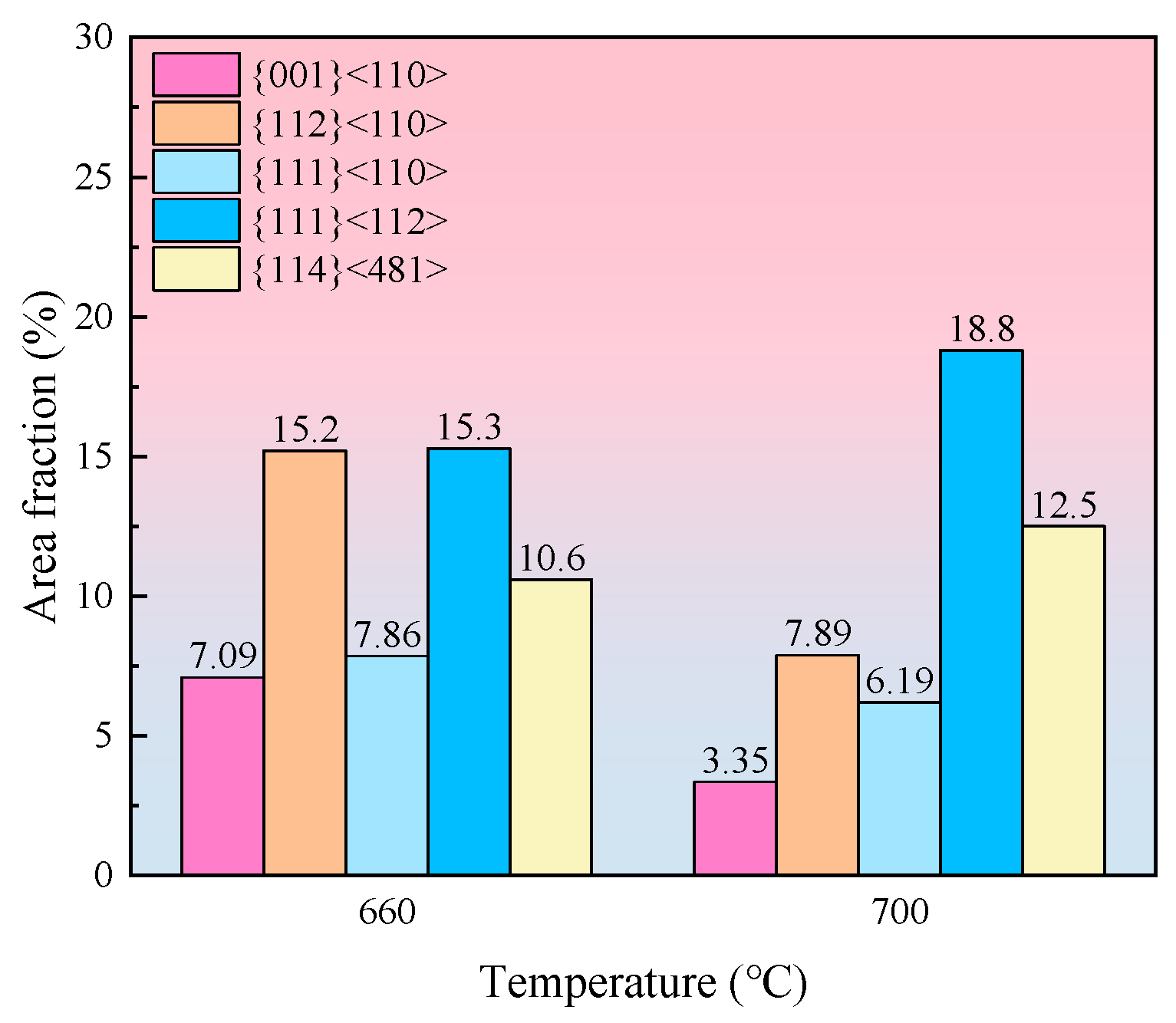

3.2. Microstructure and Texture During Recrystallization

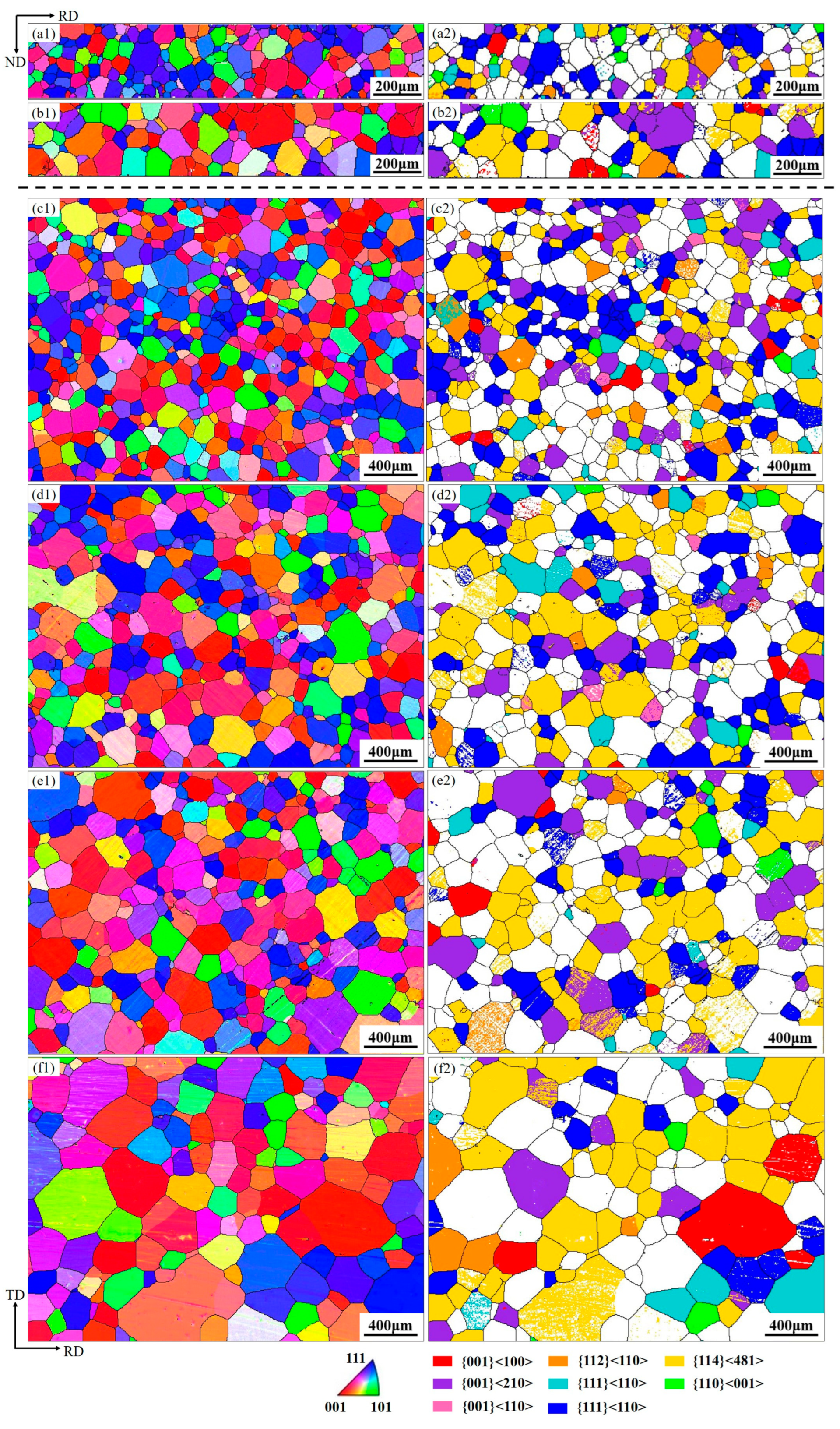

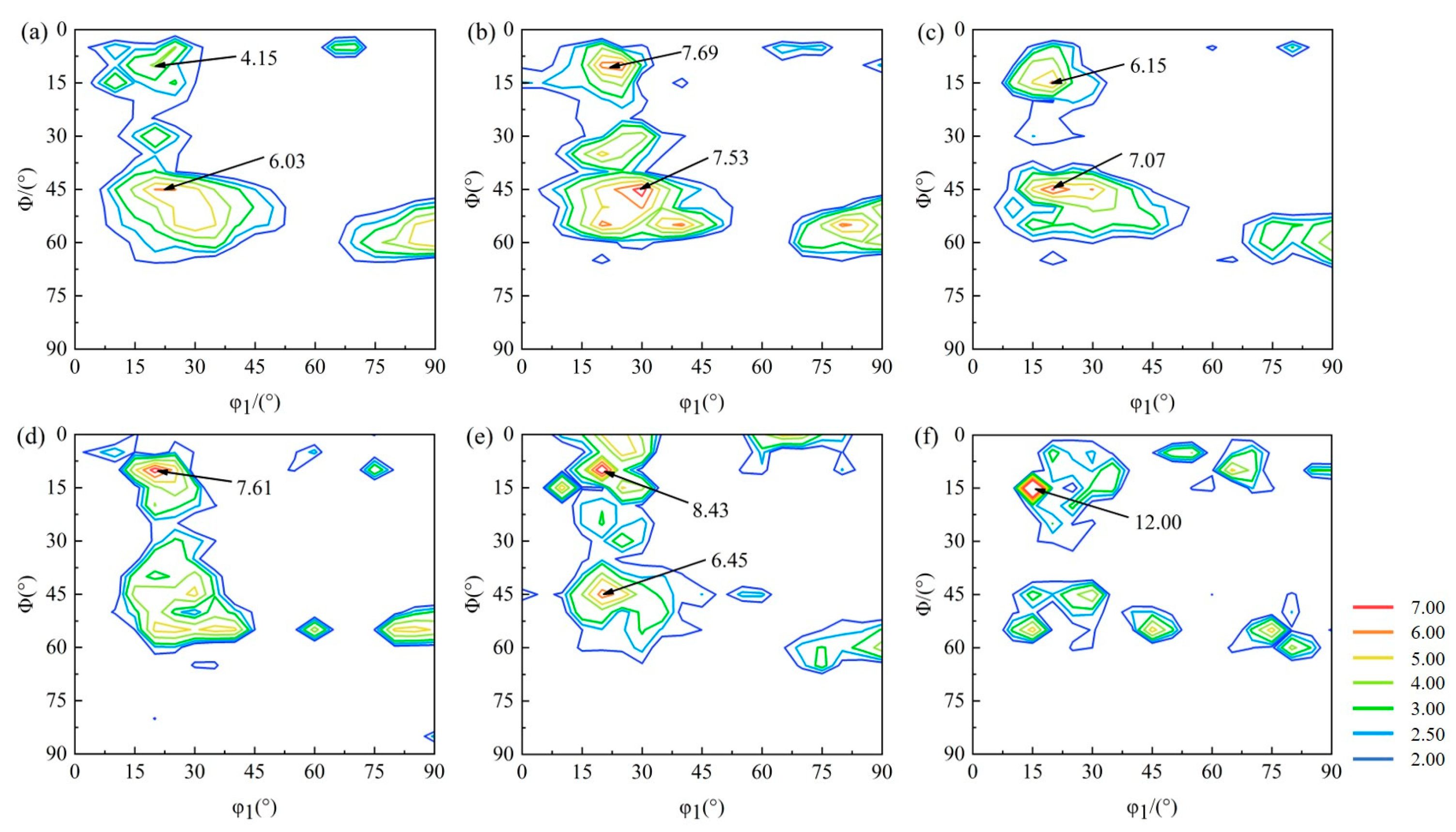

3.3. Microstructure and Texture During Grain Growth

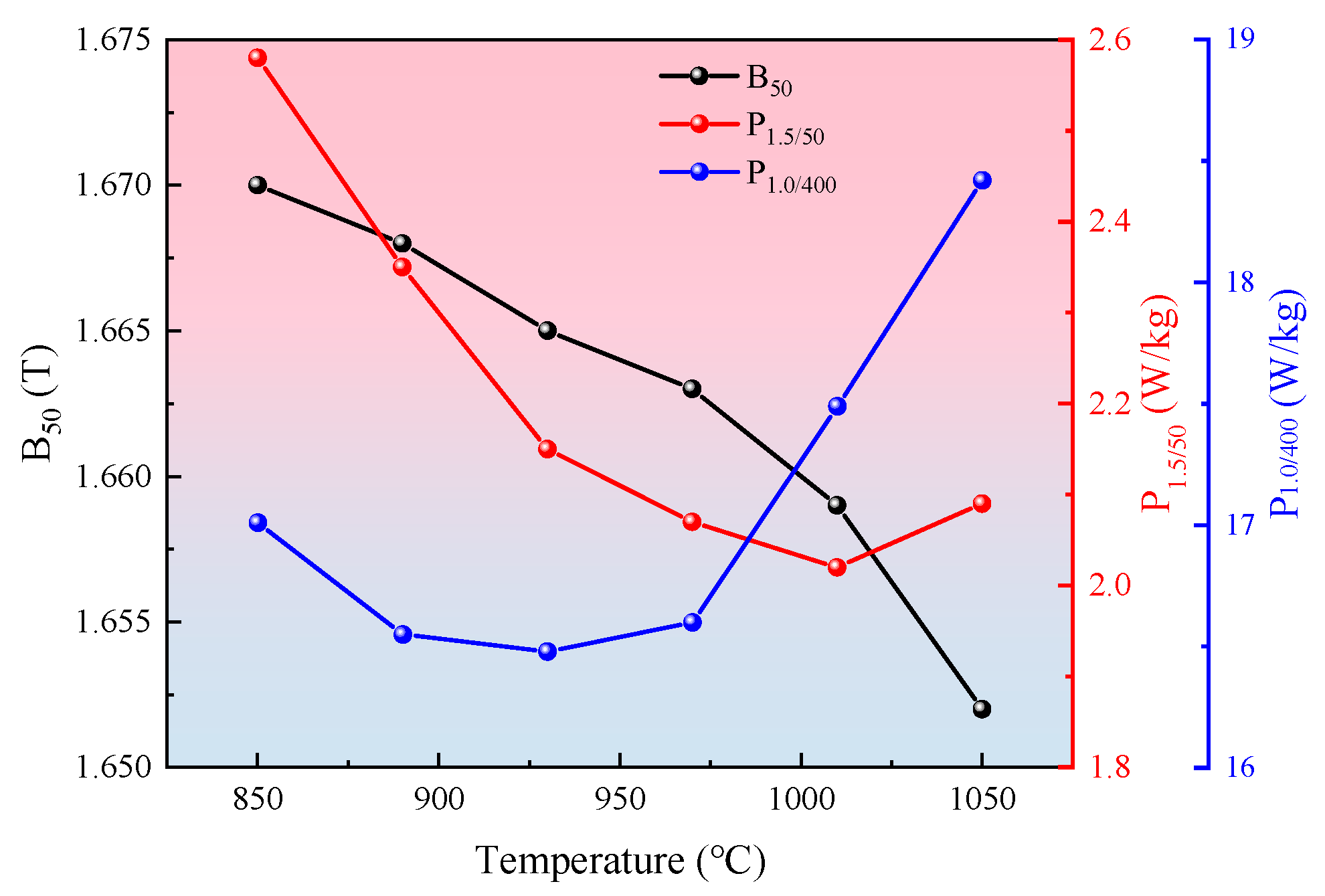

3.4. Magnetic Properties

4. Conclusions

- 1.

- Recrystallization of the cold-rolled sheet begins at 620 °C and completes at 720 °C. During this process, the original deformed microstructure is replaced by fine recrystallized grains. In the early stage of recrystallization, {111}<112> grains nucleate within the deformed {111}<110> matrix and progressively consume it. In the later stage, {114}<481> grains nucleate and grow at the grain boundaries of the deformed {112}<110> and {001}<110> matrix. After recrystallization, the {111}<112> and {114}<481> components become the dominant texture components in the annealed sheet, replacing the α-fiber texture observed before recrystallization.

- 2.

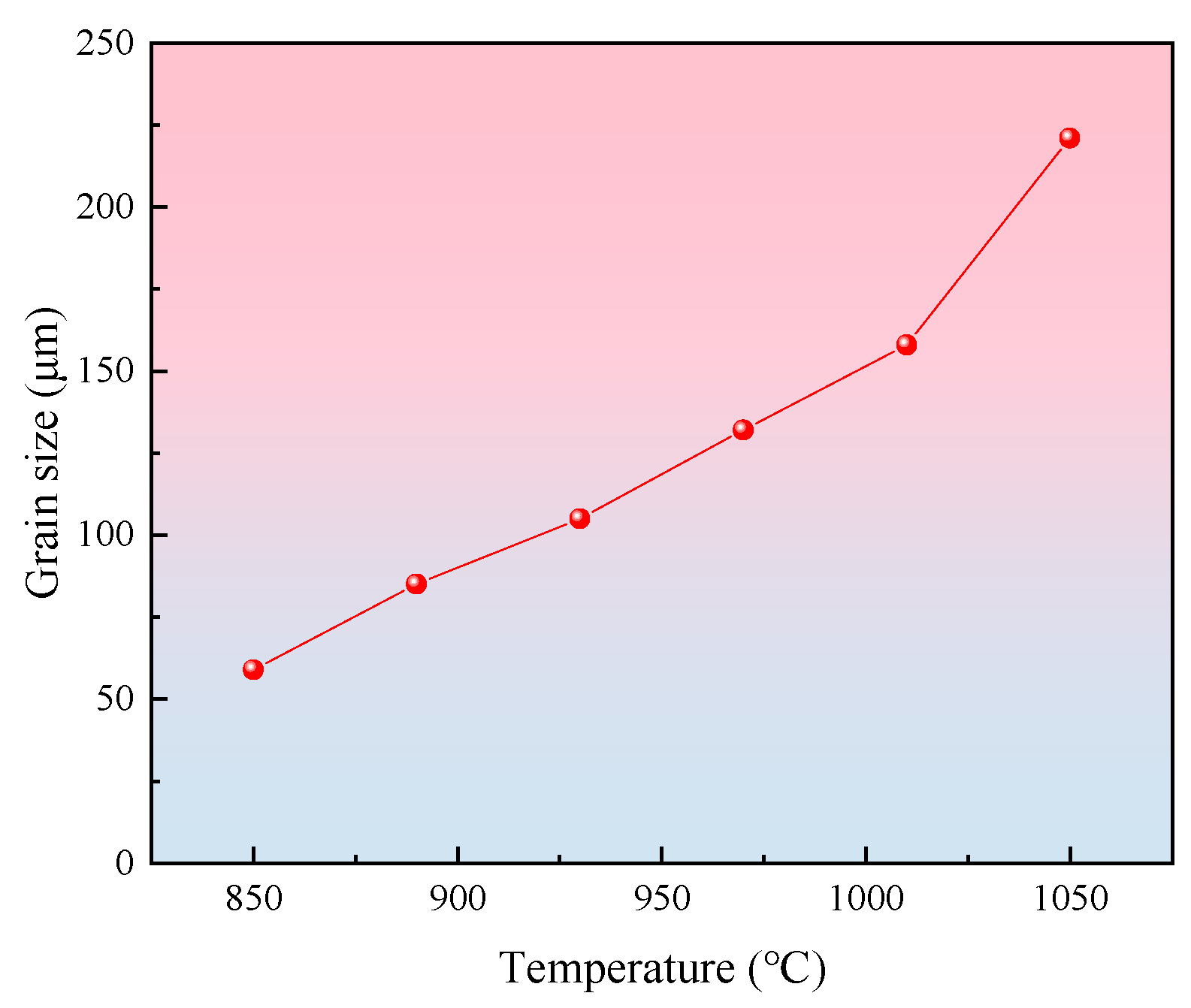

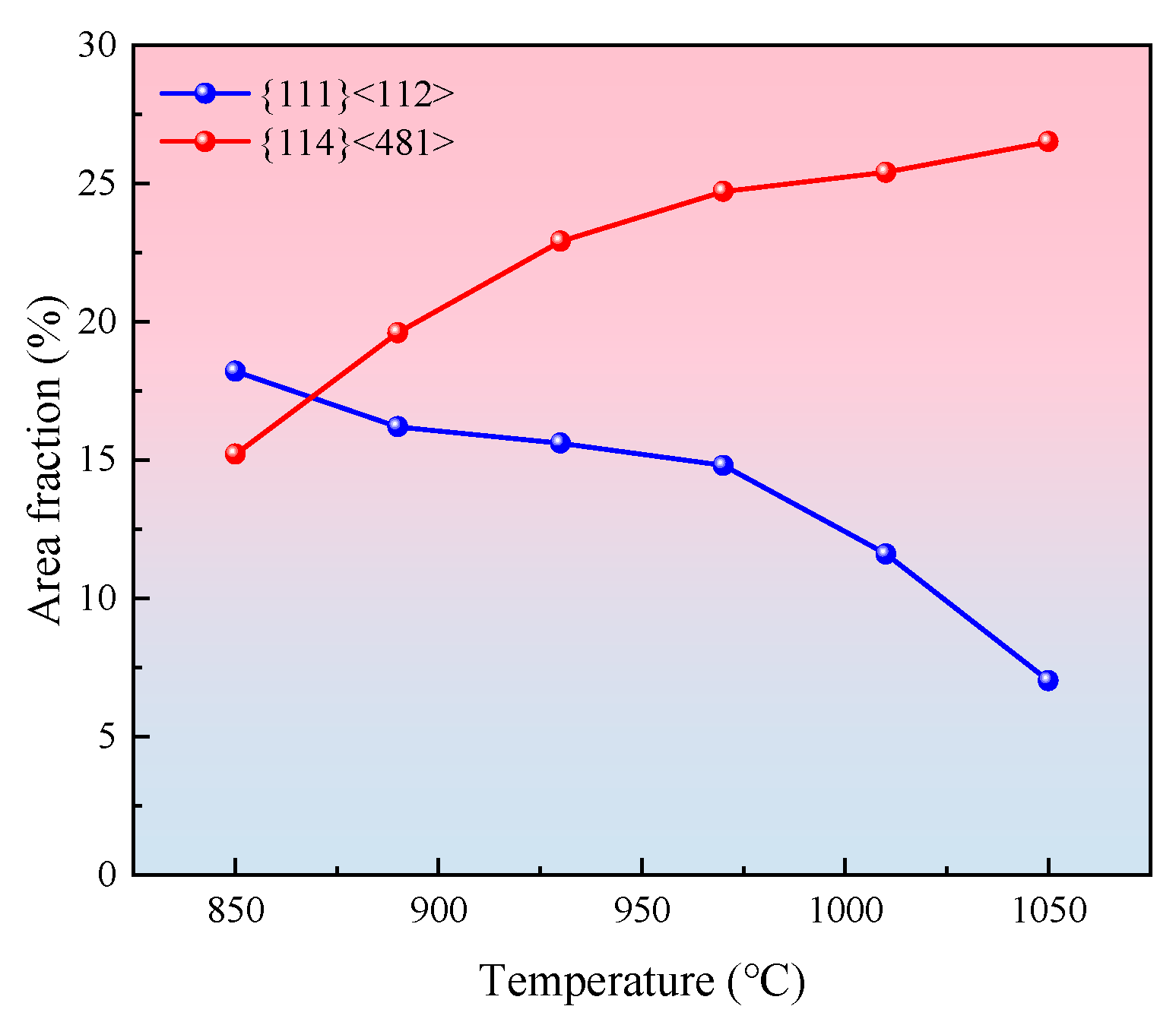

- From 850 °C to 1050 °C, the average grain size of the annealed non-oriented silicon steel sheet increases rapidly from 59 μm to 221 μm. During the grain growth process, the area fraction of {114}<481> grains surrounded by high-angle grain boundaries continuously increases, while that of {111}<112> grains surrounded by low-angle grain boundaries gradually decreases, due to high-angle grain boundaries exhibiting higher grain boundary mobility. As a result, the {114}<481> component becomes the dominant texture component in the annealed sheet at higher temperatures.

- 3.

- There is an optimal grain size at which the total core loss reaches its minimum. At high frequencies, where eddy current loss dominates, the optimal grain size tends to decrease. With increasing annealing temperature, the core losses P1.5/50 and P1.0/400 of the non-oriented silicon steel initially decrease and subsequently increase, exhibiting minimum values at 1010 °C and 930 °C, respectively. The gradual decline in magnetic induction (B50) is attributed to the increase in average grain size.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Oda, Y.; Okubo, T.; Takata, M. Recent development of non-oriented electrical steel in JFE steel. JFE Tech. Rep. 2016, 21, 7–13. [Google Scholar]

- Senda, K.; Namikawa, M.; Hayakawa, Y. Electrical steels for advanced automobiles–core materials for motors, generators and high-frequency reactors. JFE Tech. Rep. 2004, 4, 67–73. [Google Scholar]

- Akira, K.; Kazunari, T. Development of the IMA Motor for the V6 Hybrid Mid-size Sedan. In Proceedings of the SAE 2005 World Congress, Detroit, MI, USA, 11–14 April 2005. [Google Scholar]

- Pei, R.; Zeng, L.; Chen, X.; Liu, X. Studies of high-efficiency electrical steels used in electric vehicle motors. J. Shanghai Jiaotong Univ. (Sci.) 2012, 17, 319–322. [Google Scholar] [CrossRef]

- Kubota, T. Recent progress on non-oriented silicon steel. Steel Res. Int. 2005, 76, 464–470. [Google Scholar] [CrossRef]

- Toda, H.; Oda, Y.; Kohno, M.; Ishida, M.; Zaizen, Y. A new high flux density non-oriented electrical steel sheet and its motor performance. IEEE Trans. Magn. 2012, 48, 3060–3063. [Google Scholar] [CrossRef]

- Wakisaka, T.; Arai, S.; Kurosaki, Y. Electrical steel sheet for traction motor of hybrid/electrical vehicles. Nippon Steel Tech. Rep. 2013, 103, 116–120. [Google Scholar]

- Elwert, T.; Goldmann, D.; Römer, F.; Buchert, M.; Merz, C.; Schueler, D.; Sutter, J. Current developments and challenges in the recycling of key components of (hybrid) electric vehicles. Recycling 2016, 1, 25–60. [Google Scholar] [CrossRef]

- Park, J.T.; Szpunar, J.A. Evolution of recrystallization texture in nonoriented electrical steels. Acta Mater. 2003, 51, 3037–3051. [Google Scholar] [CrossRef]

- Cunha, M.A.; Paolinelli, S.C. Effect of the annealing temperature on the structure and magnetic properties of 3% Si non-oriented steel. J. Magn. Magn. Mater. 2003, 254, 379–381. [Google Scholar] [CrossRef]

- Qiao, J.; Liu, C.; Guo, F.; Xiang, L.; Qiu, S.; Wang, H. Effect of recrystallization annealing temperature on texture and magnetic properties of 2.97% Si non-oriented silicon steel. Metall. Res. Technol. 2019, 116, 412. [Google Scholar] [CrossRef]

- Li, Z.H.; Wang, G.D.; Liu, H.T. Effects of processing routes on recrystallization texture development and magnetic properties of 0.10 mm ultrathin non-oriented electrical steel sheets for high-frequency application. J. Alloys Compd. 2023, 935, 167984. [Google Scholar]

- Li, Z.; Xie, S.; Wang, G.; Liu, H. Ultrathin-gauge high silicon non-oriented electrical steel with high permeability and low core loss fabricated by optimized two-stage cold rolling method. Mater. Charact. 2022, 183, 111593. [Google Scholar] [CrossRef]

- Yu, L.; Luo, H.W. Effect of partial recrystallization annealing on magnetic properties and mechanical properties of non-oriented silicon steel. Acta Metall. Sin. 2020, 56, 291–300. [Google Scholar]

- Ushioda, K.; Hutchinson, W.B. Role of shear bands in annealing texture formation in 3% Si–Fe (111)[112] single crystals. ISIJ Int. 1989, 29, 862–867. [Google Scholar] [CrossRef]

- Böttcher, A.; Lücke, K. Influence of subsurface layers on texture and microstructure development in RGO electrical steel. Acta Metall. Mater. 1993, 41, 2503–2514. [Google Scholar] [CrossRef]

- Dorner, D.; Zaefferer, S.; Raabe, D. Retention of the Goss orientation between microbands during cold rolling of an Fe–3%Si Single Crystal. Acta Mater. 2007, 55, 2519–2530. [Google Scholar]

- Raabe, D.; Lücke, K. Rolling and annealing textures of BCC metals. Mater. Sci. Forum. 1994, 157, 597–610. [Google Scholar]

- Wang, J.; Li, J.; Wang, X.F.; Tian, J.J.; Zhang, C.H.; Zhang, S.G. Effect of heating rate on microstructure evolution and magnetic properties of cold rolled non-oriented electrical steel. J. Iron Steel Res. Int. 2010, 17, 54–61. [Google Scholar] [CrossRef]

- Inagaki, H. Fundamental aspect of texture formation in low carbon steel. ISIJ Int. 1994, 34, 313–321. [Google Scholar] [CrossRef]

- Hölscher, M.; Raabe, D.; Lücke, K. Rolling and recrystallization textures of BCC steels. Steel Res. 1991, 62, 567–575. [Google Scholar] [CrossRef]

- Liu, J.; Sha, Y.; Hu, K.; Zhang, F.; Zuo, L. Formation of Cube and Goss texture after primary recrystallization in electrical steels. Metall. Mater. Trans. A 2014, 45, 134–138. [Google Scholar] [CrossRef]

- Dafe, S.S.F.; Costa Paolinelli, S.; Cota, A.B. Influence of thermomechanical processing on shear bands formation and magnetic properties of a 3% Si non-oriented electrical steel. J. Magn. Magn. Mater. 2011, 323, 3234–3238. [Google Scholar] [CrossRef]

- Sidor, J.J.; Verbeken, K.; Gomes, E.; Schneider, J.; Calvillo, P.R.; Kestens, L.A.I. Through process texture evolution and magnetic properties of high Si non-oriented electrical steels. Mater. Charact. 2012, 71, 49–57. [Google Scholar] [CrossRef]

- Jiao, H.; Xu, Y.; Song, W.; Zhang, Y.; Cao, G.; Li, C.; Niu, J.; Misra, R.D.K. High-permeability and thin-gauge non-oriented electrical steel through twin-roll strip casting. Mater. Des. 2017, 136, 23–33. [Google Scholar] [CrossRef]

- Homma, H.; Nakamura, S.; Yoshinaga, N. On {h,1,1}<1/h,1,2>, the recrystallisation texture of heavily cold rolled BCC steel. Mater. Sci. Forum 2004, 467, 269–274. [Google Scholar]

- Hillert, M. On the theory of normal and abnormal grain growth. Acta Metall. 1965, 13, 227–238. [Google Scholar] [CrossRef]

- Turnbull, D. Theory of grain boundary migration rates. JOM 1951, 3, 661–665. [Google Scholar] [CrossRef]

- Omura, T.; Hayakawa, Y. Influence of primary-recrystallization texture on selective growth of Goss grains. Mater. Trans. 2013, 54, 14–21. [Google Scholar] [CrossRef]

- Campos, M.F.; Teixeira, J.C.; Landgraf, F.J.G. The optimum grain size for minimizing energy losses in iron. J. Magn. Magn. Mater. 2006, 301, 94–99. [Google Scholar] [CrossRef]

- Shiozaki, M.; Kurosaki, Y. The effects of grain size on the magnetic properties of nonoriented electrical steel sheets. J. Mater. Eng. 1989, 11, 37–43. [Google Scholar] [CrossRef]

- Oda, Y.; Kohno, M.; Honda, A. Recent development of non-oriented electrical steel sheet for automobile electrical devices. J. Magn. Magn. Mater. 2008, 320, 2430–2435. [Google Scholar] [CrossRef]

- Campos, M.F.; Yonamine, T.; Fukuhara, M.; Landgraf, F.J.G.; Achete, C.A.; Missell, F.P. Effect of frequency on the iron losses of 0.5% and 1.5% Si nonoriented electrical steels. IEEE Trans. Magn. 2006, 42, 2812–2814. [Google Scholar] [CrossRef]

- PremKumar, R.; Samajdar, I.; Viswanathan, N.N.; Singal, V.; Seshadri, V. Relative effect(s) of texture and grain size on magnetic properties in a low silicon non-grain oriented electrical steel. J. Magn. Magn. Mater. 2003, 264, 75–85. [Google Scholar] [CrossRef]

- Gomes, E.; Schneider, J.; Verbeken, K.; Barros, J.; Houbaert, Y. Correlation between microstructure, texture, and magnetic induction in nonoriented electrical steels. IEEE Trans. Magn. 2010, 46, 310–313. [Google Scholar] [CrossRef]

- Kestens, L.; Jacobs, S. Texture control during the manufacturing of nonoriented electrical steels. Texture Stress Microstruct. 2008, 2008, 173083. [Google Scholar] [CrossRef]

- Ning, X.; Liang, Y.; Wang, Y.; Feng, Y.; Lin, J. A comprehensive study on texture evolution and recrystallization mechanism of Fe-4.5 wt% Si with strong {114}<481>. J. Mater. Res. Technol. 2023, 27, 7506–7520. [Google Scholar]

| Si | Al | Mn | C | S | P | N |

|---|---|---|---|---|---|---|

| 3.2 | 0.9 | 0.27 | 0.0024 | 0.0019 | 0.013 | 0.0018 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chu, S.; Xiang, L.; Guo, F.; Qiu, S. Effect of Annealing Temperature on Microstructure, Texture, and Magnetic Properties of Non-Oriented Silicon Steel for Electric Vehicle Traction Motors. Metals 2025, 15, 1235. https://doi.org/10.3390/met15111235

Chu S, Xiang L, Guo F, Qiu S. Effect of Annealing Temperature on Microstructure, Texture, and Magnetic Properties of Non-Oriented Silicon Steel for Electric Vehicle Traction Motors. Metals. 2025; 15(11):1235. https://doi.org/10.3390/met15111235

Chicago/Turabian StyleChu, Shaoyang, Li Xiang, Feihu Guo, and Shengtao Qiu. 2025. "Effect of Annealing Temperature on Microstructure, Texture, and Magnetic Properties of Non-Oriented Silicon Steel for Electric Vehicle Traction Motors" Metals 15, no. 11: 1235. https://doi.org/10.3390/met15111235

APA StyleChu, S., Xiang, L., Guo, F., & Qiu, S. (2025). Effect of Annealing Temperature on Microstructure, Texture, and Magnetic Properties of Non-Oriented Silicon Steel for Electric Vehicle Traction Motors. Metals, 15(11), 1235. https://doi.org/10.3390/met15111235