Novel Alloy Designed Electrical Steel for Improved Performance in High-Frequency Electric Machines

Abstract

1. Introduction

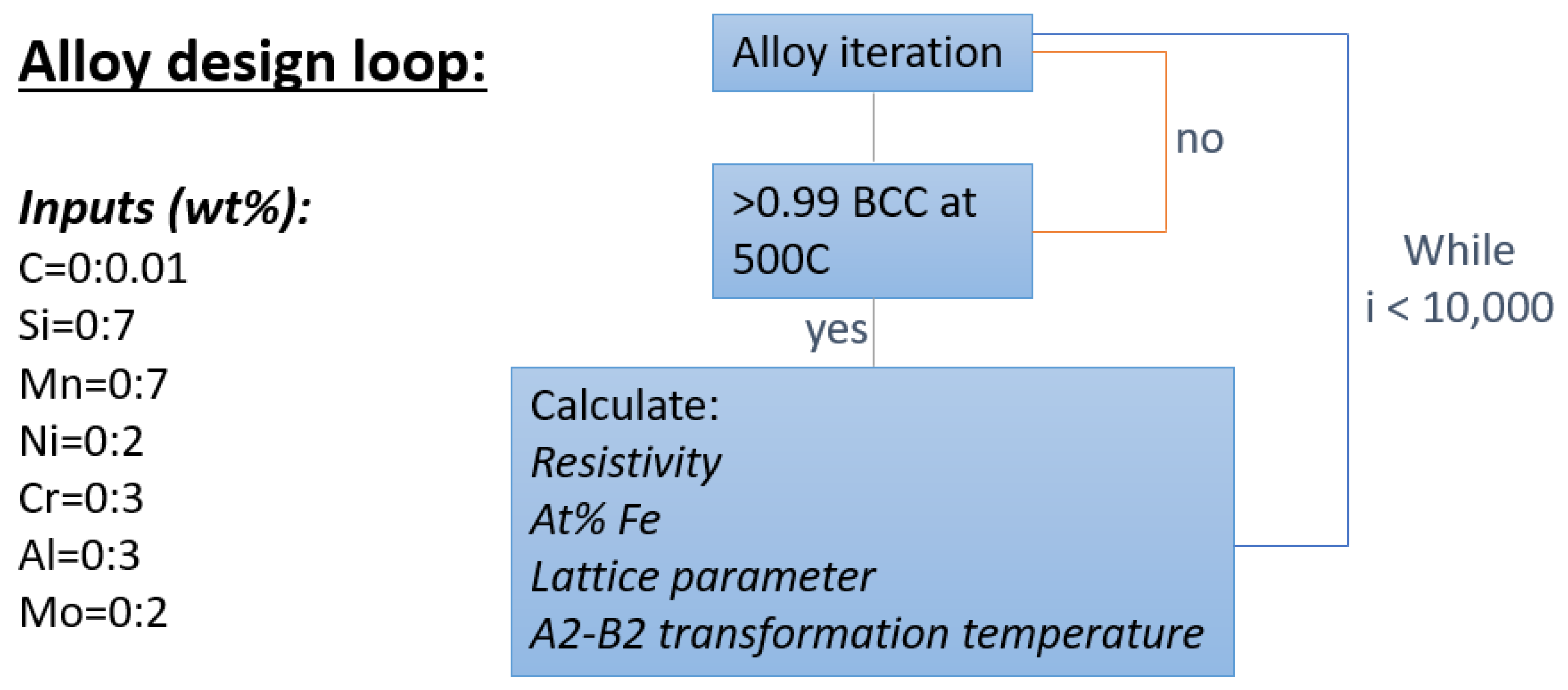

2. Fundamentals of Alloy Design for the Proposed Steels

- Carbon (C)—Provides solid solution strengthening when added in small quantities; however, the solubility of carbon in ferrite is limited, and therefore an upper limit is defined to avoid cementite/pearlite formation.

- Silicon (Si)—Known to strongly increase resistivity and reduce coercivity.

- Manganese (Mn)—Increases resistivity although a strong austenite stabilizer.

- Nickel (Ni)—Suppresses BCC B2 and D03 phases, also a weak austenite stabilizer.

- Chromium (Cr), aluminum (Al), and molybdenum (Mo)—Stabilize ferrite without promoting BCC B2 and D03 phases.

- Resistivity: Eddy current losses within a soft magnetic material can be significantly reduced through increasing electrical resistivity. This has been calculated through the empirical relationship (Equation (1)), where all additions are in wt% [13].

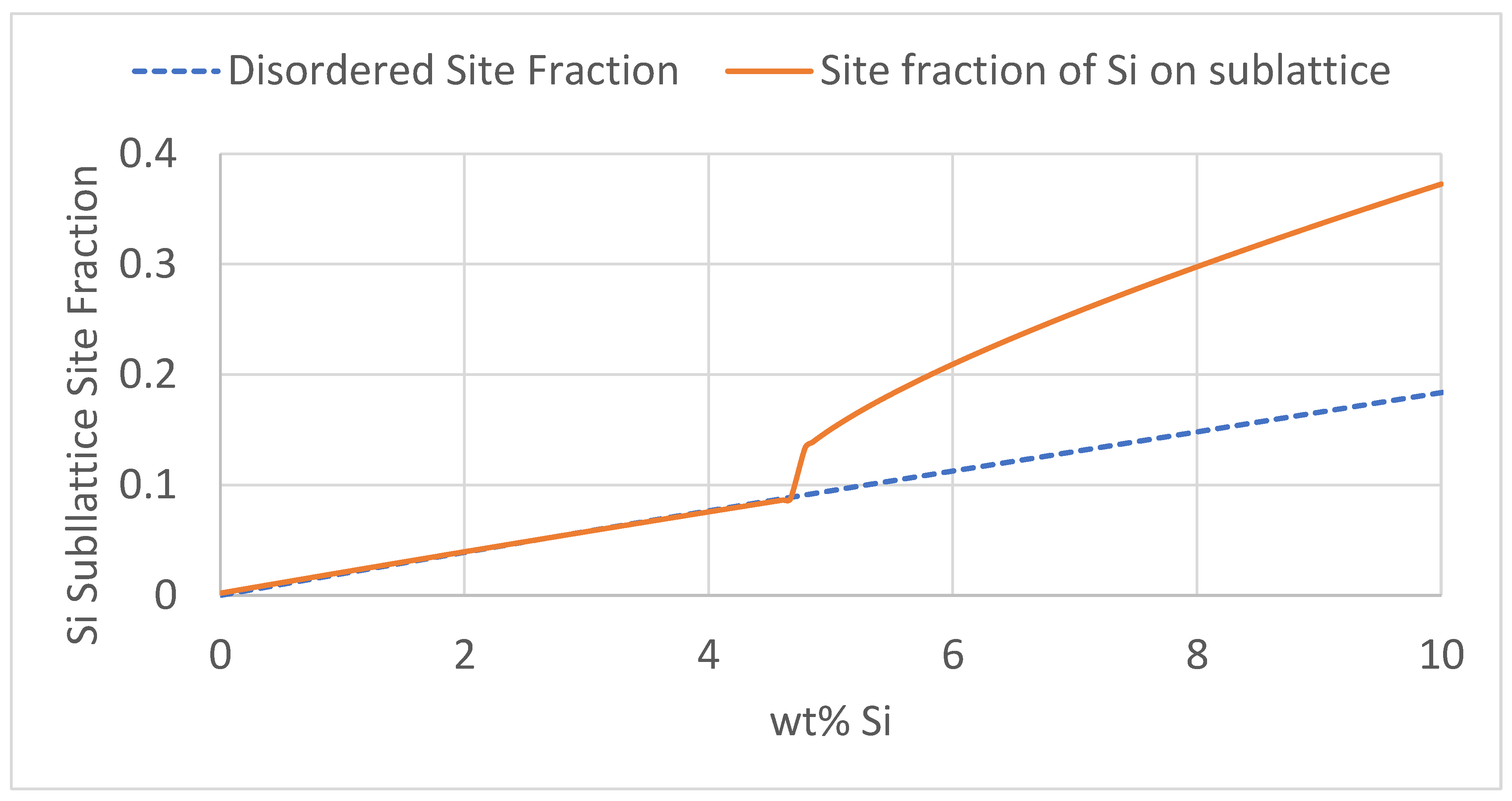

- A2-B2 Transformation Temperature: As B2 forms at a lower Si content than D03, then just the B2 phase needs to be mapped for stability to avoid the brittle ordered phase. The B2 and DO3 phases form when the silicon concentration reaches a critical concentration (around 4.2 and 5.3 wt%, respectively, for B2 and D03 phases in a Fe-Si binary system at 500 °C [14]) which is when ordering becomes more favorable between the nearest neighbor and the next nearest neighbor [15]. This can be predicted through CALPHAD type simulations when the concentration of Si on a given sublattice position deviates away from the global concentration (Figure 2). In Figure 2, the sublattice site occupancy of silicon can be seen as a function of Si wt%. For a given temperature, at the critical silicon content, it becomes energetically more favorable for silicon atoms to occupy a repeated sublattice location. This increase away from that of a random distribution has been deemed in this study as the A2-B2 transformation temperature. This approach allows the formation of ordered phases as a function of equilibrium temperature, including for more complex non-binary compositions, to be determined. Modern CALPHAD databases (such as Thermocalc TCFe10) can distinguish between BCC A2 and B2 phases and so automate this step.

- Atomic % Fe: At low frequencies, magnetic losses are governed less by resistivity and more by hysteretic losses, and as such minimizing the total alloying element content is preferential. Whilst this alloy design approach is for higher-frequency applications of electrical steels, considering a metric of the total alloy content is useful for considering potential changes to magnetic saturation. It is also important from a steel-making perspective, since making higher alloying element concentrations can be challenging, needing more master alloy additions that can chill the liquid steel and requiring reheating practices.

- Lattice parameter: Whilst the lattice parameter is the least important metric in terms of alloy design, the lattice parameter has a known correlation to a materials magnetic response to stress [16], and as such is calculated as part of this design loop.

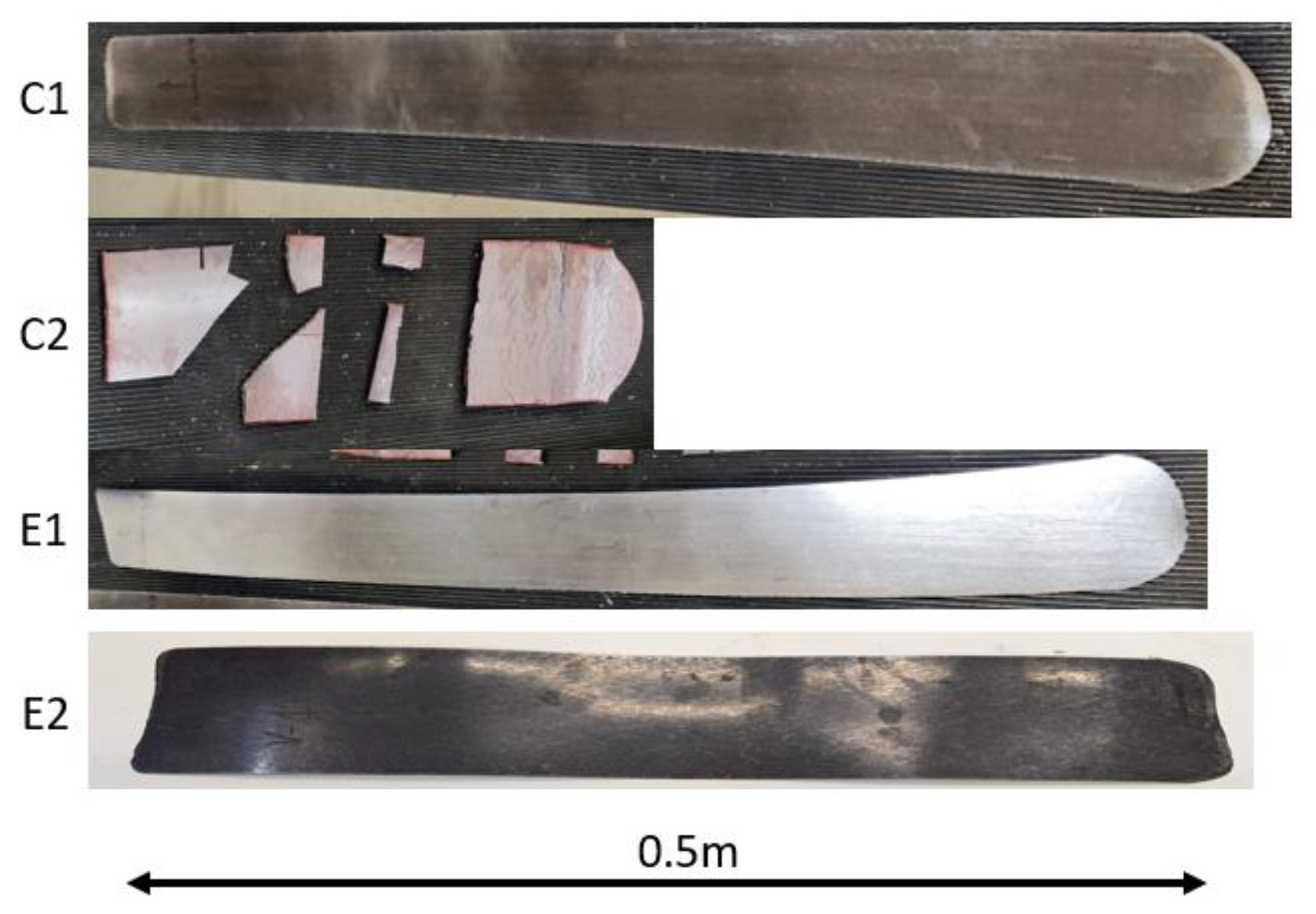

3. Experimental Methodology

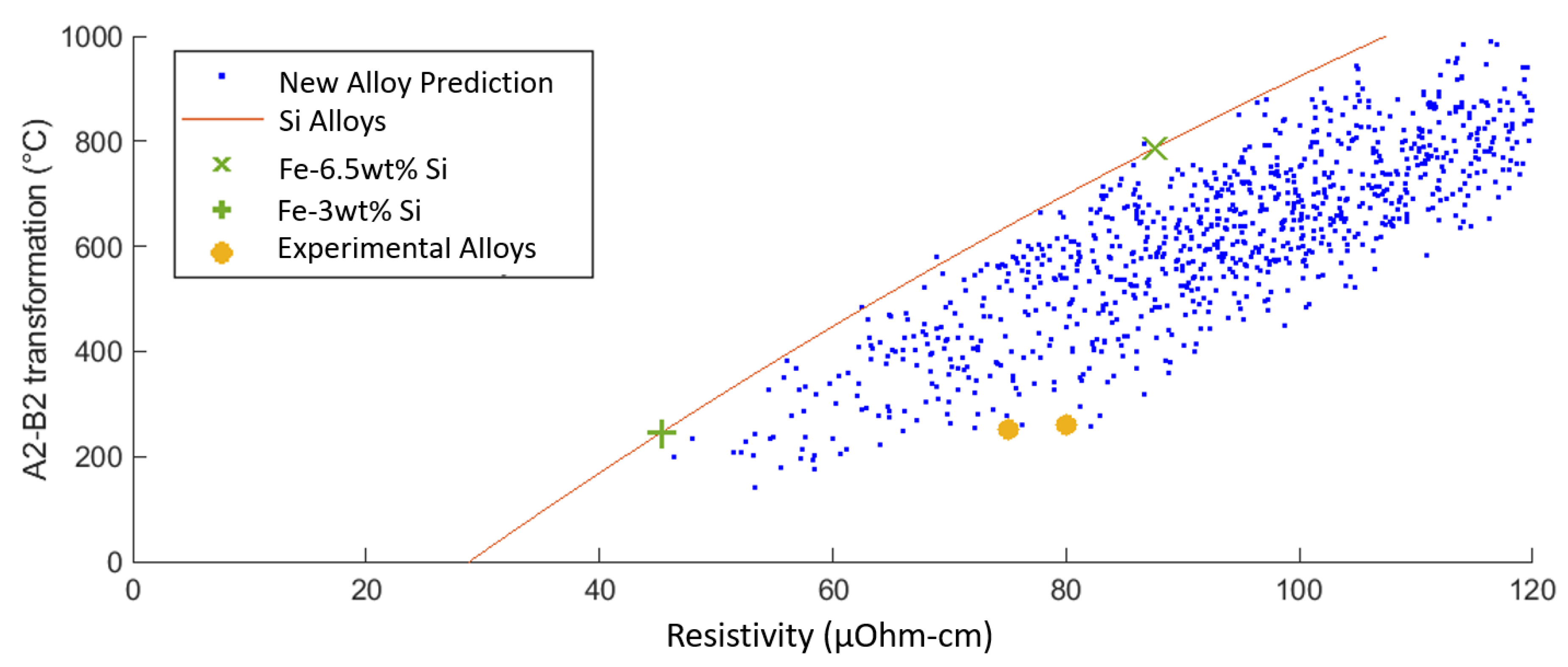

4. Results and Discussion

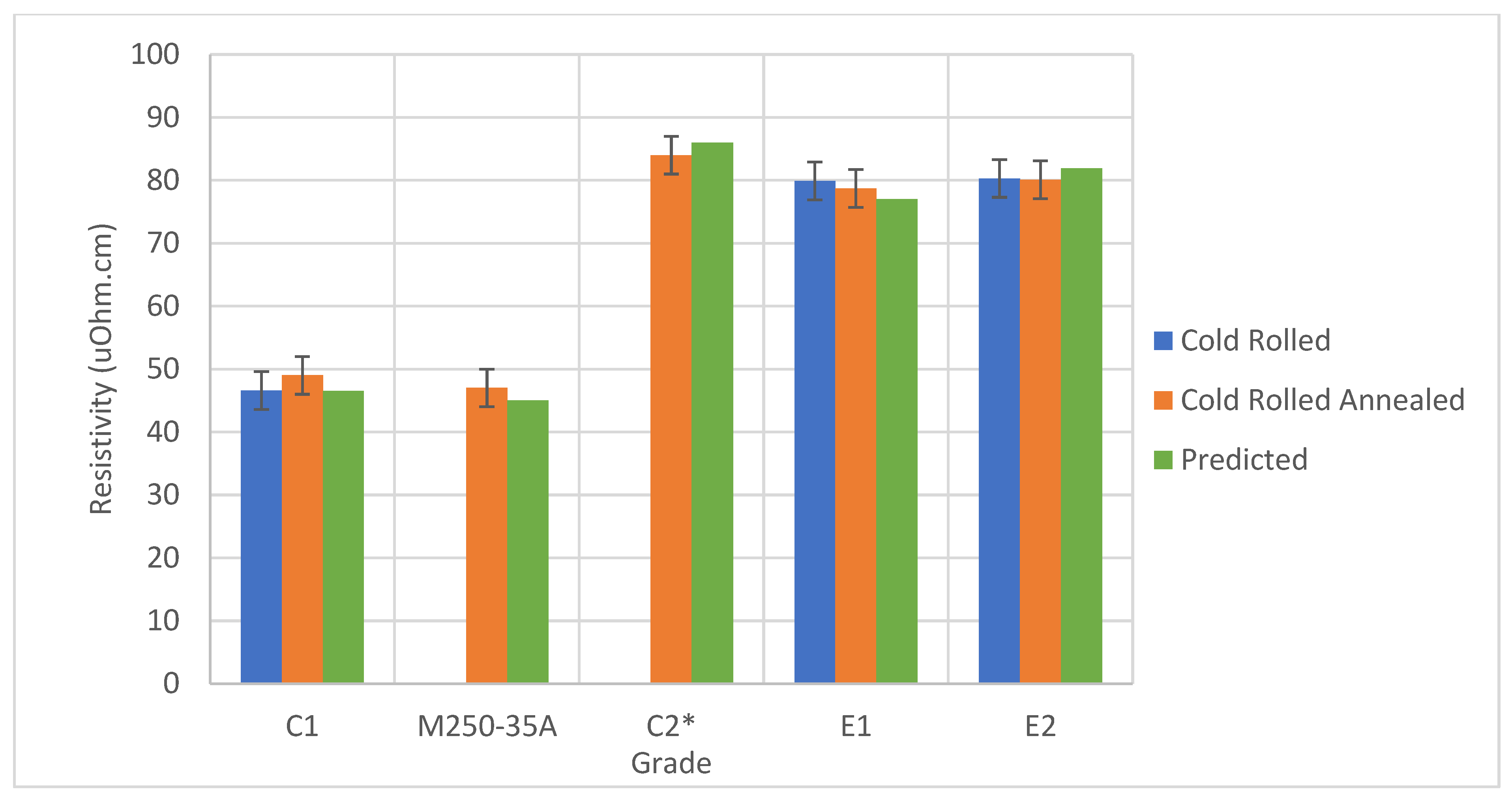

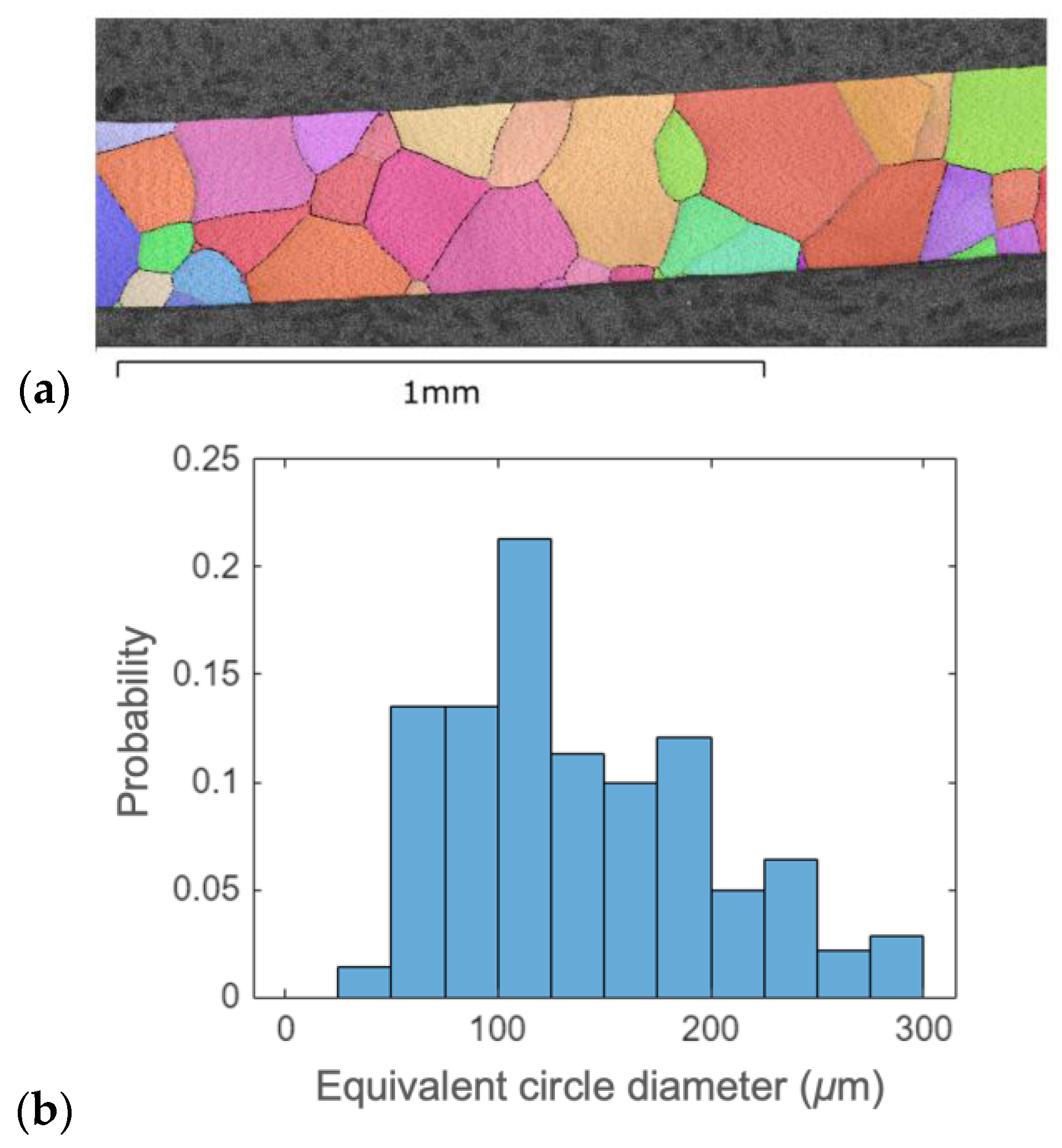

4.1. Electrical Resistivity and Microstructure

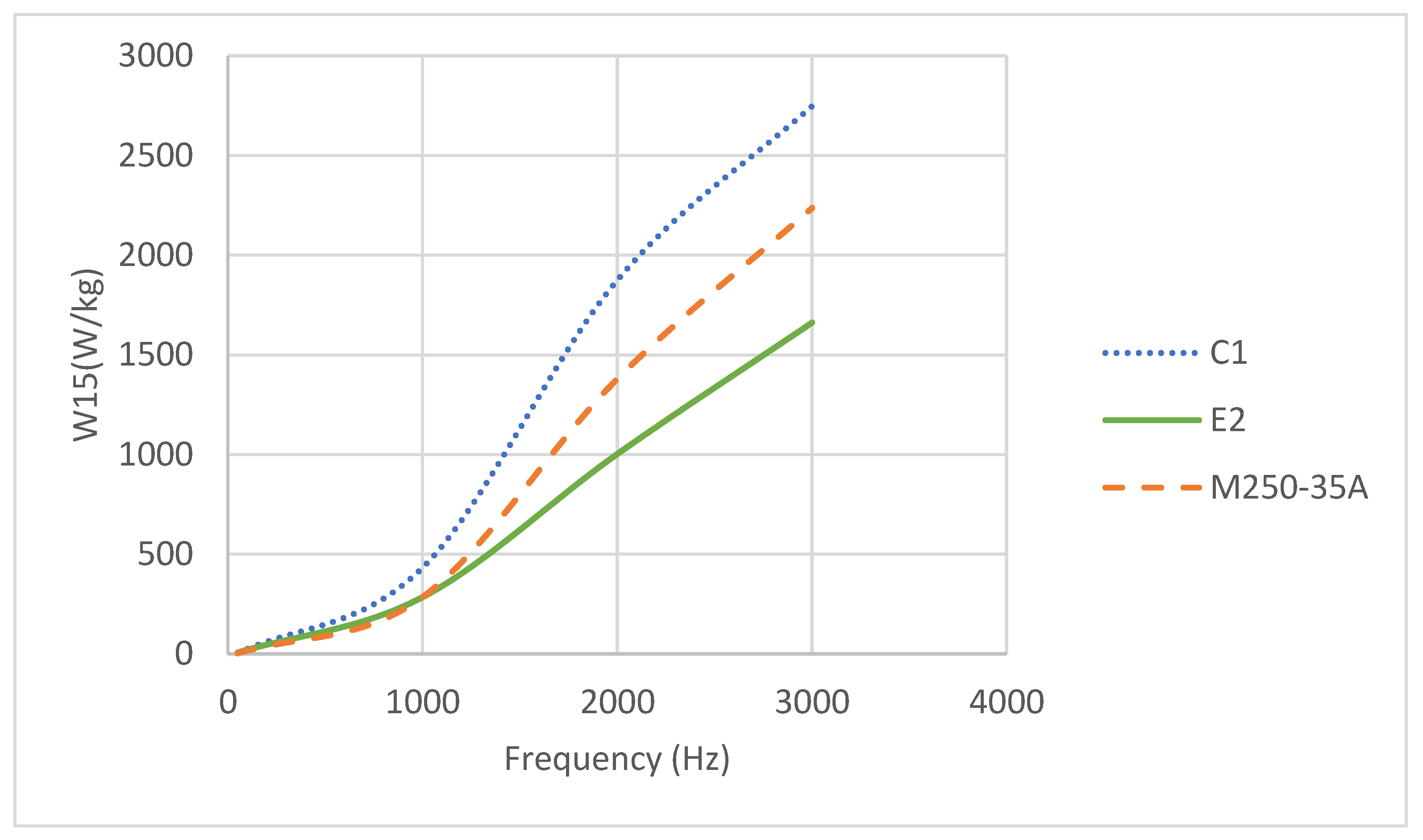

4.2. Magnetic Testing

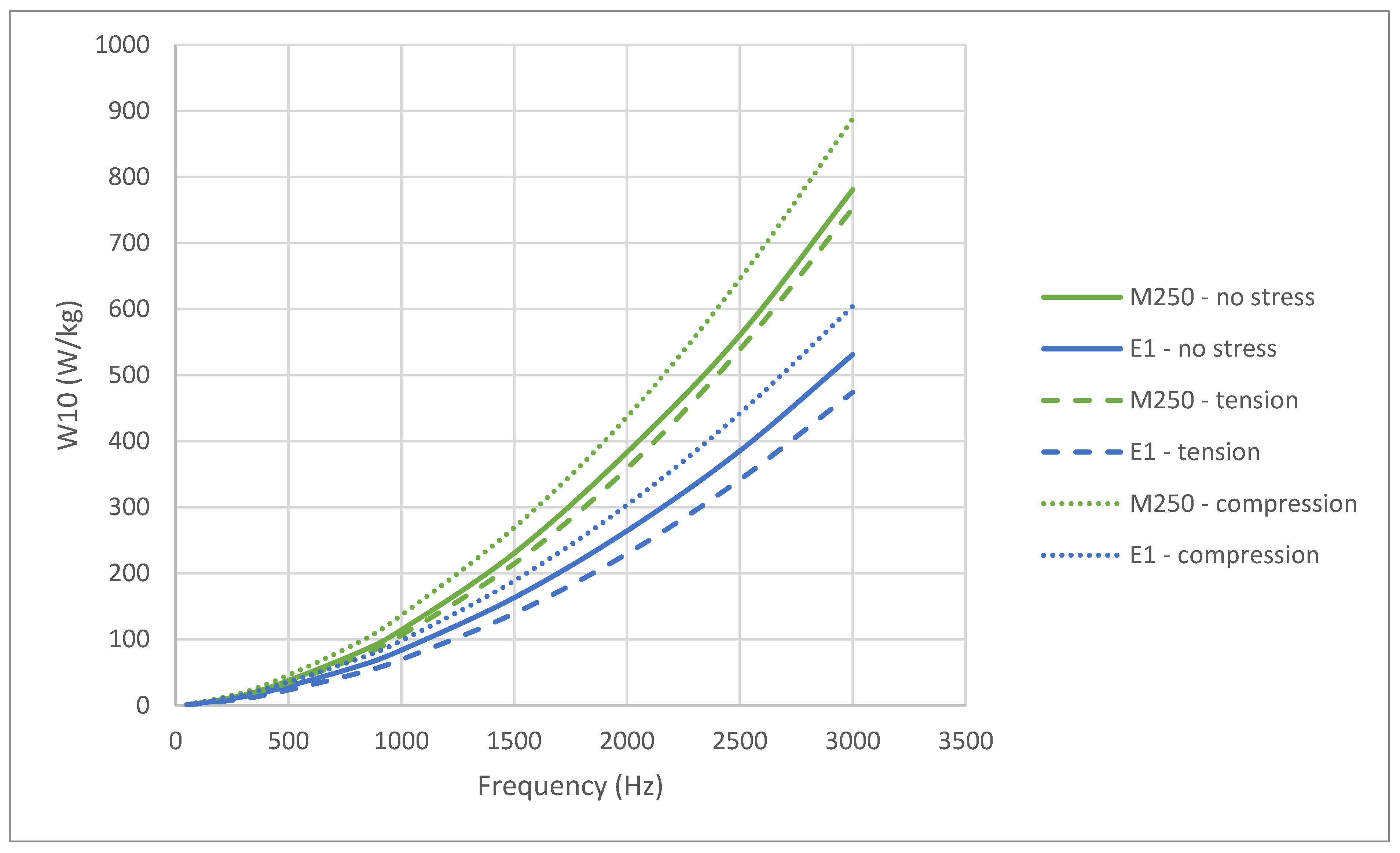

4.3. High-Frequency Testing Under Load

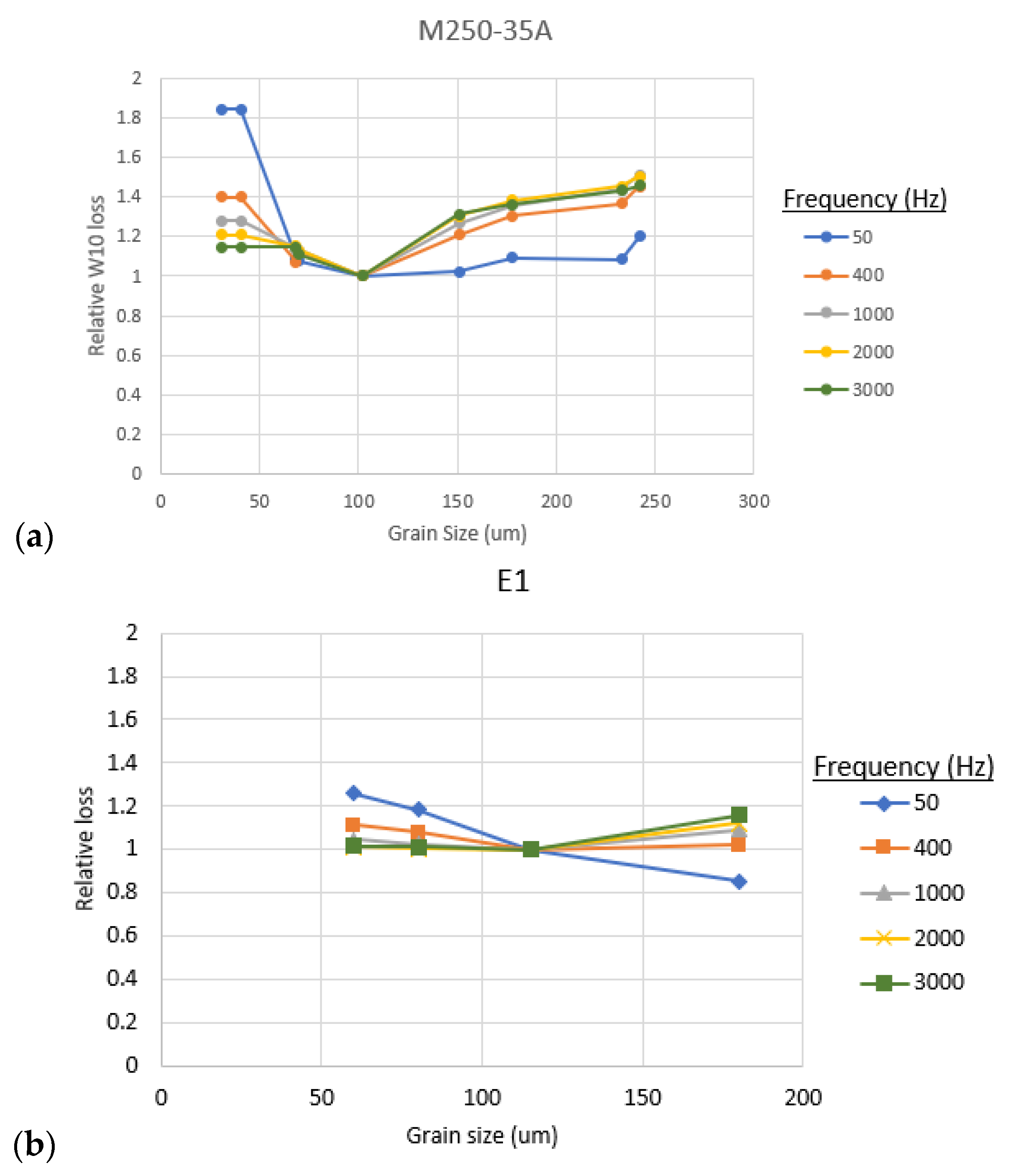

4.4. Magnetic Performance as a Function of Grain Size

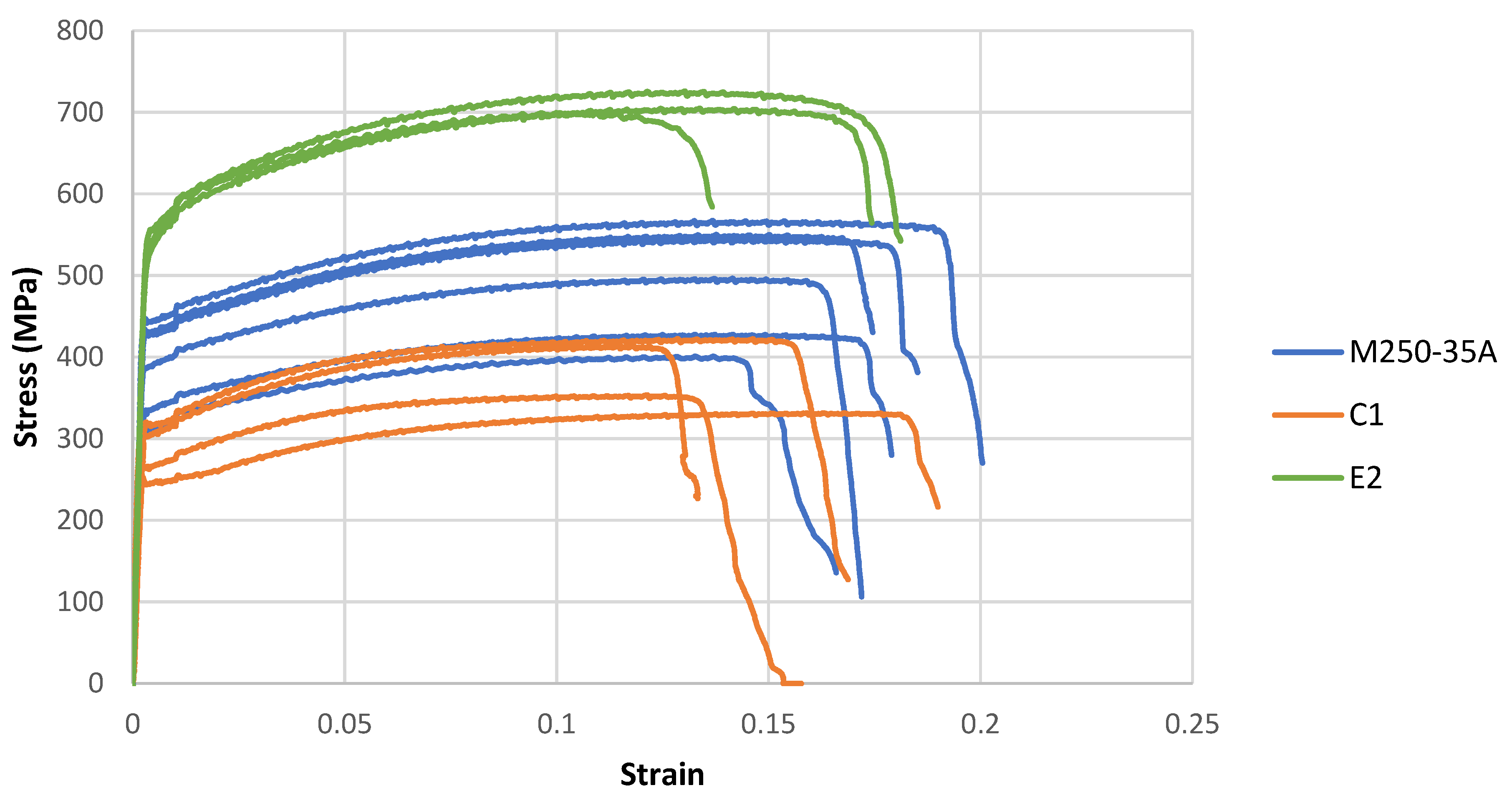

4.5. Mechanical Testing

5. Conclusions

- Fabrication: The 6.5 wt% Si electrical steel could not be cold-rolled as it was brittle, whereas both HiPPES alloys and the 3 wt% Si steel were successfully rolled to a final gauge of 0.35 mm.

- Resistivity: Predicted and measured resistivity values agreed within 6%, with the two HiPPES alloys exhibiting up to a 90% increase in resistivity compared to the 3 wt% Si steel and M250-35A.

- Magnetic Losses: At 1.5 T, a HiPPES alloy demonstrated over 40% lower losses compared to the 3 wt% Si steel and 25% lower losses than M250-35A. At 1 T, losses improved by 33% relative to M250-35A.

- Stress Sensitivity: Under compressive loads, the HiPPES alloy showed a comparable response to M250-35A. However, under tensile loads, the HiPPES alloy showed a 12% reduction in losses compared to M250-35A, which showed only a 4% reduction in losses.

- Grain Size Dependence: The HiPPES alloy exhibited little variation in magnetic losses (<20%) across grain sizes from 60 to 180 µm at frequencies above 400 Hz. By contrast, M250-35A showed over 40% variation in losses under similar conditions.

- Mechanical Strength: The HiPPES alloy demonstrated an approximately 220 MPa increase in ultimate tensile strength (UTS) compared to M250-35A and over 350 MPa compared to 3 wt% Si steel. This enhancement was primarily attributed to solid solution strengthening from alloying additions.

6. Patents

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- World Steel Association. World Steel in Figures. 2022. Available online: https://worldsteel.org/data/world-steel-in-figures/world-steel-in-figures-2022/ (accessed on 21 September 2025).

- Ouyang, G.; Chen, X.; Liang, Y.; Macziewski, C.; Cui, J. Review of Fe-6.5 wt% Si high silicon steel—A promising soft magnetic material for sub-kHz application. J. Magn. Magn. Mater. 2019, 481, 234–250. [Google Scholar] [CrossRef]

- Krings, A.; Boglietti, A.; Cavagnino, A.; Sprague, S. Soft Magnetic Material Status and Trends in Electric Machines. IEEE Trans. Ind. Electron. 2017, 64, 2405–2414. [Google Scholar] [CrossRef]

- Campbell, A. On the Magnetic Properties of Silicon Iron (Stalloy) in Alternating Magnetic Fields of Low Value. Proc. Phys. Soc. Lond. 1919, 32, 232. [Google Scholar] [CrossRef]

- Yu, J.H.; Shin, J.S.; Bae, J.S.; Lee, Z.-H.; Lee, T.D.; Lee, H.M.; Lavernia, E.J. The effect of heat treatments and Si contents on B2 ordering reaction in high-silicon steels. Mater. Sci. Eng. A 2001, 307, 29–34. [Google Scholar] [CrossRef]

- Lu, X.; Xu, Y.B.; Fang, F.; Zhang, Y.X.; Wang, Y.; Jiao, H.T.; Cao, G.M.; Li, C.G.; Yuan, G.; Wang, G.D. Microstructure. texture and precipitate of grain-oriented 4.5 wt% Si steel by strip casting. J. Magn. Magn. Mater. 2016, 404, 230–237. [Google Scholar] [CrossRef]

- Li, H.Z.; Liu, H.T.; Liu, Z.Y.; Lu, H.H.; Song, H.Y.; Wang, G.D. Characterization of microstructure. texture and magnetic properties in twin-roll casting high silicon non-oriented electrical steel. Mater. Charact. 2014, 88, 1–6. [Google Scholar] [CrossRef]

- Ouyang, G.; Jensen, B.; Tang, W.; Dennis, K.; Macziewski, C.; Thimmaiah, S.; Liang, Y. Cui Effect of wheel speed on magnetic and mechanical properties of melt spun Fe-6.5 wt.% Si high silicon steel. AIP Adv. 2018, 8, 56111. [Google Scholar] [CrossRef]

- Li, H.Z.; Liu, H.T.; Liu, Y.; Liu, Z.Y.; Cao, G.M.; Luo, Z.H.; Zhang, F.Q.; Chen, S.L.; Lyu, L.; Wang, G.D. Effects of warm temper rolling on microstructure. texture and magnetic properties of strip-casting 6.5 wt% Si electrical steel. J. Magn. Magn. Mater. 2014, 370, 6–12. [Google Scholar] [CrossRef]

- Oda, Y.; Okubo, T.; Takata, M. Recent development of non-oriented electrical steel in JFE steel. JFE Tech. Report. 2016, 21, 7–13. [Google Scholar]

- Kasai, S.; Namikawa, M.; Hiratani, T. Recent progress of high silicon electrical steel in JFE steel. JFE Tech. Report. 2016, 21, 14–19. [Google Scholar]

- Daem, A.; Sergeant, P.; Dupré, L.; Chaudhuri, S.; Bliznuk, V.; Kestens, L. Materials Magnetic Properties of Silicon Steel after Plastic Deformation. Materials 2020, 13, 4361. [Google Scholar] [CrossRef]

- Koley, S.; Ray, T.; Mohanty, I.; Chatterjee, S.; Shome, M. Prediction of electrical resistivity of steel using artificial neural network. Ironmak. Steelmak. 2019, 46, 383–391. [Google Scholar] [CrossRef]

- Shin, J.S.; Bae, J.S.; Kim, H.J.; Lee, H.M.; Lee, T.D.; Lavernia, E.J.; Lee, Z.H. Ordering–disordering phenomena and micro-hardness characteristics of B2 phase in Fe–(5–6.5%)Si alloys. Mater. Sci. Eng. A 2005, 407, 282–290. [Google Scholar] [CrossRef]

- Swann, P.R.; Grånäs, L.; Lehtinen, B. The B2 and DO 3 Ordering Reactions in Iron-Silicon Alloys in the Vicinity of the Curie Temperature. Met. Sci. 2013, 9, 90–96. [Google Scholar] [CrossRef]

- Cardias, R.; Szilva, A.; Bergman, A.; Di Marco, I.; Katsnelson, M.I.; Lichtenstein, A.I.; Nordström, L.; Klautau, A.B.; Eriksson, O.; Kvashnin, Y.O. The Bethe-Slater curve revisited; new insights from electronic structure theory OPEN. Sci. Rep. 2017, 7, 4058. [Google Scholar] [CrossRef]

- IEC 60404-2:1996; Magnetic Materials—Part 2: Methods of Measurement of the Magnetic Properties of Electrical Steel Sheet and Strip by Means of an Epstein Frame. International Electrotechnical Commission (IEC): Geneva, Switzerland, 2018.

- ASTM E8/E8M-16a; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2016.

- Boehm, L.; Hartmann, C.; Gilch, I.; Stoecker, A.; Kawalla, R.; Wei, X.; Hirt, G.; Heller, M.; Korte-Kerzel, S.; Leuning, N.; et al. Grain size influence on the magnetic property deterioration of blanked non-oriented electrical steels. Materials 2021, 14, 7055. [Google Scholar] [CrossRef]

- Beyer, E.; Lahn, L.; Schepers, C.; Stucky, T. The influence of compressive stress applied by hard coatings on the power loss of grain oriented electrical steel sheet. J. Magn. Magn. Mater. 2011, 323, 1985–1991. [Google Scholar] [CrossRef]

- Zhang, P.; Liao, W.; Lin, B.; Wang, N.; Li, C.; Zhang, J.; Gao, J. Comprehensive magnetic properties of grain-oriented silicon steel sheet considering anisotropy under mechanical stress. J. Magn. Magn. Mater. 2024, 610, 172583. [Google Scholar] [CrossRef]

- Slater, J.C. The Ferromagnetism of Nickel. Phys. Rev. 1936, 49, 537. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, J.; Zhang, C.; Ye, F.; Liu, B.; Liang, Y. Effect of initial grain size on microstructure, texture and magnetic properties of non-oriented electrical steel. J. Mater. Res. Technol. 2024, 31, 1607–1615. [Google Scholar] [CrossRef]

- Takaki, S. Review on the Hall-Petch Relation in Ferritic Steel. Mater. Sci. Forum 2010, 654–656, 11–16. [Google Scholar] [CrossRef]

- De Campos, M.F.; Teixeira, J.C.; Landgraf, F.J.G. The optimum grain size for minimizing energy losses in iron. J. Magn. Magn. Mater. 2006, 301, 94–99. [Google Scholar] [CrossRef]

- Gawne, D.T.; Lewis, G.M.H. Strengthening mechanisms in high-strength micro-alloyed steels. Mater. Sci. Technol. 1985, 1, 183–191. [Google Scholar] [CrossRef]

- Nyyssönen, T.; Hutchinson, B.; Broddefalk, A. Higher strength steels for magnetic applications in motors. Mater. Sci. Technol. 2021, 37, 883–892. [Google Scholar] [CrossRef]

| Fe | C | Mn | Si | Ni | Cr | Al | Mo | |

|---|---|---|---|---|---|---|---|---|

| E1 | Bal. | <0.004 | 3.2 | 3.61 | 0.63 | 0.75 | 0.15 | 0.4 |

| E2 | Bal. | <0.004 | 1.96 | 4.53 | 0.41 | 0.75 | 0.09 | <0.05 |

| C1 | Bal. | <0.004 | <0.01 | 3.02 | - | - | <0.005 | - |

| C2 | Bal. | <0.004 | <0.01 | 6.4 | - | - | <0.005 | - |

| M250-35A | Bal. | <0.004 | 0.5 | 3.2 | - | - | 0.06 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Slater, C.; Ma, X.; Lagorce, G.; Soulard, J.; Davis, C. Novel Alloy Designed Electrical Steel for Improved Performance in High-Frequency Electric Machines. Metals 2025, 15, 1066. https://doi.org/10.3390/met15101066

Slater C, Ma X, Lagorce G, Soulard J, Davis C. Novel Alloy Designed Electrical Steel for Improved Performance in High-Frequency Electric Machines. Metals. 2025; 15(10):1066. https://doi.org/10.3390/met15101066

Chicago/Turabian StyleSlater, Carl, Xiyun Ma, Gwendal Lagorce, Juliette Soulard, and Claire Davis. 2025. "Novel Alloy Designed Electrical Steel for Improved Performance in High-Frequency Electric Machines" Metals 15, no. 10: 1066. https://doi.org/10.3390/met15101066

APA StyleSlater, C., Ma, X., Lagorce, G., Soulard, J., & Davis, C. (2025). Novel Alloy Designed Electrical Steel for Improved Performance in High-Frequency Electric Machines. Metals, 15(10), 1066. https://doi.org/10.3390/met15101066