The Mechanism Underlying the Influence of Temperature on the Fracture Toughness of Dissimilar Steel Welded Joints in Nuclear Power Plants

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

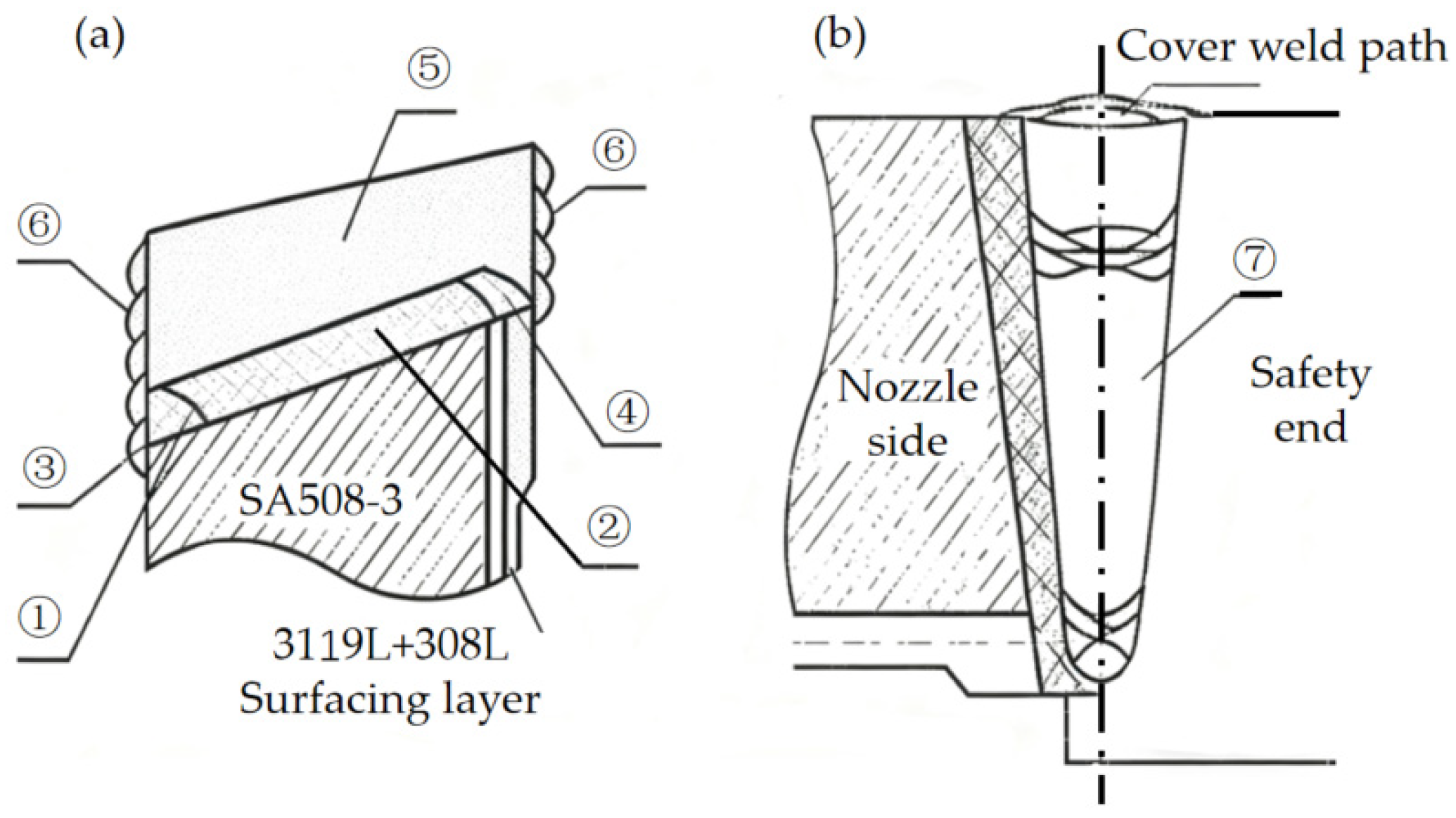

2.2. Welding Process

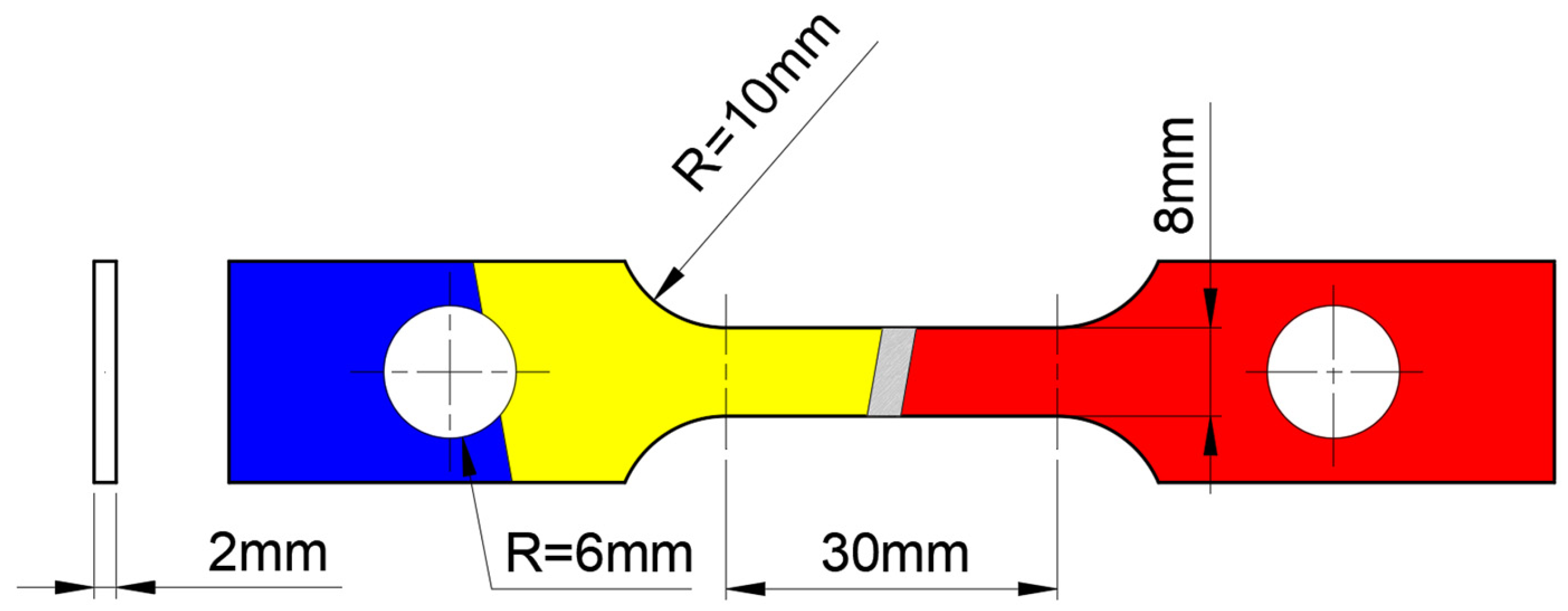

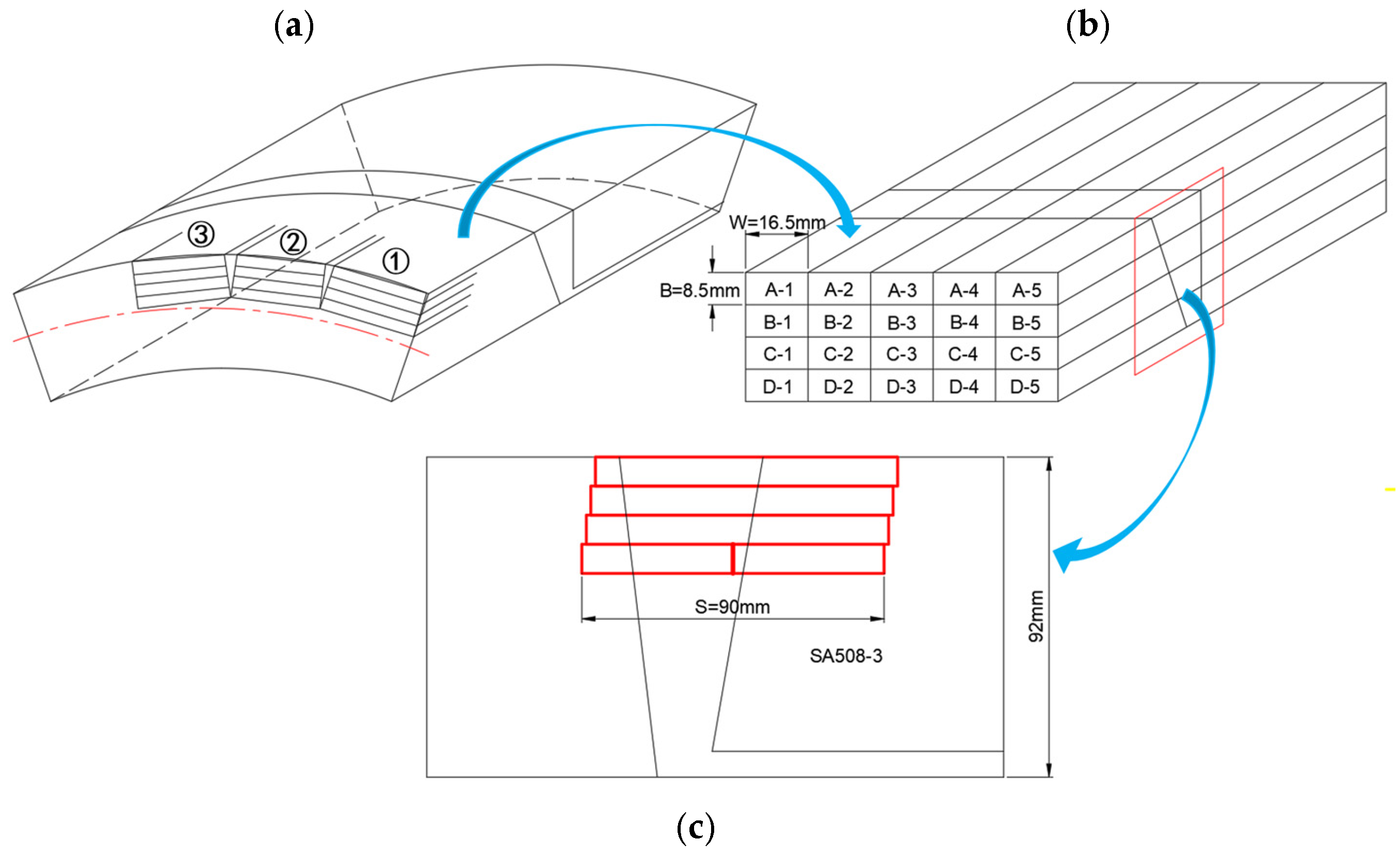

2.3. Mechanical Property Tests

2.4. Structure Observation

3. Results and Discussion

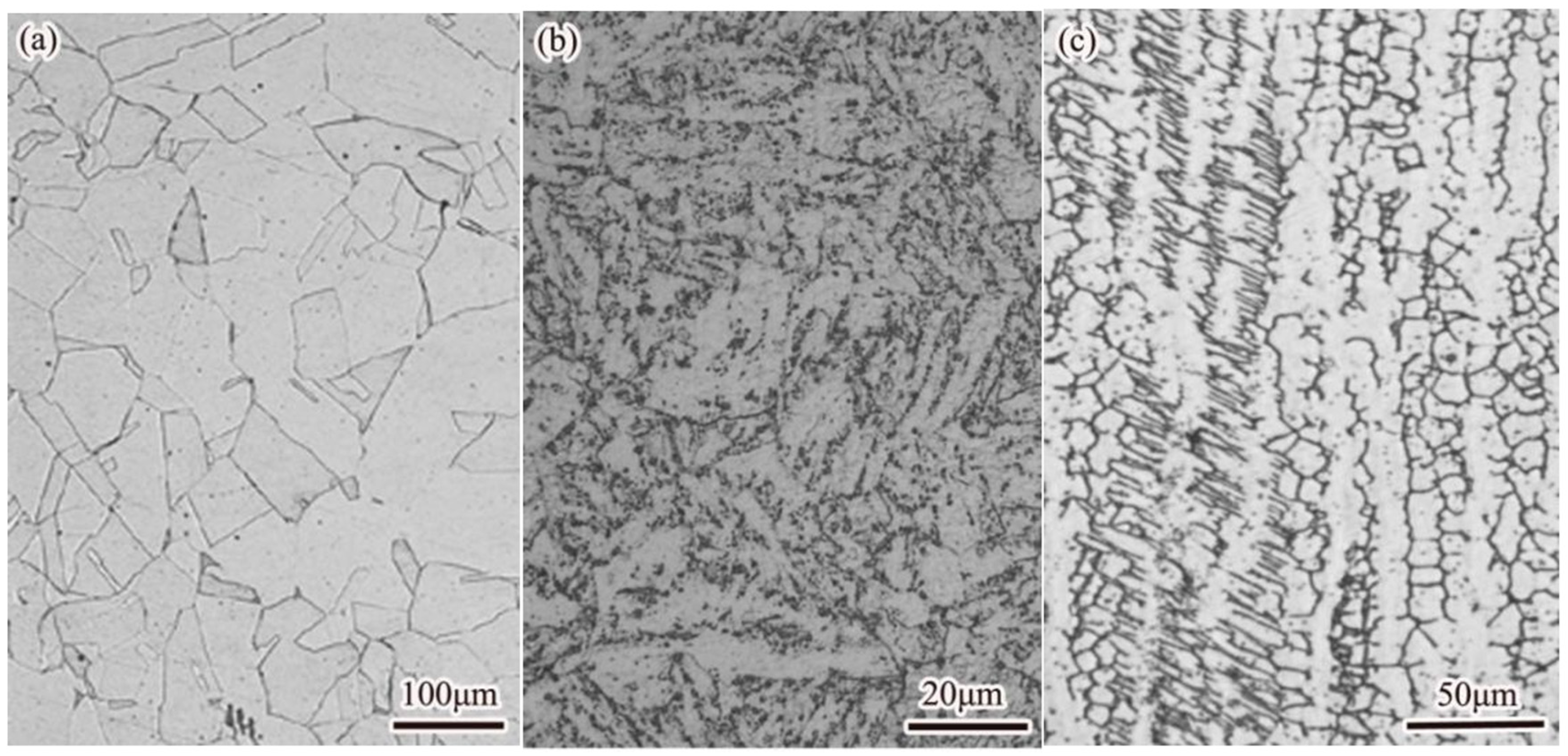

3.1. Optical Structure Characteristics of Different Regions of DMWJ

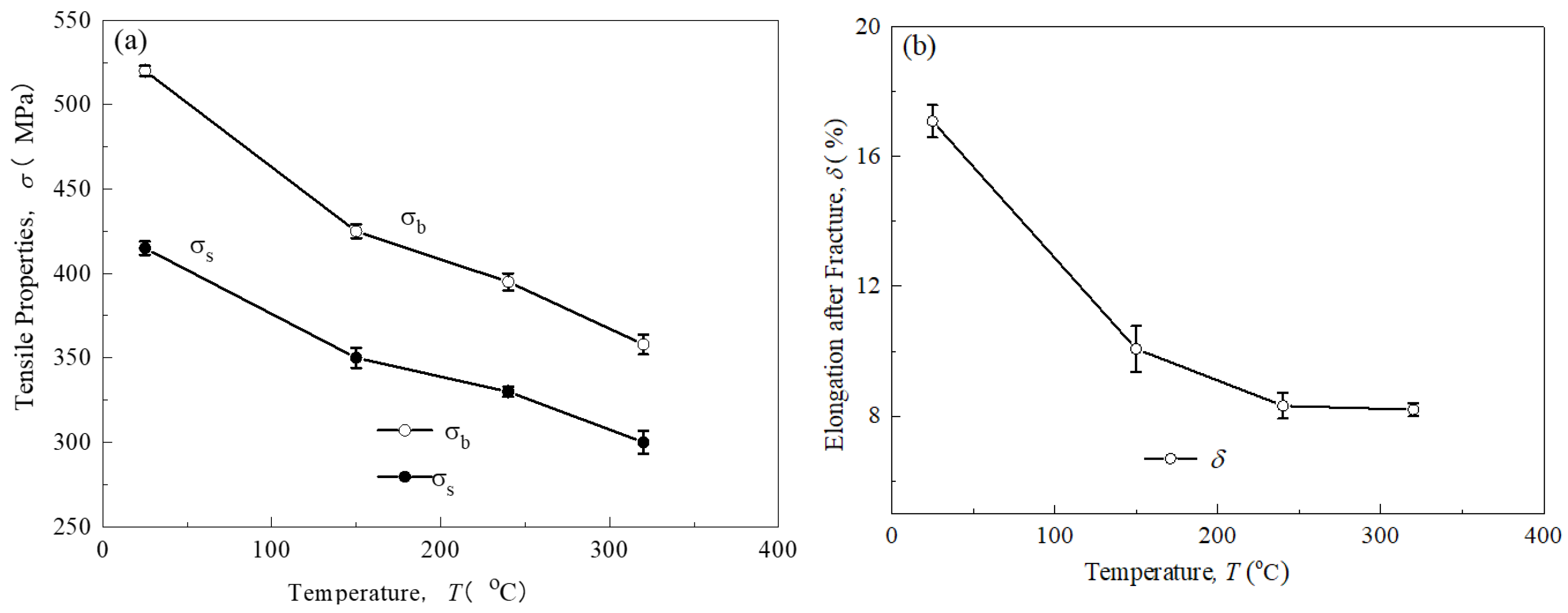

3.2. Mechanical Properties of DMWJ at Different Temperatures

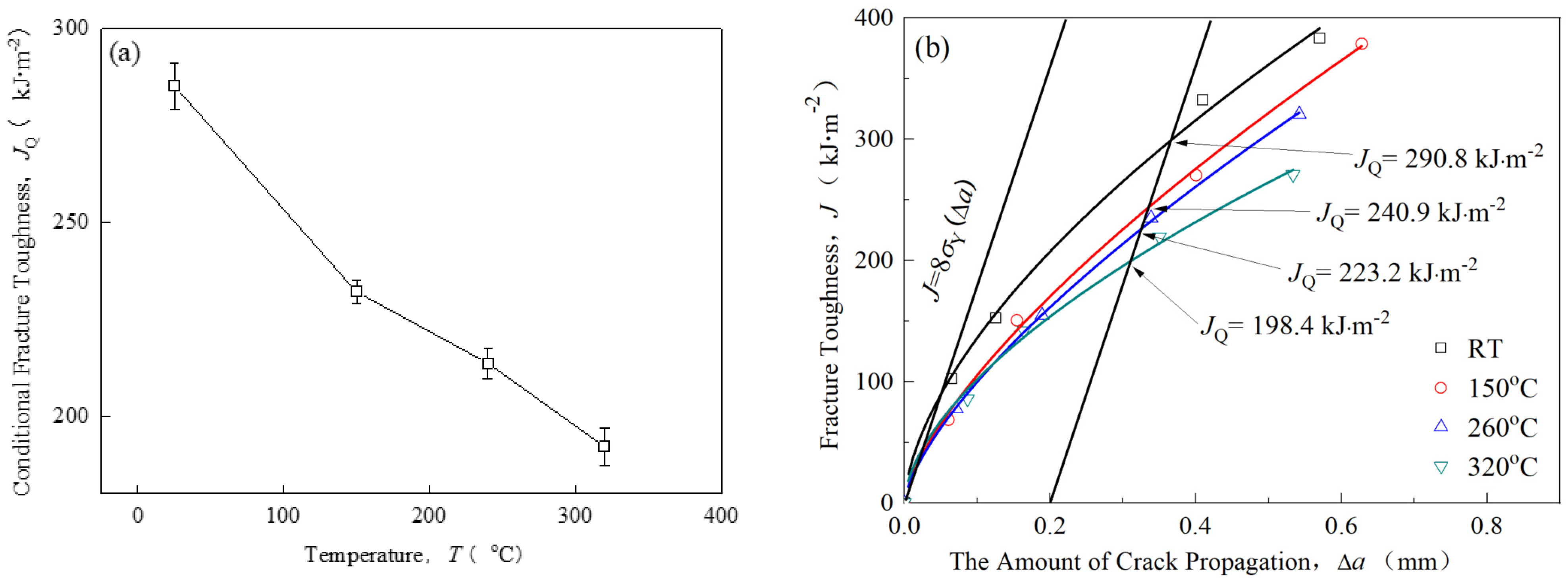

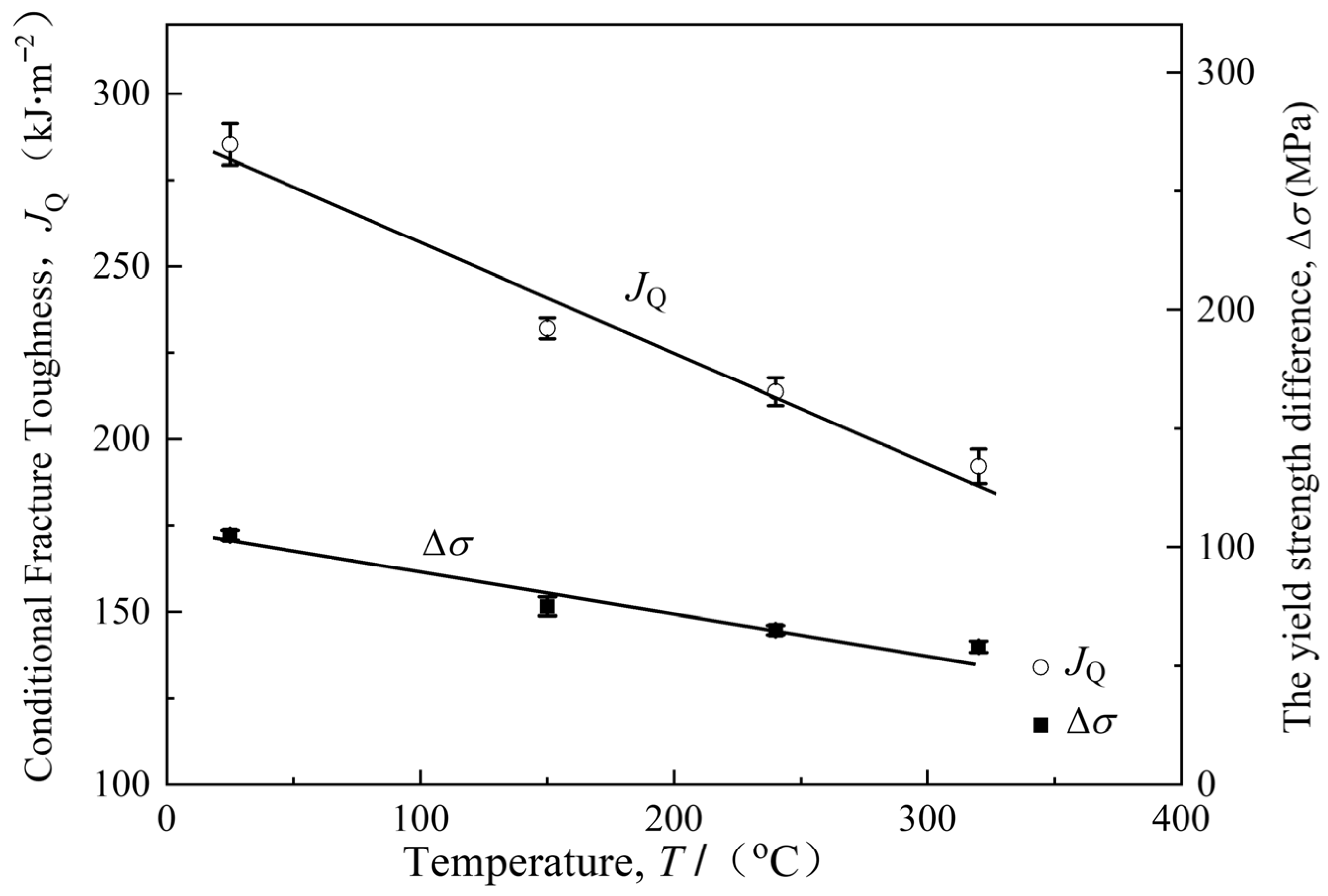

3.3. Fracture Toughness of DMWJ Weld Isolation Layer

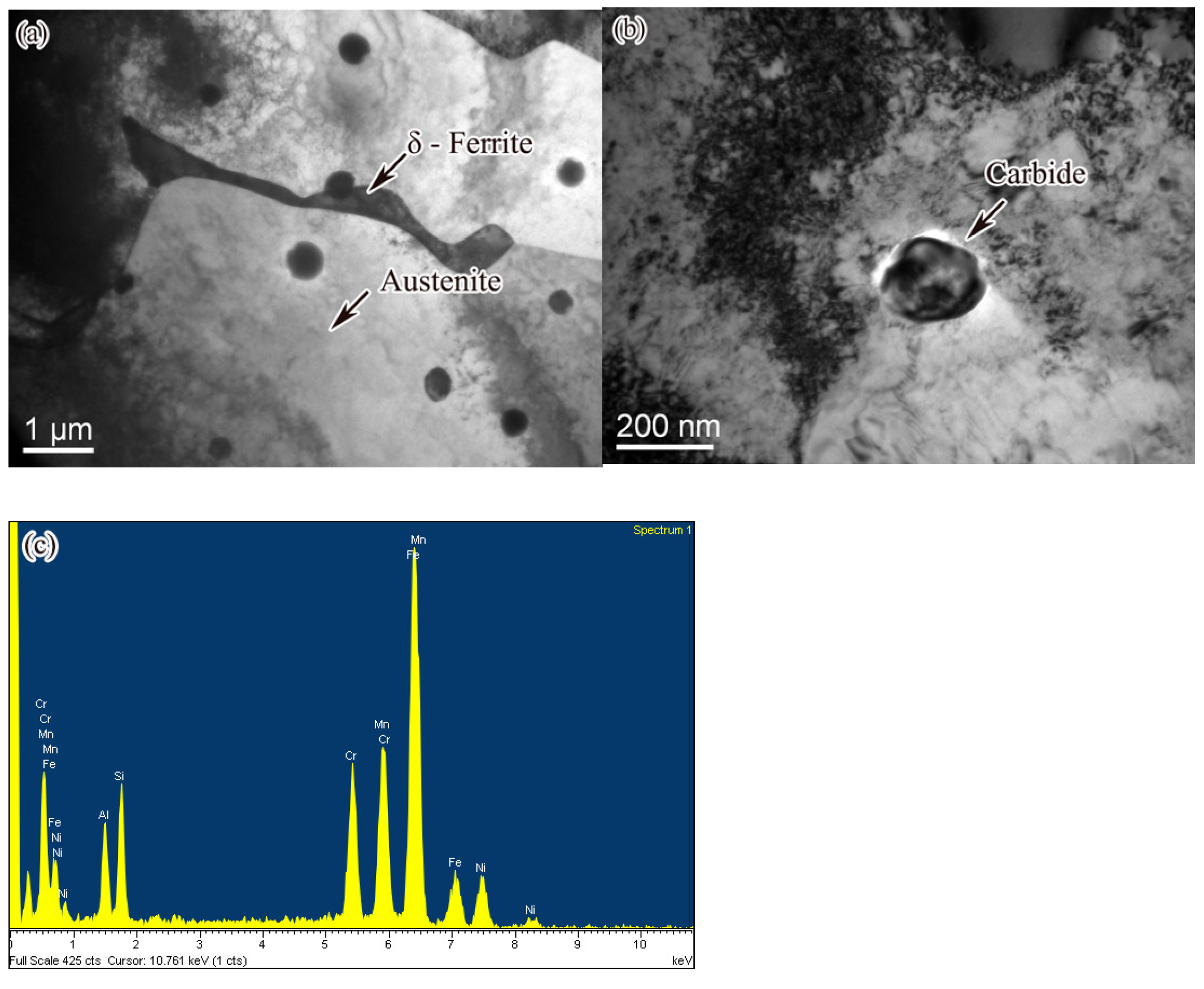

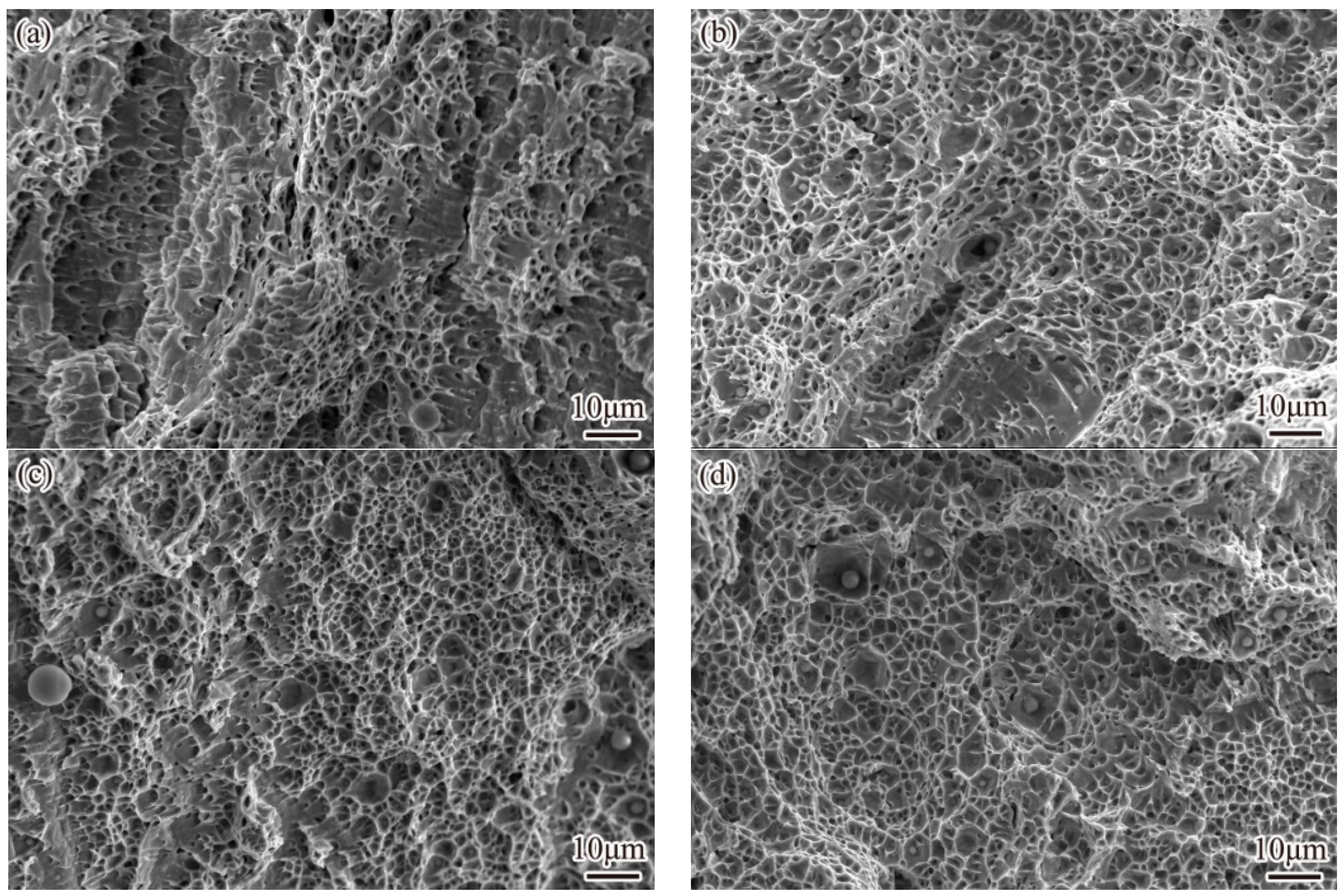

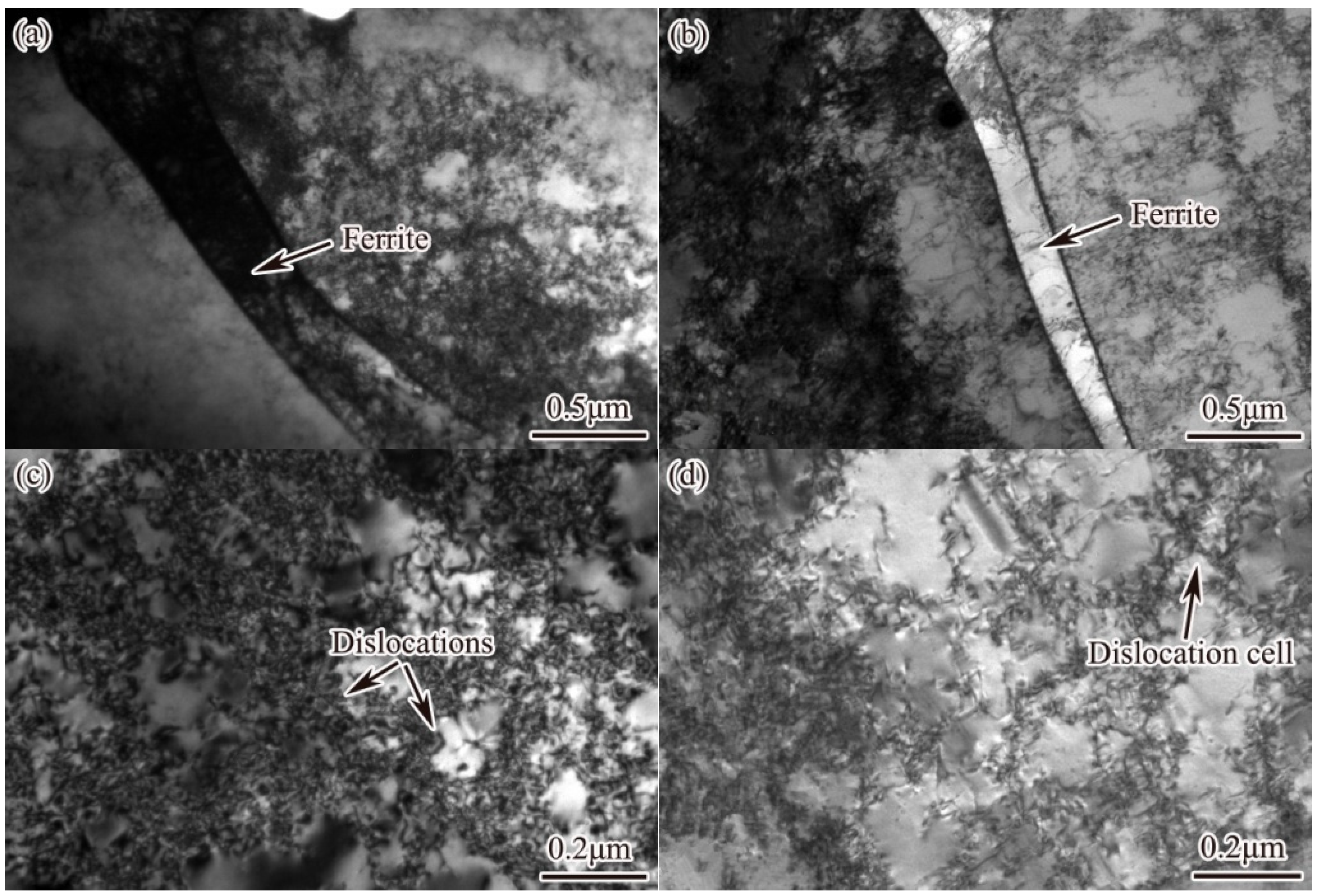

3.4. Influence of Ferrite Morphology on Joint Fracture Behavior

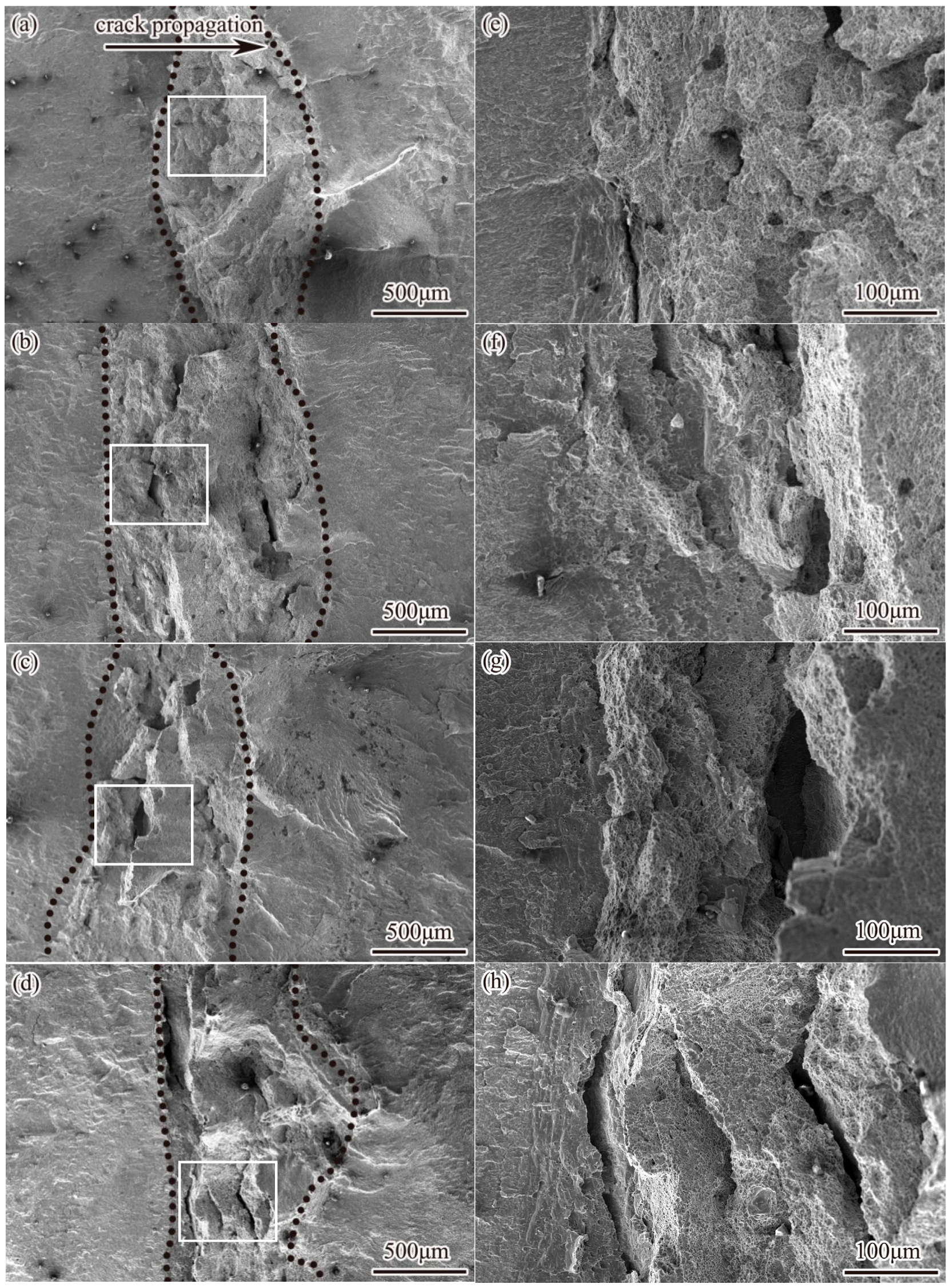

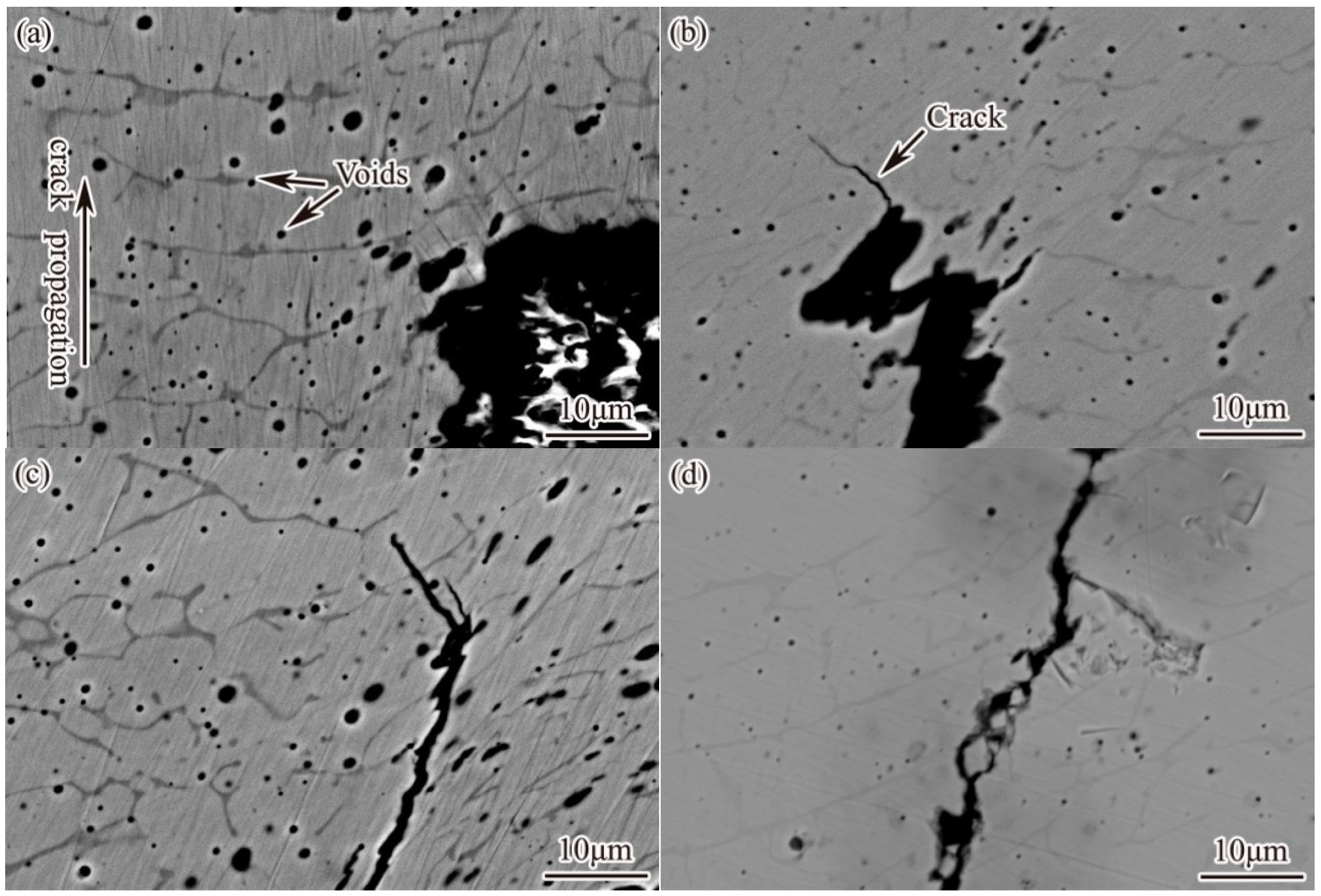

3.5. Mechanism Underlying Temperature’s Effect on DMWJ Crack Propagation

3.6. Effect of Yield Strength Difference on DMWJ Crack’s Unstable Propagation

4. Conclusions

- During the tensile process, from room temperature to 320 °C, the strength and plasticity of the DMWJ decreased significantly, and the isolation layer was the weakest area of the welded joint. The decrease in partial strength is closely related to the softening of the material, while the decrease in plasticity is due to the increased tensile residual stress caused by the increased thermal expansion, accelerating the failure of the material.

- The fracture toughness of welded joints decreases with increased temperature for the following reasons: First, the high temperature releases stacking dislocations, reduces the dislocation density, and then weakens the tensile strength and reduces the yield ratio. This change is not conducive to the redistribution of the stress field at the fatigue crack tip; secondary cracks are more easily initiated near the crack tip, accelerating crack propagation and reducing the fracture toughness of the joint. Secondly, with the increase in temperature, the thermal expansion difference between the base metal and the weld metal increases, and the dislocation cell size increases, reducing the joint’s plasticity, accelerating the crack growth rate, and further reducing the fracture toughness.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sonar, T.; Ivanov, M.; Trofimov, E.; Liu, K.; Shcherbakov, I.; Shaburova, N.; Samoilovskikh, P. A critical review on dissimilar welding of ferritic-martensitic steel and austenitic stainless steel using gas tungsten arc welding process: Weldability issues, processing, and performance characteristics of joints. J. Manuf. Process. 2025, 133, 811–864. [Google Scholar] [CrossRef]

- Gao, Z.; Zhao, L.; Han, Y. Investigation on Residual Stress in SA508/Inconel Metal/CF8A Dissimilar Welded Joint for Nuclear Steam Generator Safe End Using Different Processes. Nucl. Technol. 2023, 210, 471–485. [Google Scholar] [CrossRef]

- Zhao, L.; Sun, Y.; Shi, Z.; Yang, B. Analysis of Crack Propagation Behaviors in RPV Dissimilar Metal Welded Joints Affected by Residual Stress. Materials 2023, 16, 6578. [Google Scholar] [CrossRef] [PubMed]

- Das, M.; Kumar, S.; Singh, P.K.; Ghosh, M. Correlating Microstructure with Mechanical Properties for Different Regions of Dissimilar Metal-Welded Joints. J. Mater. Eng. Perform. 2025, 5, 1–14. [Google Scholar] [CrossRef]

- Park, J.; An, G.; Park, J. The Effect of Hydrogen Embrittlement on Fracture Toughness of Cryogenic Steels. Metals 2025, 15, 1139. [Google Scholar] [CrossRef]

- Jan, H.; Hana, S.; Sarka, M.; Ambroz, O.; Mrna, L. Cycllc Low-thermal Aging of Dissimilar Austenitic Steel Welds Used in Nuclear Power Plants. MM Sci. J. 2024, 12, 7865–7871. [Google Scholar] [CrossRef]

- Liu, Z.F.; Wu, W.H.; Ping, P.; Chen, Z.H. Research on Welding Technology of Safety End of Reactor Pressure Vessel Nozzle for Marine Nuclear Power Platform. Met. Process. 2020, 4, 38–40. [Google Scholar]

- Sun, Y.; Xue, H.; Yang, F.Q. Mechanical Properties Evaluation and Crack Propagation Behavior in Dissimilar Metal Welded Joints of 304 L Austenitic Stainless Steel and SA508 Low-Alloy Steel. Sci. Technol. Nucl. Install. 2022, 2022, 3038397. [Google Scholar] [CrossRef]

- Zhao, L.Y.; Yang, B.; Wang, Z. Prediction of Crack Propagation Directions in Dissimilar Metal Welded Joints Using Phase-Field Models and Discussion of Its Mechanisms. Sci. Technol. Nucl. Install. 2024, 2024, 5543346. [Google Scholar] [CrossRef]

- Krishnan, S.A.; Nikhil, R.; Parnaik, A.; Moitra, A.; Vasudevan, M. Investigation on fracture resistance behaviour of dissimilar metal weld joint of modified 9Cr–1Mo steel and AISI 316LN SS. Int. J. Press. Vessel. Pip. 2024, 211, 105260. [Google Scholar] [CrossRef]

- Wang, H.T.; Wang, G.Z.; Xuan, F.Z.; Tu, S.T. Numerical investigation of ductile crack growth behavior in a dissimilar metal welded DMWJ. Nucl. Eng. Des. 2011, 241, 3234–3243. [Google Scholar] [CrossRef]

- Liu, F.; Hwang, Y.H.; Nam, S.W. Precipitation of sigma-phase and creep-fatigue behavior of 308L steel weldment. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2008, 483, 418–421. [Google Scholar] [CrossRef]

- Hou, J.; Peng, Q.J.; Takeda, Y.; Kuniya, J.; Shoji, T.; Wang, J.Q.; Han, E.-H.; Ke, W. Microstructure and mechanical property of the fusion boundary region in an Alloy 182-low alloy steel dissimilar weld joint. J. Mater. Sci. 2010, 45, 5332–5338. [Google Scholar] [CrossRef]

- Xue, H.; Ogawa, K.; Shohi, T. Effect of welded mechanical heterogeneity on local stress and strain ahead of stationary and growing crack tips. Nucl. Eng. Des. 2009, 239, 628–640. [Google Scholar] [CrossRef]

- Ming, H.L.; Zhang, Z.M.; Wang, J.Q.; Han, E.H.; Ke, W. Microstructural characterization of an SA508-309L/308L-316L domestic dissimilar metal welded safe-end joint. Mater. Charact. 2014, 97, 101–115. [Google Scholar] [CrossRef]

- Kerr, M.; Prime, M.B.; Swanson, H.; Buechler, M.A.; Steinzig, M.; Clausen, B.; Sisneros, T. Residual Stress Characterization in a Dissimilar Metal Weld Nuclear Reactor Piping System Mock Up. J. Press. Vessel Technol. Trans. Ame 2013, 135, 57–89. [Google Scholar] [CrossRef]

- Lee, K.S.; Kim, W.; Lee, J.G.; Park, C.Y.; Yang, J.S.; Kim, T.R.; Park, J.H. Finite element analysis and measurement for residual stress of dissimilar metal weld in pressurizer safety nozzle mock up. J. Mech. Sci. Technol. 2009, 23, 2948–2955. [Google Scholar] [CrossRef]

- Dong, W.C.; Gao, D.B.; Lu, S.P. Numerical Investigation on Residual Stresses of the Safe-End/Nozzle Dissimilar Metal Welded Joint in CAP1400 Nuclear Power Plants. Acta Metall. Sin. 2019, 32, 618–628. [Google Scholar] [CrossRef]

- Huang, C.C.; Liu, R.F. Structural integrity analyses for preemptive weld overlay on the dissimilar metal weld of a pressurizer nozzle. Int. J. Press. Vessel. Pip. 2012, 90, 77–83. [Google Scholar] [CrossRef]

- Park, J.S.; Kim, J.M.; Sohn, G.H.; Kim, Y.H. An Analysis of Residual Stress Improvement for a Dissimilar Metal Nozzle-to-Pipe Weld by Using the Heat Sink Method. Proc. Asme Press. Vessel. Pip. Conf. 2009, 18, 585–589. [Google Scholar]

- Joseph, A.; Rai, S.K.; Jayakumar, T.; Murugan, N. Evaluation of residual stresses in dissimilar weld DMWJs. Int. J. Press. Vessel. Pip. 2005, 82, 700–705. [Google Scholar] [CrossRef]

- Gu, S.F.; Jin, W.; Wang, X.X. Effect of residual stress introduced by local loading on fracture behaviour of DMWJ under different constraints. Int. J. Press. Vessel. Pip. 2023, 202, 104885. [Google Scholar] [CrossRef]

- Younise, B.; Rakin, M.; Gljak, N.; Medjo, B.; Sedmak, A. Effect of material heterogeneity and constraint conditions on ductile fracture resistance of welded joint zones—Micromechanical assessment. Eng. Fail. Anal. 2017, 82, 435–445. [Google Scholar] [CrossRef]

- Wang, H.T.; Wang, G.Z.; Xuan, F.Z.; Liu, C.J.; Tu, S.T. Local mechanical properties of a dissimilar metal welded DMWJ in nuclear power systems. Mater. Sci. Eng. A 2013, 5, 108–117. [Google Scholar] [CrossRef]

- Li, Y.Y.; Wang, F.; Huang, Y.; Lin, X.; Lin, D.K.; Li, H.; Yang, W.B.; Ding, M.C.; Zhang, Z.W. Effect of residual stress on the fracture behavior of P91 steel. Press. Vessel. 2024, 41, 28–36. [Google Scholar]

- Samal, M.K.; Seidenfuss, M.; Roos, E. Investigation of failure behavior of ferritic-austenitic type of dissimilar steel welded joints. Eng. Fail. Anal. 2011, 18, 999–1008. [Google Scholar] [CrossRef]

- Yang, C.J.; Gong, X.H.; Gao, Z.P. Research status of fracture failure behavior of metal clad plates. World Nonferrous Met. 2024, 3, 208–210. [Google Scholar]

- Seifert, H.P.; Ritter, S.; Shoji, T.; Peng, Q.J.; Takeda, Y.; Lu, Z.P. Environmentally-assisted cracking behaviour in the transition region of an Alloy182/SA 508 Cl.2 dissimilar metal weld DMWJ in simulated boiling water reactor normal water chemistry environment. J. Nucl. Mater. 2008, 378, 197–210. [Google Scholar] [CrossRef]

- Gao, F.G. Analysis of Mechanical Field at Cracking Tip in Welded Joint Based on XFEM. Ph.D. Thesis, Xi’an University of Science and Technology, Xi’an, China, 2017. [Google Scholar]

- Wang, S.; He, X.; Gui, Y.W.; Wang, Z.; Zhao, K.; Ni, C. Investigation of the Inhomogeneous Mechanical and Crack Driving Force of Low Alloy Steel SA508 and Its Welded 309L/308L Stainless Steel Cladding. Nucl. Sci. Eng. 2022, 197, 623–632. [Google Scholar] [CrossRef]

- RCC-M S3512; Material Specifications for Nuclear Island Mechanical Equipment in Pressurized Water Reactors. AFCEN: Paris, France, 2024.

- ASTM E8/E8M–21; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM E1820-23b; Standard Test Method for Measurement of Fracture Toughness. ASTM International: West Conshohocken, PA, USA, 2023.

- Xiao, J.; Wang, D.; Yang, S.G. Solidification Microstructure and Secondary-Phase Precipitation Behavior of 310S Austenitic Stainless Steel. Metals 2025, 15, 1091. [Google Scholar] [CrossRef]

- Kim, J.W.; Lee, K.; Kim, J.S.; Byun, T.S. Local mechanical properties of Alloy 82/182 dissimilar weld DMWJ between SA508 Gr.1a and F316 SS at RT and 320 degrees C. J. Nucl. Mater. 2009, 384, 212–221. [Google Scholar] [CrossRef]

- Huang, B.X.; Wang, X.D.; Rong, Y.H.; Wang, L.; Jin, L. Mechanical behavior and martensitic transformation of an Fe-Mn-Si-Al-Nb alloy. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2006, 438, 306–311. [Google Scholar] [CrossRef]

- Silva, C.C.; Miranda, H.C. Austenitic and ferritic stainless steel dissimilar weld metal evaluation for the applications as-coating in the petroleum processing equipment. Mater. Des. 2013, 47, 1–8. [Google Scholar] [CrossRef]

- Chen, G.H.; Zhang, Q.; Liu, J.J.; Wang, J.; Yu, X.; Hua, J.; Bai, X.; Zhang, T.; Zhang, J.; Tang, W. Microstructures and mechanical properties of T92/Super304H dissimilar steel weld DMWJs after high-temperature ageing. Mater. Des. 2013, 67, 469–475. [Google Scholar] [CrossRef]

- Chung, W.-C.; Huang, J.-Y.; Tsay, L.-W.; Chen, C. Microstructure and Stress Corrosion Cracking Behavior of the Weld Metal in Alloy 52-A508 Dissimilar Welds. Mater. Trans. 2011, 52, 12–19. [Google Scholar] [CrossRef]

- Dong, L. Research summary on the correlation between impact toughness and fracture toughness of pressure vessel materials. Chem. Eng. Equip. Technol. 2024, 45, 11–14. [Google Scholar]

| Fe | C | Si | Mn | P | S | Cr | Mo | Ni | Cu | V | N | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SA508-III | Bal. | 0.17 | 0.21 | 1.47 | 0.005 | 0.002 | 0.12 | 0.51 | 0.75 | 0.02 | <0.01 | |

| 309L | Bal. | 0.015 | 0.18 | 1.55 | 0.015 | 0.012 | 19.11 | 0.09 | 9.65 | 0.05 | <0.05 | 0.0373 |

| 308L | Bal. | 0.015 | 0.31 | 1.35 | 0.015 | 0.012 | 19.02 | 0.1 | 9.61 | 0.05 | <0.05 | 0.0375 |

| 316L | Bal. | 0.028 | 0.6 | 1.77 | 0.017 | 0.007 | 17.65 | 2.37 | 11.9 | 0.16 |

| Number of Welding Layers | Welding Method | Filler Metals | Current | Voltage Range (V) | Welding Speed (mm/min) | Wire Feeding Speed (mm/min) | |||

|---|---|---|---|---|---|---|---|---|---|

| Metal Grade | Size (mm) | Current Range (A) | Hot Wire (A) | Electrode Polarity | |||||

| ①② | Mechanical TIG welding | 309L | Φ0.9 | Base value: 150~180 Peak value: 240~280 | 30~50 | DC/SP | 10~12 | 160~200 | Base value: 1600~1800 Peak value: 2200~2400 |

| ③ | Mechanical TIG welding | 309L | Φ0.9 | Base value: 120~160 Peak value: 200~240 | - | DC/SP | 10~12 | 180~220 | Base value: 1300~1500 Peak value: 1700~1900 |

| ④⑤ | Mechanical TIG welding | 308L | Φ0.9 | Base value: 150~180 Peak value: 240~280 | 30~50 | DC/SP | 10~12 | 150~200 | Base value: 1600~1800 Peak value: 2200~2400 |

| ⑥ | Mechanical TIG welding | 308L | Φ0.9 | Base value: 120~160 Peak value: 200~240 | - | DC/SP | 10~12 | 180~220 | Base value: 1300~1500 Peak value: 1700~1900 |

| ⑦ | Submerged arc mechanical welding | 308L | Φ4 | 490~530 | - | DC/RP | 30~34 | 570~620 | - |

| Cr (Wt%) | Ni (Wt%) | Fe (Wt%) | |

|---|---|---|---|

| Austenite | 20.16 | 9.77 | 66.84 |

| Ferrite | 28.74 | 4.07 | 65.78 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Zheng, A.; Wang, L.; Xu, H.; Ji, F.; Guan, L.; Luo, J. The Mechanism Underlying the Influence of Temperature on the Fracture Toughness of Dissimilar Steel Welded Joints in Nuclear Power Plants. Metals 2025, 15, 1236. https://doi.org/10.3390/met15111236

Liu J, Zheng A, Wang L, Xu H, Ji F, Guan L, Luo J. The Mechanism Underlying the Influence of Temperature on the Fracture Toughness of Dissimilar Steel Welded Joints in Nuclear Power Plants. Metals. 2025; 15(11):1236. https://doi.org/10.3390/met15111236

Chicago/Turabian StyleLiu, Jiahua, Aiquan Zheng, Lei Wang, Hongwu Xu, Feifei Ji, Liqun Guan, and Jiong Luo. 2025. "The Mechanism Underlying the Influence of Temperature on the Fracture Toughness of Dissimilar Steel Welded Joints in Nuclear Power Plants" Metals 15, no. 11: 1236. https://doi.org/10.3390/met15111236

APA StyleLiu, J., Zheng, A., Wang, L., Xu, H., Ji, F., Guan, L., & Luo, J. (2025). The Mechanism Underlying the Influence of Temperature on the Fracture Toughness of Dissimilar Steel Welded Joints in Nuclear Power Plants. Metals, 15(11), 1236. https://doi.org/10.3390/met15111236